Co-pelletization of Hemp Residues and Agricultural Biomass: Effect on Pellet Quality and Stability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Research Design

2.2. Calorific Value

2.3. Durability of Pellets

2.4. Carbon, Nitrogen, and Sulfur Content

2.5. Chlorine Content

2.6. Statistical and Numerical Analyses

3. Results and Discussion

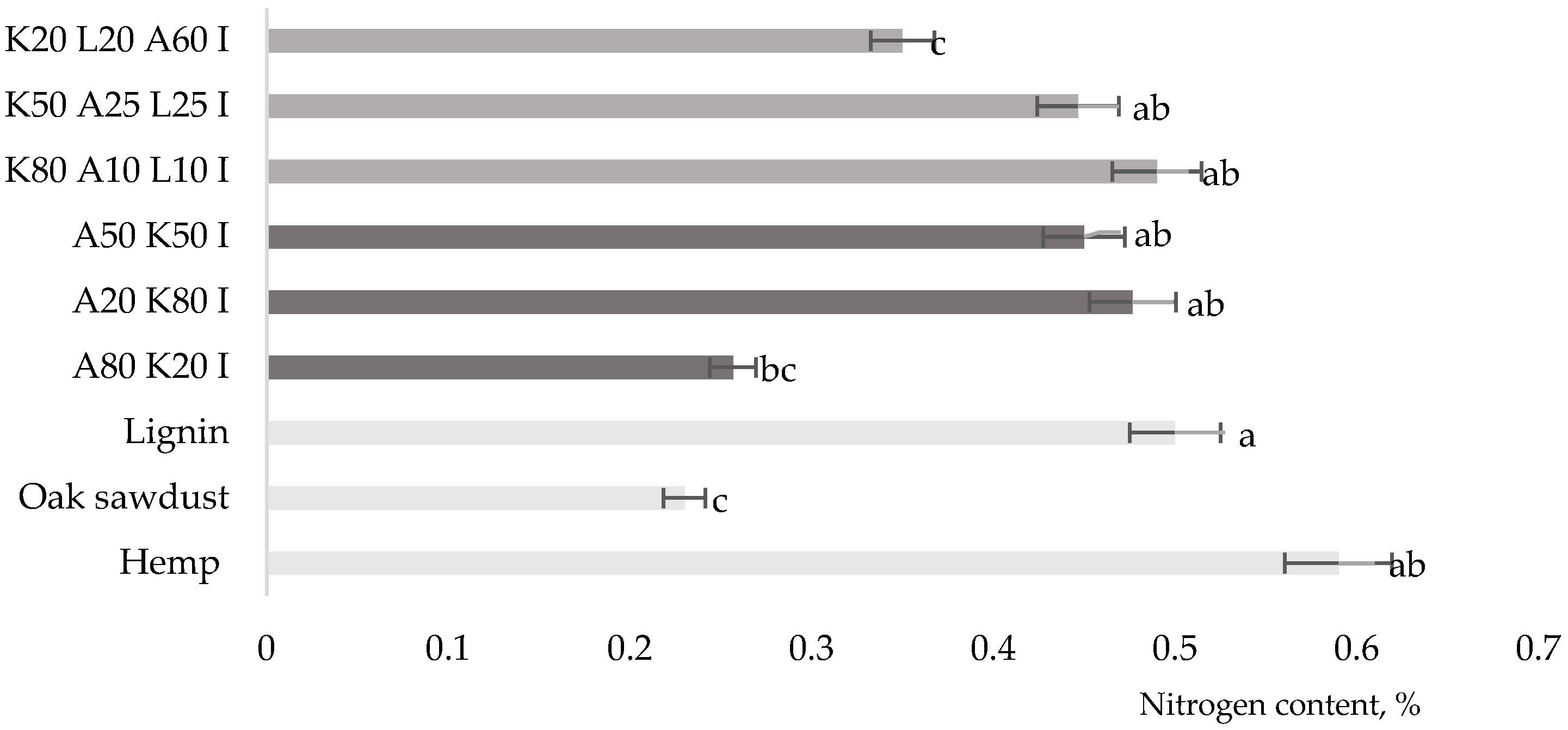

3.1. Chemical Composition of the Pellets

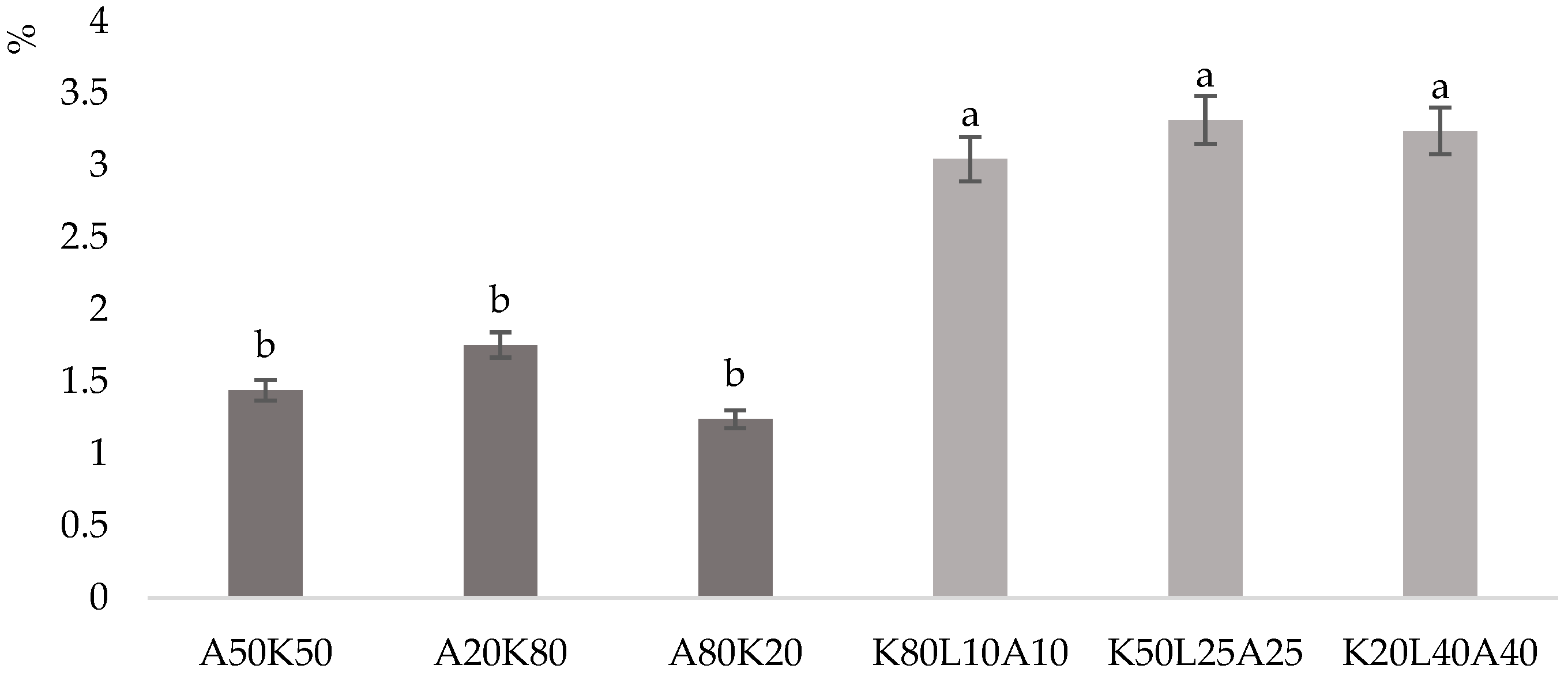

3.2. Ash Content in the Pellets and Different Raw Materials

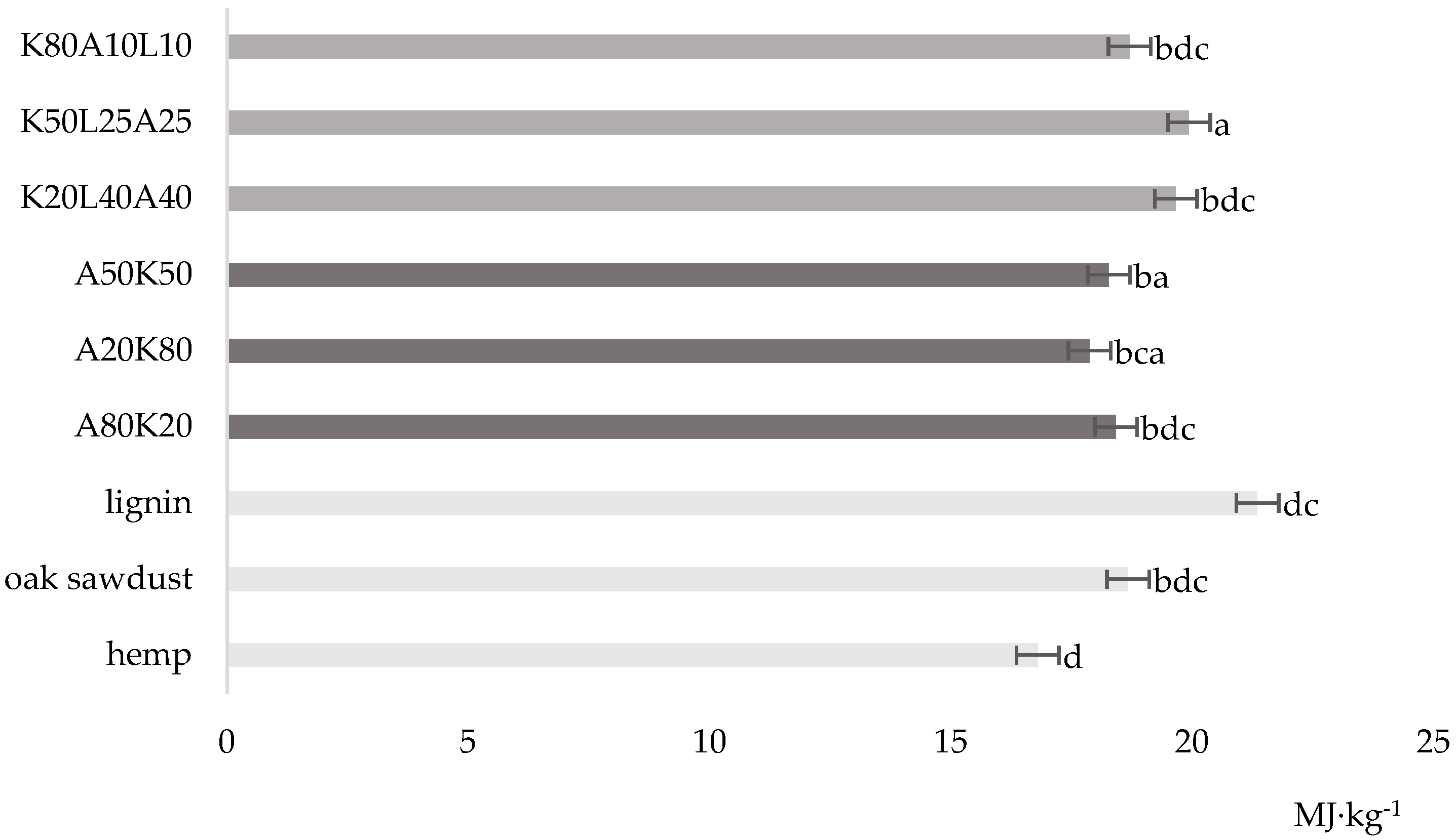

3.3. Calorific Value of Pellets and Different Raw Materials

3.4. Durability of Pellets

