Trends and Future Perspective of Electrification in Agricultural Tractor-Implement Applications

Abstract

:1. Introduction

- Improving the overall machine efficiency, looking at higher engine efficiencies, more efficient mechanical transmissions, more intelligent and efficient way of transmitting power through hydraulics, better traction capabilities;

- Introducing new alternative fuels with lower environmental impact (synthetic fuels, biofuels, etc.);

- Adopting leading-edge solutions in terms of powertrain configurations (electric, hybrid electric, fuel-cell-powered systems) and innovative implements (electrification and/or automation).

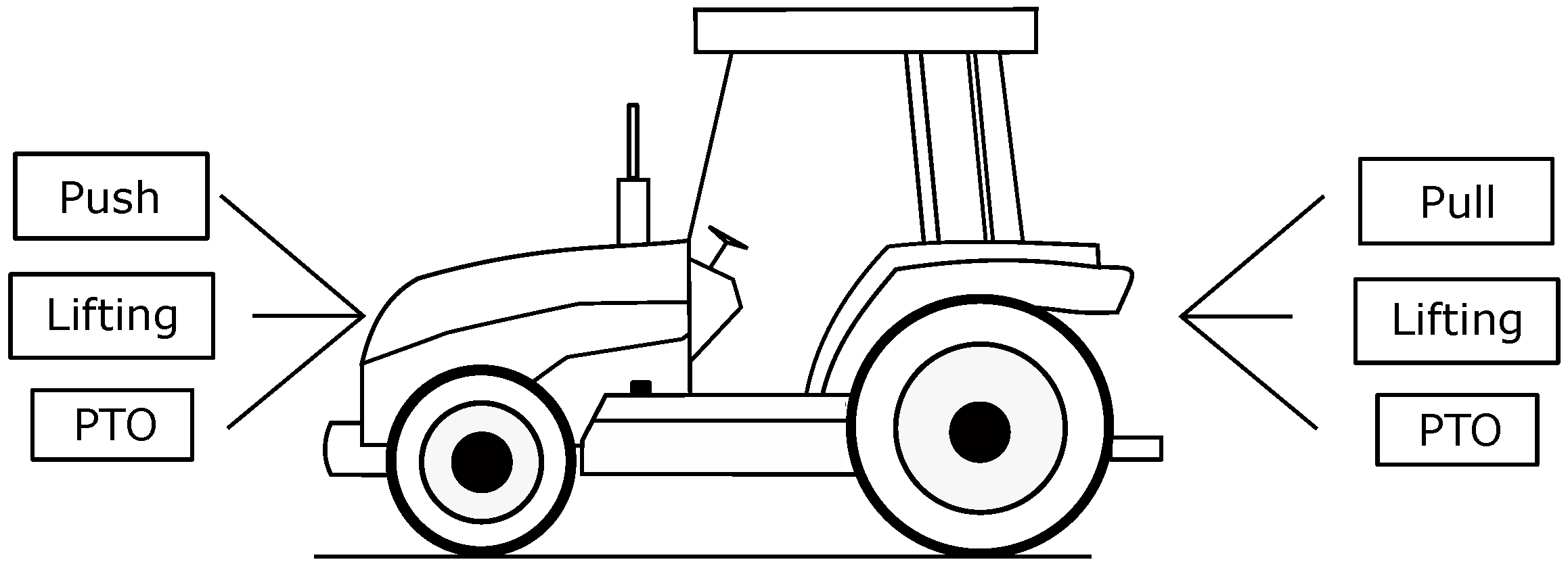

2. Definitions and Characteristics of a Traditional Agricultural Tractors

"The agricultural tractor is a self-propelled agricultural vehicle having at least two axles and wheels, endless tracks, or a combination of wheels and endless tracks, particularly designed to pull, push, carry or provide power to operate implements or pull agricultural trailers and implements, or any combination of these functions used for agricultural work (including forestry work), which may be provided with a load platform."

- By means of a mechanical power take-off (PTO), which is usually connected directly to the engine output shaft or may receive power by means of a hydrostatic transmission if the tractor layout does not allow the first option;

- Using hydraulic connections in charge of providing pressurized fluid (usually in the range of 150–205 bar) obtained from one or more pumps directly connected to the engine or to other points of the transmission depending on the tractor layout;

- In some special cases, using connections for pressurized air in some specific implements where pneumatic actuators may require it. An additional compressor needs to be installed on the tractor side if not already present on the implement itself (in this case, it would be powered by one of the previous methods).

- Open field tractors for heavy-duty tasks, such as plowing, arrowing, or transportation to be performed on very large farm areas or between farm fields far from each other.

- Specialized tractors for specific use cases, such as orchards, vineyards, cotton fields, or gardening, where the application strongly determines the characteristics of the machines (compactness, low/high clearance, narrow wheel track, high steering capability, etc.).

- Improvements of the power transmission efficiency from the main engine to each mechanical interface;

- More freedom for the internal combustion engine (ICE) operating point, thus the possibility for further optimization depending on the work task;

- Finer controllability of the power delivery, thanks to advanced power electronic converters;

- Possibility to transfer power to the attached implement through high-voltage (≥48 V) electric line.

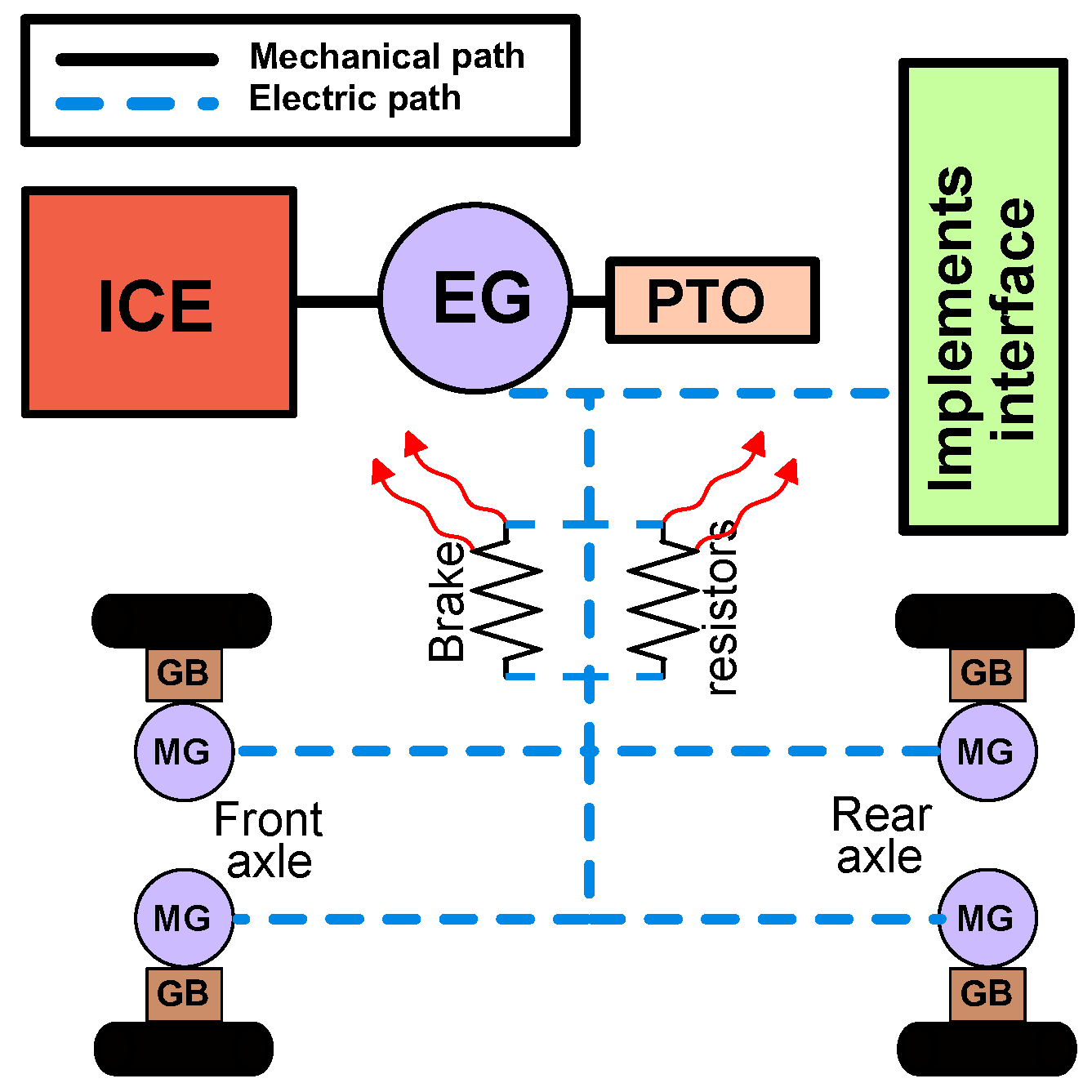

3. Tractor Electrification

- Delivery of traction power at the wheels;

- Generation of power for the implement connected to at least one of the several available mechanical interfaces.

- Hybrid powertrains, where at least two energy sources can be controlled to achieve the best possible overall efficiency for a given work task. In this category, an ICE or fuel-cell-based systems cooperate with a battery pack (or supercapacitor bank or both of them) to satisfy the power demand.

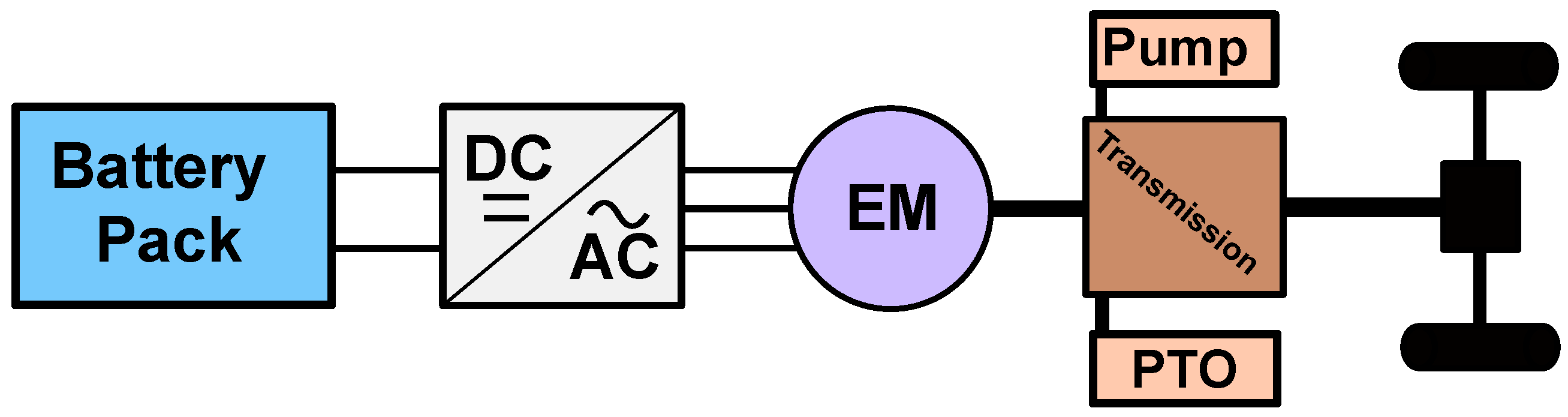

- Full-electric powertrains, where the work task is accomplished using the electric energy previously stored on board on a battery pack

- Electric transmissions, where the power coming from an ICE is entirely or partially converted into electricity through a generator and then used by an electric motor connected to the transmission.

