Application of Microbial Fuel Cell Technology in Potato Processing Industry

Abstract

:1. Introduction

2. Drawbacks of Conventional Treatment Methods for Potato Processing Wastewater

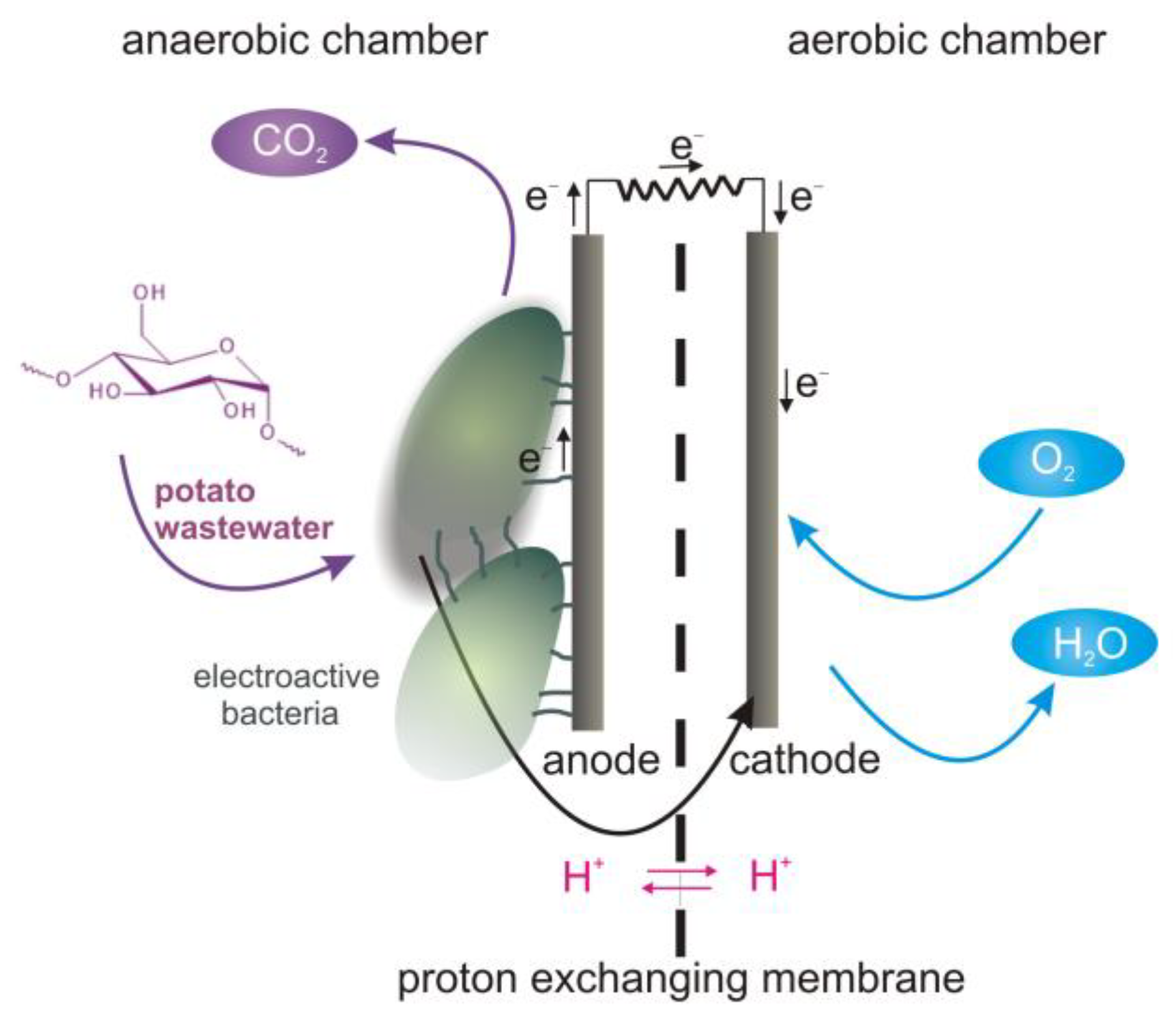

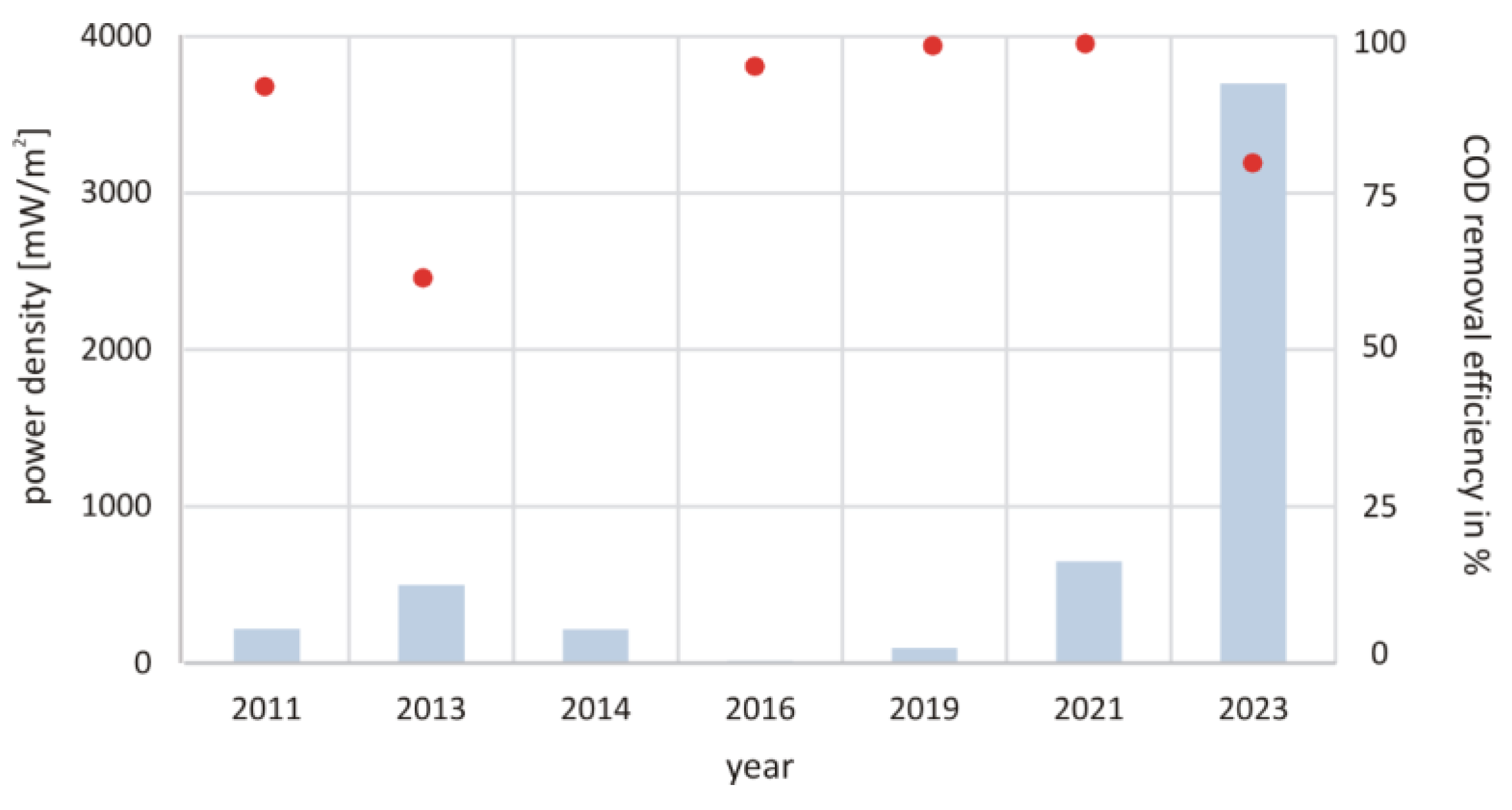

3. Application of MFC Technology to the Potato Processing Industry

| Bacteria Source | COD Removal (%) | Current Yield 1 | MFC Design | Ref. |

|---|---|---|---|---|

| Indigenous | 89 | 220 mW/m2 | Brush anode/Pt carbon cloth cathode | [43] |

| Anaerobic sludge | 92.2 | 334 mW/m2 | Graphite felt anode/graphite cloth cathode | [44] |

