Thermal Performance and Durability Evaluation of Arundo Donax towards an Improvement in the Knowledge of Sustainable Building Materials

Abstract

1. Introduction

1.1. Use of Reed in Portuguese Vernacular Buildings

1.2. Reed as a Thermal Insulation Material

2. Reed Harvest Sites

3. Experimental Campaign

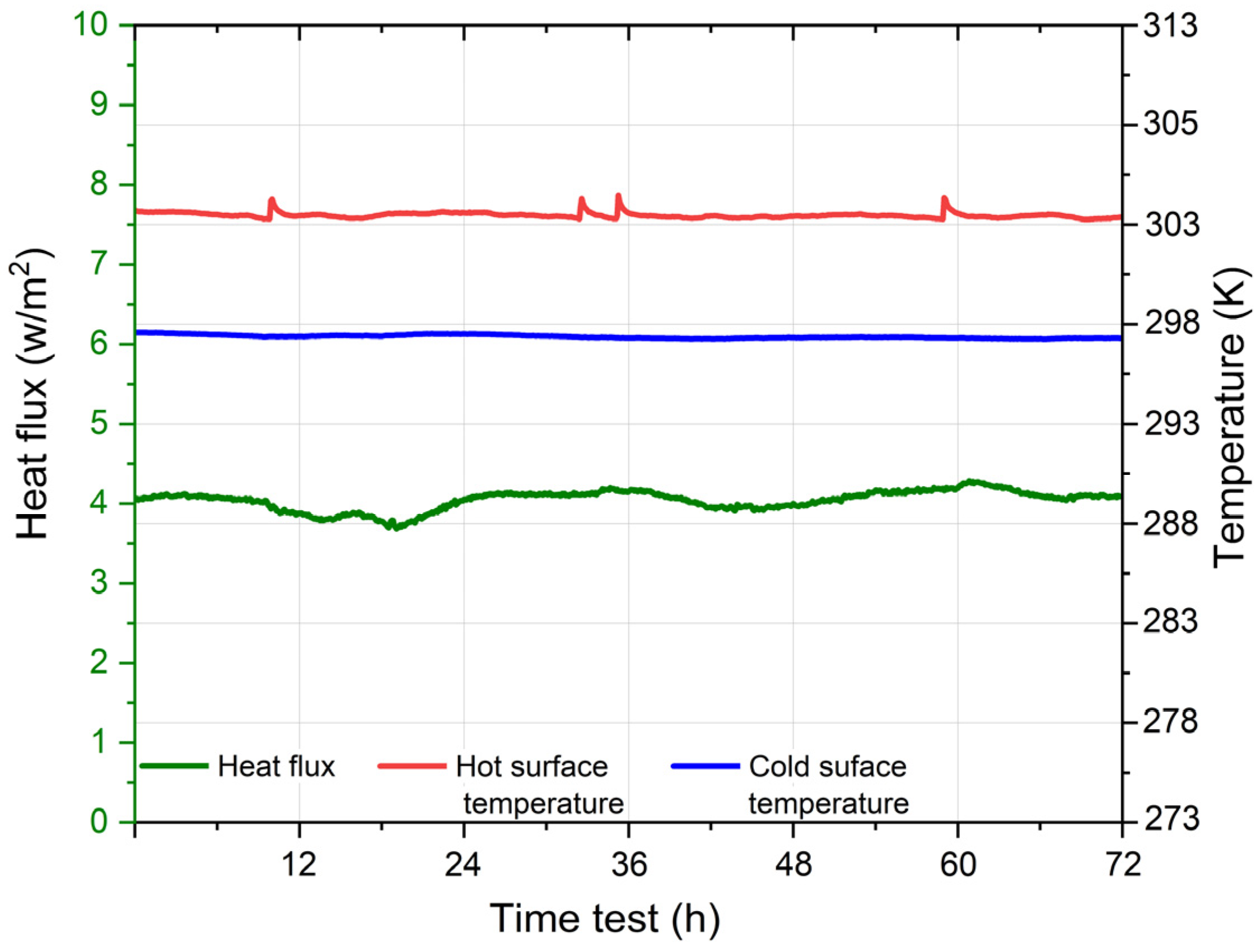

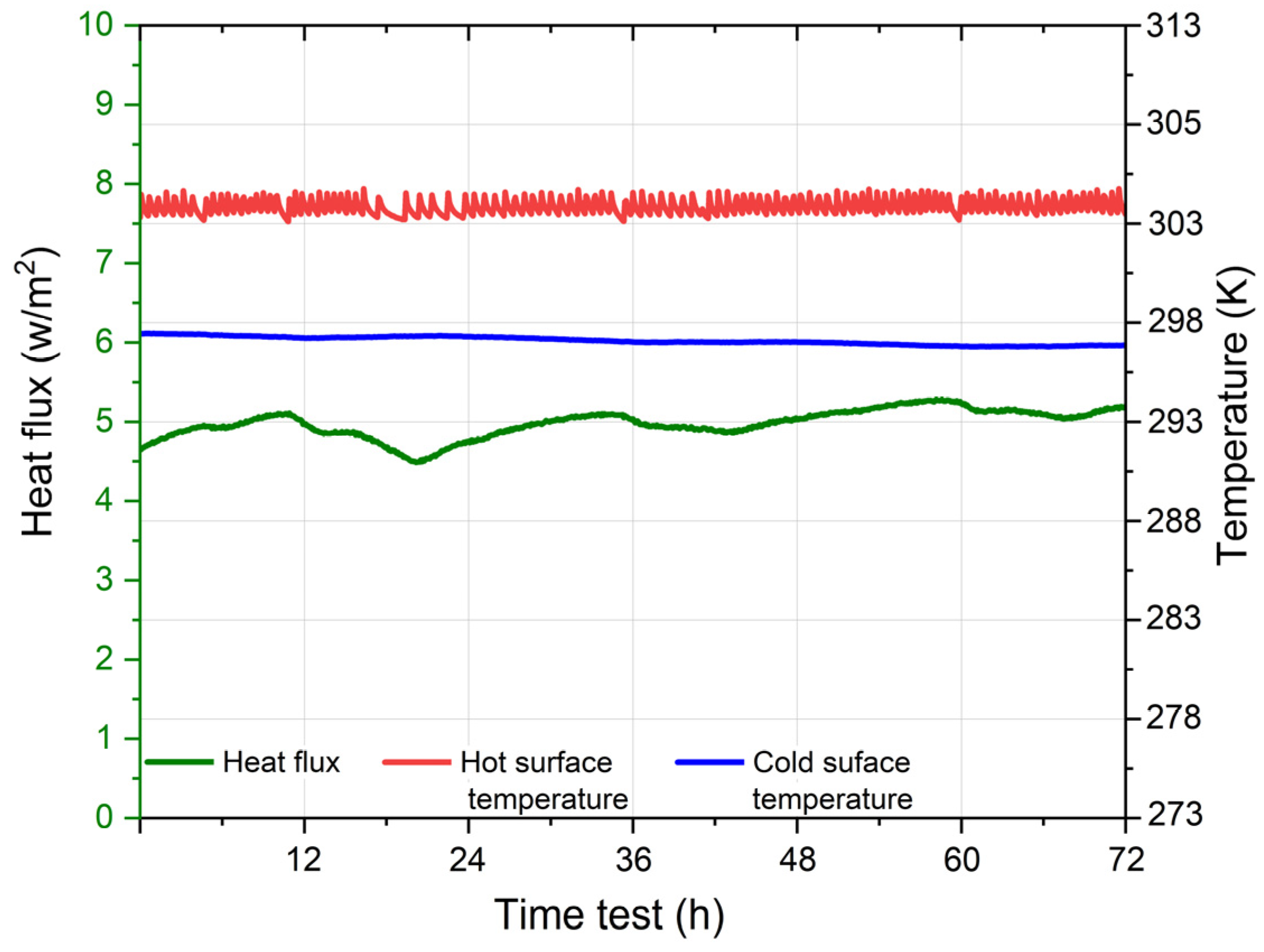

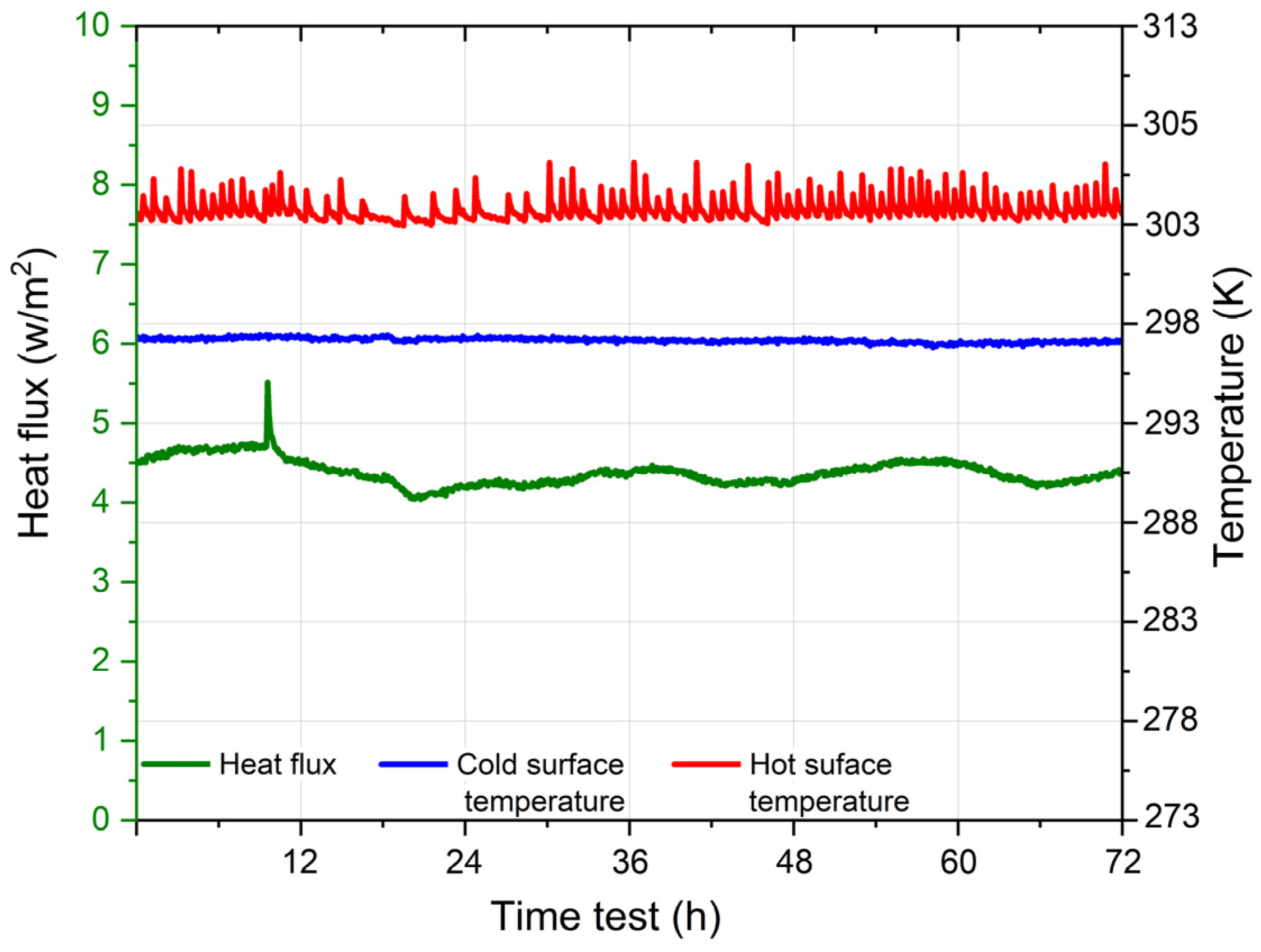

3.1. Thermal Performance

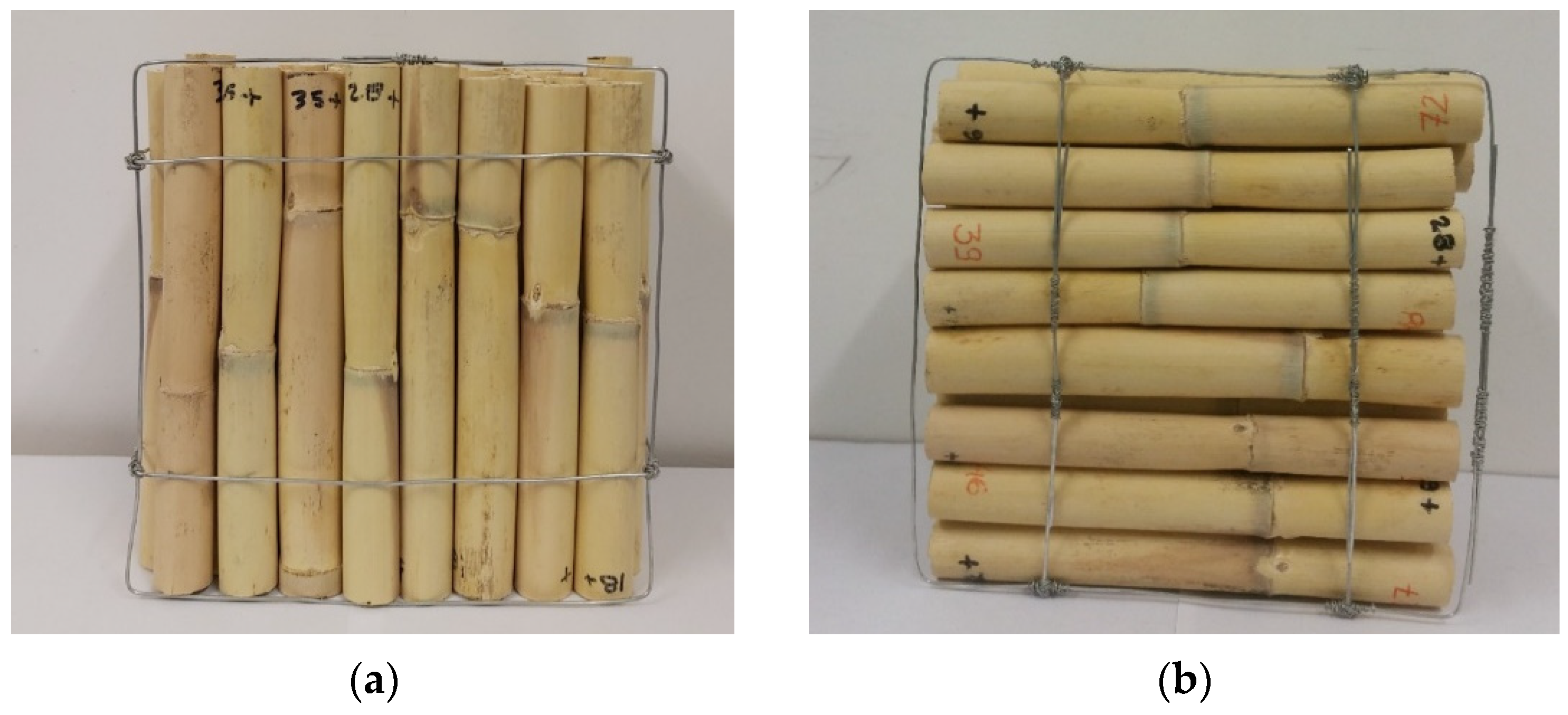

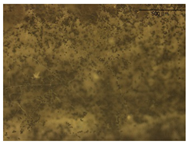

3.1.1. Giant-Reed Board Development

3.1.2. Thermal Characterisation of Giant-Reed Boards

- q—heat flow through the set (W/m2),

- ΔT—difference between the MDF surface temperature in the hot and cold chambers (K),

- e—thickness of the giant-reed board (m).

