1. Introduction

Hybrid heat pumps are a type of HS that uses two or more energy sources at the same time. The development of more efficient, cost-effective, and sustainable HSs for residential and commercial buildings is the primary focus of this research.

The innovative aspect of the hybrid concept is its optimised and integrated control strategy, which aims to maximise the efficiency of both elements: the heat pump and the gas boiler.

By combining these two heating technologies within a single control strategy, it is possible to choose HP or GB. This flexibility enables the optimisation of heat production based on various local considerations, such as CO

2 emissions, running costs, primary energy usage, grid congestion, and load balancing [

1].

The use of heat pumps in the EU contributes to a significant reduction in annual CO

2 emissions, amounting to 9.16 million tonnes. According to the International Energy Agency (IEA), heat pumps have the potential to save 50% of CO

2 emissions from the construction sector and 5% of CO

2 emissions from the industrial sector [

2,

3].

The IEA defines a hybrid heat pump as the combination of an electric heat pump and a fossil-fuel-powered boiler or furnace operating under a single optimised control strategy. The standard EN 14825:2018 [

4,

5] states the following: “encased assembly or assemblies designed as a unit consisting of an air/water(brine)/DX-to-water (brine) electrically driven HP with a second heat generator using fossil fuel, and managed by a common controller providing an optimised operation of the heat generators for space heating”.

Several advantages of HHP can be highlighted. These include the ability to utilise multiple energy sources (such as electricity and heat based on natural gas, propane, etc), greater flexibility in energy consumption, the potential for installation in a variety of building types, making them a viable retrofit option for existing structures, and their role as a transitional technology that facilitates a smoother transition to fossil fuel-free alternatives [

6,

7,

8,

9,

10]. Hybrid systems, equipped with a fossil fuel-powered heater as a backup, enable the use of heat pumps in retrofit situations, providing a reliable solution.

It is important to highlight that there are numerous cases where a system comprising combination of an electric heat pump and a gas boiler is employed on a larger scale, such as in district or industrial settings [

7,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22].

In a study by Sun et al. [

23], several buildings in Great Britain were examined, equipped with a combined gas boiler and heat pump HS. The study focused on how these systems perform when controlled with consideration for electricity price fluctuations. Results indicated that operating the heat pump primarily during periods of low-priced electricity and activating the gas boiler during periods of peak electricity prices can lead to a 5–10% increase in COP (coefficient of performance).

In the frame of research in 2018, the heat pump potential in Baltic countries was studied and the possibility of integrating heat pumps with the existing district heating grids was estimated. The report’s Baltic Energy Technology Scenarios showed that heat pumps and electric boilers are a very promising option in buildings and in district heat production in a future energy system. In Lithuania, the study explored the feasibility of a combined HP and hydroelectric plant with thermal energy storage in Kaunas Lagoon. With a COP of 3.65, using low-cost off-peak electricity, the 270 MW HP system can meet the heating demands of Kaunas. Latvian research compared solar collector and heat pump (HP) scenarios, choosing solar collectors due to their lower cost. The Baltic DH system integration of HPs can increase RES electricity demand, covering 70–90% of the annual heat demand.

Estonian research analysed large-scale heat pump integration in Tallinn’s district heating. Optimal locations and heat sources were considered, reducing natural gas reliance to 34% and achieving 16% heat production through heat pumps [

24].

By studying data from real case studies in the Baltic region, one can see data on individual comparisons of the efficiency of heat pumps with other equipment, but not an analysis of hybrid systems.

In 2015, one study of a 7.4 kW variable-speed low-temperature air-source heat pump showed that for the heating mode, the COP varied from 1.98 to 3.05 as the outdoor temperature changed from −7.0 °C to +5.0 °C. In this case, at the end of the heating season, the total electricity consumption turned out to be 1737 kWh and the total heating output was 5927 kWh, leading to an SPF of 3.41 without taking frosting into account. Consideration of frosting in a simulation model was proven to be significant, resulting in the SPF decreasing to 2.86 [

25].

Current trends indicate that HPs are also slowly replacing gas and solid fuel boilers, as well as district heating in existing buildings. The price reduction in solar photovoltaic systems and new storage technologies helped grow HPs as well. The HPs in Lithuania and similar cold-climate countries are accepted as one of the most outstanding heating technologies in both residential and commercial buildings because they provide high SPF, 1.8–3.4 for air-source heat pumps and 2.5–5.6 for ground-source heat pumps and water-source heat pump. However, the spread is large because of different equipment, designs, and installation qualities, as well as maintenance. HP efficiency has increased significantly in last decade, particularly that of ASHPs. This has influenced a growing popularity of these HPs in the residential building market [

26,

27].

1.1. Embracing Low-Carbon Heating Pathways with Hybrid Heat Pumps

While hybrid heat pumps have the capacity to act as a pathway to low-carbon heating, there are various obstacles that must be tackled to fully unlock this potential. First and foremost, it is crucial to define hybrid systems in building regulations, provide incentives for renewable heating at both EU and local levels, and establish appropriate testing standards [

28,

29].

Hybrid heat pumps are an excellent option for energy-efficient HSs. Nevertheless, certain limitations currently hinder their widespread adoption and highlight the need for further research in this field. Climate limitations, high upfront costs, maintenance requirements, compatibility issues, and noise levels are all factors that can impact the effectiveness of hybrid heat pumps. Therefore, careful consideration of these factors is essential before adopting hybrid heat pump technology [

10,

30].