| Anaerobic sludge | NA | 650 mW/m2 | Bamboo charcoal anode/Pt carbon cloth cathode | [45] |

| Indigenous/acetate suppl. | 80 | 3700 mW/m2 | Carbon fiber anode/ZnO-Cu cathode | [46] |

| Anaerobic sludge | 87 | 450 µW | Graphite anode/graphite felt cathode | [47] |

| Anaerobic sludge | 85 | 243 mA/m2 | Carbon felt anode/carbon felt cathode | [48] |

| Indigenous/anaerobic sludge | 89.6 | 155 mA/m2 | Carbon felt anode/carbon felt cathode | [49] |

| Indigenous | 68.7 | 36.8 mA/m2 | Graphite brush anode/Pt carbon cloth cathode | [51] |

| Indigenous | 84 | 208 mA/m2 | Carbon felt anode/carbon felt cathode | [52] |

| E. coli | 60.8 | 502 mW/m2 | Ti anode/Ti cathode | [53] |

| anaerobic sludge | NA | 216 mW/m2 | Carbon paper anode/Pt-coated cathode | [54] |

| Indigenous | 99 | 95.7 mW/m2 | Graphite anode/graphite cathode | [26] |

| Anaerobic sludge | 99 | 1100 mW/m3 | Graphite anode/graphite cathode | [56] |

| Indigenous | 90 | 356 mW/m2 | Carbon paper anode/graphite plate cathode | [57] |

| Indigenous | 98 | 239 mW/m2 | Carbon paper anode/carbon Pt paper cathode | [58] |

| Indigenous | 67.4 | 1200 mW/m3 | graphite felt anode/carbon cloth cathode | [59] |

| Indigenous/local pond | NA | 1.1 mW/m2 | GO-PANI anode/graphite cathode | [60] |

| Indigenous/anaerobic sludge | NA | 14.1 mW/m2 | Carbon felt anode/carbon felt cathode | [61] |

| Indigenous | NA | 5020 mW/m3 | Al graphite paper anode/Al graphite paper cathode | [62] |

| Anaerobic consortia from MFC | 88 | 16.5 mW/m2 | Carbon felt anode/carbon felt cathode | [63] |

| Cellulose degrading bacteria | 72 | 152 mW/m2 | Carbon paper anode/ carbon paper cathode | [64] |

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Potter, M.C. Electrical effects accompanying the decomposition of organic compounds. Proc. R. Soc. Lond. B Biol. Sci. 1911, 84, 260–276. [Google Scholar]

- Koch, C.; Harnisch, F. Is There a Specific Ecological Niche for Electroactive Microorganisms? ChemElectroChem 2016, 3, 1282–1295. [Google Scholar] [CrossRef]

- Sydow, A.; Krieg, T.; Mayer, F.; Schrader, J.; Holtmann, D. Electroactive bacteria-molecular mechanisms and genetic tools. Appl. Microbiol. Biotechnol. 2014, 98, 8481–8495. [Google Scholar] [CrossRef]

- Chabert, N.; Amin Ali, O.; Achouak, W. All Ecosystems Potentially Host Electrogenic Bacteria. Bioelectrochemistry 2015, 106, 88–96. [Google Scholar] [CrossRef] [PubMed]

- Tahernia, M.; Plotkin-Kaye, E.; Mohammadifar, M.; Gao, Y.; Oefelein, M.R.; Cook, L.C.; Choi, S. Characterization of Electrogenic Gut Bacteria. ACS Omega 2020, 5, 29439–29446. [Google Scholar] [CrossRef]

- Toczyłowska-Mamińska, R.; Szymona, K.; Madej, H.; Wong, W.Z.; Bala, A.; Brutkowski, W.; Krajewski, K.; H’ng, P.S.; Mamiński, M. Cellulolytic and electrogenic activity of Enterobacter cloacae in mediatorless microbial fuel cell. Appl. Energy 2015, 160, 88–93. [Google Scholar] [CrossRef]

- Miceli, J.F.; Parameswaran, P.; Kang, D.-W.; Krajmalnik-Brown, R.; Torres, C.I. Enrichment and analysis of anode-respiring bacteria from diverse anaerobic inocula. Environ. Sci. Technol. 2012, 46, 10349–10355. [Google Scholar] [CrossRef]