3.2. Physical Behaviour

3.3. Biological Behaviour

4. Results and Discussion

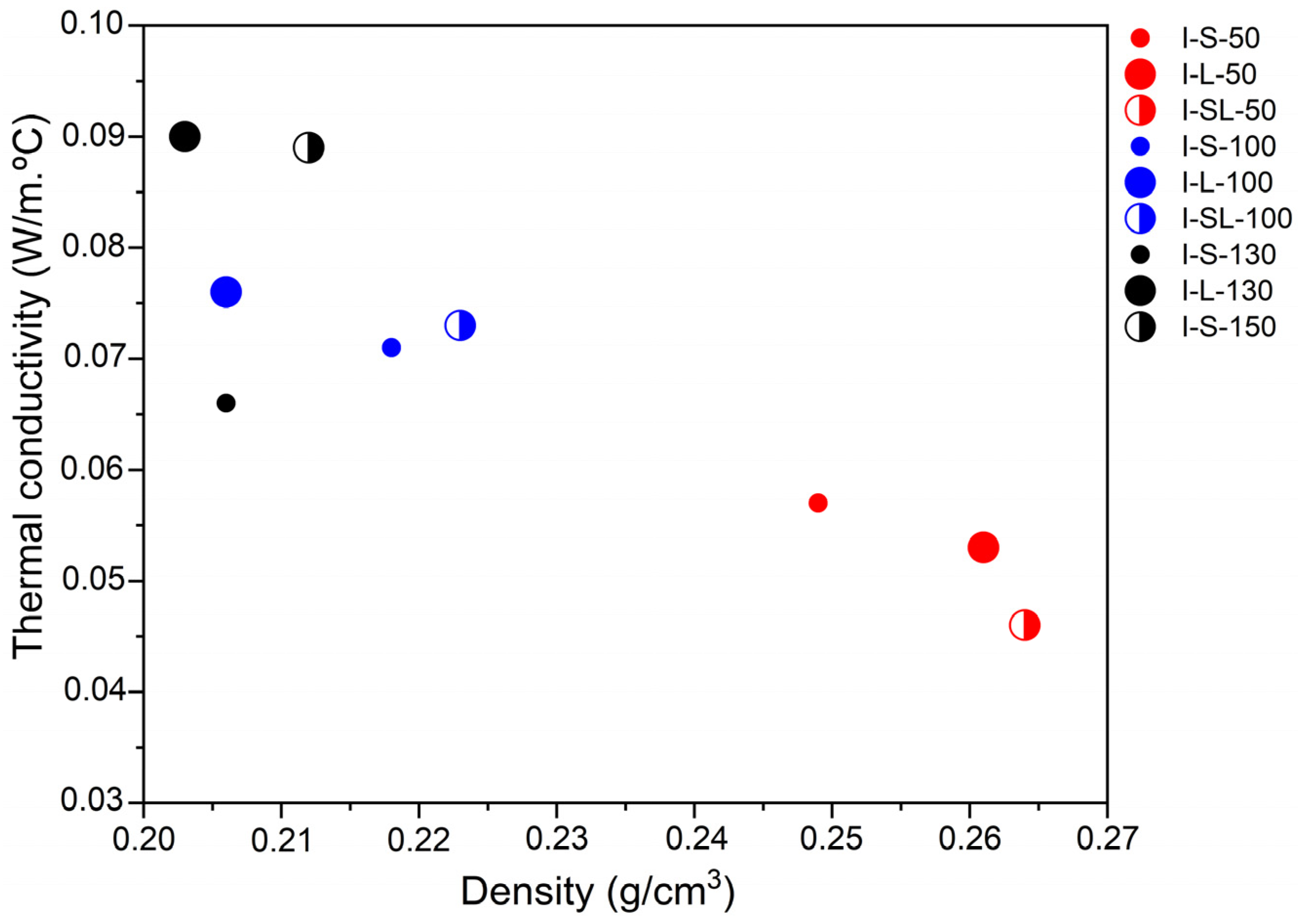

4.1. Thermal Characterisation

4.1.1. Characterisation of Giant Reeds from Different Portuguese Regions

4.1.2. Influence of Board Thickness and Giant Reed Diameter on the Thermal Parameters

4.1.3. Influence of the Position of the Giant Reed Stalks on the Thermal Performance

4.2. Physical Characterisation

4.3. Biological Behaviour

5. Discussion: Giant-Reed Board as Insulation Material

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Topics Buildings—International Energy Agency. Available online: https://www.iea.org/topics/buildings (accessed on 2 March 2021).

- The Future of Cooling—Analysis—IEA. Available online: https://www.iea.org/reports/the-future-of-cooling (accessed on 8 June 2021).

- IEA. The Covid-19 Crisis and Clean Energy Progress—Analysis—IEA. Available online: https://www.iea.org/reports/the-covid-19-crisis-and-clean-energy-progress (accessed on 3 June 2021).

- Göswein, V.; Reichmann, J.; Habert, G.; Pittau, F. Land Availability in Europe for a Radical Shift toward Bio-Based Construction. Sustain. Cities Soc. 2021, 70, 102929. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.M.; Giraldo, M.P.; Haurie, L.; Correal, E. Bio-Based Insulation Materials and Their Hygrothermal Performance in a Building Envelope System (ETICS). Energy Build. 2018, 174, 147–155. [Google Scholar] [CrossRef]

- Pittau, F.; Krause, F.; Lumia, G.; Habert, G. Fast-Growing Bio-Based Materials as an Opportunity for Storing Carbon in Exterior Walls. Build Environ. 2018, 129, 117–129. [Google Scholar] [CrossRef]