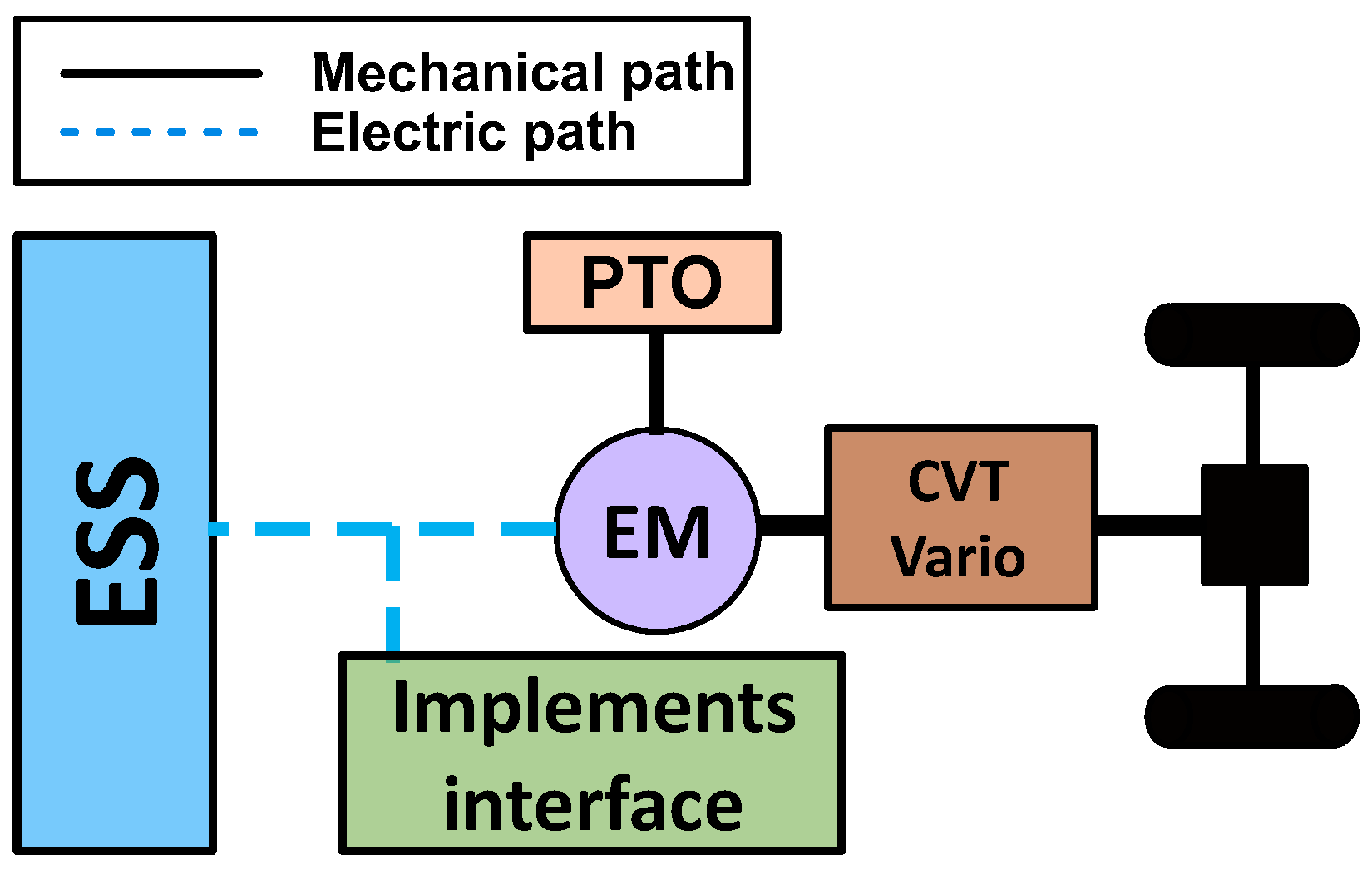

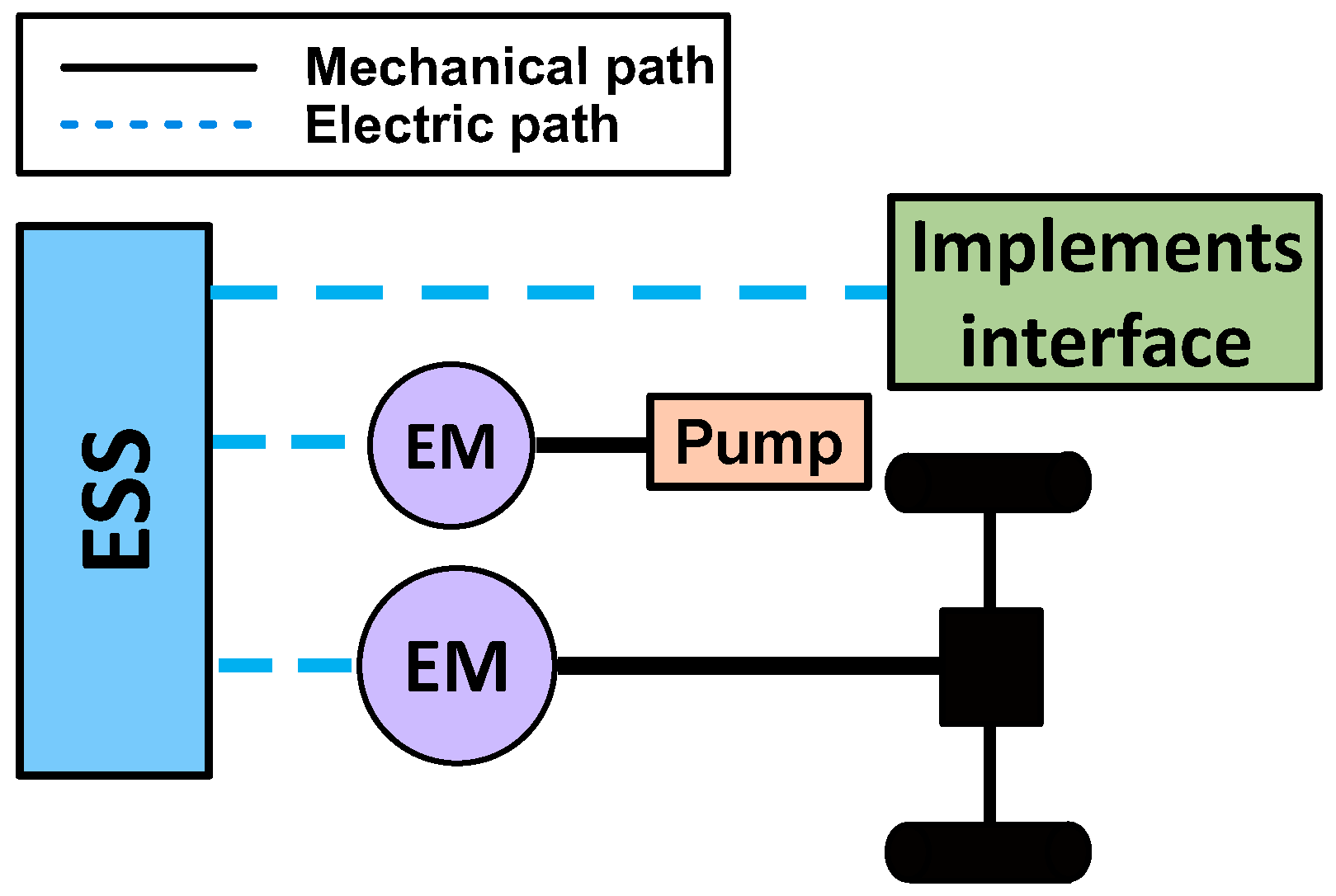

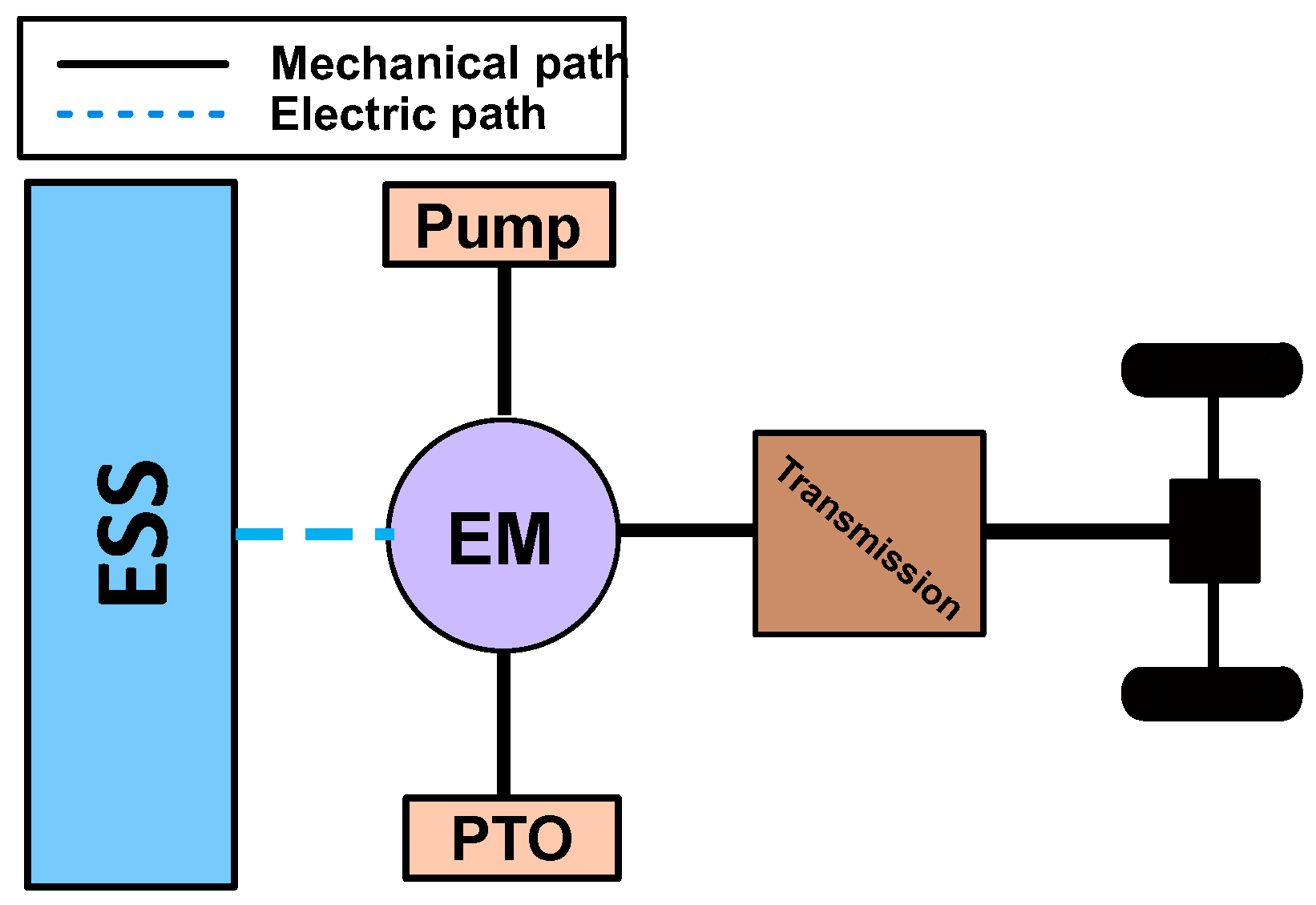

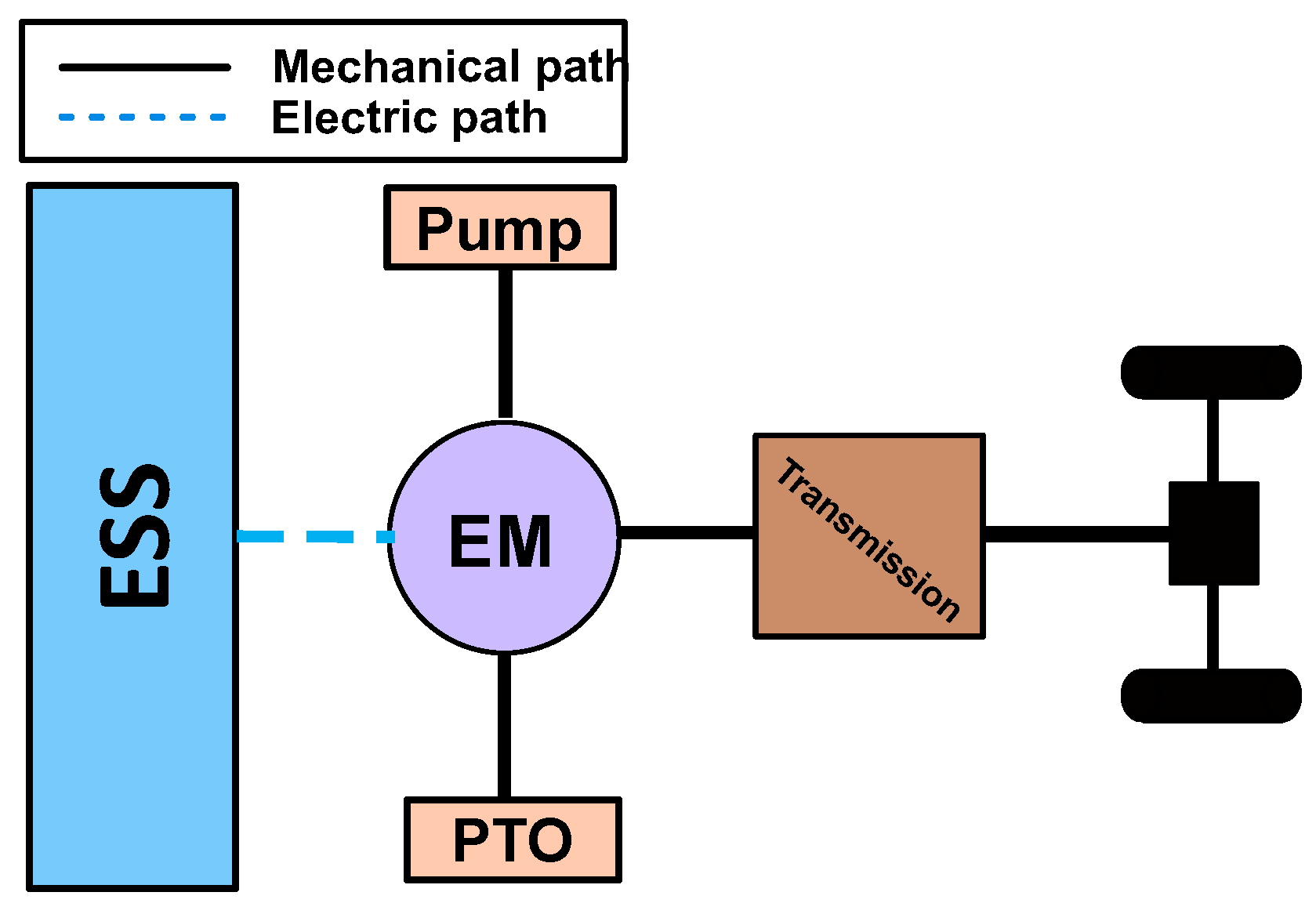

3.1. Full Electric

- The lower volumetric energy density of current battery packs in comparison with diesel fuel, which would require high onboard volume to meet the energy demand of the work cycle (Li-ion battery packs have an energy density of 350 Wh/L, against 11 kWh/L for diesel);

- The charging infrastructure, which is still not available on rural areas and probably will not have a sufficient coverage in the upcoming years.

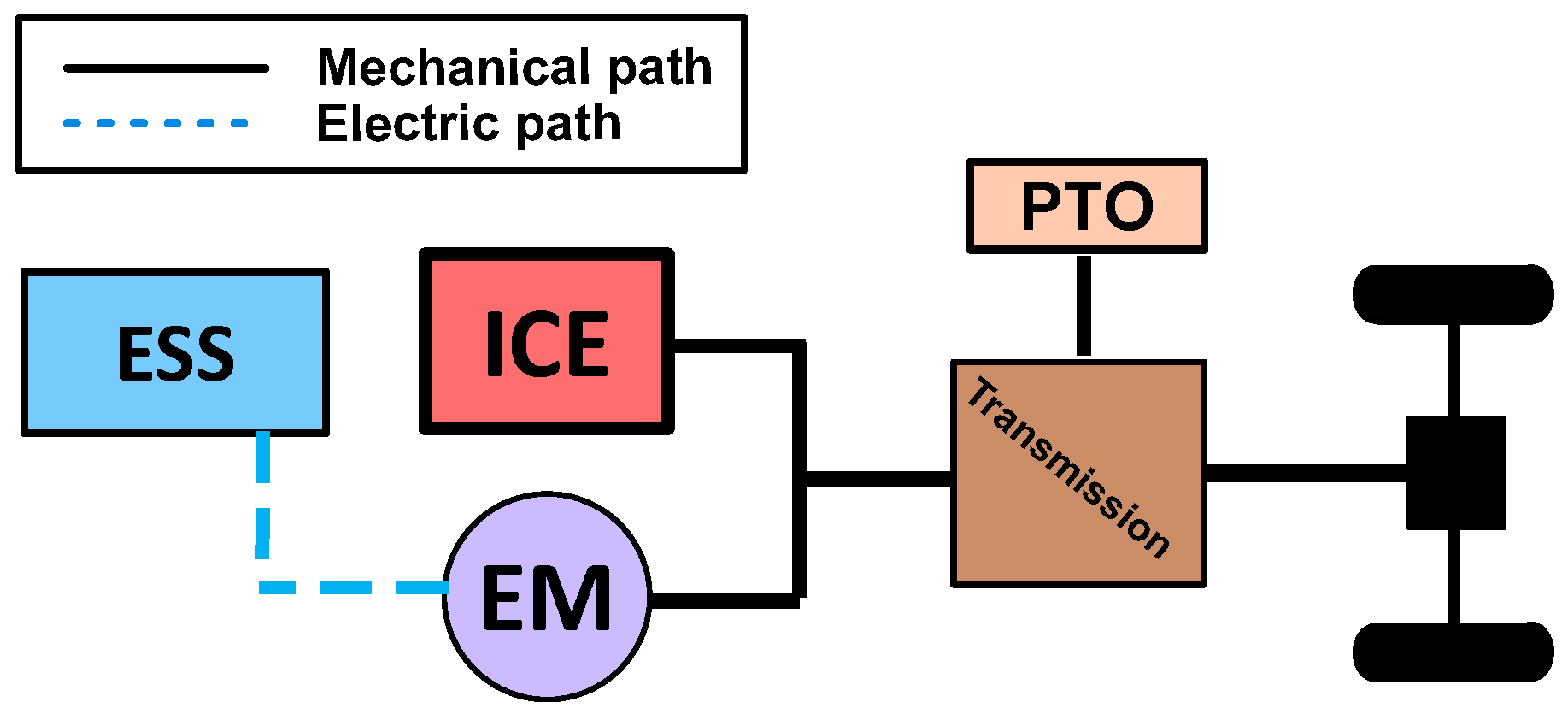

3.2. Parallel Hybrid

- Engine downsizing, covering the peaks in power demand directly with the electric system;