- Reimers, C.E.; Girguis, P.; Stecher, H.A.; Tender, L.M.; Ryckelynck, N.; Whaling, P. Microbial fuel cell energy from an ocean cold seep. Geobiology 2006, 4, 123–136. [Google Scholar] [CrossRef]

- Karra, U.; Huang, G.; Umaz, R.; Tenaglier, C.; Wang, L.; Li, B. Stability characterization and modeling of robust distributed benthic microbial fuel cell (DBMFC) system. Bioresour. Technol. 2013, 144, 477–484. [Google Scholar] [CrossRef]

- Martins, G.; Peixoto, L.; Ribeiro, D.C.; Parpot, P.; Brito, A.G.; Nogueira, R. Towards implementation of a benthic microbial fuel cell n lake Furnas (Azores): Phylogenetic affiliation and electrochemical activity of sediment bacteria. Bioelectrochemistry 2010, 78, 67–71. [Google Scholar] [CrossRef]

- Kim, J.R.; Beecroft, N.J.; Varcoe, J.; Dinsdale, R.M.; Guwy, A.J.; Slade, R.C.T.; Thumser, A.; Avignone-Rossa, C.; Premier, G.C. Spatitemporal development of the bacterial community in a tubular longitudinal microbial fuel cell. Appl. Microbiol. Biotechnol. 2011, 90, 1179–1191. [Google Scholar] [CrossRef] [PubMed]

- Erable, B.; Roncato, M.-A.; Achouak, W.; Bergel, A. Sampling natural biofilms: A new route to build efficientmicrobial anodes. Environ. Sci. Technol. 2009, 43, 3194–3199. [Google Scholar] [CrossRef] [PubMed]

- Adelaja, O.; Keshavarz, T.; Kyazze, G. The effect of salinity, redoxmediators and temperature on anaerobic biodegradation of petroleum hydrocarbons in microbial fuel cells. J. Hazard. Mater. 2015, 283, 211–217. [Google Scholar] [CrossRef] [PubMed]

- Ling, L.; Yang, C.; Li, Z.; Luo, H.; Feng, S.; Zhao, Y.; Lu, L. Plant Endophytic Bacteria: A Potential Resource Pool of Electroactive Micro-Organisms. J. Appl. Microbiol. 2022, 132, 2054–2066. [Google Scholar] [CrossRef]

- Syed, Z.; Sonu, K.; Sogani, M. Cattle manure management using microbial fuel cells for green energy generation. Biofuel. Bioprod. Bio. 2022, 16, 460–470. [Google Scholar] [CrossRef]

- Pasternak, G.; Greenman, J.; Ieropoulos, I. Removal of hepatitis B virus surface HBsAg and core HBcAg antigens using microbial fuel cells producing electricity from human urine. Sci. Rep. 2019, 9, 11787. [Google Scholar] [CrossRef]

- Wen, Q.; Wu, Y.; Cao, D.; Zhao, L.; Sun, Q. Electricity generation and modeling of microbial fuel cell from continuous beer brewery wastewater. Bioresour. Technol. 2009, 100, 4171–4175. [Google Scholar] [CrossRef]

- Li, T.; Song, H.-L.; Xu, H.; Yang, X.-L.; Chen, Q.-L. Biological detoxification and decolorization enhancement of azo dye by introducing natural electron mediators in MFCs. J. Hazard. Mater. 2021, 416, 125864. [Google Scholar] [CrossRef]

- Toczyłowska-Mamińska, R.; Mamiński, M.Ł. Wastewater as a renewable energy source–Utilisation of microbial fuel cell technology. Energies 2022, 15, 6928. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, F.; Wu, Y.; Hu, H.H.; Dai, X.F. Progress of potato staple food research and industry development in China. J. Integr. Agric. 2017, 16, 2924–2932. [Google Scholar] [CrossRef]

- Buono, V.; Paradiso, A.; Serio, F.; Gomnnella, M.; Gara, L.D.; Santamaria, P. Tuber quality and nutritional components of “early” potato subjected to chemical haulm desiccation. J. Food Comp. Anal. 2009, 22, 556–562. [Google Scholar] [CrossRef]

- Liu, X.; Mu, T.H.; Sun, H.N.; Zhang, M.; Chen, J.W.; Fauconnier, M.L. Comparative study of the nutritional quality of potato–wheat steamed and baked breads made with four potato flour cultivars. Int. J. Food Sci. Nutr. 2017, 682, 167–178. [Google Scholar] [CrossRef] [PubMed]

- Statista. Potato Production Worldwide from 2002 to 2021. Available online: https://www.statista.com/statistics/382174/global-potato-production/ (accessed on 11 February 2023).

