1. Introduction

Water-source heat pump systems are widely used for heating and cooling due to their high efficiency and significant energy savings [

1]. Wu et al. proposed a sewage- source–air-source heat pump cogeneration hot-water system that recovers and recycles the wasted heat from bath wastewater for a university bath center hot-water system project. The results show that the system has a high operational energy efficiency. In the combined operation mode of the heat pump hot-water system, the operation of the sewage-source heat pump unit was slightly better than the sewage-source–air-source tandem operation [

2]. The performance of water-source heat pump (WSHP) systems for the heating or cooling of buildings depends heavily on various conditions, such as heating and cooling demands, the water source used, and the distance to the water source. Energy efficiency and carbon emissions depend more on the source of water used. As far as economic feasibility is concerned, the most influential factor is the type of building. The distance to water abstraction, especially the vertical distance, has a significant impact on all the criteria in terms of energy and environmental and economic feasibility [

3]. However, conventional water-source heat pumps extract sensible heat from low-grade energy sources, such as river water, seawater, and industrial wastewater, to heat buildings with low energy utilization [

4]. The WPCHP was developed to extract the phase-change energy released from water icing, and the latent heat of this phase change is equivalent to the sensible heat at 80 °C, which substantially improves energy utilization [

5]. Therefore, this heat pump system uses less water and is suitable for heating areas where water resources are scarce.

At present, research on WPCHPs has focused on system improvements, energy consumption characteristics, and the heat transfer performance of PCMs. The structure and experimental parameters of WPCHPs were elaborated [

5] by Yue et al. Wu et al. calculated the primary energy utilization rate of WPCHPs using computational intelligence methods and studied the energy consumption characteristics of the heat pump system. The results show that the primary energy utilization was about 1.145 and the energy efficiency ratio of the system was between 2.8 and 3.2. Considering the energy consumption of ice melting, the effective energy efficiency ratio of the unit was between 2.42 and 2.76 [

6]. Liu et al. used the enthalpy–porosity method to describe the water solidification process and illustrate the effect of changes in the intermediate inlet water temperature, intermediate water flow rate, and cold-water flow rate on heat exchange. The results show that a change in the intermediate inlet water temperature has a large effect on the heat transfer process of the PCM, and a change in the cold-water flow rate has a small effect on the heat transfer process of the PCM. Increasing the intermediate water flow rate can improve the average heat transfer coefficient of the PCM. However, an increase in the average heat transfer coefficient of the PCM slows down with an increase in the intermediate water flow rate [

7]. Compared to conventional heating and cooling methods, WPCHPs have the advantages of low energy consumption, high energy efficiency, and significant economic benefits.

However, the study of WPCHPs also face challenges, such as high energy consumption for ice melting and severe ice jamming. Increasing the cold-water flow rate can alleviate the ice jamming problem. The energy consumption of this heat pump system can be effectively reduced by coupling cold-water phase-change energy with other energy sources. Cheng et al. simulated a coupled system of cold-water phase-change energy with an air source and analyzed the energy consumption of the coupled system when the outdoor temperature and water supply temperature were regulated simultaneously. The results show that the total energy consumption for the heating season and the total energy consumption for the coldest day were the lowest when the outdoor temperature was 1 °C and the user-side water supply temperature was 35.5 °C [

8]. However, the coupled system of cold- water phase-change energy with an air source has a relatively poor heating effect and low operational stability in extremely cold weather. Therefore, this heat pump system is not suitable for large-scale heating projects. Yang et al. proposed SAPCHPs in order to further reduce the energy consumption of WPCHPs, and compared and analyzed the ice-melting performance under three ice-melting modes. The results show that the affected serial dual-source heat pump mode has the highest system performance factor and the pure serial dual-source heat pump mode has the lowest total annual cost [

9]. The coupled heat pump system solves the challenge of ice melting for WPCHPs on the one hand, and compensates for the limitations of a single heat source on the other hand. However, the heating performance of SAPCHPs remains to be studied.

