1. Introduction

The urgent need for decarbonization and the transition to sustainable energy systems has become a critical global concern due to the growing threat of climate change [

1]. As a result, the electricity sector is undergoing a major transformation, seeking innovative approaches to reduce greenhouse gas emissions while meeting the increasing demands for energy and drinking water [

2]. On the one hand, the penetration of renewable energy resources is becoming more and more attractive for small- and medium-scale energy systems, mainly characterized by electricity and low-temperature heat demands; on the other hand, the large-scale industrial sector still requires a relevant amount of medium-to-high-temperature heat—typically in the form of steam—coupled with extensive electricity consumption [

3]. In this context, among the available energy converter technology, the most promising and most adopted is the system that concurrently generates electricity and heat for the supply of multiple end-users’ demands. Accordingly, Combined Heat and Power (CHP), also known as cogeneration plants, is a promising energy conversion solution that offer several benefits, including (i) achievement of high overall energy efficiencies (or fuel utilization rate), (ii) reduction in the primary energy consumption, and (iii) mitigation of pollutant and GHG emissions, particularly CO

2 emissions, when compared to the separate generation of heat and power [

4]. The viability of a CHP system depends on the heat and electric demands of the end-user. Indeed, the environmental techno-economic assessment of CHPs may be limited if there is a mismatch between the CHP heat output and the heat quality (or quantity) required by the end-user or if there is a substantial distance between the heat generation site and the heat utilization site [

1].

One of the primary advantages of CHP plants is their significantly higher energy conversion efficiency than conventional power plants. While traditional power plants typically achieve around 35–60% [

4], CHP plants can achieve overall efficiencies exceeding 80% [

5]. This increased efficiency is a consequence of the waste heat utilization and the related process of heat quality (temperature and pressure) requirements. Indeed, heat demands can supply different scopes, such as industrial processes, district heating, and in some cases, residential applications [

6]. By maximizing the use of energy resources, CHP plants contribute to reducing fuel consumption and minimizing the associated carbon dioxide (CO

2) emissions.

The integration of CHP plants in the electrification process plays a crucial role in the decarbonization efforts by promoting energy efficiency, reducing greenhouse gas emissions, and enhancing the energy system’s resilience. As the world strives to transition to sustainable energy systems, CHP plants can provide a viable and practical solution for maximizing energy efficiency, minimizing greenhouse gas emissions, and promoting deep electrification of the energy sector.

Furthermore, CHP plants can play a pivotal role in the electrification [

7] process by providing flexible and reliable electricity availability. Indeed, as renewable energy sources, such as wind and solar, become more integrated into the grid, their intermittent nature poses challenges to maintaining a stable power supply [

8]. CHP plants, operating on controllable and dispatchable fuel sources such as natural gas or biomass [

9], can complement intermittent renewables by providing consistent and dispatchable electricity. This integration optimizes renewable energy utilization and enhances grid stability, facilitating the transition to a low-carbon electricity system [

10]. Integrating CHP plants in the electrification process is critical to achieving decarbonization goals. Indeed, CHP-based energy converters offer exceptional energy efficiency, reliable electricity generation, and substantial emissions reductions [

11,

12].

Large-scale power plants for electricity generation are typically operated in a load-following mode. It means the optimal operating strategy aims to regulate the plant to satisfy the electric load demands. When the problem is shifted to CHP units and for different plant capacities, the concurrent demand of electric and heat loads introduces a degree of freedom in the operating policies. Indeed, the CHP unit can follow the electric load, eventually requiring an additional heat source (e.g., boiler) to supply the required heat demand, or following the heat load and eventually exporting the excess electricity generated for different purposes. In the former case, once the CHP technology, installed capacity, and plant layout are selected, the potential request of excess heating power is typically generated by an auxiliary burner [

13]—for high-temperature processes—or imported if district cooling arrangement is possible—for low-temperature processes. This approach does not allow much flexibility when electrification strategies are considered. Indeed, especially looking at high-temperature processes, it becomes expensive and difficult to implement adopting different technologies from burners and boilers.

In this paper, the authors investigate a novel approach to looking at CHP plant design, where the parameters constraining the design are addressed to entirely—100%—satisfy the heat load demands thanks to the heat generated by the CHP unit. With respect to the CHP technology, installed capacity, and plant layout, the amount of electricity generated by the CHP unit can differ, being larger than the process request, allowing the CHP system to produce alternative assets, such as desalinated water [

14,

15,

16,

17] and alternative fuels [

18,

19] (hydrogen) to lead the electrification [

18,

20] process as a pillar of the entire decarbonization roadmap towards 2050 goals. The quality of the electricity produced by the CHP system also allows for the support of fast-charging stations for electromobility purposes [

7,

21,

22].

Accordingly, the authors have mapped and built up an exhaustive database (DB) of CHP technologies, including their performance indexes, capital expenditure, operating costs, range of applicability, and heat quality (pressure and maximum temperature). The authors have also analyzed and classified many industrial processes based on operating parameters [

3], such as pressure and temperature, production capacity, market segment, and the ratio between the required electricity and heat, establishing another DB related to the industrial processes.

The adoption of the two databases is the fundamental—innovative and never explored—step to support a novel optimization methodology to support the electrification process towards the 2050 pathway for net-zero energy systems by introducing innovative environmental techno-economic assessment for accounting for a circular economy and holistic life cycle assessment where concurrent generation of multiple assets such as electricity, heating and cooling, desalinated water, and alternative fuels, such as hydrogen and biomass, can be successfully exploited and deployed.

Under this point of view, the authors are proposing to explore alternative solutions for contributing to the achievement of 2050 targets, by filling the gap in the traditional implementation of CHP units for the supply of only electricity and heat. Indeed, the main concept the authors are highlighting in the paper is that today, some of the processes can be optimally performed if relying on CHP plant layout, and with minor plant modification it will be possible to generate alternative assets (with the same primary energy source), which otherwise would have been produced with additional request of electricity or fuel with a consequent increase in the CO2 emitted.

After a deep description of the technical background where the authors describe the foundation of the innovative DBs developed, the methodology for performing the optimization is described in detail, highlighting the fundamental parameters for accomplishing an exhaustive environmental techno-economic analysis and emphasizing how the concurrent production of multiple assets changes the CHP design optimization paradigm. Once the methods and modelling approach are presented, the authors investigate ten CHP plant configurations with different production capacity. The results of the environmental techno-economic analysis are presented and analyzed in detail.

