Abstract

This paper presents a theoretical evaluation of the prices of mixed briquettes produced from coconut shells (CCS), banana peels (BNP), rattan waste (RWT), and sugarcane bagasse (SGC) and, on the other hand, an analysis of the economic viability of their use as a replacement for conventional household fuels (liquefied petroleum gas, fuelwood, and wood charcoal) in households in Cameroon. The investigation was carried out using the life cycle cost method on a typical household over a ten-year period with annual cooking energy requirements of 950 kWhth. The SGC–CCS and SGC–RWT mixed briquettes with ratios higher than 7.75% and 11.1%, respectively, have prices lower than EUR 0.063/kWhth. The Present Value of the Net Benefit is positive for the use of SGC–CCS and SGC–RWT mixed briquettes. The results show that by making the right mixes of residues, it is possible to obtain biomass briquettes that are less expensive than conventional fuels.

1. Introduction

Global energy accessibility is required to improve human survival and ensure economic, social, and environmental growth [1,2]. Most sub-Saharan African countries have faced significant growth in energy consumption as a result of growing demand, which often outstrips supply, and energy constraints [3,4]. Moreover, two-thirds of the energy consumed around the world is produced from non-renewable energy resources, such as gas, oil, and coal [5]. One way of using energy is for household cooking, which accounts for a sizable portion of overall household expenses. Wood is the main energy source in many low-income areas; it provides more than 80% of all the energy used in Africa [6]. These energy sources have finite supplies and a negative impact on the environment; it is estimated that more than 60% of the wood removed from forests and non-forests is used for energy purposes [5,7]. With a growing worldwide population, it is becoming increasingly important to have alternative, clean, and sustainable energy sources to solve environmental challenges such as climate change.

Biomass is a promising renewable energy source suitable for several uses in cooking, heating, and gasification [8,9,10]. In Africa, many users make use of direct combustion of biomass, but this conversion method is poorly efficient and depletes the environment [11]. In addition, hazardous gases and other compounds toxic to humans are released during the direct burning of biomass fuels. According to Lambe et al. (2015), in 2012, the usage of biomass in Africa caused close to 600,000 premature deaths [12]. Numerous researchers have suggested that utilizing biomass in briquette form has various benefits. Briquette manufacturing improves biomass characteristics and makes them more suitable to move about, store, place in furnaces, and burn [10,11]. A biomass briquette is a solid fuel created from carbon-rich materials like agricultural waste that has been dried, carbonized, crushed, mixed with a binder, briquetted, and then dried [13,14,15]. The quality of the fuel briquettes that are produced is significantly influenced by the biomass that is selected. The choice of wastes for briquette production relies on their properties, affordability, and accessibility in a given area.

In Cameroon, the most commonly used cooking fuels are fuelwood, charcoal, and LPG. According to data from the National Institute of Statistics of Cameroon, the energy needs of an average household are 950 kWh per year. Household food products include the fuels used to cook food [16]. Fuelwood is usually burned in a traditional three-stone fire because of its affordability. There is no need to pay for it; it is constructed of up of three similar-sized stones on which a cooking kettle is placed over a fire [17]. The common cook stoves used for charcoal burning cost an average of EUR 10 in the Cameroonian market. The LPG burned in a gas-fired cooking stove consists of pressurized gas from a gas cylinder passing through the regulator and hosepipe on its way to the command button; the package costs about EUR 60. Expenditure on cooking fuels accounts for an average of 20% of a household’s daily expenses. Nearly 7.5 million Cameroonians live in poverty, or on less than EUR 1.42 per day, making Cameroon a low-income nation [18]. Increasingly expanding economies have led to increased fuel prices and shortages, which often hit households. In this economic background, fuel and cooking expenditures represent a large part of overall household costs. Consumers’ fuel preferences are affected by a variety of factors, including cost and financial availability, in addition to energy efficiency and environmental friendliness [19,20,21]. Finding innovative approaches to reduce family expenses while making sure healthy meals are cooked is crucial. A careful economic investigation is necessary to evaluate the viability of briquettes for household cooking use.

This paper discusses the possibility of low-cost mixed briquettes made from coconut shells, rattan waste, sugarcane bagasse, and banana peels. This work is a follow-up to the work of Bot et al. [1,15,22] who produced, characterized, and carried out an economic and energy analysis of the production and use of pure CCS, RWT, SGC, and BNP briquettes. In light of the results obtained from these previous studies, the physicochemical characteristics of CCS and RWT briquettes are very satisfactory, whereas those of SGC and BNP briquettes are quite weak, even though SGC and BNP are the most widely available residues. The results of these investigations have led to the common conclusion that mixed briquettes should be produced in order to improve energy characteristics and, above all, at affordable prices. In the literature, studies have been carried out on mixed briquettes, for instance, rice straw and rice bran mixtures [23], corncob and rice husk [24], rice husk and coal [25], sawdust and palm kernel shell [26], sawdust and palm kernel shell [27], rice husk and palm oil mill sludge [28], rice husk and coconut shell [29], rice straw and sawdust [30], groundnut shells and bagasse [31], rice and coffee husks [32], cocoa pod husk and sawdust [33], sugarcane bagasse and rice bran [34], sugarcane bagasse, corncob, and rice husk [35], rice straw and banana peels [36], and coffee husk and corncob [37]. The limitations of these previous studies are that the selection of residues is not systematically justified and the mixtures are not carried out according to a clearly established relationship. Some studies use mixtures with ratio steps of 10%, some of 20%, and others of 50%, and it is after several attempts, spending money, time, and resources, that conclusions are drawn. In addition, the economic aspects of using these mixed briquettes are not fully taken into account. The aim of this study is to define the ideal ratios for preparing mixed briquettes in a single trial without repeating the experiments.

