Untapping Industrial Flexibility via Waste Heat-Driven Pumped Thermal Energy Storage Systems

Abstract

:1. Introduction

1.1. Research Novelty

1.2. Proposed Reference Case Study

1.3. Research Objectives

2. Industrial Sectors Assessment for Grid Flexibility

3. Exergy Balance to Evaluate Thermally-Assisted PTES

3.1. RTE Conventional “Electrical” Definition

3.2. Exergy Balance of an Open System

- Ex—total exergy flux [W]

- ε—total specific exergy [J/kg]

- εkin—=, kinetic exergy [J/kg]

- εpot—=gz, gravitational potential exergy [J/kg]

- εph—=h − h0 − T0(s − s0), physical exergy [J/kg]

- εch—chemical exergy (tabulated) [J/kg]

- Exergy is a property of state;

- Exergy is defined by (i) the system state and (ii) the dead state or ambient state (usually indicated as “0”);

- Exergy, unlike energy, can be destroyed.

- Exin—Exout—exergy fluxes associated to input/output mass flows [W]

- ExQ—exergy fluxes associated to thermal fluxes [W]

- ExW—exergy fluxes associated to work fluxes [W]

- I—exergy destruction or irreversibility [W]

3.3. RTE “Exergetic” Definition

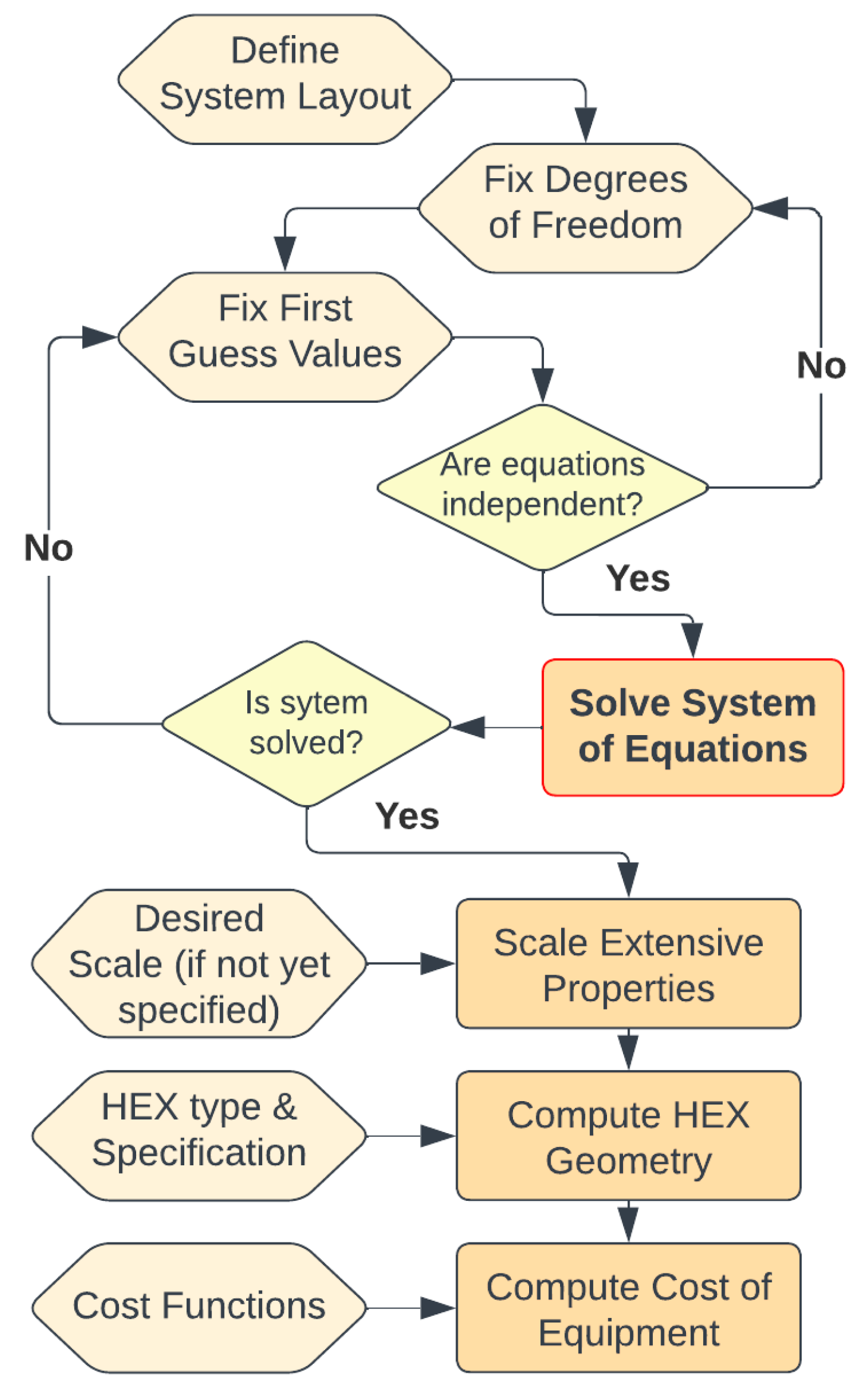

4. Material and Methods

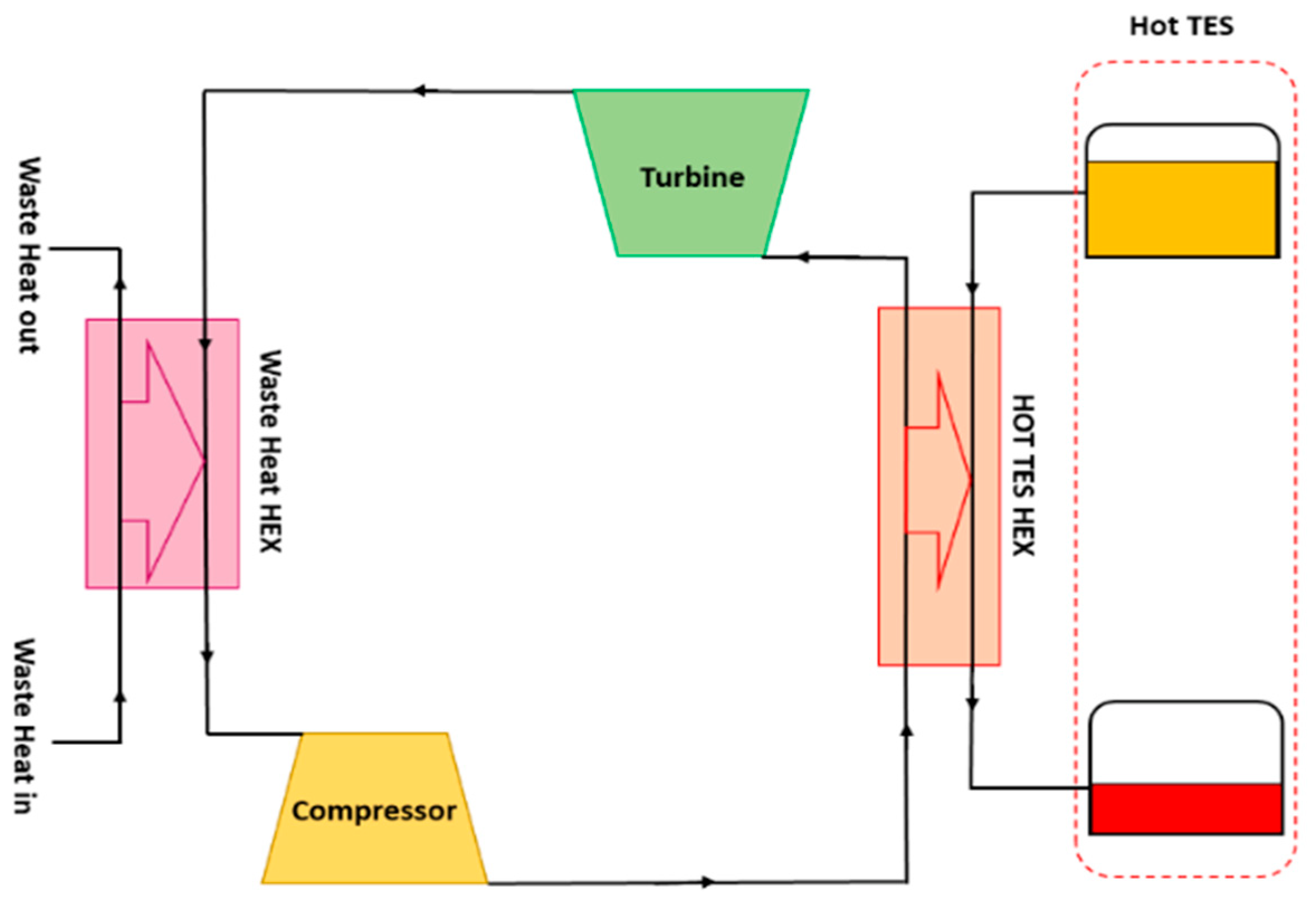

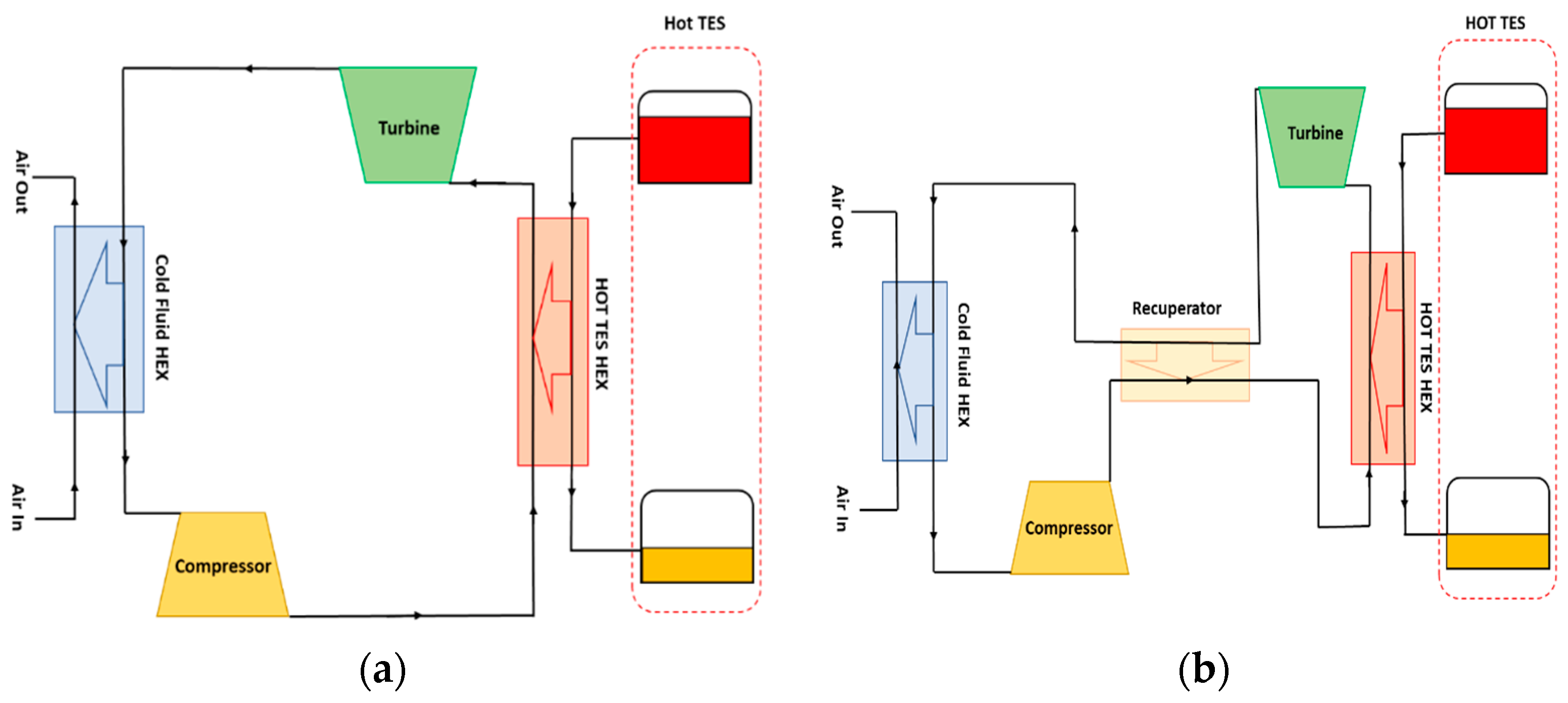

4.1. Proposed Plant Layouts

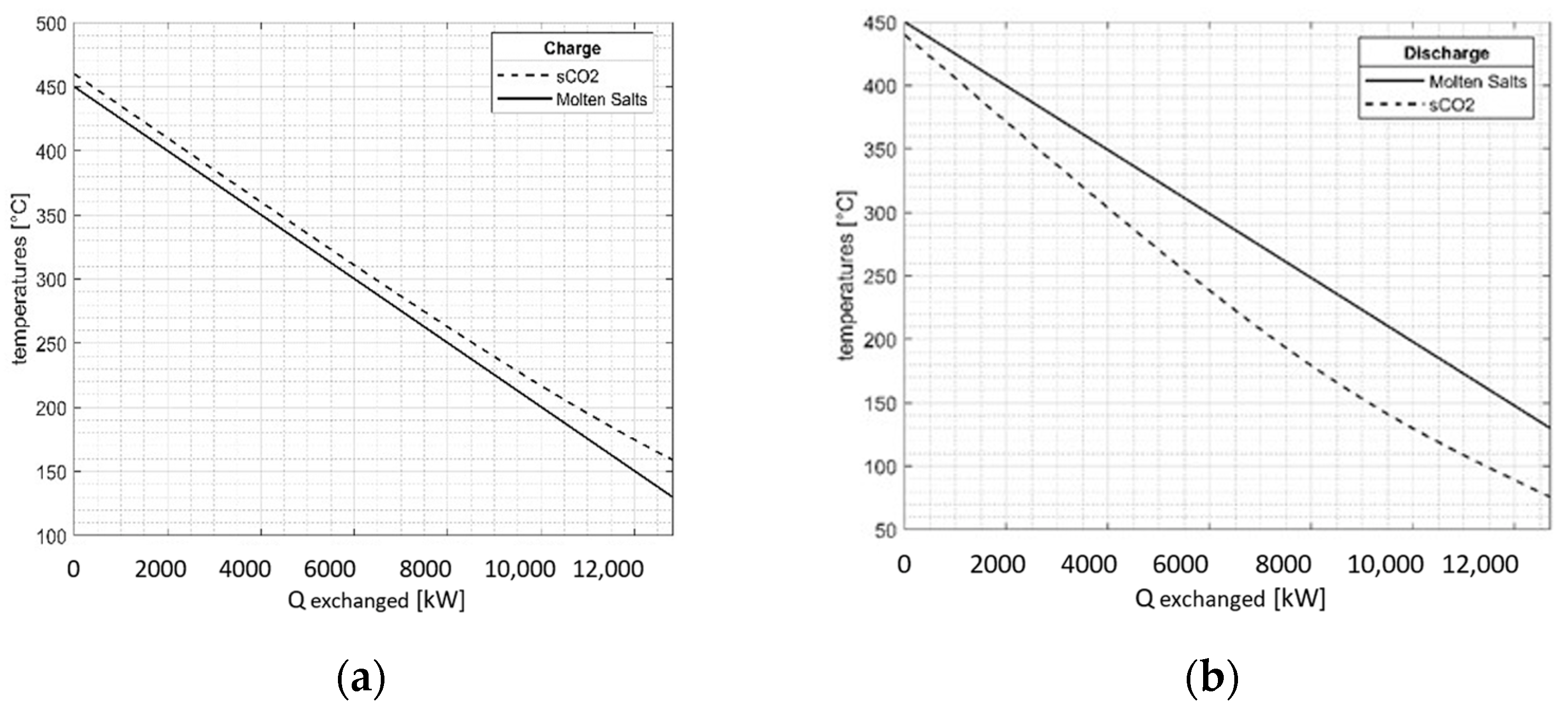

4.2. Thermodynamic Modeling

4.2.1. Cycle Modeling Technique and Information Flow

- h are enthalpies [kJ/kg]

- p are pressures [Pa]

- Q are thermal flows [kW]

- is compressor pressure ratio [-]

- is heat exchanger effectiveness [-]

- is compressor isentropic efficiency [-]

- is percentage pressure drop [-]

