Investigating the Ignition and Stability Limits of Premixed Methane/Air Combustion in Micro-Channels

Abstract

:1. Introduction

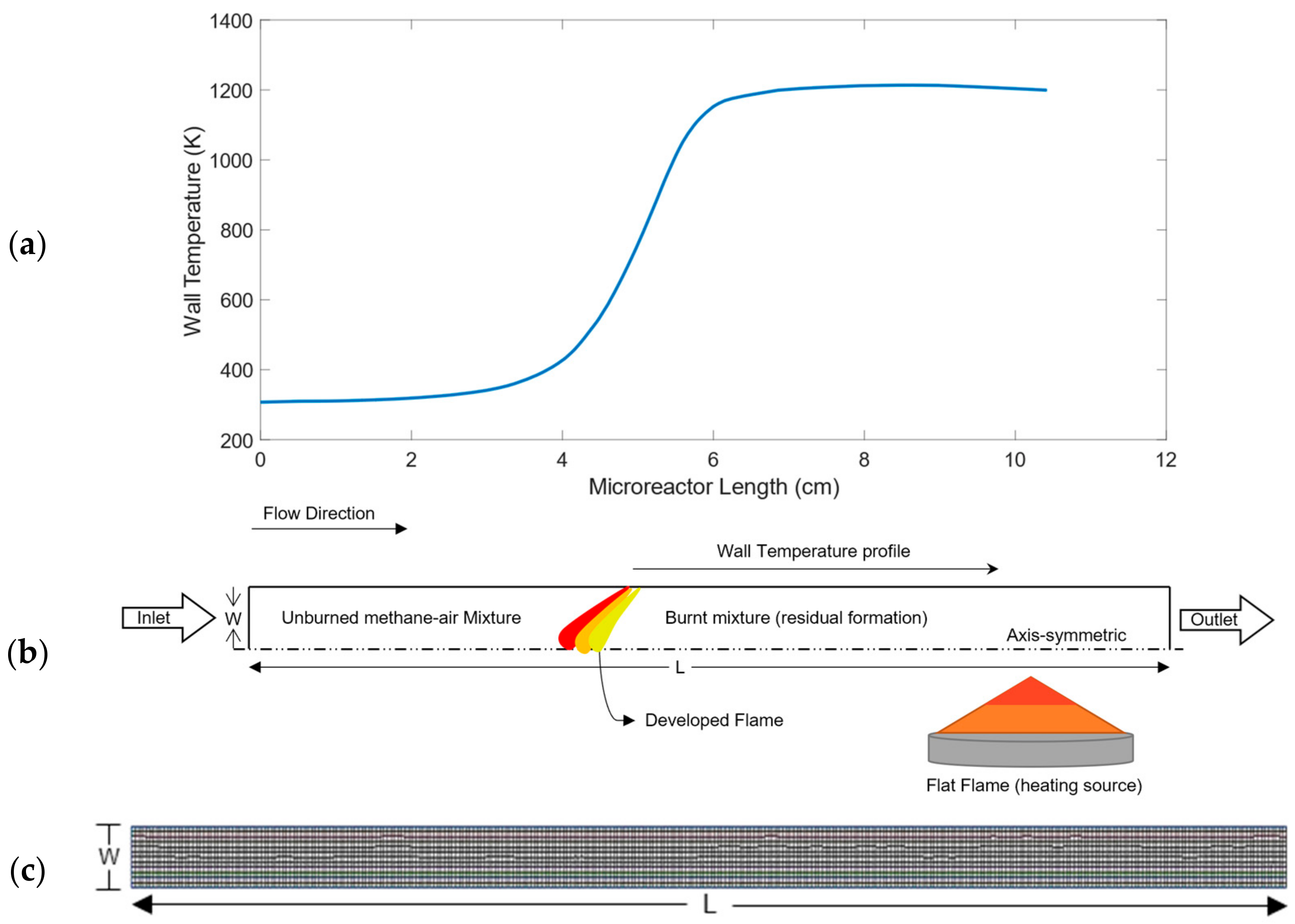

2. Methodology

2.1. Governing Equations

2.2. Operating Conditions

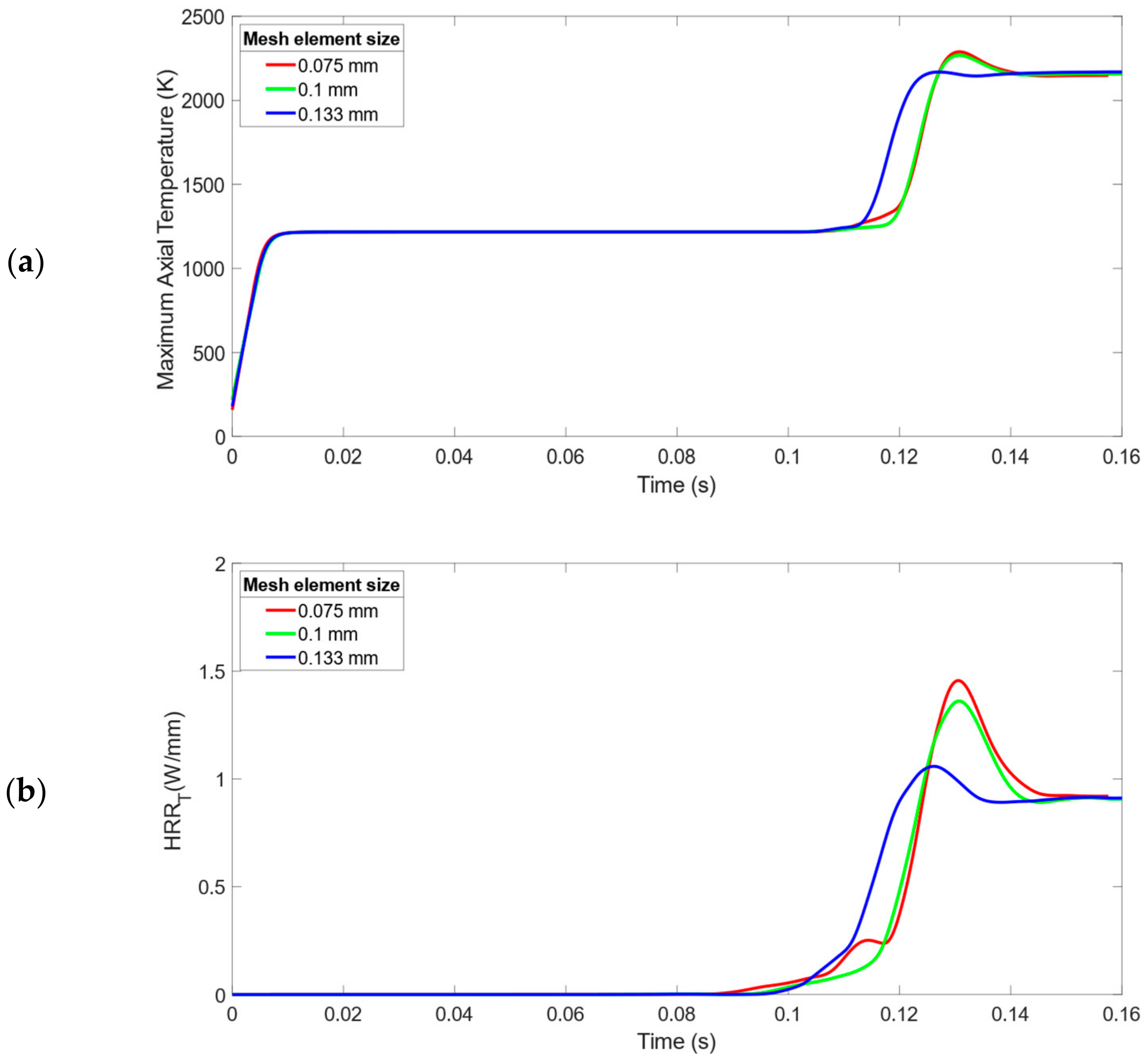

2.3. Grid Independence Test

2.4. Metrics

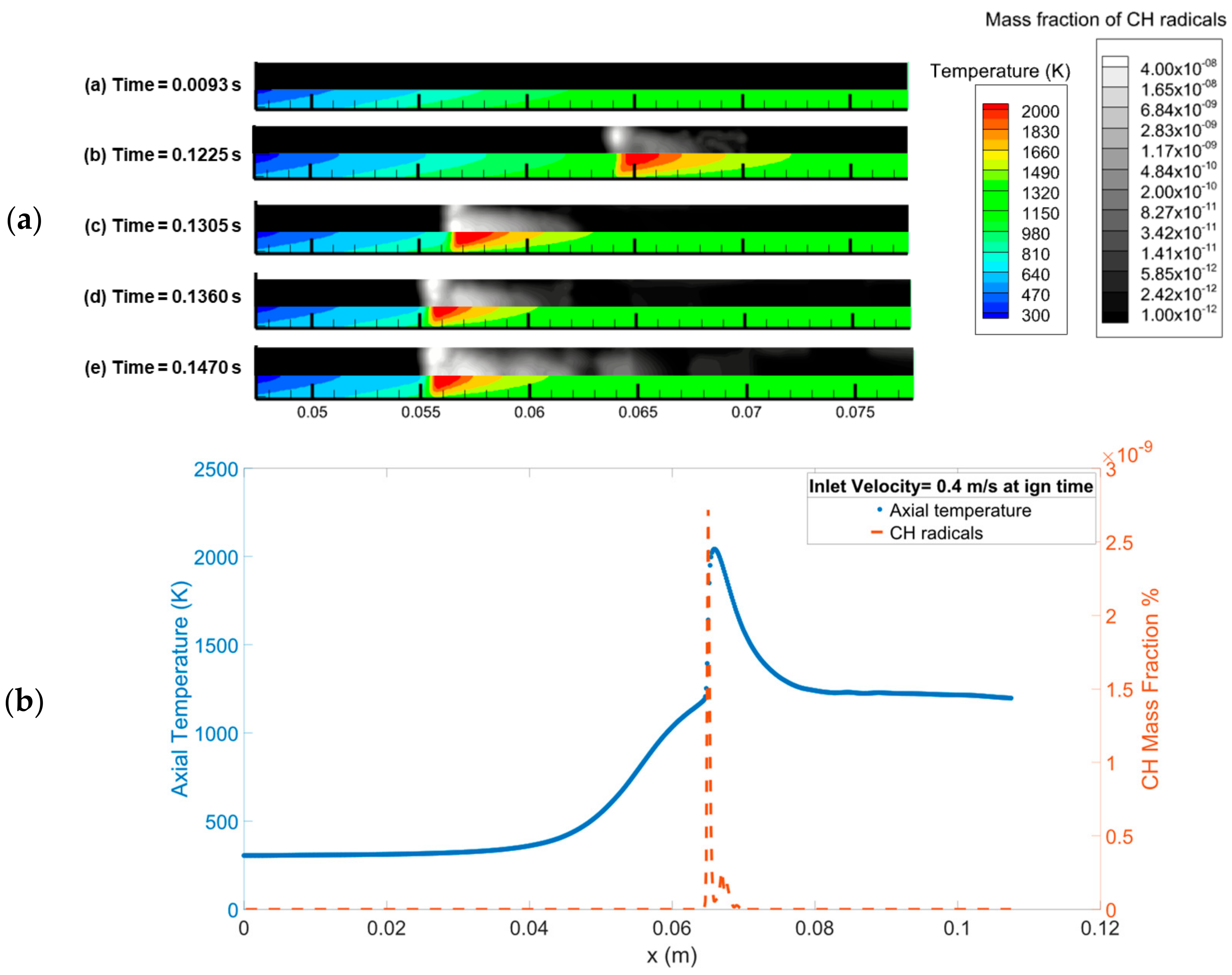

2.4.1. Ignition Metrics: Time, Location, and Span