This study presents a theoretical analysis of the economic feasibility of mixture fuel briquettes made from RWT, RWT, SGC, and BNP for Cameroonian households. The specific objectives are as follows: firstly, to evaluate the price of the mixed briquettes; secondly, to assess the Present Value of the Net Benefit of the use of the mixed briquettes as a replacement of conventional household cooking fuel, such as LPG, wood charcoal, and fuelwood. The average Cameroonian household size is five people [16]. Our investigation was conducted using the life cycle cost method in a Cameroonian sample household with an annual thermal load of 950 kWhth. This study presents a thorough energy transition strategy for Cameroonian household cooking demand in an effort to close the knowledge gap. It also contributes to (i) providing a methodology for the determination of the optimal ratio of residues in briquette making; (ii) giving information to briquette-making companies on low-cost techniques for briquette manufacturing; and (iii) informing households about the cost advantages of switching to biomass briquettes for cooking. In addition to the introduction, this paper consists of a materials and methods section describing the methodology for the determination of briquette prices, the Present Value of Net Benefit, the annualized cost of heat, and a results and discussion section reporting the results of our investigation and their interpretation.

2. Materials and Methods

The current study focuses on a single, five-person household in Douala, Cameroon, located in the Central African region. Economic analysis was performed to compare the planned household biomass briquette system. The purpose of the conducted economic analysis was to compare conventional cooking fuel systems (wood charcoal, fuelwood, and LPG) with the suggested mixed-briquette fuel system.

2.1. Assumptions

In order to conduct the assessment, the following considerations were assumed:

- -

- The thermal load of the typical household was estimated at 950 kWhth/year according to the National Institute of Statistics of Cameroon [16];

- -

- Because of the physicochemical and economic properties of pure CCS, RWT, BNP, and SGC briquettes, four types of mixed briquettes were studied: BNP−CCS, SGC−CCS, BNP−RWT, and SGC−RWT;

- -

- The property values and prices considered for pure CCS, RWT, BNP, and SGC briquettes and economic parameters were the same as those found by Bot et al. [1,15,22] and are reported in Table 1 and Table 2;

Table 1. Characteristics of conventional fuels and pure briquettes studied.

Table 1. Characteristics of conventional fuels and pure briquettes studied. Table 2. Economic parameters of the study [16,22,38,39].

Table 2. Economic parameters of the study [16,22,38,39]. - -

- The price of mixed briquettes was assumed to be proportional to that of pure briquettes;

- -

- The ratio considered was percentage by weight;

- -

- The life cycle cost method was applied as recommended by Bot et al. [1].

2.2. Determination of Optimized Mixed Briquette Price

The prices of mixed briquettes were determined consecutively by the following Equations (1)–(3).

where BP is the percentage by weight of banana or sugarcane bagasse in the mixture, CP is the percentage by weight of coconut or rattan waste in the mixture, ME is the energy of mixture in kWh/kg, CE is the energy content of the coconut or rattan waste in kWh/kg, BE is the energy content of the banana or sugarcane bagasse briquette in kWh/kg, MC is the cost of mixture in EUR/kg, CC is the energy cost of the coconut or rattan waste in EUR/kWh, and BC is the energy cost of the banana or sugarcane bagasse in EUR/kWh.

2.3. Life Cycle Cost

For LCC analysis, the current value of annual cash flow (ACt) for each simulation year (t) was first determined [40,41]:

stands for the yearly energy demand for cooking in a home (kWh), denotes the conventional fuel or mixed biomass price evaluated as in Equation (3) (EUR/kWh), denotes the maintenance cooking stove cost (EUR), denotes the initial investment cost (EUR), represents the fuel price inflation rate, and represents the cooking stove maintenance cost inflation rate.

The present value at the end of year t was calculated via Equation (5):

where d is the market discount rate.

In both instances, the LCC was calculated by adding the 10 yearly present values (Equation (6)):

Finally, is calculated as follows:

where is the life cycle cost of conventional cooking fuel and is the life cycle cost of mixed-biomass briquettes.

2.4. Annualized Cost of Heat

Equation (8) was used to determine the annualized cost of heat (ACOH) for the mixed-briquette system in addition to the LCC technique. The cost per unit of heating load and the cost-effectiveness of a system can both be calculated using the ACOH (EUR/kWhth). ACOH is a key index for determining the economic viability of a system in comparison to another [40].

where ACOH is the annualized cost of heat (EUR/kWhth), LCC is the life cycle cost (EUR), d is the discount rate, and Ed is the annual energy demand (kWhth).