- Haworth, M.; Marino, G.; Cosentino, S.L.; Brunetti, C.; De Carlo, A.; Avola, G.; Riggi, E.; Loreto, F.; Centritto, M. Increased Free Abscisic Acid during Drought Enhances Stomatal Sensitivity and Modifies Stomatal Behaviour in Fast Growing Giant Reed (Arundo donax L.). Environ. Exp. Bot. 2018, 147, 116–124. [Google Scholar] [CrossRef]

- Köbbing, J.F.; Thevs, N.; Zerbe, S. The Utilisation of Reed (Phragmites Australis): A Review. Int. Mire Conserv. Group Int. Peat Soc. 2013, 13, 1–14. [Google Scholar]

- Barreca, F. Use of Giant Reed Arundo donax L. in Rural Constructions. Agric. Eng. Int. CIGR J. 2012, 14, 46–52. [Google Scholar]

- Clamote, F.; Carapeto, A.; Pereira, E.; Holyoak, D.; Almeida, J.; Araújo, P.; Lourenço, J.M.P. Arundo_donax. Available online: http://www.flora-on.pt/#wArundo+donax (accessed on 16 April 2019).

- AAVV. Arquitectura Popular Em Portugal; Associação dos Arquitetos Portugueses: Lisboa, Portugal, 1988. [Google Scholar]

- Fernandes, J.; Malheiro, R.; De Fátima Castro, M.; Gervásio, H.; Silva, S.M.; Mateus, R. Thermal Performance and Comfort Condition Analysis in a Vernacular Building with a Glazed Balcony. Energies 2020, 13, 624. [Google Scholar] [CrossRef]

- Fernandes, J. O Contributo Da Arquitectura Vernacular Portuguesa Para a Sustentabilidade Dos Edifícios; University of Minho: Guimarães, Portugal, 2012. [Google Scholar]

- Santos, A. Telhados de Tesouro de Tavira—Modelos e Tipologias de Casas Nobres Da Ribeira Com Telhados Múltiplos. In Proceedings of the Colóquio Internacional Arquitectura Popular, Tradição e Vanguarda; ISCTE-IUL: Lisbon, Portugal, 2016; ISBN 978-989-732-985-2. [Google Scholar]

- Ferreira, D.M.; Araújo, A.; Fonseca, E.M.M.; Piloto, P.A.G.; Pinto, J. Behaviour of Non-Loadbearing Tabique Wall Subjected to Fire—Experimental and Numerical Analysis. J. Build. Eng. 2017, 9, 164–176. [Google Scholar] [CrossRef]

