A Universal Parametric Modeling Framework for Electric Machine Design

Abstract

:1. Introduction

2. Electric Machine Parametric Modeling

2.1. Electric Machine Data Structure

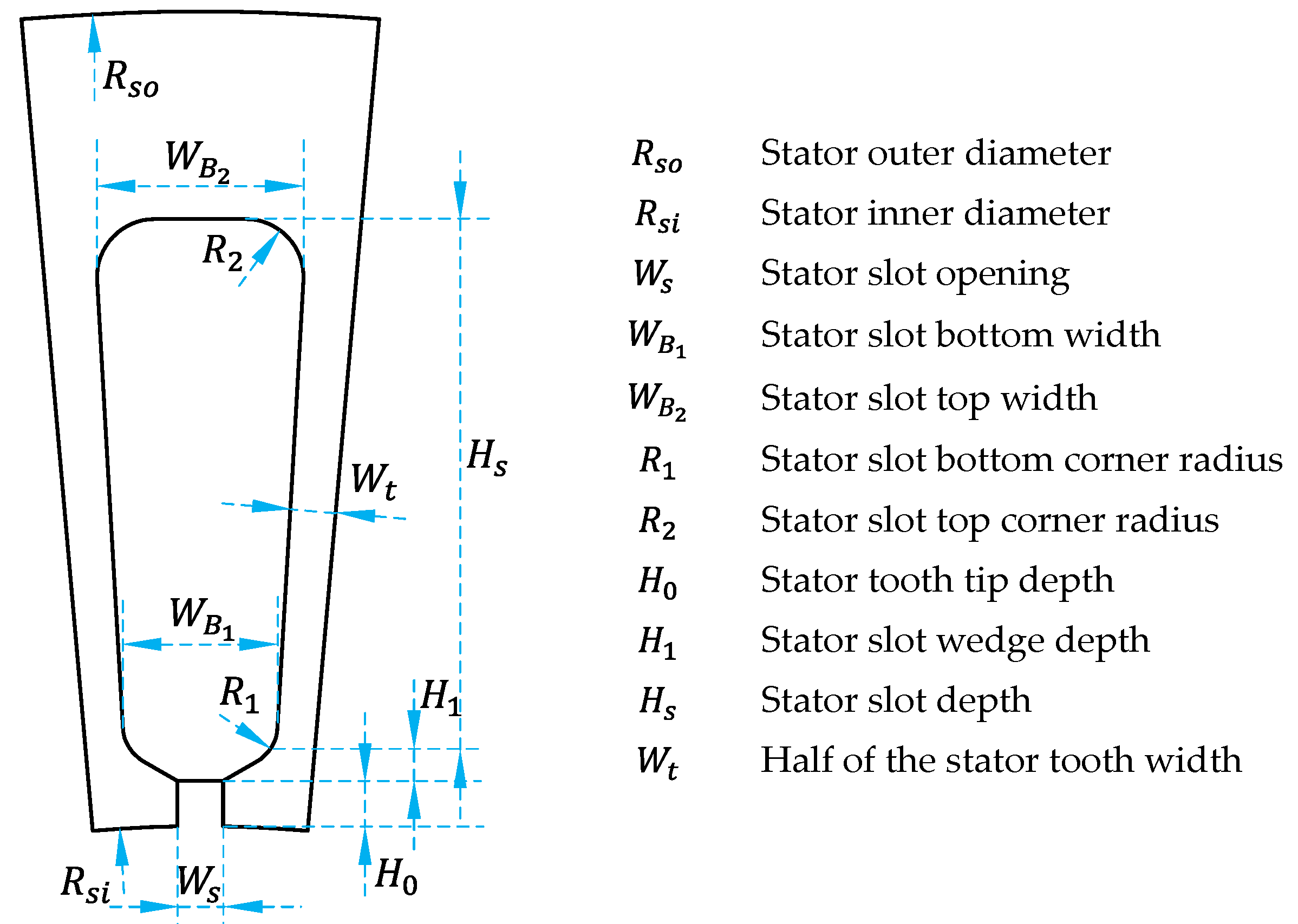

2.1.1. Geometric Structure

2.1.2. Excitations

- (1)

- The center of the tooth is located on the x+ axis;

- (2)

- The center of the tooth is located on the y+ axis;

- (3)

- The center of the slot is located on the x+ axis;

- (4)

- The center of the slot is located on the y+ axis.