3. Results and Discussion

In this section, the cost of mixed briquettes is estimated and economic analysis in conducted in order to figure out if using mixed briquettes made from CCS, RWT, SGC, and BNP is more cost-effective than using traditional fuels in a typical Cameroonian home with 950 kWhth of annual thermal load.

3.1. Price of Mixed Briquettes

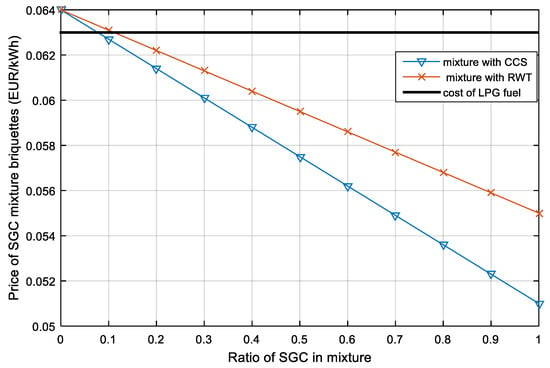

Figure 1 and Figure 2 show the prices of banana peel and sugarcane bagasse briquettes mixed with coconut husks and rattan waste, respectively. Figure 1 shows the proportion of CCS and RWT that must be added to BNP to obtain a mixed briquette with a lower cost than LPG. The figure shows that a mixed SGC–CCS briquette (92.25% SGC–7.75% CCS) or SGC–RWT briquette (88.9% SGC–11.1% RWT) costs the same as LPG, meaning EUR 0.063/kWh. These figures show that minimum percentages of 7.75% CCS and 11.1% RWT are required in mixed briquettes of SGC–CCS and SGC–RWT, respectively, for their costs to be lower than those of LPG. It can also be seen that the higher the proportion of CCS and RWT in the mixture, the lower the cost of the mixed briquette.

Figure 1.

Price of SGC mixed-biomass briquettes.

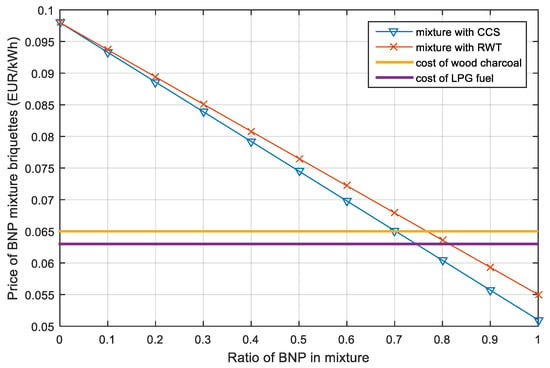

Figure 2.

Price of BNP mixed-biomass briquettes.

These findings suggest that briquette production companies should carefully consider the selection of residues in order to produce energy-efficient briquettes at lower costs. In Cameroon, the energy potential of sugarcane bagasse and coconut shells is 1541.83 TJ per year and 9.3 TJ per year, respectively [30,31]. Sugar cane is immensely grown and exploited in the Littoral and Centre regions, while coconuts are grown and processed in the Littoral, Centre, and Southern regions. However, these two crops are not harvested in the same seasons, so there are periods when one is more available than the other.

Figure 2 shows that a mixed BNP–CCS briquette (29.8% BNP–70.2% CCS) and a mixed BNP–RWT briquette (23.3% BNP–76.7% RWT) have the same cost as charcoal, i.e., EUR 0.063/kWh. On the other hand, a mixed BNP–CCS briquette (25.5% BNP–74.5% CCS) and a mixed BNP–RWT briquette (18.6% BNP–81.4% RWT) have the same cost as LPG. It also appears that a minimum proportion of 70.2% CCS and 76.7% RWT is required in BNP–CCS and BNP–RWT mixed briquettes, respectively, for their costs to be lower than those of charcoal.

Given the positive PVNBs for all blending ratios, economically viable mixed briquettes could be produced throughout the year for household use. BNP’s energy potential is one of the highest in Cameroon, with 250.84 kt of banana peels produced each year, representing a potential 4215.69 TJ. Bananas are grown and processed almost everywhere in the country, so banana residues are an easily accessible raw material for any briquette production company. That said, previous studies have reported that the production and use of pure BNP briquettes are economically expensive for both companies and households.

More than half of the work on briquette production focuses on mixed residues [24]. The approach proposed in this paper makes it easy to select the mixing ratios and prepare the optimum briquettes in a short period of time and at a low cost. Other types of residues whose pure briquettes have already been characterized and whose economic analysis has already been the subject of research could also be investigated. Given their characteristics as reported in the literature, it would also be interesting to mix banana leaves, banana stems, cotton stalks, and sugarcane leaves with one of the following residues: groundnut husk or maize cob, depending on the availability in an area.