- Asdrubali, F.; Bianchi, F.; Cotana, F.; D’Alessandro, F.; Pertosa, M.; Pisello, A.L.; Schiavoni, S. Experimental Thermo-Acoustic Characterization of Innovative Common Reed Bio-Based Panels for Building Envelope. Build. Environ. 2016, 102, 217–229. [Google Scholar] [CrossRef]

- Barreca, F.; Martinez Gabarron, A.; Flores Yepes, J.A.; Pastor Pérez, J.J. Innovative Use of Giant Reed and Cork Residues for Panels of Buildings in Mediterranean Area. Resour. Conserv. Recycl. 2019, 140, 259–266. [Google Scholar] [CrossRef]

- Miljan, M.; Miljan, M.; Miljan, J.; Akermann, K.; Karja, K. Thermal Transmittance of Reed-Insulated Walls in a Purpose-Built Test House. Mires Peat 2014, 13, 1–12. [Google Scholar]

- Costa, A.; Almeida, M.; Santos, M.; Costa, M.; Ribeiro, V. Materiais, Sistemas e Técnicas de Construção Tradicional—Contributo Para o Estudo d Arquitetura Vernácula Da Região Oriental Da Serra Do Caldeirão; Edições Afrontamento e CCDR Algarve: Porto, Portugal, 2007. [Google Scholar]

- Stein, B.A.; Kutner, L.S.; Adams, J.S. Arundo Donax vs. Phragmites Australis. Available online: http://desertfishes.org/cuatroc/organisms/arundo-vs-phragmites.html (accessed on 24 March 2021).

- Speck, O.; Spatz, H. Mechanical Properties of the Rhizome of Arundo donax L. Plant Biol. 2003, 5, 661–669. [Google Scholar] [CrossRef]

- Carneiro, P.; Jerónimo, A.; Faria, P. Reed-Cob: Tecnologia Inovadora de Baixo Carbono Para Construção de Pequeno Porte. In Proceedings of the II Encontro Nacional Sobre Reabilitação Urbana e Sustentabilidade; iiSBE Portugal & Universidade do Minho: Lisboa, Portugal, 2017. [Google Scholar]

- Hatfield, J.L.; Prueger, J.H. Temperature Extremes_Effect on Plant Growth and Development. Weather Clim. Extrem. 2015, 10, 4–10. [Google Scholar] [CrossRef]

- Hirai, G.-I.; Okumura, T.; Takeuchi, S.; Tanaka, O.; Chujo, H. Plant Production Science Studies on the Effect of the Relative Humidity of the Atmosphere on the Growth and Physiology of Rice Plants. Plant Prod. Sci. 2000, 3, 129–133. [Google Scholar] [CrossRef]

- Lautkankare, R. The Mold Test. In Guidebook of Reed Business; Tallinn, Estonia, 2013; pp. 42–46. ISBN 9789949484911. Available online: https://www.ymparisto.fi/download/noname/%7BCCDBCAB8-A4B6-400B-BF6F-4F1D04CCD126%7D/120479 (accessed on 24 March 2021).

- Bergholm, J. Susceptibility to Microbial Growth of Common Reed and Other Construction Materials. Bachelor’s Thesis, Turku University of Applied Sciences, Turku, Finland, 2012. [Google Scholar]

- García-Ortuño, T. Caracterización de La Caña Común (Arundo donax L.) Para Su Uso Como Material de Construcción; Universidad Miguel Hernández: Alicante, Spain, 2003. [Google Scholar]

- Volf, M.; Diviš, J.; Havlík, F. Thermal, Moisture and Biological Behaviour of Natural Insulating Materials. Energy Procedia 2015, 78, 1599–1604. [Google Scholar] [CrossRef]

- Topográficos, M. Mapas Topográficos Portugal. Available online: https://pt-pt.topographic-map.com/maps/gnn0/Portugal/ (accessed on 14 September 2021).

- Agencia Estatal de Meteorología. Iberian Climate Atlas: Air Temperature and Precipitation (1971/2000); Agencia Estatal de Meteorología: Ministerio de Medio Ambiente y Medio Rural y Marino, Instituto de Meteorologia de Portugal, Eds.; AEMET/IM: Madrid, Spain, 2011; ISBN 978-84-7837-079-5. [Google Scholar]

- ASTM C1363-11; Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus 1. ASTM: West Conshohocken, PA, USA, 2014; Volume 90, pp. 1–44. [CrossRef]

- ASTM C1155—95 C1155; Standard Practice for Determining Thermal Resistance of Building Envelope Components from the In-Situ Data. ASTM: West Conshohocken, PA, USA, 2013; Volume i, pp. 1–8.

- Malheiro, R.; Ansolin, A.; Guarnier, C.; Fernandes, J.; Amorim, M.; Silva, S.M.; Mateus, R. The Potential of the Reed as a Regenerative Building Material—Characterisation of Its Durability, Physical, and Thermal Performances. Energies 2021, 14, 4276. [Google Scholar] [CrossRef]

- Viitanen, H. A Mathematical Model of Mould Growth on Wooden Material. Wood Sci. Technol. 2014, 33, 475–485. [Google Scholar] [CrossRef]

- Couvreur, L.; Alejandro Buzo, R. Construir Con Caña—Estudio Del Uso de La Caña En La Arquitectura Tradicional y de Su Recuperación Para La Construcción Contemporánea; Catálogo de publicaciones del Ministerio: Madrid, Spain, 2019. Available online: www.culturaydeporte.gob.es (accessed on 13 June 2021).

