Experimental Investigation on Gasoline—Water Mixture Fuel Impingement Preparation Method and Spray Characteristics with High Injection Temperatures and Pressures

Abstract

:1. Introduction

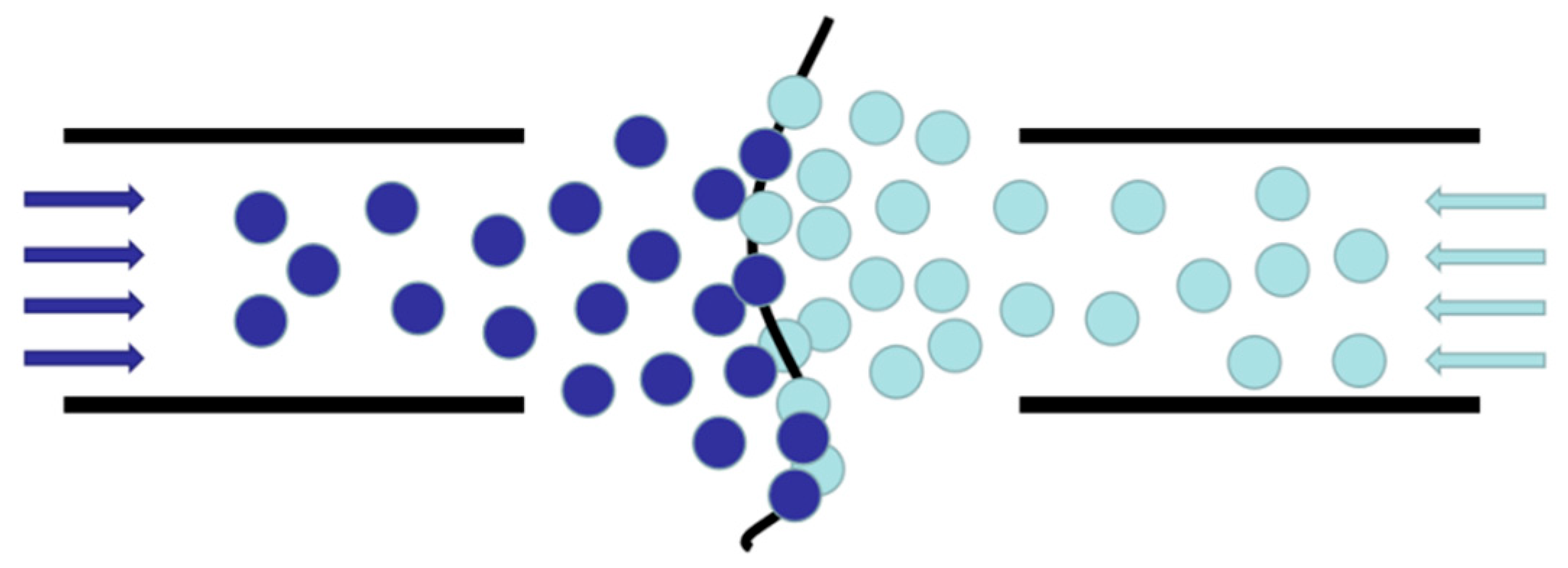

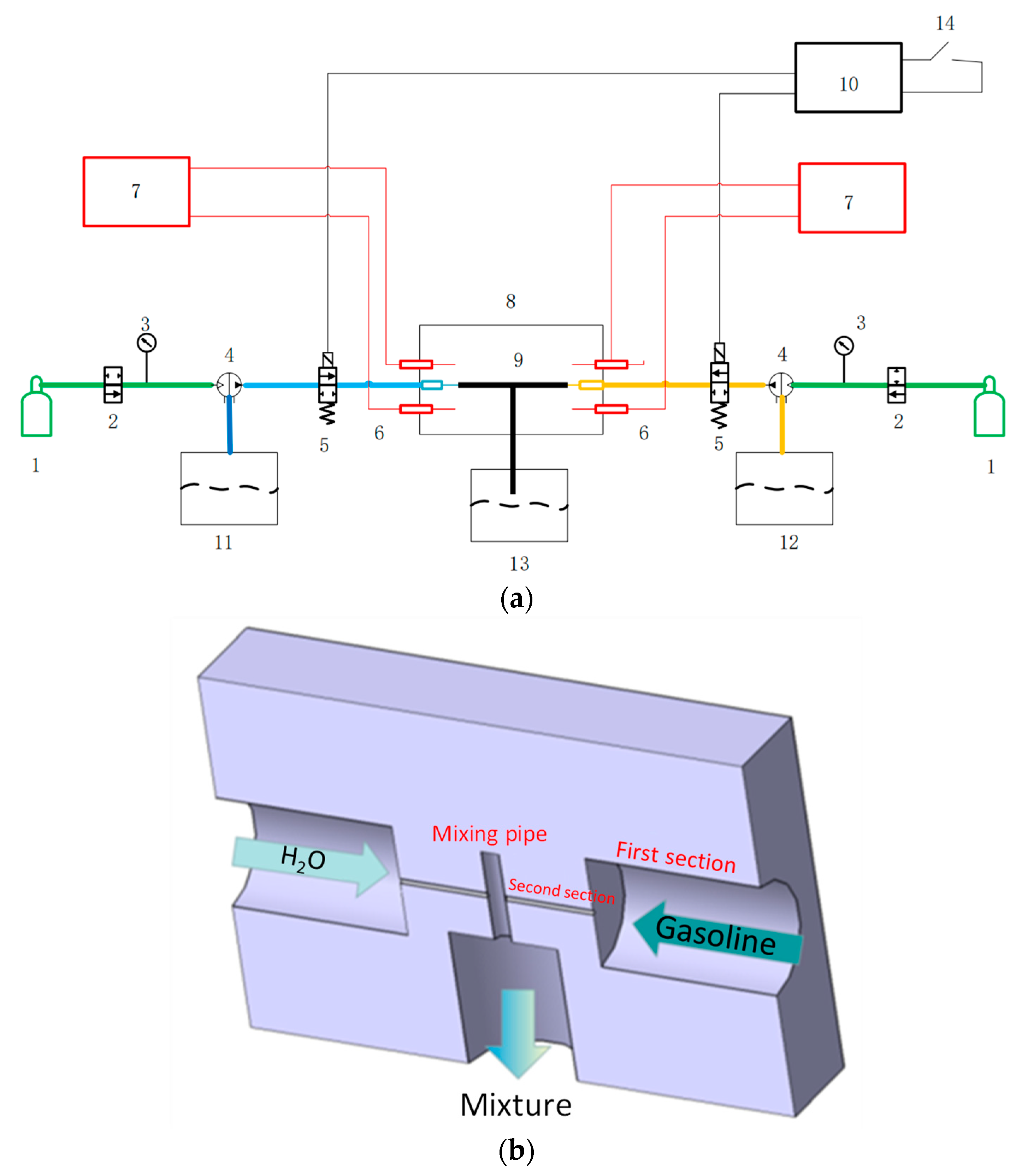

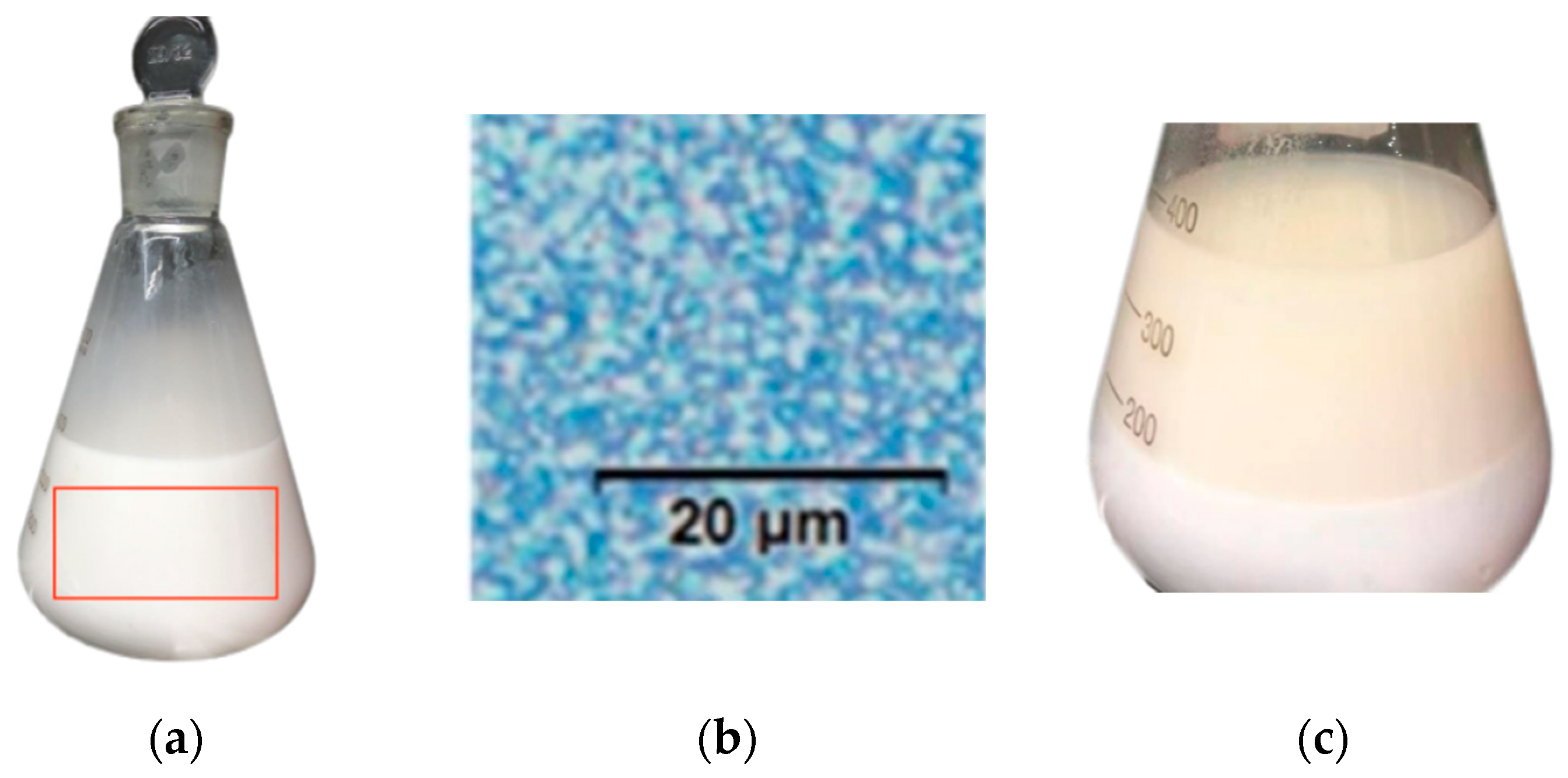

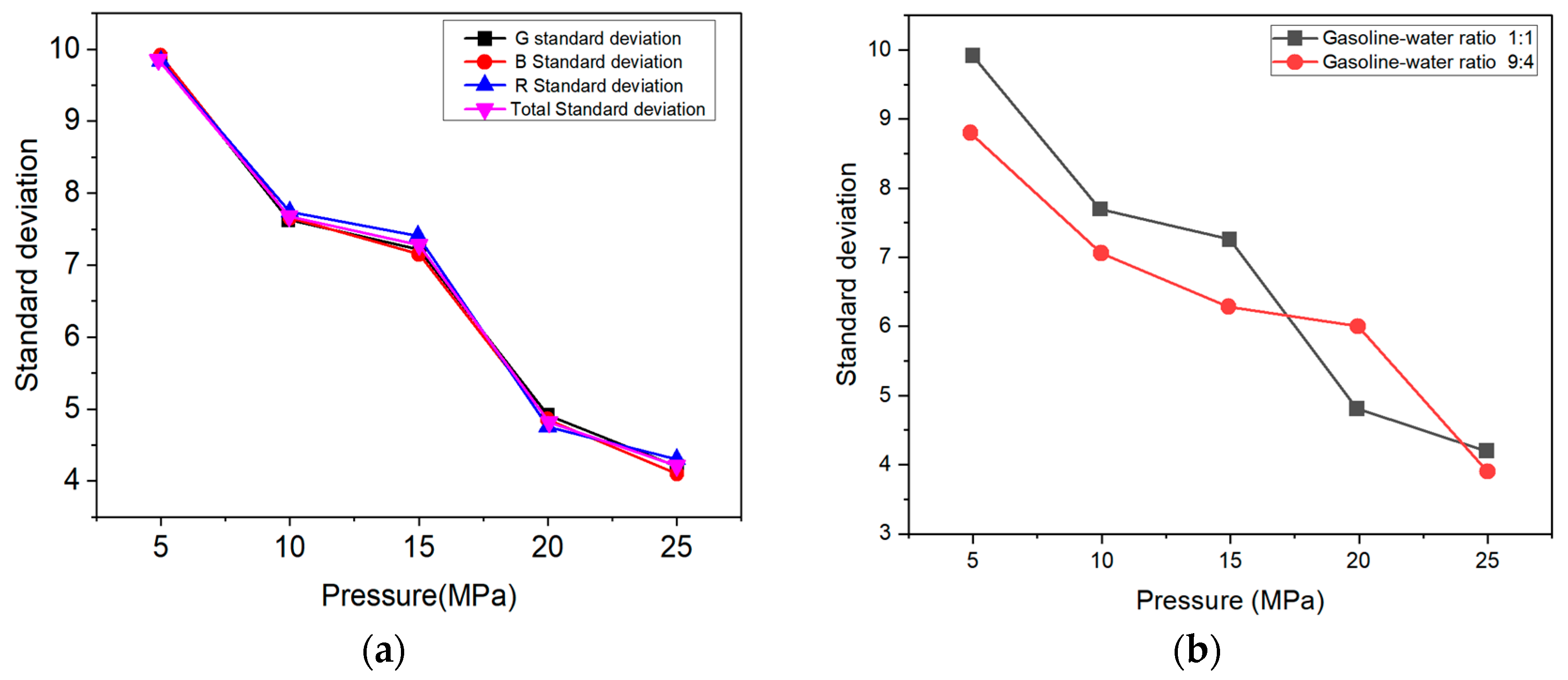