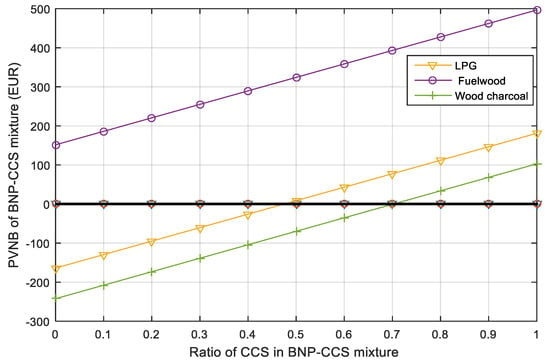

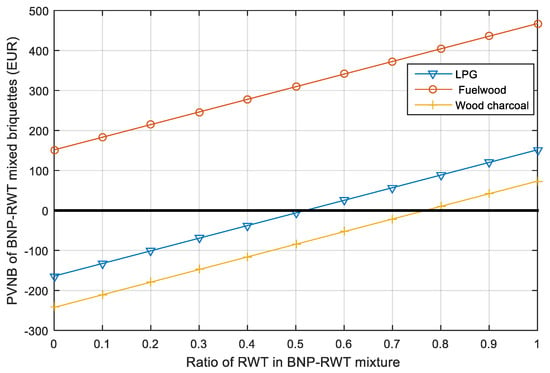

3.2. Present Value of Net Benefit

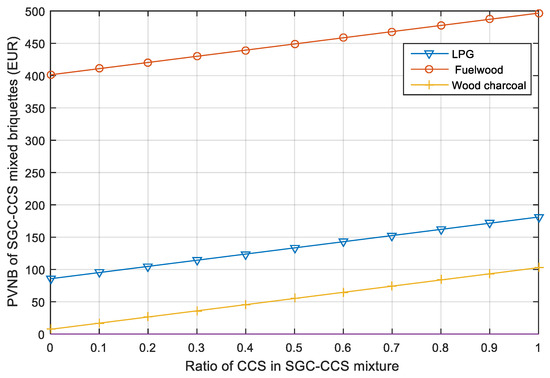

Figure 3, Figure 4, Figure 5 and Figure 6 present the results of the Present Value of Net Benefit assessment of the replacement of conventional household fuels with the studied mixed briquettes. Figure 3 and Figure 4 show the PVNB values of the SGC–CCS and SGC–RWT mixed briquettes, which are similar due to the very close characteristics of CCS and RWT briquettes. By observing these curves, it can easily be found that PVBN values are all positive, meaning that some of the biomass used to reinforce the SGC briquettes is economically viable for households. PVNB values for the replacement of LPG, fuelwood, and wood charcoal by mixed SGC-based briquettes are EUR 150, EUR 500, and EUR 100, respectively. These values are in line with the prices of conventional fuels. It may also be that the higher the proportions of CCS and RWT are in the mixture, the higher PVNB values are. In Figure 4, it can be seen that the PVNB values, for the whole range of the mixture ratio, are slightly lower than those in Figure 3, due to the higher value of RWT compared to CCS.

Figure 3.

Present Value of Net Benefit of the replacement of conventional fuel by SGC−CCS mixed briquettes.

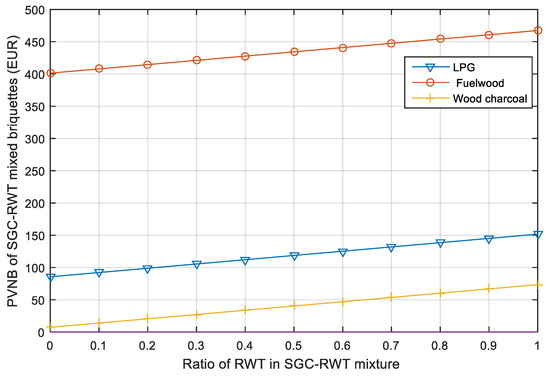

Figure 4.

Present Value of Net Benefit of the replacement of conventional fuel by SGC−RWT mixed briquettes.

Figure 5.

Present Value of Net Benefit of the replacement of conventional fuel by BNP–CCS mixed briquettes.

Figure 6.

Present Value of Net Benefit of the replacement of conventional fuel by BNP–RWT mixed briquettes.

Figure 5 illustrates the PVNB values of the replacement of fuelwood, LPG, and wood charcoal with mixed BNP–CCS biomass briquettes. It appears that the use of mixed BNP–CCS briquettes instead of fuelwood is more cost-effective for a household due to the fact that pure CCS and BNP briquettes are more beneficial than fuelwood. The use of mixed briquettes is feasible for a ratio of at least 48% of CCS as a replacement for LPG and at least 70% of CCS as the replacement of wood charcoal.

Figure 6 shows the PVNB of the replacement of traditional fuels usually used in households in Cameroon by BNP–RWT mixed briquettes. It appears that BNP–RWT mixed briquettes are more economically viable for an average household than fuelwood. The use of these mixed briquettes is viable for an RWT ratio greater than or equal to 52% as a replacement for LPG and for an RWT ratio greater than or equal to 75% as a replacement for wood charcoal. BNP briquettes require a slightly higher proportion of RWT because of their less attractive physicochemical and economic characteristics.

