Effect of Rotating Channel Turning Section Clearance Size on Heat Transfer Characteristics of Supercritical Pressure Hydrocarbon Fuel

Abstract

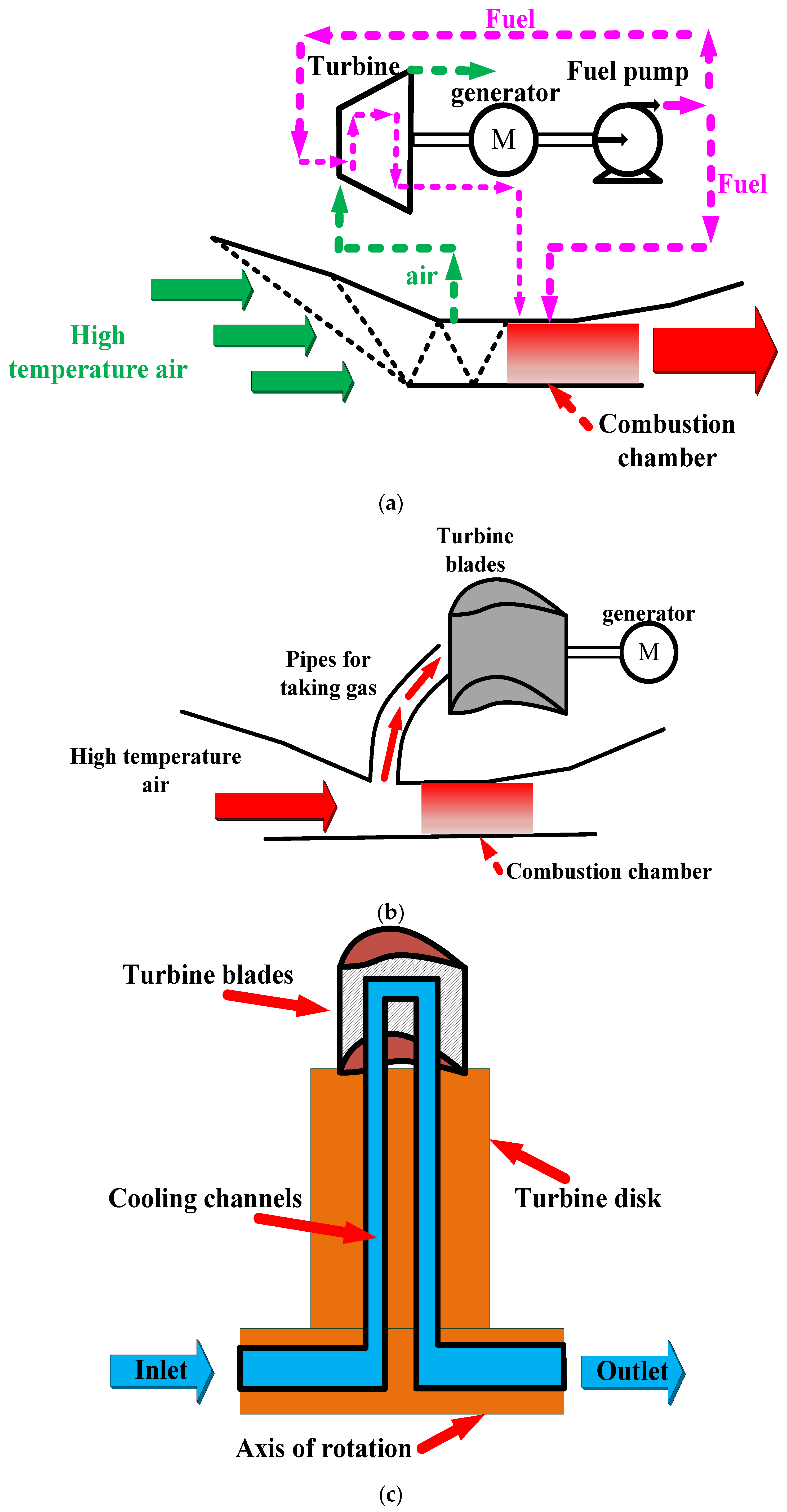

:1. Introduction

2. Numerical Calculation Details

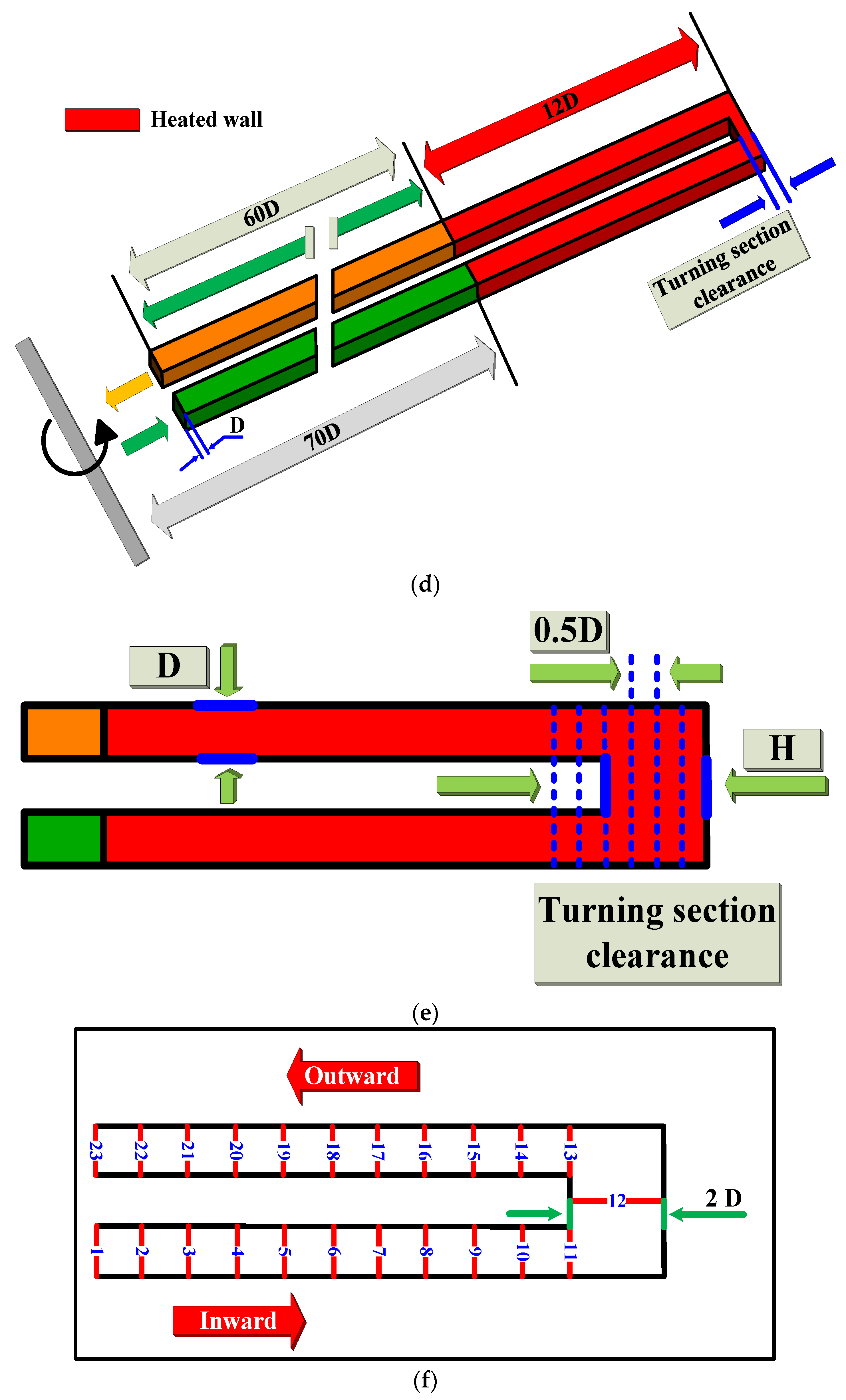

2.1. Computational Model Details

2.2. Boundary Conditions and Physical Properties Calculation Method

2.3. Turbulence Model Selection and Mesh Details

2.4. Data Reduction

3. Results and Discussions

3.1. Effect of Clearance Size on Flow Velocity Distribution

3.2. Effect of Clearance Size and Temperature of Inlet on f

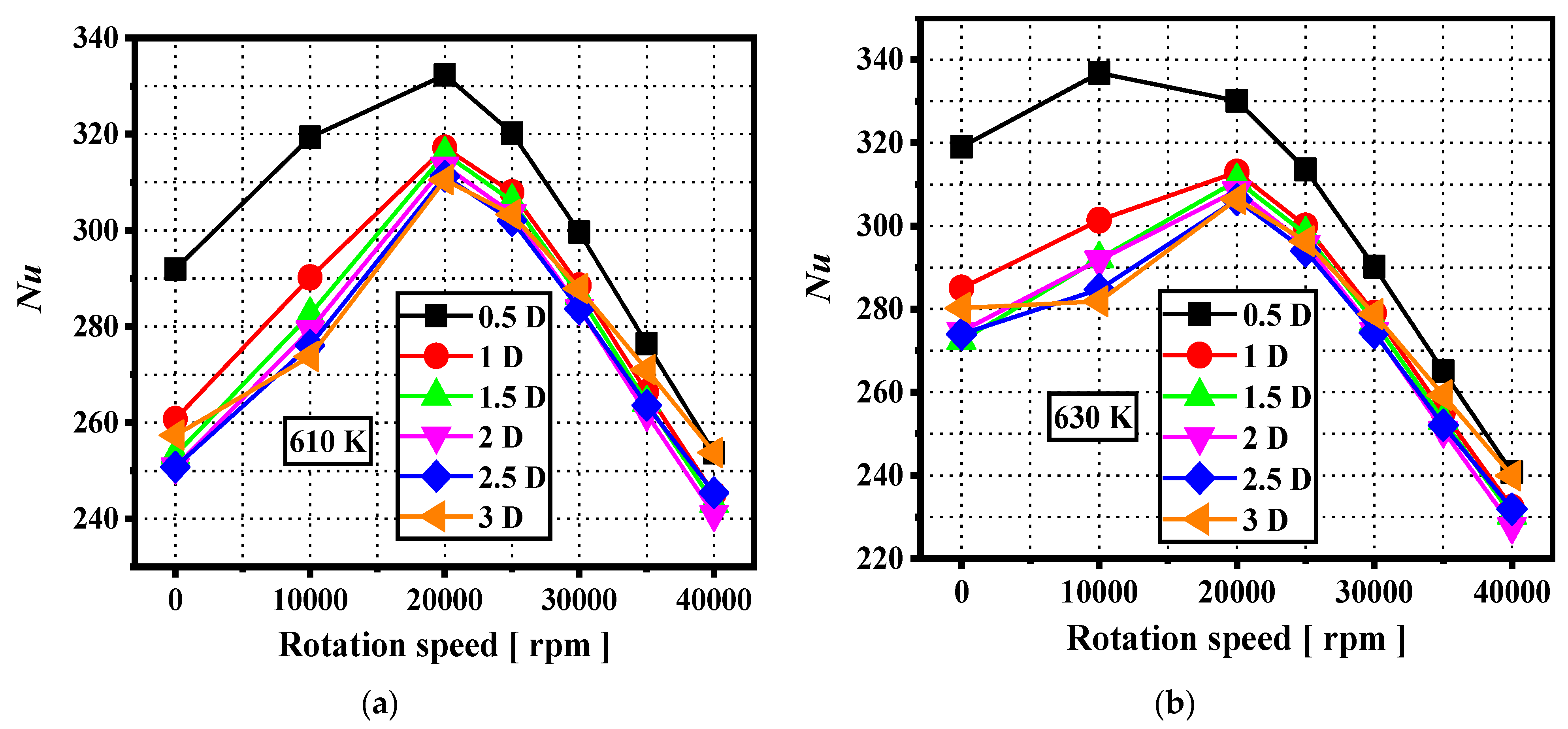

3.3. Effect of Clearance Size and Inlet Temperature on Heat Exchange Performance

4. Conclusions

- (1)

- Thermal performance can be significantly improved by changing the clearance of the turning section. The clearance size 2.5 D channel obtains the highest value of thermal performance. The thermal performance of the clearance size 2.5 D channel is maximally improved by 1.8 times.

- (2)

- The law of change of thermal performance before and after crossing the critical temperature point is completely opposite. The channel thermal performance changes from decreasing then increasing to increasing then decreasing as the clearance size increases for high rotational speed conditions as the temperature of the entrance straddles the critical temperature of the hydrocarbon fuel. The thermal performance is maximally improved by 2.3 times for the 630 K entrance temperature compared to the 610 K entrance temperature.

- (3)

- The law of change of friction coefficient before and after crossing the critical temperature point is completely opposite. Its friction coefficient changes from first increasing and then decreasing to decreasing and then increasing. The channel friction factor is maximally improved by 51 times for the 610 K entrance temperature compared to the 630 K entrance temperature.