- Optimization of the ICE use, in terms of work point for a given rotational speed or help in transient conditions;

- Reasonable integration into existing tractor architecture due to the relatively low amount of components involved.

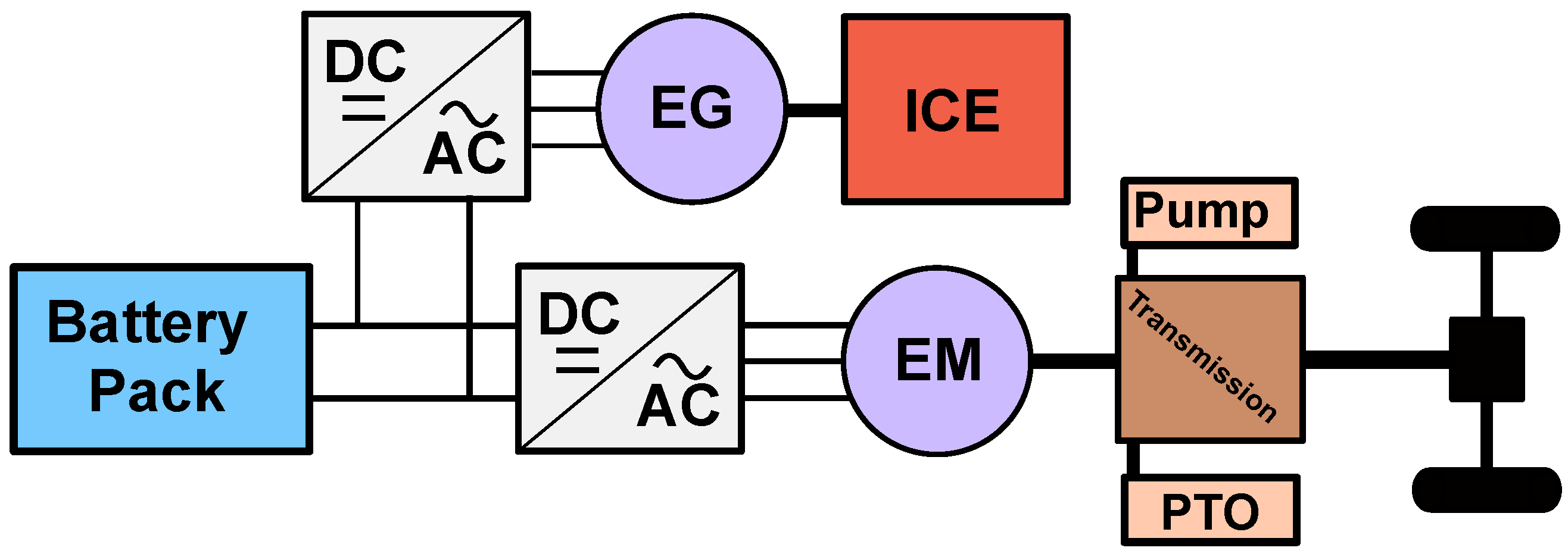

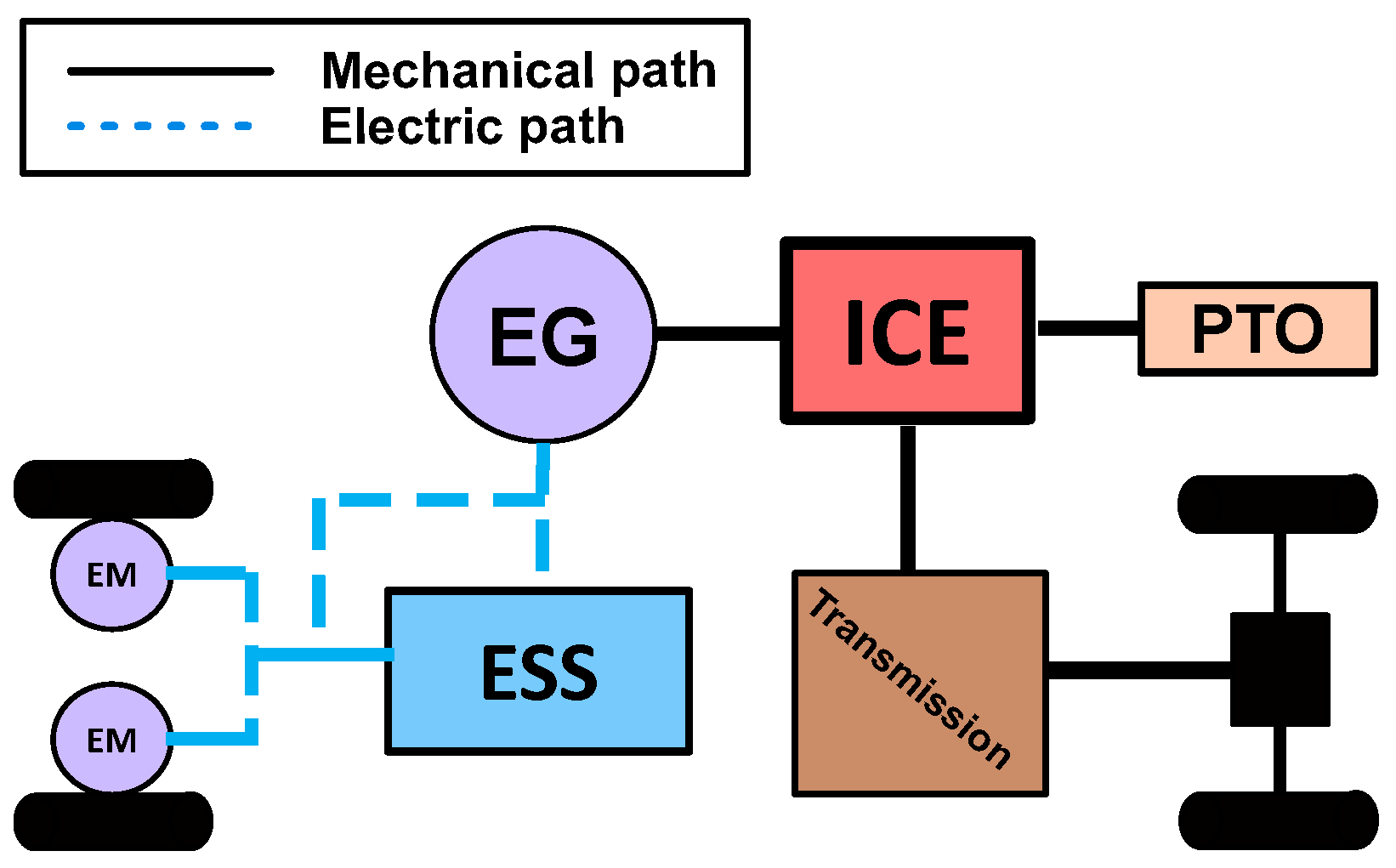

3.3. Series Hybrid

- An electric machine with the main role of generating electric energy from the electromechanical conversion of the power coming from the ICE;

- One or several electric machines acting as motors for the mechanical interfaces requiring power during field work;

- An energy storage system acting as energy buffer for the electric machines asked to cover peaks in power demand.