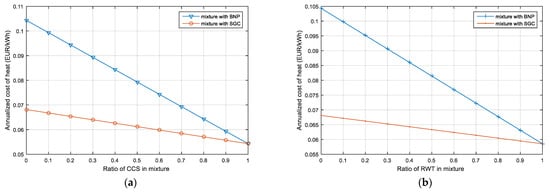

3.3. Annualized Cost of Heat

The ACOH may be utilized, as was already indicated, for the systems’ economic evaluation. The ACOH for the proposed mixed briquettes’ use in cooking is shown in Figure 7. According to Figure 7a, using mixed briquettes of BNP–CCS and SGC–CCS for cooking in households has an annualized heat cost varying between 0.055 and 0.105 (EUR/kWh) and 0.055 and 0.068 (EUR/kWh), respectively. Figure 7b shows that the use of mixed briquettes of BNP–RWT and SGC–RWT for cooking in households has an annualized heat cost varying between 0.057 and 0.104 (EUR/kWh) and 0.055 and 0.068 (EUR/kWh), respectively. It appears that the use of mixed briquettes made from BNP–RWT and BNP–CCS is more expensive because of the characteristics of pure BNP briquettes. Finally, one can say that ACOH indexes confirm the results of LCC analysis.

Figure 7.

Annualized cost of heat of (a) CCS mixture and (b) RWT mixture briquettes.

As the first study of its kind, the findings of this investigation facilitate achieving greater expertise in the proportions of mixed briquettes in Cameroon and other low–middle-income countries. In Cameroon, as in most developing countries, the transition must be strongly linked to the low cost of energy sources. Since 2011, there has been increasing inflation rates, with 2.9% growth. Money spent on cooking fuel represents a significant proportion of daily household expenditure. The lower cost of fuel is, therefore, crucial to the growth and development of households. By using mixed briquettes, households can make considerable financial savings and invest in other activities.

Some studies, such as that authored by Tamba in 2021 [42], have shown that in developing countries such as Cameroon, LPG use is increasing, but this also requires economic growth in the country. In light of the findings of the present study, it may be advisable to invest in briquette production rather than importing LPG. This will contribute to the development of the country’s national economy. Many private investors and governments should capitalize on briquette production companies and training; these companies will produce briquettes more cheaply and households will spend less on briquettes. The acceptance of fuel briquettes in sub-Saharan Africa might be hindered by consumer ignorance or a lack of knowledge.

Expanding the usage of briquettes requires greater knowledge of them and interest in them. The Cameroonian government will profit financially if a sizable portion of the population switches to this fuel, particularly those living in urban areas. It would also be interesting for other sub-Saharan countries such as Ghana, Burkina Faso, and South Africa, which are looking for clean cooking fuels, as reported in [43,44,45,46,47]. The total annual cost of petrol in sub-Saharan countries was around USD 23 billion in 2016, i.e., around USD 112 per family [47]. It would be interesting to invest this money in briquette production.

The environmental benefits of using briquettes instead of firewood have already been demonstrated. Sub-Saharan countries needed 498 million tonnes of fuelwood in 2016 (203 million tonnes for charcoal and 295 million tonnes for firewood) [48], according to a scenario established by Yvan Ayuketah et al. In 2045, the residential sector will continue to be the highest consuming sector [48]. Current consumption patterns’ increased energy intensity, particularly in rural regions, will inescapably raise both energy demand and related GHG emissions, so if this substitution is not made, the consequences could be very disastrous.

4. Conclusions

The price of mixed briquettes made from banana peels, coconut shells, rattan waste, and sugarcane bagasse was theoretically evaluated in this paper. On the other hand, the economic viability of their use as an alternative to traditional household fuels (fuelwood, LPG, and wood charcoal) in Cameroonian households is investigated as well. The investigation was carried out by using the life cycle cost method on a typical household over a ten-year period with annual cooking energy requirements of 950 kWhth. Priced at lower than EUR 0.063/kWhth are the SGC–CCS and SGC–RWT mixed briquettes with ratios greater than 7.75% and 11.1%, respectively. Using mixed briquettes made of SGC–CCS and SGC–RWT has a positive Present Value of the Net Benefit. Mixed briquettes made of BNP–CCS and BNP–RWT have positive Present Values of the Net Benefit for all mixture ratios in the case of fuelwood, while for LPG and wood charcoal, a positive Present Value of the Net Benefit is achieved from some value of the mixture ratio and higher, depending on the type of mixture. The results show that by making the right mixes of residues, one can obtain mixed-biomass briquettes that are less expensive than conventional fuels. The main limitation of this study is its theoretical aspect; consequently, in the future, preparation and characterization according to precise ratios could be carried for validation. In addition, the methodology presented here can be applied to other residues in order to make other effective mixed briquettes at a low cost.