2. Technical Background

When dealing with integrating the optimal CHP plant layout and its related installed capacity in the electrification pathways, one of the more difficult challenges lies in the establishment of the optimal match between end-user demands—in terms of heating and cooling, electricity, and other assets such as water and hydrogen—and the most suitable environmental techno-economic CHP plant configuration. It is crucial to characterize the industrial process constraints, CHP plant configuration, and related performances to achieve optimal integration between demand and supply. Accordingly, the authors present the fundamental steps required to preliminarily define the CHP plant layout optimization framework in this section:

Characterization of industrial processes and related demands;

Characterization of CHP technologies, plant layout, and related performance indexes.

The outcome of this deep-tech analysis carried out by the authors has allowed the formalization of three databases (DBs) that are implemented in the modelling approach proposed by the authors in

Section 3.

2.1. Characterization of Industrial Processes

Industrial facilities benefit from adopting CHP units due to promising results in reducing primary energy consumption and costs. Indeed, many R&D projects have been funded and sponsored in recent years to optimize these units for industrial applications. Accordingly, looking at the up-to-date state of the art (SoA), [

23] conducted a study on optimizing various cogeneration plants to feed the cement industry demands, focusing on waste heat recovery. The authors of [

24] analyzed different production processes in the paper industry and proposed technical solutions to enhance overall efficiency. Cogeneration systems were identified as the most suitable approach, as [

25] emphasized in their Austrian case examination, where minimizing energy costs was crucial for effective energy management. The authors of [

14] explored enhancing a multiple-effect distillation system coupled with thermal vapor compression desalination. They compared steam plant-based solutions with varying steam extraction pressures and evaluated the impact based on current European regulations.

Their findings show a nearly linear increase in CHP electricity production with the number of distillation units supplied. However, they expressed concerns about the significant influence of the chosen efficiency values on primary energy savings.

Looking at European industrial processes where CHP technologies are implemented, the authors of the present paper have analyzed and extrapolated the electrical and thermal consumptions of different industrial sites through a deep SoA investigation. Accordingly, such a characterization has been performed, taking into consideration the following CHP applications in the European context:

- ➢

- ➢

- ➢

food, drink, and milk industry [

26,

27];

- ➢

ceramic manufacturing industry [

28];

- ➢

refining of oil and gas [

29].

The characterization also takes into account worldwide available data looking at the production of the following:

- ➢

- ➢

rubber and plastic industry [

1];

- ➢

other relevant industries [

32].

As a result of the exhaustive SoA analysis carried out by the authors and relying on confidential data shared by the Italian Authority of Energy Services (

https://www.gse.it/ (accessed on 27 April 2023)), the development of a database (

DBPROC) related to the characterization of the demands of the industrial processes has been performed.

The database has been built up considering multiple industrial processes and the related yearly load demands (electric and heat). In order to quantify equivalent yearly average consumption, the authors have adopted a coarse-graining procedure for summarizing a specific consumption for the electric load and a specific consumption for the heat load . These specific consumptions, coupled with the capacity of the production process, allow for the definition of design constraints required to be matched by the CHP unit. The authors have classified, with respect to the electricity and the heat demands, four classes of processes characterized by the same heat-to-power ratio , and distinguished by their specific consumption per ton of product. These ten categories represent various industrial sectors, with the food sector being particularly prominent due to its wide range of products. The yarn, paper, and pharmaceutical industries stand out as sectors with the highest heat demand.

2.2. Characterization of CHP Layout and Plant Layout

Investigations of high-efficiency CHP plant solutions have been conducted in [

5,

33]. The contribution towards the international scientific community given by this paper is related to the evaluation and systematic analysis of the optimal CHP technology [

34,

35] that can be coupled with the industrial process described in

Section 2.1. The conceptual criterion for identifying the most suitable CHP technology to meet the various industrial processes has been described by [

5]. Moreover, in [

4], the authors have investigated CHP technologies’ performance in the EU legislative context, focusing on the splitting of the cogeneration unit in two virtual parts, the CHP part and non-CHP part, by using the power loss coefficient β. This parameter accounts for the electricity loss due to steam extraction for heat production. The power loss coefficient affects the techno-economic performance of CHP technologies, and the authors gave an exhaustive evaluation of the Italian case [

36].

Accordingly, [

37] has investigated the influence of such parameters on CHP electricity and primary fuel consumption, stating that this factor, along with the nominal (reference) efficiency, is crucial in assessing the CHP plan layout profitability.

Accordingly, the authors have presented an extensive analysis of the technologies and of the power loss coefficient influences. In addition to this, the authors have also taken into consideration the introduction of additional plant components for ensuring the concurrent generation of multiple assets, such as drinking water and e-fuel. An exhaustive description of the technologies taken into consideration for the optimization process and the related environmental techno-economic assessment is presented as follows:

Internal Combustion Engines (ICEs): In this study, the heat recovery generated from the exhaust gases and the engine’s water/oil circuit has been considered. Accordingly, it has been assumed that this heat, under the form of steam, is delivered at temperatures ranging from 150 °C to 300 °C.

Gas Turbines (GTs): like ICEs, GTs in cogeneration setups have β = 0. The adopted model takes a traditional configuration with a topping GT cycle and a bottoming heat recovery steam generator fed by the GT exhaust gases. Also, in this case, the steam is provided at temperatures ranging from 150 °C to 300 °C.

Steam Power Plants with Backpressure Turbine (SPP-BPT): Like ICEs and GTs, SPP-BPT plants have β = 0. The proposed technology includes a fossil fuel boiler (using natural gas), a steam turbine, and a deaerator. The model accounts for final turbine pressures ranging from 5 to 40 bars for different heat quality conditions.

Steam Power Plants with Condensing Turbine (SPP-CT): SPP-CT plants have β > 0. In this case, the proposed model accounts for a plant configuration equipped with a fossil fuel boiler (using natural gas), a steam turbine, a condenser, and a deaerator. Also, in this case, the pressure levels range from 5 to 40 bars, representing different heat quality conditions.

Combined Cycle Power Plants with Condensing Turbine (CCPP): In CHP setups, CCPP plants have β > 0. The proposed configuration includes a GT, a heat recovery steam generator with two pressure levels, and a steam section with a condensing turbine and condenser. Simulations were conducted for extraction pressures ranging from 5 to 40 bars to represent—also in this case—various heat quality conditions.

Electrolyzer for H

2 Production: The model includes the electrolyzer and the H

2 storage tank. These components work together to enable hydrogen production and storage. The model considers operating parameters such as the electrolyzer efficiency (η

ELY), the State of Charge (SOC

H2ST), and the maximum storage capacity (E

H2ST) of the H

2 storage tank. The cost of an electrolyzer [

18] is largely determined by the technology employed (such as alkaline or polymer electrolyte membrane), the capacity for producing hydrogen per hour, the operating pressure, and the efficiency of the system; accordingly, the functional expression for establishing the capital expenditure related to the electrolyzer is given as follows:

The hydrogen storage tank is also considered in the definition of the electrolyzer cost. The cost of the storage tank is established based on several factors, including the capacity of the tank, the insulation properties, and the operating pressure.

