Due to the rising primary energy shortage and environmental degradation, many countries around the world are highly encouraging and supporting the development of new energy vehicles. New energy vehicles mainly include electric vehicles, hydrogen energy vehicles and other environmental-friendly energy vehicles. Among them, electric vehicles (EVs) have received extensive attention due to their high efficiency, security and reliability [

1]. Currently, lithium-ion batteries are the most widely used energy storage system for EVs, and they highly determine EVs’ endurance and power performance. The capacity of lithium-ion batteries gradually degrades with the increase in cycle. According to the IEEE Standard 1188.1996, the battery needs to be replaced as its capacity drops to 80% of the rated capacity. In addition, some key states of the battery are closely related to the capacity, such as state of charge (SOC) [

1], state of health (SOH) [

2] and remaining useful life (RUL) [

3]. Therefore, it is of great significance to estimate battery capacity online.

1.1. Literature Review

A large number of capacity estimation methods have been proposed, which can mainly be divided into two categories: model-driven methods and data-driven methods.

The model-driven methods are usually based on the electrochemical model or the equivalent circuit model. The electrochemical model [

4,

5,

6] is based on the physical and chemical properties of the battery. It has the advantages of definite physical meaning and high accuracy. However, it is too complicated to be applied online and has many parameters to calibrate. The equivalent circuit model [

7,

8] is based on the electrical characteristics of the battery and uses electrical components, such as a resistor and a capacitor, to model the battery. Compared with the electrochemical model, the parameter number of the equivalent circuit model is greatly reduced, but the accuracy is lower. Generally, the model-driven methods require electrochemical knowledge and a profound understanding of the operating mechanism of the battery. Their flexibilities are also limited because different battery types, even cells, usually need to be modeled individually.

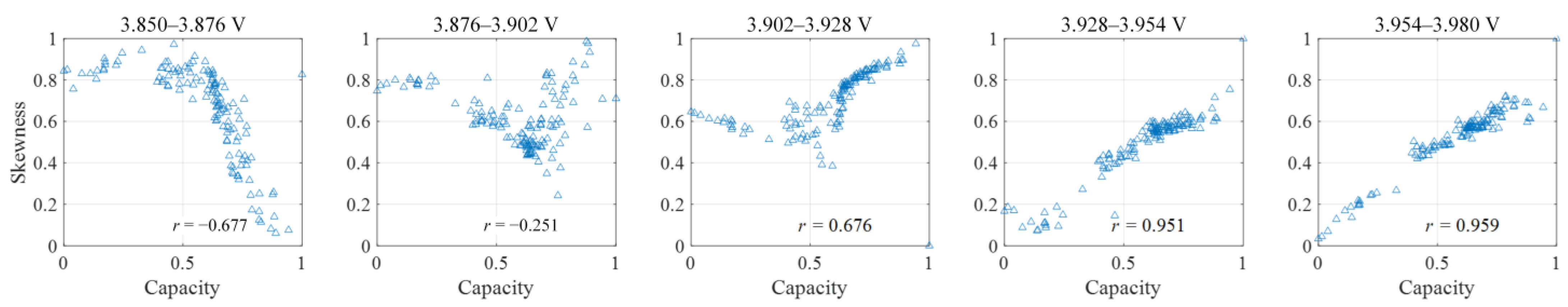

In contrast, the data-driven methods are more flexible and easier to use than the model-driven methods since they need not pay much attention to the complex electrochemical reactions inside the battery; rather, they only need to extract health features (HFs) representing the behavior of capacity degradation from historical data and then establish a machine learning model between HFs and the capacity. Chen et al. [

9] extracted four geometric HFs from the current and voltage curves. The Laplacian Eigenmap algorithm was employed to establish an intrinsic manifold, and the geodesic on the manifold was used to estimate battery capacity. Chao et al. [

10] extracted five HFs from the battery charging curve and then used the relevance vector machine (RVM) to model the relationship between HFs and the capacity. Zheng et al. [

11] extracted three HFs from the incremental capacity (IC) and differential voltage (DV) curves, and proposed a joint estimation method for SOC and capacity. In addition, some scholars use ultrasonic methods to extract HF. For example, Li et al. [

12] used a laser Doppler vibrometer to obtain the scanning signal of a lithium battery under different aging degrees and extract HF from it; Li et al. [

13] used ultrasonic signals to conduct non-destructive battery testing, and selected seven high-quality HF.