4.2.2. Thermodynamic Modeling Assumptions

4.3. Economic Modeling

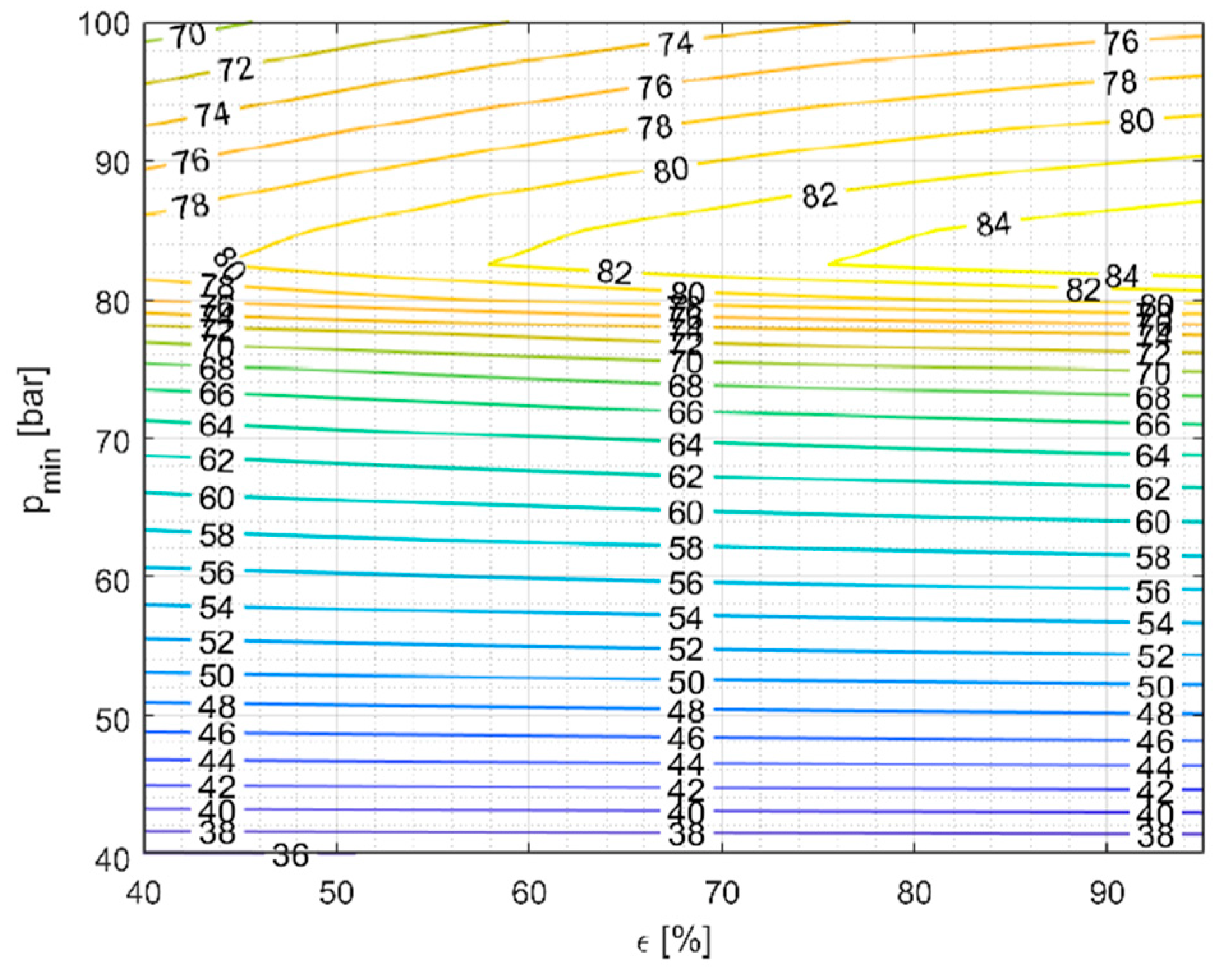

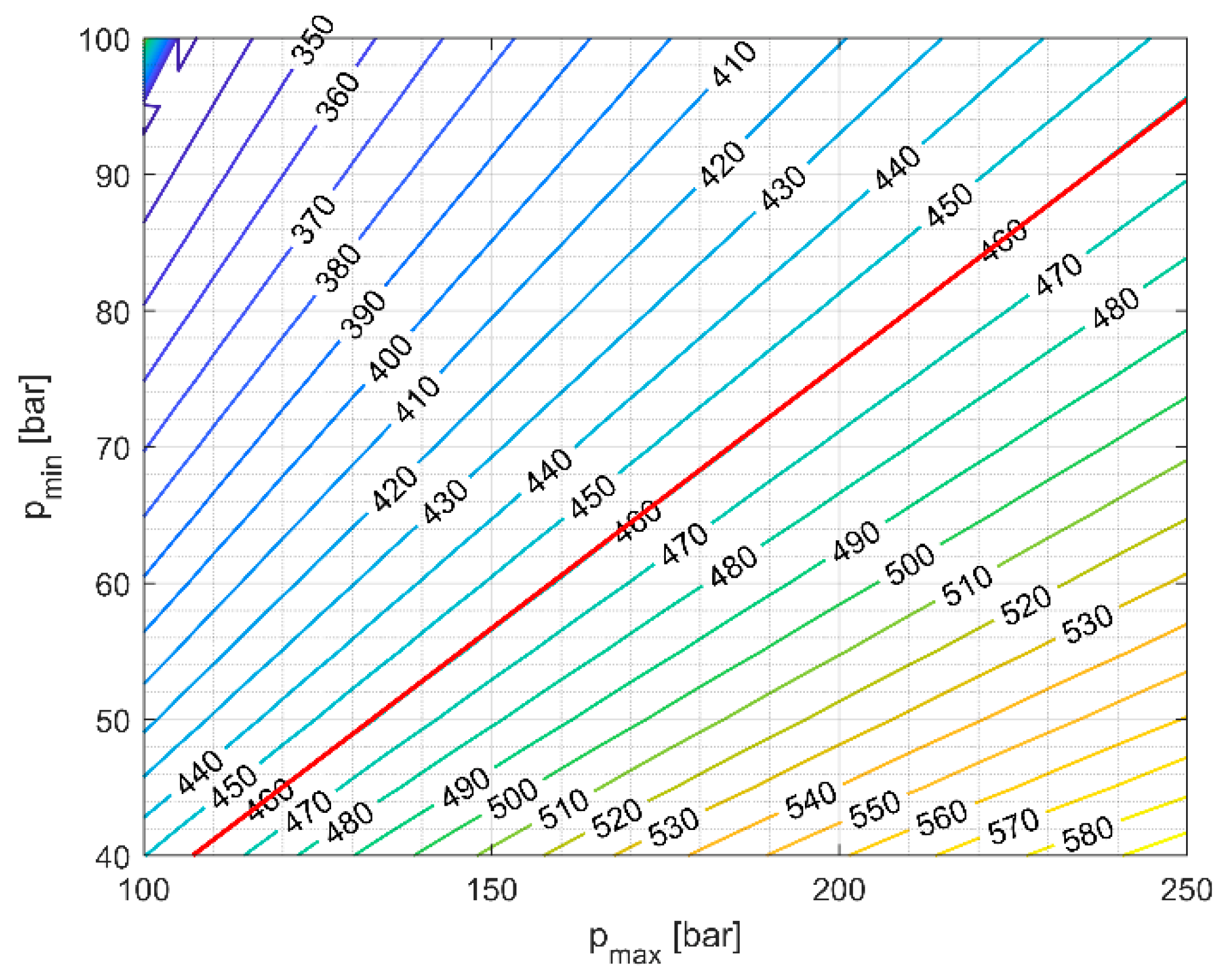

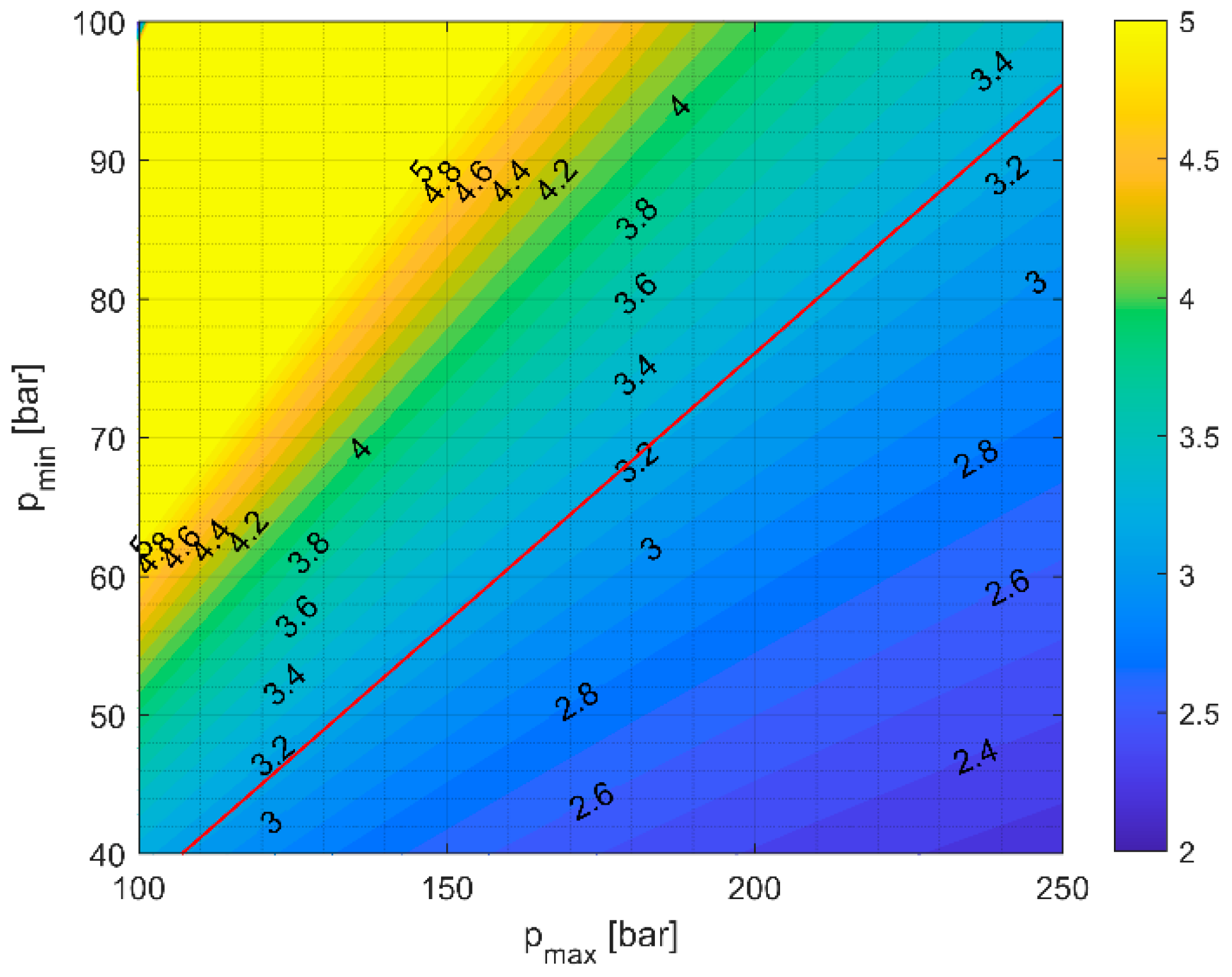

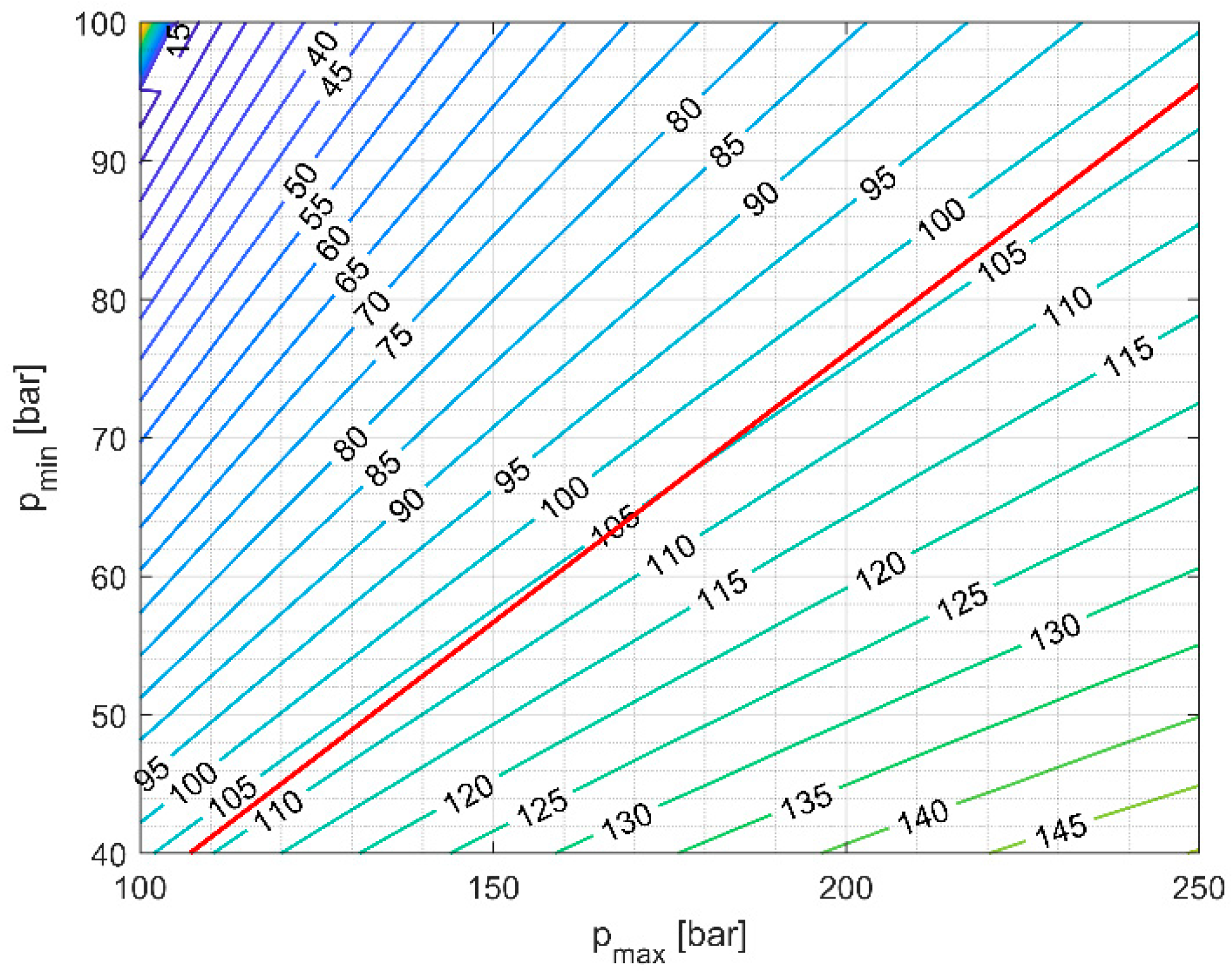

5. Analysis of the Impact of Different Operating Parameters on WH-Driven PTES Cycle Performances

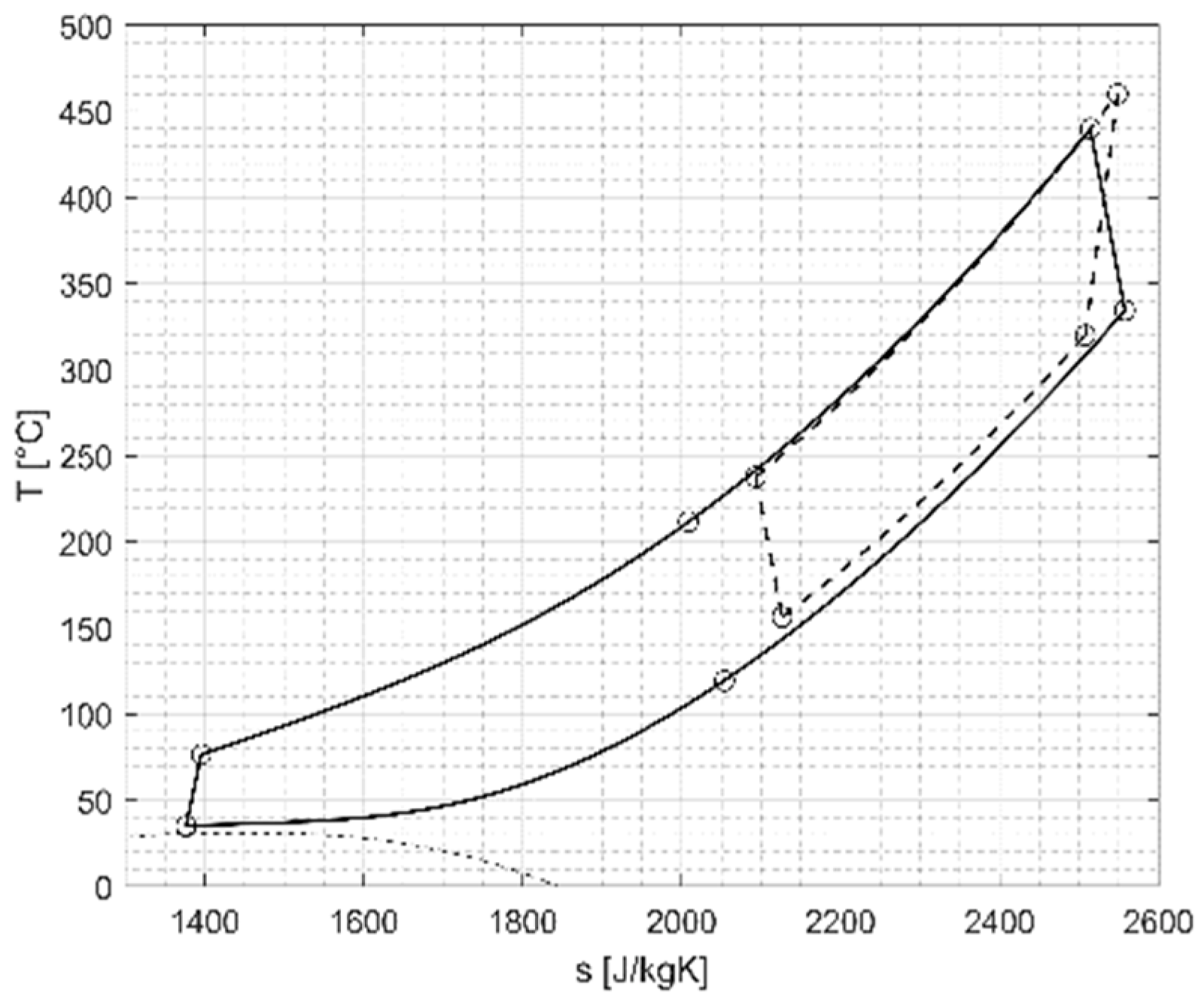

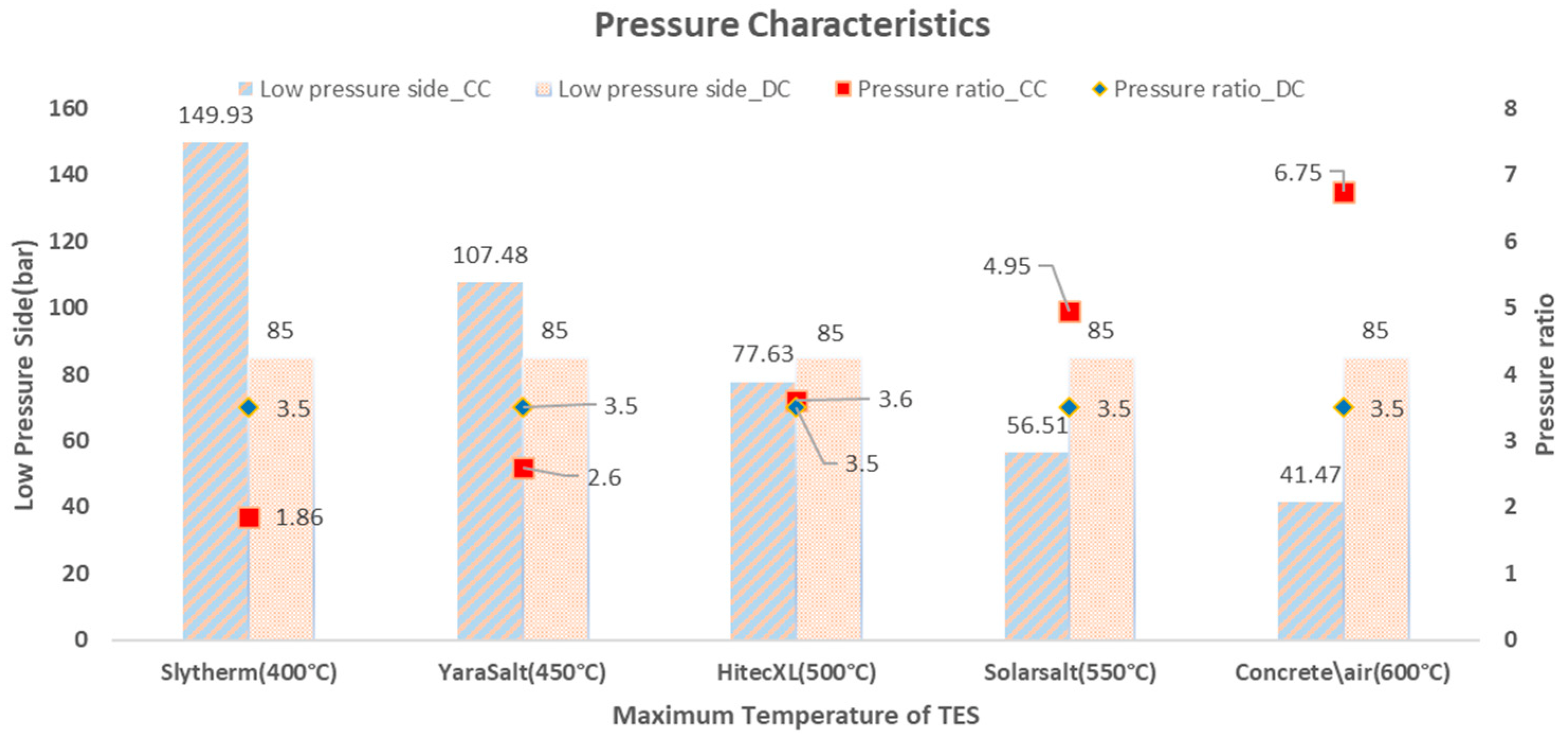

5.1. Operating Pressure of Charging and Discharging Cycles

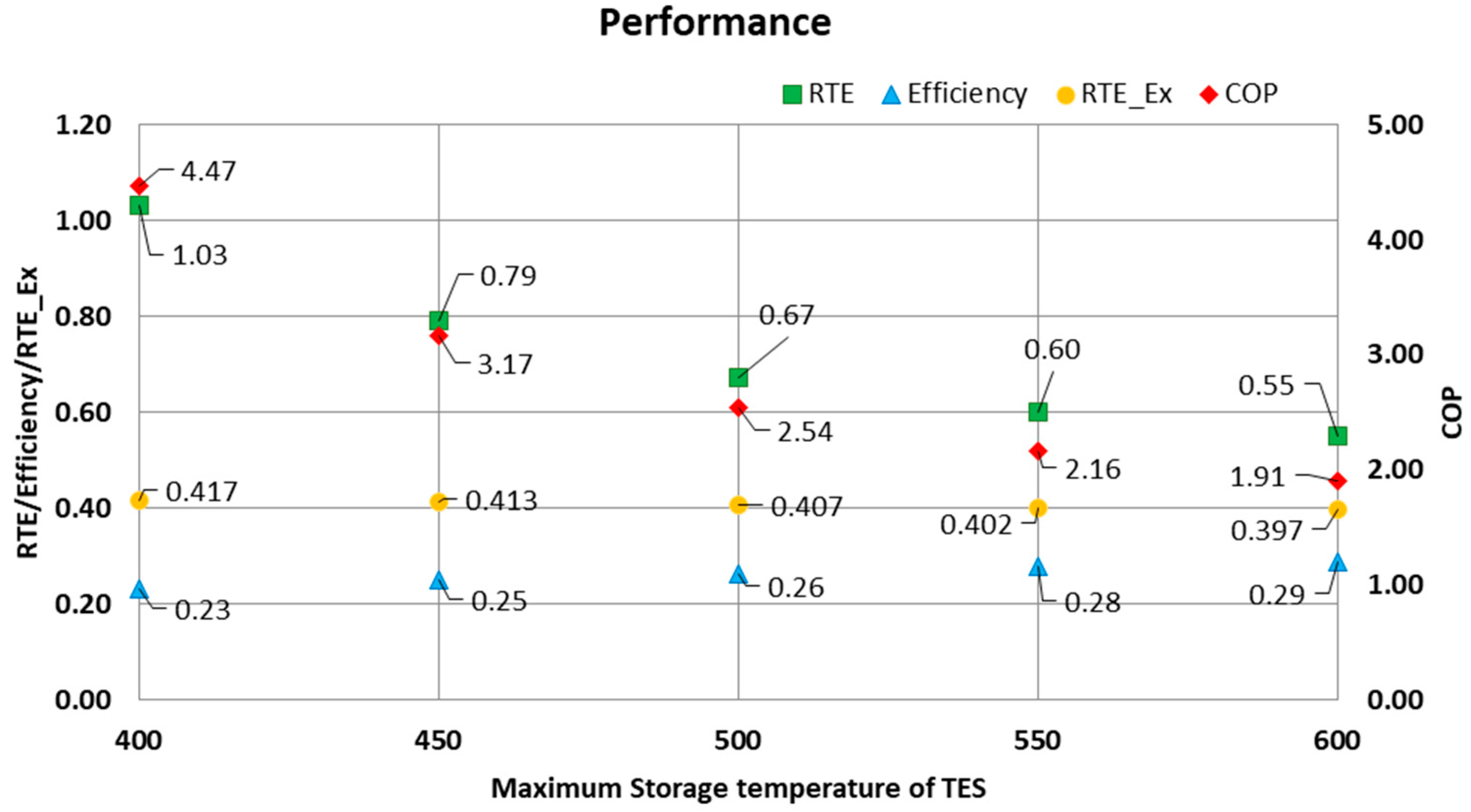

5.2. Impact of TES Temperature

6. Preliminary Economic Investigations

- -

- an electricity market interest for the proposed system in different EU electricity market (particularly those ones with weekly/monthly price volatility);

- -

- sustainable PBP around 8 to 10 years for the proposed system.

7. Conclusions

- (a)

- The use of a recuperated cycle in the discharging phase enables electrical RTE values exceeding 70%, which is higher than what can be achieved with PTES without recuperation operating under similar conditions. Furthermore, a recuperated solution achieves improved results with only a limited increase in the minimum temperature of the thermal energy storage (TES), thus minimizing the required TES size. This solution leverages the availability of waste heat recovery, potentially eliminating the need for a low-temperature TES that is necessary for standalone PTES configurations, thus allowing for cost savings. However, it is important to note that the exergetic RTE analysis, which includes the contributions of both electrical power and external thermal sources in terms of exergy flows, shows that even the best-performing configurations analyzed in this study cannot achieve an RTEex higher than 39%;

- (b)