Among all solar technologies, solar-assisted heat pump technology is currently the most popular technology for low- and medium-temperature applications, and multiple heat pump coupling is a future research direction for solar-assisted heat pump technology [

10]. Ran et al. proposed a solar–air hybrid-source heat pump. This hybrid-source heat pump system solves the problem that traditional solar collectors cannot effectively utilize solar energy of different intensities on the one hand, and solves the problem that air-source heat pumps cannot provide stable heating under defrost conditions on the other hand [

11]. Yu et al. proposed a heat pump drying system using a solar-assisted flash-tank vapor injection cycle. This system allowed solar collectors to absorb solar energy at lower temperatures and achieved a significant increase in heating capacity and drying temperature [

12]. Zhang et al. developed a solar-assisted wastewater-source heat pump hot-water system using TRNSYS and analyzed the sensitivity of different factors on the annual heating performance coefficient of the system. It was found that the system performance coefficient and the heat pump performance coefficient were strongly related to the flow rate of the pump and the storage capacity of the heat exchanger tank. The azimuth and tilt angle of the solar collector had little effect on the performance coefficient [

13]. However, solar-coupled heat pump systems still have problems, such as large footprints, mismatches between the energy-supply system and the energy-using system, and optimization of the configuration of the coupling system. Whether in areas with urgent heating demands and abundant solar energy, or in areas where clean energy heating is urgently needed to improve the air environment, the stability and integration of the coupled system should be improved as much as possible to increase solar energy collection efficiency and bring into play the coupling of multiple energy sources [

14].