3.4. Power-Split Electric Powertrain

- Part of the engine output power is taken by a hydraulic pump (usually but not necessarily of the variable displacement type).

- The hydraulic power moves the hydraulic motor (usually but not necessarily of the constant displacement type) connected to one of the three elements of a planetary gearbox.

- The engine and hydraulic motor power are then recombined within a planetary gearbox to satisfy together the requirements of the work task.

- Depending on the power characteristics of the output, each machine could be controlled to act as a motor (propulsive element) or as a generator (braking element).

- If no auxiliary ESS is considered (electric transmission), the electric system should operate as close as possible to the condition of power recirculation through the electric machines.

- Thanks to the planetary gearbox work principles, in critical faulty conditions, the engine can be mechanically coupled to the wheels just by blocking the other input component of the mechanism.

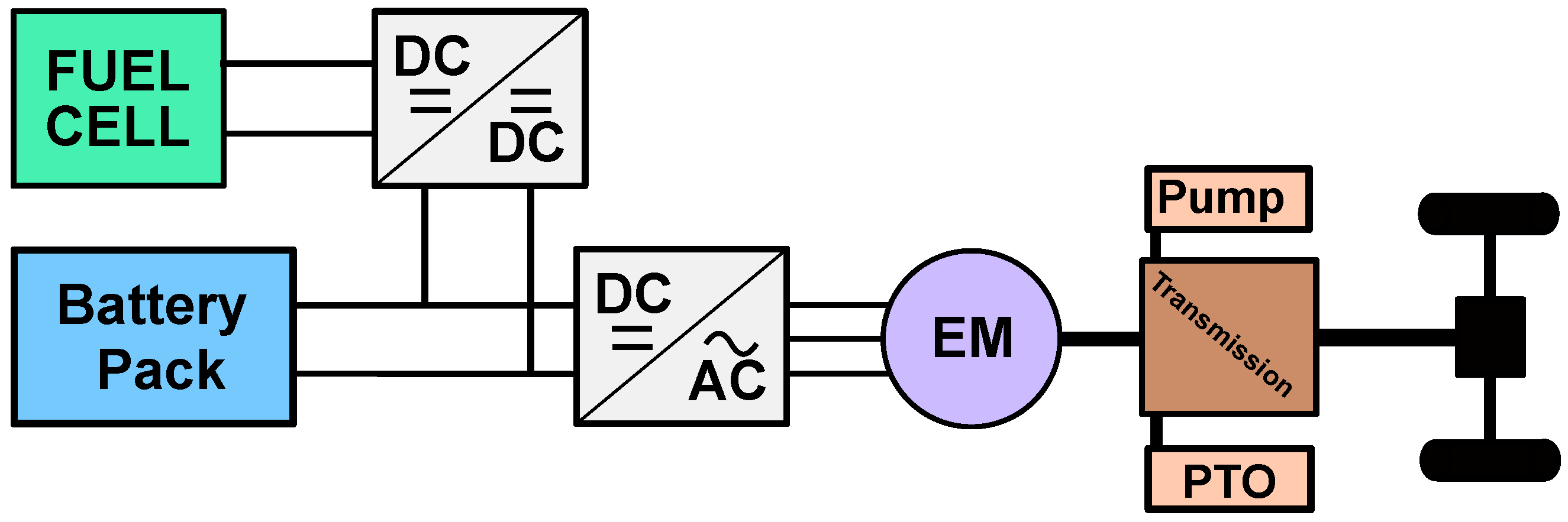

3.5. Fuel Cell Electric Powertrain

4. A New Methodology for Work Vehicle Classification: The New Hybridization Factor

- -

- indicates the power delivered by the electric motors to propel the vehicle.

- -

- indicates the power of the internal combustion engine available to propel the vehicle.

- -

- k is a coefficient that can take a value between 0 and 1 according to the machine work cycle, representing the overall power demand used for driving purposes on the total available;

- -

- represents the hybridization factor for the powertrain in charge of driving the vehicle as defined in Equation (2);

- -

- represents the hybridization factor for the powertrain in charge of powering work tasks as defined in Equation (2).

- The battery pack, if present;

- The electric generator, if present;

- The amount of energy stored and how it is distributed among the different sources of energy in the vehicle;

- The quality of the propulsion systems installed on the vehicle.

- -

- k is a coefficient that can take a value between 0 and 1 and represents the overall power demand used for driving purposes on the total power available;

- -

- represents the new hybridization factor definition applied to the driving powertrain;

- -

- represents the new hybridization factor definition applied to the load powertrain.

- -

- is the hybridization factor definition for the single power path, driveline, or PTO (namely, and );

- -

- is the power directly available to the drive shaft provided by the electric motor/s;

- -

- is the net power directly available on the drive shaft provided by the internal combustion engine but decremented by the power eventually taken by the electric generator in a series configuration;

- -

- is the nominal power of the battery pack delivered to the electric motor/s, if present in the vehicle;

- -

- is the nominal power of the electric generator delivered to the electric motor/s, if present in the vehicle;

- -

- indicates the average efficiency of the electrical path;

- -

- indicates the average efficiency of the internal combustion engine;

- -

- represents the battery pack capacity (in kWh) stored in the vehicle;

- -

- represents energy (in kWh) contained in the fuel tank of the vehicle.

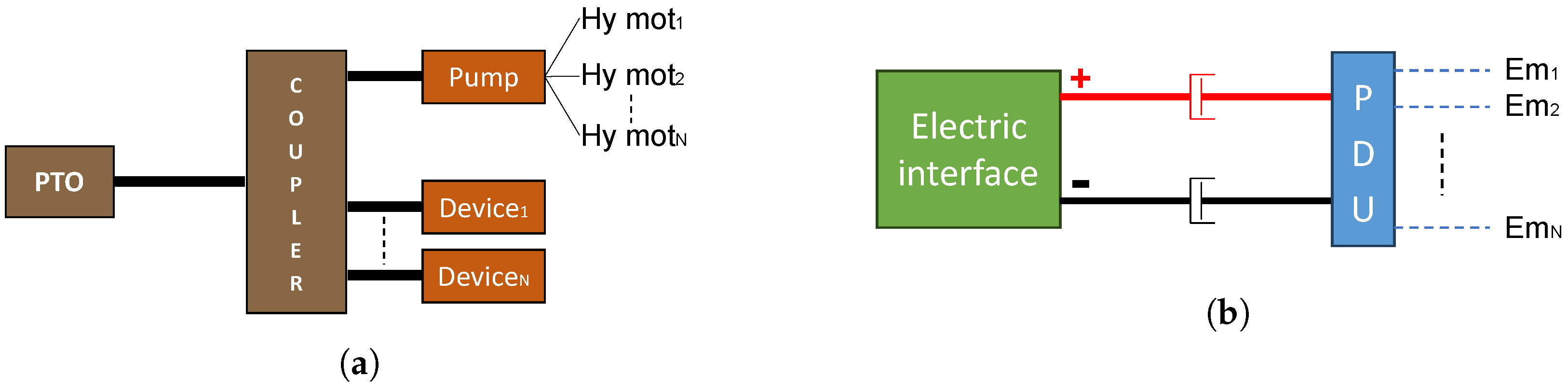

5. Implement Electrification

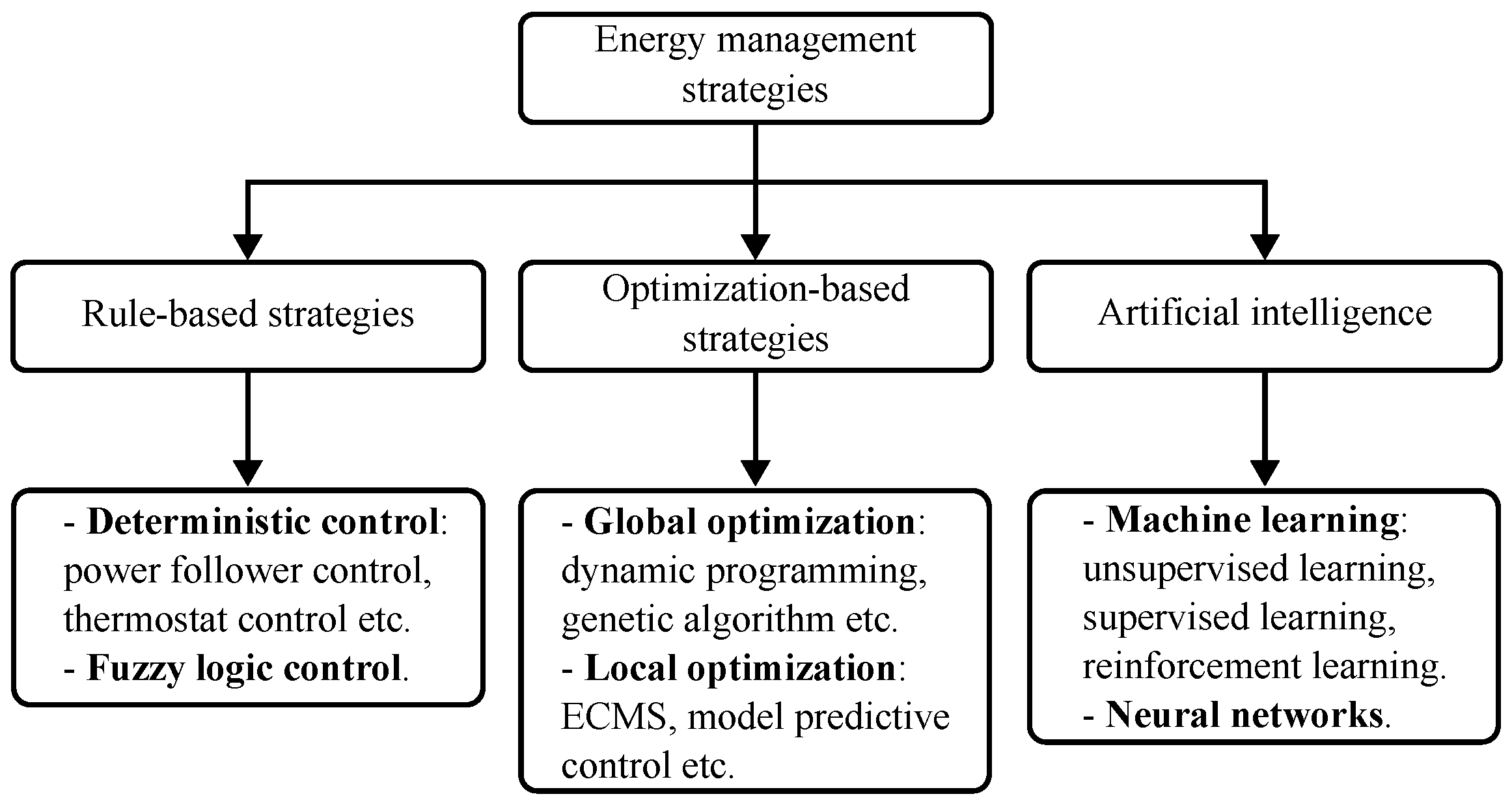

6. Control Strategies and Energy Management

6.1. EMSs for Hybrid Tractors with ICE

- An electrical path efficiency ;

- An ICE overall efficiency ;

- An ideal energy content for diesel fuel of 11.85 kWh/L;

- A nominal battery power as assuming LiFePO4 cells;