- 7.

Water Desalination Section: The authors have considered a desalination section based on reverse osmosis. Reverse osmosis (RO) is an electric-driven desalination process where the fresh water passes through semi-permeable membranes under high pressure and leaves behind a highly concentrated brine solution [

38]. Due to the simplicity and relatively low energy consumption and energy cost, more than 50% of the installed desalination plants are based on RO systems, mainly forsmall and medium-sized capacity plants globally. However, on the status of materials, modules, and technology, the energy consumption ranges between 2 and 5 kWh/m

3 [

15,

17,

39]. Several layouts were developed regarding CHP systems aiming to produce desalinated water by RO units. For example, the direct power production of natural gas turbines can be used to drive a seawater reverse osmosis desalination process. An RO desalination unit using energy recovery is integrated into a CHP layout.

The characterization of CHP technologies and related additional components for the generation of multiple assets, such as drinking water and hydrogen, allowed the authors to develop a database (

DBTECH)—similar to one of the industrial processes—related to the CHP technologies. The capacity of the CHP plant to generate electricity and heat concurrently has been defined by a non-dimensional parameter that accounts for the ratio between heat versus the electricity generated by the CHP unit. This ratio

allows us to quantify, for a given amount of heat produced by the CHP plant, the corresponding amount of electricity generated. Another important parameter used for classifying the CHP technology is the global efficiency

, which correlates the electricity and heat generated to the primary energy injected into the CHP unit with the fuel

; it is defined by the following equation (Equation (2)):

The DBTECH has been realized, also taking into consideration the fact that different CHP technologies and their application for small or large applications have practical effects on the two parameters just defined. Indeed, the DBTECH structure is based on the nominal capacity for ICEs and GTs, while it takes into account heat quality (temperature level, high and low) in the case of plants such as SPP-BPT, SPP-CT, and CCPP. The reason behind these assumptions resides in the fact that ICE and GT performance is primarily influenced by the CHP plant capacity rather than the quality of heat demanded by users. On the other hand, solutions utilizing steam cycles (SPP-BPT, SPP-CT, CCPP) are considerably affected by both the quality and quantity of heat they produce. Adjustments related to weather conditions and electric grid connection tension values have yet to be considered to simplify the analysis.

The proposed

DBTECH also includes information related to the financial indicators, such as specific capital (CAPEX) investment per installed capacity, the maintenance factor (

fMAIN), and, on the other hand, fundamental information related to the emissions factors (

fCO2), the carbon tax, and others summarized in

Table 1. Accordingly,

Table 2 provides the CHP parameters characterizing each cogeneration technology. The parameters are associated with power plant sizes: ICE (Pe > 100 kW), GT (Pe > 1500 kW), SPP (Pe > 3 MW), and CCPP (Pe > 20 MW).

Looking at the electrolyzer and reverse osmosis desalination plant component specifications, the authors have summarized in

Table 2 the main parameters required by the optimization, such as the CAPEX, the specific consumption, and the financial indicators.

3. Materials and Methods

In this section, the authors describe the methodology to build up the model for evaluating the environmental techno-economic KPIs (e.g., CO

2 Emission, Net Present Value, Pay Back Period, etc.) to identify the most promising innovative CHP plant layout among different options. Indeed, by changing the paradigm in the operating strategy of the CHP plant, it is possible to generate multiple assets such as drinking water, e-fuels, and electricity for the electromobility while ensuring the satisfaction of the electricity

and heat

demands required by each process presented in

Table 3.