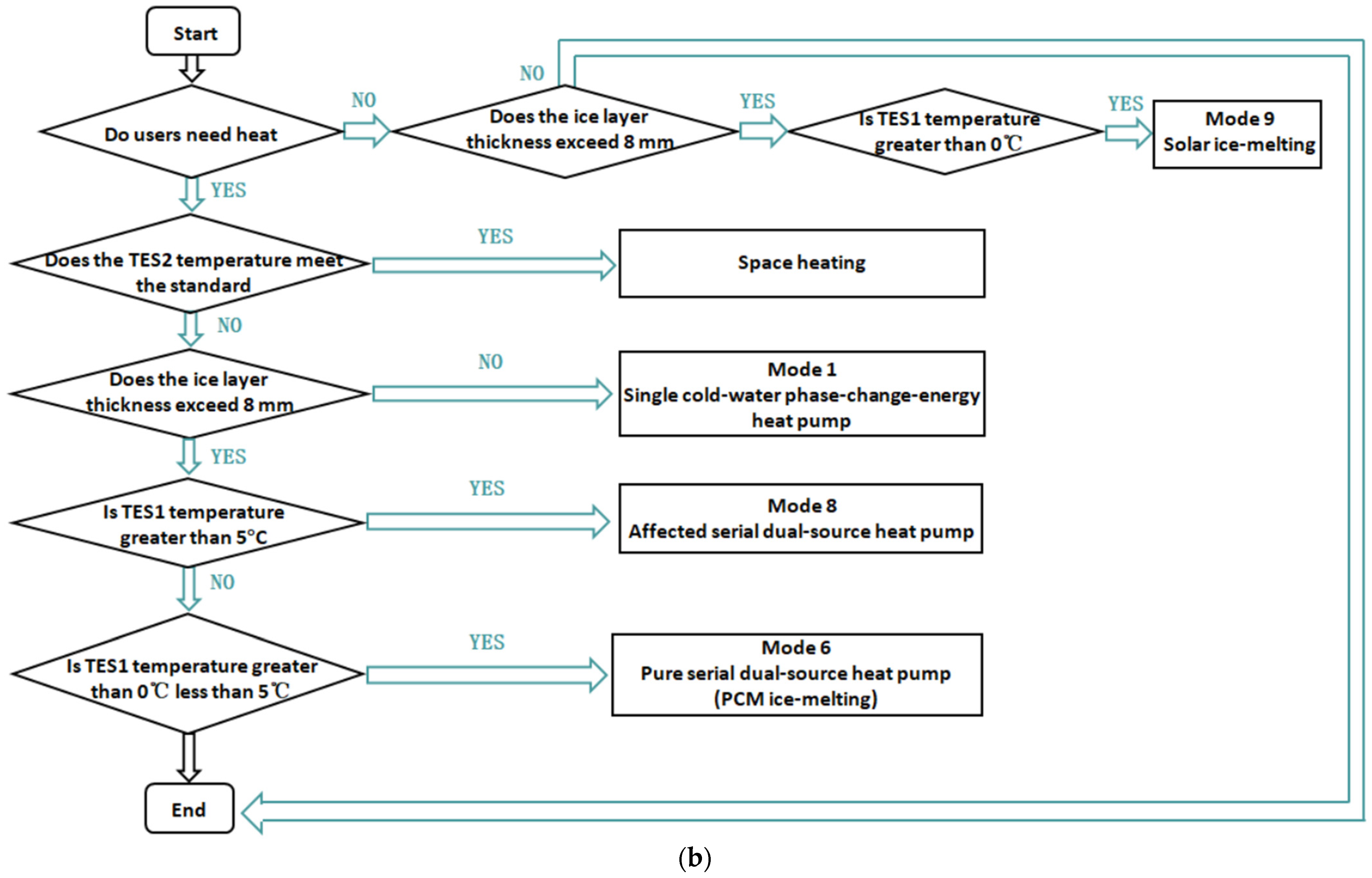

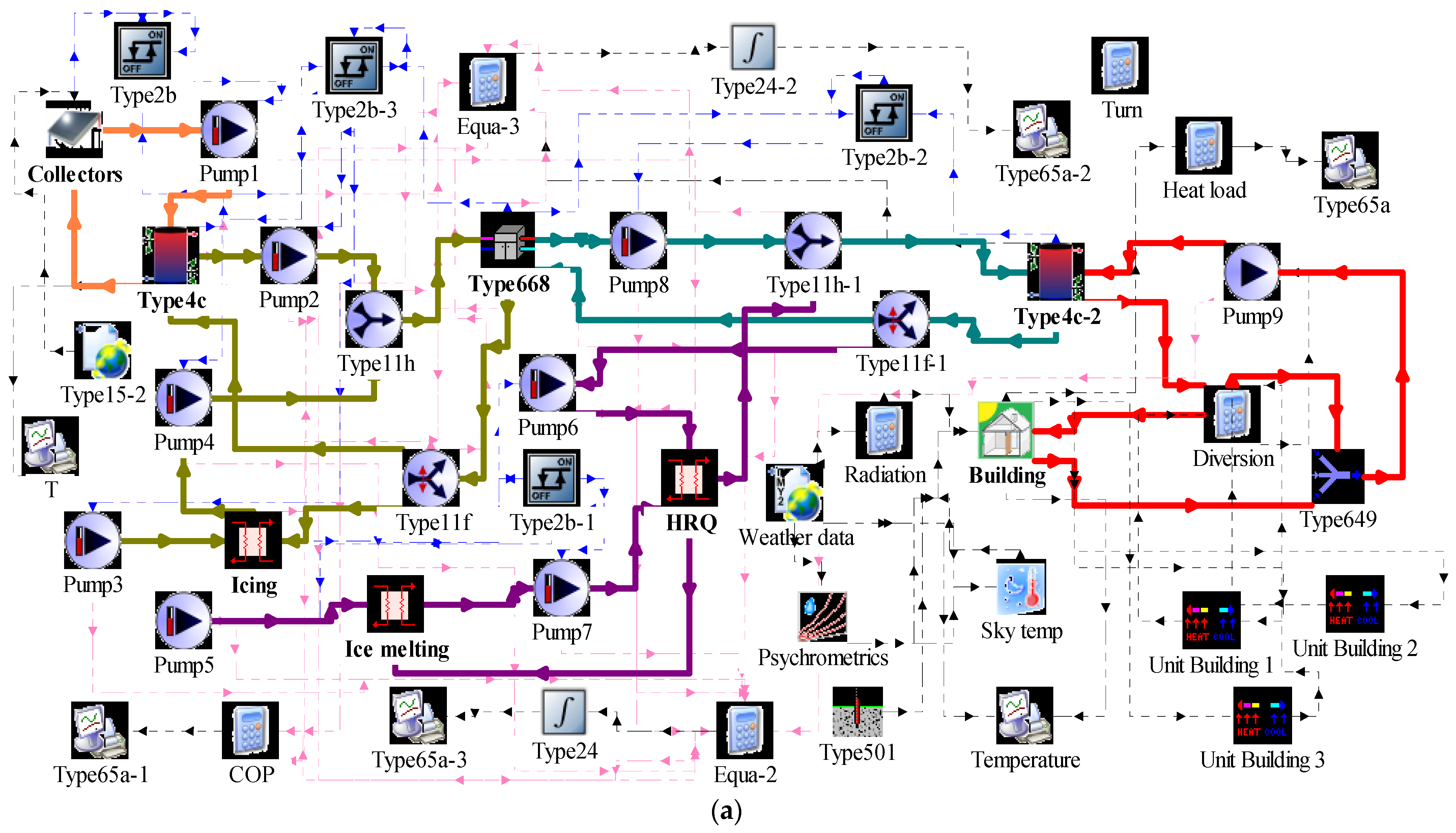

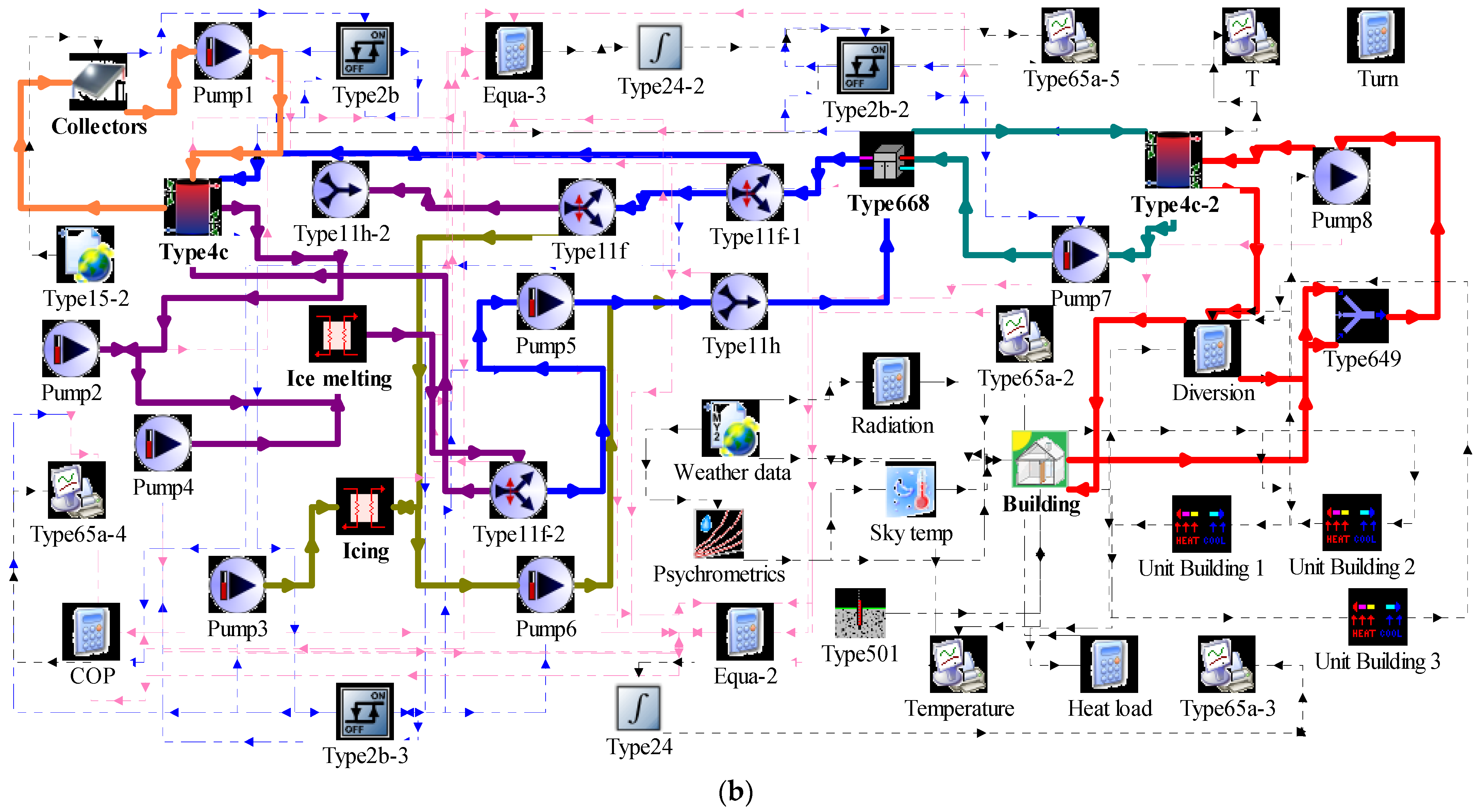

In this paper, SAPCHPs are classified into two types of connections, series and parallel. The control logic flow and operation control inquiry tables are given for the two models, respectively. A residential building in Harbin is used as the study object, and the series and parallel systems are used to supply heat to it, respectively. TRNSYS is used to simulate the series and parallel operations to obtain the relevant heating parameters, such as phase-change heat extraction, solar heat collection, ice-melting heat consumption, heat pump heat production, and terminal heat supply for the different operation modes under the two operation modes, and to obtain the relevant power parameters, such as the power consumption of the pumps, the power consumption of the unit, and the total power consumption. Finally, the payback periods for the series and parallel modes are calculated using economic parameters, such as initial investment, operating cost, and heating cost. By comparing the relevant heating parameters and economic parameters of the two connection methods, a reasonable and optimal system connection method for operation is selected. The research in this paper may enable