Oat as a Potential Source of Energy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Field Experiment

- −

- 0 kg N ha−1 (control plots);

- −

- 40 kg N ha−1;

- −

- 80 kg N ha−1;

- −

- 120 kg N ha−1.

2.2. Laboratory Analysis

2.2.1. Analysis of the Content of Macro- and Microelements in Oat Grain

2.2.2. Combustion Analysis of Samples

2.3. Statistical Analysis

3. Results and Discussion

3.1. Yield of Grain and Straw

3.2. Energetic Value of Grain and Straw

3.3. Ash Content

3.4. Analysis of the Content of Macro- and Microelements in Oat Grain

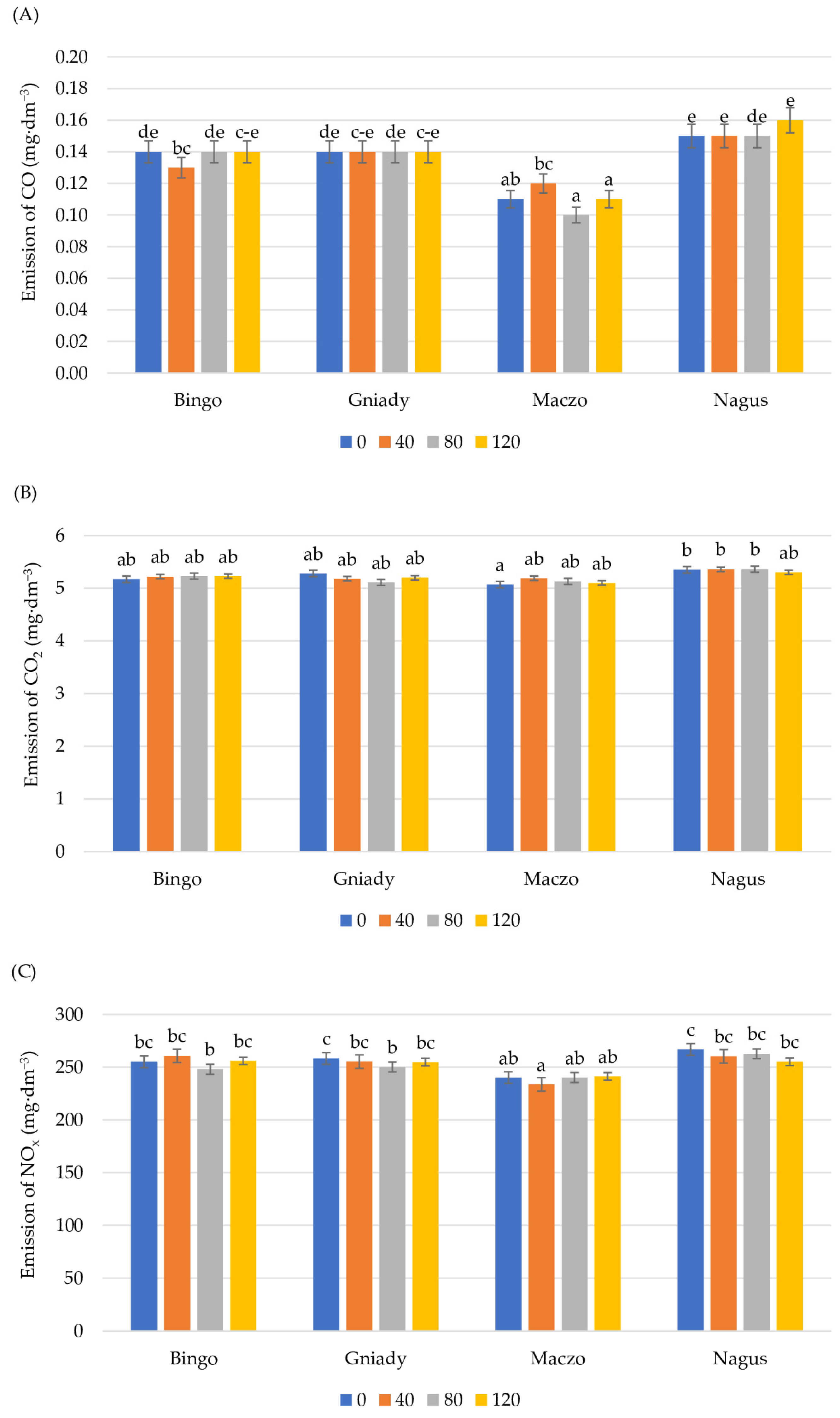

3.5. Gas Emissions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Niedziółka, I.; Szpryngiel, M.; Zaklika, B. Possibilities of using biomass for energy purposes. Agric. Eng. 2014, 1, 155–164. [Google Scholar] [CrossRef]

- Güney, T. Renewable energy, non-renewable energy and sustainable development. Int. J. Sustain. Dev. World Ecol. 2019, 26, 389–397. [Google Scholar] [CrossRef]

- Amjith, L.R.; Bavanish, B. A review on biomass and wind as renewable energy for a sustainable environment. Chemosphere 2022, 293, 133579. [Google Scholar] [CrossRef]

- In Focus: Renewable Energy in Europe. Available online: https://commission.europa.eu/news/focus-renewable-energy-europe-2020-03-18_pl (accessed on 15 March 2023).

