Unsteady Cloud Cavitation on a 2D Hydrofoil: Quasi-Periodic Loads and Phase-Averaged Flow Characteristics

Abstract

:1. Introduction

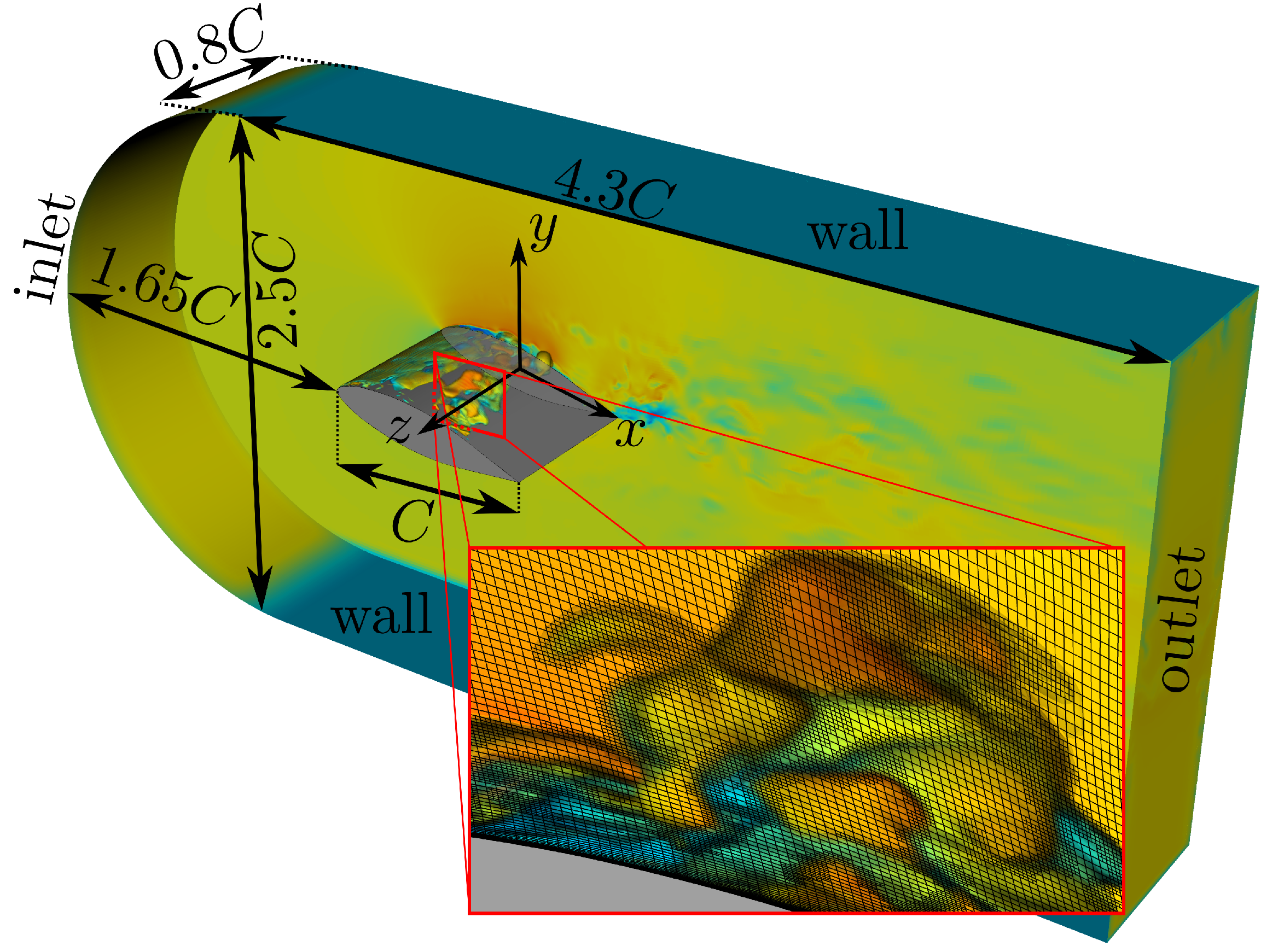

2. Modeling and Computational Details

2.1. Governing Equations

2.2. Numerical Details

2.3. Experimental Apparatus and PIV Measurement

3. Results

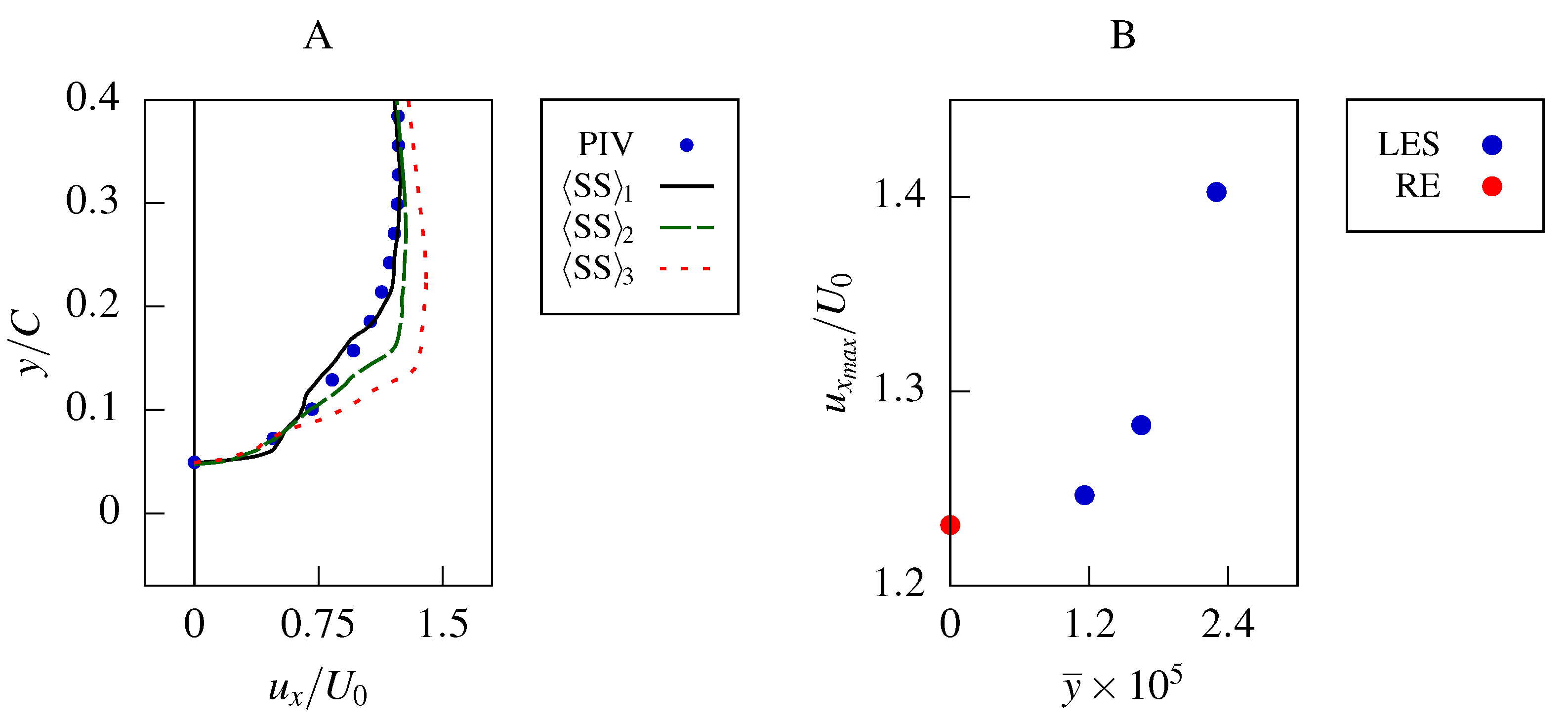

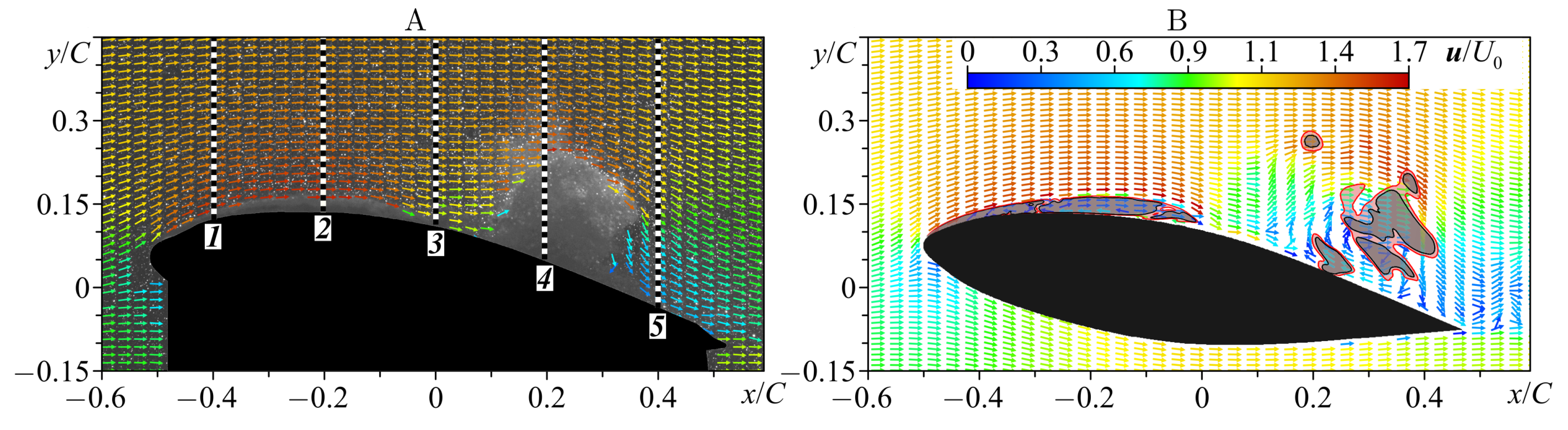

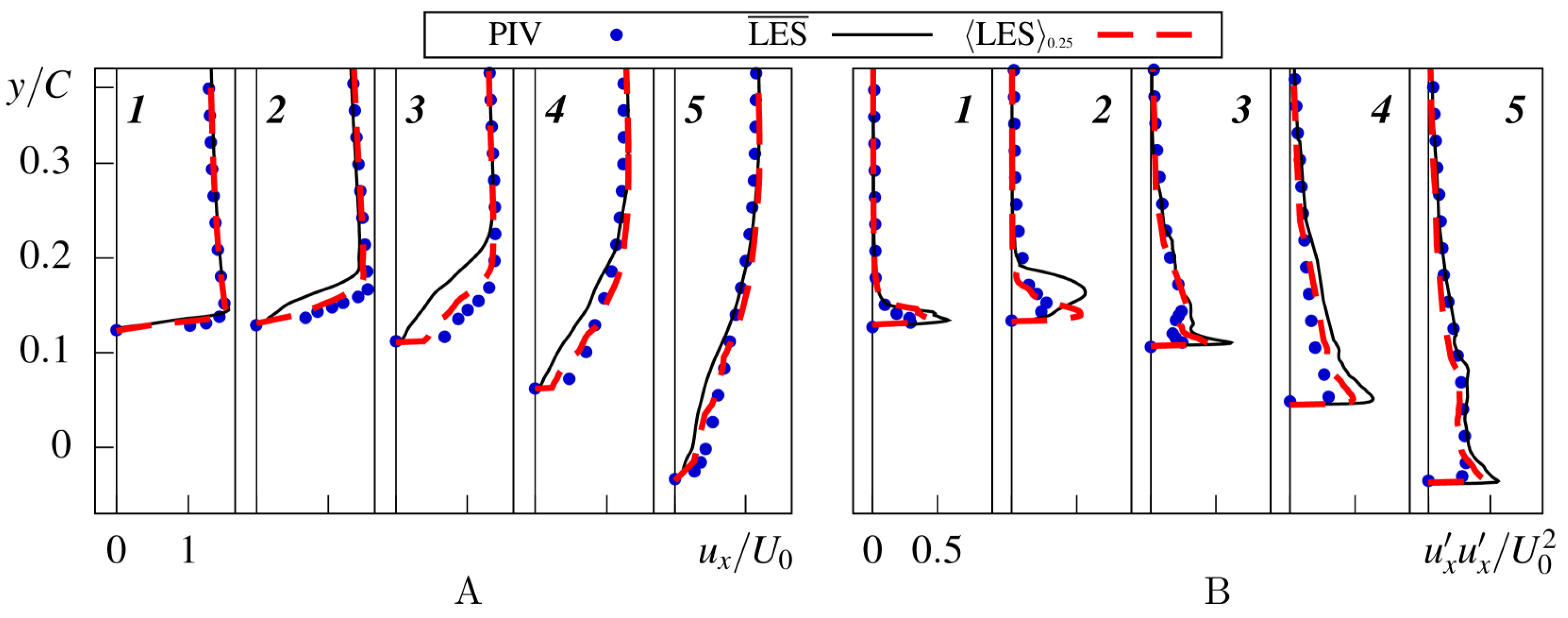

3.1. Comparison with Experiments

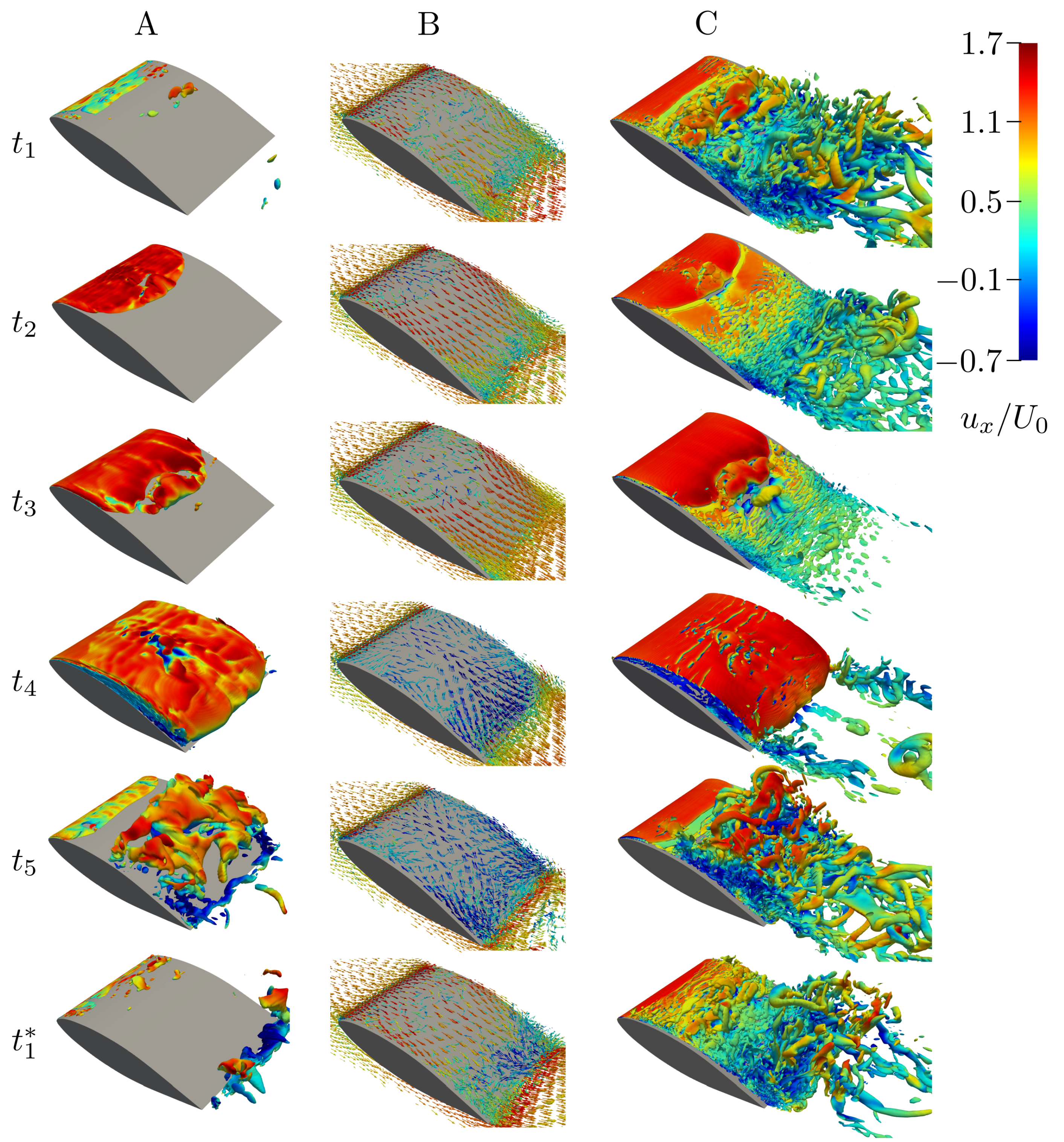