SAPCHPs to save as much as possible on operating costs by adjusting the operation mode while guaranteeing the terminal heat supply. This case study can provide a reference for heating and economic data for engineering application of SAPCHPs.

4. Results and Discussion

4.1. Analysis of the Operation of Series and Parallel Connections during the Coldest Week

The temperature data vary according to the time of day and the month of the year, so its seasonality must be preserved [

21].

Figure 5 shows the winter temperatures in a unit building and outdoors in Harbin under unheated conditions. The lowest temperatures in unit building 1, unit building 2, unit building 3, and outdoors occurred at 9104 h, 9152 h, 9104 h, and 9046 h, respectively. The time of 9046 h corresponds to 11 January, 9104 h corresponds to 13 January, and 9152 h corresponds to 16 January. Therefore, it is necessary to study the heating operation from 10 January to 17 January.

Figure 6 shows the hourly operating mode and TES2 temperature for the SAPCHPs in series and parallel connections for the period 11 January~17 January. In series operation, mode 1 was run for each hour that the system provided terminal heat supply. On top of this, mode 6, mode 8, and mode 9 were run alternately for ice melting. The heat supplied to the heat pump was mainly from the icing heat extraction of cold water, while the solar collector heat was only used for ice melting. Mode 6 was run mainly at night, and mode 9 was run mainly at noon. The TES2 temperature is roughly between 45 °C and 50 °C. When running in parallel, there are three modes of operation per hour. First, during the night, mode 1 and mode 4 run simultaneously. At this time, the heat supplied by the system to the heat pump is mainly phase-change heat extraction, and the solar collector heat is only used for ice melting. Second, at noon when the sunlight is strong, only mode 2 is run. At this time, the heat supplied by the system to the heat pump is mainly solar collector heat, and the PCM stops running. Finally, during the rest of the day, mode 3 and mode 4 run simultaneously. The PCM and TES1 provide heat to the heat pump at the same time. The TES2 temperature is roughly between 48 °C and 50 °C. In contrast, the TES2 temperature fluctuates relatively more in series operation, while the TES2 temperature is higher and more uniform in parallel operation. The temperature of TES2 is proportional to the temperature of the water supply when the system is supplied with space heating. Therefore, parallel operation provides more reliable heating compared to series operation.