- Dhillon, R.S.; von Wuehlisch, G. Mitigation of global warming through renewable biomass. Biomass Bioenergy 2013, 48, 75–89. [Google Scholar] [CrossRef]

- Nues, L.J.R.; Matias, J.C.O.; Catalao, J.P.S. Mixed biomass pellets for thermal energy production: A review of combustion models. Appl. Energy 2014, 127, 135–140. [Google Scholar] [CrossRef]

- Maj, G. Emission factors and energy properties of agro and forest biomass in aspect of sustainability of energy sector. Energies 2018, 11, 1516. [Google Scholar] [CrossRef]

- Vargas-Moreno, J.M.; Callejón-Ferre, A.J.; Pérez-Alonso, J.; Velázquez-Martí, B. A review of the mathematical models for predicting the heating value of biomass materials. Renew. Sustain. Energy 2012, 16, 3065–3083. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels production through biomass pyrolysis—A technological review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Lim, C.J.; Bim, X.T.; Kuang, X.; Melin, S.; Yazdanpanah, F.; Sokhansanj, S. Analysis on storage off-gass emissions from woody, herbaceous and torrefied biomass. Energies 2015, 8, 1745–1759. [Google Scholar] [CrossRef]

- Fournel, S.; Palacios, J.H.; Morissette, R.; Villeneuve, J.; Godbout, S.; Heitz, M.; Savoie, P. Influence of biomass properties on technical and environmental performance of a multi-fuel boiler during on-farm combustion of energy crops. Appl. Energy 2015, 141, 247–259. [Google Scholar] [CrossRef]

- Suzuki, K.; Tsuji, N.; Shirai, Y.; Hassan, M.A.; Osaki, M. Evaluation of biomass energy potential towards achieving sustainability in biomass energy utilization in Sabah, Malaysia. Biomass Bioenergy 2017, 97, 149–154. [Google Scholar] [CrossRef]

- Jegannathan, K.R.; Chan, E.S.; Ravindra, P. Harnessing biofuels: A global renaissance in energy production? Renew. Sustain. Energy Rev. 2009, 13, 2163–2168. [Google Scholar] [CrossRef]

- Maj, G. Diversification and environmental impact assessment of plant biomass energy Use. Pol. J. Environ. Stud. 2015, 24, 2055–2061. [Google Scholar] [CrossRef] [PubMed]

- Nakomcic-Smaragdakis, B.; Cepic, Z.; Dragutinovic, N. Analysis of solid biomass energy potential in Autonomous Province of Vojvodina. Renew. Sustain. Energy Rev. 2016, 57, 186–191. [Google Scholar] [CrossRef]

- Herbert, G.J.; Krishnan, A.U. Quantifying environmental performance of biomass energy. Renew. Sustain. Energy Rev. 2016, 59, 292–308. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): An overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Paula, L.E.R.; Trugilho, P.F.; Napoli, A.; Bianchi, M.L. Characterization of residues from plant biomass for use in energy generation. Cerne 2011, 17, 237–246. [Google Scholar] [CrossRef]

- Magdziarz, A.; Wilk, M. Thermal characteristics of the combustion process of biomass and sewage sludge. J. Therm. Anal. Calorim. 2013, 114, 519–529. [Google Scholar] [CrossRef]

- Khan, S.; Paliwal, V.; Pandey, V.V.; Kumar, V. Biomass as renewable energy. Int. Adv. Res. J. Sci. Eng. Technol. 2015, 2, 301–304. [Google Scholar]

- Perea-Moreno, M.A.; Samerón-Manzano, E.; Perea-Moreno, A.J. Biomass as renewable energy: Worldwide research trends. Sustainability 2019, 11, 863. [Google Scholar] [CrossRef]

- Czekała, W.; Pulka, J.; Jasiński, T.; Szewczyk, P.; Bojarski, W.; Jasiński, J. Waste as substrates for agricultural biogas plants: A case study from Poland. J. Water Land Dev. 2023, 56, 45–50. [Google Scholar] [CrossRef]

- López-Bellido, L.; Wery, J.; López-Bellido, R.J. Energy crops: Prospects in the context of sustainable agriculture. Eur. J. Agron. 2014, 60, 1–12. [Google Scholar] [CrossRef]

- Muller, A. Sustainable agriculture and the production of biomass for energy use. Clim. Change 2009, 94, 319–331. [Google Scholar] [CrossRef]

- Martyniak, D. Energy crops useful for the development of soils of poor agricultural value. In Proceedings of the Cereal Grain and Cereal Products Promotion Fund 2016, Radzików, Poland, 14 October 2016. (In Polish). [Google Scholar]

- Hauptvogl, M.; Kotrla, M.; Prčík, M.; Pauková, Ž.; Kováčik, M.; Lošák, T. Phytoremediation potential of fast-growing energy plants: Challenges and perspectives—A review. Pol. J. Environ. Stud. 2019, 29, 505–516. [Google Scholar] [CrossRef]

- Uellendahl, H.; Wang, G.; Møller, H.B.; Jørgensen, U.; Skiadas, I.V.; Gavala, H.N.; Ahring, B.K. Energy balance and cost-benefit analysis of biogas production from perennial energy crops pretreated by wet oxidation. Water Sci. Technol. 2008, 58, 1841–1847. [Google Scholar] [CrossRef] [PubMed]

- Blanco-Canqui, H. Energy crops and their implications on soil and environment. Agron. J. 2010, 102, 403–419. [Google Scholar] [CrossRef]

- Koçar, G.; Civaş, N. An overview of biofuels from energy crops: Current status and future prospects. Renew. Sustain. Energy Rev. 2013, 28, 900–916. [Google Scholar] [CrossRef]

- Małuszyńska, I.; Wodziński, M.; Małuszyński, M. The use of biomass for energy purposes. Possibilities and limitations. Sci. Rev. Eng. Environ. Sci. 2013, 62, 487–497. (In Polish) [Google Scholar]

- Dahl, J.; Obernberger, I. Evaluation of the combustion characteristics of four perennial energy crops (Arundo donax, Cynara cardunculus, Miscanthus × giganteus and Panicum virgatum). In Proceedings of the 2nd World Conference on Biomass for Energy, Industry and Climate Protection, Rome, Italy, 10–14 May 2004. [Google Scholar]