- (1)

- The center of the N pole of the magnet steel is located on the x+ axis;

- (2)

- The center of the N pole of the magnet steel is located on the y+ axis;

- (3)

- The NS interval of the magnet steel is located on the x+ axis;

- (4)

- The NS interval of the magnet steel is located on the y+ axis.

2.1.3. Materials

2.1.4. Boundaries

2.2. Geometric Constrain Implementation

2.2.1. Stator

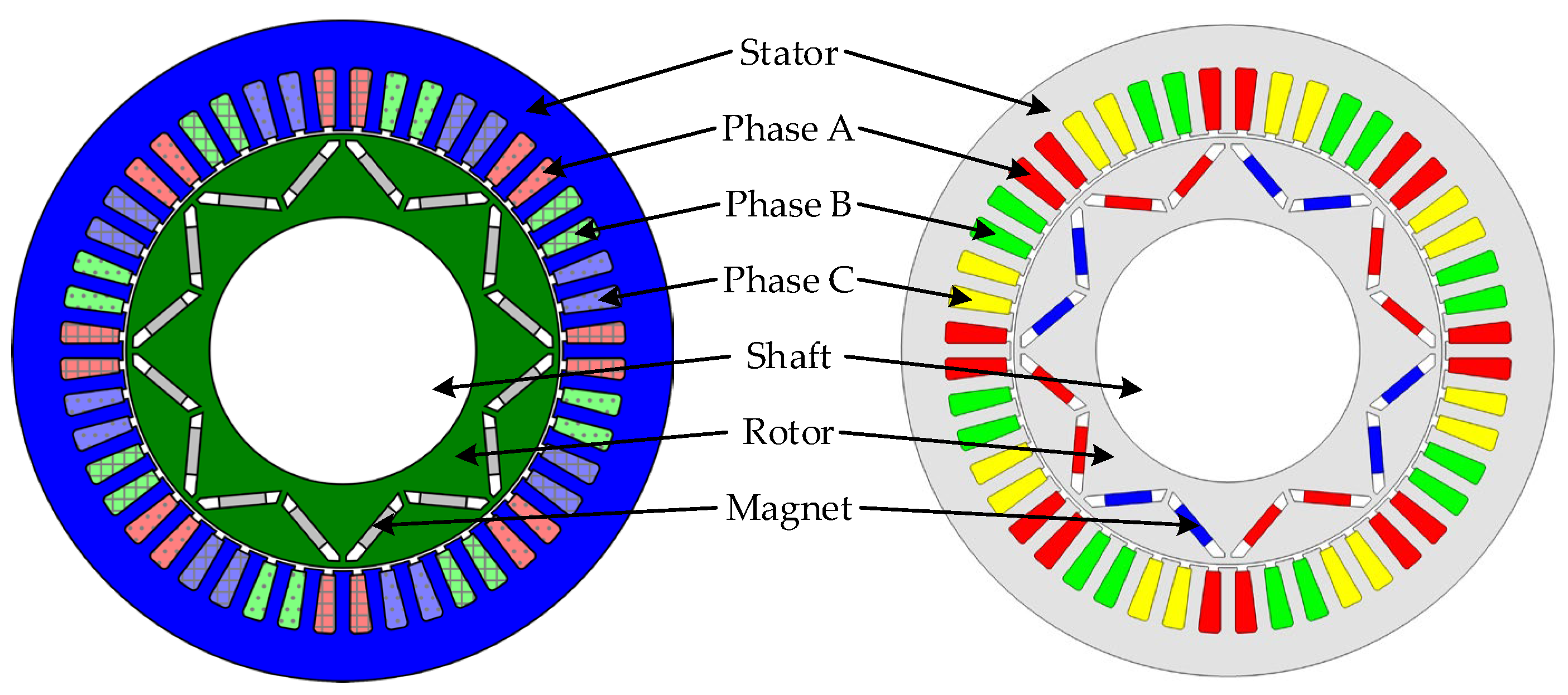