- The diesel tank capacity in L was estimated looking at tractors with a similar size of the diesel engine.

| Architecture | Em Power | Gen Power | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Year | Drive | PTO | Drive (kW) | PTO (kW) | Drive (kW) | PTO (kW) | ICE (kW) | Tank (L) | BESS (kWh) | |

| Zhang et al. [67] | 2023 | P. | P. | 40 | 40 | 0 | 0 | 60 | 50 | 22.4 | 0.44 |

| Zhu et al. [115] | 2022 | P. | P. | 45 | 45 | 0 | 0 | 132 | 150 | 16.2 | 0.26 |

| Zhang et al. [116] | 2023 | P. | P. | 30 | 30 | 0 | 0 | 162 | 180 | 25.2 | 0.17 |

| Dou et al. [68] | 2022 | S./P. | P. | 65 + 50 | 50 | 0 | 0 | 145 | 150 | 82.3 | 0.39 |

| Jia et al. [117] | 2019 | S. | S. | 90 | - | 90 | - | 104 | 85 | - | - |

| Troncon et al. [110] | 2019 | P. | P. | 9.2 | 9.2 | 0 | 0 | 55.4 | 50 | - | - |

| Jia et al. [112] | 2018 | S. | S. | - | - | - | - | 104 | 10 | - | - |

| Barthel et al. [113] | 2014 | P. | P. | - | - | - | - | - | 10 | - | - |

| Tebaldi et al. [50] | 2021 | P. | P. | - | - | - | - | 480 | 10 | - | - |

| Lee et al. [118] | 2016 | P. | P. | 9 | 52 | 0 | 0 | 50 | 50 | 3.2 | 0.34 |

| Beligoj et al. [32]—T1 | 2022 | P. | P. | 9 | 9 | 0 | 0 | 55 | 50 | 21 | 0.17 |

| Beligoj et al. [32]—T2 | 2022 | P. | P. | 26 | 26 | 0 | 0 | 151 | 150 | 24 | 0.16 |

| Beligoj et al. [32]—T3 | 2022 | P. | P. | 14 | 14 | 0 | 0 | 193 | 200 | 14 | 0.07 |

| Ghobadpour et al. [119] | 2021 | S. | S. | 2 × 21 | 15 | 8.8 | 8.8 | 8.8 | 40 | 16.8 | 0.86 |

| Dalboni et al. [114] | 2019 | P. | P. | - | - | - | - | 55 | 10 | 25 | - |

| Liu et al. [120] | 2023 | S. | S. | - | - | - | - | 300 | - | - | - |

| Mocera et al. [53]—S1 | 2022 | S. | P. | 54 | 54 | 54 | 0 | 54 | 50 | 16 | 0.51 |

| Mocera et al. [53]—S2 | 2022 | S. | P. | 63 | 54 | 54 | 0 | 54 | 50 | 16 | 0.51 |

| Mocera et al. [53]—P1 | 2022 | P. | P. | 30 | 30 | 0 | 0 | 54 | 50 | 16 | 0.38 |

| Mocera et al. [53]—P2 | 2022 | P. | P. | 22 | 22 | 0 | 0 | 54 | 50 | 16 | 0.32 |

| Mocera et al. [53]—EH | 2022 | P. | P. | 22 | 22 | 0 | 0 | 54 | 50 | 16 | 0.32 |

| Mocera et al. [64] | 2022 | S./P. | P. | 30 | 35 | 35 | 0 | 54 | 50 | 16 | 0.40 |

6.2. EMSs for Hybrid Tractors with FC

6.3. Control Strategies for Full-Electric Powertrains

7. Hybrid/Electric Agricultural Tractors: Prototypes and Industrial Investigations

- Research and development of mild-hybrid or small full-hybrid configuration for a small–medium tractor size in the 50–80 kW range;

- Research and development of full- electric tractors in the small size factor with a power range below 50 kW.

| Architecture | Em Power | Gen Power | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Year | Drive | PTO | Drive (kW) | PTO (kW) | Drive (kW) | PTO (kW) | ICE (kW) | Tank (L) | BESS (kWh) | |

| Belarus 3023e | 2009 | S. | S. | 183 | 55 | 220 | 220 | 220 | 200 | 0 | 0 |

| Rigitrac EWD 120 | 2011 | S. | ICE/S. | 4 × 33 | 0 | 85 | 80 | 91 | 85 | 0 | 0 |

| John Deere 6210 RE | 2013 | ICE | ICE/S. | 0 | 0 | 0 | 20 | 66 | 50 | 0 | 0 |

| CLAAS ARION 650 | 2015 | P. | P./S. | 90 | 40 | 0 | 90 | 136 | 330 | 5.72 * | 0.49 |

| John Deere SESAM | 2016 | F.e | F.e | 150 | 150 | - | - | - | - | 130 | 1 |

| Fendt e100 Vario | 2017 | F.e | F.e | 50 | 50 | - | - | - | - | 100 | 1 |

| Del Morino Rino | 2018 | F.e | F.e | 9 | 9 | - | - | - | - | 18 | 1 |

| Rigitrac SKE 50 | 2018 | F.e | F.e | 50 | 46 | - | - | - | - | 80 | 1 |

| Carraro Ibrido | 2018 | P. | P. | 20 | 20 | 0 | 0 | 55 | 50 | 25 | 0.31 |

| Landini REX 4 Electra | 2021 | ICE/S. | ICE | 2 × 12 | 0 | - | 0 | 80 | 50 | - | - |

| A. Carraro SRX Hy | 2021 | P. | P. | 20 | 20 | 0 | 0 | 55 | 50 | 6 | 0.28 |

| Solectrac e70N | 2021 | F.e | F.e | 52 | 52 | - | - | - | - | 60 | 1 |

| Landini REX 4 Full Hy | 2022 | P. | P. | 25 | 25 | 0 | 0 | 55 | 50 | 30 | 0.36 |

| A. Carraro eSP | 2022 | F.e | F.e | 25 | 25 | - | - | - | - | 32 | 1 |

| Kubota LXe-261 | 2022 | F.e | F.e | 19 | 19 | - | - | - | - | 25 | 1 |

| Monarch MK-V | 2022 | F.e | F.e | 55 | 55 | - | - | - | - | - | 1 |

| GOLDONI B1e | 2022 | F.e | F.e | 35 | 23.5 | - | - | - | - | 50 | 1 |

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 4WD | 4 wheel drive |

| AC | alternating current |

| AICS | artificial intelligence control strategies |

| BESS | battery energy storage system |

| CAN | controlled area network |

| CVT | continuously variable transmission |

| DC | direct current |

| DOC | diesel oxidation catalyst |

| DP | dynamic programming |

| DPF | diesel particulate filter |

| ECMS | equivalent consumption minimization strategy |

| eCVT | electric continuously variable transmission |

| EGR | exhaust gas recirculation |

| EMS | energy management strategy |

| FC | fuel cell |

| FCHET | fuel cell hybrid electric tractor |

| FCHEV | fuel cell hybrid electric vehicle |

| FET | full electric tractor |

| FLC | fuzzy logic controller |

| GHG | greenhouse gas |

| HF | hybridization factor |

| HVAC | heating, ventilation, and air conditioning |

| ICE | internal combustion engine |

| LiFePO4 | lithium iron phosphate |

| Li-ion | lithium-ion |

| MFLC | multimode fuzzy logic controller |

| NRMM | nonroad mobile machineries |

| OBS | optimization-based strategy |

| OEM | original equipment manufacturer |

| PDU | power delivery unit |

| PF | power follower |

| PHET | plug-in hybrid electric tractor |

| PTO | power take-off |

| RBS | rule-based strategy |

| SCR | selective catalyst reduction |

| SOC | state of charge |

References

- O’Regan, A.C.; Nyhan, M.M. Towards sustainable and net-zero cities: A review of environmental modelling and monitoring tools for optimizing emissions reduction strategies for improved air quality in urban areas. Environ. Res. 2023, 231, 116242. [Google Scholar] [CrossRef] [PubMed]

- Toscano, D. The Impact of Shipping on Air Quality in the Port Cities of the Mediterranean Area: A Review. Atmosphere 2023, 14, 1180. [Google Scholar] [CrossRef]

- Mofolasayo, A. Assessing and Managing the Direct and Indirect Emissions from Electric and Fossil-Powered Vehicles. Sustainability 2023, 15, 1138. [Google Scholar] [CrossRef]

- Tait, K.N.; Khan, M.A.H.; Bullock, S.; Lowenberg, M.H.; Shallcross, D.E. Aircraft Emissions, Their Plume-Scale Effects, and the Spatio-Temporal Sensitivity of the Atmospheric Response: A Review. Aerospace 2022, 9, 355. [Google Scholar] [CrossRef]

- Oreggioni, G.D.; Mahiques, O.; Monforti-Ferrario, F.; Schaaf, E.; Muntean, M.; Guizzardi, D.; Vignati, E.; Crippa, M. The impacts of technological changes and regulatory frameworks on global air pollutant emissions from the energy industry and road transport. Energy Policy 2022, 168, 113021. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Zhu, H.; Zhou, P.; Liu, S.; Lei, X.; Li, Y.; Li, B.; Ning, P. Life cycle assessment of pollutants and emission reduction strategies based on the energy structure of the nonferrous metal industry in China. Energy 2022, 261, 125148. [Google Scholar] [CrossRef]

- Wollenberg, E.; Richards, M.; Smith, P.; Havlík, P.; Obersteiner, M.; Tubiello, F.N.; Herold, M.; Gerber, P.; Carter, S.; Reisinger, A.; et al. Reducing Emissions from Agriculture to Meet the 2 °C Target. Glob. Chang. Biol. 2016, 22, 3859–3864. [Google Scholar] [CrossRef]

- Golasa, P.; Wysokiński, M.; Bieńkowska-Gołasa, W.; Gradziuk, P.; Golonko, M.; Gradziuk, B.; Siedlecka, A.; Gromada, A. Sources of Greenhouse Gas Emissions in Agriculture, with Particular Emphasis on Emissions from Energy Used. Energies 2021, 14, 3784. [Google Scholar] [CrossRef]

- Martelli, S.; Mocera, F.; Somà, A. Carbon Footprint of an Orchard Tractor through a Life-Cycle Assessment Approach. Agriculture 2023, 13, 1210. [Google Scholar] [CrossRef]

- Pradel, M. Life cycle inventory data of agricultural tractors. Data Brief 2023, 48, 109174. [Google Scholar] [CrossRef]

- Platis, D.; Anagnostopoulos, C.; Tsaboula, A.; Menexes, G.; Kalburtji, K.; Mamolos, A. Energy Analysis, and Carbon and Water Footprint for Environmentally Friendly Farming Practices in Agroecosystems and Agroforestry. Sustainability 2019, 11, 1664. [Google Scholar] [CrossRef]

- Mantoam, E.J.; Angnes, G.; Mekonnen, M.M.; Romanelli, T.L. Energy, carbon and water footprints on agricultural machinery. Biosyst. Eng. 2020, 198, 304–322. [Google Scholar] [CrossRef]

- Hagan, R.; Markey, E.; Clancy, J.; Keating, M.; Donnelly, A.; O’Connor, D.J.; Morrison, L.; McGillicuddy, E.J. Non-Road Mobile Machinery Emissions and Regulations: A Review. Air 2023, 1, 14–36. [Google Scholar] [CrossRef]

- Lovarelli, D.; Bacenetti, J. Exhaust Gases Emissions from Agricultural Tractors: State of the Art and Future Perspectives for Machinery Operators. Biosyst. Eng. 2019, 186, 204–213. [Google Scholar] [CrossRef]

- Bacenetti, J.; Lovarelli, D.; Facchinetti, D.; Pessina, D. An environmental comparison of techniques to reduce pollutants emissions related to agricultural tractors. Biosyst. Eng. 2018, 171, 30–40. [Google Scholar] [CrossRef]

- Wang, Q.; He, J.; Lu, C.; Wang, C.; Lin, H.; Yang, H.; Li, H.; Wu, Z. Modelling and Control Methods in Path Tracking Control for Autonomous Agricultural Vehicles: A Review of State of the Art and Challenges. Appl. Sci. 2023, 13, 7155. [Google Scholar] [CrossRef]

- Martelli, S.; Mocera, F.; Somà, A. Co-Simulation of a Specialized Tractor for Autonomous Driving in Orchards. SAE Tech. Pap. 2022. [Google Scholar] [CrossRef]