- The independence of the CC and DC in terms of the components and turbomachinery originating from the utilization of waste heat offers many benefits of different operating pressures in charging and discharging which in turn result in higher power gains. Specifically, reducing the CC power input by allowing lower pressure operations than the DC cycle and increasing CC turbine power output by being able to operate away from the critical point;

- (c)

- The integration of higher temperature TES material brings higher efficiency of the PTES DC: nevertheless, such an increase does not compensate for the reduction in COP of the charging HP cycle, thus lower temperature TES materials present higher RTE (while comparing different higher temperatures of the cycles at the same maximum pressure of the cycle);

- (d)

- MS-based TES systems (450 °C to 550 °C) show lower CAPEX if compared to diathermic oil or concrete and satisfactory RTE (0.55 ÷ 0.7) if compared to other currently investigated long-duration energy storage systems/CBs;

- (e)

- The charging cycle is the most critical and relevant part (in terms of impact on the RTE) of the proposed systems and, to ensure cost-effective systems, highly efficient HPs and components (mainly ”hot sCO2 compressors”) are needed. This also highlights the need for further development of sCO2 high-temperature heat pumps which today could reach up to 160–200 °C with good COP values;

- (f)

- The proposed systems can ensure flexibility by the thermal energy storage units, thus easily enabling a decouple energy/power rate that the system can provide to ensure significant grid support, particularly with high RTE values, by being continuously charged and discharged along the day which is particularly attractive in markets with high electricity price volatility and fluctuations as well as the presence of negative prices.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations | |