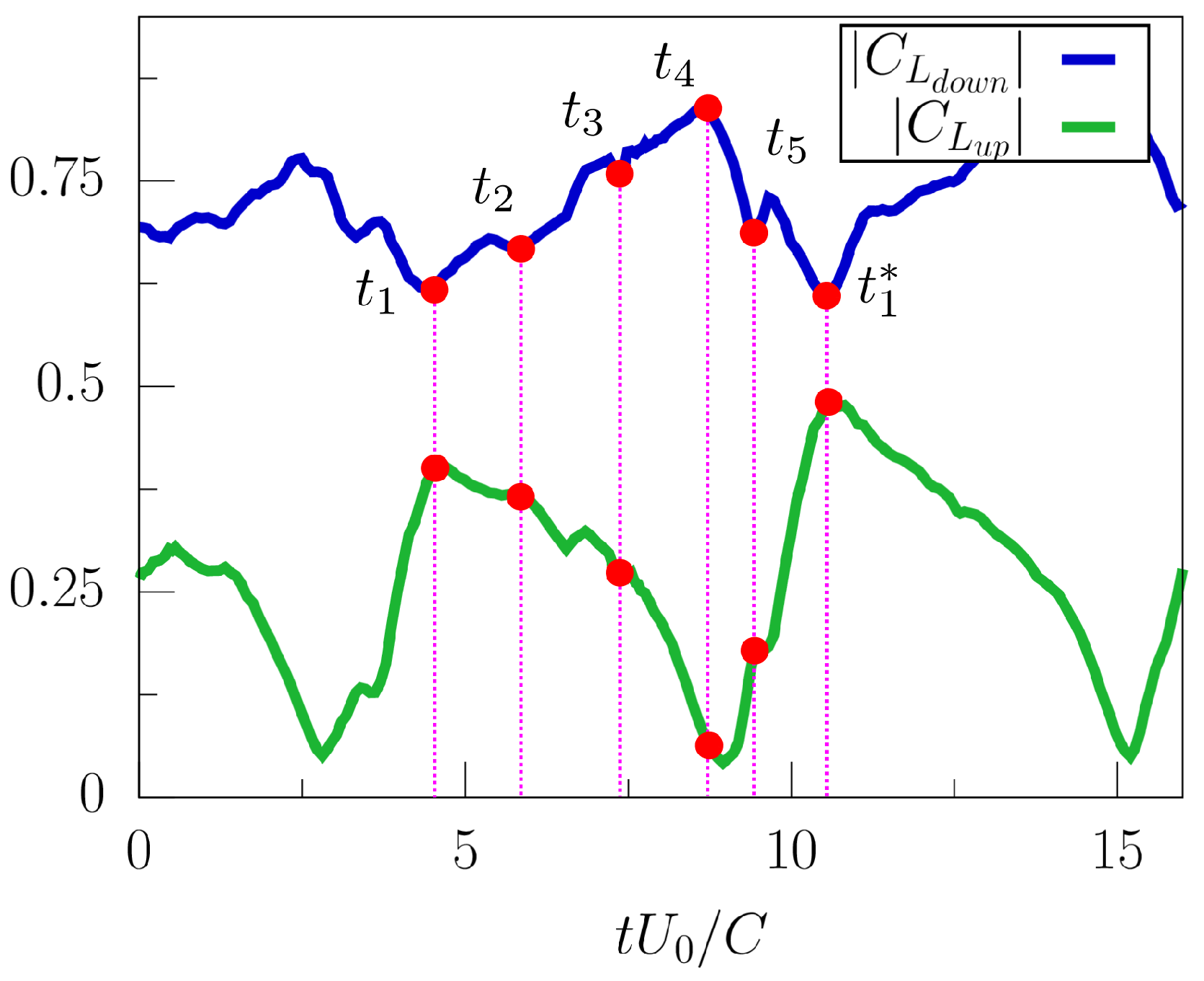

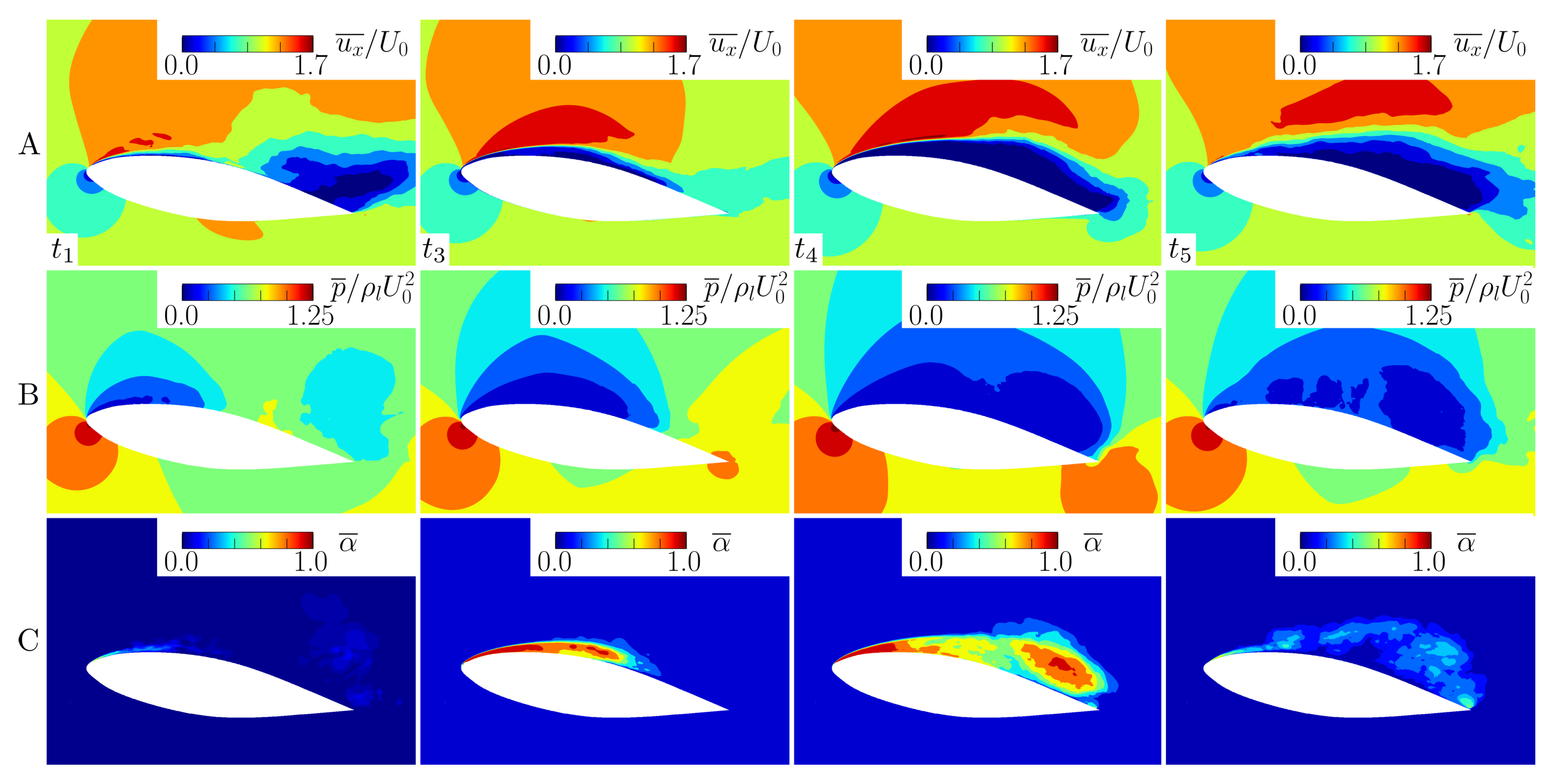

3.2. Lift/Drag Force Coefficients and Conditional Averaged Characteristics

3.3. Spectral Characteristics

4. Conclusions

- The simulations revealed the presence of vapor cavities leading to an increase in large-scale vortical structures and the occurrence of a re-entrant jet mechanism;

- Two dominant frequencies in cavitation sheet auto-oscillations were identified, and their interaction with cavitation surge instability was explored;