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation Materials for the Building Sector: A Review and Comparative Analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Decree-Law No. 80/2006; Diário da República—Série-A N.o 67-4 de Abril de 2006. UN: Lisbon, Portugal, 2006; pp. 2468–2513.

- Termolan Isolamentos Acústicos, S.A. RocTerm—MN230. Available online: https://termolan.pt/wp-content/uploads/2021/03/ft-roctermmn230-pt-compressed.pdf (accessed on 29 September 2021).

- Danosa Danosa—Danopren TR-P 50. Available online: https://portal.danosa.com/danosa/CMSServlet?node=484103&lng=4&site=3 (accessed on 29 September 2021).

- Mantingança, S. Secil Argamassas SecilVit Painel EPS. Isovit Painel em Poliestireno Expandido. Available online: https://www.secil.pt/pt/produtos/argamassas/sistema-etics/isovit-painel-em-poliestireno-expandido---eps-100 (accessed on 29 September 2021).

- Amorim Cork Insulation Amorim Cork Insulation. Available online: https://www.amorimcorkinsulation.com/xms/files/FICHAS_TECNICAS_2021/FT_Corkboard_PT_2021.pdf (accessed on 29 September 2021).

| ID | Köpp–Geiger Climate Classification | Total Annual Precipitation (mm) | Annual Average Mean Temperature (K) | Annual Average Minimum Temperature (K) | Annual Average Maximum Temperature (K) | |

|---|---|---|---|---|---|---|

| Type | Sub-Type | |||||

| Region I | C | Csa | 400 | 290.65 | 285.65 | 298.15 |

| Region II | C | Csa | 800 | 288.15 | 283.15 | 290.65 |

| Region III | C | Csb | 1400 | 288.15 | 283.15 | 290.65 |

| Giant-Reed Board Identification | Region from Giant Reed | Thickness of Board (mm) | Quantity of Reed in the Board (Unit) | Density of Board (g/cm3) |

|---|---|---|---|---|

| I-55 | I | 55 | 41 | 0.237 |

| II-50 | II | 50 | 33 | 0.231 |

| III-50 | III | 50 | 29 | 0.256 |

| Giant-Reed Board Identification | Region from Giant Reed | Diameter of Giant Reed | Thickness of Board (mm) | Quantity of Reed in the Board (Unit) | Density of Board (g/cm3) |

|---|---|---|---|---|---|

| I-S-50 | I | S | 50 | 47 | 0.249 |

| I-L-50 | I | L | 50 | 31 | 0.261 |

| I-SL-50 | I | SL | 50 | 38 | 0.264 |

| I-S-100 | I | S | 100 | 84 | 0.218 |

| I-S-100-H | I | S | 100 | 84 | 0.217 |

| I-L-100 | I | L | 100 | 52 | 0.206 |

| I-SL-100 | I | SL | 100 | 71 | 0.223 |

| I-SL-100-H | I | SL | 100 | 71 | 0.221 |

| I-S-130 | I | S | 130 | 102 | 0.206 |

| I-L-130 | I | L | 130 | 71 | 0.203 |

| I-SL-150 | I | SL | 150 | 101 | 0.212 |

| I-SL-150-H | I | SL | 150 | 98 | 0.209 |

| Mould Index | Coverage | Description of Classification |

|---|---|---|

| 0 | 0 | No growth |

| 1 | 0 | Some growth detected only with microscopy |

| 2 | >10% | Moderated growth detected with microscopy |

| 3 | 0–10% | Some growth detected visually |

| 4 | 10–50% | Visually detected |

| 5 | 50–80% | Visually detected |

| 6 | 80–100% | Visually detected |

| Giant-Reed Board Identification | Superficial Temperature (K) | Heat Flux (W/m2) | Reset (m2.K/W) | Rereed_board (m2.K/W) | λreed_board (W/m.K) | |

|---|---|---|---|---|---|---|

| Hot Chamber | Cold Chamber | |||||

| I-55 | 305.93 | 298.94 | 5.33 | 1.313 | 1.019 | 0.049 |

| II-50 | 303.78 | 297.11 | 5.35 | 1.247 | 0.953 | 0.052 |

| III-50 | 303.89 | 297.31 | 4.39 | 1.501 | 1.207 | 0.041 |

| Giant-Reed Board Identification | Superficial Temperature (K) | Heat Flux (W/m2) | Reset (m2.K/W) | Rereed_board (m2.K/W) | λreed_board (W/m.K) | |