For instance, HHP performs best in moderate to mild climates, as colder climates may exceed the heating capacity of heat pumps alone, leading to increased reliance on backup fossil fuel boilers. Moreover, the initial cost of HHP can be higher compared to traditional HSs, considering the installation expenses for both the heat pump and the backup boiler. It may take several years to recover the initial investment. Additionally, hybrid heat pumps require more maintenance due to the increased number of components compared to traditional HSs, and they can generate higher noise levels compared to conventional heat pumps [

22].

On the other hand, a comprehensive review conducted by the authors of [

31] (covering studies from 2016 to 2022) highlighted the potential advantages of hybrid systems. The authors of [

32] noted that the energy and economic efficiencies of these systems vary considerably due to the control strategies employed and the chosen objective functions. Climate conditions can also have an impact on system performance by influencing both the coefficient of performance (COP) of the heat pump and the accessibility of energy sources. Additionally, country-specific tariff structures play a crucial part in shaping the overall performance of hybrid systems [

3].

The fundamental components of ASHP include a compressor, a high-temperature heat exchanger (condenser), a pressure relief valve, and a low-temperature heat exchanger (evaporator) [

17].

Regarding the layout of hybrid heat pumps, they can either be integrated into a single system with the boiler or exist as separate elements. Systems designed for domestic hot water (DHW) production typically feature a storage tank [

31].

It has been noticed that integrated hybrid packages are overwhelmingly the most commonly accessible solution on the market. In the case of the most prevalent hybrid packages, the available configurations are limited by local preferences regarding the inclusion of hot water production storage.

The system in its entirety, including the allocation of loads between the two heating devices, is coordinated to minimise the overall cost of the energy process [

31,

33].

In the analysed hybrid HS presented by the authors of [

34], optimising the energy performance of the HHP system occurs exclusively during the winter season, which is of paramount importance in colder-climate regions.

Incorporating thermal storage enhances the system’s thermal stability and decreases the frequency of HP on–off cycles. Heat pump systems coupled with thermal storage tanks can improve system performance by enabling the HP operation to be scheduled during the economically advantageous periods, taking into account factors like energy prices and outdoor temperatures [

16,

35]. This optimisation approach minimises both operating expenditures and primary energy consumption.

In a study conducted by Fitzpatrick et al., a cost-optimal sizing and hourly control strategy were applied to a hybrid heat pump (HHP) system. The decoupled system components could be independently activated. It was found that, in contrast to a baseline scenario lacking storage capacity, scenarios incorporating storage capacity and predictive capabilities could reduce energy costs by as much as 8%, demonstrating a saturation effect on potential cost savings [

36]. Similarly, it was explored two distinct arrangements with differing parameters for the hybrid heating system (HS) [

37].

In comparison to a heat pump-only approach, the hybrid solution achieved greater energy savings ranging from 24% to 30% in systems with radiators in moderate and cold climates, and approximately 5% to 12% when implementing hybrid systems in newer homes with radiant panels in similar climates [

37].

The authors of [

36] conducted a comparison between a system incorporating a tank and one without. The study showcased the cost-effectiveness of utilising a tank, especially by taking advantage of periods with low electricity tariffs. The outcomes revealed that the inclusion of the tank resulted in a decrease in primary energy consumption of up to 13% and cost savings of up to 8%.

In a combined air heat pump and gas boiler system, it is essential to determine the temperature at which the air heat pump ceases operation and the system switches entirely to the gas boiler. The study by Dongellini yielded results indicating that the HS achieved its highest efficiency when the air heat pump stopped operating entirely at 0 °C [

34].

The control mechanisms used in HHP plants can have a considerable impact on their performance in terms of energy and economic aspects [

38]. The universally standardised “optimal” strategy cannot be established as it hinges on diverse factors, encompassing operational cost reductions, CO

2 emission reductions, primary energy considerations, and external variables linked to local conditions like climate, expenses, and overarching limitations. Furthermore, factory operation regulations for certain system components may have an impact on the control strategy.

Control strategies can be classified into two types. The first type are rule-based control methods (RBC), which rely on predefined trigger parameter thresholds (e.g., energy price, load, power, and time) that are continuously monitored. The other type are predictive algorithms such as model predictive control (MPC) [

1].

The HHP smart system automatically manages the HS based on the most cost-effective regulations [

23]. Nonetheless, irrespective of the control methodology employed, it is vital to underscore that optimal performance can only be attained through meticulous system sizing and a thorough analysis of heating demands [

39].

1.2. Electricity Market in Latvia

In the electricity market in Latvia, prices are formed through the mutual competition of electricity traders and the fluctuations in electricity stock market prices.

Consumers have the freedom to choose their electricity trader, with electricity primarily purchased in the exchange. The combination of consumer demand and producer supply determines the price of electricity in the stock market. Total electricity costs consist of four components: electricity prices, system service tariffs, OIK, and VAT. The electricity stock market operator in Latvia is “Nord Pool” AS [

40].

In recent months, there has been a noticeable increase in wholesale electricity prices in Nord Pool trading areas. In August 2022, the average electricity price in the Latvian trading area increased to 467.75 EUR/MWh, which was 53% higher than the July electricity price, and 435% higher than the August 2021 price. A similar situation can also be observed in other Baltic states [

40].

The increase in electricity prices can be attributed to the electricity balance in the Baltic States, where consumption exceeds generation, as well as the rising prices of energy resources. Consequently, electricity prices experience continuous fluctuations depending on the overall network load. As countries strive to transition from fossil fuels to low-carbon sources of electricity (such as renewables, including hydropower, solar, and wind), the electricity mix—the balance of electricity sources in the supply—becomes increasingly significant.

Energy intensity, as depicted in the below chart, is a crucial metric for tracking a country’s progress in emissions reduction.