- The presence of cavitation structures was correlated with pressure fields and resultant forces, revealing a significant effect on flow dynamics.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| St | Strouhal number |

| LES | large-eddy simulation |

| C | chord length |

| L | foil span and width of the test section |

| Reynolds number | |

| cavitation number | |

| density of the liquid (water) | |

| dynamic viscosity of the liquid (water) | |

| incoming flow velocity | |

| reference static pressure | |

| saturation vapor pressure of water | |

| spatially filtered quantity | |

| Favre-averaged quantity | |

| time-averaged quantity | |

| conditionally averaged quantity | |

| vapor volume fraction | |

| vapor volume fraction threshold | |

| velocity component | |

| viscous stress tensor | |

| phase transitions | |

| subgrid stresses | |

| bubble concentration per a unit volume of liquid | |

| mean radius of a cavitation microbubble | |

| FVM | finite volume method |

| subgrid-scale kinetic energy | |

| pressure at the inlet cross-section | |

| PIV | Particle Image Velocimetry |

| lift force coefficient | |

| drag force coefficient | |

| S | hydrofoil surface area |

| selected stage in time | |

| i | intensity of image pixel |

| N | number of images |

| I | normalized value of pixel image intensity |

Appendix A

| Mesh | ||

|---|---|---|

| fine | ||

| medium | ||

| coarse |

References

- Plesset, M. Bubble dynamics and cavitation. Annu. Rev. Fluid Mech. 1977, 9, 145–185. [Google Scholar] [CrossRef]