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mandley, S.; Daioglou, V.; Junginger, H.; van Vuuren, D.; Wicke, B. EU bioenergy development to 2050. Renew. Sustain. Energy Rev. 2020, 127, 109858. [Google Scholar] [CrossRef]

- Liakas, V.; Klimas, E. Private communication.

- Mai-Moulin, T.; Armstrong, S.; van Dam, J.; Junginger, M. Toward a harmonization of national sustainability requirements and criteria for solid biomass. Biofuels Bioprod. Biorefining 2019, 13, 405–421. [Google Scholar] [CrossRef] [Green Version]

- Zimon, D.; Wozniak, J.; Domingues, P.; Kus, H. Proposition of improving selected logistics processes of pellet production. Int. J. Qual. Res. 2021, 15, 387–402. [Google Scholar] [CrossRef]

- Deleuran, L.C.; Flengmark, P.K. Yield Potential of Hemp (Cannabis sativa L.) Cultivars in Denmark Yield Potential of Hemp (Cannabis sativa L.) Cultivars in Denmark. J. Ind. Hemp. 2008, 10, 7881. [Google Scholar] [CrossRef]

- Schluttenhofer, C.; Yuan, L. Challenges towards Revitalizing Hemp: A Multifaceted Crop. Trends Plant Sci. 2017, 22, 917–929. [Google Scholar] [CrossRef] [Green Version]

- Vitale, I.; Dondo, R.G.; González, M.; Cóccola, M.E. Modelling and optimization of material flows in the wood pellet supply chain. Appl. Energy 2022, 313, 118776. [Google Scholar] [CrossRef]