Most of the CO

2 emissions originate from the combustion of fossil fuels for energy generation and industrial activities, such as cement production.

Figure 1 illustrates the breakdown of yearly CO

2 emissions by their sources, including coal, oil, gas, cement production, and other gases. This distribution is significantly influenced by a nation’s energy composition and shifts when the country transitions toward or away from particular energy sources.

By analysing the electricity price schedules available in Nord Pool (2022), peak consumption hours with the highest electricity prices and low consumption hours with lower electricity prices can be identified. Utilising this information, there is a potential to save costs by adjusting the heat source of the hybrid HS based on the prevailing electricity prices.

2. Methods and Materials

2.1. CASE Study

Figure 2 illustrates the system diagram created using IDA ICE, consisting of heating unit equipment models, logic elements (available in the IDA-ICE 4.8 version), and user-created objects (referred to as “macro objects”, designated as MX). On

Figure 2, number 1 is the heat pump unit, 2—gas boiler, 3—heating system tank, 5—hot water tank.

The simulation represents a HHP comprising a condensation-type GB and an ASHP, represented by the macro-objects “HP” (heat pump) and “GB” (gas boiler).

The heat consumers in the system are the domestic hot water system (DHW) and the heating system (HS). Hot water is prepared in a 300-litre tank, which is heated with a spiral heat exchanger. The HS is represented by an accumulation tank object with a volume of 70 litres (equivalent to the total volume of the HS). The heating consumption is generated using the IDA ICE building climate model.

The flow of the heat carrier to the CHP (combined heat and power) tank is facilitated by “pump 1”, while “pump 2” supplies the HS.

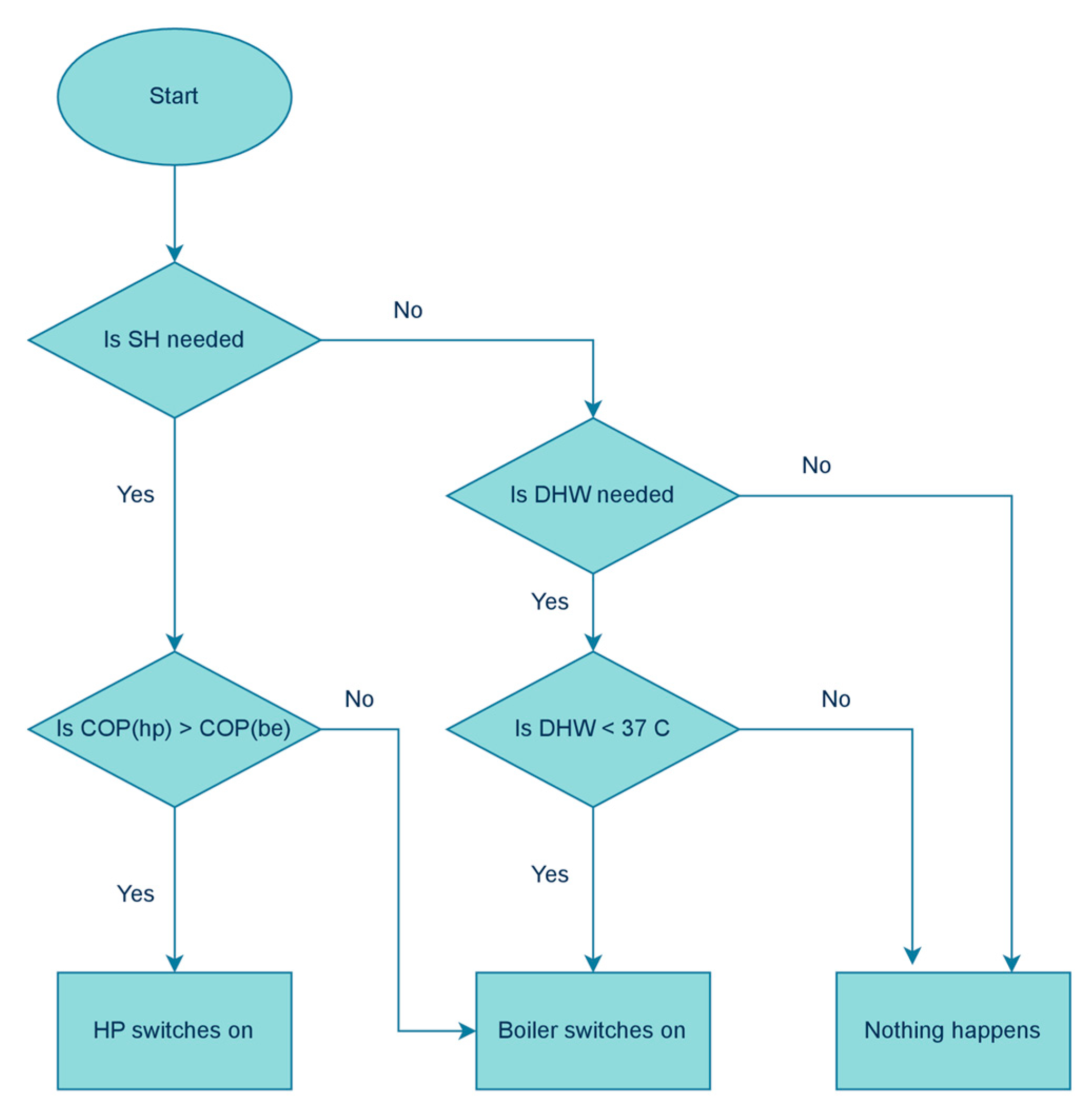

In the specific model of the heating unit, only one of the heat sources operates at a time. The optimal heat source is determined based on the following parameters:

Outdoor air temperature.

COP limits of the HP.