- Sims, R.E.; Hastings, A.; Schlamadinger, B.; Taylor, G.; Smith, P. Energy crops: Current status and future prospects. Glob. Change Biol. 2006, 12, 2054–2076. [Google Scholar] [CrossRef]

- Borkowska, H.; Molas, R. Yield comparison of four lignocellulosic perennial energy crop species. Biomass Bioenergy 2013, 51, 145–153. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Warmiński, K.; Tworkowski, J.; Szczukowski, S.; Olba–Zięty, E.; Gołaszewski, J. Energy efficiency of perennial herbaceous crops production depending on the type of digestate and mineral fertilizers. Energy 2017, 134, 50–60. [Google Scholar] [CrossRef]

- Feledyn-Szewczyk, B.; Matyka, M.; Staniak, M. Comparison of the effect of perennial energy crops and agricultural crops on weed flora diversity. Agronomy 2019, 9, 695. [Google Scholar] [CrossRef]

- FAO. Crops and Livestock Products. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 24 February 2023).

- Keppel, A.; Finnan, J.; Rice, B.; Owende, P.; MacDonnell, K. Cereal grain combustion in domestic boilers. Biosyst. Eng. 2013, 115, 136–143. [Google Scholar] [CrossRef]

- Pinto, C.W.; Barth, G.; Molin, R.; Silva, D.A.D.; Pauletti, V. Characterization of oat biomass for energy production. Rev. Caatinga 2021, 34, 537–547. [Google Scholar] [CrossRef]

- Zhang, K.; Dong, R.; Hu, X.; Ren, C.; Li, Y. Oat-based foods: Chemical constituents, glycemic index, and the effect of processing. Foods 2021, 10, 1304. [Google Scholar] [CrossRef]

- Yue, J.; Gu, Z.; Zhu, Z.; Yi, J.; Ohm, J.B.; Chen, B.; Rao, J. Impact of defatting treatment and oat varieties on structural, functional properties, and aromatic profile of oat protein. Food Hydrocoll. 2021, 112, 106368. [Google Scholar] [CrossRef]

- Singh, R.; De, S.; Belkheir, A. Avena sativa (Oat), a potential neutraceutical and therapeutic agent: An overview. Crit. Rev. Food Sci. Nutr. 2013, 53, 126–144. [Google Scholar] [CrossRef]

- Sterna, V.; Zute, S.; Brunava, L. Oat grain composition and its nutrition benefice. Agric. Agric. Sci. Procedia 2016, 8, 252–256. [Google Scholar] [CrossRef]

- Martínez-Villaluenga, C.; Peñas, E. Health benefits of oat: Current evidence and molecular mechanisms. Curr. Opin. Food Sci. 2017, 14, 6–31. [Google Scholar] [CrossRef]

- Kelling, K.A.; Fixen, P.E. Soil and nutrient requirements for oat production. In Oat Science and Technology; Marshall, H.G., Sorrells, M.E., Eds.; American Society of Agronomy, Inc.: Madison, WI, USA; Crop Science Society of America, Inc.: Madison, WI, USA, 1992; Volume 33, pp. 165–190. [Google Scholar] [CrossRef]

- Menon, R.; Gonzalez, T.; Ferruzzi, M.; Jackson, E.; Winderl, D.; Watson, J. Oat—From farm to fork. Adv. Food Nutr. Re. 2016, 77, 1–55. [Google Scholar] [CrossRef]

- Marshall, A.; Cowan, S.; Edwards, S.G.; Griffiths, I.; Howarth, C.; Langdon, T.; White, E. Crops that feed the world 9. Oat—A cereal crop for human and livestock feed with industrial applications. Food Sec. 2013, 5, 13–33. [Google Scholar] [CrossRef]

- Banaś, A.; Dębski, H.; Banaś, W.; Heneen, W.K.; Dahlqvist, A.; Bafor, M.; Stymn, S. Lipids in grain tissues of oat (Avena sativa): Differences in content, time of deposition, and fatty acid composition. J. Exp. Bot. 2007, 58, 2463–2470. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, E.S.; Wallo, W. Colloidal oatmeal: History, chemistry and clinical properties. J. Drugs Dermatol. 2007, 6, 167–170. [Google Scholar] [PubMed]

- Thro, A.M.; Frey, K.J. Inheritance of groat-oil content and high-oil selection in oat Avena sativa L.). Euphytica 1985, 34, 251–263. [Google Scholar] [CrossRef]

- Biel, W.; Bobko, K.; Maciorowski, R. Chemical composition and nutritive value of husked and naked oat grain. J. Cereal Sci. 2009, 49, 413–418. [Google Scholar] [CrossRef]

- Kouřimská, L.; Sabolová, M.; Horčička, P.; Rys, S.; Božik, M. Lipid content, fatty acid profile, and nutritional value of new oat cultivars. J. Cereal Sci. 2018, 84, 44–48. [Google Scholar] [CrossRef]

- Kwaśniewski, D. Production and utilization of the oats grain as renewable energy source. Probl. Inż. Roln. 2010, 3, 95–101. (In Polish) [Google Scholar]

- Adapa, P.; Tabil, L.; Schoenau, G. Compaction characteristics of barley, canola, oat and wheat straw. Biosyst. Eng. 2009, 104, 335–344. [Google Scholar] [CrossRef]

- Proszak-Miąsik, D.; Jarecki, W.; Nowak, K. Selected parameters of oat straw as an alternative energy raw material. Energies 2022, 15, 331. [Google Scholar] [CrossRef]