Figure 7 shows the comparison of phase-change heat extraction, solar heat collection, heat pump heat production, terminal heat supply, and ice-melting heat consumption for the series and parallel operation methods, with the ice thickness set to 8 mm. Mode 1 operates without solar heat collection and the heat pump heat production is the sum of the terminal heat supply and ice-melting heat consumption. In mode 1, the cold-water phase-change icing-heat extraction process cannot occur continuously without the ice- melting process. Therefore, the experimental data were added to the system operation in mode 1 with the consideration of ice-melting heat extraction. Mode 2 operates without phase-change heat extraction and ice-melting heat consumption. The heat pump heat production is equal to the terminal heat supply. When mode 3 is running, PCM and TES1 provide heat to the heat pump at the same time. The solar collector heat and phase-change heat extraction are equally divided. Mode 4 uses solar energy to melt ice, and does not consume the terminal supply heat. Mode 6 and mode 8 have the same heat in each part. However, it is difficult to regulate the balance between the temperature and flow rate of mode 8 in practical engineering applications, so the better handling of mode 6 is preferred. Mode 9 is operated on the three premises that the solar energy is sufficient, the PCM needs to melt ice, and the terminal users can temporarily stop heating, which occurs less frequently in this mode of operation.

When the ice thickness is 8 mm, phase-change heat extraction exists in mode 1 and mode 3, and the phase-change heat extraction of mode 1 is higher than that of mode 3. Solar heat collection exists in all modes except mode 1. Among them, mode 2, mode 4, mode 6, mode 8, and mode 9 have equal solar heat extraction and have twice the solar heat extraction of mode 3. Mode 1 has the highest heat pump heat production. Mode 2 and mode 3 have equal heat pump heat production and are second only to mode 1. Mode 4, mode 6, and mode 8 have the lowest heat pump heat production.

Among all the modes, mode 2 and mode 3 supply the most heat to the users. Compared to mode 2 and mode 3, mode 1 supplies about 98.89% of their terminal heat, mode 4 supplies about 87.29% of their terminal heat, and mode 6 and mode 8 supply about 87.49% of their terminal heat. Therefore, the parallel operation provides more heat to the users than series operation. Mode 2 and mode 3 operate without ice-melting heat consumption. This means that the heat loss during parallel operation is less compared to series operation. Therefore, considering only the heating performance, the parallel system should be preferred for this heating project.

4.2. Effect of Ice Thickness on the Heating Performance of Different Operation Modes

When the icing thickness setting of the PCM is changed, the phase-change heat extraction and ice-melting heat consumption of the system change accordingly, and the heat pump heat production and the terminal heat supply may also change accordingly.

Figure 8 illustrates the trend of heat change with ice thickness for each mode of operation. For mode 1, the change in ice thickness has no effect on the amount of solar collector heat. As the ice thickness increases, there is a microscopic increase in the amount of heat consumed by ice melting. For each 1 mm increase in ice thickness from 6 mm to 9 mm, the heat production of the heat pump increases by 16.67%, 14.29%, and 12.50%, respectively, and the terminal heat supply increases by 17.55%, 14.98%, and 13.10%, respectively. The change in ice thickness has no effect on the heat of each part of mode 2. This is because mode 2 is the solar heat pump operation mode. In this operation mode, the PCM stops operating. For mode 3, increasing the ice thickness increases the amount of phase-change heat extraction, but the increase in the phase-change heat extraction is smaller. For each 1 mm increase in ice thickness from 6 mm to 9 mm, the terminal heat supply increases by 7.14%, 6.67%, and 6.25%, respectively. The increase in ice thickness has no effect on the solar collector heat or the terminal heat supply of mode 4, but the ice-melting heat consumption shows a microscopic increase with an increase in ice thickness. Mode 6 and mode 8 show the same trend changes of the heat of each part with a change in ice thickness. The heat consumption of ice melting increases microscopically with the increase in ice thickness, but the terminal heat supply shows a microscopic decreasing trend. From 6 mm to 9 mm, the decrease in the terminal heat supply is 0.26%, 0.19%, and 0.22% for each 1 mm increase in ice thickness, respectively. Mode 9 does not have phase-change heat extraction, heat pump heat production, or terminal heat supply, and the effect of an ice- thickness change on the ice-melting heat consumption is small, so mode 9 is not explored in depth.