The machine learning model also plays an important role in the accurate estimation of battery capacity. With the rapid development of machine learning and artificial intelligence, an increasing number of algorithms, such as support vector machine (SVM) [

14,

15], correlation vector machine [

16], and Gaussian process regression [

17], are being introduced to battery capacity estimation. With the rise in neural networks (NNs), especially due to their outstanding nonlinear fitting ability, these are being widely used for capacity or SOH estimation. Zhang et al. [

18] constructed a three-layer back propagation neural network (BPNN) to train the model between internal resistance and capacity for achieving accurate state estimation. Wen et al. [

19] extracted HFs from IC curves and established an SOH estimation model at different temperatures also using BPNN. Pan et al. [

20] extracted multi-dimensional HFs from historical data, and established the extreme learning machine (ELM) to realize the SOH estimation. Li et al. [

21] proposed a framework incorporating the concepts of transfer learning and network pruning to build compact convolutional neural network (CNN) models on a relatively small dataset with improved estimation performance. Tan et al. [

22] proposed a SOH prediction method based on transfer learning, and designed a model by combining the long short-term memory (LSTM) and fully connected (FC) layers.

Most existing studies on capacity estimation are realized on the basis of full charging/discharging conditions. However, this is not practical for EV applications. EV users prefer to recharge the battery before its full discharging to 0% SOC due to range anxiety, while also preferring to stop charging before 100% SOC to avoiding over-charging. Especially in the case of fast charging, the battery is only charged to about 80% SOC. In other words, lithium-ion batteries are likely to experience an incomplete charging process. Accordingly, some researchers proposed capacity estimation methods based on fixed voltage/SOC segments. Fan et al. [

23] extracted HFs from specific segments in the constant current stage (3.8–4.1 V) and constant voltage stage (1.5–0.2 A), respectively, and utilized Gaussian process regression (GPR) to establish a model between HFs and the capacity. Schaltz et al. [

24] introduced a first-order linear equation to model the relationship between the sectional capacity and full capacity, verifying that different charging rates have little impact on the estimation results. Zheng et al. [

25] proposed the particle swarm optimization (PSO) algorithm to select an optimal charging voltage segment under different conditions and employed a linear model to estimate full capacity based on sectional capacity. Park et al. [

26] chose the sectional capacity corresponding to a fixed SOC segment as HF, and constructed a multi-layer perceptron (MLP) model for capacity estimation based on the extracted HF.