- The Potato and Its Uses. Available online: https://www.onions-potatoes.com/processing/various.php (accessed on 20 April 2023).

- International Potato Center. Potato Processing and Uses. Available online: https://cipotato.org/potato/potato-processing-uses/ (accessed on 20 April 2023).

- Radeef, A.Y.; Ismail, Z.Z. Polarization model of microbial fuel cell for treatment of actual potato chips processing wastewater associated with power generation. J. Electroanal. Chem. 2019, 836, 176–181. [Google Scholar] [CrossRef]

- Charmley, E.; Nelson, D.; Zvomuya, F. Nutrient cycling in the vegetable processing industry: Utilization of potato by-products. Canad. J. Soil Sci. 2006, 86, 621–629. [Google Scholar] [CrossRef]

- Barampouti, E.M.; Christofi, A.; Malamis, D.; Mai, S. A sustainable approach to valorize potato peel waste towards biofuel production. Biomass Conv. Bioref. 2021, 13, 8197–8208. [Google Scholar] [CrossRef]

- Walker, C.; Beretta, C.; Sanjuán, N.; Hellweg, S. Calculating the energy and water use in food processing and assessing the resulting impacts. Int. J. Life Cycle Assess. 2018, 23, 824–839. [Google Scholar] [CrossRef]

- EMR. Global Potato Starch Market. Available online: https://www.expertmarketresearch.com/reports/potato-starch-market-report (accessed on 4 July 2023).

- Li, M.; Zhu, X.; Yang, H.; Xie, X.; Zhu, Y.; Xu, G.; Hu, X.; Jin, Z.; Hu, Y.; Hai, Z.; et al. Treatment of potato starch wastewater by dual natural flocculants of chitosan and poly-glutamic acid. J. Clean. Prod. 2020, 264, 121641. [Google Scholar] [CrossRef]

- Lorenc-Plucińska, G.; Walentynowicz, M.; Lewandowski, A. Poplar growth and wood production on a grassland irrigated for decades with potato starch wastewater. Agrofor. Syst. 2017, 91, 307–324. [Google Scholar] [CrossRef]

- Antwi, P.; Li, J.; Boadi, P.O.; Meng, J.; Koblah, Q.F.; Wang, X.; Ren, N.; Buelna, G. Efficiency of an upflow anaerobic sludge blanket reactor treating potato starch processing wastewater and related process kinetics, functional microbial community and sludge morphology. Bioresur. Technol. 2017, 239, 105–116. [Google Scholar] [CrossRef]

- Han, M.; Dong, C.; Ma, S.; Feng, C.; Lei, C.; Gu, Z.; Liu, X. Food web responses to a cyanobacterial bloom in a freshwater eutrophic lake. Water 2021, 13, 1296. [Google Scholar] [CrossRef]

- Bouchareb, R.; Bilici, Z.; Dizge, N. Potato processing wastewater treatment using a combined process of chemical coagulation and membrane filtration. Clean Soil Air Water 2021, 49, 2100017. [Google Scholar] [CrossRef]

- Lindkvist, E.; Karlsson, M.; Ivner, J. System analysis of biogas production–Part II Application in food industry systems. Energies 2019, 12, 412. [Google Scholar] [CrossRef]

- Tufvesson, L.M.; Lantz, M.; Börjesson, P. Environmental performance of biogas produced from industrial residues including competition with animal feed–life-cycle calculations according to different methodologies and standards. J. Clean. Prod. 2013, 53, 214–223. [Google Scholar] [CrossRef]

- Starch Europe. Available online: https://starch.eu/ingredients/ (accessed on 29 June 2023).