Author Contributions

B.V.B.: writing original draft; P.J.A.: Conceptualization, methodology, review, and editing original draft; E.I.S.: Review and editing original draft; O.T.S.: Software and visualization; J.G.T.: Supervision and project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data that support the findings of this study are available on request from the corresponding author (BVB).

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| ACOH | Annualized cost of heat, EUR/kWhth |

| ACt | Annual cash flow in the year t, EUR |

| BNP | Banana peels |

| BNP–CCS | Banana peels and coconut shells mixture |

| BNP–RWT | Banana peels and rattan waste mixture |

| CCS | Coconut shells |

| d | Discount rate, % |

| Ed | Energy demand, kWhth |

| FC | Fuel cost, EUR/kWhth |

| GHG | Greenhouse Gases |

| i | Fuel cost inflation rate, % |

| INV | Initial investment cost, EUR |

| j | Maintenance cost inflation rate, % |

| kWhth | Kilowatt-hour thermal |

| LCC | Life cycle cost, EUR |

| LCCbio | Life cycle cost of biomass briquette, EUR |

| LCCconv | Life cycle cost of conventional fuel, EUR |

| LPG | Liquefied petroleum gas |

| MC | Cost of mixture, EUR/kg |

| ME | Energy of mixture, kWhth/kg |

| NM | Number of mixtures |

| PVNB | Present Value of Net Benefit, EUR |

| PVt | Present Value at the year t, EUR |

| RC | Cost of replaced energy EUR/kWhth |

| RWT | Rattan waste |

| SGC | Sugarcane bagasse |

| SGC–CCS | Sugarcane bagasse and coconut shells mixture |

| SGC–RWT | Sugarcane bagasse and rattan waste mixture |

| t | Year of simulation |

References

- Bot, B.V.; Axaopoulos, P.J.; Sosso, O.T.; Sakellariou, E.I.; Tamba, J.G. Economic analysis of biomass briquettes made from coconut shells, rattan waste, banana peels and sugarcane bagasse in households cooking. Int. J. Energy Environ. Eng. 2022, 14, 179–187. [Google Scholar] [CrossRef]

- Sakellariou, E.I.; Axaopoulos, P.J.; Bot, B.V.; Sarris, I.E. Energy Performance Evaluation of a Solar PVT Thermal Energy Storage System Based on Small Size Borefield. Energies 2022, 15, 7906. [Google Scholar] [CrossRef]

- Armah, F.A.; Ekumah, B.; Yawson, D.O.; Odoi, J.O.; Afitiri, A.R.; Nyieku, F.E. Predictive Probabilities of Access to Clean Cooking: Evidence from the Demographic and Health Surveys in 31 Countries in Sub-Saharan Africa. Environ. Justice 2019, 12, 118–131. [Google Scholar] [CrossRef]

- Garba, I.; Bellingham, R. Energy poverty: Estimating the impact of solid cooking fuels on GDP per capita in developing countries—Case of sub-Saharan Africa. Energy 2021, 221, 119770. [Google Scholar] [CrossRef]

- Tomen, W.T.; Diboma, B.S.; Bot, B.V.; Tamba, J.G. Physical and Combustion properties investigation of hybrid briquettes from tropical Sawdust: Case study of Iroko (Milicia excelsa) and Padouk (Pterocarpus soyauxii). Energy Rep. 2023, 9, 3177–3191. [Google Scholar] [CrossRef]

- Atyi, E.; Lescuyer, G.; Ngouhouo Poufoun, J.; Moulende Fouda, T.; Abdon, A.; Betti, J.-L.; Cerutti, P.O.; Chupezi Tieguhong, J.; Defo, L.; Foundjem-Tita, D.; et al. Étude de L’importance Économique et Sociale du Secteur Forestier et Faunique au Cameroun: Rapport Final; CIFOR: Yaoundé, Cameroon, 2013. [Google Scholar]

- Diboma, B.S.; Atiotsia, V.H.; Che, L.C.; Essomba, P.B.; Bot, B.V.; Tamba, J.G. Gasification of charcoal derived from tropical wood residues in an updraft fixed bed reactor. Bioresour. Technol. Rep. 2023, 21, 101308. [Google Scholar] [CrossRef]

- Meng, S.; Li, W.; Li, Z.; Song, H. Recent progress of the transition metal-based catalysts in the catalytic biomass gasification: A mini-review. Fuel 2023, 353, 129169. [Google Scholar] [CrossRef]

- Dziva, G.; Jia, Z.; Xue, Y.; Zeng, L. Hydrogen production from biomass via moving bed sorption-enhanced reforming: Kinetic modeling and process simulation. Fuel 2023, 352, 129024. [Google Scholar] [CrossRef]

- Chianese, S.; Fail, S.; Binder, M.; Rauch, R.; Hofbauer, H.; Molino, A.; Blasi, A.; Musmarra, D. Experimental investigations of hydrogen production from CO catalytic conversion of tar rich syngas by biomass gasification. Catal. Today 2016, 277, 182–191. [Google Scholar] [CrossRef]

- Rahman, M.A.; Møller, H.B.; Alam, M.M. Assessing the energy potential of agricultural residues and an approach to meet the rural energy demand: The Bangladesh perspective. Biomass Convers. Biorefinery 2018, 8, 925–934. [Google Scholar] [CrossRef]

- Lambe, F.; Jürisoo, M.; Wanjiru, H.; Senyagwa, J. Bringing Clean, Safe, Affordable Cooking Energy to Kenyan Households: An Agenda for Action; SEI: Nairobi, Kenya, 2015; p. 38. Available online: www.newclimateeconomy.report (accessed on 15 June 2023).