- Gomiero, T.; Paoletti, M.G.; Pimentel, D. Biofuels: Efficiency, ethics, and limits to human appropriation of ecosystem services. J. Agric. Environ. Ethics 2010, 23, 403–434. [Google Scholar] [CrossRef]

- Rozakis, S.; Kremmydas, D.; Pudełko, R.; Borzęcka-Walker, M.; Faber, A. Straw potential for energy purposes in Poland and optimal allocation to major co-firing power plants. Biomass Bioenergy 2013, 58, 275–285. [Google Scholar] [CrossRef]

- Maral, H.; Dumlupınar, Z.; Dokuyucu, T.; Akkaya, A. Response of six oat (Avena sativa L.) cultivars to nitrogen fertilization for agronomical traits. Turk. J. Field. Crops. 2013, 18, 254–259. Available online: https://dergipark.org.tr/en/pub/tjfc/issue/17121/179032 (accessed on 15 May 2023).

- Sylvester-Bradley, R.; Kindred, D.R. Analysing nitrogen responses of cereals to prioritize routes to the improvement of nitrogen use efficiency. J. Exp. Bot. 2009, 60, 1939–1951. [Google Scholar] [CrossRef] [PubMed]

- Pecio, A.; Bichonski, A. Nitrogen fertilization and fungicide application as elements of oat production. Pol. J. Environ. Stud. 2010, 19, 1297–1305. [Google Scholar]

- Neugschwandtner, R.W.; Kaul, H.P. Sowing ratio and N fertilization affect yield and yield components of oat and pea in intercrops. Field Crops Res. 2014, 155, 159–163. [Google Scholar] [CrossRef]

- Podolska, G.; Maj, L.; Nita, Z. Effect of sowing density and nitrogen fertilization doses on grain yield and chemical components of naked short-shoot oat. Biul. IHAR 2006, 239, 49–59. (In Polish) [Google Scholar]

- Tobiasz-Salach, R.; Bobrecka-Jamro, D. Impacts of nitrogen fertilisation on yields and nutritional values of oats grains. Przegląd. Zboż.-Młyn. 2016, 60, 28–30. (In Polish) [Google Scholar]

- Da Silva, J.A.G.; Neto, C.J.G.; Fernandes, S.B.V.; Mantai, R.D.; Scremin, O.B.; Pretto, R. Nitrogen efficiency in oat on grain yield with stability. Rev. Bras. Eng. Agric. E Ambient. 2016, 20, 1095–1100. [Google Scholar] [CrossRef]

- Ma, B.L.; Zheng, Z.; Pageau, D.; Vera, C.G.; Fregeau-Reid, J.; Xue, A.; Yan, W. Nitrogen and phosphorus uptake, yield and agronomic traits of oat cultivars as affected by fertilizer N rates under diverse environments. Nutr. Cycl. Agroecosyst. 2017, 108, 245–265. [Google Scholar] [CrossRef]

- May, W.E.; Brandt, S.; Hutt-Taylor, K. Response of oat grain yield and quality to nitrogen fertilizer and fungicides. Agron. J. 2020, 112, 1021–1034. [Google Scholar] [CrossRef]

- Oleszek, M.; Matyka, M. Nitrogen fertilization level and cutting affected lignocellulosic crops properties important for biogas production. BioResources 2017, 4, 8565–8580. [Google Scholar] [CrossRef]

- Krzystek, L.; Wajszczuk, K.; Pazera, A.; Matyka, M.; Slezak, R.; Ledakowicz, S. The influence of plant cultivation conditions on biogas production: Energy efficiency. Waste Biomass Valorization 2020, 11, 513–523. [Google Scholar] [CrossRef]

- Klikocka, H.; Kasztelan, A.; Zakrzewska, A.; Wyłupek, T.; Szostak, B.; Skwaryło-Bednarz, B. The energy efficiency of the production and conversion of spring triticale grain into bioethanol. Agronomy 2019, 9, 423. [Google Scholar] [CrossRef]

- PN-EN ISO 18122:2016-01; English Version—Solid Biofuels—Determination of Ash Content. ISO: Geneva, Switzerland, 2016. Available online: https://sklep.pkn.pl/pn-en-iso-18122-2016-01e.html (accessed on 10 March 2023).

- Zhou, Q.P.; Biswas, D.K.; Ma, B.L. Comparisons among cultivars of wheat, hulless and hulled oat: Dry matter, N and P accumulation and partitioning as affected by N supply. J. Plan Nutr. Soil Sci. 2013, 176, 929–941. [Google Scholar] [CrossRef]

- Mantai, R.D.; da Silva, J.A.; Carbonera, R.; Carvalho, I.R.; Lautenchleger, F.; Pereira, L.M. Technical and agronomic efficiency of nitrogen use on the yield and quality of oat grains. Rev. Bras. Eng. Agric. E Ambient. 2021, 25, 529–537. [Google Scholar] [CrossRef]

- Wróbel, E.; Budzyński, W.; Dubis, B. Agricultural, energy and economic efficiency of oat and spring barley cultivation on light soil. Żywn Ńauka Technol. Jakość 1999, 1, 166–172. (In Polish) [Google Scholar]

- Gorash, A.; Armonienė, R.; Mitchell Fetch, J.W.; Liatukas, Ž.; Danytė, V. Aspects in oat breeding: Nutrition quality, nakedness and disease resistance, challenges and perspectives. Ann. Appl. Biol. 2017, 171, 281–302. [Google Scholar] [CrossRef]

- Nakonieczny, P.; Kluza, P.A.; Tatar, G.; Bródka, R. Characteristics of types and selected utilization problems of boilers and stoves fired by different fuels. Acta Scie Pol. Tech. Agrar. 2014, 13, 27–40. (In Polish) [Google Scholar] [CrossRef]