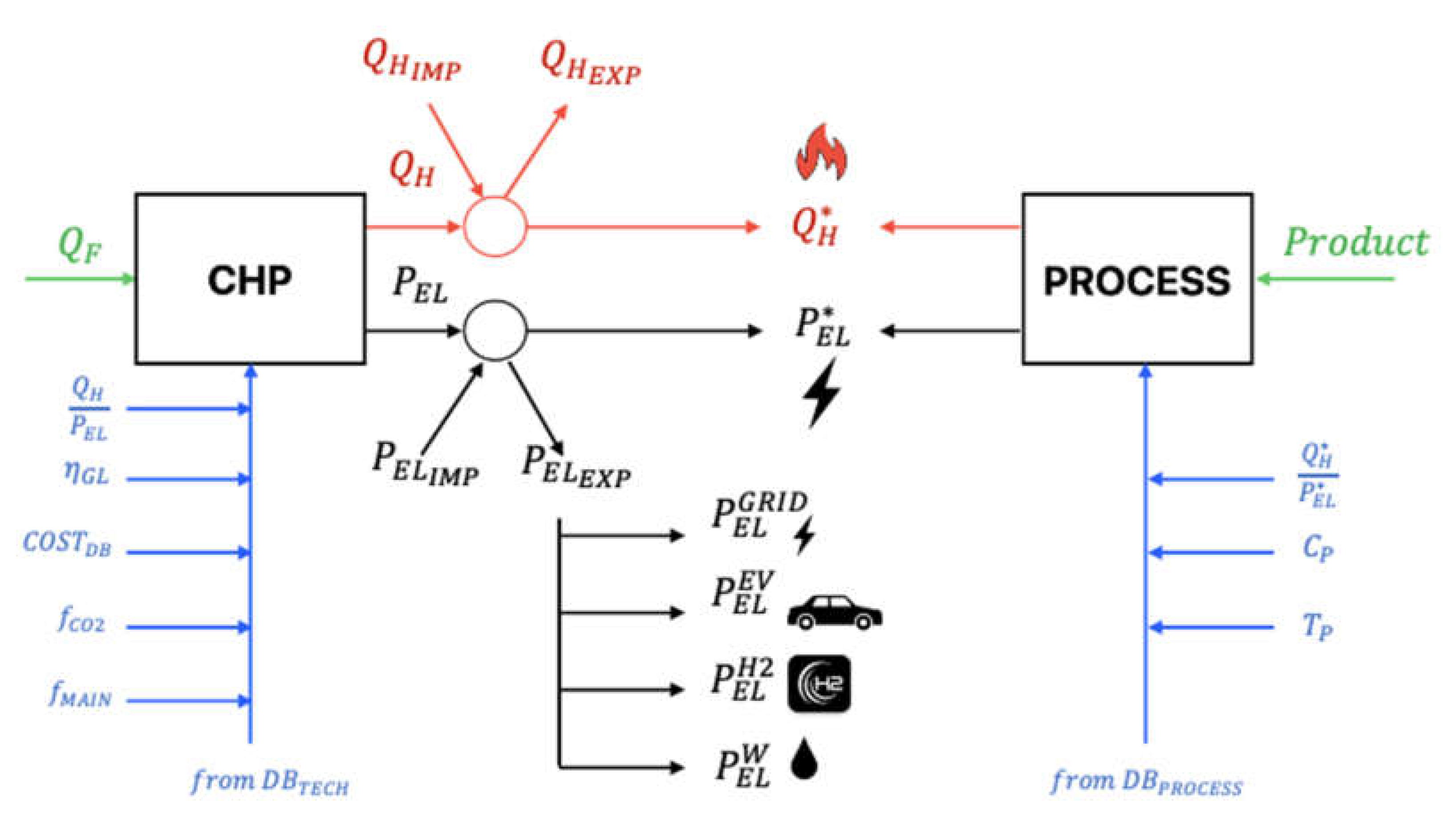

In

Figure 1, the authors have sketched out the scheme of the proposed model for exhaustively evaluating the functional parameters and the output variables required for performing the environmental techno-economic assessment. The concept behind the proposed layout is that the outlet variables from the CHP block (

and

) need to match the outlet variables of the process block

and

, to satisfy the energy demands. Since the system made of the CHP plant and the industrial process can interact with other sub-systems (e.g., national grid, district heating, auxiliary boilers, desalination units, etc.), the model allows for accounting for the possibility of exporting and importing electricity and heat, by integrating two nodes on both electricity and heat buses.

The model has been built by considering a zero-dimensional steady-state grey box model, where mass and energy conservation equations have been implemented for describing the system behavior. The source and sink terms of the various equations and the model attributes have been collected and stored in dedicated DBs, related to the CHP and process, respectively, as described in the previous paragraph.

Indeed, by means of Equation (3), the database related to the CHP technology

allows us to determine, for each CHP technology, the heat-to-power ratio of the CHP

, the global efficiency

, also called fuel utilization rate, the capital cost per unit of production (e.g., EUR/kW), the operating costs (EUR/kWh), and the maintenance cost

, expressed as a fraction of the capital cost and the emission factor

.

The other

related to the process specification allows us to correlate the process’s heat-to-power ratio

to the process’s typology and to the production capacity

of the process. Equation (4) summarizes the

.

The heat-to-power ratio and the global efficiency of the CHP plant are used to solve the energy conservation equation, as shown by Equation (5), by relating the heat injected with the fuel

to the heat generated

.

In order to evaluate the imported and exported quantities for electricity and heat, the energy conservation equations on the two nodes, related to the heat bus and the electricity bus, are expressed by Equations (6) and (7), respectively.

The model has been formulated to be capable of simulating all the potential configurations of injection and extraction of energy flows, even if, for the specific paper, it has been assumed that no heat can be exported (

). The CHP design strategy is addressed to satisfy the heat balance while allowing the production of more electricity than that required by the process

. In this configuration, it is automatically established that no imported electricity is required (

), while some exported electricity

can be available for supplying the national grid (

j = 1), the electromobility (

j = 2), or the electricity demands of electrolyzers (

j = 3) for H

2 production or of desalination plants (

j = 4), if drinking water is required. In a general form, the excess of electricity can also be split among the different utilizations proposed in this paper by satisfying the energy conservation equation on the export bus, as summarized by Equation (8).

where the different scopes investigated are characterised by different indexes and different weights

w, where j = 1, …, 4 represent the different scopes.

Equations (11) and (12) require a further step to quantify the environmental and economic benefits of generating hydrogen and drinking water via CHP electricity excess by correlating the electricity to the mass flow rates per hour. Accordingly, the electrolyzer and desalination components have been modelled by means of two transfer functions

,

derived by data available in the scientific literature [

17,

39,

40,

41] that correlate the produced assets (drinking water and hydrogen) to the related electricity consumption. Accordingly, the hydrogen and water production are expressed by Equations (13) and (14), respectively.

The evaluation of quantifiable assets to be included in the formulation of the environmental techno-economic assessment also requires establishing the evaluation of the carbon emissions produced by the CHP plant layout, as described by Equation (15)

and of the carbon emissions avoided, expressed as a carbon credit by Equation (16):

In Equations (15) and (16), the carbon emissions and the carbon credit are evaluated as the integral value of the CHP plant operations of the specific emissions factor multiplied by the assets of each process. The emission factors of the different processes have been assumed according to the most up-to-date standard related to verification and certification authorities, such as the GHG protocol, Verra and Gold Standards [

42], and it has been assumed that

and

have the same value.

From the economic point of view, the evaluation of the capital investment (

) plays an important role in the full accomplishment of the environmental techno-economic assessment, and they are expressed as in (17):

where

is the capital investment, expressed in EUR, of each component constituting the CHP plant layout. According to the authors, in

DBTECH,

is established as the product of the specific cost of the technology

), expressed in EUR/kW, and the related Nominal Capacity (

NC), expressed in kW. Equation (18) allows us to better understand what was just expressed.

Looking at the yearly CHP plant operations, the yearly cash flow (

CFy) requires the definition of revenues (

R) and operating expenditures (

OPEX). Accordingly, Equation (19) describes the sum of all the CHP plant layout-related revenues.

where the revenues related to the utilization of the exceeding exported electricity are summarized by Equations (20)–(23), while Equation (24) shows the potential contribution of the tokenization and bankability of the carbon credit.

On the other hand, looking at the CHP operating costs (

), the main contribution to the definition of these terms is related to the plant maintenance

, the carbon tax

, and the consumable costs

. Fuel consumptions and the purchase of electricity and heat, if required, are the terms related to the CHP plant technology and can be calculated thanks to the proprietary

DBTECH developed by the authors. Accordingly, Equation (25) expresses exhaustively the yearly

:

The maintenance costs are calculated—as per Equation (26)—based on the maintenance factor

given in the

DBTECH:

The carbon tax is established as the product of the carbon emission

—defined in Equation (27)—over the year multiplied by the specific carbon tax (

):

The running (consumable) costs are calculated for the different assets as the product between the specific cost per unit of the yearly quantity, as expressed in Equation (28):

The comparison between the CHP plant layout and the separated generation of the assets required by the processes is part of the investigation carried out by the authors. The model allows for the computation of the consumptions for generating the process assets in terms of electricity and heat by taking into account the reference national grid efficiency and the traditional efficiency of a natural gas-fed boiler. Accordingly, the primary energy savings, the reduction in carbon emissions, and the environmental techno-economic analysis can be completely carried out.