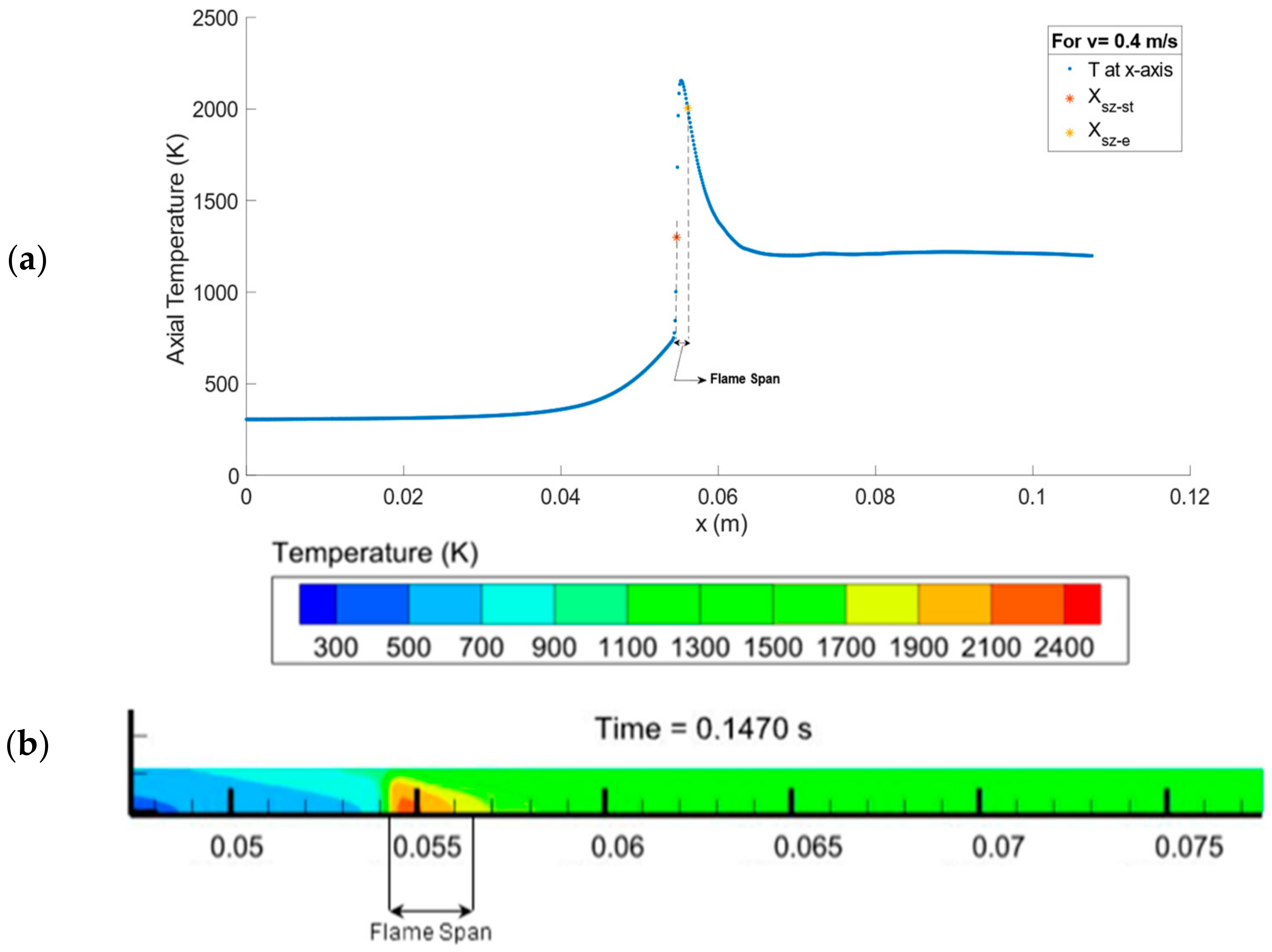

2.4.2. Stable Flame Metrics: Location and Span

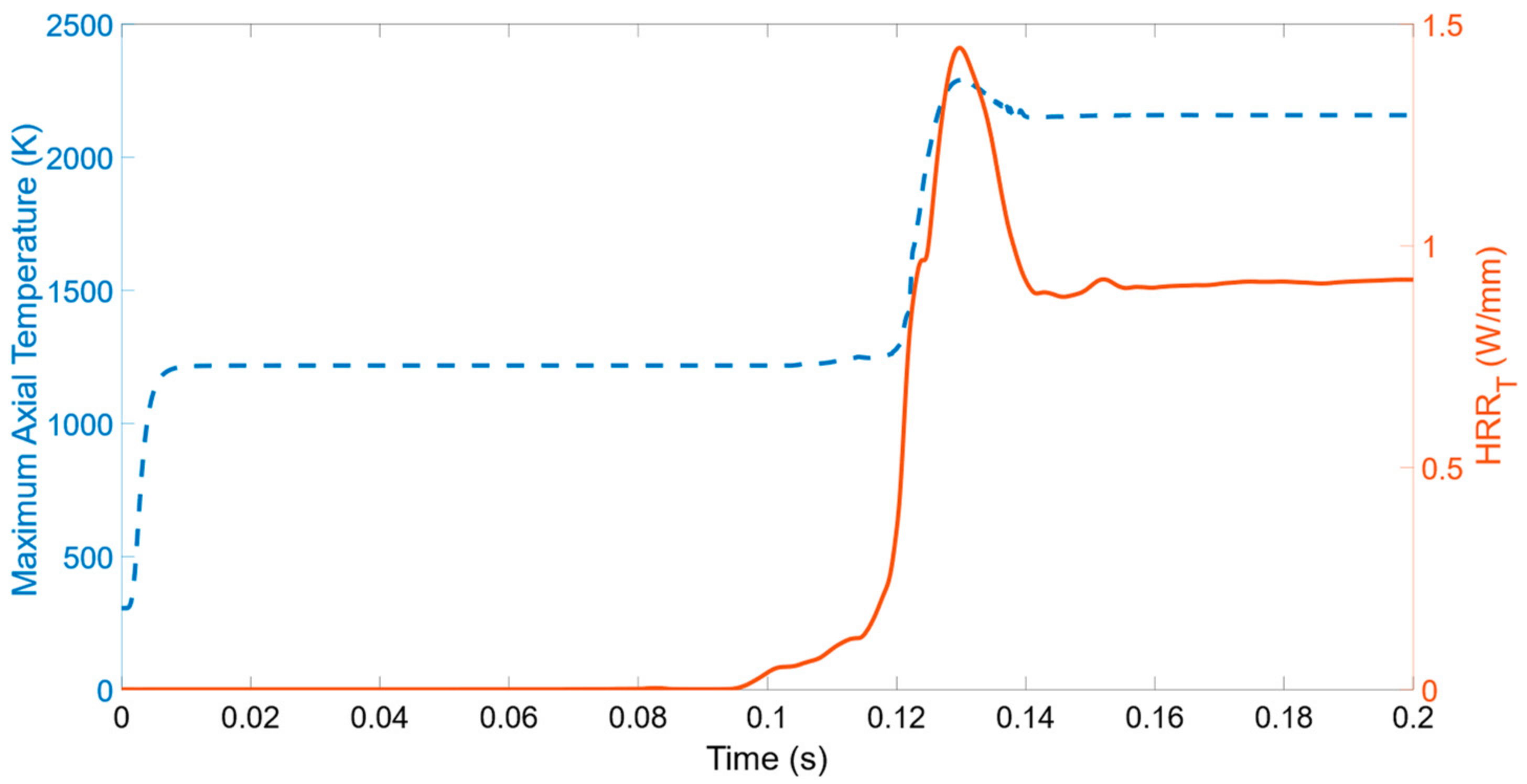

2.4.3. FREI Metrics: Length, Period, Frequency, Ignition-to-Extinction Time, and Extinction-to-Ignition Time

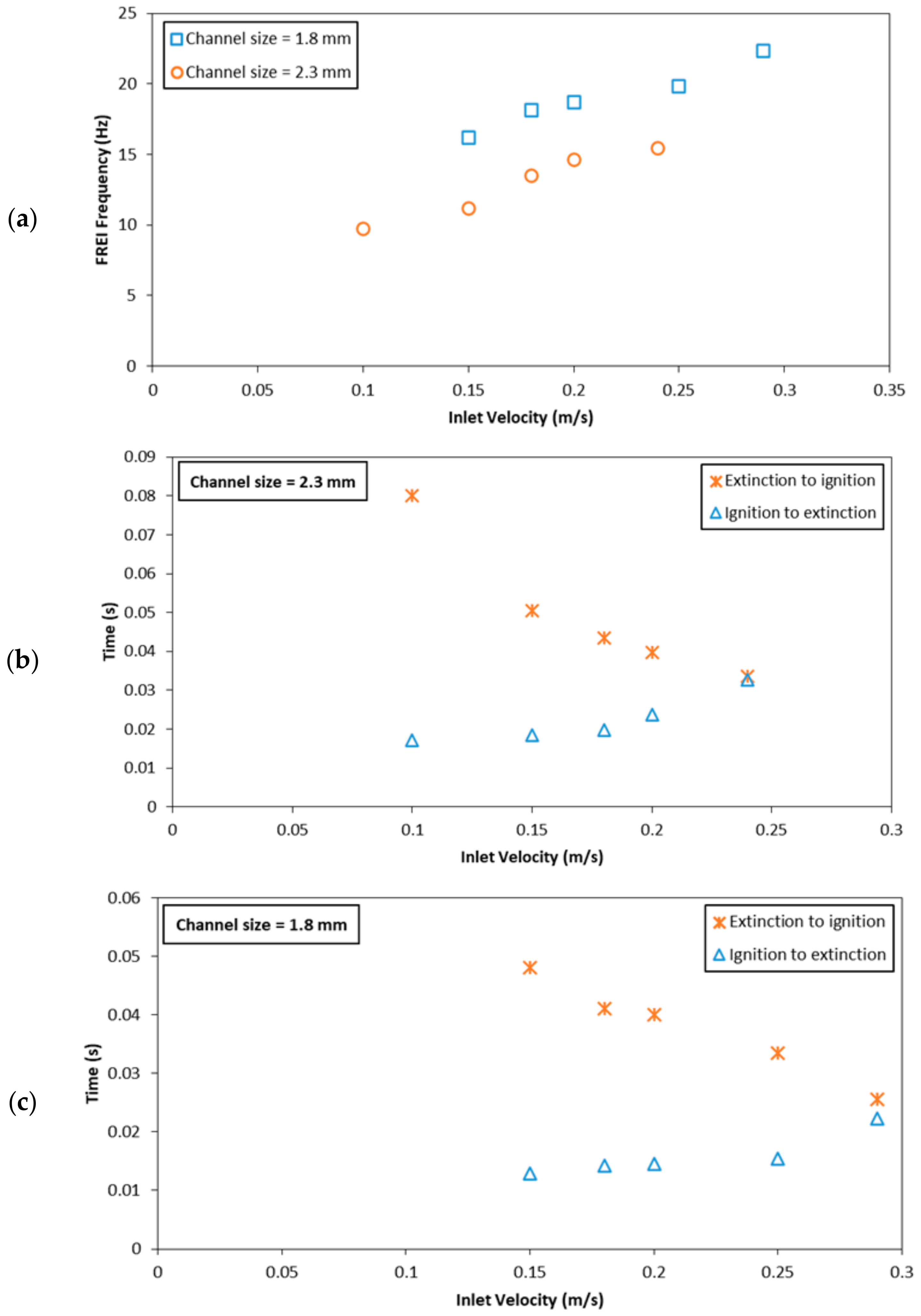

- The FREI length: defined as the distance the flame travels along the channel before extinction;

- The FREI period (τFREI) defined as the time duration required for a flame to attain two successive ignition events [34];

- The FREI frequency: the reciprocal of the FREI period (τFREI)

- The ignition-to-extinction time: defined as the time duration from the ignition time to the extinction time in the same FREI cycle [22];

- The extinction-to-ignition time: defined as the time duration from the extinction time to the ignition time of the subsequent cycle [22].