- Arndt, R. Bubble dynamics and cavitation. Cavitation Fluid Mach. Hydraul. Struct. 1981, 13, 273–328. [Google Scholar]

- Arndt, R. Cavitation in vortical flows. Annu. Rev. Fluid Mech. 2002, 34, 143–175. [Google Scholar]

- Brennen, C. Cavitation and Bubble Dynamics; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Laberteaux, K.R.; Ceccio, S.L. Partial cavity flows. Part 1. Cavities forming on models without spanwise variation. J. Fluid Mech. 2001, 431, 1–41. [Google Scholar] [CrossRef]

- Laberteaux, K.R.; Ceccio, S.L. Partial cavity flows. Part 2. Cavities forming on test objects with spanwise variation. J. Fluid Mech. 2001, 431, 43–63. [Google Scholar] [CrossRef]

- Kjeldsen, M.; Arndt, R.E.A.; Effertz, M. Spectral characteristics of sheet/cloud cavitation. J. Fluids Eng. 2000, 112, 481–487. [Google Scholar] [CrossRef]

- Callenaere, M.; Franc, J.P.; Michel, J.M.; Riondet, M. The cavitation instability induced by the development of a re-entrant jet. J. Fluid Mech. 2001, 444, 223–256. [Google Scholar] [CrossRef]

- Pham, T.M.; Larrarte, F.; Fruman, D.H. Investigation of unsteady sheet cavitation and cloud cavitation mechanisms. J. Fluids Eng. 1999, 121, 289–296. [Google Scholar] [CrossRef]

- Watanabe, S.; Tsujimoto, Y.; Furukawa, A. Theoretical analysis of transitional and partial cavity instabilities. J. Fluids Eng. 2001, 123, 692–697. [Google Scholar]

- Timoshevskiy, M.V.; Churkin, S.A.; Kravtsova, A.Y.; Pervunin, K.S.; Markovich, D.M.; Hanjalić, K. Cavitating flow around a scaled-down model of guide vanes of a high-pressure turbine. Int. J. Multiph. Flow 2016, 78, 75–87. [Google Scholar] [CrossRef]

- Kawanami, Y.; Kato, H.; Yamaguchi, H.; Tanimura, M.; Tagaya, Y. Mechanism and control of cloud cavitation. J. Fluids Eng. 1997, 119, 788–794. [Google Scholar] [CrossRef]

- Kubota, A.; Kato, H.; Yamaguchi, H.; Maeda, M. Unsteady structure measurement of cloud cavitation on a foil section using conditional sampling technique. J. Fluids Eng. 1989, 111, 204–210. [Google Scholar] [CrossRef]

- Ganesh, H.; Makiharju, S.A.; Ceccio, S.L. Bubbly shock propagation as a mechanism for sheet-to-cloud transition of partial cavities. J. Fluid Mech. 2016, 802, 37–78. [Google Scholar] [CrossRef]

- Reisman, G.E.; Wang, Y.C.; Brennen, C.E. Observations of shock waves in cloud cavitation. J. Fluid Mech. 1998, 355, 255–283. [Google Scholar]

- Leroux, J.B.; Astolfi, J.A.; Billard, J.Y. An experimental study of unsteady partial cavitation. J. Fluids Eng. 2004, 126, 94–101. [Google Scholar] [CrossRef]

- Ji, B.; Luo, X.W.; Arndt, R.E.; Peng, X.; Wu, Y. Large eddy simulation and theoretical investigations of the transient cavitating vortical flow structure around a NACA66 hydrofoil. Int. J. Multiph. Flow 2015, 68, 121–134. [Google Scholar]

- Zhang, G.; Wang, Z.; Wu, C.; Li, H.; Sun, T. Numerical investigation of multistage cavity shedding around a cavitating hydrofoil based on different turbulence models. Ocean Eng. 2023, 284, 115248. [Google Scholar] [CrossRef]

- Bhatt, A.; Ganesh, H.; Ceccio, S.L. Partial cavity shedding on a hydrofoil resulting from re-entrant flow and bubbly shock waves. J. Fluid Mech. 2023, 957, A28. [Google Scholar] [CrossRef]

- Kawakami, D.T.; Fuji, A.; Tsujimoto, Y.; Arndt, R.E.A. An assessment of the influence of environmental factors on cavitation instabilities. J. Fluids Eng. 2008, 130, 031303. [Google Scholar] [CrossRef]

- Decaix, J.; Goncalves, E. Investigation of three-dimensional effects on a cavitating venturi flow. J. Heat Fluid Flow 2013, 44, 576–595. [Google Scholar] [CrossRef]