The proposed methodology takes into consideration the fact that investors and stakeholders typically use financial indicators such as Net Present Value (NPV), Internal Rate of Return (IRR), Discounted Payback Period (DPBP), and Total Cost of Ownership (TCO) to evaluate the viability and risk of a project.

Accordingly, the authors have implemented the calculation of two financial indicators in the model. One—the most used financial indicator for determining the feasibility of a project—is the Net Present Value (NPV). This parameter considers various factors such as the yearly cash flow, the interest rate, inflation, and the system’s lifetime. It is calculated by subtracting the yearly costs from the yearly revenues. The compact formulation adopted by the authors for describing the

NPV is presented in Equation (29):

The other—the Discounted Payback Period (DPBP)—is a metric that determines the number of years needed for the Net Present Value (NPV) of a project to reach zero, as presented in Equation (30):

This financial indicator is useful for assessing the risk of an investment and also for understanding the potential for growth in revenue. For example, if two projects have the same NPV, the project with the shorter DPBP will generally have a higher return on investment over the lifetime of the project. Additionally, a shorter DPBP also means less exposure to risk.

4. Case Study

In this section, the authors present the overall matrix of the configurations (calculations) investigated and analyzed in the paper, together with the assumptions and the input parameters required by the proposed optimization model to perform the environmental techno-economic assessment. Accordingly, the case studies have been built up following the steps given below:

Electricity and heat demands of the process are established adopting the DB

PROCESS given in

Table 1;

Definition of the CHP Plant Operating Strategy (100% satisfaction of the heat demands, in the case of this paper);

Definition of the CHP technology and related capacity, together with the CHP performance (e.g., efficiency, specific CO2 emissions factor, etc.), as per DB

TECH given in

Table 2;

Evaluation of the excess of the electricity generated by the CHP unit, once the heat demands are completely satisfied;

Environmental techno-economic assessment, taking into consideration the parameters given in

Table 4.

In order to establish the entire domain of the optimization, the authors have defined the overall matrix of the investigation, depending on four parameters:

- (1)

Number of Case Studies → 4;

- (2)

Number of CHP Plant Layouts → 5;

- (3)

Number of Industrial Processes → 10;

- (4)

Number of Production Capacities → 3.

The overall number of the explored configurations (not all feasible) is 600 (4 × 5 × 10 × 3), requiring significant computation time and costs. Accordingly, in this section, the authors describe the parameters adopted in defining the configuration matrix. First, the authors have proposed four (4) cases (A1, A2, B1, B2) that differ from the utilization of the excess amount of electricity generated by the CHP unit:

CASE—A1: Export to the Nation Grid;

CASE—A2: Export to EV Charging Station;

CASE—B1: Export for H2 production through the Electrolyzer;

CASE—B2: Export for W production through the RO Desalination Plant.

Second, according to

Table 2, the authors have investigated five (5) CHP technologies based on Large ICE, GT, High-Temperature CCGT, SPP-BPT, and SPP-CT. Third, the authors have combined the cases (A1 to B2) with the CHP technologies (1 to 5) to supply the heat and electricity demands from the industrial process. Also, in this case, for all ten (10) industrial processes described in

Table 1, the authors have considered three (3) production capacities, in terms of the number of products per process, classified as small production (SP = 1000 units), medium production (MP = 50,000 units), and large production (LP = 400,000 units).

In order to run the optimization, calculate the optimal CHP installed capacity for all scenarios in terms of power and heat, carbon emissions, DPBP, NPV, and the overall plant investment (I =

), assumptions related to import, export, and carbon tax costs have been made by the authors, according to the data available in the SoA. Indeed, some of the variables introduced in the previous section related to the cost of importing and exporting electricity, heat, and the additional produced assets such as drinking water and H

2 are the parameters required to perform the economic evaluation of the CHP plant layout operating costs and revenues. Accordingly, in

Table 4, specific costs/prices for a unit of imported and exported assets are summarized, together with the assumption related to the Grid Emission Factor and of the price of the carbon emissions in terms of Carbon Tax.

Results and discussion of the optimization outcome on the best solutions for reducing pollutant emissions, maximizing the NPV, and ensuring CHP layout reliability and availability are given in the next section.