2.2.2. Rotor

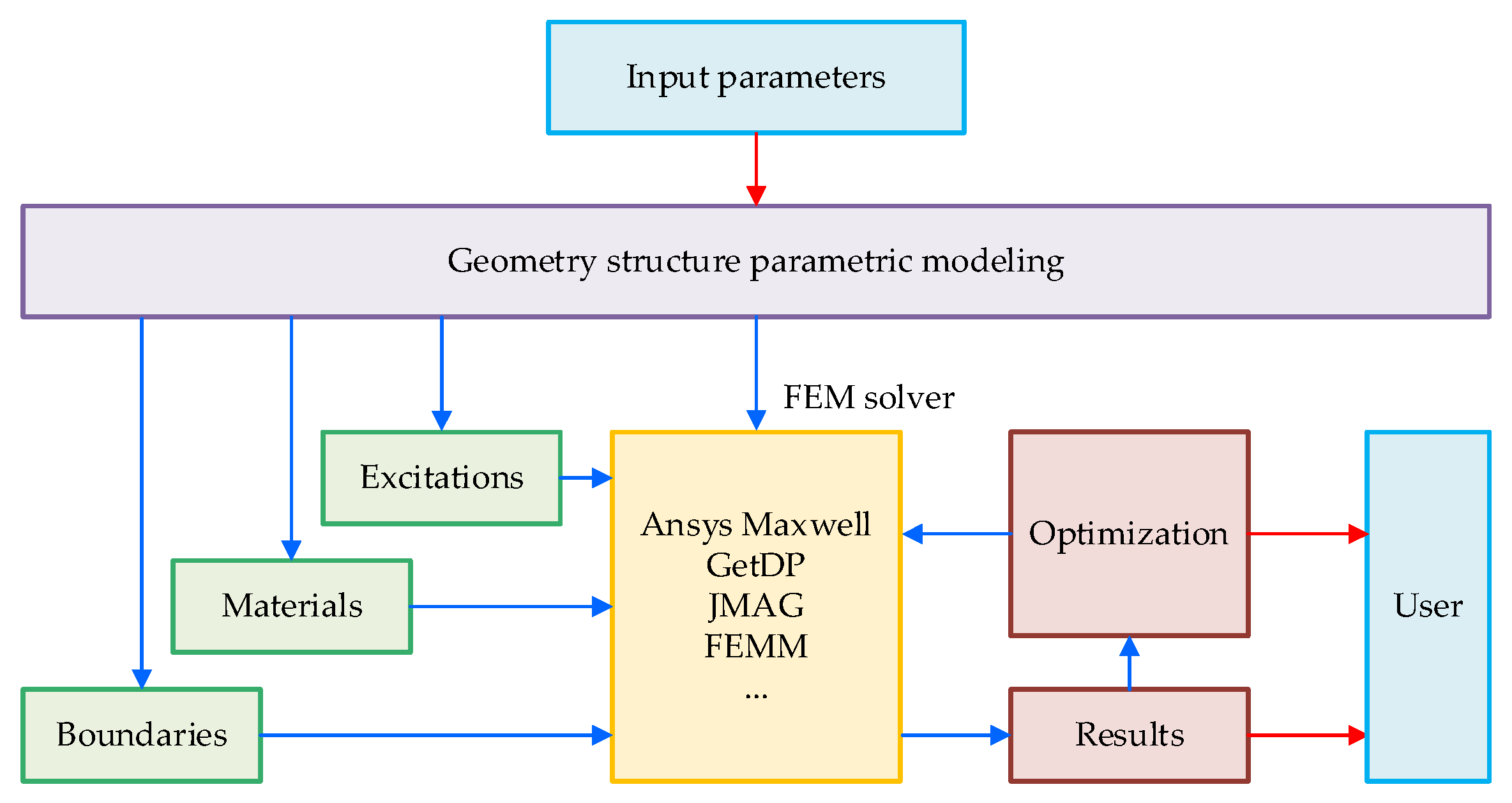

3. Universal Design Framework

- Geometry structure parameters are input, such as slot/pole configurations, excitations, and materials. For optimization purposes, the numerical variables should have specified lower and upper limits, as well as step values. If using type variables like predefined topologies or materials, the defined number range should be provided.