- Struik, P.C.; Amaducci, S.; Bullard, M.J.; Stutterheim, N.C. Agronomy of fibre hemp (Cannabis sati 6 a L.) in Europe. Ind. Crops Prod. 2000, 11, 107–118. [Google Scholar] [CrossRef]

- Fike, J.H.; Pease, J.W.; Owens, V.N.; Farris, R.L.; Hansen, J.L.; Heaton, E.A.; Hong, C.O.; Mayton, H.S.; Mitchell, R.B.; Viands, D.R. Switchgrass nitrogen response and estimated production costs on diverse sites. GCB Bioenergy 2017, 9, 1526–1542. [Google Scholar] [CrossRef]

- Agricultural Area Dedicated to Hemp Cultivation in Europe in 2019, by Country. Available online: https://www.statista.com/statistics/1204146/area-for-hemp-cultivation-by-country-europe/ (accessed on 26 June 2023).

- An, H. The closed-open truck and loader routing problem for biomass transportation from satellite storage locations to a bioenergy plant. Comput. Electron. Agric. 2022, 194, 106764. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L.; National, I. A review of biomass densifi cation systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Effect of pellet die diameter on density and durability of pellets made from high moisture woody and herbaceous biomass. Carbon Resour. Convers. 2018, 1, 44–54. [Google Scholar] [CrossRef]

- Gong, C.; Thomsen, S.T.; Meng, X.; Pu, Y.; Puig-Arnavat, M.; Bryant, N.; Bhagia, S.; Felby, C.; Ragauskas, A.J.; Thygesen, L.G. Effects of different pelleting technologies and parameters on pretreatment and enzymatic saccharification of lignocellulosic biomass. Renew. Energy 2021, 179, 2147–2157. [Google Scholar] [CrossRef]

- Rudolfsson, M.; Agar, D.A.; Lestander, T.A.; Larsson, S.H. Energy savings through late-steam injection–A new technique for improving wood pellet production. J. Clean. Prod. 2020, 254, 120099. [Google Scholar] [CrossRef]

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status, and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Serrano, C.; Monedero, E.; Lapuerta, M.; Portero, H. Effect of moisture content, particle size and pine addition on quality parameters of barley straw pellets. Fuel Process. Technol. 2011, 92, 699–706. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Tabil, L.; Opoku, A.; Mosqueda, M.R.; Fadeyi, O. Effect of process variables on the quality characteristics of pelleted wheat distiller’s dried grains with solubles. Biosyst. Eng. 2010, 105, 466–475. [Google Scholar] [CrossRef]

- Xie, F.; Huang, Y.; Eksioglu, S. Integrating multimodal transport into cellulosic biofuel supply chain design under feedstock seasonality with a case study based on California. Bioresour. Technol. 2014, 152, 15–23. [Google Scholar] [CrossRef]

- Aghalari, A.; Aladwan, B.S.; Marufuzzaman, M.; Tanger, S.; Da Silva, B.K.; Gude, V.G. Optimizing a pellet supply system: Market-specific pellet production with biomass quality considerations. Comput. Chem. Eng. 2021, 153, 107417. [Google Scholar] [CrossRef]

- BS ISO 14918:2009; Solid Biofuels. Determination of Calorific Value. International Organization for Standardization: Geneva, Switzerland, 2009.

- Tang, K.; Wang, J.; Yang, Y.; Deng, G.; Yu, J.; Hu, W.; Guo, L.; Du, G.; Liu, F. Fiber hemp (Cannabis sativa L.) yield and its response to fertilization and planting density in China. Ind. Crop. Prod. 2022, 177, 114542. [Google Scholar] [CrossRef]

- Leoni, M.; Musio, S.; Croci, M.; Tang, K.; Magagnini, G.M.; Thouminot, C.; Müssig, J.; Amaducci, S. The effect of agronomic management of hemp (Cannabis sativa L.) on stem processing and fibre quality. Ind. Crop. Prod. 2022, 188, 115520. [Google Scholar] [CrossRef]