- (4)

- The Nusselt number first increases and then decreases for all channels with different clearance sizes with an increasing rotational speed. When the clearance size is less than 1 D, the Nusselt number of the channel can be significantly improved by reducing the clearance size. The Nusselt number maximum is achieved in the range of rotational speeds from 10,000 rpm to 20,000 rpm for all clearance size channels.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| D | hydraulic diameter [mm] |

| T | temperature [K] |

| h | convective heat transfer coefficient [W/m2/K] |

| ∆p | pressure difference [Pa] |

| q | heat flux [W/m2] |

| Nu | Nusselt number |

| Re | Reynolds number |

| f | friction factor |

| Pr | Prandtl number |

| Greek symbols | |

| ρ | density [kg/m3] |

| μ | dynamic viscosity [Pa·s] |

| λ | thermal conductivity [W/m/K] |

| Subscripts | |

| heat-in | inlet of heating section |

| heat-out | outlet of heating section |

| b | bulk value |

| w | wall |

| Abbreviations | |

| TP | thermal performance |

References

- Zhang, D.; Qin, J.; Feng, Y.; Ren, F.; Bao, W. Performance evaluation of power generation system with fuel vapor turbine onboard hydrocarbon fueled scramjets. Energy 2014, 77, 732–741. [Google Scholar] [CrossRef]

- Macheret, S.; Shneider, M.; Miles, R. Magnetohydrodynamic Power Extraction from Cold Hypersonic Airflows with External Ionizers. J. Propuls. Power 2002, 18, 424–431. [Google Scholar] [CrossRef]

- Li, H.; Qin, J.; Jiang, Y.; Zhang, D.; Cheng, K.; Bao, W.; Huang, H. Experimental and theoretical investigation of power generation scheme driven by thermal cracked gaseous hydrocarbon fuel for hypersonic vehicle. Energy Convers. Manag. 2018, 165, 334–343. [Google Scholar] [CrossRef]

- Saad, M.M.M.; Mohd, S.; Zulkafli, M.F. A survey on the use of ram air turbine in aircraft. Aip. Conf. Proc. 2017, 1831, 020048. [Google Scholar]

- Sun, H.; Qin, J.; Huang, H.; Yan, P. Investigation of hydrocarbon fuel rotating flow considering the variation of physical properties. Int. J. Heat Mass Transf. 2019, 142, 118372. [Google Scholar] [CrossRef]

- Sun, H.; Qin, J.; Huang, H.; Yan, P. Numerical simulation of flow and heat transfer in a square rotating U-duct using hydrocarbon fuel. ASME J. Heat Transf. 2019, 141, 031701. [Google Scholar] [CrossRef]

- Han, J.-C. Turbine Blade Cooling Studies at Texas A&M University: 1980–2004. J. Thermophys. Heat Transf. 2006, 20, 161–187. [Google Scholar]

- Al-Hadhrami, L.; Han, J.-C. Effect of rotation on heat transfer in two-pass square channels with five different orientations of 45° angled rib turbulators. Int. J. Heat Mass Transf. 2003, 46, 653–669. [Google Scholar] [CrossRef]

- Qiu, L.; Deng, H.; Sun, J.; Tao, Z.; Tian, S. Pressure drop and heat transfer in rotating smooth square U-duct under high rotation numbers. Int. J. Heat Mass Transf. 2013, 66, 543–552. [Google Scholar] [CrossRef]

- Xu, G.; Li, Y.; Deng, H. Effect of rib spacing on heat transfer and friction in a rotating two-pass square channel with asymmetrical 90-deg rib turbulators. Appl. Therm. Eng. 2015, 80, 386–395. [Google Scholar] [CrossRef]

- Wang, L.; Wang, S.; Wen, F.; Zhou, X.; Wang, Z. Heat transfer and flow characteristics of U-shaped cooling channels with novel wavy ribs under stationary and rotating conditions. Int. J. Heat Mass Transf. 2018, 126, 312–333. [Google Scholar] [CrossRef]

- Singh, P.; Ji, Y.; Ekkad, S.V. Experimental and numerical investigation of heat and fluid flow in a square duct featuring criss-cross rib patterns. Appl. Therm. Eng. 2018, 128, 415–425. [Google Scholar] [CrossRef]