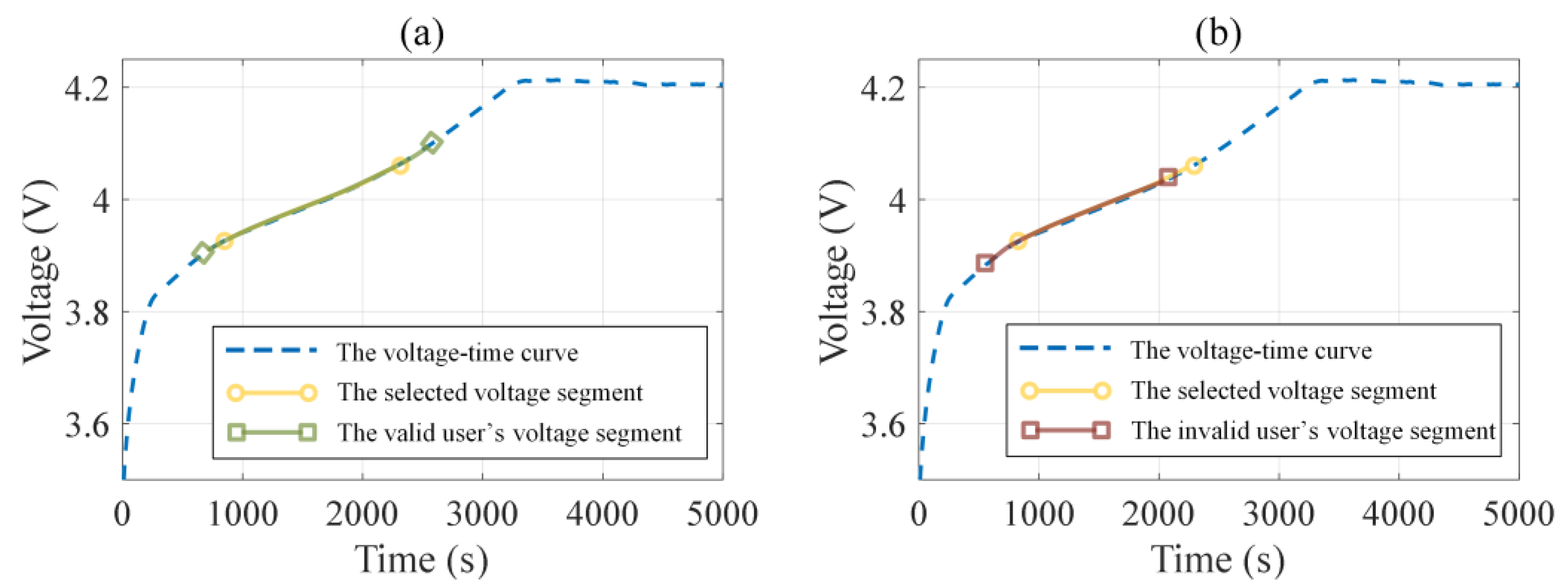

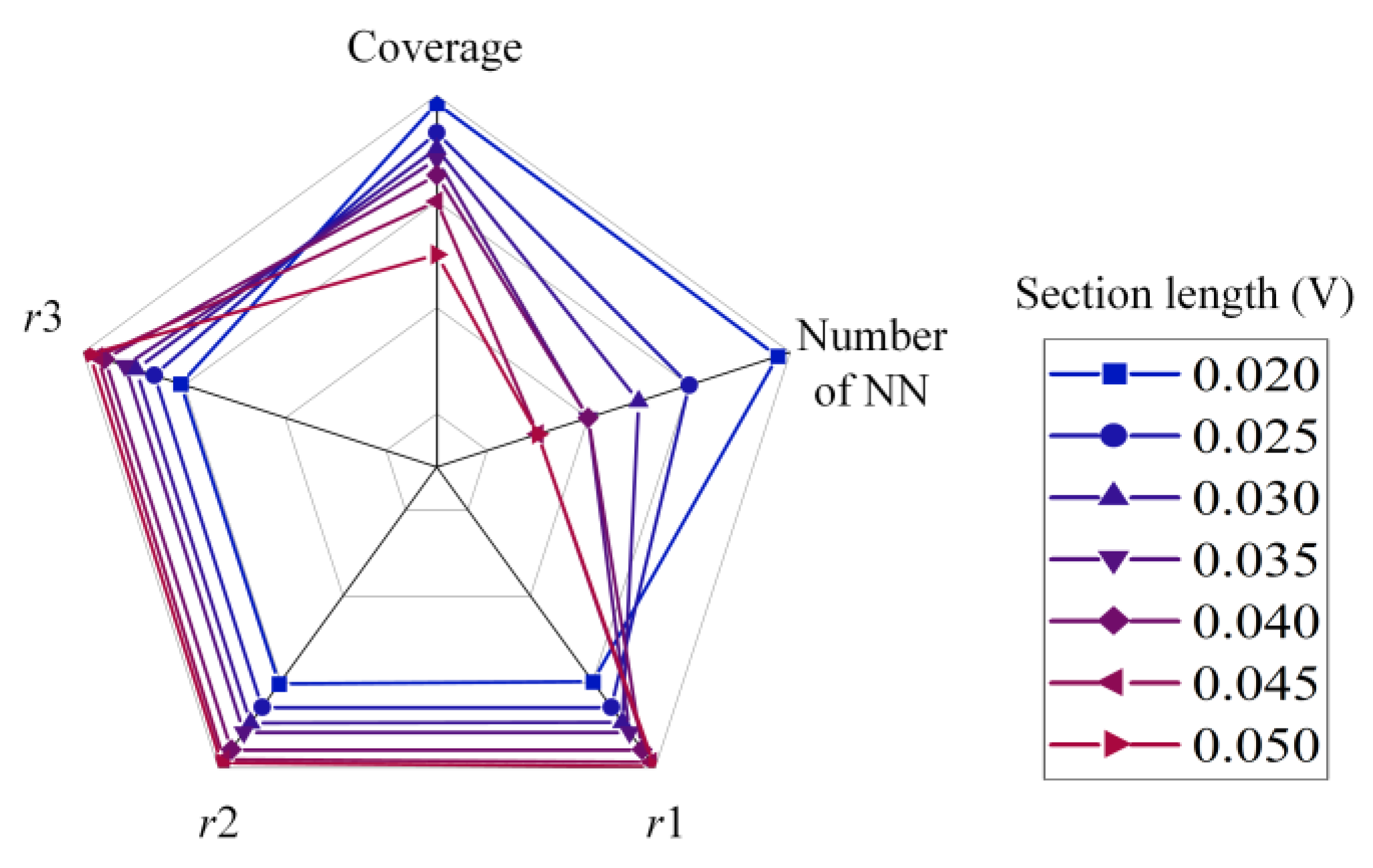

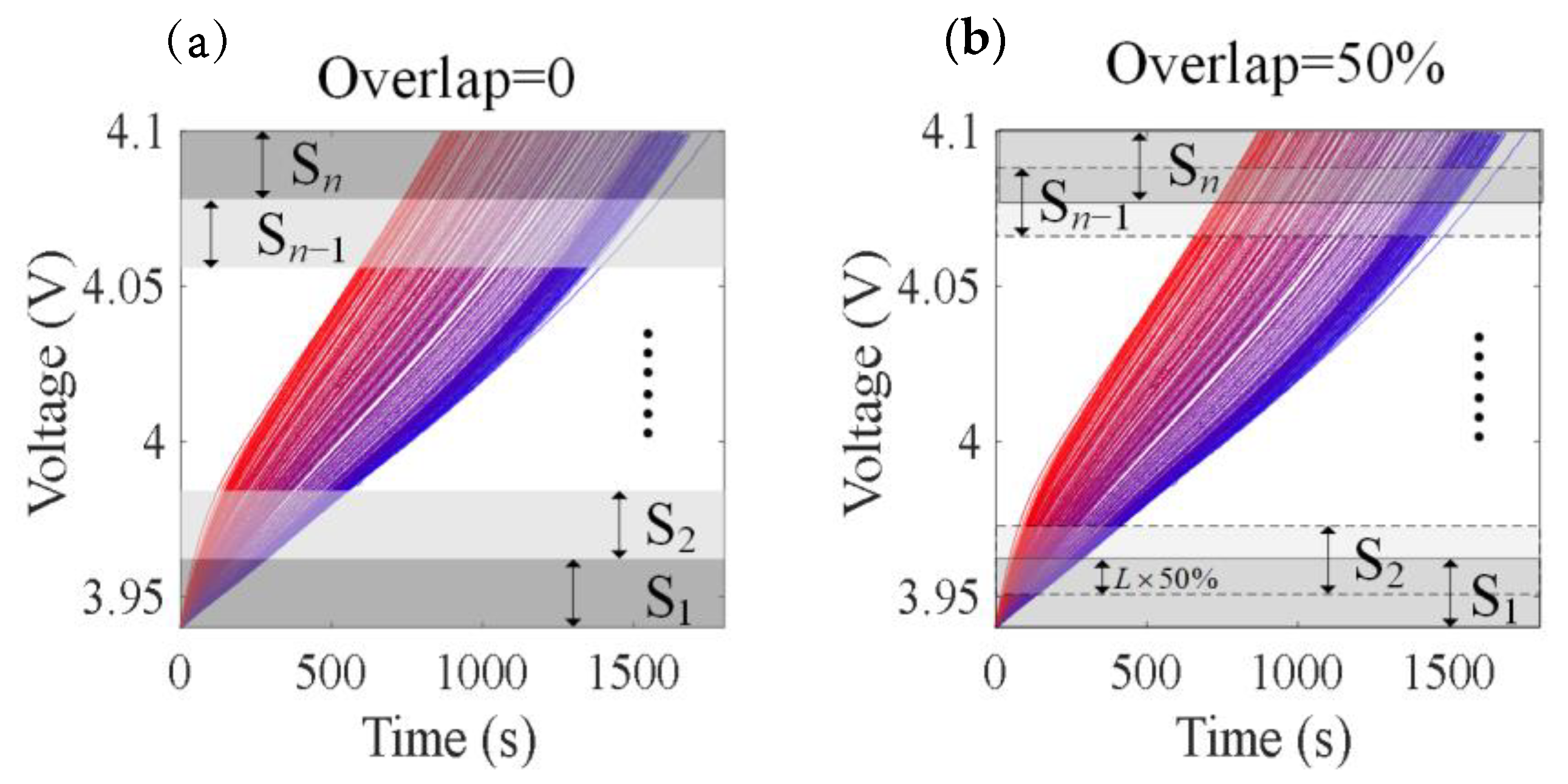

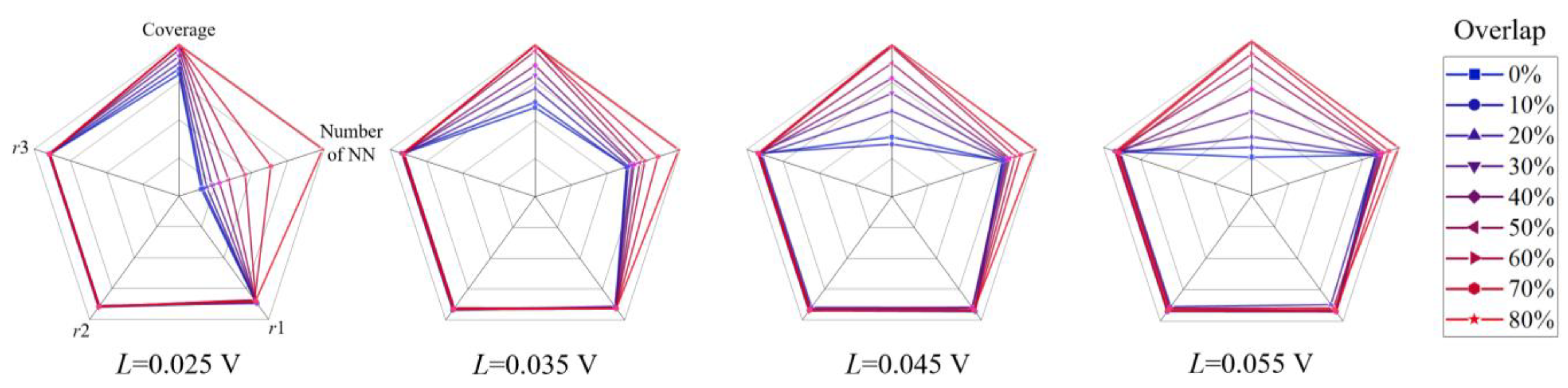

