Green Production of Biodiesel from High Acid Value Oil via Glycerol Esterification and Transesterification Catalyzed by Nano Hydrated Eggshell-Derived CaO

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Catalyst Preparation and Optimization

2.3. Catalyst Characterization

2.4. Glycerol Esterification of Feedstock

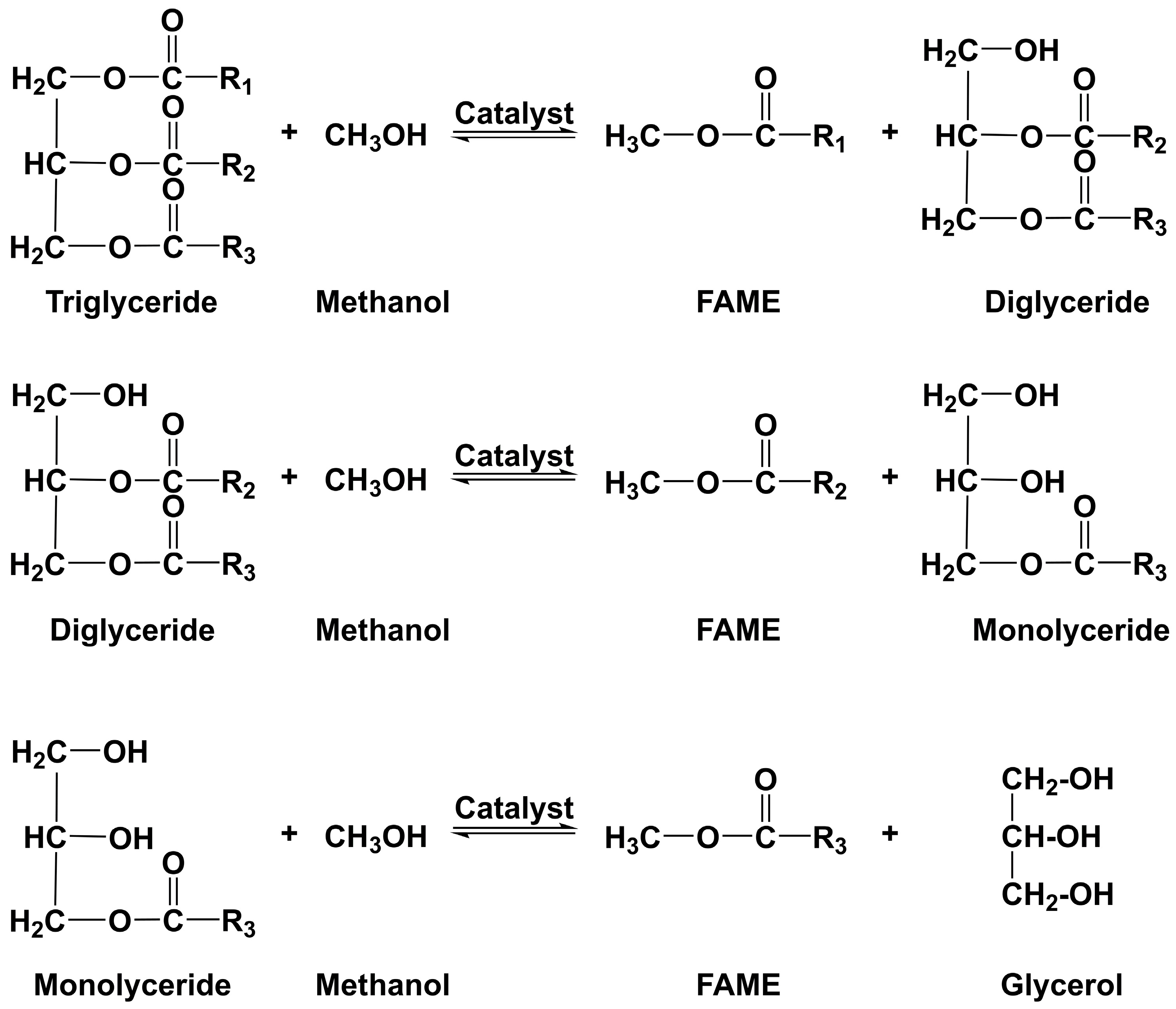

2.5. Catalytic Tests and Product Analysis

2.6. Catalyst Reusability

3. Results and Discussion

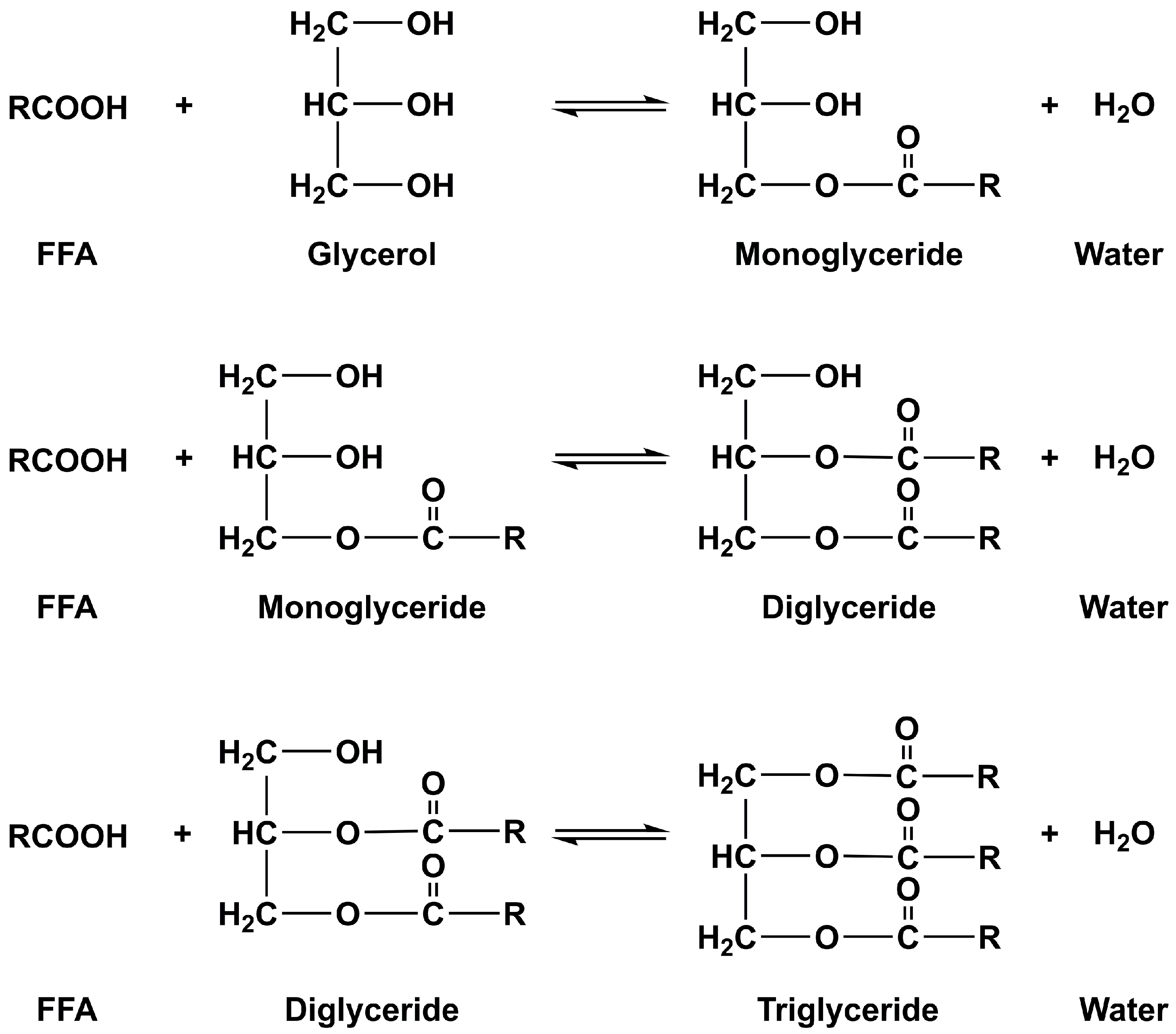

3.1. Results of Glycerol Esterification

3.2. Catalyst Optimization

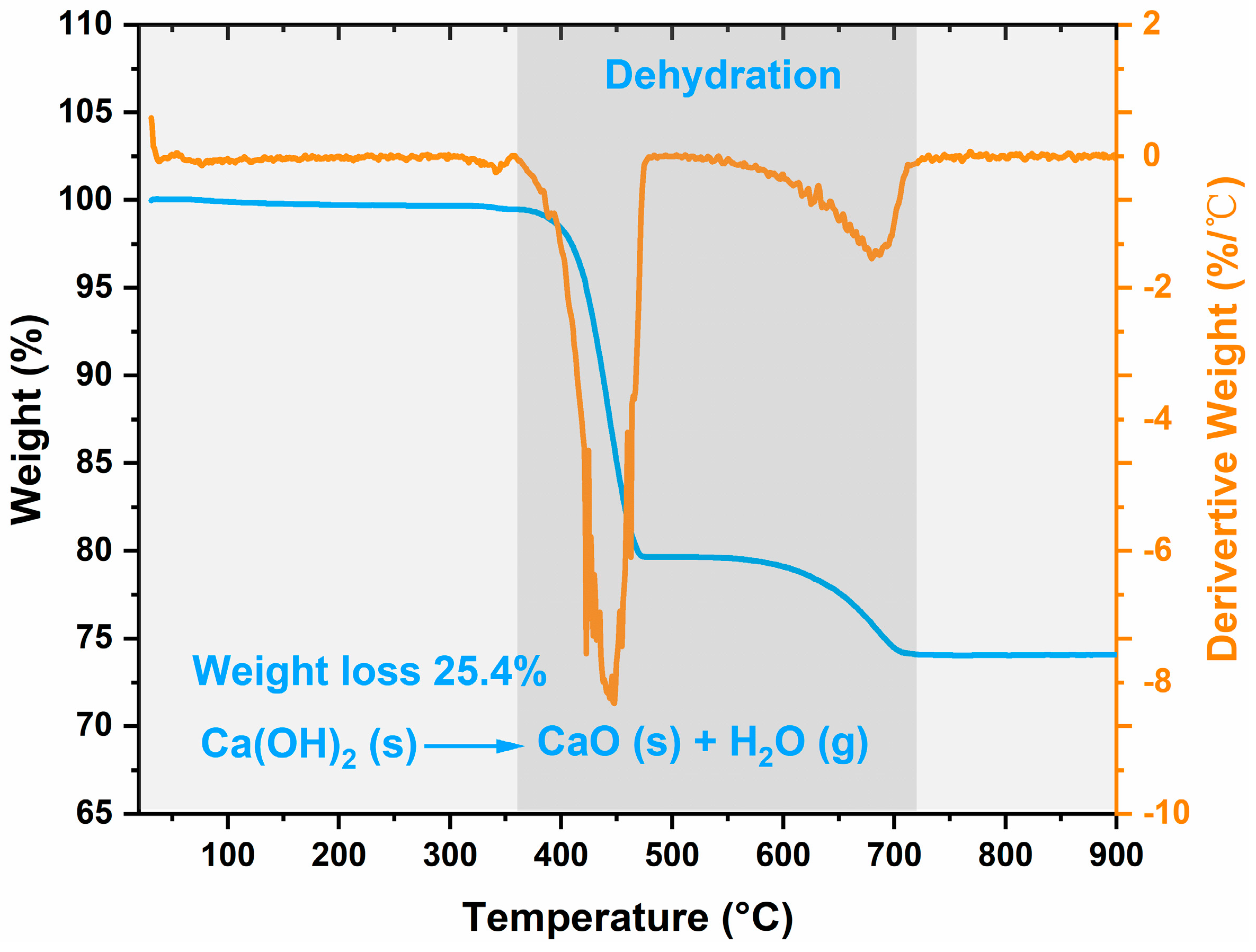

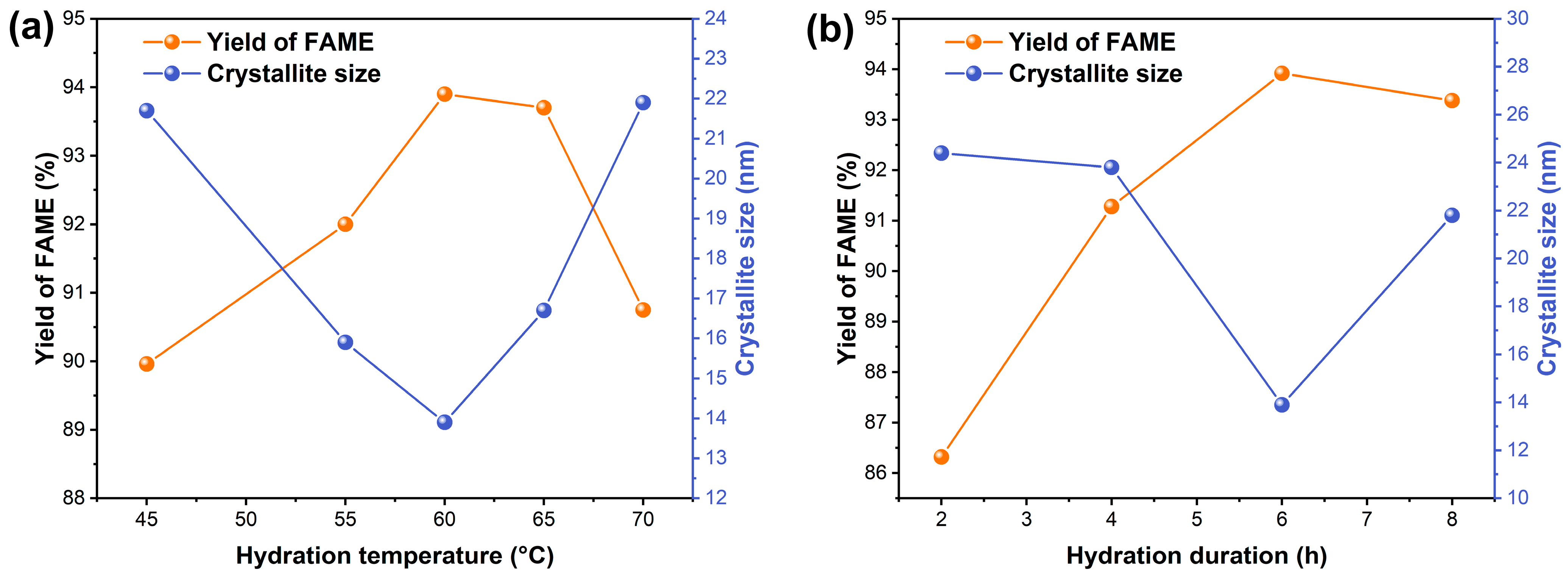