2. The Real Time Gasoline–Water Preparation Principle and Test

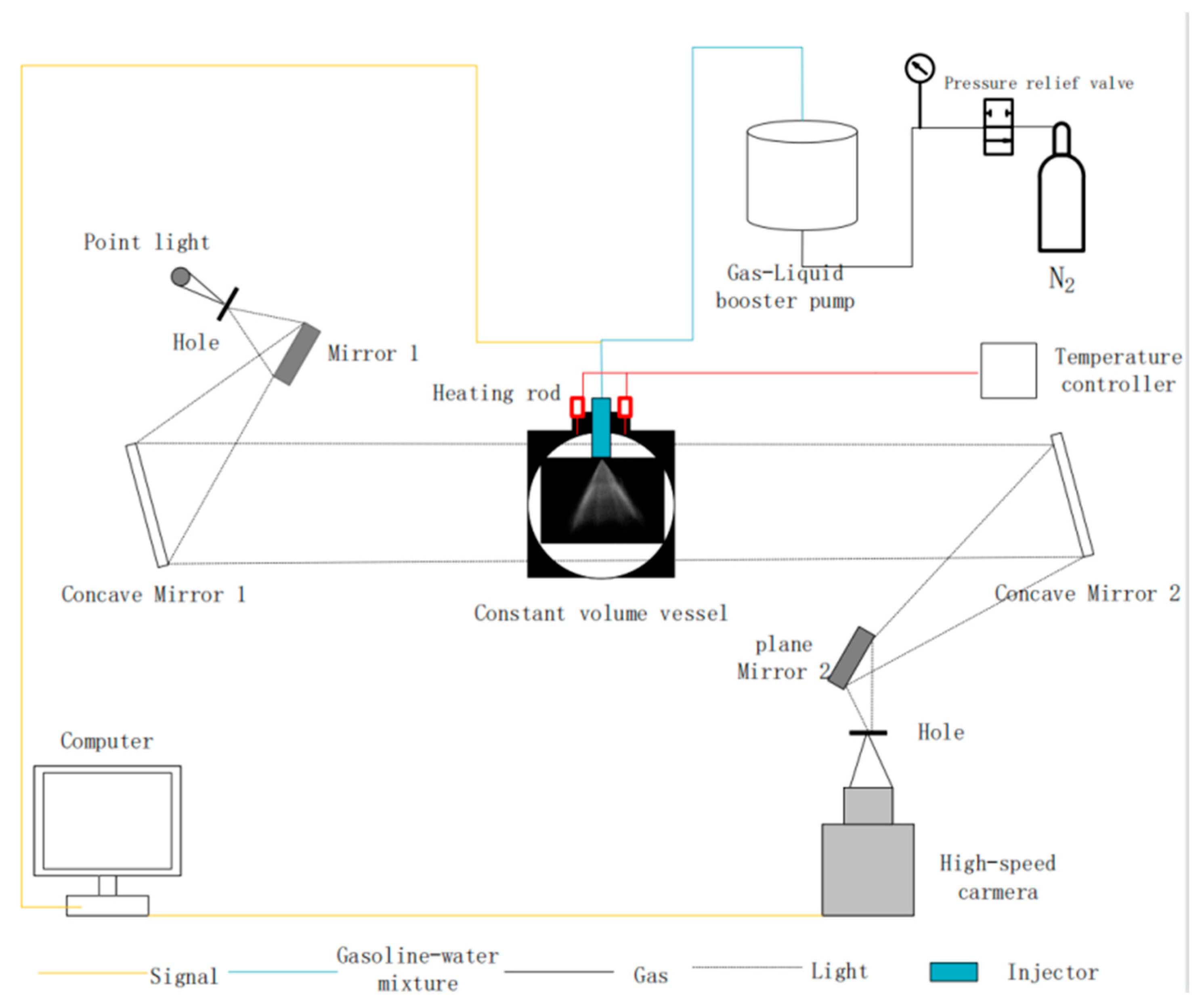

3. The Experimental System for Spray Analysis

4. The Spray Experimental Results and Discussion

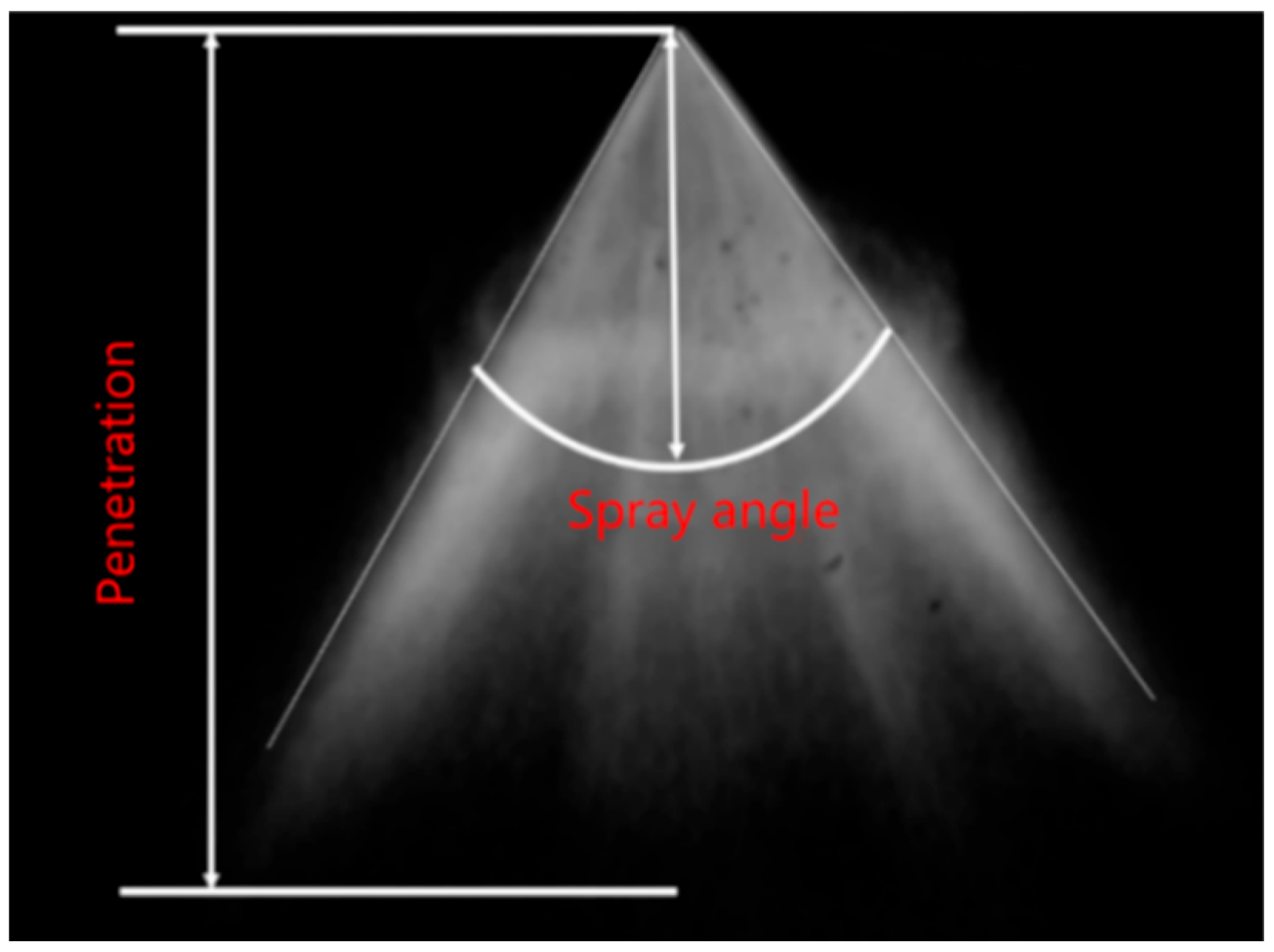

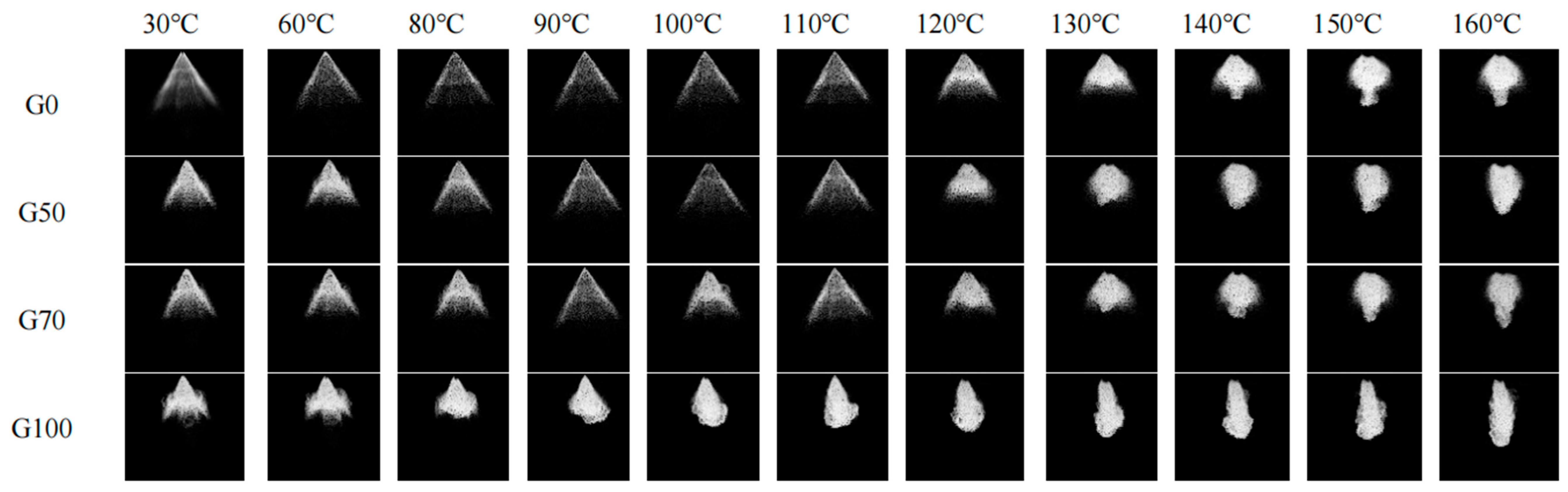

4.1. Spray Morphology

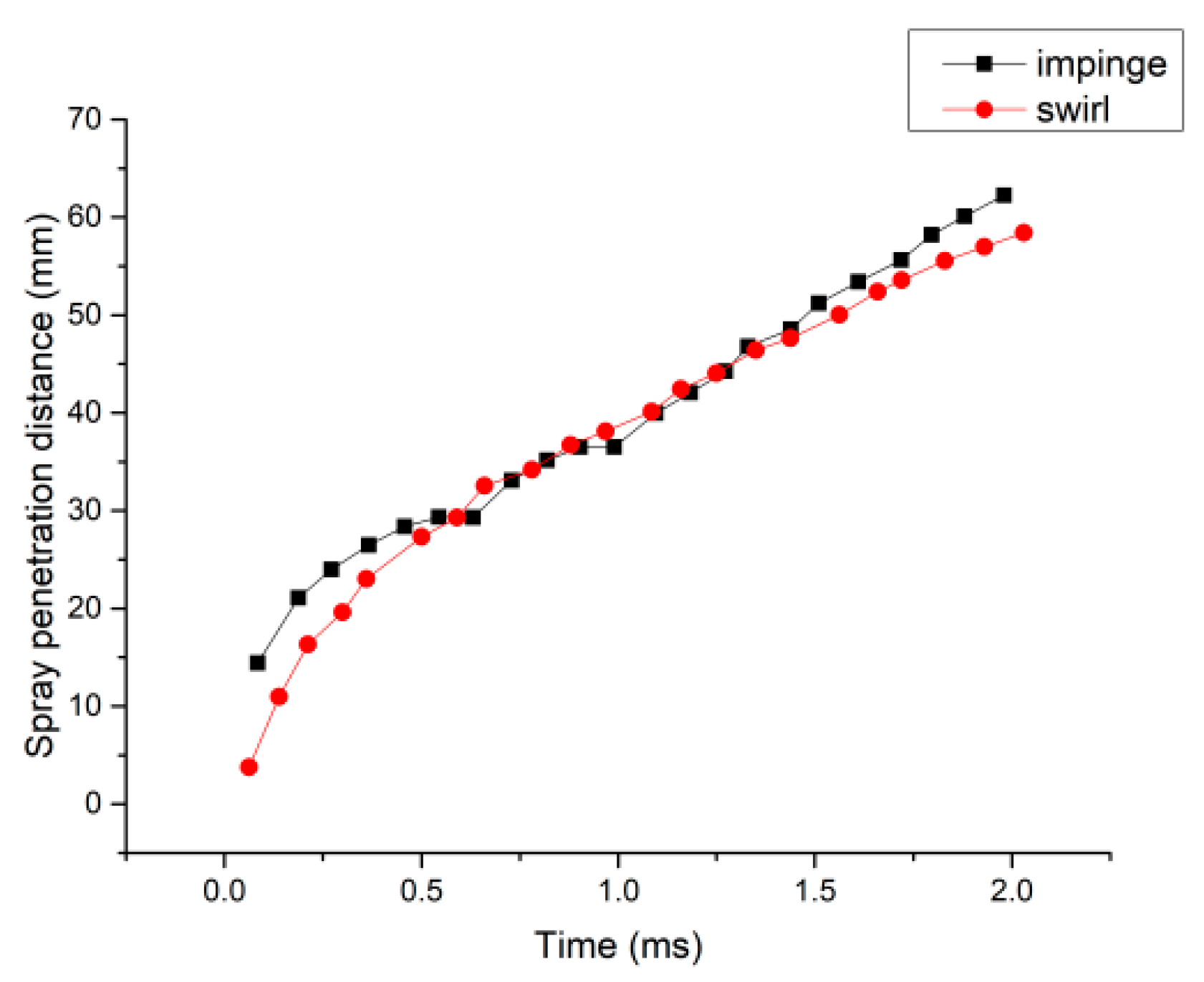