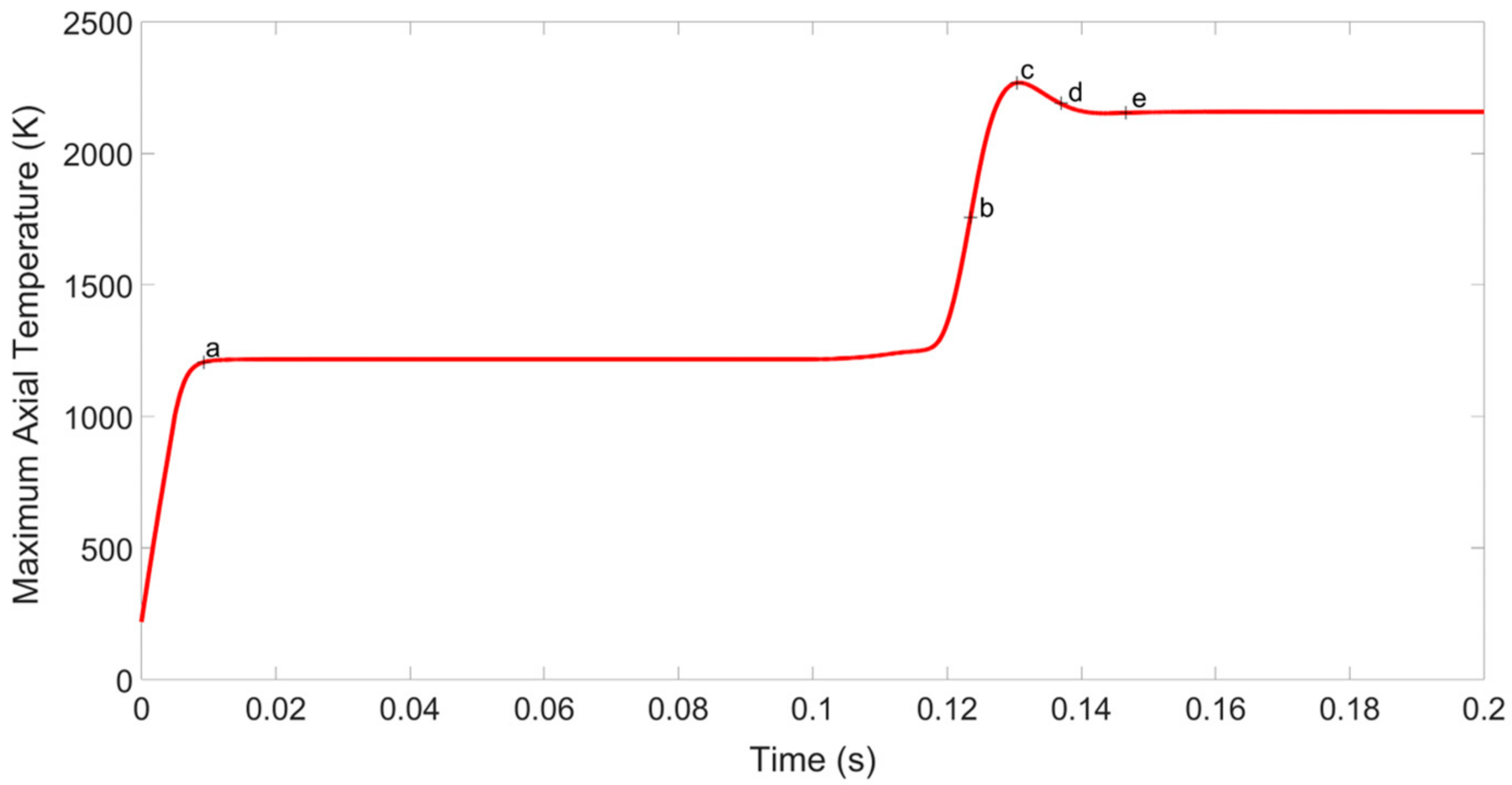

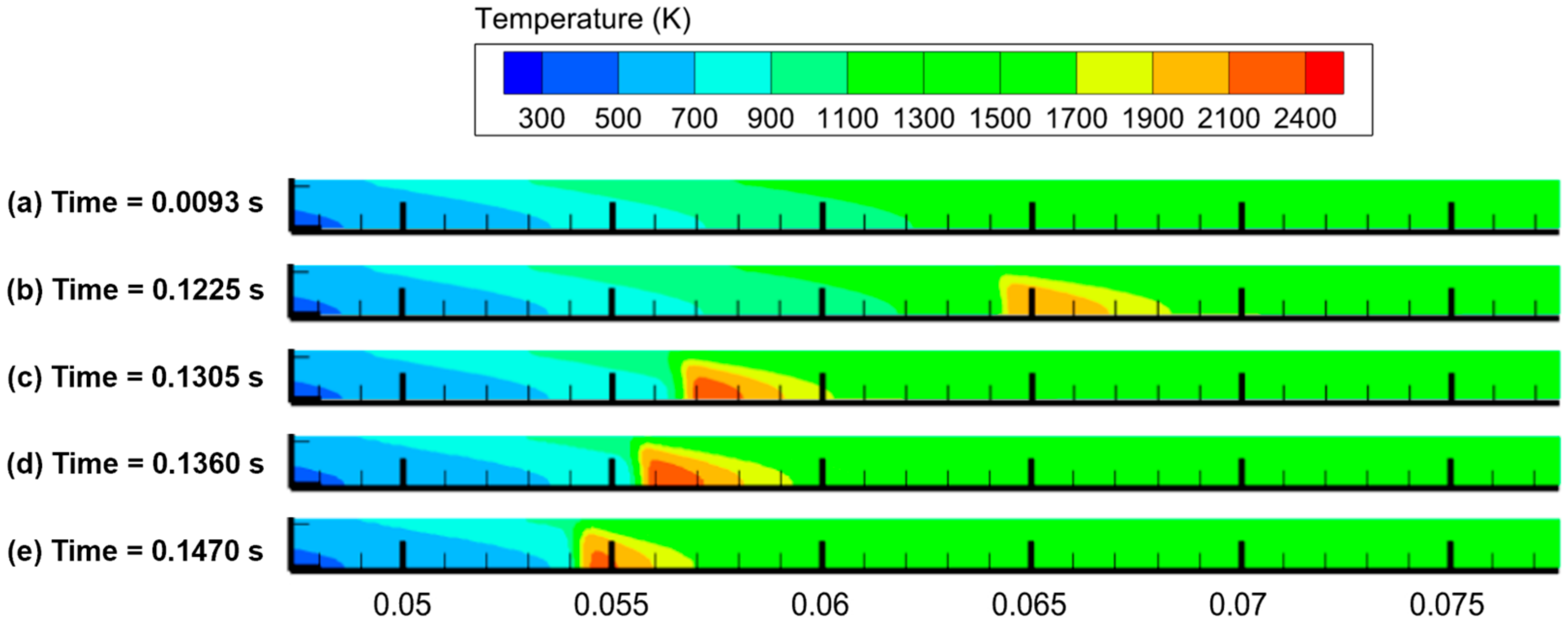

3. Results

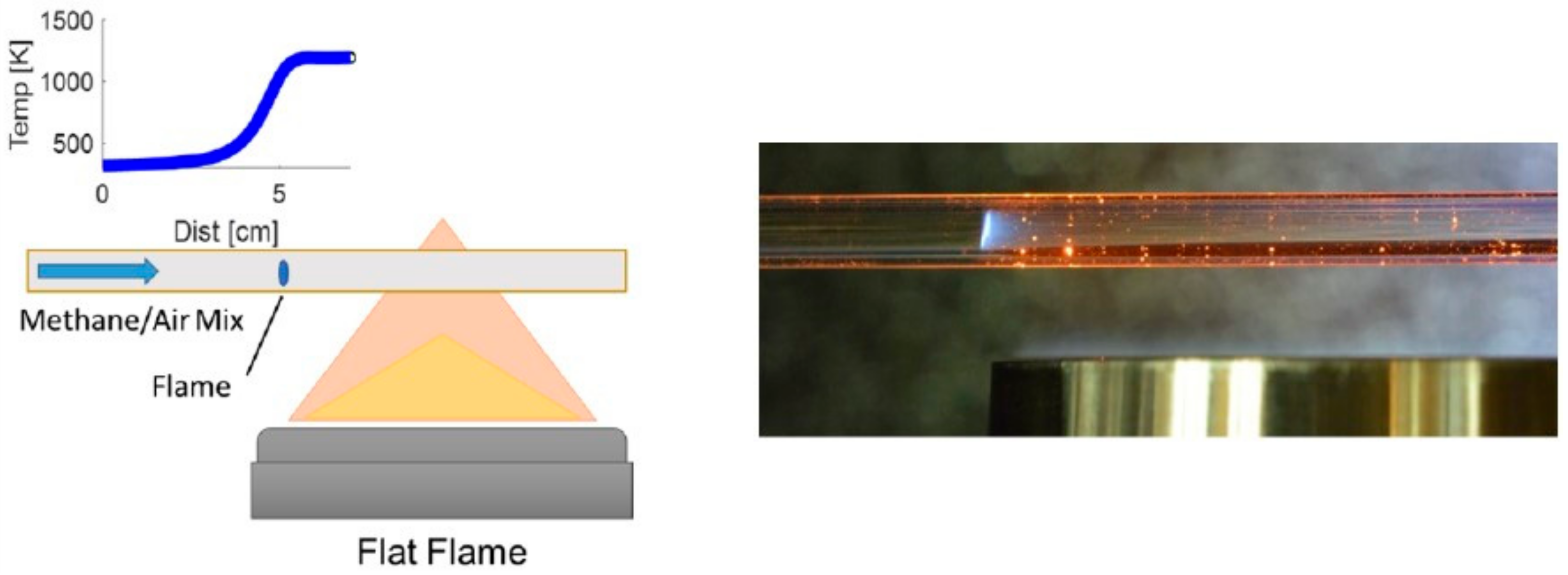

3.1. Comparison with Experimental Observations

3.1.1. Experimental Work Overview

3.1.2. Comparison with Experimental Work: Axial Temperature

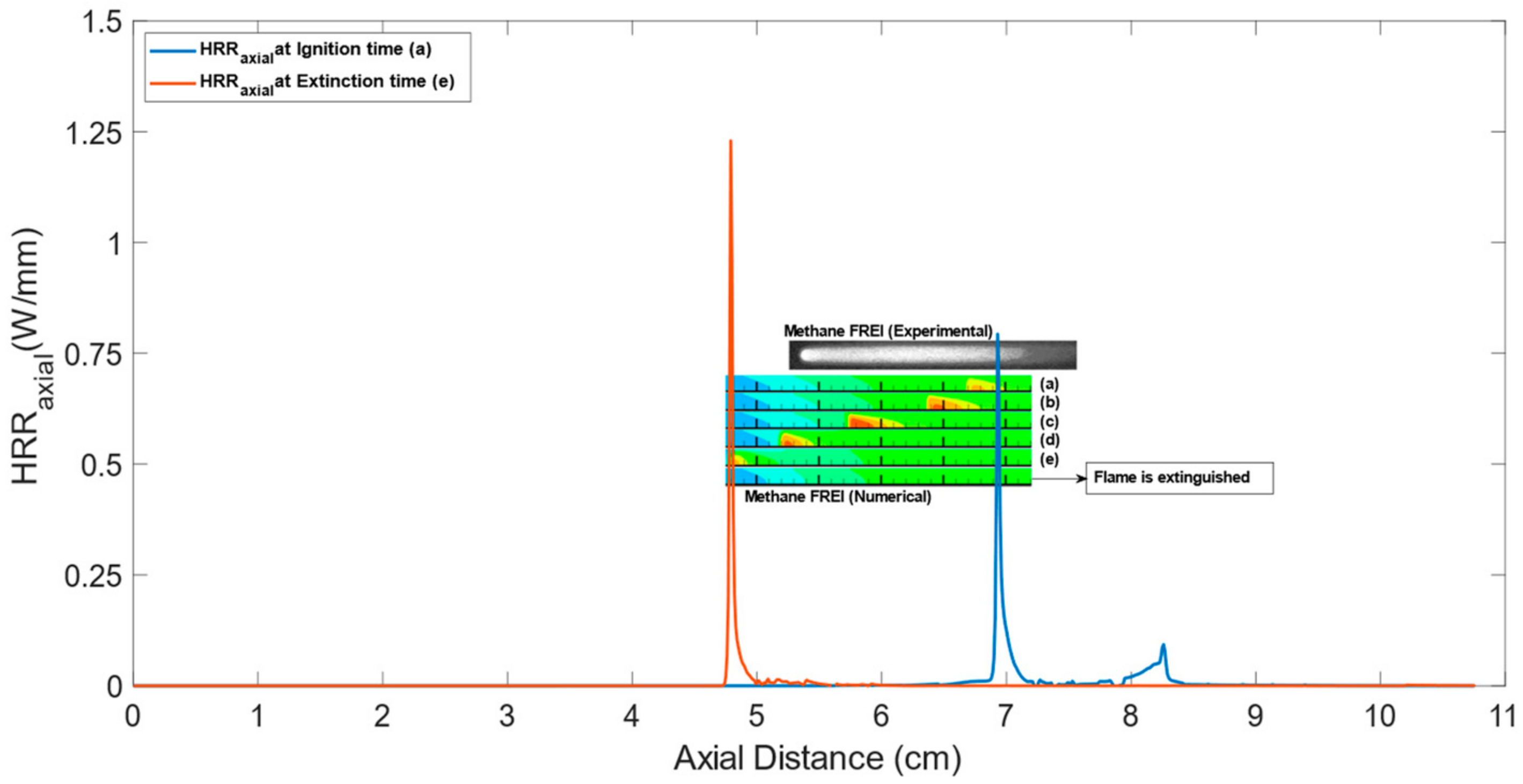

3.1.3. Comparison with Experimental Work: Local Heat Release Rate (HRRaxial)

3.2. Impact of the Inlet Velocity

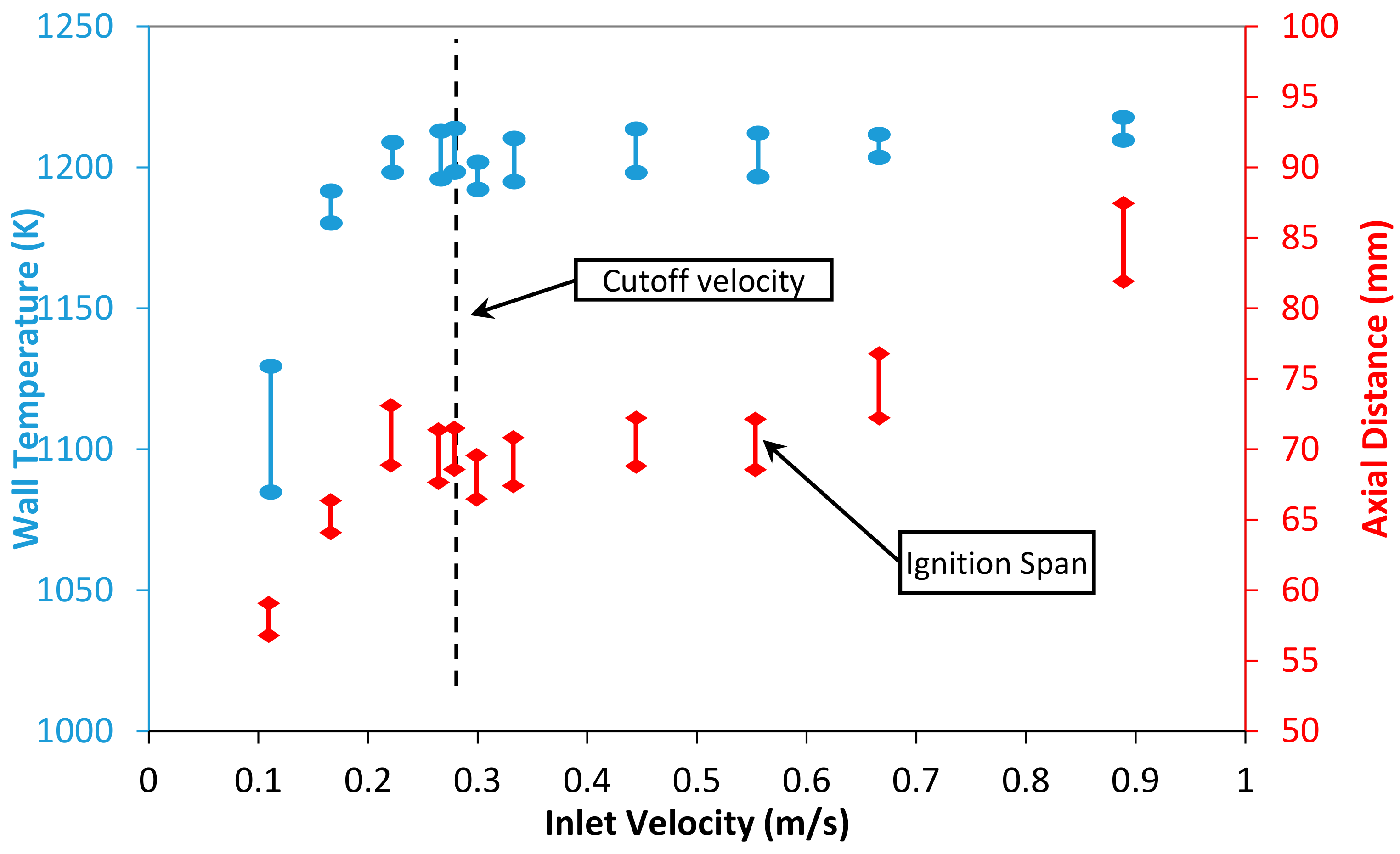

3.2.1. Impact of Inlet Velocity on Ignition Process

3.2.2. Impact of Inlet Velocity on Stable Flames

3.2.3. Impact of Inlet Velocity on the FREI Mode

3.3. Impact of Equivalence Ratio

3.3.1. Impact of Equivalence Ratio on Ignition Process

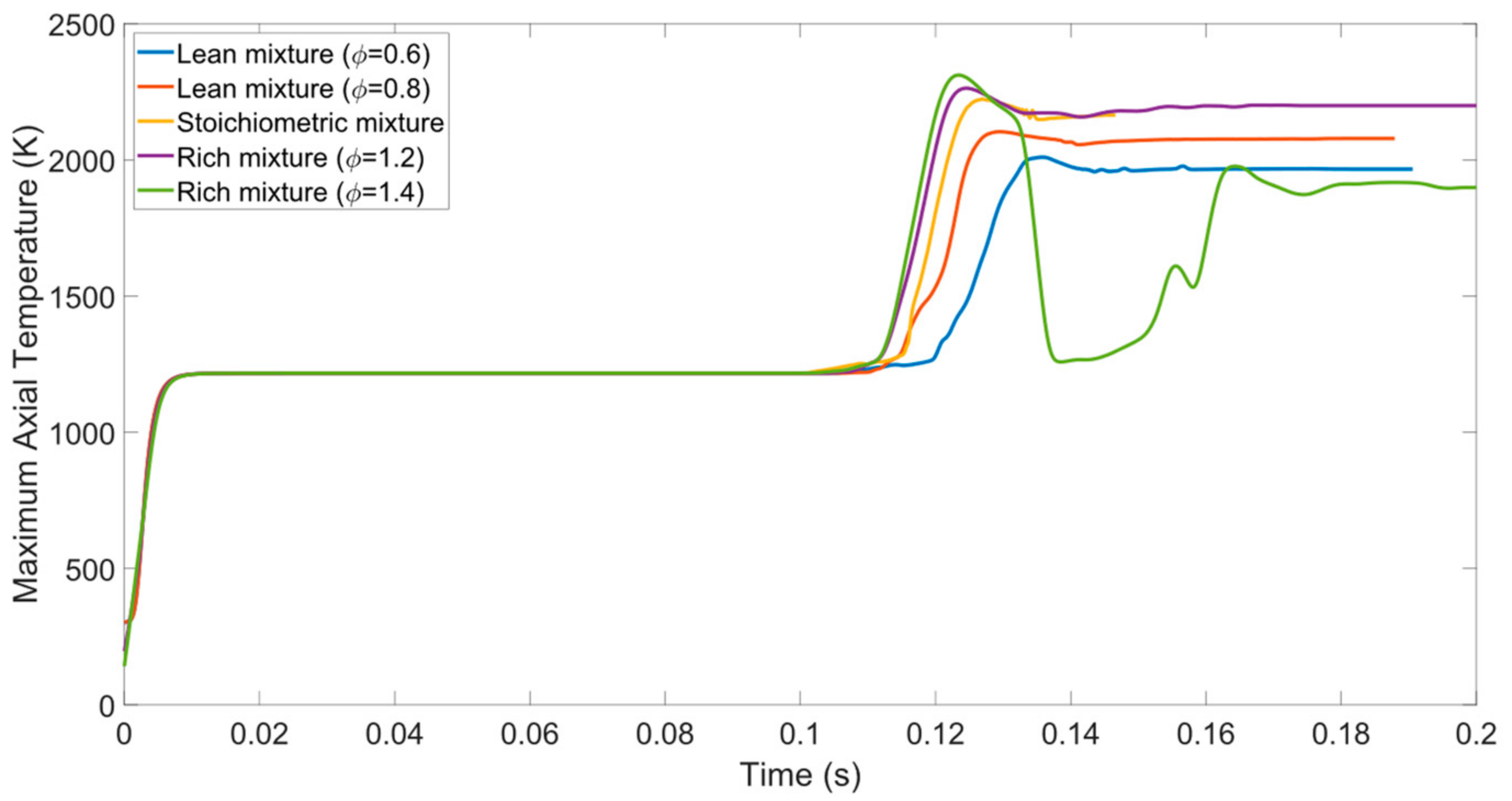