3.2.1. Catalyst Dehydration Temperature Optimization

3.2.2. Hydration Optimization

3.3. Catalyst Characterization

3.3.1. XRD Analysis

3.3.2. N2 Physisorption Analysis and Basic Strength Analysis

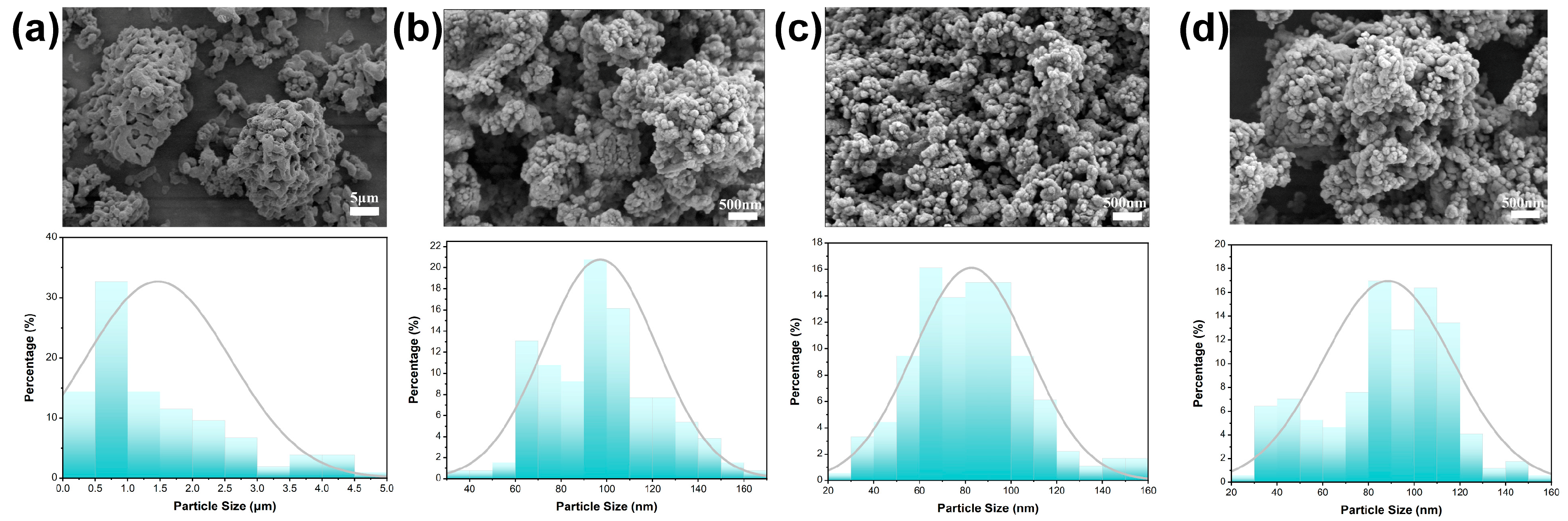

3.3.3. SEM Analysis

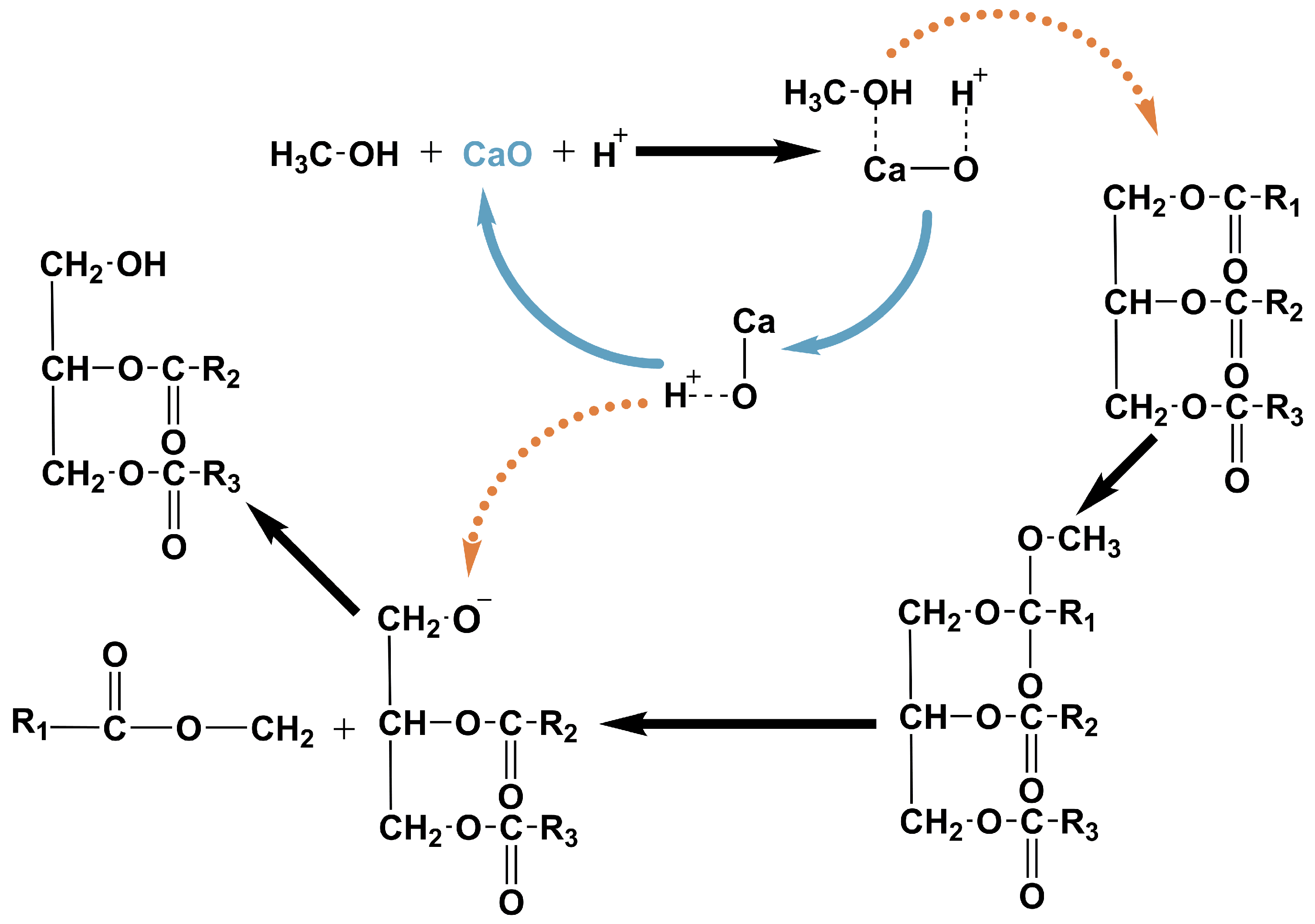

3.4. Transesterification Process Optimization

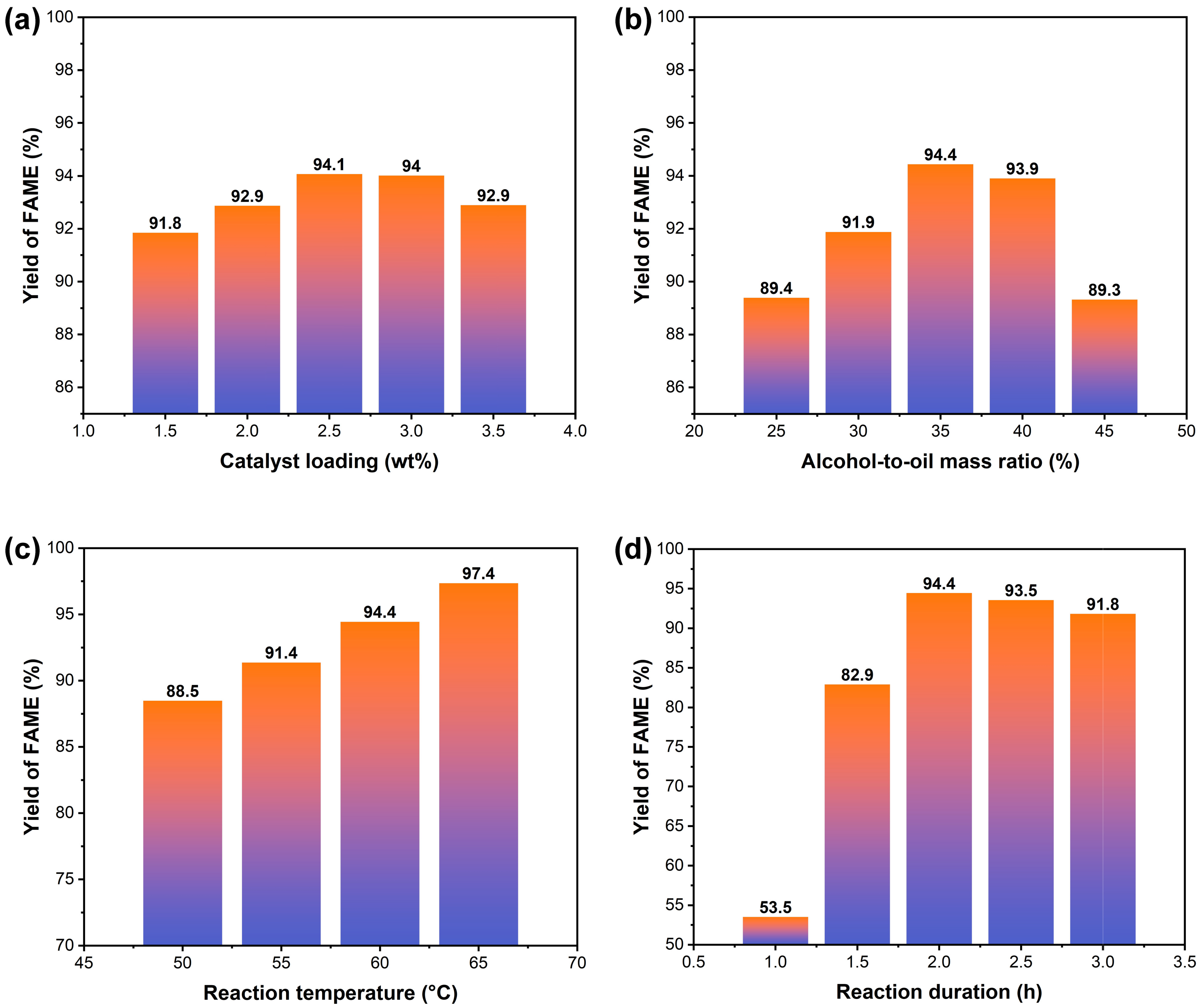

3.4.1. Catalyst Loading

3.4.2. Alcohol-to-Oil Mass Ratio

3.4.3. Reaction Temperature

3.4.4. Reaction Duration

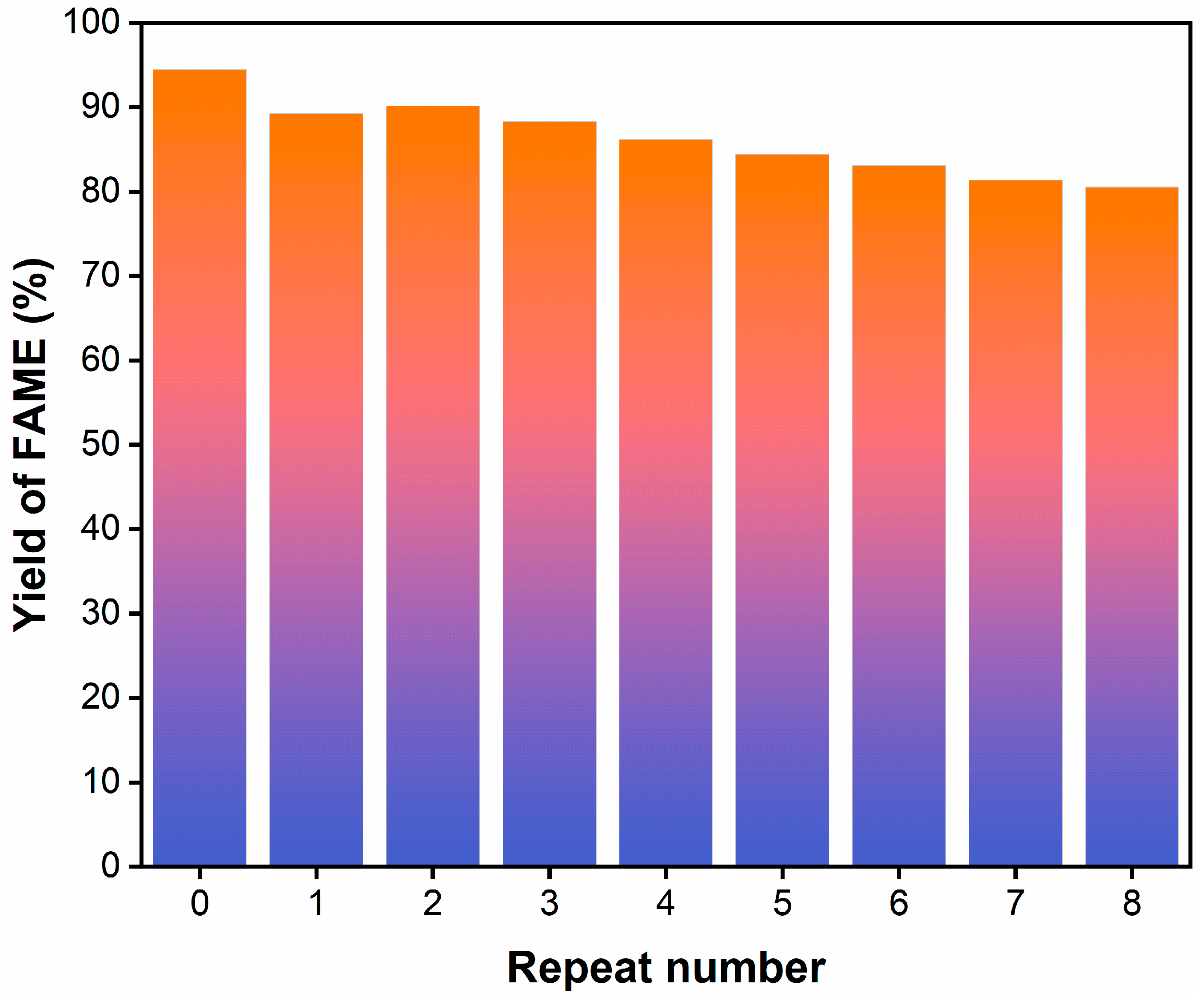

3.5. Catalyst Reusability

3.6. Comparison of FAME Production Using the Eggshell-Derived CaO