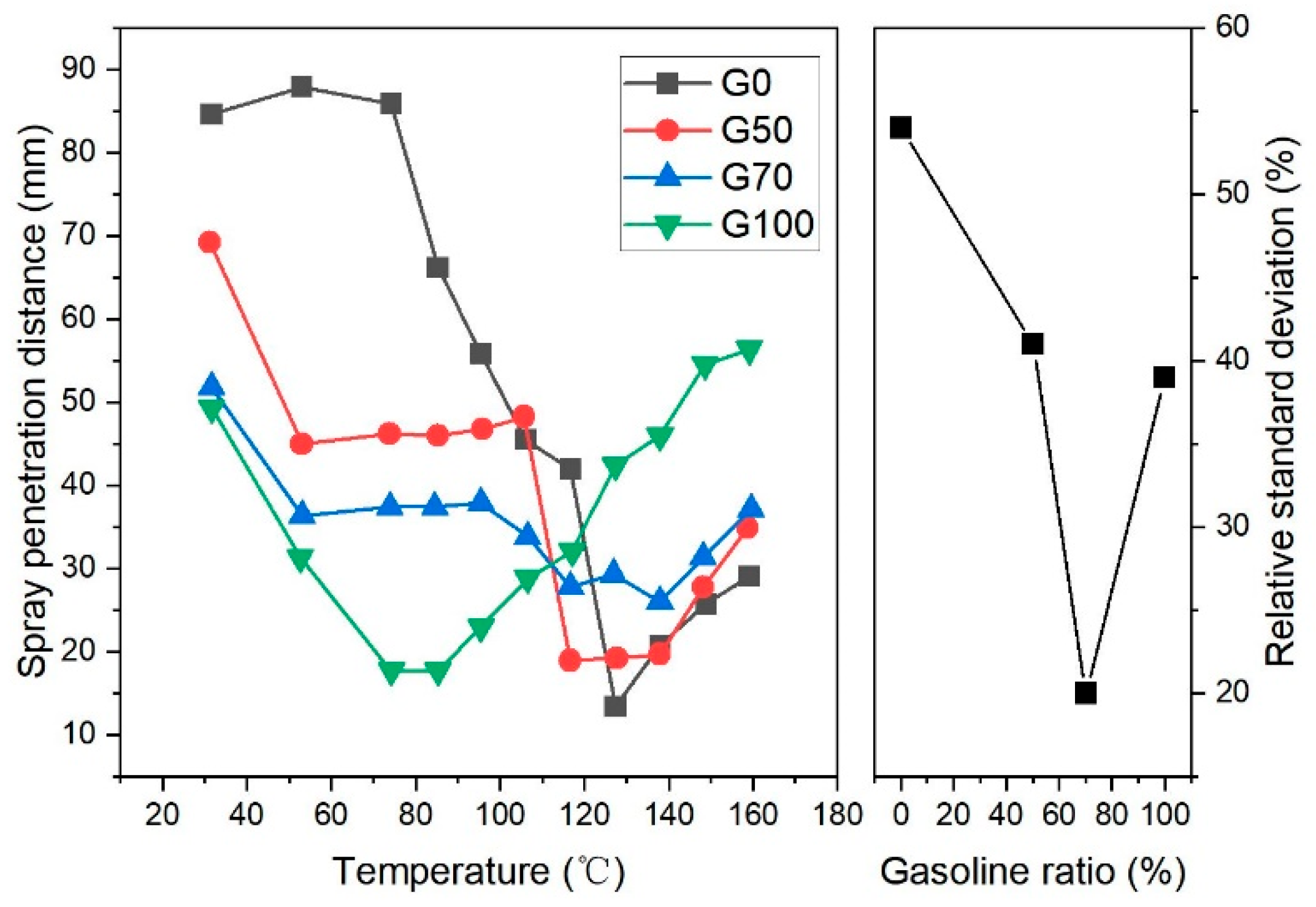

4.2. Effect of Injection Temperature on Penetration Distance

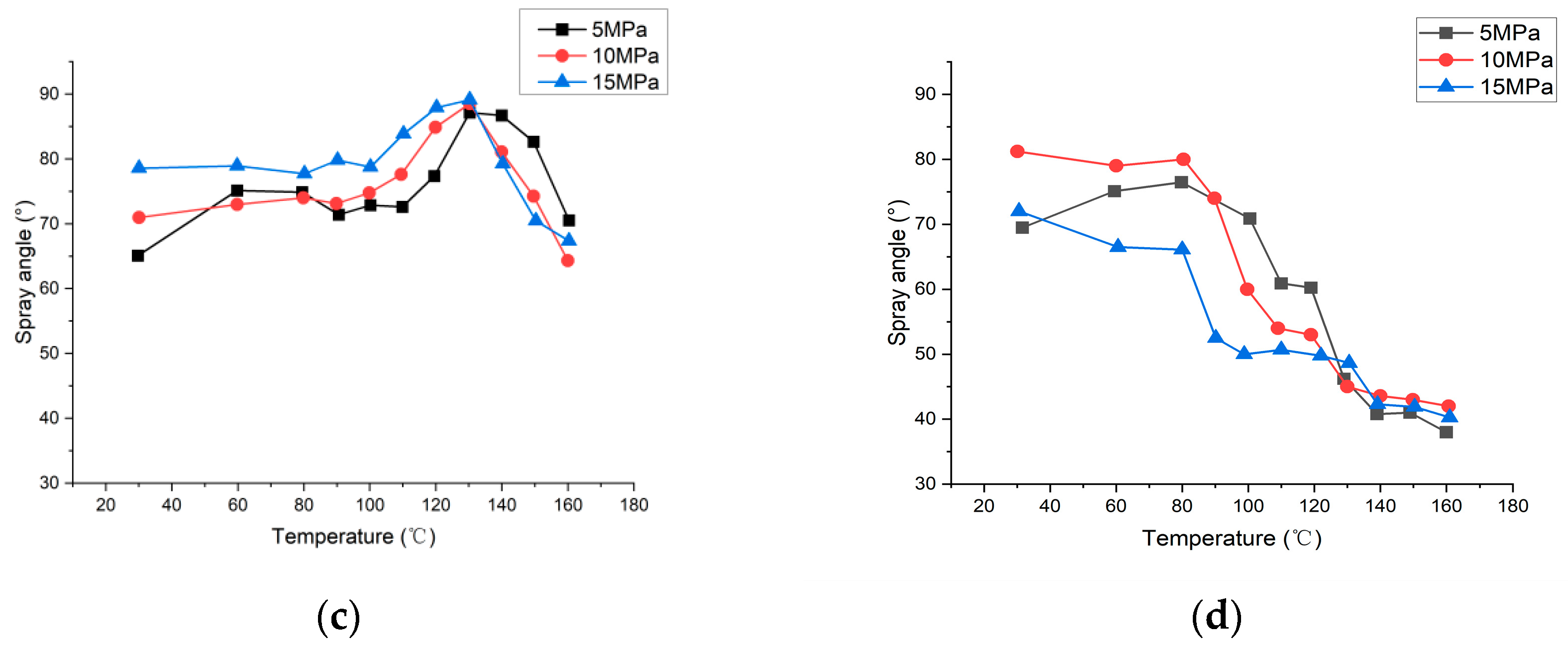

4.3. Effect of Injection Temperature on Spray Angle

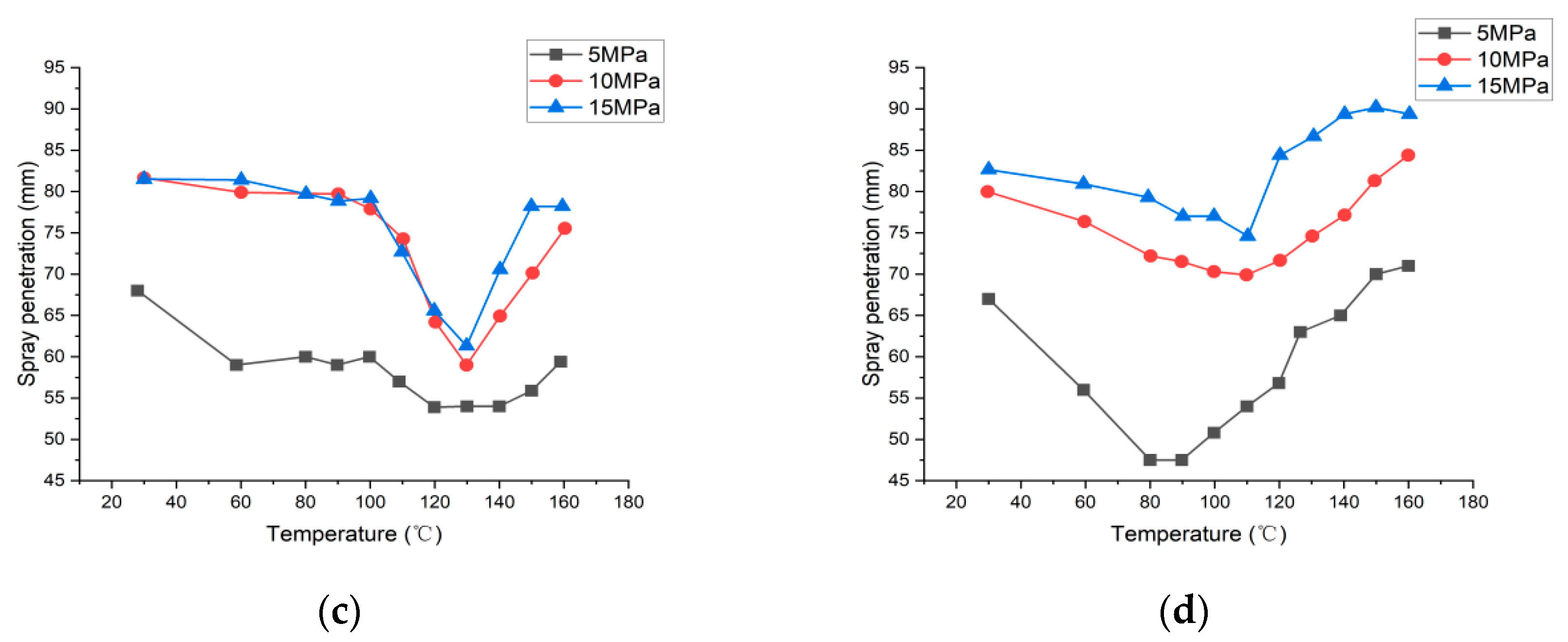

4.4. Effect of Injection Pressure on Penetration Distance

4.5. Effect of Injection Pressure on Spray Angle

5. Conclusions

- The RGB analysis (mean values and standard deviations) is used as a quantitative tool for evaluation of the mixing characteristics of the obtained real-time gasoline–water mixture and of the performance of the new gasoline–water mixing technique based on impingement. The RGB values and their standard deviations were determined by selecting a particular image-processing area. When the injection pressure increases, the uniformity and time stability of the gasoline–water fuel mixture improves: the longest obtained stability is 5 h and a saturation for the impingement pressure (Pimp) occurs at 20 MPa.

- As the temperature increases, the spray penetration referring to G0, G50, G70 and G100 decreases and then increases: the local minimum point virtually coincides with the flash boiling condition. A significant reduction in penetration length is due to the momentum loss caused by the evaporation and the diminished inertial force. After the flash-boiling condition, the spray plumes collapse in a single spray characterized by an augmented axial momentum, that allow the penetration to rise again.