3.3.2. Impact of Equivalence Ratio on Stable Flames

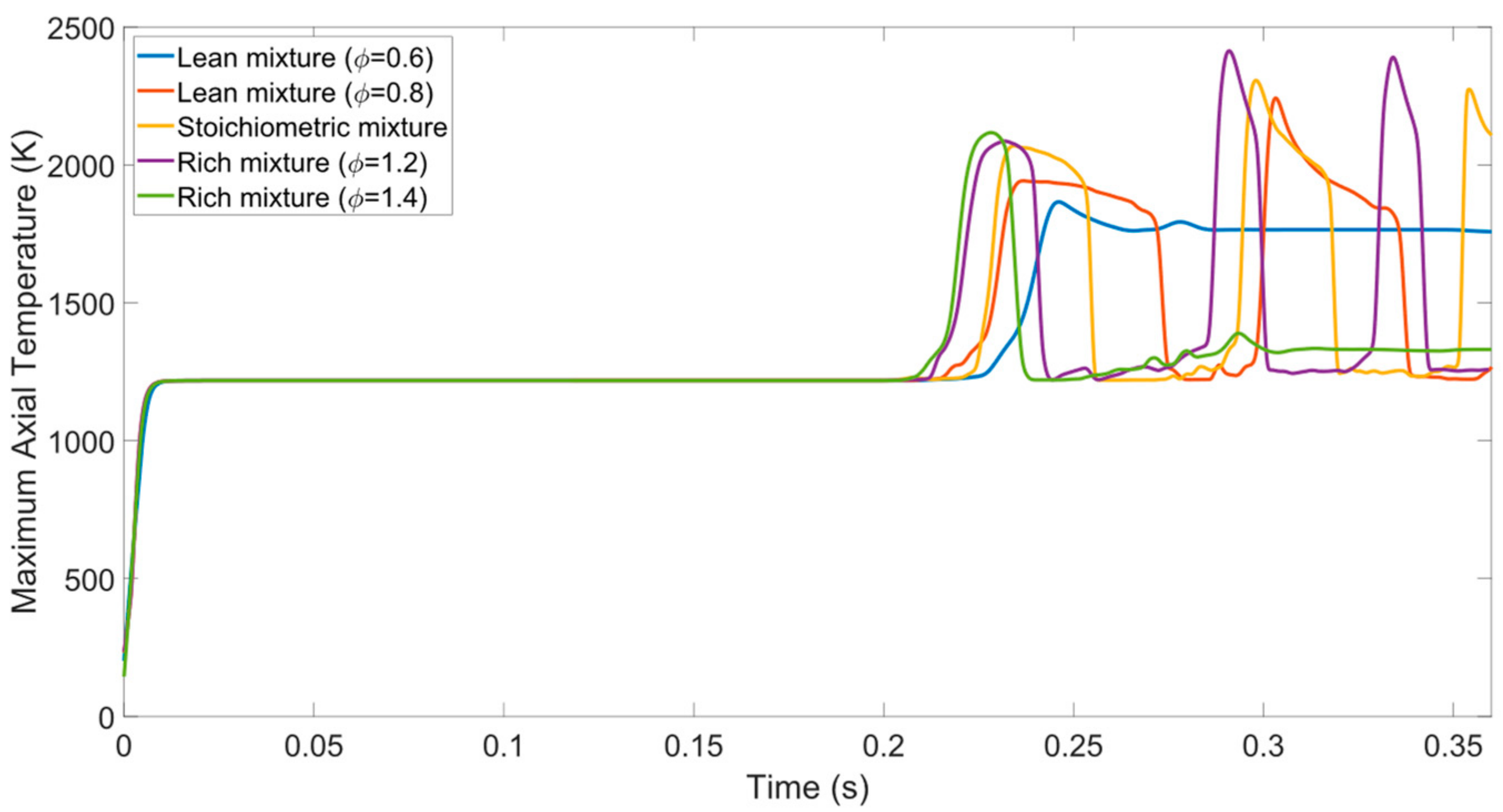

3.3.3. Impact of Equivalence Ratio on FREI Mode

3.4. Impact of Channel Width

3.4.1. Impact of Channel Width on Stability

3.4.2. Impact of Channel Width on FREI Characteristics

4. Conclusions

- The flow rates can directly affect the behavior of the propagating flame and its stability conditions. Specifically, it was shown that at lower inlet velocities, the flames propagate further upstream towards the cold wall temperature region, increasing the likelihood for the flame to experience FREI.

- At a given inlet velocity and channel size, the equivalence ratio can play a role in controlling the stability (e.g., a flame may lose its stability if going to an ultra-rich regime or an unstable flame may become stable if going to an ultra-lean regime, producing a weak, but stable flame).

- At a given channel size and in the case of the FREI mode, the rich fuel/air mixture ignites faster than the other cases and it produces the longest FREI frequency.

- At a given equivalence ratio, the cutoff velocity is higher for narrower channels, i.e., it is more likely for a flame to experience a FREI mode; the flame extinction occurs at a higher temperature as the channel narrows and the difference between the characteristic ignition and extinction points diminishes, increasing the chance of developing a FREI mode. This is directly associated with the competition between the heat release rate and the wall heat losses, impacting the temperature, the location, and the stability mode of the flame.