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akram, F.; ul Haq, I.; Raja, S.I.; Mir, A.S.; Qureshi, S.S.; Aqeel, A.; Shah, F.I. Current Trends in Biodiesel Production Technologies and Future Progressions: A Possible Displacement of the Petro-Diesel. J. Clean. Prod. 2022, 370, 133479. [Google Scholar] [CrossRef]

- Choudhary, S.; Tripathi, S.; Poluri, K.M. Microalgal-Based Bioenergy: Strategies, Prospects, and Sustainability. Energy Fuels 2022, 36, 14584–14612. [Google Scholar] [CrossRef]

- Liu, Z.; Lian, T.; Li, W.; Cao, C.; Xiong, H.; Li, Y. Mini Review of Current Combustion Research Progress of Biodiesel and Model Compounds for Gas Turbine Application. Energy Fuels 2021, 35, 13569–13584. [Google Scholar] [CrossRef]

- Zulqarnain; Mohd Yusoff, M.H.; Ayoub, M.; Ramzan, N.; Nazir, M.H.; Zahid, I.; Abbas, N.; Elboughdiri, N.; Mirza, C.R.; Butt, T.A. Overview of Feedstocks for Sustainable Biodiesel Production and Implementation of the Biodiesel Program in Pakistan. ACS Omega 2021, 6, 19099–19114. [Google Scholar] [CrossRef] [PubMed]

- Tangy, A.; Pulidindi, I.N.; Dutta, A.; Borenstein, A. Strontium Oxide Nanoparticles for Biodiesel Production: Fundamental Insights and Recent Progress. Energy Fuels 2021, 35, 187–200. [Google Scholar] [CrossRef]

- Maheshwari, P.; Haider, M.B.; Yusuf, M.; Klemeš, J.J.; Bokhari, A.; Beg, M.; Al-Othman, A.; Kumar, R.; Jaiswal, A.K. A Review on Latest Trends in Cleaner Biodiesel Production: Role of Feedstock, Production Methods, and Catalysts. J. Clean. Prod. 2022, 355, 131588. [Google Scholar] [CrossRef]

- Elgharbawy, A.S.; Sadik, W.A.; Sadek, O.M.; Kasaby, M.A. A Review on Biodiesel Feedstocks and Production Technologies. J. Chil. Chem. Soc. 2021, 66, 5098–5109. [Google Scholar] [CrossRef]

- Nie, Y.; Xia, F.; Xie, Q.; Lu, M.; Liang, X.; Su, Y.; Ji, J. Method for Preparing Low-Sulfur Biodiesel 2021. Available online: https://patents.justia.com/patent/20200095511 (accessed on 2 November 2021).