- The spray cone angles of G0, G50 and G70 increase slowly and similarly as the injection temperature rises. The spray angle of the gasoline–water mixture is mainly determined by the water. For the G100, when the injection temperature reaches the flash boiling value (around 75 °C) of gasoline, the spray cone angle drops sharply. Instead, for a gasoline–water mixture, when the flash-boiling point of water is reached (around 130 °C), a large amount of steam is generated, which increases the spray angle. However, when the temperature overwhelms the flash-boiling condition, in the 140–160 °C range, the spray plume collapse leads to a dramatic drop in the spray angle.

- By increasing the injection pressure (Pj), the penetration length of the spray generally augments for a fixed injection temperature. Before the flash-boiling condition, the angle increases with the injection pressure, due to a promoted nucleation and the occurrence of micro explosions of bubbles near the nozzle, which make the spray wider. Beyond the flash-boiling temperature, the spray plume collapse reduces the spray angle and enhances the axial penetration. This effect is less evident for the lowest injection pressure, since in this case the spray experiences a higher aerodynamic drag force beyond the flash-boiling condition that counteracts the axial propagation, keeping the spray width larger if compared with the sprays with higher Pj values.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- BP World Energy Outlook 2020-Possible Developments in Global Energy to 2050. Available online: https://www.bp.com/en/global/corporate/news-and-insights/press-releases/bp-energy-outlook-2020.html (accessed on 14 September 2020).

- BP Statistical Review of World Energy 2021 70th Edition. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2021-full-report.pdf (accessed on 1 July 2021).

- Ferrari, A.; Vento, O. Influence of frequency-dependent friction modeling on the simulation of transient flows in high-pressure flow pipelines. J. Fluids Eng. 2020, 142, 081205. [Google Scholar] [CrossRef]

- Ferrari, A.; Vento, O. Thermal effects on Common Rail injection system hydraulic performance. Int. J. Engine Res. 2023, 14680874231162412. [Google Scholar] [CrossRef]

- Ferrari, A.; Novara, C.; Paolucci, E.; Vento, O.; Violante, M.; Zhang, T. Design and rapid prototyping of a closed-loop control strategy of the injected mass for the reduction of CO2, combustion noise and pollutant emissions in diesel engines. Appl. Energy 2018, 232, 358–367. [Google Scholar] [CrossRef]

- Ferrari, A.; Novara, C.; Paolucci, E.; Vento, O.; Violante, M.; Zhang, T. A new closed-loop control of the injected mass for a full exploitation of digital and continuous injection-rate shaping. Energy Convers. Manag. 2018, 177, 629–639. [Google Scholar] [CrossRef]

- Ferrari, A.; Novara, C.; Vento, O.; Violante, M.; Zhang, T. A novel fuel injected mass feedback-control for single and multiple injections in direct injection systems for CI engines. Fuel 2023, 334, 126670. [Google Scholar] [CrossRef]

- Ferrari, A.; Jin, Z.; Vento, O.; Zhang, T. An injected quantity estimation technique based on time–frequency analysis. Control. Eng. Pract. 2021, 116, 104910. [Google Scholar] [CrossRef]

- Jin, Z.; Vento, O.; Zhang, T.; Ferrari, A.; Mittica, A.; Ouyang, L.; Tan, S. Numerical-Experimental Optimization of the Common-Feeding Injection System Concept for Application to Light-Duty Commercial Vehicles. ASME J. Energy Resour. Technol. 2021, 143, 122304. [Google Scholar] [CrossRef]

- Shahed, S.M.; Bauer, K.H. Parametric studies of the impact of turbocharging on gasoline engine downsizing. SAE Int. J. Engines 2009, 2, 1347–1358. [Google Scholar] [CrossRef]

- Reitz, R.D. Directions in internal combustion engine research. Combust. Flame 2013, 160, 1–8. [Google Scholar] [CrossRef]

- Bozza, F.; Siano, D.; Torella, E. Cycle-by-cycle analysis, knock modeling and spark-advance setting of a “downsized” spark-ignition turbocharged engine. SAE Int. J. Engines 2010, 2, 381–389. [Google Scholar] [CrossRef]

- Fontana, G.; Galloni, E. Knock Resistance in a Small Turbocharged Spark-Ignition Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar] [CrossRef]

- Dahnz, C.; Spicher, U. Irregular combustion in supercharged spark ignition engines–pre-ignition and other phenomena. Int. J. Engine Res. 2010, 11, 485–498. [Google Scholar] [CrossRef]

- Attard, W.P.; Toulson, E.; Watson, H.; Hamori, F. Abnormal Combustion Including Mega Knock in a 60% Downsized Highly Turbocharged PFI Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, H.; Song, T.; Qi, Y.; He, X.; Shuai, S.; Wang, J. Relationship between super-knock and pre-ignition. Int. J. Engine Res. 2015, 16, 166–180. [Google Scholar] [CrossRef]

- Qi, Y.; Wang, Z.; Wang, J.; He, X. Effects of thermodynamic conditions on the end gas combustion mode associated with engine knock. Combust. Flame 2015, 162, 4119–4128. [Google Scholar] [CrossRef]

- Lanzafame, R. Water Injection Effects in a Single-Cylinder CFR Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef]

- Miganakallu, N.; Naber, J.D.; Rao, S.; Atkinson, W.; Barros, S. Experimental investigation of water injection technique in gasoline direct injection engine. In Proceedings of the Internal Combustion Engine Division Fall Technical Conference, Washington, DC, USA, 15–18 October 2017. [Google Scholar] [CrossRef]

- Worm, J.; Naber, J.; Duncan, J.; Barros, S.; Atkinson, W. Water injection as an enabler for increased efficiency at high-load in a direct injected, boosted, SI engine. SAE Int. J. Engines 2017, 10, 951–958. [Google Scholar] [CrossRef]

- Mingrui, W.; Sa, N.T.; Turkson, R.F.; Jinping, L.; Guanlun, G. Water injection for higher engine performance and lower emissions. J. Energy Inst. 2017, 90, 285–299. [Google Scholar] [CrossRef]

- Hunger, M.; Böcking, T.; Walther, U.; Günther, M.; Freisinger, N.; Karl, G. Potential of direct water injection to reduce knocking and increase the efficiency of gasoline engines. In Proceedings of the Knocking in Gasoline Engines: 5th International Conference, Berlin, Germany, 12–13 December 2017. [Google Scholar] [CrossRef]

- De Bellis, V.; Bozza, F.; Teodosio, L.; Valentino, G. Experimental and numerical study of the water injection to improve the fuel economy of a small size turbocharged SI engine. SAE Int. J. Engines 2017, 10, 550–561. [Google Scholar] [CrossRef]