In terms of the degree of influence on the terminal heat supply, the ice thickness has the greatest influence on mode 1. Because mode 1 is the WPCHPs operation mode, the main influencing factor on its heating performance is the ice thickness. Therefore, the ice thickness affects the series connection using only cold-water phase-change energy to a greater extent than the parallel connection using both cold-water phase-change energy and solar energy.

4.3. Comparison of the Heating Performance of Series and Parallel Connection Methods

Figure 9 shows the effect of ice thickness on the heat of each component of the series and parallel connections. As the ice thickness increases, phase-change heat extraction, heat pump heat production, terminal heat supply, and ice-melting heat consumption increase for both the series and parallel connections, but the magnitude of the increase varies for each component. For the series connection, for each 1 mm increase in ice thickness from 6 mm to 9 mm, the phase-change heat extraction increases by 16.67%, 14.29%, and 12.50%, respectively. The heat pump heat production increases by 8.11%, 7.53%, and 6.99%, respectively. The terminal heat supply increases by 8.26%, 7.69%, and 7.12%, respectively. The ice-melting heat consumption increases by 3.50%, 2.49%, and 2.82%, respectively. For the parallel connection method, for each 1 mm increase in ice thickness from 6 mm to 9 mm, the phase-change heat extraction increases by 16.67%, 14.29%, and 12.50%, respectively. The heat pump heat production increases by 5.60%, 5.30%, and 5.04%, respectively. The terminal heat supply increases by 5.64%, 5.35%, and 5.08%, respectively. The ice-melting heat consumption increases by 3.50%, 2.49%, and 2.82%, respectively.

The ice thickness affects the phase-change heat extraction and ice-melting heat consumption of the series and parallel connections to the same extent. However, as the ice thickness increases, the heat pump heat production and terminal heat supply of the series connection method grows faster, indicating that the ice thickness has a greater effect on the series connection method. This is consistent with the findings of the previous section.

Figure 10 shows the effect of ice thickness on the power consumption of each part of the series and parallel connection methods. As the ice thickness increases, the water pumps power consumption, the heat pump power consumption, and the total power consumption increases for both the series and parallel connections, but the magnitude of the increase varies for each component. For the series connection, the power consumption of the water pumps increases by 14.97%, 10.51%, and 15.77%; the power consumption of the heat pump increases by 8.54%, 8.89%, and 13.17%; and the total power consumption increases by 9.07%, 9.03%, and 13.40%, respectively, for each 1 mm increase in the ice thickness from 6 mm to 9 mm. For the parallel connection method, the power consumption of the water pumps increases by 10.00%, 8.70%, and 12.10%; the power consumption of the heat pump increases by 4.17%, 3.13%, and 5.40%; and the total power consumption increases by 4.63%, 3.60%, and 5.99%, respectively, for each 1 mm increase in the ice thickness from 6 mm to 9 mm.

The increase in the power consumption of the water pumps decreases first and then increases. This is because from 6 mm to 8 mm, the heat exchange at the wall of the phase-change machine is strengthened continuously, and the increase in the power consumption of the water pump slows down at this time. From 8 mm to 9 mm, the thicker the ice layer, the more serious the ice-plugging phenomenon is, and the increase in the power consumption of the water pump is accelerated. The increase in the total power consumption is close to the increase in the power consumption of the heat pump, because the heat pump’s power consumption accounts for a relatively large amount of the total power consumption. In terms of the total power consumption, ice thickness has a greater effect on the series connection method.

Figure 11 shows the effect of ice thickness on HSPF for the various modes of series and parallel operations. From the figure, it can be seen that the HSPF of mode 1 and mode 3 increase and then decrease as the ice thickness increases, and the HSPF is the largest at 8 mm. The ice thickness has no effect on the HSPF of mode 2. The HSPF of mode 4 decreases with increasing ice thickness. The HSPF of mode 6 and mode 8 decrease with increasing ice thickness, and the decrease is the same. For each 1 mm increase in ice thickness from 6 mm to 9 mm, the HSPF increased by 3.75%, 5.26%, and −2.19% for mode 1; 1.65%, 2.52%, and −0.81% for mode 3; and 1.09%, 1.10%, and 1.11% for mode 4, respectively. The HSPF decreased by 5.12%, 8.29%, and 10.35% for mode 6 and mode 8, respectively.