- Parametric modeling of the geometry structure, excitations, materials, and boundary settings is conducted based on the input parameters. The geometry parameters can be modified parametrically for topology optimization. The electric machine model can be automatically split into a symmetrical model to accelerate the optimization process. Excitations can be adjusted to simulate different driving cycles.

- Calculations are performed on the electric machine model by calling the chosen FEA software (e.g., Ansys Maxwell, GetDP, JMAG, FEMM, etc.). The framework generates the corresponding FEM model based on the user’s selection. Once the FEM model is created, the framework invokes the FEA solver to perform the necessary calculations. The solver can be called in the front end or in the background to enhance parallel computing capabilities.

- The calculation process serves various purposes, including early design performance analysis or optimization. The calculated results are immediately available for general electromagnetic performance analysis tasks. Additionally, the results can be utilized for optimization, data sampling (for surrogate models), sensitivity analysis, and other tasks according to the user’s requirements.

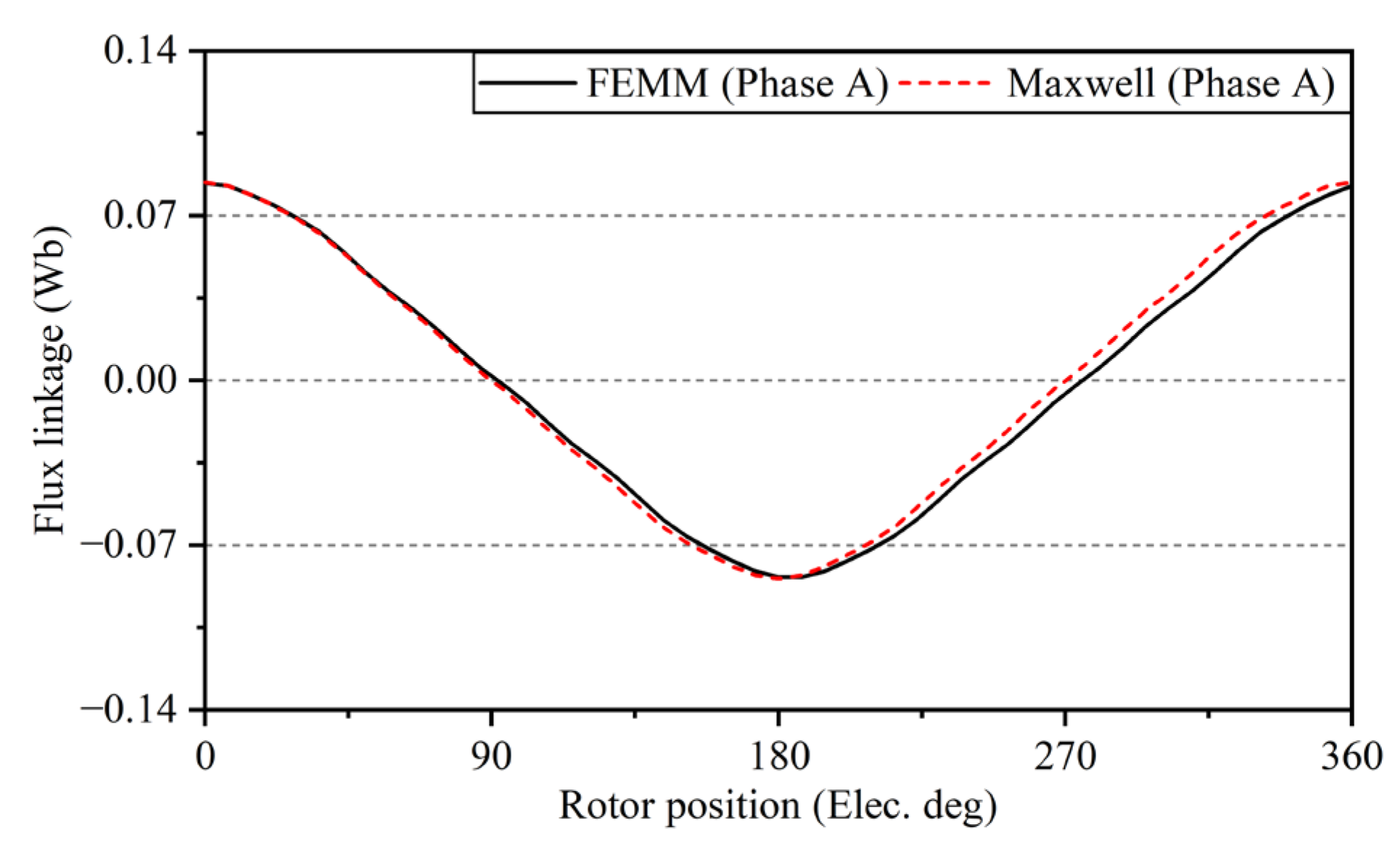

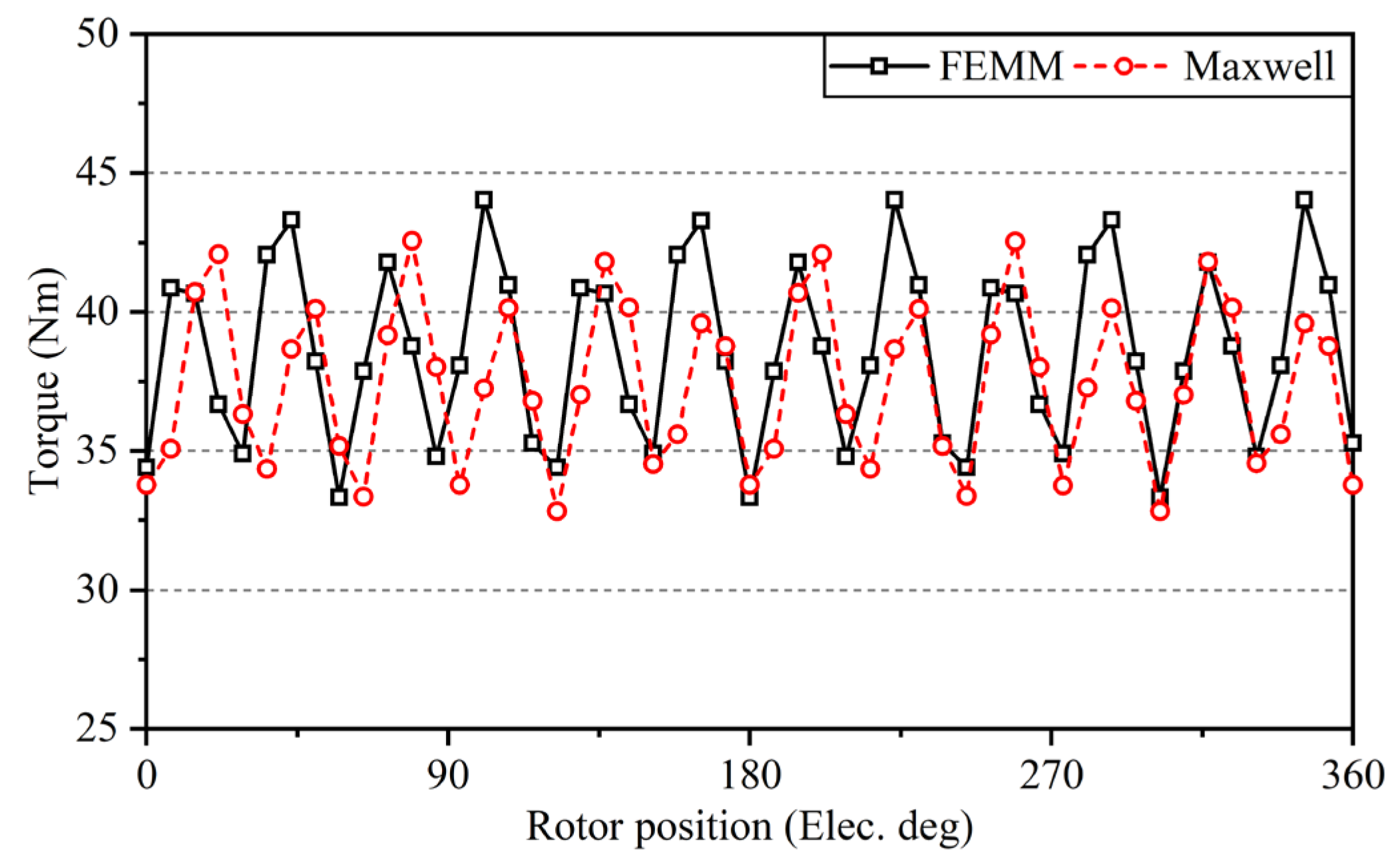