- Kadota, T.; Yamasaki, H. Recent advances in the combustion of water fuel emulsion. Prog. Energy Combust. Sci. 2002, 28, 385–404. [Google Scholar] [CrossRef]

- Zhu, S.; Hu, B.; Akehurst, S.; Copeland, C.; Lewis, A.; Yuan, H.; Branney, C. A review of water injection applied on the internal combustion engine. Energy Convers. Manag. 2019, 184, 139–158. [Google Scholar] [CrossRef]

- Wu, Z.; Xie, W.; Yu, Y.; Li, L.; Deng, J. Comparison of spray characteristics of gasoline and water-in-gasoline mixture at elevated fuel temperature conditions. Fuel 2021, 304, 121409. [Google Scholar] [CrossRef]

- Zhou, X.; Zhai, Q.; Hung, D.L.; Li, X.; Xu, M. Study of component proportion effects on flash boiling atomization with ternary-alkane fuel mixtures. Fuel 2021, 298, 120798. [Google Scholar] [CrossRef]

- Yan, J.; Gao, S.; Liu, W.; Chen, T.; Lee, T.H.; Lee, C.F. Experimental study of flash boiling spray with isooctane, hexane, ethanol and their binary mixtures. Fuel 2021, 292, 120415. [Google Scholar] [CrossRef]

- Senda, J.; Asai, T.; Kawaguchi, B.; Fujimoto, H. Characteristics of gas-dessolved diesel fuel spray: Spray characteristics and simulating flash boiling process. JSME Int. J. Ser. B Fluids Therm. Eng. 2000, 43, 503–510. [Google Scholar] [CrossRef]

- Senda, J.; Wada, Y.; Kawano, D.; Fujimoto, H. Improvement of combustion and emissions in diesel engines by means of enhanced mixture formation based on flash boiling of mixed fuel. Int. J. Engine Res. 2008, 9, 15–27. [Google Scholar] [CrossRef]

- Vellaiyan, S.; Amirthagadeswaran, K.S. The role of water-in-diesel emulsion and its additives on diesel engine performance and emission levels: A retrospective review. Alex. Eng. J. 2016, 55, 2463–2472. [Google Scholar] [CrossRef]

- Ithnin, A.M.; Noge, H.; Kadir, H.A.; Jazair, W. An overview of utilizing water-in-diesel emulsion fuel in diesel engine and its potential research study. J. Energy Inst. 2014, 87, 273–288. [Google Scholar] [CrossRef]

- Heinrich, C.; Dörksen, H.; Esch, A.; Krämer, K. Gasoline water direct injection (GWDI) as a key feature for future gasoline engines. In Proceedings of the Knocking in Gasoline Engines: 5th International Conference, Berlin, Germany, 12–13 December 2017. [Google Scholar] [CrossRef]

- Tamir, A.; Kitron, A. Applications of impinging-streams in chemical engineering processes. Chem. Eng. Commun. 1987, 50, 241–330. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, S.; Huang, Y.; Huang, S.; Shi, S.; Cheng, X.; Huang, R. Experimental investigation on spray, evaporation and combustion characteristics of ethanol-diesel, water-emulsified diesel and neat diesel fuels. Fuel 2018, 231, 138–448. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Y.; Hou, X.; Wu, Z. Effects of Water Addition on Flash-Boiling Spray of Gasoline and Gasoline/Water Mixtures; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Kapusta, Ł.J. Understanding the collapse of flash-boiling sprays formed by multi-hole injectors operating at low injection pressures. Energy 2022, 247, 123388. [Google Scholar] [CrossRef]

- Zeng, W.; Xu, M.; Zhang, G.; Zhang, Y.; Cleary, D.J. Atomization and vaporization for flash-boiling multi-hole sprays with alcohol fuels. Fuel 2012, 95, 287–297. [Google Scholar] [CrossRef]

- Yu, Y.S.; Shin, D.; Jeong, M.; Park, J.; Park, S. Effect on flash boiling spray characteristics in the far-field and near-field and nozzle tip wetting with multi-hole LPDI injector. Appl. Therm. Eng. 2023, 219, 119676. [Google Scholar] [CrossRef]

| G50 (Swirl) | G70 (Swirl) | G70 (Impingement) | |

|---|---|---|---|

| RGB standard deviation | 2.28% | 2.05% | 1.65% |

| R standard deviation | 2.96% | 2.13% | 1.69% |

| G standard deviation | 2.37% | 2.04% | 1.75% |

| B standard deviation | 1.51% | 1.69% | 1.53% |

| Unsettled Mixture | Settled Mixture (5 h) | |

|---|---|---|

| R mean value | 235.7 | 134.6 |

| G mean value | 240.2 | 143.2 |

| B mean value | 242.3 | 142.9 |

| R standard deviation | 1.70% | 6.46% |

| G standard deviation | 1.75% | 5.73% |

| B standard deviation | 1.53% | 5.67% |

| RGB standard deviation | 1.66% | 5.95% |

| Pressure [MPa] | The Stability Time (Ratio 1:1) [h] | The Stability Time (Ratio 9:4) [h] |

|---|---|---|

| 5 | 2 | 2 |

| 10 | 3 | 3 |

| 15 | 3 | 3 |

| 20 | 5 | 5 |

| 25 | 5 | 5 |

| Parameter | |

|---|---|

| Injection pressure Pj [MPa] | 5, 10, 15 |

| Gasoline–water volumetric ratio | G0, G50, G70, G100 |

| Injection temperature [°C] | 30–160 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, M.; Wu, Z.; Ferrari, A.; Fu, L.; Vento, O. Experimental Investigation on Gasoline—Water Mixture Fuel Impingement Preparation Method and Spray Characteristics with High Injection Temperatures and Pressures. Energies 2023, 16, 6026. https://doi.org/10.3390/en16166026

Ji M, Wu Z, Ferrari A, Fu L, Vento O. Experimental Investigation on Gasoline—Water Mixture Fuel Impingement Preparation Method and Spray Characteristics with High Injection Temperatures and Pressures. Energies. 2023; 16(16):6026. https://doi.org/10.3390/en16166026

Chicago/Turabian StyleJi, Meng, Zhijun Wu, Alessandro Ferrari, Lezhong Fu, and Oscar Vento. 2023. "Experimental Investigation on Gasoline—Water Mixture Fuel Impingement Preparation Method and Spray Characteristics with High Injection Temperatures and Pressures" Energies 16, no. 16: 6026. https://doi.org/10.3390/en16166026

APA StyleJi, M., Wu, Z., Ferrari, A., Fu, L., & Vento, O. (2023). Experimental Investigation on Gasoline—Water Mixture Fuel Impingement Preparation Method and Spray Characteristics with High Injection Temperatures and Pressures. Energies, 16(16), 6026. https://doi.org/10.3390/en16166026