- Terlikowski, J. Biomass from permanent grassland as a source of renewable energy. Prob. Agric. Eng. 2012, 20, 43–49. (In Polish) [Google Scholar]

- Żabiński, A.; Sadowska, U. Heat of combustion of grains caryopses of lowered quality properties. Agric. Eng. 2012, 136, 353–359. (In Polish) [Google Scholar]

- de Witt, M.; Faaji, A. European biomass resource potential and costs. Biomass Bioenergy 2010, 34, 188–202. [Google Scholar] [CrossRef]

- De la Torre Ugarte, D.G. Bioenergy and agriculture promises and challenges. In Developing Bioenergy Economic and Social Issues; Hazell, P.B.R., Pachauri, R.K., Eds.; International Food Policy Research Institute (IFPRI): Washington, DC, USA, 2006; Volume 14, pp. 5–8. [Google Scholar] [CrossRef]

- Özyuğuran, A.; Yaman, S. Prediction of calorific value of biomass from proximate analysis. Energy Procedia 2017, 107, 130–136. [Google Scholar] [CrossRef]

- Deshannavar, U.B.; Hegde, P.G.; Dhalayat, Z.; Patil, V.; Gavas, S. Production and characterization of agro-based briquettes and estimation of calorific value by regression analysis: An energy application. Mater. Sci. Technol. 2018, 1, 175–181. [Google Scholar] [CrossRef]

- Smaga, M. Comparison of energy crops grown in Poland. Mag. Biomasa 2017, 1, 22–24. [Google Scholar]

- Kaszkowiak, E.; Kaszkowiak, J. Energetic use of oat grain and spring barley. Inż. Ap. Chem. 2010, 49, 57–58. (In Polish) [Google Scholar]

- Mółka, J.; Łapczyńska-Kordon, B. Energy properties of selected types of biomass. Agric. Eng. 2011, 6, 141–147. (In Polish) [Google Scholar]

- Piątkowska, E.; Witkowicz, R.; Pisulewska, E. Basic chemical composition of selected cultivars of oat. Food Sci. Technol. Qual. 2010, 3, 88–99. (In Polish) [Google Scholar] [CrossRef]

- Sykut-Domańska, E.; Rzedzicki, Z.; Nita, Z. Chemical composition variability of naked and husked oat grain (Avena sativa L.). Cereal Res. Commun. 2013, 41, 327–337. [Google Scholar] [CrossRef]

- Biel, W.; Jacyno, E.; Kawęcka, M. Chemical composition of hulled, dehulled and naked oat grains. S. Afr. J. Anim. Sci. 2014, 44, 189–197. [Google Scholar] [CrossRef]

- Pisulewska, E.; Tobiasz-Salach, R.; Witkowicz, R.; Cieślik, E.; Bobrecka-Jamro, D. Effect of habitat conditions on content and quality of lipids in selected oat forms. Food. Sci. Tech. Qu. 2011, 3, 66–77. (In Polish) [Google Scholar] [CrossRef]

- Jarecki, W.; Buczek, J.; Bobrecka-Jamro, D. Influence of nitrogen fertilization on yield of durum wheat (Triticum durum Desf). Frag. Agron. 2013, 30, 68–75. (In Polish) [Google Scholar]

- Lewandowski, I.; Kauter, D. The influence of nitrogen fertilizer on the yield and combustion quality of whole grain crops for solid fuel use. Ind. Crops. Prod. 2003, 17, 103–117. [Google Scholar] [CrossRef]

- Sheng, C.; Azevedo, J.L.T. Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenergy 2005, 28, 499–507. [Google Scholar] [CrossRef]

- Huang, C.; Han, L.; Liu, X.; Yang, Z. Models predicting calorific value of straw from the ash content. Int. J. Green Energy 2008, 5, 533–539. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassilevam, C.G.; Song, Y.C.; Li, W.Y.; Feng, J. Ash contents and ash-forming elements of biomass and their significance for solid biofuel combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Carroll, J.P.; Finnan, J. Physical and chemical properties of pellets from energy crops and cereal straws. Biosyst. Eng. 2012, 112, 151–159. [Google Scholar] [CrossRef]

- Kaķītis, A.; Šmits, M.; Belicka, I. Suitability of crop varieties for energy production. In Proceedings of the 8th International Scientific Conference Engineering for Rural Development 2009, Jelgava, Lativia, 28–29 May 2009. [Google Scholar]

- Vassilev, S.V.; Vassileva, C.G.; Bai, J. Content, modes of occurrence, and significance of phosphorous in biomass and biomass ash. J. Energy Inst. 2023, 108, 101205. [Google Scholar] [CrossRef]

- Ibrahim, M.S.; Ahmad, A.; Sohail, A.; Asad, M.J. Nutritional and functional characterization of different oat (Avena sativa L.) cultivars. Int. J. Food Prop. 2020, 23, 1373–1385. [Google Scholar] [CrossRef]

- Witkowicz, R.; Antonkiewicz, J.; Pisulewska, E.; Bogocz, D. The impact of agronomic factors on the content of selected microelements in naked oat (Avena sativa var. nuda) grain. Ecol. Chem. Eng. 2015, 22, 239–250. [Google Scholar] [CrossRef]

- Schmitz, E.; Nordberg Karlsson, E.; Adlercreutz, P. Warming weather changes the chemical composition of oat hulls. Plant Biol. 2020, 22, 1086–1091. [Google Scholar] [CrossRef]

- Tang, Y.M.; Qiu, S.N.; Li, Q.Y.; Di, G.L.; Wang, J.L.; Sun, H.X. Simulated global climate change benefits the nutritive value of oat grass. Plant Biol. 2022, 24, 846–853. [Google Scholar] [CrossRef] [PubMed]