- Ngusale, G.K.; Luo, Y.; Kiplagat, J.K. Briquette making in Kenya: Nairobi and peri-urban areas. Renew. Sustain. Energy Rev. 2014, 40, 749–759. [Google Scholar] [CrossRef]

- Kauter, D.; Lewandowski, I.; Claupein, W. Quantity and quality of harvestable biomass from Populus short rotation coppice for solid fuel use—A review of the physiological basis and management influences. Biomass Bioenergy 2003, 24, 411–427. [Google Scholar] [CrossRef]

- Bot, B.V.; Sosso, O.T.; Tamba, J.G.; Lekane, E.; Bikai, J.; Ndame, M.K. Preparation and characterization of biomass briquettes made from banana peels, sugarcane bagasse, coconut shells and rattan waste. Biomass Convers. Biorefinery 2021, 13, 7937–7946. [Google Scholar] [CrossRef]

- Cameroun National Institute of Statistics. 2019 National Accounts—Institut National de la Statistique du Cameroun. 2020. Available online: https://ins-cameroun.cm/en/statistique/english-2019-national-accounts/ (accessed on 3 June 2023).

- Obi, O.F.; Ezema, J.C.; Okonkwo, W.I. Energy performance of biomass cookstoves using fuel briquettes. Biofuels 2020, 11, 467–478. [Google Scholar] [CrossRef]

- Tchatat, G. Cameroun—Contribution a La Preparation Du Rapport National Pour La Formulation Du Livre Blanc Regional Sur L’Acces Universel Aux Services Energetiques Integrant Le Developpement Des Energies Renouvelables Et De L’Efficacite Energetique. 2014, pp. 1–245. Available online: http://www.se4all.org/sites/default/files/Cameroon_RAGA_FR_Released.pdf (accessed on 3 June 2023).

- Pye, A.; Ronzi, S.; Ngahane, B.H.M.; Puzzolo, E.; Ashu, A.H.; Pope, D. Drivers of the adoption and exclusive use of clean fuel for cooking in sub-saharan africa: Learnings and policy considerations from cameroon. Int. J. Environ. Res. Public Health 2020, 17, 5874. [Google Scholar] [CrossRef] [PubMed]

- Pope, D.; Bruce, N.; Higgerson, J.; Hyseni, L.; Stanistreet, D.; Mbatchou, B.; Puzzolo, E. Household Determinants of Liquified Petroleum Gas (LPG) as a Cooking Fuel in SW Cameroon. Ecohealth 2018, 15, 729–743. [Google Scholar] [CrossRef] [PubMed]

- Nlom, J.H.; Karimov, A.A. Modeling Fuel Choice among Households in Northern Cameroon. Sustainability 2015, 7, 9989–9999. [Google Scholar] [CrossRef]

- Bot, B.V.; Axaopoulos, P.J.; Sakellariou, E.I.; Sosso, O.T.; Tamba, J.G. Energetic and economic analysis of biomass briquettes production from agricultural residues. Appl. Energy 2022, 321, 119430. [Google Scholar] [CrossRef]

- Chou, C.-S.; Lin, S.-H.; Lu, W.-C. Preparation and characterization of solid biomass fuel made from rice straw and rice bran. Fuel Process. Technol. 2009, 90, 980–987. [Google Scholar] [CrossRef]

- Oladeji, J. Fuel characterization of briquettes produced from corncob and rice husk resides. Pacific J. Sci. Technol. 2010, 11, 101–106. [Google Scholar]

- Ikelle, I.I.; Chukwuma, A.; Philip Ivoms, O.S. The Characterization of the Heating Properties of Briquettes of Coal and Rice Husk. IOSR J. Appl. Chem. 2014, 7, 100–105. [Google Scholar] [CrossRef]

- Obi, O.F. Evaluation of the physical properties of composite briquette of sawdust and palm kernel shell. Biomass Convers. Biorefinery 2015, 5, 271–277. [Google Scholar] [CrossRef]

- Obi, O.F.; Okongwu, K.C. Characterization of fuel briquettes made from a blend of rice husk and palm oil mill sludge. Biomass Convers. Biorefinery 2016, 6, 449–456. [Google Scholar] [CrossRef]

- Yuliah, Y.; Kartawidjaja, M.; Suryaningsih, S.; Ulfi, K. Fabrication and characterization of rice husk and coconut shell charcoal based bio-briquettes as alternative energy source. IOP Conf. Ser. Earth Environ. Sci. 2017, 65, 012021. [Google Scholar] [CrossRef]