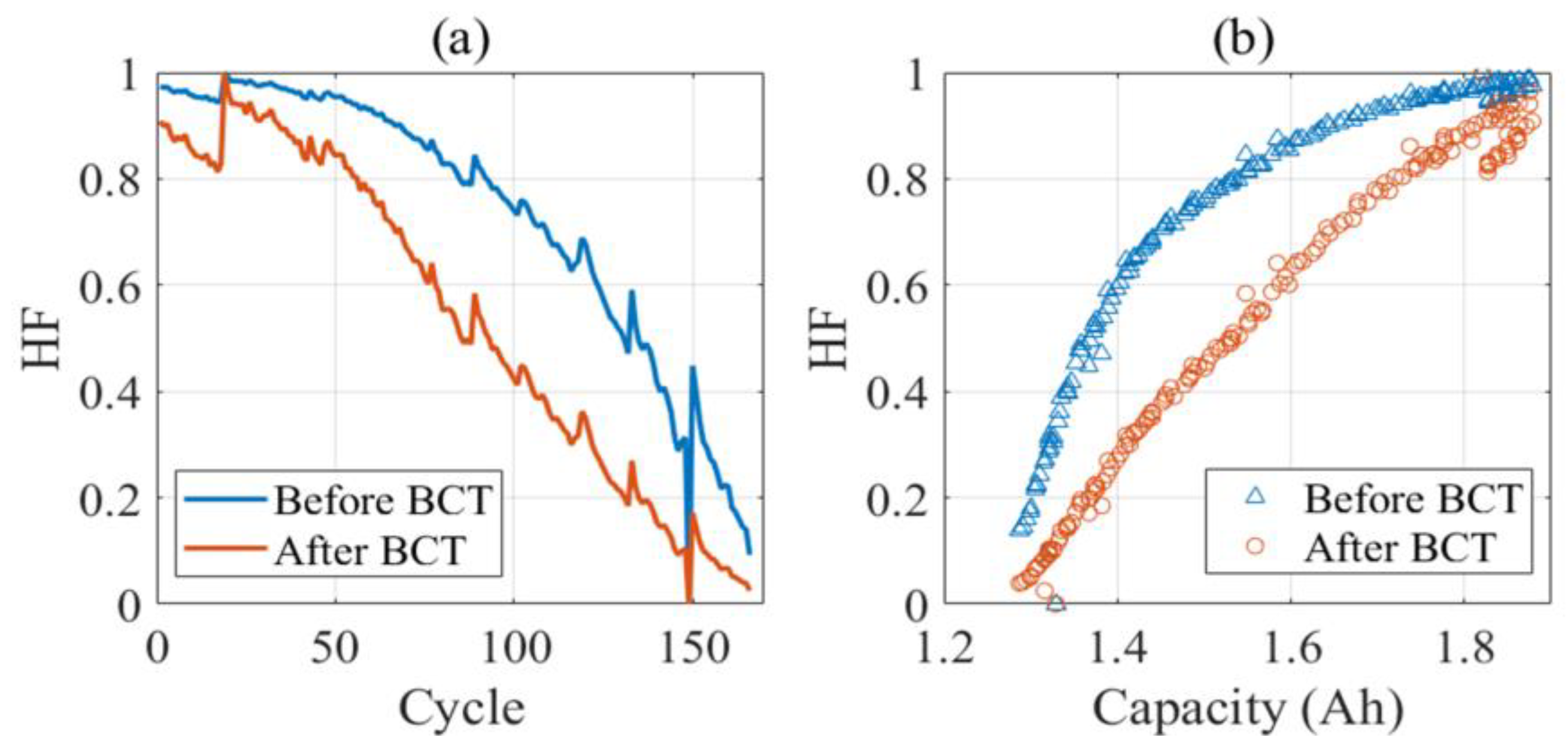

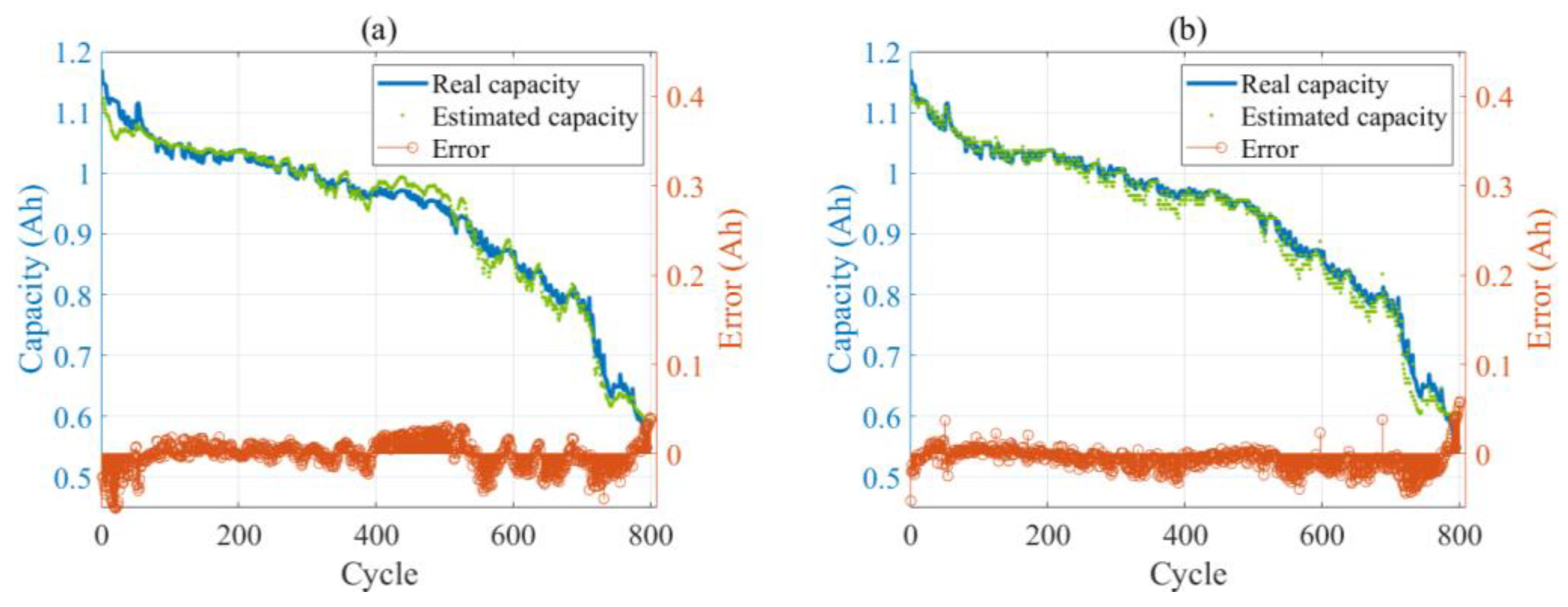

The above studies have proven the feasibility of using a charging segment for capacity estimation. In practice, however, EV users often exhibit free and inconsistent charging behaviors. In this case, a pre-determined and fixed charging segment cannot be fully covered (called a valid voltage segment in this paper), as shown in

Figure 1, leading to the failure of existing methods.