- Miao, Y.; Hynan, P.; von Jouanne, A.; Yokochi, A. Current Li-Ion Battery Technologies in Electric Vehicles and Opportunities for Advancements. Energies 2019, 12, 1074. [Google Scholar] [CrossRef]

- Amir, M.; Deshmukh, R.G.; Khalid, H.M.; Said, Z.; Raza, A.; Muyeen, S.M.; Nizami, A.-S.; Elavarasan, R.M.; Saidur, R.; Sopian, K. Energy storage technologies: An integrated survey of developments, global economical/environmental effects, optimal scheduling model, and sustainable adaption policies. J. Energy Storage 2023, 72, 108694. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, L.; Coskun, S.; Pang, H.; Cui, Y.; Xi, J. Energy Management Strategies for Hybrid Electric Vehicles: Review, Classification, Comparison, and Outlook. Energies 2020, 13, 3352. [Google Scholar] [CrossRef]

- Alaswad, A.; Omran, A.; Sodre, J.R.; Wilberforce, T.; Pignatelli, G.; Dassisti, M.; Baroutaji, A.; Olabi, A.G. Technical and Commercial Challenges of Proton-Exchange Membrane (PEM) Fuel Cells. Energies 2021, 14, 144. [Google Scholar] [CrossRef]

- Scolaro, E.; Beligoj, M.; Estevez, M.P.; Alberti, L.; Renzi, M.; Mattetti, M. Electrification of Agricultural Machinery: A Review. IEEE Access 2021, 9, 164520–164541. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. A Review of Hybrid Electric Architectures in Construction, Handling and Agriculture Machines. In New Perspectives on Electric Vehicles; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Somà, A. Trends and Hybridization Factor for Heavy-Duty Working Vehicles. In Hybrid Electric Vehicles; IntechOpen: London, UK, 2017. [Google Scholar] [CrossRef]

- ISO 12934:2021; Tractors and Machinery for Agriculture and Forestry. Basic Types. Vocabulary. International Standard Organisation ISO: Geneva, Switzerland. Available online: https://www.iso.org/standard/72617.html (accessed on 31 July 2023).

- Renius, K.T. Fundamentals of Tractor Design; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Mattetti, M.; Maraldi, M.; Lenzini, N.; Fiorati, S.; Sereni, E.; Molari, G. Outlining the mission profile of agricultural tractors through CAN-BUS data analytics. Comput. Electron. Agric. 2021, 184, 106078. [Google Scholar] [CrossRef]

- Singh, T.; Verma, A.; Singh, M. Development and implementation of an IOT based instrumentation system for computing performance of a tractor-implement system. J. Terramech. 2021, 97, 105–118. [Google Scholar] [CrossRef]

- Rohrer, R.A.; Pitla, S.K.; Luck, J.D. Tractor CAN bus interface tools and application development for real-time data analysis. Comput. Electron. Agric. 2019, 163, 104847. [Google Scholar] [CrossRef]

- Paraforos, D.S.; Sharipov, G.M.; Griepentrog, H.W. ISO 11783-compatible industrial sensor and control systems and related research: A review. Comput. Electron. Agric. 2019, 163, 104863. [Google Scholar] [CrossRef]

- Marx, S.E.; Luck, J.D.; Pitla, S.K.; Hoy, R.M. Comparing various hardware/software solutions and conversion methods for Controller Area Network (CAN) bus data collection. Comput. Electron. Agric. 2016, 128, 141–148. [Google Scholar] [CrossRef]

- Beligoj, M.; Scolaro, E.; Alberti, L.; Renzi, M.; Mattetti, M. Feasibility Evaluation of Hybrid Electric Agricultural Tractors Based on Life Cycle Cost Analysis. IEEE Access 2022, 10, 28853–28867. [Google Scholar] [CrossRef]

- Balsari, P.; Biglia, A.; Comba, L.; Sacco, D.; Eloi Alcatrão, L.; Varani, M.; Mattetti, M.; Barge, P.; Tortia, C.; Manzone, M.; et al. Performance analysis of a tractor—Power harrow system under different working conditions. Biosyst. Eng. 2021, 202, 28–41. [Google Scholar] [CrossRef]

- European Parliament—Council of the European Union. Regulation (EU) 2016/1628 of the European Parliament and of the Council of 14 September 2016 on requirements relating to gaseous and particulate pollutant emission limits and type-approval for internal combustion engines for non-road mobile machinery, amending Regulations (EU) No 1024/2012 and (EU) No 167/2013, and amending and repealing Directive 97/68/EC. Off. J. Eur. Union 2016, 50, 1–76. [Google Scholar]

- European Parliament—Council of the European Union. Regulation (EU) 167/2013 of the European Parliament and of the Council of 5 February 2013 on the Approval and Market Surveillance of Agricultural and Forestry Vehicles. 2013. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2013:060:0001:0051:en:PDF (accessed on 31 July 2023).

- Commission Delegated Regulation (EU) 2018/985 of 12 February 2018 Supplementing Regulation (EU) No 167/2013 of the European Parliament and of the Council as Regards Environmental and Propulsion Unit Performance Requirements for Agricultural and Forestry Vehicles and Their Engines and Repealing Commission Delegated Regulation (EU) 2015/96. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32018R0985 (accessed on 31 July 2023).

- McCaffery, C.; Yang, J.; Karavalakis, G.; Yoon, S.; Johnson, K.C.; Miller, J.W.; Durbin, T.D. Evaluation of small off-road diesel engine emissions and aftertreatment systems. Energy 2022, 251, 123903. [Google Scholar] [CrossRef]

- Nassar, M.Y.; Shaltout, M.L.; Hegazi, H.A. Multi-objective optimum energy management strategies for parallel hybrid electric vehicles: A comparative study. Energy Convers. Manag. 2023, 277, 116683. [Google Scholar] [CrossRef]

- Silva, S.F.; Eckert, J.J.; Silva, F.L.; Silva, L.C.A.; Dedini, F.G. Multi-objective optimization design and control of plug-in hybrid electric vehicle powertrain for minimization of energy consumption, exhaust emissions and battery degradation. Energy Convers. Manag. 2021, 234, 113909. [Google Scholar] [CrossRef]

- Xue, N.; Du, W.; Greszler, T.A.; Shyy, W.; Martins, J.R.R.A. Design of a lithium-ion battery pack for PHEV using a hybrid optimization method. Appl. Energy 2014, 115, 591–602. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. Working Cycle requirements for an electrified architecture of a vertical feed mixer vehicle. Procedia Struct. Integr. 2018, 12, 213–223. [Google Scholar] [CrossRef]

- Mocera, F.; Vergori, E.; Somà, A. Battery Performance Analysis for Working Vehicle Applications. IEEE Trans. Ind. Appl. 2019, 56, 644–653. [Google Scholar] [CrossRef]

- Mocera, F.; Martelli, S.; Costamagna, M. Dynamic behaviour of a battery pack for agricultural applications. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1214, 012032. [Google Scholar] [CrossRef]

- Long, C.; Yagian, Y.; Quan, C.; Guoli, L. Wavelet-Based Hybrid Energy Storage System for Smoothing Electric Tractor Power Fluctuations. In Proceedings of the 2023 International Conference on Future Energy Solutions (FES), Vaasa, Finland, 12–14 June 2023. [Google Scholar] [CrossRef]

- Emadi, A. Handbook of Automotive Power Electronics and Motor Drives; CRC Press: Boca Raton, FL, USA, 2017; Available online: https://books.google.it/books?id=c984D31D2sQC (accessed on 10 June 2023).

- Maroti, P.K.; Padmanaban, S.; Bhaskar, M.S.; Ramachandaramurthy, V.K.; Blaabjerg, F. The state-of-the-art of power electronics converters configurations in electric vehicle technologies. Power Electron. Devices Compon. 2022, 1, 100001. [Google Scholar] [CrossRef]

- Lagnelöv, O.; Larsson, G.; Nilsson, D.; Larsolle, A.; Hansson, P.A. Performance comparison of charging systems for autonomous electric field tractors using dynamic simulation. Biosyst. Eng. 2020, 194, 121–137. [Google Scholar] [CrossRef]

- Lombardi, G.V.; Berni, R. Renewable energy in agriculture: Farmers willingness-to-pay for a photovoltaic electric farm tractor. J. Clean. Prod. 2020, 313, 127520. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. Analysis of a Parallel Hybrid Electric Tractor for Agricultural Applications. Energies 2020, 13, 3055. [Google Scholar] [CrossRef]

- Tebaldi, D.; Zanasi, R. Modeling control and simulation of a parallel hybrid agricultural tractor. In Proceedings of the 2021 29th Mediterranean Conference on Control and Automation (MED), Puglia, Italy, 22–25 June 2021; pp. 317–323. [Google Scholar] [CrossRef]

- Troncon, D.; Alberti, L. Case of Study of the Electrification of a Tractor: Electric Motor Performance Requirements and Design. Energies 2020, 13, 2197. [Google Scholar] [CrossRef]

- Bin, X.; Hao, L.; Zheng-He, S.; EnRong, M. Powertrain System Design of Medium-sized Hybrid Electric Tractor. Inf. Technol. J. 2013, 12, 7228–7233. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V.; Somà, A. Comparative Analysis of Hybrid Electric Architectures for Specialized Agricultural Tractors. Energies 2022, 15, 1944. [Google Scholar] [CrossRef]

- Mattetti, M.; Michielan, E.; Mantovani, G.; Varani, M. Objective evaluation of gearshift process of agricultural tractors. Biosyst. Eng. 2022, 224, 324–335. [Google Scholar] [CrossRef]

- Kim, Y.J.; Chung, S.O.; Choi, C.H. Effects of gear selection of an agricultural tractor on transmission and PTO load during rotary tillage. Soil Tillage Res. 2013, 134, 90–96. [Google Scholar] [CrossRef]

- Molari, G.; Sedoni, E. Experimental evaluation of power losses in a power-shift agricultural tractor transmission. Biosyst. Eng. 2008, 100, 177–183. [Google Scholar] [CrossRef]

- Baek, S.Y.; Kim, Y.S.; Kim, W.S.; Baek, S.M.; Kim, Y.J. Development and Verification of a Simulation Model for 120 kW Class Electric AWD (All-Wheel-Drive) Tractor during Driving Operation. Energies 2020, 13, 2422. [Google Scholar] [CrossRef]

- Baek, S.Y.; Baek, S.M.; Jeon, H.H.; Kim, W.S.; Kim, Y.S.; Sim, T.Y.; Choi, K.H.; Hong, S.J.; Kim, H.; Kim, Y.J. Traction Performance Evaluation of the Electric All-Wheel-Drive Tractor. Sensors 2022, 22, 785. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, Z. Research on Load Disturbance Based Variable Speed PID Control and a Novel Denoising Method Based Effect Evaluation of HST for Agricultural Machinery. Agriculture 2021, 11, 960. [Google Scholar] [CrossRef]

- Guo, X.; Vacca, A. Advanced Design and Optimal Sizing of Hydrostatic Transmission Systems. Actuators 2021, 10, 243. [Google Scholar] [CrossRef]

- Florentsev, S.; Izosimov, D.; Makarov, L.; Baida, S.; Belousov, A. Complete traction electric equipment sets of electro-mechanical drive trains for tractors. In Proceedings of the 2010 IEEE Region 8 International Conference on Computational Technologies in Electrical and Electronics Engineering (SIBIRCON), Irkutsk, Russia, 11–15 July 2010; pp. 611–616. [Google Scholar] [CrossRef]

- Wang, G.; Song, Y.; Wang, J.; Xiao, M.; Cao, Y.; Chen, W.; Wang, J. Shift quality of tractors fitted with hydrostatic power split CVT during starting. Biosyst. Eng. 2020, 196, 183–201. [Google Scholar] [CrossRef]

- Xia, Y.; Sun, D.; Qin, D.; Zhou, X. Optimisation of the power-cycle hydro-mechanical parameters in a continuously variable transmission designed for agricultural tractors. Biosyst. Eng. 2020, 193, 12–24. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V. Numerical Performance Investigation of a Hybrid eCVT Specialized Agricultural Tractor. Appl. Sci. 2022, 12, 2438. [Google Scholar] [CrossRef]