Hot water system demand.

Space heating demand.

In the control programme of the heating source, signals with values of “1” and “0” are utilised to control both pumps mentioned earlier. The operation of the heat pump is controlled by elements M2 and M3. Object M2 verifies whether the COP value of the HP exceeds the calculated COP limit during a specific time period. It generates a positive value (actual COP greater than the COP limit) or a negative value (actual COP less than the COP limit), which is then transmitted to the boiler and heat pump objects [

41].

Object M2 checks whether the COP value of the heat pump is higher than the calculated COP limit during a specific period of time. As a result, the object generates a positive value (actual COP higher than COP limit) or a negative value (actual COP lower than COP limit). The resulting value is transmitted to the boiler and heat pump object.

Similarly, object M3 assesses whether the outdoor temperature remains above the temperature limit setting. It generates a signal with a value of “1” as long as the outdoor temperature remains above this threshold. Once the temperature setting is reached, it generates a signal with a value of “0”. This value is conveyed to both the heat pump and gas boiler, with the opposite value transmitted to the gas boiler (if it is “0”, then “1”; if “1”, then “0”).

Furthermore, the HS control thermostat regulates the operation of the HP and GB. When the heating demand in the building starts to decrease, causing the HS temperature to rise above the set temperature, a signal with a value of “0” is sent to both heat sources. Once the HS temperature cools sufficiently, a signal with a value of “1” is sent to both heat sources again. This thermostat also controls pump 2 by turning it off when there is no heating demand in the system.

Similarly, the DHW tank thermostat operates on a similar principle. When there is a demand for hot water, the HW system thermostat turns off the HP and circulation pump 2, while activating the GB and circulation pump 1.

Figure 3 demonstrates the algorithm of HHP in different operation modes.

2.2. Methods and Research Object

The following conditions (steps) explain the methods of the HHP in this study.

The system chooses the most advantageous heat source whenever the outdoor air temperature drops below a specific threshold.

Electricity prices are derived from 2022 electricity exchange data. Gas prices remain constant throughout the year at 98 EUR/MWh. The efficiency coefficient η boiler of the condensing-type gas boiler is considered to have a constant value of 0.93. Using Microsoft Excel, the COPBE value is calculated for each hour of the year, taking into account the electricity exchange prices.

In ECONO mode, the break-even COP represents the point at which the heat pump operates with the same cost efficiency as the boiler, producing 1 kWh of thermal output at the same cost. This break-even COP is dependent on the electricity price (EUR/kWh), gas price (EUR/kWh), and the boiler’s thermal efficiency (%); the latter is assumed to remain a constant value regardless of flow temperature, return temperature, and ambient temperature. The user or installer can set and adjust the energy prices.

If there is no demand for thermal power in the HS, the operation of HP and circulation pump 2 is interrupted. The temperature in the HS is monitored using the HS’s thermostat element. The thermostat is set at 40 °C, and HP is activated when the system temperature drops to 38 °C.

The operation of the HP is suspended if there is a demand for heat supply in the potable hot water tank.

Within the scope of this study, a real installation of a combined system consisting of natural gas and a heat pump for heating equipment was examined. The subject of the project is a two-story single-family house located in Babite, Latvia, where four people reside. The overall heated space of the premises is 125 m2. The calculated total heat loss (including transmission and ventilation) amounts to 6.8 kW, while the required heat flow for hot water preparation is 12.18 kW.

2.3. Data Reading Process

The following meters were installed in the object:

An electricity meter, recording the consumption of combined equipment. Data include date and time, current, and total consumed energy (MWh).

A natural gas control meter, which records the amount of natural gas consumed for heating and hot water preparation. Data include date and time, flow rate (m3) per hour, and total flow rate.

Heat meter 1, which counts the energy consumed for the preparation of DHW. Data include date and time, produced energy (MWh), hourly and total flow (m3/h), and hourly supply and return temperature, t1 and t2, respectively (°C).

Heat meter 2, which counts the energy consumed for the needs of the HS. Data include date and time, produced energy (MWh), hourly and total flow (m3/h), and hourly supply and return temperature, t1 and t2, respectively (°C).

2.4. Equipment

The connected Metbox device reads data from meters, sensors, or controllers through a wireless interface. The gathered data are sent to the Metbox server. The Metbox equipment operates with a Modbus interface.

By dividing the produced power by the consumed power, the COP (coefficient of performance) for the heat pump can be calculated.

In order for a heat pump to be efficient, it must deliver more heat energy than it consumes. This proportion is referred to as the COP (coefficient of performance) or transformation coefficient.

The coefficient of performance (COP) is the relationship between the heat output generated and the electrical energy consumed [

42],

where

—thermal energy produced by HP, kWh;

N—electricity consumed by HP, kWh.

The COP of the air heat pump is affected by both the outside air temperature and humidity.

The seasonal coefficient of performance (SCOP) describes the average COP during a heating season. In addition to COP and SCOP, an essential factor to assess the energy efficiency of heat pumps (HPs) is the seasonal performance factor (SPF). SPF represents the “net seasonal coefficient of performance in active mode” and quantifies the overall efficiency of HPs over an entire year in practical operating conditions. It is calculated as the ratio between the total annual usable energy delivered by the HP and the annual energy input to the entire heating and/or domestic hot water (DHW) system. SPF provides a comprehensive view of how efficiently HPs perform over a typical year, accounting for real-world variations in demand and conditions [

27].

The maximum possible efficiency coefficient of HP can be calculated using the formula

where

—maximum efficiency coefficient of the heat pump;

—average condenser temperature (consumer), K;

—average evaporator temperature (heat source), K.