- Toczyłowska-Mamińska, R. Limits and perspectives of pulp and paper industry wastewater treatment—A review. Renew. Sustain. Energy Rev. 2017, 78, 764–772. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, M.; Zhang, G.; Liu, W.; Xu, J.; Tian, Y.; Wang, Y.; Xie, X.; Peng, Z.; Li, A.; et al. Efficient treatment of the starch wastewater by enhanced flocculation–coagulation of environmentally benign materials. Sep. Purif. Technol. 2023, 307, 122788. [Google Scholar] [CrossRef]

- Hung, Y.T.; Lo, H.H. Potato Wastewater Treatment in Handbook of Industrial and Hazardous Wastes Treatment; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Rajewska, P.; Janiszewska, J.; Rajewski, J. Integration of ultra- and nanofiltration for potato processing water (PPW) treatment in a circular water recovery system. Membranes 2023, 13, 59. [Google Scholar] [CrossRef]

- Kiely, P.D.; Cusick, R.; Call, D.F.; Selembo, P.A.; Regan, J.M.; Logan, B.E. Anode microbial communities produced by changing from microbial fuel cel to microbial electrolysis cell operation using two different wastewaters. Bioresour. Technol. 2011, 102, 388–394. [Google Scholar] [CrossRef]

- Cai, X.B.; Yang, Y.; Sun, Y.P.; Zhang, L.; Xiao, Y.; Zhao, H. Electricity generation from sweet potato fuel ethanol wastewater using microbial fuel cell technology. Huanjing Kexue 2010, 31, 2512–2517. [Google Scholar]

- Sato, C.; Paucar, N.E.; Chiu, S.; Mahmud, M.Z.I.M.; Dudgeon, J. Single-chamber microbial fuel cell with multiple plates of bamboo charcoal anode: Performance evaluation. Processes 2021, 9, 2194. [Google Scholar] [CrossRef]

- Din, M.I.; Ahmed, M.; Ahmad, M.; Iqbal, M.; Ahmad, Z.; Hussain, Z.; Khalid, R.; Samad, A. Investigating the activity of carbon fiber electrode for electricity generation from waste potatoes in a single-chambered microbial fuel cell. J. Chem. 2023, 2023, 8520657. [Google Scholar] [CrossRef]

- Durruty, I.; Bonanni, P.S.; González, J.F.; Busalmen, J.P. Evaluation of potato-processing wastewater treatment in a microbial fuel cel. Bioresour. Technol. 2012, 105, 81–87. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Guo, J.; Xu, Y.; Wu, Y.; Li, F.; Wu, H. Enhancing microbial fuel cell (MFC) performance in treatment of solid potato waste by mixed feeding of boiled potato and waste activated sludge. Water Sci. Technol. 2018, 78, 1054–1063. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Li, F. Enhancement of solid potato waste treatment by microbial fuel cell with mixed feeding of waste activated sludge. J. Clean. Prod. 2017, 143, 336–344. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Al-Zaqri, N.; Yaakop, A.S.; Umar, K. Potato waste as an effective source of electron generation and bioremediation of pollutant through benthic microbial fuel cell. Sustain. Energy Technol. Assoc. 2022, 53, 1025603. [Google Scholar] [CrossRef]

- Tian, Y.; Mei, X.; Liang, Q.; Wu, D.; Ren, N.; Xing, D. Biological degradation of potato pulp waste and microbial community structure in microbial fuel cells. RSC Adv. 2017, 7, 8376–8380. [Google Scholar] [CrossRef]

- Du, H.; Li, F.; Huang, K.; Li, W.; Feng, C. Potato waste treatment by microbial fuel cell. Evaluation based on electricity generation, organic matter removal and microbial structure. Environ. Prot. Eng. 2017, 43, 5–18. [Google Scholar] [CrossRef]

- Herrero-Hernandez, E.; Smith, T.J.; Akid, R. Electricity generation from wastewaters with starch as carbon source using a mediatorless microbial fuel cell. Biosens. Bioelectron. 2013, 39, 194–198. [Google Scholar] [CrossRef]