- Onyenwoke, C.; Tabil, L.G.; Dumonceaux, T.; Cree, D.; Mupondwa, E.; Adapa, P.; Karunakaran, C. Investigation of Steam Explosion Pretreatment of Sawdust and Oat Straw to Improve Their Quality as Biofuel Pellets. Energies 2022, 15, 7168. [Google Scholar] [CrossRef]

- Górnicki, K.; Kaleta, A.; Winiczenko, R. Prediction of higher heating value of oat grain and straw biomass. E3S Web. Conf. 2020, 154, 01003. [Google Scholar] [CrossRef]

- Bobrecka-Jamro, D.; Jarecki, W.; Buczek, J. Response of soya bean to different nitrogen fertilization levels. J. Elem. 2018, 2. [Google Scholar] [CrossRef]

- Klikocka, H.; Marks, M. Sulphur and nitrogen fertilization as a potential means of agronomic biofortification to improve the content and uptake of microelements in spring wheat grain DM. J. Chem. 2018, 2018, 9326820. [Google Scholar] [CrossRef]

- Jurkowska, H.; Wiśniowska-Kielian, B.; Rogoż, A.; Wojciechowicz, T. The effect of nitrogen fertilizer rate on the levels of mineral components in various plant species. II. Microelements. Zesz. Nauk. A. Roln. Im. H. Kołłątaja W Krakowie 1990, 29, 51–64. (In Polish) [Google Scholar]

- Pandey, V.C.; Bajpai, O.; Singh, N. Energy crops in sustainable phytoremediation. Renew. Sustain. Energ. 2016, 54, 58–73. [Google Scholar] [CrossRef]

- Perzon, M. Emissions of organic compounds from the combustion of oat—A comparison with softwood pellets. Biomass Bioenergy 2010, 34, 828–837. [Google Scholar] [CrossRef]

| Calculated Parameters | Method |

|---|---|

| Calculated volume of CO2 | S CO2 = 0.5 · (|Xn−1 − Xn|) · (tn−1 − tn) |

| Calculated volume of gas mixture collected | Sg = tc · 100 |

| % CO2 in the gas mixture under analysis | % CO2 = SCO2/Sg |

| Quantity of gas mixture taken during the test | AL. = tc · 0.025 (dm3 s−1) |

| Volume of CO2 taken during the test | ACO2 = AL.· % CO2 |

| Density of CO2 at room temperature (20 °C) (mg·dm−3) | 1977 |

| Volume of CO2 taken during the measurement (mg) | ACO2 · 1977 |

| Cultivar | N Fertilization (kg·ha−1) | Grain Yield (t·ha−1) | Straw Yield (t·ha−1) |

|---|---|---|---|

| Bingo | 0 | 6.22 ± 0.44 e | 5.92 ± 0.22 ef |

| 40 | 5.88 ± 1.60 e | 5.98 ± 1.62 f | |

| 80 | 7.45 ± 0.69 f | 7.31 ± 0.69 g | |

| 120 | 7.73 ± 0.45 f | 7.54 ± 0.40 g | |

| Gniady | 0 | 6.13 ± 0.38 e | 5.92 ± 0.27 ef |

| 40 | 7.30 ± 0.31 f | 7.11 ± 0.25 g | |

| 80 | 7.21 ± 0.52 f | 7.04 ± 0.48 g | |

| 120 | 7.29 ± 0.71 f | 7.11 ± 0.70 g | |

| Maczo | 0 | 3.58 ± 0.43 a | 3.45 ± 0.38 a |

| 40 | 4.66 ± 0.42 cd | 4.80 ± 0.35 cd | |

| 80 | 4.92 ± 0.51 cd | 4.99 ± 0.42 cd | |

| 120 | 5.13 ± 0.37 d | 5.27 ± 0.26 de | |

| Nagus | 0 | 3.91 ± 0.21 ab | 3.82 ± 0.21 ab |

| 40 | 4.29 ± 0.30 a–c | 4.45 ± 0.22 bc | |

| 80 | 4.53 ± 0.37 b–d | 4.76 ± 0.31 cd | |

| 120 | 5.02 ± 0.75 cd | 5.14 ± 0.68 d | |

| Average | Bingo | 6.82 ± 1.18 B | 6.69 ± 1.14 B |

| Gniady | 6.98 ± 0.69 B | 6.80 ± 0.67 B | |

| Maczo | 4.57 ± 0.73 A | 4.63 ± 0.79 A | |

| Nagus | 4.44 ± 0.59 A | 4.54 ± 0.62 A | |

| Average | 0 | 4.96 ± 1.30 A | 4.78 ± 1.20 A |

| 40 | 5.53 ± 1.44 B | 5.59 ± 1.33 B | |

| 80 | 6.03 ± 1.43 C | 6.03 ± 1.27 C | |

| 120 | 6.29 ± 1.37 C | 6.26 ± 1.21 C | |

| Average | 5.70 | 5.66 | |

| C | *** | *** | |

| F | *** | *** | |

| CxF | *** | *** | |

| Cultivar | N Fertilization (kg·ha−1) | Calorific Value (CV) of Grain (MJ·kg−1) | Calorific Value (CV) of Straw (MJ·kg−1) | Energetic Value (EV) of Grain Yield (MJ ha−1) | Energetic Value (EV) of Straw Yield (MJ ha−1) |

|---|---|---|---|---|---|

| Bingo | 0 | 19.05 ± 0.13 hi | 15.61 ± 0.71 g | 118,507 ± 8160 de | 92,430 ± 4150 de |

| 40 | 18.13 ± 0.07 de | 14.89 ± 0.27 cd | 106,559 ± 29,237 d | 89,402 ± 25,479 d | |