COP can vary greatly depending on operating parameters and usage conditions.

2.5. Energy, Exergy, Environmental, and Economic Issues

The primary energy factor (PEF) signifies the efficiency of energy conversion from primary sources [

43]. It is defined as the ratio of primary energy to secondary energy for a particular energy carrier, making it a valuable metric for evaluating the primary energy efficiency of the heat source under investigation [

44] presented the following equation for calculating

PEFs in the case of HSs with oil and natural gas (NG) boilers:

Here,

PEFhp represents the primary energy factor for heat production,

PEFhs is the primary energy factor of the heat source, and η

hs is the efficiency of the heating system (HS). In the case of an air-source HP, the PEF for heat production is calculated as:

where

PEFel is the primary energy factor of electricity and

SPF is the seasonal performance factor of the HP. The

SPF of the HP is calculated using the following formula [

45]:

where

Qhp is the annually produced heat and

Wel is the annual electricity consumption of the HP system.

Because the COP (coefficient of performance) of a standard electric HP is insufficient for HHP, a calculation that considers both the boiler efficiency and the COP of the HP should be used. The Stafford [

46] methodology was used to define the performance factor of the HHP system, yielding the equation

where

SPFhhp is the HHP performance factor,

is the total generated heating energy, and

is the total input energy into the HHP system.

For the specific system analysed in this project,

In this equation,

Rgas stands for the ratio of space heating (SH) provided by the gas boiler,

Rel represents the ratio of space heating provided by the heat pump (HP), and SPF denotes the seasonal performance factor of the HP [

31].

3. Results

In this context, we consider the results from three different calculation methods: the heat pump manufacturer’s calculation, the simulator programme, and the calculations based on real measured data. Analysing these three methods will help us understand how different calculation approaches can impact the final results and the accuracy and usefulness of various data analysis methods.

Table 1 reveals notable differences in the distribution of energy resources between the manufacturer’s calculation programme, IDA, and the actual measured data.

The consumed energy calculated by the manufacturer’s programme is 12,607.3 kWh, which is 15.36% higher than the 10,671 kWh from the measured data. Similarly, the produced energy based on the manufacturer’s calculation is 20,114 kWh, 25.81% higher than the measured data of 15,987 kWh.

The IDA results significantly differ from the project’s data for both consumed and produced energy. IDA suggests that energy consumption should be half of what the project indicates, while the energy produced should be 38.9% less.