- Xie, Q.; Cai, L.; Xia, F.; Liang, X.; Wu, Z.; Liu, Y.; Li, X.; Lu, M.; Nie, Y.; Ji, J. High Vacuum Distillation for Low-Sulfur Biodiesel Production: From Laboratory to Large Scale. J. Clean. Prod. 2019, 223, 379–385. [Google Scholar] [CrossRef]

- Anderson, E.; Addy, M.; Xie, Q.; Ma, H.; Liu, Y.; Cheng, Y.; Onuma, N.; Chen, P.; Ruan, R. Glycerin Esterification of Scum Derived Free Fatty Acids for Biodiesel Production. Bioresour. Technol. 2016, 200, 153–160. [Google Scholar] [CrossRef]

- Demirbas, A. Comparison of Transesterification Methods for Production of Biodiesel from Vegetable Oils and Fats. Energy Convers. Manag. 2008, 49, 125–130. [Google Scholar] [CrossRef]

- Sharma, Y.C.; Singh, B.; Korstad, J. Latest Developments on Application of Heterogenous Basic Catalysts for an Efficient and Eco Friendly Synthesis of Biodiesel: A Review. Fuel 2011, 90, 1309–1324. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Wu, X.; Leung, M.K.H. A Review on Biodiesel Production Using Catalyzed Transesterification. Appl. Energy 2010, 87, 1083–1095. [Google Scholar] [CrossRef]

- MacLeod, C.S.; Harvey, A.P.; Lee, A.F.; Wilson, K. Evaluation of the Activity and Stability of Alkali-Doped Metal Oxide Catalysts for Application to an Intensified Method of Biodiesel Production. Chem. Eng. J. 2008, 135, 63–70. [Google Scholar] [CrossRef]

- Boey, P.-L.; Maniam, G.P.; Hamid, S.A. Performance of Calcium Oxide as a Heterogeneous Catalyst in Biodiesel Production: A Review. Chem. Eng. J. 2011, 168, 15–22. [Google Scholar] [CrossRef]

- Gupta, J.; Agarwal, M.; Dalai, A.K. An Overview on the Recent Advancements of Sustainable Heterogeneous Catalysts and Prominent Continuous Reactor for Biodiesel Production. J. Ind. Eng. Chem. 2020, 88, 58–77. [Google Scholar] [CrossRef]

- Patil, P.D.; Deng, S. Transesterification of Camelina Sativa Oil Using Heterogeneous Metal Oxide Catalysts. Energy Fuels 2009, 23, 4619–4624. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, A.; Chandra Sharma, Y. Biodiesel Production from Microalgal Oil Using Barium–Calcium–Zinc Mixed Oxide Base Catalyst: Optimization and Kinetic Studies. Energy Fuels 2019, 33, 1175–1184. [Google Scholar] [CrossRef]

- Aleman-Ramirez, J.L.; Moreira, J.; Torres-Arellano, S.; Longoria, A.; Okoye, P.U.; Sebastian, P.J. Preparation of a Heterogeneous Catalyst from Moringa Leaves as a Sustainable Precursor for Biodiesel Production. Fuel 2021, 284, 118983. [Google Scholar] [CrossRef]

- Faruque, M.O.; Razzak, S.A.; Hossain, M.M. Application of Heterogeneous Catalysts for Biodiesel Production from Microalgal Oil—A Review. Catalysts 2020, 10, 1025. [Google Scholar] [CrossRef]

- Liu, X.; He, H.; Wang, Y.; Zhu, S.; Piao, X. Transesterification of Soybean Oil to Biodiesel Using CaO as a Solid Base Catalyst. Fuel 2008, 87, 216–221. [Google Scholar] [CrossRef]

- Chouhan, A.P.S.; Sarma, A.K. Modern Heterogeneous Catalysts for Biodiesel Production: A Comprehensive Review. Renew. Sustain. Energy Rev. 2011, 15, 4378–4399. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Ma, X.; Wu, Z.; Cui, P.; Lu, W.; Liu, F.; Chu, H.; Wang, Y. A Novel Magnetic CaO-Based Catalyst Synthesis and Characterization: Enhancing the Catalytic Activity and Stability of CaO for Biodiesel Production. Chem. Eng. J. 2020, 391, 123549. [Google Scholar] [CrossRef]

- Mazaheri, H.; Ong, H.C.; Amini, Z.; Masjuki, H.H.; Mofijur, M.; Su, C.H.; Anjum Badruddin, I.; Khan, T.M.Y. An Overview of Biodiesel Production via Calcium Oxide Based Catalysts: Current State and Perspective. Energies 2021, 14, 3950. [Google Scholar] [CrossRef]

- Boey, P.-L.; Maniam, G.P.; Hamid, S.A. Biodiesel Production via Transesterification of Palm Olein Using Waste Mud Crab (Scylla Serrata) Shell as a Heterogeneous Catalyst. Bioresour. Technol. 2009, 100, 6362–6368. [Google Scholar] [CrossRef]

- Nakatani, N.; Takamori, H.; Takeda, K.; Sakugawa, H. Transesterification of Soybean Oil Using Combusted Oyster Shell Waste as a Catalyst. Bioresour. Technol. 2009, 100, 1510–1513. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.; Wang, Y.; Han, H. Utilization of Waste Freshwater Mussel Shell as an Economic Catalyst for Biodiesel Production. Biomass Bioenergy 2011, 35, 3627–3635. [Google Scholar] [CrossRef]

- Wei, Z.; Xu, C.; Li, B. Application of Waste Eggshell as Low-Cost Solid Catalyst for Biodiesel Production. Bioresour. Technol. 2009, 100, 2883–2885. [Google Scholar] [CrossRef]

- Buasri, A.; Chaiyut, N.; Loryuenyong, V.; Worawanitchaphong, P.; Trongyong, S. Calcium Oxide Derived from Waste Shells of Mussel, Cockle, and Scallop as the Heterogeneous Catalyst for Biodiesel Production. Sci. World J. 2013, 2013, 460923. [Google Scholar] [CrossRef]