- Rossi, C.; Pontara, D.; Falcomer, C.; Bertoldi, M.; Mandrioli, R. A Hybrid–Electric Driveline for Agricultural Tractors Based on an e-CVT Power-Split Transmission. Energies 2021, 14, 6912. [Google Scholar] [CrossRef]

- Medzevepryte, U.K.; Makaras, R.; Lukosevicius, V.; Kilikevicius, S. Application and Efficiency of a Series-Hybrid Drive for Agricultural Use Based on a Modified Version of the World Harmonized Transient Cycle. Energies 2023, 16, 5379. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, G.; Liu, M.; Yan, X.; Xu, L.; Shang, C. Research on Global Optimal Energy Management Strategy of Agricultural Hybrid Tractor Equipped with CVT. World Electr. Veh. J. 2023, 14, 127. [Google Scholar] [CrossRef]

- Dou, H.; Wei, H.; Zhang, Y.; Ai, Q. Configuration Design and Optimal Energy Management for Coupled-Split Powertrain Tractor. Machines 2022, 10, 1175. [Google Scholar] [CrossRef]

- Dash, S.K.; Chakraborty, S.; Roccotelli, M.; Sahu, U.K. Hydrogen Fuel for Future Mobility: Challenges and Future Aspects. Sustainability 2022, 14, 8285. [Google Scholar] [CrossRef]

- Rivard, E.; Trudeau, M.; Zaghib, K. Hydrogen Storage for Mobility: A Review. Materials 2019, 12, 1973. [Google Scholar] [CrossRef]

- Ji, M.; Wang, J. Review and comparison of various hydrogen production methods based on costs and life cycle impact assessment indicators. Int. J. Hydrogen Energy 2021, 46, 38612–38635. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, Q.; Yu, D. The future of hydrogen energy: Bio-hydrogen production technology. Int. J. Hydrogen Energy 2022, 47, 33677–33698. [Google Scholar] [CrossRef]

- Klopčič, N.; Grimmer, I.; Winkler, F.; Sartory, M.; Trattner, A. A review on metal hydride materials for hydrogen storage. J. Energy Storage 2023, 72, 108456. [Google Scholar] [CrossRef]

- Kudriakov, S.; Studer, E.; Bernard-Michel, G.; Bouix, D.; Domergue, L.; Forero, D.; Gueguen, H.; Ledier, C.; Manicardi, P.; Martin, M.; et al. Full-scale tunnel experiments: Blast wave and fireball evolution following hydrogen tank rupture. Int. J. Hydrogen Energy 2022, 47, 18911–18933. [Google Scholar] [CrossRef]

- Liu, K.; Jiang, J.; He, C.; Lin, S. Numerical analysis of the diffusion and explosion characteristics of hydrogen-air clouds in a plateau hydrogen refuelling station. Int. J. Hydrogen Energy, 2023; in press. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, X.; Zhang, T.; Pei, P. The reactant starvation of the proton exchange membrane fuel cells for vehicular applications: A review. Energy Convers. Manag. 2019, 182, 282–298. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, L.; Zhou, Y.; Pan, B.; Wang, R.; Wang, L.; Yan, X. Energy management strategies for fuel cell hybrid electric vehicles: Classification, comparison, and outlook. Energy Convers. Manag. 2022, 270, 116179. [Google Scholar] [CrossRef]

- Ahluwalia, R.K.; Wang, X.; Star, A.G.; Papadias, D.D. Performance and cost of fuel cells for off-road heavy-duty vehicles. Int. J. Hydrogen Energy 2022, 47, 10990–11006. [Google Scholar] [CrossRef]

- Bolvashenkov, I.; Herzog, H.-G.; Engstle, A. Factor of Hybridization as a Design Parameter for Hybrid Vehicles. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM 2006), Taormina, Italy, 23–26 May 2006; pp. 926–929. [Google Scholar] [CrossRef]

- Liao, G.Y.; Weber, T.R.; Pfaff, D.P. Modelling and Analysis of Powertrain Hybridization on All-Wheel-Drive Sport Utility Vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2004, 218, 1125–1134. [Google Scholar] [CrossRef]

- Katrašnik, T. Analytical Framework for Analyzing the Energy Conversion Efficiency of Different Hybrid Electric Vehicle Topologies. Energy Convers. Manag. 2009, 50, 1924–1938. [Google Scholar] [CrossRef]

- Somà, A.; Bruzzese, F.; Mocera, F.; Viglietti, E. Hybridization Factor and Performance of Hybrid Electric Telehandler Vehicle. IEEE Trans. Ind. Appl. 2016, 52, 5130–5138. [Google Scholar] [CrossRef]

- Husain, I. Hybrid and Electric Vehicles, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar] [CrossRef]

- Kim, W.S.; Kim, Y.J.; Park, S.U.; Kim, Y.S. Influence of soil moisture content on the traction performance of a 78-kW agricultural tractor during plow tillage. Soil Tillage Res. 2021, 207, 104851. [Google Scholar] [CrossRef]

- Servadio, P.; Bergonzoli, S.; Beni, C. Soil Tillage Systems and Wheat Yield under Climate Change Scenarios. Agronomy 2016, 6, 43. [Google Scholar] [CrossRef]

- Salcedo, R.; Sánchez, E.; Zhu, H.; Fàbregas, X.; García-Ruiz, F.; Gil, E. Evaluation of an electrostatic spray charge system implemented in three conventional orchard sprayers used on a commercial apple trees plantation. Crop Prot. 2023, 167, 106212. [Google Scholar] [CrossRef]

- Salcedo, R.; Fonte, A.; Grella, M.; Garcerá, C.; Chueca, P. Blade pitch and air-outlet width effects on the airflow generated by an airblast sprayer with wireless remote-controlled axial fan. Comput. Electron. Agric. 2021, 190, 106428. [Google Scholar] [CrossRef]

- Rathnayake, A.P.; Chandel, A.K.; Schrader, M.J.; Hoheisel, G.A.; Khot, L.R. Spray patterns and perceptive canopy interaction assessment of commercial airblast sprayers used in Pacific Northwest perennial specialty crop production. Comput. Electron. Agric. 2021, 184, 106097. [Google Scholar] [CrossRef]

- Rahe, F.; Resch, R. Electrification of Agricultural Machinery From the Perspective of an Implement Manufacturer. SAE Tech. Pap. 2017. [Google Scholar] [CrossRef]

- Varani, M.; Mattetti, M.; Molari, G. Performance Evaluation of Electrically Driven Agricultural Implements Powered by an External Generator. Agronomy 2021, 11, 1447. [Google Scholar] [CrossRef]

- Bals, R.; Jünemann, D.; Berghaus, A. Partial Electrification of an Agricultural Implement. ATZheavy Duty Worldw. 2019, 12, 38–41. [Google Scholar] [CrossRef]

- Yue, H.; Lin, J.; Dong, P.; Chen, Z.; Xu, X. Configurations and Control Strategies of Hybrid Powertrain Systems. Energies 2023, 16, 725. [Google Scholar] [CrossRef]

- Rezk, H.; Nassef, A.M.; Abdelkareem, M.A.; Alami, A.H.; Fathy, A. Comparison among various energy management strategies for reducing hydrogen consumption in a hybrid fuel cell/supercapacitor/battery system. Int. J. Hydrogen Energy 2021, 46, 6110–6126. [Google Scholar] [CrossRef]

- Iqbal, M.; Laurent, J.; Benmouna, A.; Becherif, M.; Ramadan, H.S.; Claude, F. Ageing-aware load following for composite-cost optimal energy management of fuel cell hybrid electric vehicle. Energy 2022, 254, 124233. [Google Scholar] [CrossRef]

- Ebbesen, S.; Elbert, P.; Guzzella, L. Battery State-of-Health Perceptive Energy Management for Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2012, 61, 2893–2900. [Google Scholar] [CrossRef]

- Kandidayeni, M.; Trovão, J.P.; Soleymani, M.; Boulom, L. Towards health-aware energy management strategies in fuel cell hybrid electric vehicles: A review. Int. J. Hydrogen Energy 2022, 47, 10021–10043. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Z.; Chen, Z. Rule-based energy management strategy of a lithium-ion battery, supercapacitor and PEM fuel cell system. Energy Procedia 2019, 158, 2555–2560. [Google Scholar] [CrossRef]

- Bai, Y.; He, H.; Li, J.; Li, S.; Wang, Y.; Yang, Q. Battery anti-aging control for a plug-in hybrid electric vehicle with a hierarchical optimization energy management strategy. J. Clean. Prod. 2019, 237, 117841. [Google Scholar] [CrossRef]

- Pei, P.; Chang, Q.; Tang, T. A quick evaluating method for automotive fuel cell lifetime. Int. J. Hydrogen Energy 2008, 33, 3829–3836. [Google Scholar] [CrossRef]

- Xue, Q.; Zhang, X.; Teng, T.; Zhang, J.; Feng, Z.; Lv, Q. A Comprehensive Review on Classification, Energy Management Strategy, and Control Algorithm for Hybrid Electric Vehicles. Energies 2020, 13, 5355. [Google Scholar] [CrossRef]

- Trinh, H.-A.; Truong, H.V.A.; Do, T.C.; Nguyen, M.H.; Phan, V.D.; Ahn, K.K. Optimization-based energy management strategies for hybrid construction machinery: A review. Energy Rep. 2022, 8, 6035–6057. [Google Scholar] [CrossRef]

- Shi, D.; Guo, J.; Liu, K.; Cai, Q.; Wang, Z.; Qu, X. Research on an Improved Rule-Based Energy Management Strategy Enlightened by the DP Optimization Results. Sustainability 2023, 15, 10472. [Google Scholar] [CrossRef]

- Dextreit, C.; Kolmanovsky, I.V. Game Theory Controller for Hybrid Electric Vehicles. IEEE Trans. Ind. Electron. 2016, 63, 4266–4277. [Google Scholar] [CrossRef]

- Lü, X.; Wu, Y.; Lian, J.; Zhang, Y.; Chen, C.; Wang, P.; Meng, L. Energy management of hybrid electric vehicles: A review of energy optimization of fuel cell hybrid power system based on genetic algorithm. Energy Convers. Manag. 2020, 205, 112474. [Google Scholar] [CrossRef]

- Du, Y.; Zhao, Y.; Wang, Q.; Zhang, Y.; Xia, H. Trip-oriented stochastic optimal energy management strategy for plug-in hybrid electric bus. Energy 2016, 115, 1259–1271. [Google Scholar] [CrossRef]

- Paganelli, G.; Guerra, T.M.; Delprat, S.; Santin, J.J.; Delhom, M.; Combes, E. Simulation and assessment of power control strategies for a parallel hybrid car. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2000, 214, 705–717. [Google Scholar] [CrossRef]

- Sun, C.; Sun, F.; He, H. Investigating adaptive-ECMS with velocity forecast ability for hybrid electric vehicles. Appl. Energy 2017, 185, 1644–1653. [Google Scholar] [CrossRef]

- Sorlei, I.-S.; Bizon, N.; Thounthong, P.; Varlam, M.; Carcadea, E.; Culcer, M.; Iliescu, M.; Raceanu, M. Fuel Cell Electric Vehicles—A Brief Review of Current Topologies and Energy Management Strategies. Energies 2021, 14, 252. [Google Scholar] [CrossRef]

- Reddy, N.P.; Pasdeloup, D.; Zadeh, M.K.; Skjetne, R. An Intelligent Power and Energy Management System for Fuel Cell/Battery Hybrid Electric Vehicle Using Reinforcement Learning. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Novi, MI, USA, 19–21 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Troncon, D.; Alberti, L.; Mattetti, M. A Feasibility Study for Agriculture Tractors Electrification: Duty Cycles Simulation and Consumption Comparison. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Mocera, F. A Model-Based Design Approach for a Parallel Hybrid Electric Tractor Energy Management Strategy Using Hardware in the Loop Technique. Vehicles 2021, 3, 1–19. [Google Scholar] [CrossRef]

- Jia, C.; Qiao, W.; Qu, L. Modeling and Control of Hybrid Electric Vehicles: A Case Study for Agricultural Tractors. In Proceedings of the 2018 IEEE Vehicle Power and Propulsion Conference (VPPC), Chicago, IL, USA, 27–30 August 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Barthel, J.; Gorges, D.; Bell, M.; Munch, P. Energy Management for Hybrid Electric Tractors Combining Load Point Shifting, Regeneration and Boost. In Proceedings of the 2014 IEEE Vehicle Power and Propulsion Conference (VPPC), Coimbra, Portugal, 27–30 October 2014. [Google Scholar] [CrossRef]