| CAPEX | Capital Expenditure |

| CB | Carnot Battery |

| CC | Charging Cycle |

| CHP | Combined Heat and Power |

| COP | Coefficient of Performance |

| CSP | Concentrating Solar Power |

| DC | Discharging Cycle |

| E | Energy |

| Ex | Exergy |

| EU | European Union |

| h | Enthalpy |

| HEX | Heat Exchanger |

| HP | Heat Pump |

| LDES | Long-Duration Energy Storage |

| LMTD | Log Mean Temperature Difference |

| LMP | Location Marginal Prices |

| MS | Molten Salts |

| PCM | Phase Change Material |

| PTES | Pumped Thermal Energy Storage |

| PV | Photovoltaic |

| P2H2P | Power-to-heat-to-power |

| Q | Heat |

| RES | Renewable Energy Sources |

| RTE | Round Trip Efficiency |

| sCO2 | Supercritical Carbon Dioxide |

| T | Temperature |

| TES | Thermal Energy Storage |

| US | United States |

| WH | Waste Heat |

| WHR | Waste Heat Recovery |

| Subscripts | |

| avg | Average |

| cc/CC | Charging Cycle |

| dc/DC | Discharging Cycle |

| el | Electric |

| HEX | Heat exchanger |

| in | Input |

| out | Output |

| TES | Thermal Energy Storage |

References

- The Guardian. Weather Tracker: Power Prices Dip to Negative in Europe Amid Clean Energy Boost. Available online: https://www.theguardian.com/environment/2023/may/29/weather-tracker-power-prices-dip-to-negative-in-europe-amid-clean-energy-boost (accessed on 5 May 2023).

- Jafarizadeh, H.; Soltani, M.; Nathwani, J. A Novel Analysis of Energy Density Considerations and Its Impacts on the Cost of Electrical Energy Storage (EES) Plants. Energies 2023, 16, 3330. [Google Scholar] [CrossRef]