| 80 | 17.63 ± 0.06 b | 14.57 ± 0.22 ab | 131,297 ± 12,528 fg | 106,617 ± 10,820 f | |

| 120 | 17.15 ± 0.04 a | 14.24 ± 0.24 a | 132,479 ± 7380 g | 107,357 ± 6452 f | |

| Gniady | 0 | 19.06 ± 0.11 hi | 15.08 ± 0.22 e | 116,853 ± 7592 de | 89,402 ± 3720 d |

| 40 | 18.67 ± 0.13 f | 15.18 ± 0.10 f | 136,287 ± 6378 g | 107,956 ± 3838 f | |

| 80 | 17.70 ± 0.05 b | 14.69 ± 0.16 c | 127,627 ± 9097 ef | 103,361 ± 6184 f | |

| 120 | 17.56 ± 0.04 b | 14.44 ± 0.11 a | 128,078 ± 12,299 ef | 102,638 ± 9955 ef | |

| Maczo | 0 | 18.89 ± 0.11 gh | 15.15 ± 0.17 ef | 67,528 ± 8122 a | 52,309 ± 6105 a |

| 40 | 18.82 ± 0.07 fg | 14.81 ± 0.06 c | 87,629 ± 8016 bc | 71,123 ± 5065 c | |

| 80 | 17.92 ± 0.05 c | 14.66 ± 0.05 ab | 88,138 ± 9035 bc | 73,123 ± 6242 c | |

| 120 | 17.95 ± 0.06 cd | 14.48 ± 0.13 ab | 92,107 ± 6639 c | 76,270 ± 3667 c | |

| Nagus | 0 | 19.70 ± 0.15 j | 15.05 ± 0.10 e | 77,075 ± 3986 ab | 57,423 ± 3474 ab |

| 40 | 19.20 ± 0.14 i | 15.01 ± 0.07 cd | 82,321 ± 5581 bc | 66,704 ± 3225 bc | |

| 80 | 18.20 ± 0.09 e | 14.77 ± 0.08 c | 823,45 ± 6490 bc | 70,336 ± 4490 c | |

| 120 | 17.91 ± 0.08 c | 14.60 ± 0.18 ab | 89,935 ± 13,322 bc | 75,185 ± 10,817 c | |

| Average | Bingo | 17.99 ± 0.72 A | 14.83 ± 0.65 A | 122,211 ± 19,047 B | 98,951 ± 15,748 B |

| Gniady | 18.25 ± 0.65 B | 14.85 ± 0.34 A | 127,211 ± 11,044 B | 100,810 ± 9307 B | |

| Maczo | 18.39 ± 0.48 C | 14.77 ± 0.27 A | 82,919 ± 12,306 A | 68,206 ± 10,793 A | |

| Nagus | 18.75 ± 0.75 D | 14.86 ± 0.21 A | 83,851 ± 8938 A | 67,412 ± 8880 A | |

| Average | 0 | 19.17 ± 0.34 D | 15.22 ± 0.43 D | 94,991 ± 24,377 A | 72,861 ± 18,976 A |

| 40 | 18.70 ± 0.41 C | 14.97 ± 0.20 C | 103,199 ± 26,094 B | 83,796 ± 20,754 B | |

| 80 | 17.86 ± 0.24 A | 14.67 ± 0.15 B | 107,352 ± 24,398 BC | 88,359 ± 18,374 C | |

| 120 | 17.64 ± 0.33 B | 14.44 ± 0.21 A | 110,650 ± 22,317 C | 90,363 ± 16,897 C | |

| Average | 18.35 | 14.83 | 104,048 | 83,845 | |

| C | *** | n.s. | *** | *** | |

| F | *** | *** | *** | *** | |

| CxF | *** | ** | *** | *** | |

| Cultivar | N Fertilization (kg·ha−1) | Ash Content in Grain (% of Dry Mass) | Ash Content in Straw (% of Dry Mass) |