- Rahaman, S.A.; Salam, P.A. Characterization of cold densified rice straw briquettes and the potential use of sawdust as binder. Fuel Process. Technol. 2017, 158, 9–19. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A. Development of groundnut shells and bagasse briquettes as sustainable fuel sources for domestic cooking applications in Uganda. Renew. Energy 2017, 111, 532–542. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A. Characteristics of briquettes developed from rice and coffee husks for domestic cooking applications in Uganda. Renew. Energy 2018, 118, 43–55. [Google Scholar] [CrossRef]

- Ofori, P.; Akoto, O. Production and Characterisation of Briquettes from Carbonised Cocoa Pod Husk and Sawdust. Open Access Libr. J. 2020, 7, 1. [Google Scholar] [CrossRef]

- Navalta, C.J.L.G.; Banaag, K.G.C.; Raboy, V.A.O.; Go, A.W.; Cabatingan, L.K.; Ju, Y.H. Solid fuel from Co-briquetting of sugarcane bagasse and rice bran. Renew. Energy 2020, 147, 1941–1958. [Google Scholar] [CrossRef]

- Nagarajan, J.; Prakash, L. Preparation and characterization of biomass briquettes using sugarcane bagasse, corncob and rice husk. Mater. Today Proc. 2021, 47, 4194–4198. [Google Scholar] [CrossRef]

- Duangkham, S.; Thuadaij, P. Characterization of charcoal briquettes produced from blending rice straw and banana peel. Heliyon 2023, 9, e16305. [Google Scholar] [CrossRef] [PubMed]

- Aliah, H.; Rahmah, B.L.; Sawitri, A.; Iman, R.N.; Syarif, D.G.; Setiawan, A.; Nuryadin, B.W. Physical properties of briquettes composite from coffee husks (Coffea arabica L.) and corncob (Zea mays) for alternative fuel. AIP Conf. Proc. 2023, 2646, 060004. [Google Scholar] [CrossRef]

- Tchatat, G. Contribution à la préparation du rapport national pour la formulation du livre blanc régional sur l’accès universel aux services énergétiques. In Rapport Final Cameroun Préparé pour le PNUD; CIFOR: Yaoundé, Cameroon, 2014. [Google Scholar]

- INS Agriculture. Annuaire Statistique; Chapitre 13; INS Agriculture: Paris, France, 2017. [Google Scholar]

- Sakellariou, E.I.; Axaopoulos, P.J.; Wright, A.J. Energy and economic evaluation of a solar assisted ground source heat pump system for a north Mediterranean city. Energy Build. 2021, 231, 110640. [Google Scholar] [CrossRef]

- Sakellariou, E.I.; Wright, A.J.; Axaopoulos, P.J. Energy, economic and emission assessment of a solar assisted shallow earth borehole field heat pump system for domestic space heating in a north European climate. Geothermics 2021, 95, 102159. [Google Scholar] [CrossRef]

- Bot, B.V.; Gaston, J.; Olivier, T.; Sosso, T.; Pascal, M. Assessment of biomass briquette energy potential from agricultural residues in Cameroon. Biomass Convers. Biorefinery 2022, 27, 1–13. [Google Scholar] [CrossRef]

- Tamba, J.G. LPG consumption and economic growth, 1975–2016: Evidence from Cameroon. Int. J. Energy Sect. Manag. 2021, 15, 195–208. [Google Scholar] [CrossRef]

- Doggart, N.; Ruhinduka, R.; Meshack, C.K.; Ishengoma, R.C.; Morgan-Brown, T.; Abdallah, J.M.; Spracklen, D.V.; Sallu, S.M. The influence of energy policy on charcoal consumption in urban households in Tanzania. Energy Sustain. Dev. 2020, 57, 200–213. [Google Scholar] [CrossRef]

- Wiafe, E.D. Fuel-wood usage assessment among rural households in Ghana. Spanish J. Rural Dev. 2013, 4, 41–48. [Google Scholar] [CrossRef]

- Sana, A.; Kafando, B.; Dramaix, M.; Meda, N.; Bouland, C. Household energy choice for domestic cooking: Distribution and factors influencing cooking fuel preference in Ouagadougou. Environ. Sci. Pollut. Res. 2020, 27, 18902–18910. [Google Scholar] [CrossRef] [PubMed]

- Uhunamure, S.E.; Nethengwe, N.S.; Musyoki, A. Driving forces for fuelwood use in households in the Thulamela municipality, South Africa. J. Energy S. Africa 2017, 28, 25–34. [Google Scholar] [CrossRef]

- Dagnachew, A.G.; Hof, A.F.; Lucas, P.L.; van Vuuren, D.P. Scenario analysis for promoting clean cooking in Sub-Saharan Africa: Costs and benefits. Energy 2020, 192, 116641. [Google Scholar] [CrossRef]

- Ayuketah, Y.; Gyamfi, S.; Diawuo, F.A.; Dagoumas, A.S. Assessment of low-carbon energy transitions policies for the energy demand sector of Cameroon. Energy Sustain. Dev. 2023, 72, 252–264. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).