- Correia, L.M.; Saboya, R.M.A.; de Sousa Campelo, N.; Cecilia, J.A.; Rodríguez-Castellón, E.; Cavalcante, C.L.; Vieira, R.S. Characterization of Calcium Oxide Catalysts from Natural Sources and Their Application in the Transesterification of Sunflower Oil. Bioresour. Technol. 2014, 151, 207–213. [Google Scholar] [CrossRef]

- Asikin-Mijan, N.; Lee, H.V.; Taufiq-Yap, Y.H. Synthesis and Catalytic Activity of Hydration–Dehydration Treated Clamshell Derived CaO for Biodiesel Production. Chem. Eng. Res. Des. 2015, 102, 368–377. [Google Scholar] [CrossRef]

- Yoosuk, B.; Udomsap, P.; Puttasawat, B.; Krasae, P. Improving Transesterification Acitvity of CaO with Hydration Technique. Bioresour. Technol. 2010, 101, 3784–3786. [Google Scholar] [CrossRef]

- Niju, S.; Meera, K.M.; Begum, S.; Anantharaman, N. Modification of Egg Shell and Its Application in Biodiesel Production. J. Saudi Chem. Soc. 2014, 18, 702–706. [Google Scholar] [CrossRef]

- Ashine, F.; Kiflie, Z.; Prabhu, S.V.; Tizazu, B.Z.; Varadharajan, V.; Rajasimman, M.; Joo, S.-W.; Vasseghian, Y.; Jayakumar, M. Biodiesel Production from Argemone Mexicana Oil Using Chicken Eggshell Derived CaO Catalyst. Fuel 2023, 332, 126166. [Google Scholar] [CrossRef]

- Roschat, W.; Phewphong, S.; Thangthong, A.; Moonsin, P.; Yoosuk, B.; Kaewpuang, T.; Promarak, V. Catalytic Performance Enhancement of CaO by Hydration-Dehydration Process for Biodiesel Production at Room Temperature. Energy Convers. Manag. 2018, 165, 1–7. [Google Scholar] [CrossRef]

- GB/T 5530-2005; Animal and Vegetable Fats and Oils—Determination of Acid Value and Acidity. National Grain Bureau: Beijing, China, 2005.

- Maquirriain, M.A.; Querini, C.A.; Pisarello, M.L. Glycerine Esterification with Free Fatty Acids: Homogeneous Catalysis. Chem. Eng. Res. Des. 2021, 171, 86–99. [Google Scholar] [CrossRef]

- Ngamcharussrivichai, C.; Totarat, P.; Bunyakiat, K. Ca and Zn Mixed Oxide as a Heterogeneous Base Catalyst for Transesterification of Palm Kernel Oil. Appl. Catal. Gen. 2008, 341, 77–85. [Google Scholar] [CrossRef]

- Lee, S.L.; Wong, Y.C.; Tan, Y.P.; Yew, S.Y. Transesterification of Palm Oil to Biodiesel by Using Waste Obtuse Horn Shell-Derived CaO Catalyst. Energy Convers. Manag. 2015, 93, 282–288. [Google Scholar] [CrossRef]

- Buasri, A.; Chaiyut, N.; Loryuenyong, V.; Wongweang, C.; Khamsrisuk, S. Application of Eggshell Wastes as a Heterogeneous Catalyst for Biodiesel Production. Sustain. Energy 2013, 1, 7–13. [Google Scholar] [CrossRef]

- Lam, M.K.; Lee, K.T.; Mohamed, A.R. Homogeneous, Heterogeneous and Enzymatic Catalysis for Transesterification of High Free Fatty Acid Oil (Waste Cooking Oil) to Biodiesel: A Review. Biotechnol. Adv. 2010, 28, 500–518. [Google Scholar] [CrossRef]

- Minaria, M.; Mohadi, R. Preparation and Characterization of Calcium Oxide from Crab Shells (Portunus Pelagicus) and Its Application in Biodiesel Synthesis of Waste Cooking Oil, Palm and Coconut Oil. Sci. Technol. Indones. 2016, 1, 1–7. [Google Scholar] [CrossRef][Green Version]

- Boro, J.; Konwar, L.J.; Deka, D. Transesterification of Non Edible Feedstock with Lithium Incorporated Egg Shell Derived CaO for Biodiesel Production. Fuel Process. Technol. 2014, 122, 72–78. [Google Scholar] [CrossRef]

- Yan, S.; Kim, M.; Mohan, S.; Salley, S.O.; Ng, K.Y.S. Effects of Preparative Parameters on the Structure and Performance of Ca–La Metal Oxide Catalysts for Oil Transesterification. Appl. Catal. Gen. 2010, 373, 104–111. [Google Scholar] [CrossRef]

- Cao, M.; Peng, L.; Xie, Q.; Xing, K.; Lu, M.; Ji, J. Sulfonated Sargassum Horneri Carbon as Solid Acid Catalyst to Produce Biodiesel via Esterification. Bioresour. Technol. 2021, 324, 124614. [Google Scholar] [CrossRef] [PubMed]

- Torkzaban, S.; Feyzi, M.; Norouzi, L. A Novel Robust CaO/ZnFe2O4 Hollow Magnetic Microspheres Heterogenous Catalyst for Synthesis Biodiesel from Waste Frying Sunflower Oil. Renew. Energy 2022, 200, 996–1007. [Google Scholar] [CrossRef]

- Pandit, P.R.; Fulekar, M.H. Egg Shell Waste as Heterogeneous Nanocatalyst for Biodiesel Production: Optimized by Response Surface Methodology. J. Environ. Manag. 2017, 198, 319–329. [Google Scholar] [CrossRef] [PubMed]

- Maniam, G.P.; Hindryawati, N.; Nurfitri, I.; Manaf, I.S.A.; Ramachandran, N.; Rahim, M.H.A. Utilization of Waste Fat from Catfish (Pangasius) in Methyl Esters Preparation Using CaO Derived from Waste Marine Barnacle and Bivalve Clam as Solid Catalysts. J. Taiwan Inst. Chem. Eng. 2015, 49, 58–66. [Google Scholar] [CrossRef]