- Dalboni, M.; Santarelli, P.; Patroncini, P.; Soldati, A.; Concari, C.; Lusignani, D. Electrification of a Compact Agricultural Tractor: A Successful Case Study. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Novi, MI, USA, 19–21 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Zhu, Z.; Zeng, L.; Chen, L.; Zou, R.; Cai, Y. Fuzzy Adaptive Energy Management Strategy for a Hybrid Agricultural Tractor Equipped with HMCVT. Agriculture 2022, 12, 1986. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, G.; Xu, L.; Yan, X.; Wang, W.; Liu, M. Energy-Saving Control of Hybrid Tractors Based on Instantaneous Optimization. World Electr. Veh. J. 2023, 14, 27. [Google Scholar] [CrossRef]

- Jia, C.; Qiao, W.; Qu, L. Numerical Methods for Optimal Control of Hybrid Electric Agricultural Tractors. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Lee, H.S.; Kim, J.S.; Park, Y.I.; Cha, S.W. Rule-based power distribution in the power train of a parallel hybrid tractor for fuel savings. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 231–237. [Google Scholar] [CrossRef]

- Ghobadpour, A.; Mousazadeh, H.; Kelouwani, S.; Zioui, N.; Kandidayeni, M.; Boulon, L. An intelligent energy management strategy for an off-road plug-in hybrid electric tractor based on farm operation recognition. IET Electr. Syst. Transp. 2021, 11, 333–347. [Google Scholar] [CrossRef]

- Liu, S.; Wu, Z.; Chen, X.; Li, Z. Deep Reinforcement Learning-Based Energy Management Strategy for Hybrid Electric Agricultural Tractor. In Proceedings of the 2023 IEEE International Conference on Intelligent Control, Measurement and Signal Processing (ICMSP), Chengdu, China, 19–21 May 2023. [Google Scholar] [CrossRef]

- Martini, V.; Mocera, F.; Somà, A. Numerical Investigation of a Fuel Cell-Powered Agricultural Tractor. Energies 2022, 15, 8818. [Google Scholar] [CrossRef]

- Tritschler, P.J.; Bacha, S.; Rullière, E.; Husson, G. Energy Management Strategies for an embedded Fuel Cell System on Agricultural Vehicles. In Proceedings of the XIX International Conference on Electrical Machines—ICEM 2010, Rome, Italy, 6–8 September 2010. [Google Scholar] [CrossRef]

- Xu, W.; Liu, M.; Xu, L.; Zhang, S. Energy Management Strategy of Hydrogen Fuel Cell/Battery/Ultracapacitor Hybrid Tractor Based on Efficiency Optimization. Appl. Sci. 2023, 13, 151. [Google Scholar] [CrossRef]

- Yang, H.; Sun, Y.; Xia, C.; Zhang, H. Research on Energy Management Strategy of Fuel Cell Electric Tractor Based on Multi-Algorithm Fusion and Optimization. Energies 2022, 15, 6389. [Google Scholar] [CrossRef]

- Yang, X.; Liu, T.; Ge, S.; Leng, Y.; Wang, D.; Wang, C. Asymmetric Temperature Modulation for Extreme Fast Charging of Lithium-Ion Batteries. Joule 2019, 3, 3002–3019. [Google Scholar] [CrossRef]

- Li, B.; Kuo, H.; Wang, X.; Chen, Y.; Wang, Y.; Gerada, D.; Worall, S.; Stone, I.; Yan, Y. Thermal Management of Electrified Propulsion System for Low-Carbon Vehicles. Automot. Innov. 2020, 3, 299–316. [Google Scholar] [CrossRef]

- Hemmati, S.; Doshi, N.; Hanover, D.; Morgan, C.; Shahbakhti, M. Integrated cabin heating and powertrain thermal energy management for a connected hybrid electric vehicle. Appl. Energy 2021, 283, 116353. [Google Scholar] [CrossRef]

- Wang, D.; Guan, C.; Wang, J.; Wang, H.; Zhang, Z.; Guo, D.; Yang, F. Review of Energy-Saving Technologies for Electric Vehicles, from the Perspective of Driving Energy Management. Sustainability 2023, 15, 7617. [Google Scholar] [CrossRef]

- Gade, C.R.; W, R.S. Control of Permanent Magnet Synchronous Motor Using MPC–MTPA Control for Deployment in Electric Tractor. Sustainability 2022, 14, 12428. [Google Scholar] [CrossRef]

- Lu, M.; Zhang, Y.; Wu, Y.; Cai, X.; Li, H. Optimization of MTPA Algorithm of Permanent Magnet Synchronous Motor For Electric Tractor. In Proceedings of the 2018 Internation Conference on Electrical Machines and Systems, Jeju, Republic of Korea, 7–10 October 2018. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, B.; Mao, E. Electric Tractor Motor Drive Control Based on FPGA. IFAC-PapersOnLine 2016, 49, 271–276. [Google Scholar] [CrossRef]

- Mantriota, G.; Reina, G. Dual-Motor Planetary Transmission to Improve Efficiency in Electric Vehicles. Machines 2021, 9, 58. [Google Scholar] [CrossRef]

- De Melo, R.R.; Tofoli, F.L.; Daher, S.; Antunes, F.L.M. Wheel Slip Control Applied to an Electric Tractor for Improving Tractive Efficiency and Reducing Energy Consumption. Sensors 2022, 22, 4527. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Xie, B.; Li, Z.; Li, J. Design and Optimization of a Dual-Input Coupling Powertrain System: A Case Study for Electric Tractors. Appl. Sci. 2020, 10, 1608. [Google Scholar] [CrossRef]

- Wang, S.; Wu, X.; Zhao, X.; Wang, S.; Xie, B.; Song, Z.; Wang, D. Co-optimization energy management strategy for a novel dual-motor drive system of electric tractor considering efficiency and stability. Energy 2023, 281, 128074. [Google Scholar] [CrossRef]

- Zhang, S.; Wen, C.; Ren, W.; Luo, Z.; Xie, B.; Zhu, Z.; Chen, Z. A joint control method considering travel speed and slip for reducing energy consumption of rear wheel independent drive electric tractor in ploughing. Energy 2023, 263, 126008. [Google Scholar] [CrossRef]

- Yu, Y.; Hao, S.; Guo, S.; Tang, Z.; Chen, S. Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors. Agriculture 2022, 12, 1373. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, B.; Yan, X.; Liu, M.; Xu, L.; Shang, C. Design and optimization of dual-motor electric tractor drive system based on driving cycles. PLoS ONE 2023, 18, e0286378. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Ren, W.; Xie, B.; Luo, Z.; Wen, C.; Chen, Z.; Zhu, Z.; Li, T. A combined control method of traction and ballast for an electric tractor in ploughing based on load transfer. Comput. Electron. Agric. 2023, 207, 107750. [Google Scholar] [CrossRef]

- Grostracteurspassion. Belarus 3022 E—Médaille d’argent Pour Un Tracteur Branche! Available online: https://www.grostracteurspassion.com/actualite/tracteurs/belarus-3022-e-medaille-dargent-pour-un-tracteur-branche (accessed on 2 July 2023).

- RigiTrac. RigiTrac EWD 120—Diesel Electric. Available online: https://tu-dresden.de/ing/maschinenwesen/int/ast/ressourcen/dateien/forschung/files/Datenblatt_Rigitrac.pdf?lang=de (accessed on 2 July 2023).

- Tetzlaff, S. Schnittstellenübergreifende Elektrifizierung und Funktionen von Traktor und Anbaugerät. Landtechnik 2015, 70, 203–217. [Google Scholar]

- Stoss, J.; Sobotzik, J.; Shi, B.; Kreis, E.R. Tractor Power for Implement Operation—Mechanical, Hydraulic, and Electrical: An Overview. In Proceedings of the Agricultural Equipment Technology Conference, Kansas City, MO, USA, 28–30 January 2013; pp. 1–25. [Google Scholar]

- Kalociński, T. Modern Trends in Development of Alternative Powertrain Systems for Non-Road Machinery. Combust. Engines 2022, 188, 42–54. [Google Scholar] [CrossRef]

- TopGear Autoguide. John Deere SESAM E-Tractor Concept: It Works Purely Electrically. Available online: https://topgear-autoguide.com/category/traffic/john-deere-sesam-e-tractor-concept-it-works-purely-electrically1607390084 (accessed on 26 June 2023).

- Fendt. Fendt e100 Vario: The Battery-Powered Compact Tractor. 2017. Available online: https://www.fendt.com/int/fendt-e100-vario (accessed on 26 June 2023).

- Multifunctional Tractor Rino del Morino. Available online: https://rinoelectric.com/ (accessed on 10 June 2023).

- Future Farming. 2019. Available online: https://www.futurefarming.com/tech-in-focus/rigitrac-introduces-100-electric-tractor/ (accessed on 10 June 2023).

- Carraro Ibrido. 2018. Available online: https://www.carrarotractors.com/en/news-eventi-2/news-2/the-carraro-ibrido-tractor-has-received-two-awards-from-federunacoma-928 (accessed on 10 June 2023).

- Mocera, F.; Martelli, S.; Somà, A. State of the Art and Future Trends of Electrification in Agricultural Tractors. SAE Tech. Pap. 2022. [Google Scholar] [CrossRef]

- Landini REX4 Electra—Evolving Hybrid. Available online: https://www.landini.it/as/landini-rex4-electra-evolving-hybrid/ (accessed on 5 April 2022).

- Farm Equipment. Antonio Carraro SRX Hybrid Tractor 2021. Available online: https://www.farm-equipment.com/articles/19849-antonio-carraro-srx-hybrid-tractor (accessed on 10 June 2023).

- Soletrac. Available online: https://solectrac.com/e70n-electric-tractor/ (accessed on 10 June 2023).

- Landini REX4 Full Hybrid—Technical Innovation at Eima 2022. Available online: https://www.landini.it/as/landini-rex4-full-hybrid-technical-innovation-at-eima-2022/ (accessed on 10 June 2023).

- Pala, S.G. Motori Agricoli: Avanti Tutta per l’Ibrido e l’Elettrico. Available online: https://agronotizie.imagelinenetwork.com/agrimeccanica/2023/04/06/motori-agricoli-avanti-tutta-per-l-ibrido-e-l-elettrico/78786 (accessed on 23 July 2023).

- Monarch. Available online: https://www.monarchtractor.com/ (accessed on 10 June 2023).

- Bredice, E. B1e, Goldoni’s In-House Electric Tractor. 2023. Available online: https://www.mondomacchina.it/en/b1e-goldoni-in-house-electric-tractor-c3764 (accessed on 10 June 2023).

| Open Field | Specialized | |

|---|---|---|

| Mass (kg) | 14,000 | 2500 |

| Vehicle wheelbase (mm) | 3300 | 1900 |

| Track width (mm) | 2100 | 1500 |

| Wheel radius (mm) | 1050 | 680 |

| Nominal power | 290 kW @1700 rpm | 75 kW @2300 rpm |

| Top speed (km/h) | 60 | 40 |

| Minimum speed (km/h) | 0.02 | 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mocera, F.; Somà, A.; Martelli, S.; Martini, V. Trends and Future Perspective of Electrification in Agricultural Tractor-Implement Applications. Energies 2023, 16, 6601. https://doi.org/10.3390/en16186601

Mocera F, Somà A, Martelli S, Martini V. Trends and Future Perspective of Electrification in Agricultural Tractor-Implement Applications. Energies. 2023; 16(18):6601. https://doi.org/10.3390/en16186601

Chicago/Turabian StyleMocera, Francesco, Aurelio Somà, Salvatore Martelli, and Valerio Martini. 2023. "Trends and Future Perspective of Electrification in Agricultural Tractor-Implement Applications" Energies 16, no. 18: 6601. https://doi.org/10.3390/en16186601

APA StyleMocera, F., Somà, A., Martelli, S., & Martini, V. (2023). Trends and Future Perspective of Electrification in Agricultural Tractor-Implement Applications. Energies, 16(18), 6601. https://doi.org/10.3390/en16186601