- The FREI frequency is affected by the channel size and the inlet velocity, such that the frequency is higher for narrower channels at a given inlet velocity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ju, Y.; Maruta, K. Microscale combustion: Technology development and fundamental research. Prog. Energy Combust. Sci. 2011, 37, 669–715. [Google Scholar] [CrossRef]

- Walther, D.C.; Ahn, J. Advances and challenges in the development of power-generation systems at small scales. Prog. Energy Combust. Sci. 2011, 37, 583–610. [Google Scholar] [CrossRef]

- Dogwiler, U.; Mantzaras, J.; Benz, P.; Kaeppeli, B.; Bombach, R.; Arnold, A. Homogeneous ignition of methane-air mixtures over platinum: Comparison of measurements and detailed numerical predictions. In Proceedings of the International Symposium of Combustion, Boulder, CO, USA, 2–7 August 1998. [Google Scholar] [CrossRef]

- Kamada, T.; Nakamura, H.; Tezuka, T.; Hasegawa, S.; Maruta, K. Study on combustion and ignition characteristics of natural gas components in a micro flow reactor with a controlled temperature profile. Combust. Flame 2014, 161, 37–48. [Google Scholar] [CrossRef]

- Chigier, N.; Gemci, T. A review of micro propulsion technology. In Proceedings of the 41st Aerospace Sciences Meeting and Exhibit, Reno, Nevada, 6–9 January 2003. [Google Scholar] [CrossRef]

- Buliński, Z.; Szczygieł, I.; Kabaj, A.; Krysiński, T.; Gładysz, P.; Czarnowska, L.; Stanek, W. Performance analysis of the small-scale α-type Stirling engine using computational fluid dynamics tools. J. Energy Resour. Technol. 2018, 140, 3. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, Y.; Li, H.; Huang, W.; Chen, Y.; Li, L.; Yang, Z. Effect of cavity coupling factors of opposed counter-flow microcombustor on the methane-fueled catalytic combustion characteristics. J. Energy Resour. Technol. 2019, 141, 2. [Google Scholar] [CrossRef]

- Li, H.; Chen, Y.; Yan, Y.; Hu, C.; Fan, H.; Feng, S. Numerical study on heat transfer enhanced in a microcombustor with staggered cylindrical array for micro-thermophotovoltaic system. J. Energy Resour. Technol. 2018, 140, 11. [Google Scholar] [CrossRef]

- Kaisare, N.; Vlachos, D. A review on microcombustion: Fundamentals, devices and applications. Prog. Energy Combust. Sci. 2012, 38, 321–359. [Google Scholar] [CrossRef]

- Epstein, A.H. Millimeter-scale, micro-electro-mechanical systems gas turbine engines. J. Eng. Gas Turbines Power 2004, 126, 205–226. [Google Scholar] [CrossRef]

- Maruta, K.; Kataoka, T.; Kim, N.; Minaev, S.; Fursenko, R. Characteristics of combustion in a narrow channel with a temperature gradient. Proc. Combust. Inst. 2005, 30, 2429–2436. [Google Scholar] [CrossRef]

- Maruta, K.; Parc, J.K.; Oh, K.C.; Fujimori, T.; Minaev, S.S.; Fursenko, R.V. Characteristics of microscale combustion in a narrowheated channel. Combust. Explos. Shock Waves 2004, 40, 516–523. [Google Scholar] [CrossRef]

- Kikui, S.; Kamada, T.; Nakamura, H.; Tezuka, T.; Hasegawa, S.; Maruta, K. Characteristics of n-butane weak flames at elevated pressures in a micro flow reactor with a controlled temperature profile. Proc. Combust. Inst. 2015, 35, 3405–3412. [Google Scholar] [CrossRef]

- Nakamura, H.; Yamamoto, A.; Hori, M.; Tezuka, T.; Hasegawa, S.; Maruta, K. Study on pressure dependences of ethanol oxidation by separated weak flames in a micro flow reactor with a controlled temperature profile. Proc. Combust. Inst. 2013, 34, 3435–3443. [Google Scholar] [CrossRef]

- Hori, M.; Nakamura, H.; Tezuka, T.; Hasegawa, S.; Maruta, K. Characteristics of n-heptane and toluene weak flames in a micro flow reactor with a controlled temperature profile. Proc. Combust. Inst. 2013, 34, 3419–3426. [Google Scholar] [CrossRef]

- Watson, G.M.; Bergthorson, J.M. The effect of chemical energy release on heat transfer from flames in small channels. Combust. Flame 2012, 159, 1239–1252. [Google Scholar] [CrossRef]

- Yamamoto, A.; Oshibe, H.; Nakamura, H.; Tezuka, T.; Hasegawa, S.; Maruta, K. Stabilized three-stage oxidation of gaseous n-heptane/air mixture in a micro flow reactor with a controlled temperature profile. Proc. Combust. Inst. 2011, 33, 3259–3266. [Google Scholar] [CrossRef]

- Nakamura, H.; Fan, A.; Minaev, S.; Sereshchenko, E.; Fursenko, R.; Tsuboi, Y.; Maruta, K. Bifurcations and negative propagation speeds of methane/air premixed flames with repetitive extinction and ignition in a heated microchannel. Combust. Flame 2012, 159, 1631–1643. [Google Scholar] [CrossRef]

- Di Stazio, A.; Chauveau, C.; Dayma, G.; Dagaut, P. Combustion in micro-channels with a controlled temperature gradient. Exp. Therm. Fluid Sci. 2016, 73, 79–86. [Google Scholar] [CrossRef]

- Edalati-nejad, A.; Fanaee, S.A.; Ghodrat, M.; Khadem, J. Investigation of unsteady premixed micro/macro counterflow flames for lean to rich methane/air mixture. J. Energy Resour. Technol. 2021, 143, 052302. [Google Scholar] [CrossRef]

- Kayed, H.; Mohamed, A.; Yehia, M.; Nemitallah, M.A.; Habib, M.A. Numerical investigation of auto-ignition characteristics in microstructured catalytic honeycomb reactor for CH4–air and CH4–H2–air mixtures. J. Energy Resour. Technol. 2019, 141, 082209. [Google Scholar] [CrossRef]

- Akita, K.; Morii, Y.; Murakami, Y.; Nakamura, H.; Tezuka, T.; Maruta, K. Dynamics of FREI with/without cool flame interaction. Proc. Combust. Inst. 2023, 39, 1957–1965. [Google Scholar] [CrossRef]

- Pizza, G.; Frouzakis, C.E.; Mantzaras, J.; Tomboulides, A.G.; Boulouchos, K. Three-dimensional simulations of premixed hydrogen/air flames in microtubes. J. Fluid Mech. 2010, 658, 463–491. [Google Scholar] [CrossRef]

- Pizza, G.; Frouzakis, C.E.; Mantzaras, J.; Tomboulides, A.G.; Boulouchos, K. Dynamics of premixed hydrogen/air flames in mesoscale channels. Combust. Flame 2008, 155, 2–20. [Google Scholar] [CrossRef]

- Nakamura, Y.; Yamashita, H.; Saito, K. A numerical study on extinction behavior of laminar micro-diffusion flames. Combust. Theor. Model. 2007, 10, 927–938. [Google Scholar] [CrossRef]

- Miyata, E.; Fukushima, N.; Naka, Y.; Shimura, M.; Tanahashi, M.; Miyauchi, T. Direct numerical simulation of micro combustion in a narrow circular channel with a detailed kinetic mechanism. Proc. Combust. Inst. 2015, 35, 3421–3427. [Google Scholar] [CrossRef]

- Ayoobi, M.; Schoegl, I. Numerical analysis of flame instabilities in narrow channels: Laminar premixed methane/air combustion. Int. J. Spray Combust. Dyn. 2017, 9, 155–171. [Google Scholar] [CrossRef]

- Norton, D.G.; Vlachos, D.G. Combustion characteristics and flame stability at the microscale: A CFD study of premixedmethane/air mixtures. Chem. Eng. Sci. 2003, 58, 4871–4882. [Google Scholar] [CrossRef]

- Di Stazio, A.; Chauveau, C.; Dayma, G.; Dagaut, P. Oscillating flames in micro-combustion. Combust. Flame 2016, 167, 392–394. [Google Scholar] [CrossRef]

- Singh, S.; Veetil, J.E.; Kumbhakarna, N.; Velamati, R.K.; Kumar, S. Flame dynamics of premixed CH4/H2/air flames in a microchannel with a wall temperature gradient. Combust. Theor. Model. 2022, 26, 989–1013. [Google Scholar] [CrossRef]

- Ansys|Engineering Simulation Software. Available online: https://www.ansys.com (accessed on 10 July 2023).