- Liou, T.; Chang, S.; Chan, S. Effect of rib orientation on thermal and fluid-flow features in a two-pass parallelogram channel with abrupt entrance. Int. J. Heat Mass Transf. 2018, 116, 152–165. [Google Scholar] [CrossRef]

- Nakayama, H.; Hirota, M.; Fujita, H.; Yamada, T.; Koide, Y. Fluid flow and heat transfer in two-pass smooth rectangular channels with different turn clearances. ASME J. Turbomach. 2006, 128, 772–785. [Google Scholar] [CrossRef]

- Hirota, M.; Fujita, H.; Syuhada, A.; Araki, S.; Yoshida, T.; Tanaka, T. Heat/mass transfer characteristics in two-pass smooth channels with a sharp 180-deg turn. Int. J. Heat Mass Transf. 1999, 42, 3757–3770. [Google Scholar] [CrossRef]

- Syuhada, A.; Hirota, M.; Fujita, H.; Araki, S.; Yanagida, M.; Tanaka, T. Heat (mass) transfer in serpentine flow passage with rectangular cross-section. Energy Convers. Manag. 2001, 42, 1867–1885. [Google Scholar] [CrossRef]

- Hirota, M.; Fujita, H.; Tanaka, A.; Araki, S.; Tanaka, T. Local heat (mass) transfer characteristics in rectangular ducts with a sharp 180-degree turn. Energy Convers. Manag. 1997, 38, 1155–1168. [Google Scholar] [CrossRef]

- Wang, T.-S.; Chyu, M.K. Heat convection in a 180-deg turning duct with different turn configurations. J. Thermophys. Heat Transf. 1994, 8, 595–601. [Google Scholar] [CrossRef]

- Pape, D.; Jeanmart, H.; von Wolfersdorf, J.; Weigand, B. Influence of the 180 Bend Geometry on the Pressure Loss and Heat Transfer in a High Aspect Ratio Rectangular Smooth Channel; ASME Paper No. GT2004-53753; ASME: New York, NY, USA, 2004. [Google Scholar]

- He, P.; Mader, C.A.; Martins, J.R.; Maki, K.J. Aerothermal optimization of a ribbed U-bend cooling channel using the adjoint method. Int. J. Heat Mass Transf. 2019, 140, 152–172. [Google Scholar] [CrossRef]

- Saha, K.; Acharya, S. Effect of Bend Geometry on Heat Transfer and Pressure Drop in a Two-Pass Coolant Square Channel for a Turbine. J. Turbomach. 2012, 135, 021035. [Google Scholar] [CrossRef]

- Wu, B.; Yang, X.; Liu, Z.; Feng, Z. Effects of novel turning vanes on pressure loss and tip-wall heat transfer in an idealized U-bend channel. Int. Commun. Heat Mass Transf. 2020, 121, 105072. [Google Scholar] [CrossRef]

- Yan, H.; Luo, L.; Zhu, P.-M.; Du, W.; Wang, S. Effects of varied bend turning vanes on flow control and heat transfer performance in a smooth twopass channel. Int. Commun. Heat Mass Transf. 2022, 135, 106044. [Google Scholar] [CrossRef]

- Xie, G.; Zhang, W.; Sunden, B. Computational analysis of the influences of guide ribs/vanes on enhanced heat transfer of a turbine blade tip-wall. Int. J. Therm. Sci. 2012, 51, 184–194. [Google Scholar] [CrossRef]

- Guo, Z.; Rao, Y.; Li, Y.; Wang, W. Experimental and numerical investigation of turbulent flow heat transfer in a serpentine channel with multiple short ribbed passes and turning vanes. Int. J. Therm. Sci. 2021, 165, 106931. [Google Scholar] [CrossRef]

- Lei, J.; Su, P.; Xie, G.; Lorenzini, G. The effect of a hub turning vane on turbulent flow and heat transfer in a four-pass channel at high rotation numbers. Int. J. Heat Mass Transf. 2016, 92, 578–588. [Google Scholar] [CrossRef]

- Sun, X.; Meng, H.; Zheng, Y. Asymmetric heating and buoyancy effects on heat transfer of hydrocarbon fuel in a horizontal square channel at supercritical pressures. Aerosp. Sci. Technol. 2019, 93, 105358. [Google Scholar] [CrossRef]