- Novotny, V.; Basta, V.; Smola, P.; Spale, J. Review of Carnot Battery Technology Commercial Development. Energies 2022, 15, 647. [Google Scholar] [CrossRef]

- Alfani, D.; Binotti, M.; Macchi, E.; Silva, P.; Astolfi, M. sCO2 power plants for waste heat recovery: Design optimization and part-load operation strategies. Appl. Therm. Eng. 2021, 195, 117013. [Google Scholar] [CrossRef]

- Kaushik, E.; Prakash, V.; Mahela, O.P.; Khan, B.; El-Shahat, A.; Abdelaziz, A.Y. Comprehensive Overview of Power System Flexibility during the Scenario of High Penetration of Renewable Energy in Utility Grid. Energies 2022, 15, 516. [Google Scholar] [CrossRef]

- Zhou, C.; Li, Y.; Wang, F.; Wang, Z.; Xia, Q.; Zhang, Y.; Liu, J.; Liu, B.; Cai, W. A Review of the Performance Improvement Methods of Phase Change Materials: Application for the Heat Pump Heating System. Energies 2023, 16, 2676. [Google Scholar] [CrossRef]

- Jacob, R.; Liu, M. Design and Evaluation of a High Temperature Phase Change Material Carnot Battery. Energies 2023, 16, 189. [Google Scholar] [CrossRef]

- Linares, J.I.; Martín-Colino, A.; Arenas, E.; Montes, M.J.; Cantizano, A.; Pérez-Domínguez, J.R. Carnot Battery Based on Brayton Supercritical CO2 Thermal Machines Using Concentrated Solar Thermal Energy as a Low-Temperature Source. Energies 2023, 16, 3871. [Google Scholar] [CrossRef]

- de la Quintana, J.L.; Sebastián, A.; Abbas, R. Economic assessment of installed CSP plants as Carnot Batteries: Spanish grid market case study. AIP Conf. Proc. 2022, 2445, 050002. [Google Scholar] [CrossRef]

- Beck, A.; Unterluggauer, J.; Helminger, F.; Solís-Gallego, I. Decarbonisation Pathways for the Finishing Line in a Steel Plant and Their Implications for Heat Recovery Measures. Energies 2023, 16, 852. [Google Scholar] [CrossRef]