4. Numerical Validation and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Donghui, C.; Wenliang, Z.; Jinghua, J.; Yanyang, W. Parametric equivalent magnetic network modeling approach for multiobjective optimization of PM machine. IEEE Trans. Ind. Electron. 2020, 68, 6619–6629. [Google Scholar]

- Lee, S.-H.; Hong, J.-P.; Lee, J.-Y.; Kwon, Y.K.; Jo, Y.S.; Baik, S.K.; Lee, J.D. Parametric design for superconducting synchronous motor with 3D equivalent magnetic circuit network model. IEEE Trans. Appl. Supercond. 2007, 17, 1541–1544. [Google Scholar] [CrossRef]

- Tikhonova, O.; Malygin, I.; Plastun, A. Electromagnetic calculation for induction motors of various designs by ANSYS maxwell. In Proceedings of the 2017 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), St. Petersburg, Russia, 16–19 May 2017. [Google Scholar]

- Oh, S.-Y.; Hwang, K.-Y.; Song, B.-K.; Kim, S.-I. Motor parametric design using an electro-hydraulic model of a brake system. IEEE Access 2022, 10, 61375–61384. [Google Scholar] [CrossRef]

- Wei, L.; Yongling, H. Parameterization and performance of permanent magnet synchronous motor for vehicle based on Motor-CAD and optiSLang. Wirel. Commun. Mob. Comput. 2022, 2022, 8217386. [Google Scholar]

- Xing, F.; Zhao, W.; Kwon, B.-I. Design and optimisation of a novel asymmetric rotor structure for a PM-assisted synchronous reluctance machine. IET Electr. Power Appl. 2019, 13, 573–580. [Google Scholar] [CrossRef]