- Sun, X.; Meng, H. Large eddy simulations and analyses of hydrocarbon fuel heat transfer in vertical upward flows at supercritical pressures. Int. J. Heat Mass Transf. 2021, 170, 120988. [Google Scholar] [CrossRef]

- Sun, F.; Li, Y.; Manca, O.; Xie, G. An evaluation on the laminar effect of buoyancy-driven supercritical hydrocarbon fuel flow and heat transfer characteristics. Int. J. Heat Mass Transf. 2019, 142, 118414. [Google Scholar] [CrossRef]

- Wen, J.; Huang, H.; Jia, Z.; Fu, Y.; Xu, G. Buoyancy effects on heat transfer to supercritical pressure hydrocarbon fuel in a horizontal miniature tube. Int. J. Heat Mass Transf. 2017, 115, 1173–1181. [Google Scholar] [CrossRef]

- Zhu, J.Q.; Tao, K.H.; Tao, Z.; Qu, L. Heat transfer degradation of buoyancy involved convective RP-3 hydrocarbon fuel in vertical tubes with various diameters under supercritical pressure. Appl. Therm. Eng. 2019, 163, 114392. [Google Scholar] [CrossRef]

- Fu, Y.C.; Wen, J.E.; Tao, Z.; Xu, G.Q.; Huang, H.R. Experimental research on convective heat transfer of supercritical hydrocarbon fuel flowing through U-turn tubes. Appl. Therm. Eng. 2017, 116, 43–55. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, Y.; Qin, J.; Zhang, S.; Chetehouna, K.; Gascoin, N.; Bao, W. The flow rate distribution of hydrocarbon fuel in parallel channels with different cross section shapes. Appl. Therm. Eng. 2018, 137, 173–183. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, Y.; Zhang, S.; Chetehouna, K.; Gascoin, N.; Qin, J.; Bao, W. Parametric study on the distribution of flow rate and heat sink utilization in cooling channels of advanced aero-engines. Energy 2017, 138, 1056–1068. [Google Scholar] [CrossRef]

- Zhang, S.; Feng, Y.; Zhang, D.; Jiang, Y.; Qin, J.; Bao, W. Parametric numerical analysis of regenerative cooling in hydrogen fueled SCRamjet engines. Int. J. Hydrogen Energy 2016, 41, 10942–10960. [Google Scholar] [CrossRef]

- Zhang, S.; Qin, J.; Xie, K.; Feng, Y.; Bao, W. Thermal behavior inside SCRamjet cooling channels at different channel aspect ratios. J. Propuls. Power 2016, 32, 57–70. [Google Scholar] [CrossRef]

- Zhang, S.; Cui, N.; Xiong, Y.; Feng, Y.; Qin, J.; Bao, W. Effect of channel aspect ratio on chemical recuperation process in advanced aeroengines. Energy 2017, 123, 9–19. [Google Scholar] [CrossRef]

- Guo, Y.; Yang, Z.; Jiang, L.; Liu, Z.; Bi, Q. Convective heat transfer characteristics of supercritical hydrocarbon fuel in small non-circular cross-section channels. In Proceedings of the 11th AIAA/ASME Joint Thermophysics and Heat Transfer Conference, Atlanta, GA, USA, 16–20 June 2014. [Google Scholar]

- Cheng, Z.; Tao, Z.; Zhu, J.; Wu, H. Diameter effect on the heat transfer of supercritical hydrocarbon fuel in horizontal tubes under turbulent conditions. Appl. Therm. Eng. 2018, 134, 39–53. [Google Scholar] [CrossRef]

- Guo, Y.; Bi, Q.; Liu, Z.; Yang, Z.; Jiang, L. Experimental investigation on thermal-hydraulic characteristics of endothermic hydrocarbon fuel in 1 mm and 2 mm diameter mini-channels. Appl. Therm. Eng. 2017, 122, 420–428. [Google Scholar] [CrossRef]

- Jiang, P.; Lu, Z.; Guo, Y.; Zhu, Y. Experimental investigation of convective heat transfer of hydrocarbon fuels at supercritical pressures within rotating centrifugal channel. Appl. Therm. Eng. 2018, 147, 101–112. [Google Scholar] [CrossRef]

- Lu, Z.; Zhu, Y.; Guo, Y.; Jiang, P. Experimental Investigation of Convective Heat Transfer of Supercritical Pressure Hydrocarbon Fuel in a Horizontal Section of a Rotating U-Duct. J. Heat Transf. 2019, 141, 101702. [Google Scholar] [CrossRef]