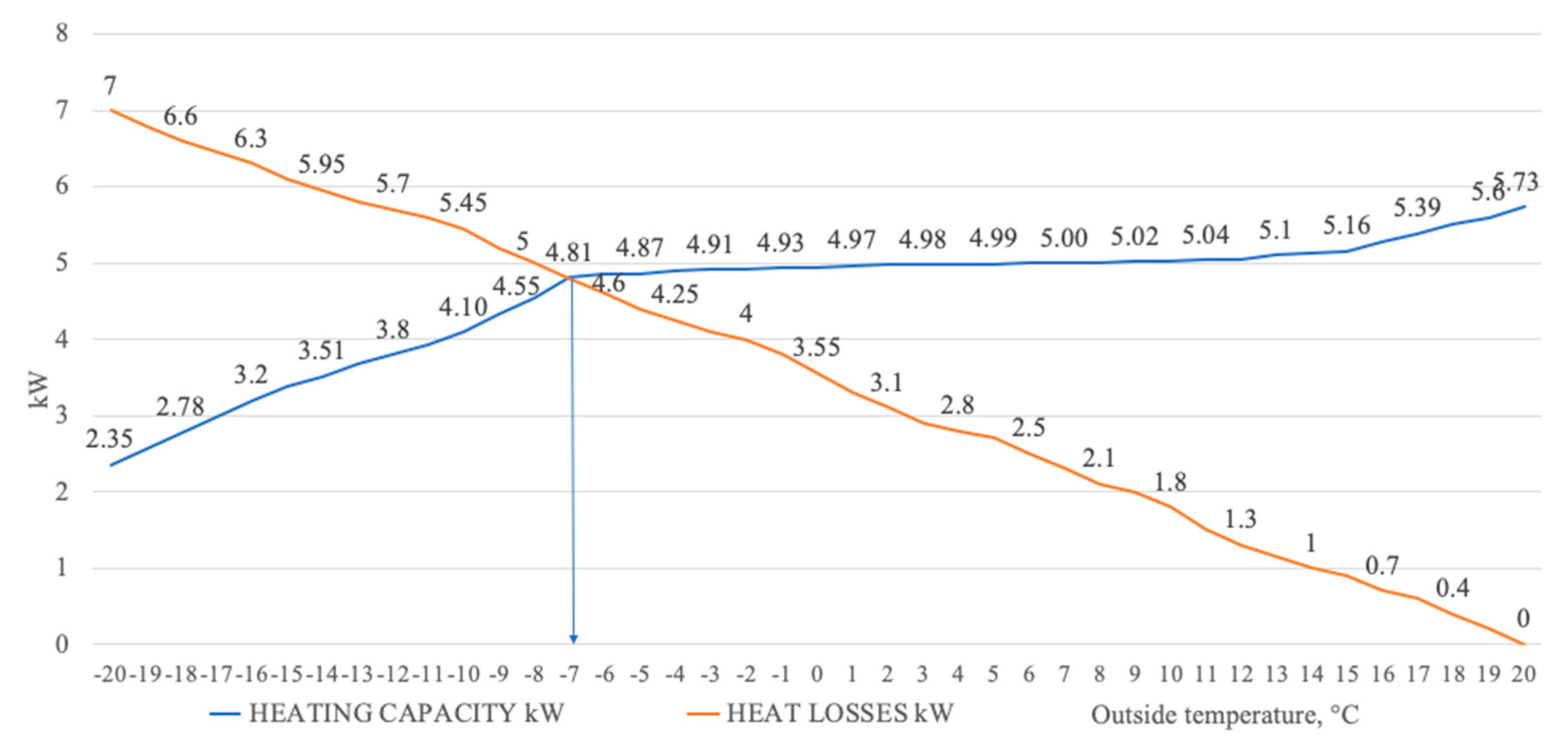

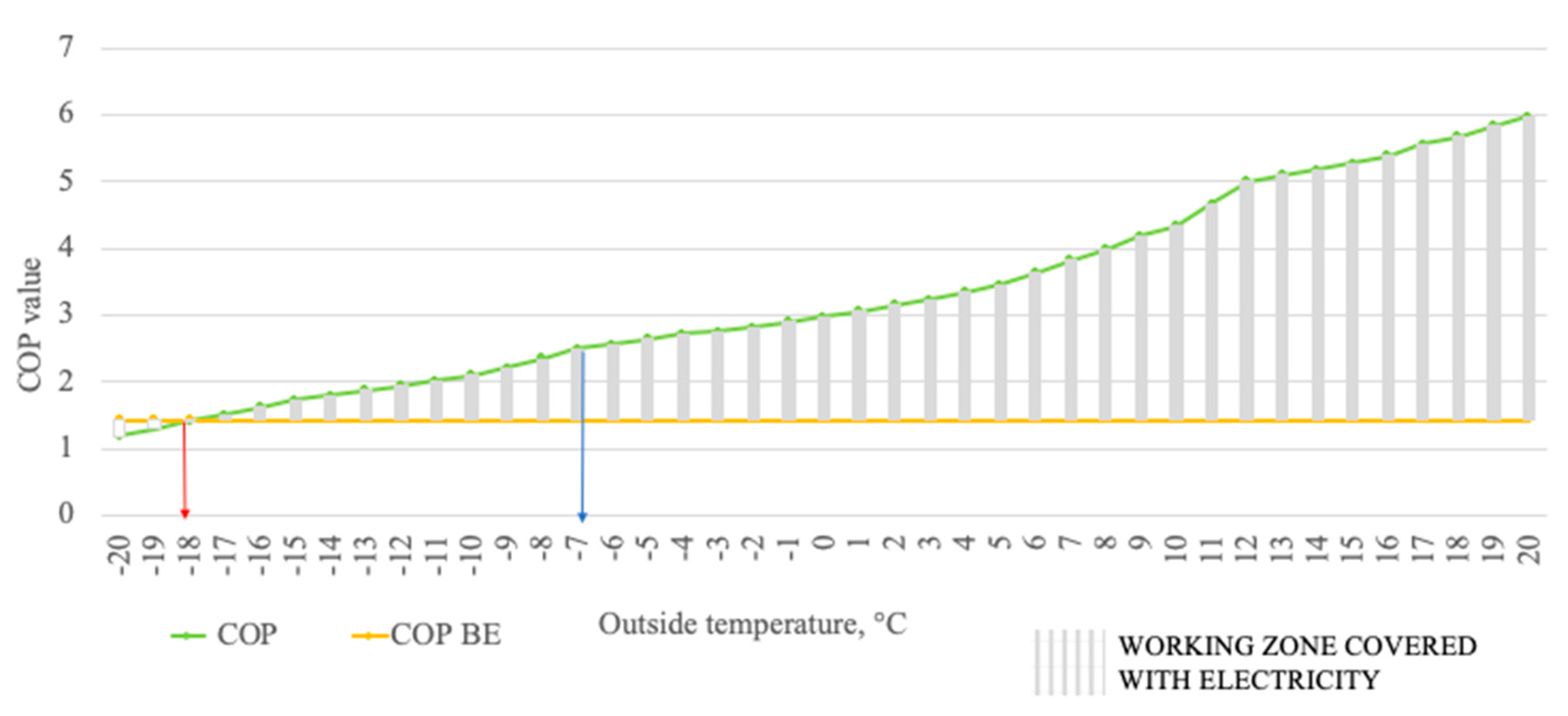

To understand the algorithm of the hybrid equipment regarding the moment of switching between energy resources, we applied the formula COP BE. This was calculated for the equipment operating at different electricity prices, while the price of natural gas remained constant in all three variants (0.098 EUR/kWh). The graph illustrates that the heating capacity of the HP unit in the combined system drops from 5.73 kW to 2.35 kW as the outside air temperature decreases from +20 °C to −20 °C. The hybrid unit can cover necessary heat losses until −7 °C, (blue arrow shown on the chart), where HP heating capacity matches the building’s heat losses. However, at lower temperatures, the equipment cannot fully meet the required heat losses, as seen in

Figure 4, where, at −7 °C, the required power is 5 kWh, but the heating capacity of the device is only 4.55 kW.

Figure 4 depicts the moment of transition from hybrid heat pump operation mode to gas boiler operation mode.

Figure 5 illustrates the intersection of COP and COP BE at +4 °C, (red arrow shown on the chart) indicating that the system switches to natural gas below this temperature as it becomes less cost-effective to use electricity at the given prices. The electricity price is 0.35 EUR/kWh and the gas price is 0.098 EUR/kWh for case 1.

Upon changing the electricity price to 0.15 EUR/kWh (case 2), it is evident that the operating range using electricity significantly expanded, as shown in

Figure 6.

At −18 °C, (red arrow shown on the chart), COP and COP BE intersect, but according to

Figure 4, which shows that the equipment can only cover heat losses up to −7 °C, it is assumed that at this electricity price, the system will switch to gas beyond the −7 °C limit. (blue arrow shown on the chart).