- Malagoli, J.A.; Camacho, J.R.; da Luz, M.V.F. Optimal electromagnetic torque of the induction motor generated automatically with Gmsh/GetDP software. Int. Trans. Electr. Energy Syst. 2021, 31, e12773. [Google Scholar] [CrossRef]

- Baluta, G.; Graur, A.; Pentiuc, R.; Diaconescu, C.; Popa, C. FEM analysis of brushless DC servomotor with fractional number of slots per pole. Adv. Electr. Comput. Eng. 2014, 14, 103–108. [Google Scholar] [CrossRef]

- Iyer, L.V.; Lai, C.; Dhulipati, H.; Mukundan, S.; Mukherjee, K.; Kar, N.C. A novel MTPA theory based bottom-up approach towards parametric and structural design of interior PMSM for electric vehicles. Int. Trans. Electr. Energy Syst. 2018, 28, e2489. [Google Scholar] [CrossRef]

- Fu, W.; Chen, Y. Data structures and program techniques of finite element methods for analysis and optimization of electric devices. Int. J. Appl. Electromagn. Mech. 2015, 47, 875–883. [Google Scholar] [CrossRef]

- Bianchi, N.; Dai Pre, M. Use of the star of slots in designing fractional-slot single-layer synchronous motors. IEE Proc.-Electr. Power Appl. 2006, 153, 459–466. [Google Scholar] [CrossRef]

- Caruso, M.; Di Tommaso, A.O.; Marignetti, F.; Miceli, R.; Ricco Galluzzo, G. A general mathematical formulation for winding layout arrangement of electrical machines. Energies 2018, 11, 446. [Google Scholar] [CrossRef] [Green Version]