- Li, Z.; Haynes, R.; Sato, E.; Shields, M.S.; Fujita, Y.; Sato, C. Microbial community analysis of a single chamber microbial fuel cell using potato wastewater. Water Environ. Res. 2014, 86, 324–330. [Google Scholar] [CrossRef]

- Radeef, A.Y.; Ismail, Z.Z. New application of microbial fuel cell-based biosensor for monitoring the quality of actual potato chips’ processing wastewater. Waste Dispos. Sustain. Energy 2019, 1, 227–235. [Google Scholar] [CrossRef]

- Radeef, A.Y.; Ismail, Z.Z. Resource recovery in potato chips processing industry: Green bioelectricity production using continuous mediatorless microbial fuel cell. Int. J. Green Energy 2021, 8, 910–919. [Google Scholar] [CrossRef]

- Mathuriya, A.S. Novel microbial fuel cell design to operate with different wastewaters simultaneously. J. Environ. Sci. 2016, 42, 105–111. [Google Scholar] [CrossRef] [PubMed]

- Lu, N.; Zhou, S.; Zhuang, L.; Zhang, J.; Ni, J. Electricity generation from starch processing wastewater using microbial fuel cell technology. Biochem. Eng. J. 2009, 43, 246–251. [Google Scholar] [CrossRef]

- Iigatani, R.; Ito, T.; Watanabe, F.; Nagamine, M.; Suzuki, Y.; Inoue, K. Electricity generation from sweet potato-shochu waste using microbial fuel cells. J. Biosci. Bioenergy 2019, 128, 56–63. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Ibrahim, M.N.M.; Umar, K.; Bhawani, S.A.; Khan, A.; Asiri, A.M.; Khan, M.R.; Azam, M.; Al Ammar, A.M. Anode for Energy Generation and Bioremediation of Toxic Metals via Benthic Microbial Fuel Cells. Polymers 2021, 13, 135. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Shao, Z. Synergistic effects between solid potato waste and waste activated sludge for waste-to-power conversion in microbial fuel cells. Appl. Energy 2022, 314, 18994. [Google Scholar] [CrossRef]

- Nara, S.; Kandpal, R.; Jaiswal, V.; Augustine, S.; Wahie, S.; Sharma, J.G.; Takeuchi, R.; Takenaka, S.; Malhotra, B.D. Exploring Providencia rettgeri for application to eco-friendly paper based microbial fuel cell. Biosens. Bioelectron. 2020, 165, 112323. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Li, F. Size effects of potato waste on its treatment by microbial fuel cell. Environ. Technol. 2016, 37, 1305–1313. [Google Scholar] [CrossRef]

- Flimban, S.G.A.; Hassan, S.H.A.; Rahman, M.M.; Oh, S.E. The effect of Nafion membrane fouling on the power generation of a microbial fuel cell. Int. J. Hydrogen Energy 2020, 45, 13643–13651. [Google Scholar] [CrossRef]

| Treatment | Main Advantages | Main Disadvantages |

|---|---|---|

| Anaerobic digestion | Produces biogas | High power consumption |

| Coagulation/flocculation 1 | Easy aggregate separation | Secondary wastewater pollution with flocculants |

| Adsorption | Easy operation | Low selectivity |

| Membrane filtration | Removes physical and chemical pollutants | Membrane fouling |

| MFC | No secondary pollution | Zero or minimal energy input |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toczyłowska-Mamińska, R.; Mamiński, M.Ł. Application of Microbial Fuel Cell Technology in Potato Processing Industry. Energies 2023, 16, 6581. https://doi.org/10.3390/en16186581

Toczyłowska-Mamińska R, Mamiński MŁ. Application of Microbial Fuel Cell Technology in Potato Processing Industry. Energies. 2023; 16(18):6581. https://doi.org/10.3390/en16186581

Chicago/Turabian StyleToczyłowska-Mamińska, Renata, and Mariusz Ł. Mamiński. 2023. "Application of Microbial Fuel Cell Technology in Potato Processing Industry" Energies 16, no. 18: 6581. https://doi.org/10.3390/en16186581

APA StyleToczyłowska-Mamińska, R., & Mamiński, M. Ł. (2023). Application of Microbial Fuel Cell Technology in Potato Processing Industry. Energies, 16(18), 6581. https://doi.org/10.3390/en16186581