By adjusting the electricity price to 0.05 EUR/kWh (case 3, see

Figure 7), it is noticeable that COP BE never reaches the COP value. This implies that using electricity with such an indicator will always be more cost-effective than using natural gas. Again, referring to

Figure 4, it is assumed that after the −7 °C limit, the system will switch to natural gas.

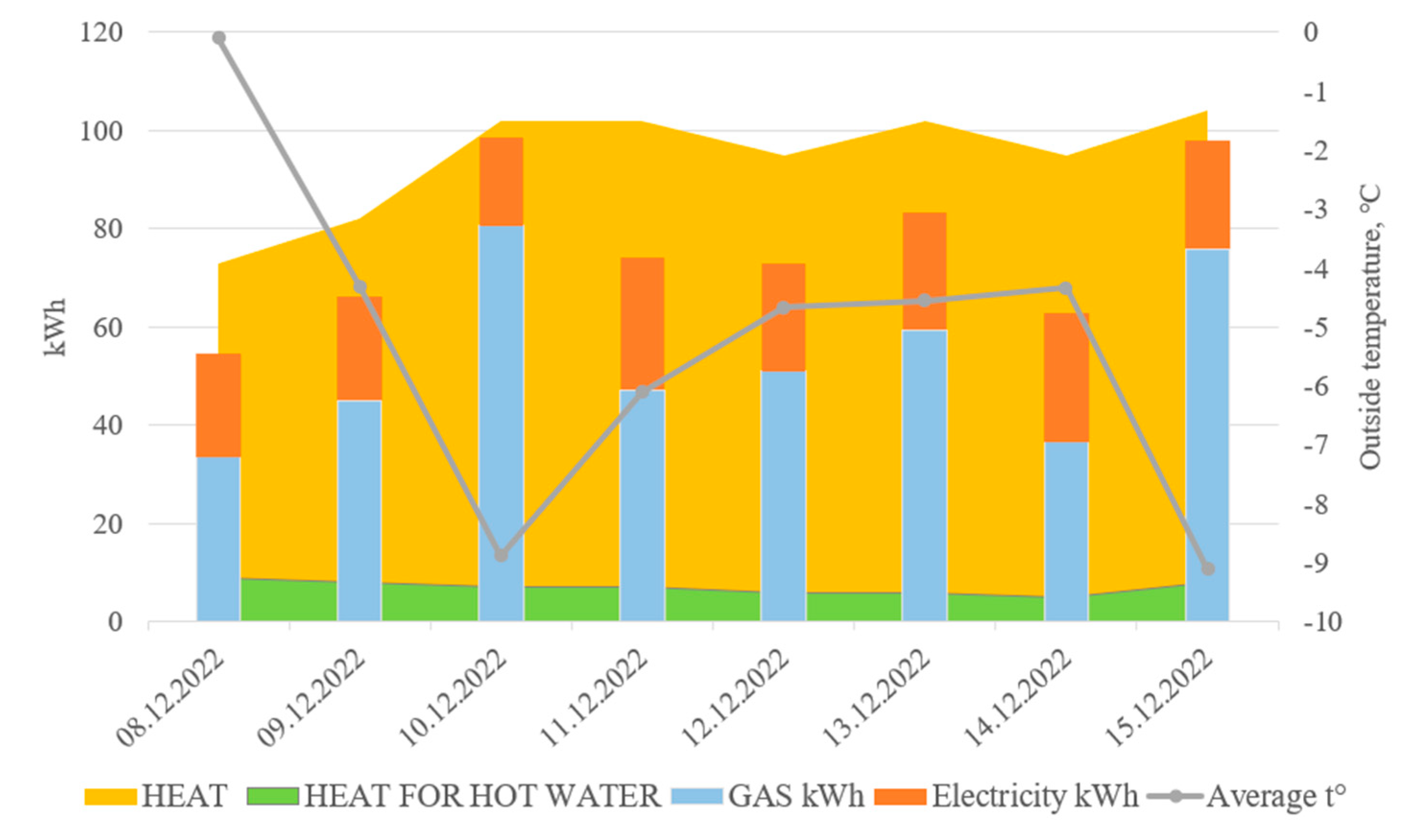

The following table provides a summary of an 8-day period in December when the outside temperature ranged from −0.1 °C to −9.1 °C.

From

Table 2, it is evident that when the outdoor air temperature was −0.10 °C, natural gas consumption was 33.55 kWh, but when the temperature dropped to −9.11 °C, gas consumption increased to 75.96 kWh, which is 126% more.

Similarly, the heat produced also increased, from 73 kWh at −0.10 °C to 104 kWh at −9.11 °C, representing a 42.50% increase. Due to the gas also being used for hot water, the increase is not proportional. The visual representation of the device’s operation is depicted in

Figure 8.