5. Results and Discussion

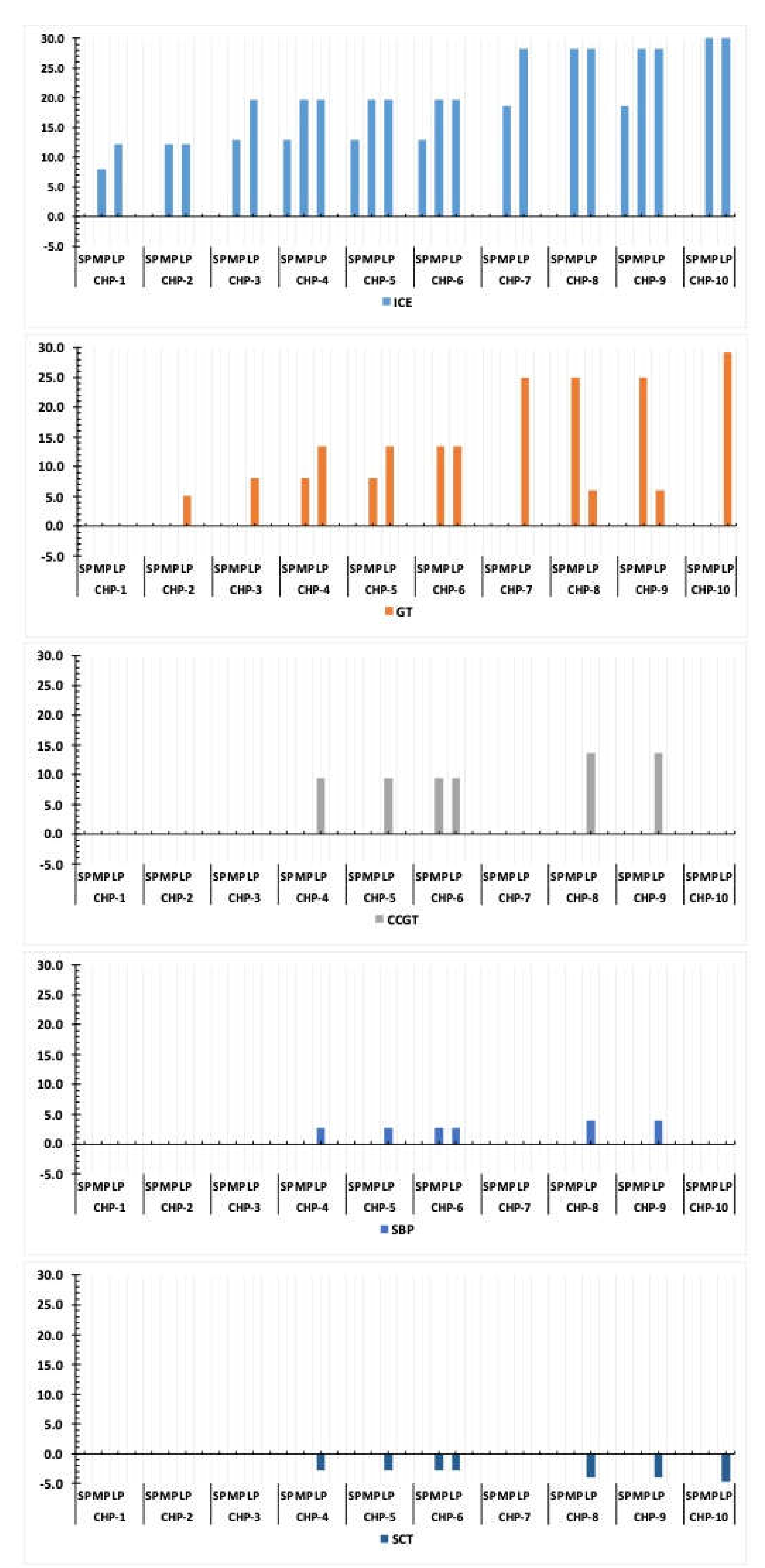

As a benchmarking step, prodromic to the full exploitation of the investigation described in

Section 4, the authors have compared the carbon emissions generated in the scenario in which heat and power are produced separately with the five (5) CHP technologies for all ten (10) industrial processes described in

Table 1 and for the three production capacities. Indeed, the comparison encompasses the fact that, in the separated production, the electric and heat demands of the industrial process are supplied by the electricity imported from the national grid—characterized by its efficiency and generally lower when compared with the large CCGT power plants—and from boilers fed by natural gas. Details of the procedure for evaluating the CO

2 emissions savings between separated production and combined heat and power production have been deeply discussed by the authors in [

4,

5], while in this paper, the attention is focused on the comparison between the different CHP plan layouts. Accordingly, for the purposes of the paper, we investigate the CHP contribution to the electrification pathway. The authors present the results of the benchmark in

Figure 2, where for each CHP technology (ICE = light blue; GT = orange; CCGT = grey; SBP = blue; and SCT = dark blue), for 10 industrial processes (CHP-1 to CHP-10), and for each production capacity (SP, MP, and LP), the CO

2 savings are depicted. The comparison between separated and CHP production allows us to establish the percentage of the CO

2 savings related to the adoption of CHP technologies, leading to an immediate understanding of which combinations have the greatest potential to support the transition to net-zero targets, including the adoption of CHP solutions in the electrification process. Not all the configurations are viable for CHP integration, and this aspect is formalized graphically by the fact that in

Figure 2, not all candlesticks are available. The reason for this trend resides in the fact that the heat-to-power ratio of some industrial processes, especially when massively unbalanced to the heat generation, are not suitable for the specification of a well-defined CHP technology.

Accordingly, it can be observed that for the ICE and GT, almost all the industrial processes can benefit of the adoption of CHP technology, while for larger CCGT, SPP-BPT, and SPP-CT, the cogeneration configuration poorly contributes to CO2 emission reduction.

From the analysis of the numbers shown in

Figure 2, it can be observed that for larger production capacity, especially looking at paper and refinery industrial processes, the implementation of CHP technologies based on ICE and GT allows for massive CO

2 savings of up to 30%. The reason for these promising results resides in the fact that the heat-to-power ratio of those processes ranges between 2.0 and 3.0 and matches well with the capability of ICE and GT to support the cogeneration processes mainly oriented to heat supply. On the other hand, CCGT plants allow for up to 15% CO

2 savings, but for industrial processes characterized by an even ratio between heat and electricity supply. As mentioned before, the steam plants do not ensure massive CO

2 savings, since the systems are designed to produce mainly electricity, and only by sacrificing the steam turbine performance can the plant support a more unbalanced production towards industrial heat process.