- Prothin, S.; Billard, J.Y.; Djeridi, H. Image processing using POD and DMD for the study of cavitation development on a NACA0015. In Proceedings of the 13th Journées de l’Hydrodynamique, Laboratoire Saint-Venant, Chatou, France, 21–23 November 2012. [Google Scholar]

- Watanabe, S.; Yamaoka, W.; Furukawa, A. Unsteady lift and drag characteristics of cavitating Clark Y-11.7% hydrofoil. IOP Conf. Ser. Earth Environ. Sci. 2014, 22, 052009. [Google Scholar] [CrossRef]

- Tsuru, W.; Ehara, Y.; Kitamura, S.; Watanabe, S.; Tsuda, S. Mechanism of lift increase of cavitating Clark Y-11.7% hydrofoil. In Proceedings of the 10th International Symposium on Cavitation (CAV2018), Baltimore, MD, USA, 14–16 May 2018. [Google Scholar]

- Keller, A.P. Cavitation Scale Effects Empirically Found Relations and the Correlation of Cavitation Number and Hydrodynamic Coefficients. Lecture 001. 2001. Available online: https://caltechconf.library.caltech.edu/92/ (accessed on 17 August 2023).

- Liu, Y.; Li, X.; Wang, W.; Li, L.; Huo, Y. Numerical investigation on the evolution of forces and energy features in thermo-sensitive cavitating flow. Eur. J. Mech. B/Fluids 2020, 84, 233–249. [Google Scholar] [CrossRef]

- Zhao, W.G.; Zhang, L.X.; Shao, X.M. Numerical simulation of cavitation flow under high pressure and temperature. J. Hydrodyn. Ser. B 2011, 23, 289–294. [Google Scholar] [CrossRef]

- Hong, F.; Yuan, J.; Zhou, B. Application of a new cavitation model for computations of unsteady turbulent cavitating flows around a hydrofoil. J. Mech. Sci. Technol. 2017, 31, 249–260. [Google Scholar] [CrossRef]

- Matsunari, H.; Watanabe, S.; Konishi, Y.; Suefuji, N.; Furukawa, A. Experimental/numerical study on cavitating flow around Clark Y 11.7% hydrofoil. In Proceedings of the Eighth International Symposium on Cavitation, Singapore, 13–16 August 2012; pp. 358–363. [Google Scholar]

- Deng, L.F.; Long, Y.; Cheng, H.Y.; Ji, B. Some notes on numerical investigation of three cavitation models through a verification and validation procedure. J. Hydrodyn. 2023, 35, 185–190. [Google Scholar] [CrossRef]

- Arabnejad, M.; Amini, A.; Farhat, M.; Bensow, R. Numerical and experimental investigation of shedding mechanisms from leading-edge cavitation. Int. J. Multiph. Flow 2019, 119, 123–143. [Google Scholar] [CrossRef]

- Long, Y.; Long, X.; Ji, B.; Xing, T. Verification and validation of Large Eddy Simulation of attached cavitating flow around a Clark-Y hydrofoil. Int. J. Multiph. Flow 2019, 115, 93–107. [Google Scholar] [CrossRef]

- Chen, T.; Huang, B.; Wang, G. Numerical study of cavitating flows in a wide range of water temperatures with special emphasis on two typical cavitation dynamics. Int. J. Heat Mass Transf. 2016, 101, 886–900. [Google Scholar] [CrossRef]

- Hsiao, C.T.; Ma, J.; Chahine, G.L. Multiscale tow-phase flow modeling of sheet and cloud cavitation. Int. J. Multiph. Flow 2017, 90, 102–117. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Gong, Z.; Chen, X.; Lu, C. Large eddy simulation and investigation on the laminar-turbulent transition and turbulence-cavitation interaction in the cavitating flow around hydrofoil. Int. J. Multiph. Flow 2019, 112, 300–322. [Google Scholar] [CrossRef]

- Pendar, M.R.; Esmaeilifar, E.; Roohi, E. LES study of unsteady cavitation characteristics of a 3-D hydrofoil with wavy leading edge. Int. J. Multiph. Flow 2020, 132, 103415. [Google Scholar] [CrossRef]

- Li, D.; Miao, B.; Li, Y.; Gong, R.; Wang, H. Numerical study of the hydrofoil cavitation flow with thermodynamic effects. Renew. Energy 2021, 169, 894–904. [Google Scholar] [CrossRef]

- Liu, H.; Tang, F.; Yan, S.; Li, D. Experimental and numerical studies of cloud cavitation behavior around a reversible S-shaped hydrofoil. J. Mar. Sci. Eng. 2022, 10, 386. [Google Scholar] [CrossRef]

- Sun, T.; Wang, Z.; Zou, L.; Wang, H. Numerical investigation of positive effects of ventilated cavitation around a NACA66 hydrofoil. Ocean Eng. 2020, 197, 106831. [Google Scholar] [CrossRef]

- Yin, T.; Pavesi, G.; Pei, J.; Yuan, S. Numerical investigation of unsteady cavitation around a twisted hydrofoil. Int. J. Multiph. Flow 2021, 135, 103506. [Google Scholar] [CrossRef]