3.1. Ecological Mode

As mentioned above, the device can operate in two modes: economic mode, where the cheapest energy resource becomes the priority, and ecological mode, where the device consumes the energy resource that emits less CO

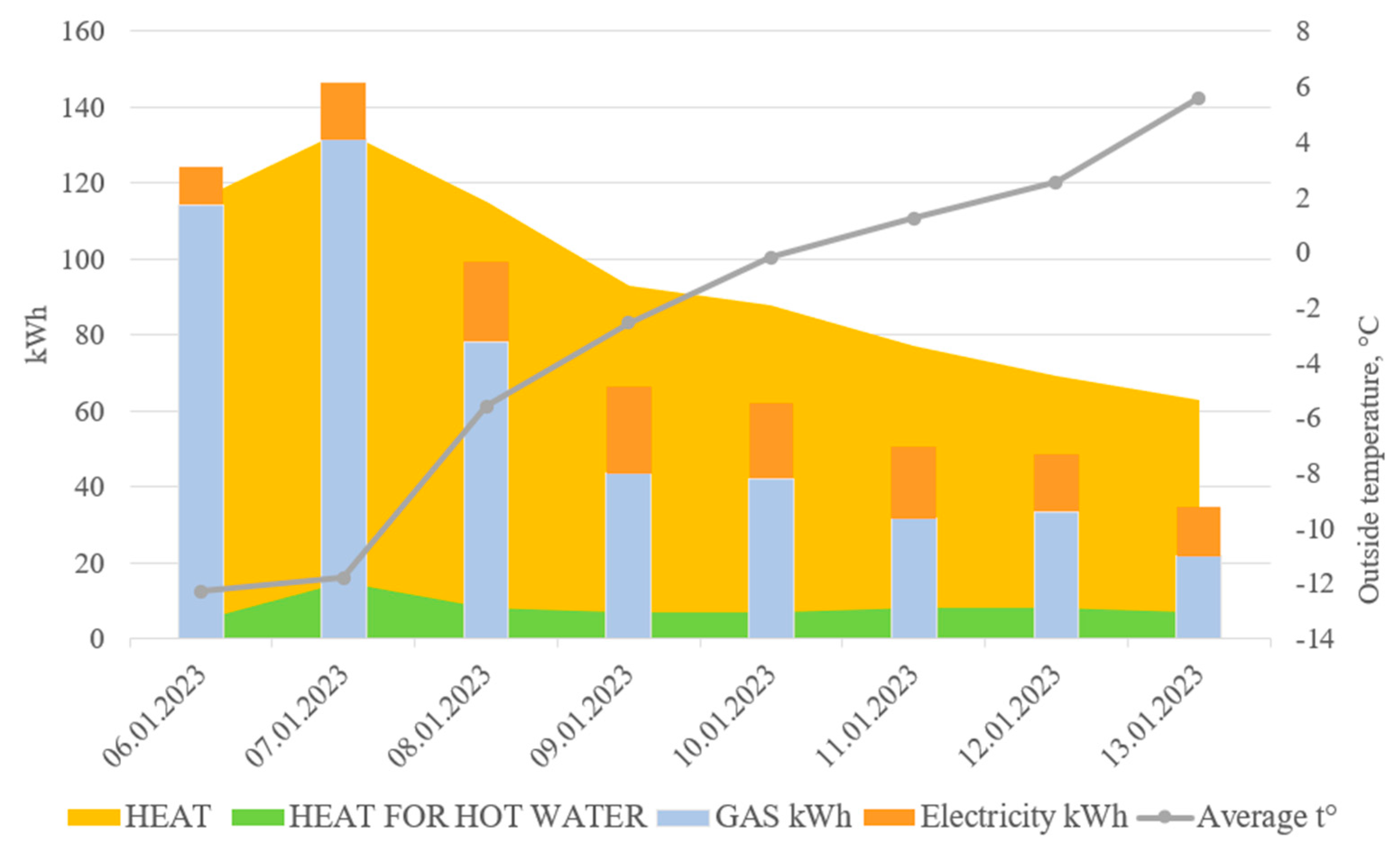

2. The 8-day data for December represents the device operating in ecological mode. To understand the difference in indicators between the two modes, another period with similar temperature fluctuations was considered, and the unit was operating in economic mode during this time. Below (see

Figure 9 and

Table 3) is a summary of the 8-day readings in January, with temperatures ranging from 5.58 °C to −12.29 °C.

3.2. Economy Mode

According to the table, when the external air temperature was 5.58 °C, natural gas consumption was 21.70 kWh; however, when the temperature plummeted to −12.29 °C, gas consumption climbed to 114.26 kWh, a 427% increase.

As a result, at 5.58 °C, 63 kWh of heat was created, whereas at −12.29 °C, 116 kWh was produced, representing an 84% increase. Below are graphical generators illustrating the device’s operation. Data are demonstrated in

Figure 10 and

Figure 11.

In the ecology mode, the average air temperature was −5.26 °C, gas consumption was 429.6 m

3, and electricity was 181 kWh. In economy mode, the outside temperature was −2.89 °C (slightly warmer), but more gas and less electricity were used, indicating higher CO

2 output but cheaper costs at colder peak temperatures.

Table 4 shows the data overview for the two different operation modes.

The data in

Table 4 and

Figure 12 illustrate a substantial increase in gas consumption, primarily due to its higher profitability, particularly in scenarios where the gas price was lower than that of electricity. Furthermore, the hybrid heat pump was proven to be inadequate in meeting all the required loads when the outdoor temperature fell below −7 °C.

4. Conclusions

In the context of this study, the characteristics of the system were assessed through three methods: manufacturer-provided equipment calculations, software simulations, and real measurements taken from the object itself. The observed disparity in energy production and consumption can be attributed to variations between the actual measured outdoor temperature profile and that utilised by both the manufacturer’s calculator and the simulator. Such discrepancies influence occupancy durations, potentially misleading end users and eroding confidence in hybrid technologies and sustainable energy within the region.

The recorded difference in energy consumption between the manufacturer’s program and the measured data stands at 15.36%, while the difference in the produced energy is 25.81%.

Through an examination of the economic and ecological operating modes of the HHP systems, it was discerned that the shifting of the switching point does not invariably align with practicality. The cost of electricity does not consistently serve as the decisive factor, and this point cannot fall below the threshold at which the heat pump can effectively offset the building’s heat losses.