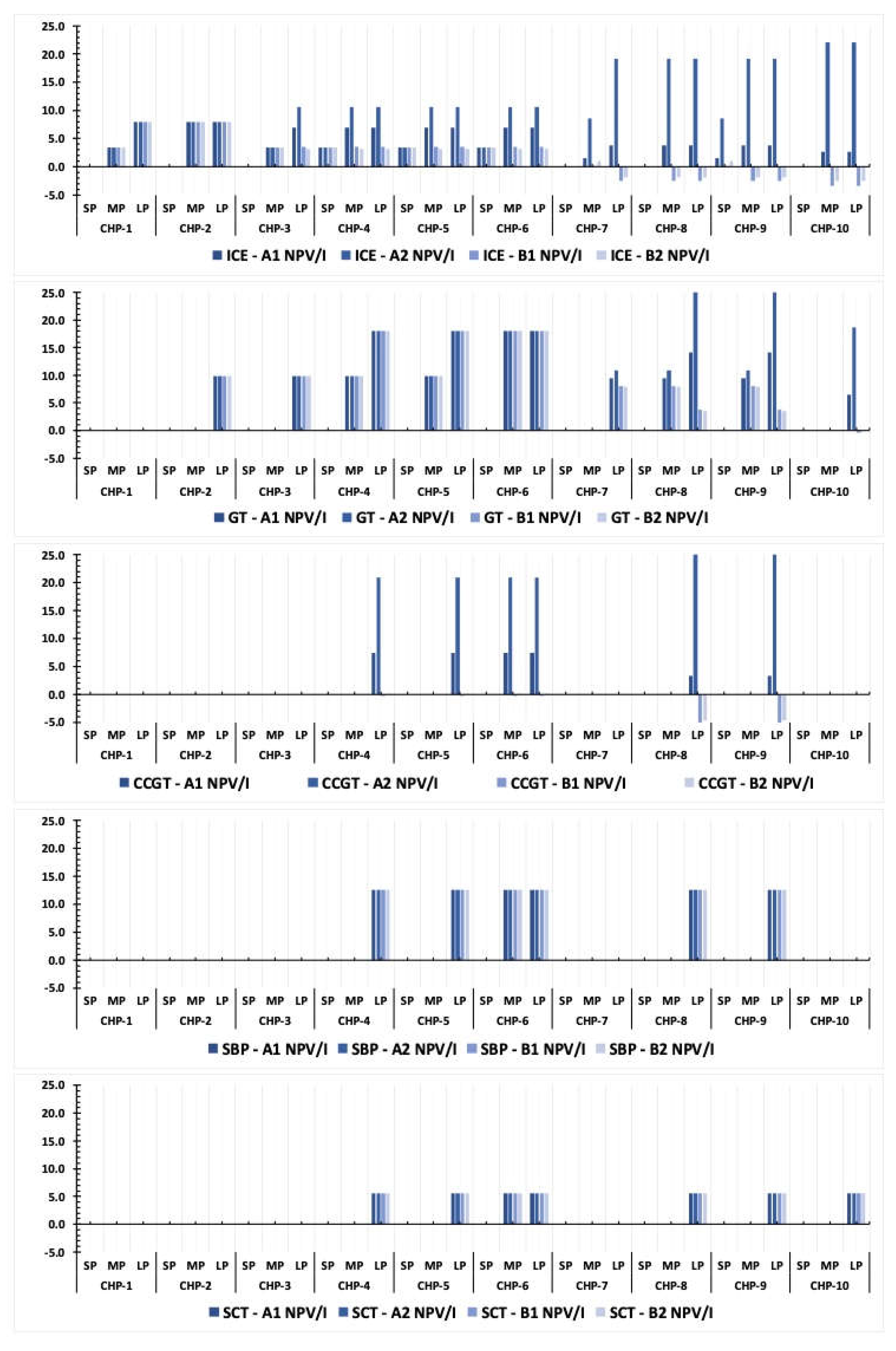

This preliminary analysis is the foundation for supporting the results obtained from the optimization of innovative CHP plant layouts addressed to supply additional assets to the heat and electricity demands of the industrial process. According to the description provided in

Section 4, the authors have presented the optimization results comparing each chart of

Figure 3,

Figure 4, and

Figure 5, and the case studies (A1, A2, B1, and B2), characterized by different shades of a similar color. In

Figure 3, characterized by grey candlesticks, the authors have compared the DPBP for the five (5) CHP technologies and all the cases (10 industrial processes * 3 production capacities). In

Figure 4 and

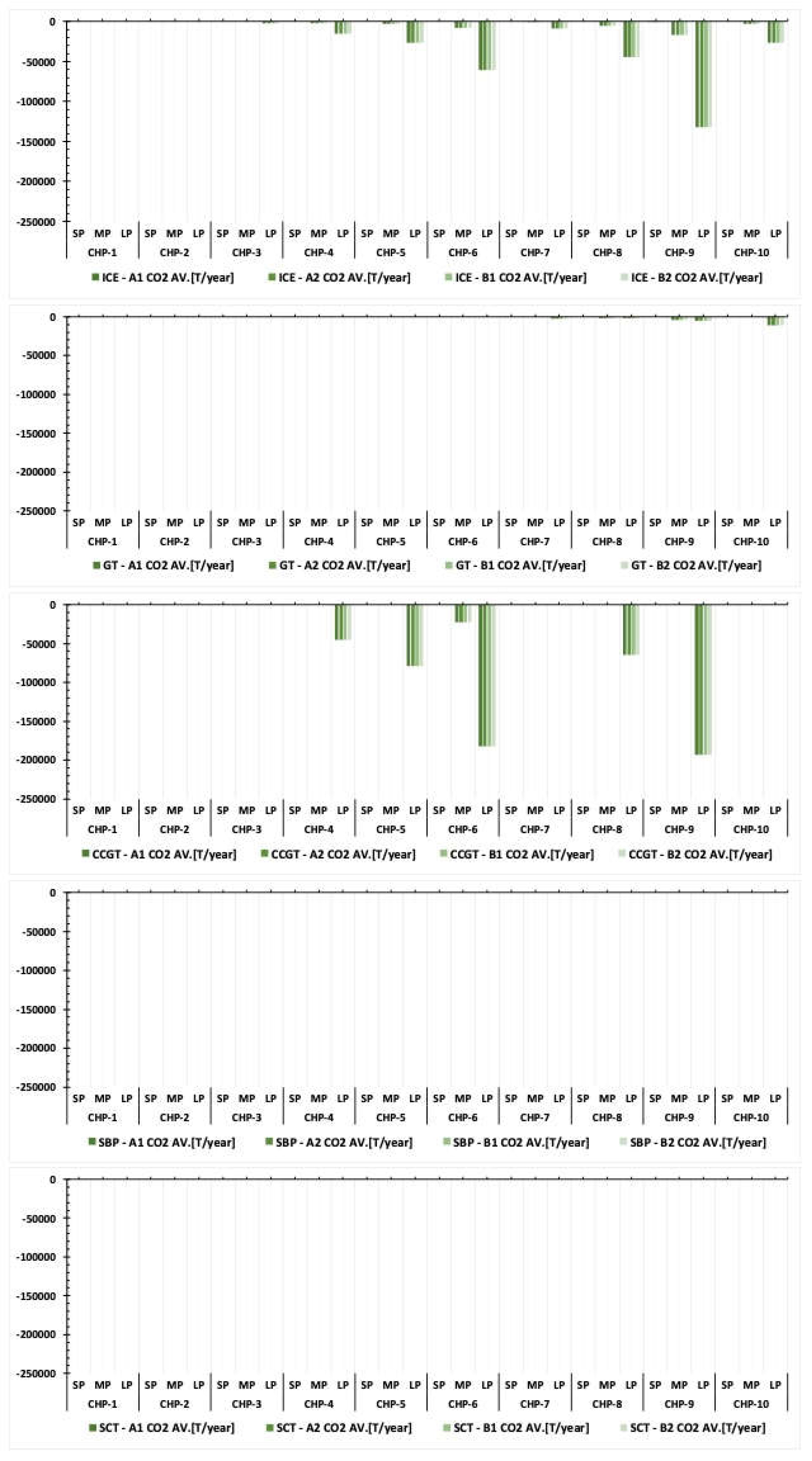

Figure 5, characterized by blue and green candlesticks, respectively, the authors have summarized the results in terms of NPV divided by the investment and the carbon credits. The carbon credits have been evaluated by considering that the various assets have been directly obtained by means of the CHP unit.

The results in

Figure 3 show that, according to the industrial process classification given in

Table 1 and the related heat-to-power ratio, the ICE and GT are the CHP technologies that show the shorter DPBP. The DPBP for cases A1 and A2 is always positive. At the same time, for B1 and B2, the integration of additional plant equipment, such as the electrolyzer and the RO desalination plant, does not allow us to have a feasible DPBP during the entire lifespan of the plant’s operation. The authors have presented these results with a ‘negative’ DPBP for differentiating unfeasible solutions from the CHP technology perspective (that have not been depicted at all) and from an economic standpoint. Indeed, those solutions could become viable if incentives and environmental agencies and regulators find mechanisms to reward the CHP plant layout flexibility in concurrently generating multiple assets.