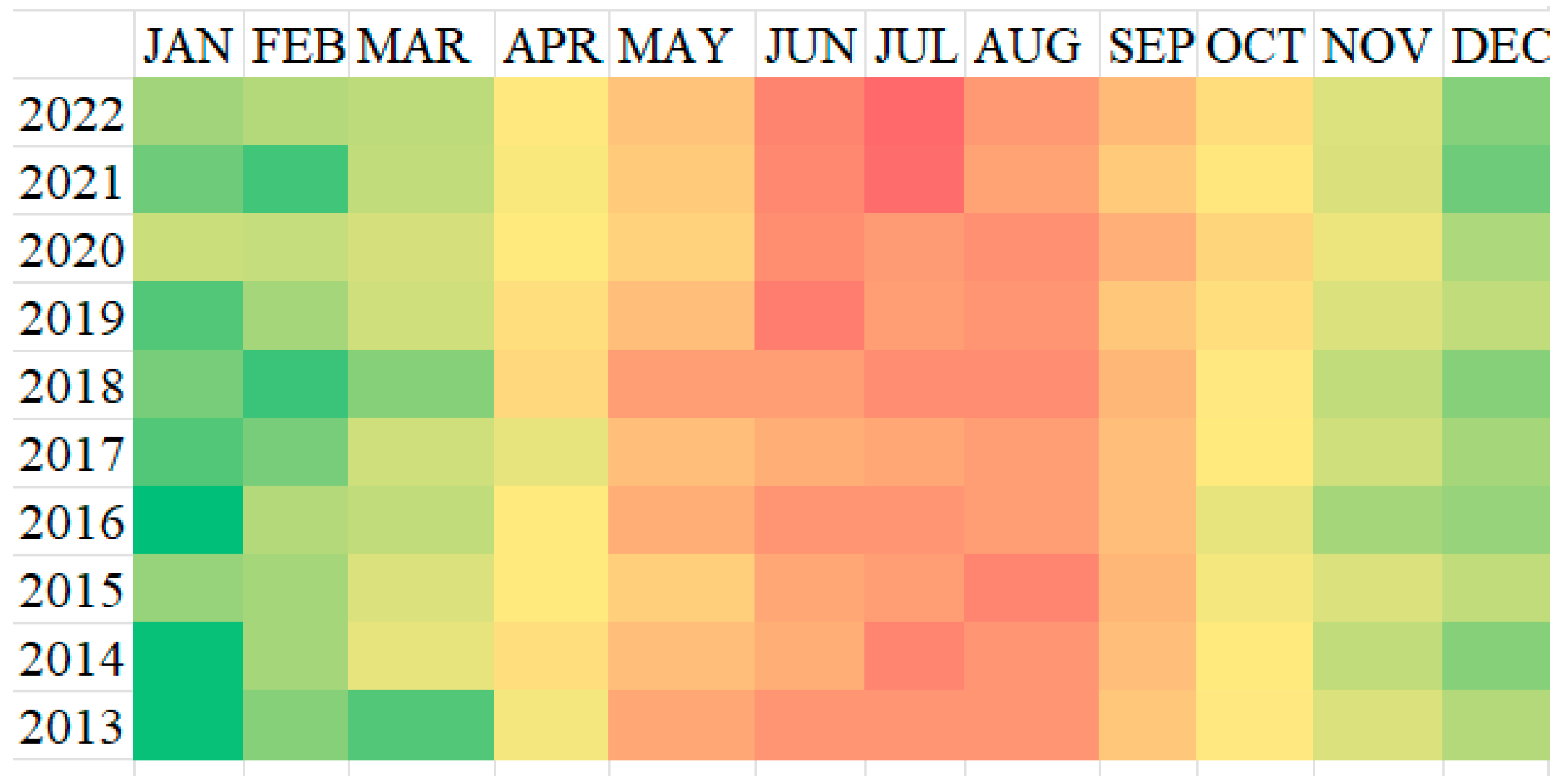

- Žydelis, R.; Herbst, M.; Weihermüller, L.; Ruzgas, R.; Volungevičius, J.; Barčauskaitė, K.; Tilvikienė, V. Yield potential and factor influencing yield gap in industrial hemp cultivation under nemoral climate conditions. Eur. J. Agron. 2022, 139, 126576. [Google Scholar] [CrossRef]

- Aubin, M.; Seguin, P.; Vanasse, A.; Tremblay, G.F.; Mustafa, A.F.; Charron, J. Industrial Hemp Response to Nitrogen, Phosphorus, and Potassium Fertilization. Crop. Forage Turfgrass Manag. 2015, 1, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Civitarese, V.; Acampora, A.; Sperandio, G.; Assirelli, A.; Picchio, R. Production of Wood Pellets from Poplar Trees Managed as Coppices with Di ff erent Harvesting Cycles. Energies 2019, 12, 2973. [Google Scholar] [CrossRef] [Green Version]