- Seffati, K.; Honarvar, B.; Esmaeili, H.; Esfandiari, N. Enhanced Biodiesel Production from Chicken Fat Using CaO/CuFe2O4 Nanocatalyst and Its Combination with Diesel to Improve Fuel Properties. Fuel 2019, 235, 1238–1244. [Google Scholar] [CrossRef]

- Putra, M.D.; Irawan, C.; Udiantoro; Ristianingsih, Y.; Nata, I.F. A Cleaner Process for Biodiesel Production from Waste Cooking Oil Using Waste Materials as a Heterogeneous Catalyst and Its Kinetic Study. J. Clean. Prod. 2018, 195, 1249–1258. [Google Scholar] [CrossRef]

- Viriya-empikul, N.; Krasae, P.; Nualpaeng, W.; Yoosuk, B.; Faungnawakij, K. Biodiesel Production over Ca-Based Solid Catalysts Derived from Industrial Wastes. Fuel 2012, 92, 239–244. [Google Scholar] [CrossRef]

- Erchamo, Y.S.; Mamo, T.T.; Workneh, G.A.; Mekonnen, Y.S. Improved Biodiesel Production from Waste Cooking Oil with Mixed Methanol–Ethanol Using Enhanced Eggshell-Derived CaO Nano-Catalyst. Sci. Rep. 2021, 11, 6708. [Google Scholar] [CrossRef]

| Index | Unit | Value |

|---|---|---|

| Acid value | mg KOH/g | 0.83 |

| Saponification value | mg KOH/g | 199.05 |

| Monoglyceride content | % (m/m) | 2.95 |

| Diglyceride content | % (m/m) | 3.61 |

| Triglyceride content | % (m/m) | 93.44 |

| Catalyst | BET Surface Area (m2/g) | Mean Pore Diameter (nm) | Total Pore Volume (cm3/g) | Basic Strength |

|---|---|---|---|---|

| CaO | 1.6429 | 10.8644 | 0.004449 | 9.3 < H_ < 12.2 |

| CaOH-45-6h | 11.6408 | 48.2618 | 0.135590 | 9.3 < H_ < 12.2 |

| CaOH-55-6h | 9.6729 | 50.4828 | 0.077243 | 12.2 < H_ < 15.6 |

| CaOH-60-6h | 14.8209 | 43.8119 | 0.130846 | 12.2 < H_ < 15.6 |

| CaOH-65-6h | 12.4565 | 40.6488 | 0.111106 | 12.2 < H_ < 15.6 |

| CaOH-70-6h | 13.9873 | 29.0470 | 0.106863 | 9.3 < H_ < 12.2 |

| CaOH-60-2h | 13.7889 | 45.9859 | 0.110861 | 12.2 < H_ < 15.6 |

| CaOH-60-4h | 12.4309 | 36.4223 | 0.084373 | 12.2 < H_ < 15.6 |

| CaOH-60-8h | 12.8146 | 41.8096 | 0.093936 | 12.2 < H_ < 15.6 |

| Catalyst | Feedstock | Reaction Conditions | Yield/ Conversion (%) | Reusability (Cycles) | Ref. | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Type | Preparation Method | Calcination Temperature (°C) | Catalyst Amount (wt%) | Alcohol-to-Oil Molar/Mass Ratio | Temperature (°C) | Duration (h) | ||||

| Loaded CaO (CuFe2O4) | Precipitation | 800 | Chicken fat | 3.0 | 15:1 (molar) | 70 | 4.0 | 94.52 (Y) | - | [49] |

| Bio-CaO | Calcination | 900 | Sunflower oil | 3.0 | 9:1 (molar) | 60 | 3.0 | 97.75 (C) | - | [30] |

| Supported CaO (SiO2) | Impregnation | 900 | Waste cooking oil | 8.0 | 14:1 (molar) | 60 | 1.5 | 91.00 (Y) | 2 | [50] |

| Bio-CaO | Calcination | 800 | Palm olein oil | 10.0 | 12:1 (molar) | 60 | 2.0 | 94.10 (Y) | - | [51] |

| Bio-CaO | Calcination | 900 | Palm oil | 20.0 | 9:1 (molar) | 60 | 3.0 | 94.49 (C) | 4 | [40] |

| Hydrated-dehydrated CaO | Calcination-hydration-dehydration-calcination | 1st—900 2nd—600 | Waste frying oil | 5.0 | 12:1 (molar) | 60 | 1.0 | 94.52 (C) | 6 | [33] |

| Hydrated-dehydrated CaO | Calcination-hydration-dehydration-calcination | 1st—900 2nd—800 | Waste cooking oil | 2.5 | 12:1 (molar) | 60 | 2.0 | 94.00 (Y) | - | [52] |

| Hydrated-dehydrated CaO | Calcination-hydration-dehydration-calcination | 1st—875 2nd—725 | Glycerol-esterified oil | 2.5 | 35 wt% | 60 | 2.0 | 94.44 (Y) | 8 | This Study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, Z.; Tao, Y.; Fei, H.; Deng, W.; Chen, Y.; Zhao, Z.; Liang, X.; Nie, Y. Green Production of Biodiesel from High Acid Value Oil via Glycerol Esterification and Transesterification Catalyzed by Nano Hydrated Eggshell-Derived CaO. Energies 2023, 16, 6717. https://doi.org/10.3390/en16186717

Weng Z, Tao Y, Fei H, Deng W, Chen Y, Zhao Z, Liang X, Nie Y. Green Production of Biodiesel from High Acid Value Oil via Glycerol Esterification and Transesterification Catalyzed by Nano Hydrated Eggshell-Derived CaO. Energies. 2023; 16(18):6717. https://doi.org/10.3390/en16186717

Chicago/Turabian StyleWeng, Zhenghui, Yuanzhe Tao, Haotian Fei, Weishan Deng, Yiyao Chen, Zhiqi Zhao, Xiaojiang Liang, and Yong Nie. 2023. "Green Production of Biodiesel from High Acid Value Oil via Glycerol Esterification and Transesterification Catalyzed by Nano Hydrated Eggshell-Derived CaO" Energies 16, no. 18: 6717. https://doi.org/10.3390/en16186717

APA StyleWeng, Z., Tao, Y., Fei, H., Deng, W., Chen, Y., Zhao, Z., Liang, X., & Nie, Y. (2023). Green Production of Biodiesel from High Acid Value Oil via Glycerol Esterification and Transesterification Catalyzed by Nano Hydrated Eggshell-Derived CaO. Energies, 16(18), 6717. https://doi.org/10.3390/en16186717