Taking the large-scale and high-temperature CCGT configuration into account, the CCGT’s larger capacity introduces significant investment also on the components for H

2 and water production, making the solution viable from an environmental perspective—as can be seen in

Figure 5—where the same configuration allows for up to 200,000 tons’ credit of CO

2 per year. In all the charts of

Figure 3, it can be observed that case A2, characterized by the support to electromobility, where the export of electricity is highly rewarded (0.7 EUR/kWh), the DPBP is always the shortest, and it matches perfectly the trend presented in NPV/I charts, in

Figure 4.

SPP-BPT and SPP-CT are characterized by larger DPBP when compared to the other technologies, since the heat-to-power ratio of the technology does not allow for a significant amount of kWh per year of electricity exported. For this reason, the DPBP agrees with the typical DPBP of similar plants, about 5–7 years.

The DPBP is strictly correlated with the NPV, and results expressed in a non-dimensional form of NPV/I are presented in

Figure 4. This non-dimensional parameter gives information about the lifespan profitability of the configuration. Indeed, the higher the ratio, the higher the profitability.

Due to the large capacity and flexibility of the GT CHP layout, it can be observed that for pharmaceutical, food and beverage, and paper large industrial process production, the GT and CCGT CHP technology in case A2—where electromobility is supported by the excess of electricity—allows for NPV/I values up to 25. These numbers are deeply promising since, assuming 20 years of CHP plant layout lifespan, the internal rate of return is much higher than the bank interest rate or well-performing hedge funds.

It is worth noting that for the same combination, cases B1 and B2 also become viable, and this is a remarkable outcome since the economic viability of H2 and water generation systems is still debatable, and the scientific community is working hard to reduce the generation cost for making the electrification and decarbonization viable under different perspectives.

The economic viability of the solutions, supported by

Figure 3 and

Figure 4, is not sufficient for fully understanding the environmental impact of the innovative CHP technologies towards the electrification process and consequently towards 2050 targets. Accordingly, results in terms of carbon avoidance of generating the excess of electricity thanks to the CHP technology versus generating from the grid are reported in

Figure 5. Combining the analysis described at the beginning of the paragraph described in

Figure 2 with the results given in

Figure 3,

Figure 4 and

Figure 5, it is clear that ICE and CCGT CHP technologies are the most capable solution for effectively supporting the electrification pathway.

Indeed, it can be observed that the CHP-9 configuration, when equipped with ICE, allows for 150,000 tons of CO2 per year of carbon avoidance, while the CCGT configuration allows for 60% more avoidance, leading to up to 200,000 tons of CO2 per year. The carbon avoidance can be seen as a sort of carbon credit, since it represents the reduction in the overall CO2 footprints that an innovative CHP plant layout can achieve when compared with the separated generation or with the production of the required assets in a traditional way. SPP-BPT and SPP-CT do not contribute to carbon avoidance due to the heat-to-power ratio of the technology. Similarly, the GT technology in the simple configuration provides minimal carbon avoidance only for the CHP-10 industrial process.

6. Conclusions

The paper aims to investigate the role of CHP technologies in the electrification process to support the energy transition towards cleaner and more environmentally sustainable energy systems. Traditionally, CHP plants support the industrial process demands for electricity and heat by adopting operating strategies addressed to designing the CHP unit based on the electricity or heat demands, without considering the possibility that multiple assets such as high-tension electricity for electromobility, hydrogen, and desalinated water can be concurrently generated with the utilization of the same primary fuel source.

Accordingly, to fill the gap in the existing state of the art, the authors have presented a novel modelling approach based on an extensive database for industrial processes and CHP technologies. The proposed approach allows for systematic computations and environmental techno-economic assessments. Indeed, after having developed an up-to-date database for the most effective CHP technologies (e.g., ICE, GT, CCGT, SPP-BPT, and SPP-CT) and industrial process of different typologies (e.g., refinery, food and beverage, paper, iron, etc.), the authors have proposed a novel algorithm to perform a complete and exhaustive environmental techno-economic assessment. In addition, the definition of environmental and economic parameters has been adopted in order to perform an exhaustive optimization process. Accordingly, more than 600 configurations for small, medium, and large industrial production have been explored.

The optimization results have been presented, highlighting how, from the technological standpoint, the implementation of Internal Combustion Engines and the Gas Turbine Combined Cycles are the most promising CHP technologies for achieving reliable and environmentally friendly electrified novel CHP plan layouts. Indeed, by implementing innovative and suitable plant configurations, for satisfying the various processes’ demands, up to 250,000 tons/year of CO2 can be avoided when electricity for electro-mobility, hydrogen, and desalinated water are produced by the CHP unit. Indeed, the optimization has been performed, constraining the CHP heat production to be equal to the industrial process demand. Thus, the excess of electricity has been established, and the design of the CHP unit has been obtained.

From the economic perspective, under a carbon tax price of EUR 100/ton of CO2, the avoidance of 250,000 tons/year leads to up to EUR 25 M saved on the system operations owing to carbon credit mechanisms. On the economics of the various CHP plant layouts, the additional initial investment for generating hydrogen and drinking water still limits the development of novel—more integrated—CHP plants, where longer payback times of up to 20 years are observed. On the other hand, the utilization of excess electricity for supplying fast-charging stations for electromobility looks promising, ensuring a payback period shorter than two years and NPV 25 times larger than the investment.

In summary, the results of the techno-economic optimization have led to identify in internal combustion engines and in CCGTs the most promising CHP layout for ensuring up to 250,000 tons/year of CO2 emissions avoided when concurrent generation of multiple assets is ensured. The economic viability of the various solutions allows for up to EUR 25 M savings related to carbon tax and relatively high NPV, up to 25 times the related investment.

The paper represents a first step towards investigating the role of CHP plants in the electrification process. Indeed, the authors have mapped various industrial processes and the CHP technologies, building a novel database. In this workload, demands are assumed to be constant over the year. The next step for tailoring the solutions to a specific industrial process is to run a scenario analysis—with the proposed model—varying the main financial parameters, such as the import and export price of the various assets and identify which industrial process shows the maximum benefit related to the integration of innovative CHP plant layouts. Once the process is established, it will be required for hourly load profile optimization to identify the optimal CHP design, and a master-planning optimization will be carried out.