- Ivashchenko, E.; Hrebtov, M.; Timoshevskiy, M.; Pervunin, K.; Mullyadzhanov, R. Systematic validation study of an unsteady cavitating flow over a hydrofoil using conditional averaging: LES and PIV. J. Mar. Sci. Eng. 2021, 9, 1193. [Google Scholar] [CrossRef]

- Timoshevskiy, M.V.; Ilyushin, B.B.; Pervunin, K.S. Statistical structure of the velocity field in cavitating flow around a 2D hydrofoil. Int. J. Heat Fluid Flow 2020, 85, 108646. [Google Scholar] [CrossRef]

- Sagaut, P.; Adams, N.; Garnier, E. Large-Eddy Simulation for Compressible Flows; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Yoshizawa, A.; Horiuti, K. A statistically-derived subgrid-scale kinetic energy model for the large-eddy simulation of turbulent flows. J. Phys. Soc. Jpn. 1985, 54, 2834–2839. [Google Scholar] [CrossRef]

- Schnerr, G.; Sauer, J. Physical and numerical modeling of unsteady cavitation dynamics. In Proceedings of the Fourth International Conference on Multiphase Flow, New Orleans, LO, USA, 27 May–1 June 2001; ICMF New Orleans: New Orleans, LO, USA, 2001; Volume 1. [Google Scholar]

- Project Site OpenFOAM. 2004. Available online: http://www.openfoam.com (accessed on 17 August 2023).

- Warming, R.F.; Beam, R. Upwind second-order difference schemes and applications in aerodynamic flows. Aiaa J. 1976, 14, 1241–1249. [Google Scholar] [CrossRef]

- Van Leer, B. Towards the ultimate conservative difference scheme. II. Monotonicity and conservation combined in a second-order scheme. J. Comput. Phys. 1974, 14, 361–370. [Google Scholar] [CrossRef]

- Crank, J.; Nicolson, P. A practical method for numerical evaluation of solutions of partial differential equations of the heat-conduction type. In Mathematical Proceedings of the Cambridge Philosophical Society; Cambridge University Press: Cambridge, UK, 1947; Volume 43, pp. 50–64. [Google Scholar]

- Moukalled, F.; Mangani, L.; Darwish, M. The Finite Volume Method in Computational Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Jasak, H. Error Analysis and Estimation for the Finite Volume Method with Applications to Fluid Flows; Imperial College London, University of London: London, UK, 1996. [Google Scholar]

- Ferziger, J.H.; Perić, M.; Street, R.L. Computational Methods for Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- OpenFOAM Dynamic Mesh Refine Library. 2019. Available online: http://voluntary.holzmann-cfd.de/software-development/libraries/direfinefvmesh (accessed on 17 August 2023).

- Cadieux, F.; Sun, G.; Domaradzki, J.A. Effects of numerical dissipation on the interpretation of simulation results in computational fluid dynamics. Comput. Fluids 2017, 154, 256–272. [Google Scholar]

- Kravtsova, A.Y.; Markovich, D.M.; Pervunin, K.S.; Timoshevskiy, M.V.; Hanjalic, K. High-speed visualization and PIV measurements of cavitating flows around a semi-circular leading-edge flat plate and NACA0015 hydrofoil. Int. J. Multiph. Flow 2014, 60, 119–134. [Google Scholar] [CrossRef]

- Ilyushin, B.B.; Timoshevskiy, M.V.; Pervunin, K.S. Vapor concentration and bimodal distributions of turbulent fluctuations in cavitating flow around a hydrofoil. Int. J. Heat Fluid Flow 2023, 103, 109197. [Google Scholar] [CrossRef]

- Roache, P.J. Verification and Validation in Computational Science and Engineering; Hermosa: Albuquerque, NM, USA, 1998; Volume 895, p. 895. [Google Scholar]

| [m/s] | [-] | [kPa] | [kPa] |

|---|---|---|---|

| [-] | [kg/m] | [Pa×s] | [kPa] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivashchenko, E.; Hrebtov, M.; Timoshevskiy, M.; Pervunin, K.; Mullyadzhanov, R. Unsteady Cloud Cavitation on a 2D Hydrofoil: Quasi-Periodic Loads and Phase-Averaged Flow Characteristics. Energies 2023, 16, 6990. https://doi.org/10.3390/en16196990

Ivashchenko E, Hrebtov M, Timoshevskiy M, Pervunin K, Mullyadzhanov R. Unsteady Cloud Cavitation on a 2D Hydrofoil: Quasi-Periodic Loads and Phase-Averaged Flow Characteristics. Energies. 2023; 16(19):6990. https://doi.org/10.3390/en16196990

Chicago/Turabian StyleIvashchenko, Elizaveta, Mikhail Hrebtov, Mikhail Timoshevskiy, Konstantin Pervunin, and Rustam Mullyadzhanov. 2023. "Unsteady Cloud Cavitation on a 2D Hydrofoil: Quasi-Periodic Loads and Phase-Averaged Flow Characteristics" Energies 16, no. 19: 6990. https://doi.org/10.3390/en16196990

APA StyleIvashchenko, E., Hrebtov, M., Timoshevskiy, M., Pervunin, K., & Mullyadzhanov, R. (2023). Unsteady Cloud Cavitation on a 2D Hydrofoil: Quasi-Periodic Loads and Phase-Averaged Flow Characteristics. Energies, 16(19), 6990. https://doi.org/10.3390/en16196990