|---|---|---|---|

| Bingo | 0 | 2.07 ± 0.02 e | 3.12 ± 0.02 a |

| 40 | 2.15 ± 0.03 fg | 3.11 ± 0.12 a | |

| 80 | 2.06 ± 0.01 de | 3.06 ± 0.11 a | |

| 120 | 2.05 ± 0.01 de | 3.05 ± 0.02 a | |

| Gniady | 0 | 2.17 ± 0.02 gh | 4.33 ± 0.04 j |

| 40 | 2.00 ± 0.02 c | 4.26 ± 0.05 h-j | |

| 80 | 1.87 ± 0.02 a | 4.18 ± 0.04 fg | |

| 120 | 1.92 ± 0.01 b | 4.14 ± 0.04 f | |

| Maczo | 0 | 2.03 ± 0.02 c–e | 4.02 ± 0.05 e |

| 40 | 2.02 ± 0.01 cd | 3.92 ± 0.06 d | |

| 80 | 1.86 ± 0.02 a | 3.76 ± 0.09 c | |

| 120 | 1.95 ± 0.02 b | 3.61 ± 0.05 b | |

| Nagus | 0 | 2.20 ± 0.03 hi | 4.27 ± 0.05 ij |

| 40 | 2.24 ± 0.03 i | 4.28 ± 0.04 ij | |

| 80 | 2.11 ± 0.05 f | 4.24 ± 0.05 g–i | |

| 120 | 1.87 ± 0.03 a | 4.19 ± 0.03 f–h | |

| Mean | Bingo | 2.08 ± 0.04 C | 3.09 ± 0.04 A |

| Gniady | 1.99 ± 0.12 B | 4.23 ± 0.08 C | |

| Maczo | 1.96 ± 0.07 A | 3.83 ± 0.17 B | |

| Nagus | 2.11 ± 0.015 D | 4.24 ± 0.05 C | |

| Mean | 0 | 2.12 ± 0.07 D | 3.94 ± 0.50 D |

| 40 | 2.10 ± 0.10 C | 3.89 ± 0.49 C | |

| 80 | 1.97 ± 0.12 B | 3.81 ± 0.48 B | |

| 120 | 1.95 ± 0.07 A | 3.75 ± 0.47 A | |

| Mean | 2.03 | 3.85 | |

| C | *** | *** | |

| F | *** | *** | |

| CxF | *** | *** | |

| Cultivar | Ntot | Ca | K | Mg | Na | P | S |

|---|---|---|---|---|---|---|---|

| (g·kg−1 DM) | |||||||

| Bingo | 2.27 ± 0.35 A | 0.98 ± 0.09 C | 3.20 ± 0.25 A | 1.26 ± 0.07 A | 0.024 ± 0.002 B | 4.61 ± 0.42 B | 1.64 ± 0.14 A |

| Gniady | 2.34 ± 0.38 A | 0.97 ± 0.09 C | 3.23 ± 0.28 AB | 1.25 ± 0.07 A | 0.022 ± 0.004 A | 3.90 ± 0.36 A | 1.67 ± 0.13 A |

| Maczo | 2.47 ± 0.38 B | 0.89 ± 0.05 B | 3.30 ± 0.20 B | 1.45 ± 0.09 B | 0.023 ± 0.003 B | 5.64 ± 0.36 C | 2.08 ± 0.13 B |

| Nagus | 2.59 ± 0.36 C | 0.84 ± 0.06 A | 3.70 ± 0.21 C | 1.59 ± 0.07 C | 0.025 ± 0.004 C | 6.30 ± 0.35 D | 2.19 ± 0.13 C |

| N Fertilization (kg·ha−1) | (g·kg−1 DM) | ||||||

| 0 | 2.21 ± 0.22 A | 0.89 ± 0.08 A | 3.28 ± 0.33 A | 1.39 ± 0.18 AB | 0.023 ± 0.004 A | 5.09 ± 1.16 A | 1.84 ± 0.30 A |

| 40 | 2.24 ± 0.27 A | 0.95 ± 0.11 B | 3.38 ± 0.29 BC | 1.40 ± 0.15 B | 0.024 ± 0.003 A | 5.07 ± 0.98 A | 1.86 ± 0.27 A |

| 80 | 2.62 ± 0.39 B | 0.92 ± 0.10 A | 3.30 ± 0.30 AB | 1.37 ± 0.15 A | 0.023 ± 0.004 A | 5.01 ± 0.97 A | 1.88 ± 0.29 A |

| 120 | 2.61 ± 0.43 B | 0.92 ± 0.07 A | 3.46 ± 0.28 C | 1.39 ± 0.15 AB | 0.024 ± 0.003 A | 5.28 ± 0.85 B | 2.01 ± 0.23 B |

| Mean | 2.42 | 0.92 | 3.36 | 1.39 | 0.023 | 5.11 | 1.90 |

| C | *** | *** | *** | *** | *** | *** | |

| F | *** | *** | * | * | *** | *** | |

| CxF | *** | *** | ** | *** | ** | *** | |

| Cultivar | Cu | Fe | Mn | Zn |

|---|---|---|---|---|

| (mg·kg−1 DM) | ||||

| Bingo | 2.11 ± 0.07 A | 31.5 ± 4.39 A | 39.7 ± 5.09 B | 20.7 ± 2.38 A |

| Gniady | 4.44 ± 0.70 B | 29.6 ± 10.5 A | 35.2 ± 5.44 A | 23.7 ± 3.04 B |

| Maczo | 3.71 ± 0.06 B | 46.4 ± 9.4 B | 34.9 ± 3.56 A | 29.0 ± 2.32 D |

| Nagus | 3.45 ± 0.05 AB | 47.7 ± 10.3 B | 34.6 ± 2.89 A | 26.8 ± 1.97 C |

| N Fertilization (kg·ha−1) | (mg·kg−1 DM) | |||

| 0 | 3.00 ± 0.10 A | 33.8 ± 3.25 A | 34.0 ± 4.92 A | 25.5 ± 3.92 BC |

| 40 | 2.92 ± 0.10 A | 38.8 ± 4.12 A | 35.9 ± 3.35 B | 24.8 ± 3.65 AB |

| 80 | 2.81 ± 0.09 A | 37.6 ± 5.15 B | 36.1 ± 3.92 B | 24.1 ± 4.75 A |

| 120 | 4.98 ± 0.06 B | 45.0 ± 8.24 C | 38.4 ± 5.81 C | 25.8 ± 3.57 C |

| Average | 3.43 | 38.8 | 36.1 | 25.1 |

| C | *** | *** | *** | *** |

| F | *** | *** | *** | *** |

| CxF | *** | *** | *** | *** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tobiasz-Salach, R.; Stadnik, B.; Bajcar, M. Oat as a Potential Source of Energy. Energies 2023, 16, 6019. https://doi.org/10.3390/en16166019

Tobiasz-Salach R, Stadnik B, Bajcar M. Oat as a Potential Source of Energy. Energies. 2023; 16(16):6019. https://doi.org/10.3390/en16166019

Chicago/Turabian StyleTobiasz-Salach, Renata, Barbara Stadnik, and Marcin Bajcar. 2023. "Oat as a Potential Source of Energy" Energies 16, no. 16: 6019. https://doi.org/10.3390/en16166019

APA StyleTobiasz-Salach, R., Stadnik, B., & Bajcar, M. (2023). Oat as a Potential Source of Energy. Energies, 16(16), 6019. https://doi.org/10.3390/en16166019