Mode 4, mode 6, and mode 8 all require ice melting for the PCM. Therefore, the thicker the ice layer, the smaller the HSPF of mode 4, mode 6, and mode 8. Compared to mode 3 and mode 4, the ice thickness affects the HSPF of mode 6 and mode 8 to a greater extent. Therefore, the ice thickness has a greater effect on the HSPF of the series connection method.

4.4. Economic Comparison of Series and Parallel Connection Methods

The economics of SAPCHPs in series and parallel connections are compared in terms of initial investment, operating cost, and payback period. The initial investment mainly includes equipment and material purchase costs, design costs, installation costs, civil construction costs, management costs, and other unforeseen costs. The operating costs include water and electricity. The PCM uses less water, so the water costs in the operating costs are negligible. The savings in sustainable operating costs offset the higher initial costs over time [

22]. When considering the time value of capital, a dynamic payback period is used to calculate and compare the economics of the two connection methods. With the introduction of the new billing tariff, there is added complexity in calculating the payback period of the system [

23]. The dynamic payback period can be calculated using Equation (15).

Compared with the series connection method, the SAPCHPs in a parallel connection method have an additional set of ice-melting heat exchangers. Therefore, the initial investment under the parallel connection method is relatively high. The total electricity consumption during the heating season in parallel operation is relatively higher than in series operation; therefore, the operating cost of parallel connection is also higher than that of series connection. The current residential heating charge in Harbin City is 5.47 USD/m

2 for the area used. The net cash flow can be calculated by using the initial investment, operating cost, and heating charge. The net cash flow is negative during the first year of system operation for both the series and parallel methods. From the second year onward, the net cash flow is positive. In the case of the series method, for example, the initial investment of the project is USD 51,257.14, the operating cost is 3.23 USD/m

2, and the residential heating cost is 5.47 USD/m

2, so the net cash flow in the first year is USD −42,515.57 USD, and from the second year onward, the net cash flow is USD 8741.57. According to the benchmark rate of return of 5% for the heating project, the present value of net cash flow and the present value of cumulative net cash flow can be calculated, as shown in

Table 5.

As can be seen from

Table 5, the year in which the present value of cumulative net cash flow for the series connection has a positive value is year 7, while the year in which the present value of cumulative net cash flow for parallel connection has a positive value is year 8. The dynamic payback period is calculated to be 6.72 years for the series connection and 7.28 years for the parallel connection. Compared to the parallel method, the series method has the lower initial investment, operating cost, and dynamic payback period. Therefore, the series connection is preferred for economic reasons. The PCM has a service life of 20 to 25 years, and the project is profitable for the second 10 to 15 years of operation, whether in series or parallel mode.

Table 6 shows the comparison of the economics of SAPCHPs with series and parallel connections.

5. Conclusions

The heating performance of SAPCHPs in series and parallel modes is investigated. In order to select the optimal heating operation mode, the water supply temperature and terminal heat supply under both operation modes are simulated using TRNSYS, the effect of ice thickness on both operation modes is analyzed, and the economics of the series and parallel operation modes are compared.

(1) When comparing both the water supply temperature and the terminal heat supply, the water supply temperature fluctuates relatively more in series operation, and the water supply temperature is higher and more uniform in parallel operation. Compared with series operation, parallel operation provides more heat to the users. Therefore, under the premise of considering only the heating performance, the parallel connection method should be preferred for this heating project.

(2) Compared with a parallel connection using both cold-water phase-change energy and solar energy, the ice thickness has a greater impact on the series connection using only cold-water phase-change energy. Whether in terms of heat pump heat production, the terminal heat supply, total power consumption, or HSPF, the ice thickness has a greater impact on the series connection compared to the parallel connection method.

(3) The initial investment, operating costs, and dynamic payback period of the parallel method are higher than those of the series method. The dynamic payback period is 6.72 years for the series connection and 7.28 years for the parallel connection. Therefore, when comparing in terms of economics, the series connection method should be preferred. The service life of the PCM is 20~25 years, and the project is profitable during the latter 10~15 years of operation.