- Miranda, T.; Montero, I.; Sepúlveda, F.J.; Arranz, J.I.; Rojas, C.V.; Nogales, S. A Review of Pellets from Different Sources. Materials 2015, 8, 1413–1427. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, C.; Li, Y.; Parnas, R. Shortcut design of sulfur reduction distillation system using pseudo-component description of biodiesel and the sulfur contaminants. Chem. Eng. J. 2021, 430, 133028. [Google Scholar] [CrossRef]

- Stachowicz, P.; Stolarski, M.J. Short rotation woody crops and forest biomass sawdust mixture pellet quality. Ind. Crop. Prod. 2023, 197, 116604. [Google Scholar] [CrossRef]

- Qu, W.; Liu, J.; Xue, Y.; Wang, X.; Bai, X. Potential of producing carbon fiber from biorefinery corn stover lignin with high ash content. J. Appl. Polym. Sci. 2017, 135, 45736. [Google Scholar] [CrossRef]

- Carvalho, L.; Wopienka, E.; Pointner, C.; Lundgren, J.; Verma, V.K.; Haslinger, W.; Schmidl, C. Performance of a pellet boiler fired with agricultural fuels. Appl. Energy 2013, 104, 286–296. [Google Scholar] [CrossRef]

- PN-EN ISO 17225-2:2021-10E; Solid Biofuels—Fuel Specifications and Classes—Part 2: Graded Wood Pellets, October 21, 2021. International Organization for Standardization: Geneva, Switzerland, 2021.

- Oh, J.; Hwang, J.; Cha, D. Fuel Properties of Woody Pellets in Domestic Markets of Korea. J. For. Environ. Sci. 2014, 30, 362–369. [Google Scholar] [CrossRef] [Green Version]

- Hroncová, E.; Ladomerský, J. The Environmental and Energy Potential of Incinerating Various Biomass Mixtures. Adv. Mater. Res. 2014, 1001, 114–117. [Google Scholar] [CrossRef]

- Biokuro Naudotojo Žinynas. Available online: https://www.ena.lt/uploads/PDF-AEI/Leidiniai-LT/4-Biokuro-zinynas.pdf (accessed on 26 June 2023).

- Salentijn, E.M.J.; Zhang, Q.; Amaducci, S.; Yang, M.; Trindade, L.M. New developments in fiber hemp (Cannabis sativa L.) breeding. Ind. Crop. Prod. 2015, 68, 32–41. [Google Scholar] [CrossRef]

- Rajput, S.P.; Jadhav, S.V.; Thorat, B.N. Methods to improve properties of fuel pellets obtained from different biomass sources: Effect of biomass blends and binders. Fuel Process. Technol. 2019, 199, 106255. [Google Scholar] [CrossRef]

- Soleimani, M.; Tabil, X.L.; Grewal, R.; Tabil, L.G. Carbohydrates as binders in biomass densification for biochemical and thermochemical processes. Fuel 2017, 193, 134–141. [Google Scholar] [CrossRef]

| Nomenclature | Percentage of Biomass in Mixtures |

|---|---|

| A80K20 | Oak sawdust 80% hemp residues 20% |

| A50K50 | Oak sawdust 50% hemp residues 50% |

| A20K80 | Oak sawdust 20% hemp residues 80% |

| K80L10A10 | Hemp residues 80% lignin 10% oak sawdust 10% |

| K50L25A25 | Hemp residues 50% lignin 25% oak sawdust 25% |

| K20L40A40 | Hemp residues 20% lignin 20% oak sawdust 60% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stulpinaite, U.; Tilvikiene, V.; Zvicevicius, E. Co-pelletization of Hemp Residues and Agricultural Biomass: Effect on Pellet Quality and Stability. Energies 2023, 16, 5900. https://doi.org/10.3390/en16165900

Stulpinaite U, Tilvikiene V, Zvicevicius E. Co-pelletization of Hemp Residues and Agricultural Biomass: Effect on Pellet Quality and Stability. Energies. 2023; 16(16):5900. https://doi.org/10.3390/en16165900

Chicago/Turabian StyleStulpinaite, Urte, Vita Tilvikiene, and Egidijus Zvicevicius. 2023. "Co-pelletization of Hemp Residues and Agricultural Biomass: Effect on Pellet Quality and Stability" Energies 16, no. 16: 5900. https://doi.org/10.3390/en16165900

APA StyleStulpinaite, U., Tilvikiene, V., & Zvicevicius, E. (2023). Co-pelletization of Hemp Residues and Agricultural Biomass: Effect on Pellet Quality and Stability. Energies, 16(16), 5900. https://doi.org/10.3390/en16165900