|---|---|---|---|---|---|---|

| Hot Chamber | Cold Chamber | |||||

| I-S-50 | 304.77 | 298.03 | 5.76 | 1.172 | 0.878 | 0.057 |

| I-L-50 | 305.62 | 298.7 | 5.62 | 1.233 | 0.939 | 0.053 |

| I-SL-50 | 305.68 | 298.76 | 5.03 | 1.382 | 1.088 | 0.046 |

| I-S-100 | 308.68 | 298.77 | 5.81 | 1.707 | 1.413 | 0.071 |

| I-L-100 | 311.71 | 300.77 | 6.77 | 1.618 | 1.324 | 0.076 |

| I-SL-100 | 308.41 | 299.32 | 5.49 | 1.659 | 1.365 | 0.073 |

| I-S-130 | 305.87 | 295.91 | 4.44 | 2.259 | 1.965 | 0.066 |

| I-L-130 | 305.73 | 294.59 | 6.44 | 1.741 | 1.447 | 0.090 |

| I-SL-150 | 309.5 | 299.43 | 5.12 | 1.973 | 1.679 | 0.089 |

| ID | Direction | Density (kg/m3) | Superficial Temperature (K) | Heat Flux (W/m2) | Reset (m2.K/W) | Rereed_board (m2.K/W) | λreed_board (W/m.K) | |

|---|---|---|---|---|---|---|---|---|

| Hot Chamber | Cold Chamber | |||||||

| I-S-100 | V | 0.218 | 308.68 | 298.77 | 5.81 | 1.707 | 1.413 | 0.071 |

| I-S-100-H | H | 0.217 | 307.89 | 297.84 | 5.8 | 1.734 | 1.44 | 0.069 |

| I-SL-100 | V | 0.223 | 308.41 | 299.32 | 5.49 | 1.659 | 1.365 | 0.073 |

| I-SL-100-H | H | 0.221 | 307.48 | 299.37 | 4.87 | 1.672 | 1.378 | 0.073 |

| I-SL-150 | V | 0.212 | 309.5 | 299.43 | 5.12 | 1.973 | 1.679 | 0.089 |

| I-SL-150-H | H | 0.209 | 309.79 | 298.57 | 5.05 | 2.229 | 1.935 | 0.078 |

| ID | Water Content (%) | SD |

|---|---|---|

| Region I | 7.9 | 0.36 |

| Region II | 8.2 | 0.34 |

| Region III | 8.9 | 0.36 |

| Region | Bare Eyes: Before the Test | Bare Eyes: During the Test | Microscope (5×): During the Test | |

|---|---|---|---|---|

| Individual | I |  |  |  |

| II |  |  |  | |

| III |  |  |  | |

| Grouped | I |  |  |  |

| II |  |  |  | |

| III |  |  |  |

| Material | Thickness (mm) | Density (g/cm3) | Re (m2.K/W) | λ (W/m.K) | Reference |

|---|---|---|---|---|---|

| Rock wool | 50 | 0.025 | 1.60 | 0.037 | [39] |

| XPS | 50 | 0.032 | 1.40 | 0.036 | [40] |

| EPS | 50 | 0.020 | 1.30 | 0.036 | [41] |

| Cork | 50 | 0.110 | 1.25 | 0.039 | [42] |

| Giant-reed boards | 50–55 | 0.231–0.264 | 0.88–1.21 | 0.041–0.057 | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malheiro, R.; Morillas, A.; Ansolin, A.; Fernandes, J.; Camões, A.; Amorim, M.T.; Silva, S.M.; Mateus, R. Thermal Performance and Durability Evaluation of Arundo Donax towards an Improvement in the Knowledge of Sustainable Building Materials. Energies 2023, 16, 989. https://doi.org/10.3390/en16020989

Malheiro R, Morillas A, Ansolin A, Fernandes J, Camões A, Amorim MT, Silva SM, Mateus R. Thermal Performance and Durability Evaluation of Arundo Donax towards an Improvement in the Knowledge of Sustainable Building Materials. Energies. 2023; 16(2):989. https://doi.org/10.3390/en16020989

Chicago/Turabian StyleMalheiro, Raphaele, Aurora Morillas, Adriana Ansolin, Jorge Fernandes, Aires Camões, Maria Teresa Amorim, Sandra Monteiro Silva, and Ricardo Mateus. 2023. "Thermal Performance and Durability Evaluation of Arundo Donax towards an Improvement in the Knowledge of Sustainable Building Materials" Energies 16, no. 2: 989. https://doi.org/10.3390/en16020989

APA StyleMalheiro, R., Morillas, A., Ansolin, A., Fernandes, J., Camões, A., Amorim, M. T., Silva, S. M., & Mateus, R. (2023). Thermal Performance and Durability Evaluation of Arundo Donax towards an Improvement in the Knowledge of Sustainable Building Materials. Energies, 16(2), 989. https://doi.org/10.3390/en16020989