- Agner, R.; Ong, B.H.Y.; Stampfli, J.A.; Krummenacher, P.; Wellig, B. A Graphical Method for Combined Heat Pump and Indirect Heat Recovery Integration. Energies 2022, 15, 2829. [Google Scholar] [CrossRef]

- White, M.T.; Bianchi, G.; Chai, L.; Tassou, S.A.; Sayma, A.I. Review of supercritical CO2 technologies and systems for power generation. Appl. Therm. Eng. 2021, 185, 116447. [Google Scholar] [CrossRef]

- Morandin, M.; Maréchal, F.; Mercangöz, M.; Buchter, F. Conceptual design of a thermo-electrical energy storage system based on heat integration of thermodynamic cycles—Part A: Methodology and base case. Energy 2012, 45, 375–385. [Google Scholar] [CrossRef]

- Morandin, M.; Maréchal, F.; Mercangöz, M.; Buchter, F. Conceptual design of a thermo-electrical energy storage system based on heat integration of thermodynamic cycles—Part B: Alternative system configurations. Energy 2012, 45, 386–396. [Google Scholar] [CrossRef]

- MMercangöz, M.; Hemrle, J.; Kaufmann, L.; Z’graggen, A.; Ohler, C. Electrothermal energy storage with transcritical CO2 cycles. Energy 2012, 45, 407–415. [Google Scholar] [CrossRef]

- Vinnemeier, P.; Wirsum, M.; Malpiece, D.; Bove, R. Supercritical CO2-Based Heat Pump Cycle for Electrical Energy Storage for Utility Scale Dispatchable Renewable Energy Power Plants. In Proceedings of the 5th International Symposium—Supercritical CO2 Power Cycles, San Antonio, TX, USA, 28–31 March 2016. [Google Scholar]

- Aga, V.; Conte, E.; Carroni, R.; Burcker, B.; Ramond, M. Integration of Pumped-Heat-Electricity-Storage into Water/Steam Cycles of Thermal Power Plants. In Proceedings of the 5th International Symposium—Supercritical CO2 Power Cycles, San Antonio, TX, USA, 28–31 March 2016. [Google Scholar]

- Cho, J.; Shin, H.; Cho, J.; Choi, B.; Roh, C.; Lee, B.; Lee, G.; Ra, H.-S.; Baik, Y.-J. Electric-thermal energy storage for large-scale renewables and a supercritical carbon dioxide power cycle. AIP Conf. Proc. 2020, 2303, 130004. [Google Scholar] [CrossRef]

- Liu, J.; Chen, H.; Xu, Y.; Wang, L.; Tan, C. A solar energy storage and power generation system based on supercritical carbon dioxide. Renew. Energy 2014, 64, 43–51. [Google Scholar] [CrossRef]

- McTigue, J.; Farres-Antunez, P.; Ellingwood, K.; Neises, T.; White, A. Pumped thermal electricity storage with supercritical CO2 cycles and solar heat input. AIP Conf. Proc. 2020, 2303, 190024. [Google Scholar] [CrossRef]

- Trevisan, S.; Guédez, R.; Laumert, B. Thermo-economic optimization of an air driven supercritical CO2 Brayton power cycle for concentrating solar power plant with packed bed thermal energy storage. Sol. Energy 2020, 211, 1373–1391. [Google Scholar] [CrossRef]

- Tafur-Escanta, P.; Valencia-Chapi, R.; López-Guillem, M.; Fierros-Peraza, O.; Muñoz-Antón, J. Electrical energy storage using a supercritical CO2 heat pump. Energy Rep. 2022, 8 (Suppl. S3), 502–507. [Google Scholar] [CrossRef]

- Liu, L.; Yang, Q.; Cui, G. Supercritical Carbon Dioxide(s-CO2) Power Cycle for Waste Heat Recovery: A Review from Thermodynamic Perspective. Processes 2020, 8, 1461. [Google Scholar] [CrossRef]

- Kacludis, A.; Lyons, S.; Nadav, D.; Zdankiewicz, E. Waste Heat to Power (WH2P) Applications Using a Supercritical CO2-Based Power Cycle. In Proceedings of the Power-Gen International 2012, Orlando, FL, USA, 11–13 December 2012. [Google Scholar]

- CO2OLHEAT Project Website. Available online: https://co2olheat-h2020.eu/ (accessed on 27 July 2022).

- Lechtenböhmer, S.; Schneider, C.; Yetano Roche, M.; Höller, S. Re-Industrialisation and Low-Carbon Economy—Can They Go Together? Results from Stakeholder-Based Scenarios for Energy-Intensive Industries in the German State of North Rhine Westphalia. Energies 2015, 8, 11404–11429. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Zuberi, M.J.S. Electrification of Steam and Thermal Oil Boilers in the Textile Industry: Techno-Economic Analysis for China, Japan, and Taiwan. Energies 2022, 15, 9179. [Google Scholar] [CrossRef]

- Maccarini, S.; Barberis, S.; Mehdi, S.S.S.; Gini, L.; Traverso, A. Performance analysis of PTES layouts evolving sCO2 for industrial WHR integration. In Proceedings of the 5th European sCO2 Conference for Energy Systems, Prague, Czech Republic, 14–16 March 2023. [Google Scholar] [CrossRef]

- Shamsi, S.S.M.; Maccarini, S.; Trevisan, S.; Barberis, S.; Guedez, R. sCO2 Based Pumped Heat Thermal Energy Storage Systems Valorizing Industrial Waste Heat Recovery: A Techno-Economic Analysis of the Role of High Temperature TES. In Proceedings of the ASME Turbo Expo 2023 Turbomachinery Technical Conference and Exposition, Boston, MA, USA, 26–30 June 2023. GT2023-103080. [Google Scholar]

- Waste Heat Recovery—FIVES PILLARD—PDF Catalogs|Technical Documentation|Brochure. Available online: https://pdf.directindustry.com/pdf/fives-pillard/waste-heat-recovery/196705-752096.html (accessed on 27 October 2022).

- Lipiäinen, S.; Apajalahti, E.-L.; Vakkilainen, E. Decarbonization Prospects for the European Pulp and Paper Industry: Different Development Pathways and Needed Actions. Energies 2023, 16, 746. [Google Scholar] [CrossRef]

- Madeddu, S.; Ueckerdt, F.; Pehl, M.; Peterseim, J.; Lord, M.; Kumar, K.A.; Krüger, C.; Luderer, G. The CO2 reduction potential for the European industry via direct electrification of heat supply (power-to-heat). Environ. Res. Lett. 2020, 15, 124004. [Google Scholar] [CrossRef]

- Marchionni, M.; Bianchi, G.; Tassou, S.A. Review of supercritical carbon dioxide (sCO2) technologies for high-grade waste heat to power conversion. SN Appl. Sci. 2020, 2, 611. [Google Scholar] [CrossRef]

- Sorknæs, P.; Johannsen, R.M.; Korberg, A.D.; Nielsen, T.B.; Petersen, U.R.; Mathiesen, B.V. Electrification of the industrial sector in 100% renewable energy scenarios. Energy 2022, 254 Pt B, 124339. [Google Scholar] [CrossRef]

- Guédez, R.; Barberis, S.; Maccarini, S.; López-Román, A.; Milani, A.; Pesatori, E.; Oyarzábal, U.; Sánchez, A. Design of a 2 MW Molten Salt Driven Supercritical CO2 Cycle and Turbomachinery for the SOLARSCO2OL Demonstration Project. In Proceedings of the ASME Turbo Expo 2022: Turbomachinery Technical Conference and Exposition, Rotterdam, The Netherlands, 13–17 June 2022. Volume 9: Supercritical CO2, V009T28A008. [Google Scholar] [CrossRef]

- Niknam, P.H.; Barberis, S.; Sciacovelli, A. High temperature industrial thermal energy storage—Assessment of potential applications and benefits toward industrial decarbonization. In Proceedings of the EUROTHERM 2023 Conference, Lleida, Spain, 24–26 May 2023. [Google Scholar]

- SO-WHAT Project Website. Available online: https://sowhatproject.eu/ (accessed on 6 June 2023).

- SCALER Project Website. Available online: https://www.scalerproject.eu/ (accessed on 6 June 2023).