- Sun, H.; Qin, J.; Li, H.; Huang, H.; Yan, P. Research of a combined power and cooling system based on fuel rotating cooling air turbine and organic Rankine cycle on hypersonic aircraft. Energy 2019, 189, 116183. [Google Scholar] [CrossRef]

- Qin, J.; Zhang, S.; Bao, W.; Zhou, W.; Yu, D. Thermal management method of fuel in advanced aeroengines. Energy 2012, 49, 459–468. [Google Scholar] [CrossRef]

- Kim, S.-K.; Choi, H.-S.; Kim, Y. Thermodynamic modeling based on a generalized cubic equation of state for kerosene/LOx rocket combustion. Combust. Flame 2012, 159, 1351–1365. [Google Scholar] [CrossRef]

- Poling, B.E.; Prausnitz, J.M.; O’connell, J.P. The Properties of Gases and Liquids, 5th ed.; McGraw-Hill Professional: New York, NY, USA, 2001. [Google Scholar]

- Feng, Y.; Qin, J.; Bao, W.; Yang, Q.; Huang, H.; Wang, Z. Numerical analysis of convective heat transfer characteristics of supercritical hydrocarbon fuel in cooling panel with local flow blockage structure. J. Supercrit. Fluids 2014, 88, 8–16. [Google Scholar] [CrossRef]

- Dong, M.; Feng, Y.; Wu, K.; Qin, J.; Huang, H. Heat transfer characteristics of supercritical pressure hydrocarbon fuels in rotating trapezoidal channels. Int. Commun. Heat Mass Transf. 2023, 140, 106556. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Y.; Liang, C.; Zhang, Q.; Li, X. Heat transfer analysis of n-decane with variable heat flux distributions in a mini-channel. Appl. Therm. Eng. 2018, 144, 695–701. [Google Scholar] [CrossRef]

- Li, Y.; Xie, G.; Zhang, Y.; Ferla, P.; Sunden, B. Flow Characteristics and Heat Transfer of Supercritical n-decane in Novel Nested Channels for Scramjet Regenerative Cooling. Int. J. Heat Mass Transf. 2021, 167, 120836. [Google Scholar] [CrossRef]

- Li, X.; Qin, J.; Zhang, S.; Cui, N.; Bao, W. Effects of micro-ribs on the thermal behavior of transcritical n-decane in asymmetric heated rectangular mini-channels under near critical pressure. J. Heat Transf. 2018, 140, 122402. [Google Scholar] [CrossRef]

- Li, X.; Zhang, S.; Qin, J.; Bao, W. Parametric analysis on the thermal behavior of cracking hydrocarbon fuel flow inside asymmetry heated cooling channels with micro-ribs. Int. J. Heat Mass Transf. 2020, 160, 120154. [Google Scholar] [CrossRef]

- Ravi, B.V.; Singh, P.; Ekkad, S.V. Numerical investigation of turbulent flow and heat transfer in two-pass ribbed channels. Int. J. Therm. Sci. 2017, 112, 31–43. [Google Scholar] [CrossRef]

| Model Clearance Parameters | Turning Section Clearance |

|---|---|

| H | 0.5 D |

| 1 D | |

| 1.5 D | |

| 2 D | |

| 2.5 D | |

| 3 D |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, M.; Huang, H. Effect of Rotating Channel Turning Section Clearance Size on Heat Transfer Characteristics of Supercritical Pressure Hydrocarbon Fuel. Energies 2023, 16, 6051. https://doi.org/10.3390/en16166051

Dong M, Huang H. Effect of Rotating Channel Turning Section Clearance Size on Heat Transfer Characteristics of Supercritical Pressure Hydrocarbon Fuel. Energies. 2023; 16(16):6051. https://doi.org/10.3390/en16166051

Chicago/Turabian StyleDong, Mengqiang, and Hongyan Huang. 2023. "Effect of Rotating Channel Turning Section Clearance Size on Heat Transfer Characteristics of Supercritical Pressure Hydrocarbon Fuel" Energies 16, no. 16: 6051. https://doi.org/10.3390/en16166051

APA StyleDong, M., & Huang, H. (2023). Effect of Rotating Channel Turning Section Clearance Size on Heat Transfer Characteristics of Supercritical Pressure Hydrocarbon Fuel. Energies, 16(16), 6051. https://doi.org/10.3390/en16166051