- Chemical-Kinetic Mechanisms for Combustion Applications, San Diego Mechanism, Mechanical and Aerospace Engineering (Combustion Research), University of California at San Diego. Available online: http://combustion.ucsd.edu (accessed on 16 July 2023).

- Baumgardner, M.E. Microreactor combustion of simple hydrocarbons. In Proceedings of the 11th U.S. National CombustionMeeting, Pasadena, CA, USA, 24–27 March 2019. [Google Scholar]

- Pokharel, S.; Ayoobi, M.; Akkerman, V. Computational analysis of premixed syngas/air combustion in micro-channels: Impacts of flow rate and fuel composition. Energies 2021, 14, 4190. [Google Scholar] [CrossRef]

- Zettervall, N.; Fureby, C.; Nilsson, E.J. Evaluation of chemical kinetic mechanisms for methane combustion: A review from a CFD perspective. Fuels 2021, 2, 210–240. [Google Scholar] [CrossRef]

- Minaev, S.; Maruta, K.; Fursenko, R. Nonlinear dynamics of flame in a narrow channel with a temperature gradient. Combust. Theor Model. 2007, 11, 187–203. [Google Scholar] [CrossRef]

- Baumgardner, M.E.; Harvey, J. Analyzing OH*, CH*, and C2* chemiluminescence of bifurcating FREI propane-air flames in a micro flow reactor. Combust. Flame 2020, 221, 349–351. [Google Scholar] [CrossRef]

- Fan, Y.; Suzuki, Y.; Kasagi, N. Experimental study of micro-scale premixed flame in quartz channels. Proc. Combust. Inst. 2015, 35, 3429–3437. [Google Scholar] [CrossRef]

- Schoegl, I.; Sauer, V.M.; Sharma, P. Predicting combustion characteristics in externally heated micro-tubes. Combust. Flame 2019, 204, 33–48. [Google Scholar] [CrossRef]

- Bucci, M.; Di Stazio, A.; Chauveau, C.; Dayma, G.; Legros, G.; Dagaut, P.; Chibbaro, S. Numerical and experimental analysis of combustion in microchannels with controlled temperature. Chem. Eng. Sci. 2019, 4, 100034. [Google Scholar] [CrossRef]

| Parameters | Methods |

|---|---|

| Solver type | Pressure-based solver |

| Flow viscous model | Laminar |

| Species reaction (chemical kinetics) | Volumetric species transport, San Diego mechanism (46 species and 235 reactions) [32] |

| Discretization | Second-order upwind |

| Pressure–velocity coupling | COUPLE scheme |

| Transient formulation | First-order implicit |

| Boundary conditions | Inlet: velocity-inlet, Outlet: pressure-outlet External wall: temperature thermal conditions Axis: axisymmetric line |

| Initialization method | Standard |

| Inlet Velocity (m/s) | Mixture Regime | Equivalence Ratio (ϕ) |

|---|---|---|

| 0.10 | Stoichiometric | 1 |

| 0.15 | Stoichiometric | 1 |

| 0.20 | Stoichiometric, lean, rich | 0.6, 0.8, 1, 1.2, 1.4 |

| 0.24 | Stoichiometric | 1 |

| 0.30 | Stoichiometric | 1 |

| 0.40 | Stoichiometric, lean, rich | 0.6, 0.8, 1, 1.2, 1.4 |

| 0.50 | Stoichiometric | 1 |

| 0.60 | Stoichiometric | 1 |

| Equivalence Ratio (ϕ) | Reactants’ Mass Fractions (yx) | |||

|---|---|---|---|---|

| yCH4 | yO2 | yN2 | ||

| Fuel-lean | 0.6 | 0.0337 | 0.2252 | 0.7411 |

| 0.8 | 0.0445 | 0.2227 | 0.7328 | |

| Stoichiometric | 1 | 0.0550 | 0.2202 | 0.7248 |

| Fuel-rich | 1.2 | 0.0655 | 0.2178 | 0.7167 |

| 1.4 | 0.0754 | 0.2155 | 0.7091 | |

| Inlet Velocity (m/s) | Ignition Time (s) | Ignition Location (mm) | Ignition Span (mm) | |

|---|---|---|---|---|

| tig | xig−st | xig−e | ∆xig | |

| 0.10 | 0.4405 | 54.90 | 56.80 | 1.90 |

| 0.15 | 0.2430 | 64.00 | 66.20 | 2.20 |

| 0.20 | 0.2285 | 67.40 | 69.85 | 2.45 |

| 0.24 | 0.1625 | 67.50 | 69.80 | 2.30 |

| 0.30 | 0.1580 | 66.80 | 69.20 | 2.40 |

| 0.40 | 0.1195 | 64.50 | 67.90 | 3.40 |

| 0.50 | 0.0975 | 67.00 | 70.50 | 3.50 |

| 0.60 | 0.0835 | 74.10 | 78.00 | 3.90 |

| Inlet Velocity (m/s) | Flame Location (mm) | Flame Span (mm) | |

|---|---|---|---|

| xsz−st | xsz−e | ∆xsz | |

| 0.30 | 51.10 | 52.60 | 1.50 |

| 0.40 | 54.40 | 56.15 | 1.75 |

| 0.50 | 56.90 | 58.80 | 1.90 |

| 0.60 | 58.90 | 61.00 | 2.10 |

| Inlet Velocity (m/s) | 0.10 | 0.15 | 0.20 | 0.24 |

|---|---|---|---|---|

| τFREI (ms) | 102.53 | 89.60 | 63.65 | 64.67 |

| Inlet Velocity | Equivalence Ratio (ϕ) | Ignition Time (s) | Ignition Location (mm) | Ignition Span (mm) | ||

|---|---|---|---|---|---|---|

| 0.4 m/s | Fuel-lean | 0.6 | 0.1275 | 67.20 | 69.40 | 2.20 |

| 0.8 | 0.1225 | 69.70 | 72.50 | 2.80 | ||

| Stoichiometric | 1 | 0.1195 | 64.50 | 67.90 | 3.40 | |

| Fuel-rich | 1.2 | 0.1170 | 69.00 | 72.10 | 3.10 | |

| 1.4 | 0.1160 | 69.95 | 72.90 | 2.95 | ||

| 0.2 m/s | Fuel-lean | 0.6 | 0.2390 | 62.20 | 64.45 | 2.25 |

| 0.8 | 0.2305 | 60.05 | 62.45 | 2.40 | ||

| Stoichiometric | 1 | 0.2285 | 67.40 | 69.85 | 2.45 | |

| Fuel-rich | 1.2 | 0.2215 | 61.00 | 62.95 | 1.95 | |

| 1.4 | 0.2195 | 60.05 | 62.05 | 2.00 | ||

| Equivalence Ratio (ϕ) | Flame Location (mm) | Flame Span (mm) | ||

|---|---|---|---|---|

| Fuel-lean | 0.6 | 56.51 | 58.23 | 1.72 |

| 0.8 | 54.90 | 56.60 | 1.70 | |

| Stoichiometric | 1 | 54.40 | 56.15 | 1.75 |

| Fuel-rich | 1.2 | 56.60 | 58.05 | 1.45 |

| Equivalence Ratio (ϕ) | 0.8 | 1 | 1.2 | 1.4 |

|---|---|---|---|---|

| τFREI (ms) | 66.85 | 63.65 | 59.10 | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kutkut, A.; Ayoobi, M.; Baumgardner, M.E.; Akkerman, V. Investigating the Ignition and Stability Limits of Premixed Methane/Air Combustion in Micro-Channels. Energies 2023, 16, 6752. https://doi.org/10.3390/en16186752

Kutkut A, Ayoobi M, Baumgardner ME, Akkerman V. Investigating the Ignition and Stability Limits of Premixed Methane/Air Combustion in Micro-Channels. Energies. 2023; 16(18):6752. https://doi.org/10.3390/en16186752

Chicago/Turabian StyleKutkut, Almoutazbellah, Mohsen Ayoobi, Marc E. Baumgardner, and V’yacheslav Akkerman. 2023. "Investigating the Ignition and Stability Limits of Premixed Methane/Air Combustion in Micro-Channels" Energies 16, no. 18: 6752. https://doi.org/10.3390/en16186752

APA StyleKutkut, A., Ayoobi, M., Baumgardner, M. E., & Akkerman, V. (2023). Investigating the Ignition and Stability Limits of Premixed Methane/Air Combustion in Micro-Channels. Energies, 16(18), 6752. https://doi.org/10.3390/en16186752