- Manente, G.; Ding, Y.; Sciacovelli, A. Structured procedure for the selection of thermal energy storage options for utilization and conversion of industrial waste heat. J. Energy Storage 2022, 51, 104411. [Google Scholar] [CrossRef]

- Bejan, A.; Tsatsaronis, G.; Moran, M. Thermal Design & Optimization; John Wiley & Sons Inc.: New York, NY, USA, 1996. [Google Scholar]

- Welcome to CoolProp—CoolProp 6.4.3 Documentation. Available online: http://www.coolprop.org/ (accessed on 4 January 2023).

- Baglietto, G.; Maccarini, S.; Traverso, A.; Bruttini, P. Techno-Economic Comparison of Supercritical CO2, Steam, and Organic Rankine Cycles for Waste Heat Recovery Applications. J. Eng. Gas Turbines Power 2022, 145, 041021. [Google Scholar] [CrossRef]

- Wu, D.; Wei, M.; Tian, R.; Zheng, S.; He, J. A Review of Flow and Heat Transfer Characteristics of Supercritical Carbon Dioxide under Cooling Conditions in Energy and Power Systems. Energies 2022, 15, 8785. [Google Scholar] [CrossRef]

- Stamatellos, G.; Stamatelos, T. Effect of Actual Recuperators’ Effectiveness on the Attainable Efficiency of Supercritical CO2 Brayton Cycles for Solar Thermal Power Plants. Energies 2022, 15, 7773. [Google Scholar] [CrossRef]

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A. Analysis Synthesis and Design of Chemical Processes, 5th ed.; Pearson Education: New York, NY, USA, 2018. [Google Scholar]

- Weiland, N.T.; Lance, B.W.; Pidaparti, S.R. sCO2 Power Cycle Component Cost Correlations from DOE Data Spanning Multiple Scales and Applications. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar] [CrossRef]

- Steger, D.; Feist, M.; Schlücker, E. Using a screw-type machine as reversible compressor–expander in a Carnot Battery: An analytical study towards efficiency. Appl. Energy 2022, 316, 118950. [Google Scholar] [CrossRef]

- ENTSO-E Transparency Platform. Available online: https://transparency.entsoe.eu/ (accessed on 14 August 2023).

| Item | Units | Chemical | Refinery | Paper and Pulp | Food and Beverages | Non-Ferrous Metals | Iron and Steel | Cement | Ceramics | Non-Metallic Mineral (Lime) | Glass |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Process heat Lower bound | °C | 170 | 180 | 150 | 50 | 150 | 100 | 150 | 250 | 300 | 200 |

| Process heat Higher bound | °C | 900 | 600 | 800 | 200 | 1200 | 1500 | 1200 | 1250 | 900 | 1600 |

| Reference plant average heat demand | MWh/day | 667 | 2286 | 319 | 272 | 472 | 672 | 750 | 472 | 847 | 503 |

| No. of EU industries | - | 210 | 97 | 145 | 2600 | 341 | 263 | 245 | 1302 | 108 | 360 |

| Waste heat potential | % | 11.00 | 7.40 | 10.56 | 8.64 | 9.59 | 11.40 | 11.40 | 11.40 | 11.40 | 11.40 |

| Waste heat average temperature | °C | 150–400 | 150–400 | 150–400 | 65–150 | 300–700 | 300–700 | 250–600 | 250–600 | 300–500 | 300–700 |

| Recoverable heat by TES | MWh/day | 73 | 169 | 34 | 8 | 37 | 47 | 69 | 40 | 97 | 33 |

| Process electrification rate | % | 30 | 30 | 90 | 100 | 50 | 25–75 | 20 | 30 | 35 | 30 |

| Assumptions | Value | UoM |

|---|---|---|

| TES max temperature | Between 400 and 600 | °C |

| Recuperator effectiveness | 60; 80 | % |

| Isentropic efficiency turbomachinery | 80 | % |

| Thermal losses of the TES | 1 | % |

| Electrical efficiency | 98 | % |

| Mechanical efficiency | 98 | % |

| Pressure loss in heat exchanger | 2 | % |

| Min ΔT heat exchangers | 10 | K |

| Compressor inlet temperature | 35 | °C |

| Ambient temperature | 25 | °C |

| Air temperature cooler exit | 45 | °C |

| Waste heat temperature | 330 | °C |

| Waste heat mass flow rate | 38.6 | kg/s |

| TES Material | Max TTES [°C] | Density [kg/m3] | Specific Heat [kJ/kgK] | Thermal Conductivity [W/mK] | Heat Transfer Fluid | Min Temp. [°C] | Cost |

|---|---|---|---|---|---|---|---|

| Syltherm | 400 | 548 | 2.26 | 0.064 | Oil | −40 | 4 $/kg |

| Yara Salt | 450 | 1913 | 1.43 | 0.52 | Salt | 220 | 1.5 $/kg |

| HitecXL | 500 | 1877 | 1.43 | 0.52 | Salt | 220 | 1.6 $/kg |

| Solar salt | 550 | 1740 | 1.54 | 0.5 | Salt | 250 | 1.3 $/kg |

| Concrete\air | 600 | 1008 | 1.10 | 1.9 | Air | 25 | 30 k$/MWh and 0.04 $/kg |

| CC pmin | DC pmin | TES Tmin | CC COP | DC Efficiency | DC Net Power | CC Net Power | RTE (Electrical) | RTE (Exergetic) |

|---|---|---|---|---|---|---|---|---|

| 95.5 bar | 83 bar | 222 °C | 3.24 | 22.9% | 2.18 MW | 2.98 MW | 73.3% | 38.8% |

| TES Material | TTES [°C] | TES Capacity [MWhth] | Charging Time | Discharging Time |

|---|---|---|---|---|

| Syltherm | 400 | 447 | 10 | 10.33 |

| Yara Salt | 450 | 317 | 10 | 7.91 |

| HitecXL | 500 | 253 | 10 | 6.71 |

| Solar salt | 550 | 215 | 10 | 5.99 |

| Concrete\air | 600 | 190 | 10 | 5.50 |

| Component | Syltherm (400 °C) | YaraSalt (450 °C) | HitecXL (500 °C) | Solarsalt (550 °C) | Concrete\Air (600 °C) |

|---|---|---|---|---|---|

| CC_Compressor | 7.51 | 7.56 | 7.61 | 7.66 | 7.71 |

| CC_Turbine | 1.62 | 1.69 | 1.75 | 1.81 | 1.87 |

| WH_HEX(WH-CO2) | 2.64 | 1.86 | 1.43 | 1.16 | 0.97 |

| WH_HEX(WH-TES) | - | - | - | - | - |

| DC_Compressor | 5.13 | 4.83 | 4.60 | 4.40 | 4.24 |

| DC_Turbine | 3.74 | 3.58 | 3.47 | 3.38 | 3.30 |

| DC_Air_HEX | 0.30 | 0.25 | 0.22 | 0.20 | 0.18 |

| DC_Recuperator | 1.11 | 0.88 | 0.74 | 0.63 | 0.56 |

| HOT_HEX | 9.06 | 7.24 | 6.46 | 6.01 | 5.65 |

| Thermal Storage | 13.54 | 6.52 | 6.25 | 4.10 | 10.39 |

| Total CAPEX (M$) | 44.65 | 34.43 | 32.54 | 29.35 | 34.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barberis, S.; Maccarini, S.; Shamsi, S.S.M.; Traverso, A. Untapping Industrial Flexibility via Waste Heat-Driven Pumped Thermal Energy Storage Systems. Energies 2023, 16, 6249. https://doi.org/10.3390/en16176249

Barberis S, Maccarini S, Shamsi SSM, Traverso A. Untapping Industrial Flexibility via Waste Heat-Driven Pumped Thermal Energy Storage Systems. Energies. 2023; 16(17):6249. https://doi.org/10.3390/en16176249

Chicago/Turabian StyleBarberis, Stefano, Simone Maccarini, Syed Safeer Mehdi Shamsi, and Alberto Traverso. 2023. "Untapping Industrial Flexibility via Waste Heat-Driven Pumped Thermal Energy Storage Systems" Energies 16, no. 17: 6249. https://doi.org/10.3390/en16176249

APA StyleBarberis, S., Maccarini, S., Shamsi, S. S. M., & Traverso, A. (2023). Untapping Industrial Flexibility via Waste Heat-Driven Pumped Thermal Energy Storage Systems. Energies, 16(17), 6249. https://doi.org/10.3390/en16176249