- Ramesh, P.; Lenin, N.C. High power density electrical machines for electric vehicles—Comprehensive review based on material technology. IEEE Trans. Magn. 2019, 55, 0900121. [Google Scholar] [CrossRef]

- Bramerdorfer, G.; Goldbeck, G.; Kitzberger, M. On the accuracy and improvement of FE-based electric machine evaluation concerning soft magnetic material modeling. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019. [Google Scholar]

- Li, H.L.; Ho, S.L.; Fu, W.N. Precise magnetic field modeling techniques of rotary machines using transient finite-element method. IEEE Trans. Magn. 2012, 48, 4192–4195. [Google Scholar] [CrossRef]

- Nicolae, P.-M.; Bida, E.-F. Aspects regarding the simulation of an electric drive pm motor used in light electric vehicles. In Proceedings of the 2016 International Conference on Applied and Theoretical Electricity (ICATE), Craiova, Romania, 6–8 October 2016. [Google Scholar]

- Nugraha, Y.U.; Yuniarto, M.N.; Herizal, H.; Asfani, D.A.; Riawan, D.C.; Wahyudi, M. Design analysis of axial flux permanent magnet BLDC motor 5 kW for electric scooter application. In Proceedings of the 2018 International Seminar on Intelligent Technology and Its Applications (ISITIA), Bali, Indonesia, 30–31 August 2018. [Google Scholar]

- Sadrossadat, S.A.; Rahmani, O. ANN-based method for parametric modelling and optimising efficiency, output power and material cost of BLDC motor. IET Electr. Power Appl. 2020, 14, 951–960. [Google Scholar] [CrossRef]

- Raia, M.R.; Ciceo, S.; Chauvicourt, F.; Martis, C. Multi-attribute machine learning model for electrical motors performance prediction. Appl. Sci. 2023, 13, 1395. [Google Scholar] [CrossRef]

- You, Y.-M. Multi-objective optimal design of permanent magnet synchronous motor for electric vehicle based on deep learning. Appl. Sci. 2020, 10, 482. [Google Scholar] [CrossRef] [Green Version]

- Sato, T.; Fujita, M. A data-driven automatic design method for electric machines based on reinforcement learning and evolutionary optimization. IEEE Access 2021, 9, 71284–71294. [Google Scholar] [CrossRef]

- Poudel, B.; Amiri, E. Deep learning based design methodology for electric machines: Data acquisition, training and optimization. IEEE Access 2023, 11, 18281–18290. [Google Scholar] [CrossRef]

| Coil Pitch | Phase A | Phase B | Phase C |

|---|---|---|---|

| 5 | (1, −6) (12, −7) | (4, −11) (5, −10) | (8, −3) (9, −2) |

| 3 | (1, −4) (10, −7) | (2, −11) (5, −8) | (6, −3) (9, −12) |

| 1 | (1, −2) (8, −7) | (4, −3) (9, −10) | (5, −6) (12, −11) |

| Parameters | Phase A | Unit |

|---|---|---|

| Number of stator slots | 48 | - |

| Number of rotor poles | 8 | - |

| Rotation speed | 3000 | r/min |

| Stack length | 83.82 | mm |

| Stator outer diameter | 198 | mm |

| Stator inner diameter | 132 | mm |

| Stator slot top width | 6.6 | mm |

| Stator slot top corner radius | 1.5 | mm |

| Stator slot depth | 17.5 | mm |

| Stator slot bottom width | 4.3 | mm |

| Stator slot wedge depth | 0.3 | mm |

| Stator tooth tip depth | 1 | mm |

| Stator slot opening | 3 | mm |

| Air gap length | 1 | mm |

| Rotor outer diameter | 65 | mm |

| Rotor bridge thickness | 2 | mm |

| Rotor pole shoe opening angle | 36.76 | deg. |

| Rotor magnet pole V angle | 125 | deg. |

| Rotor magnet pole inner interval width | 2 | mm |

| Rotor magnet pole outer interval width | 2 | mm |

| Rotor magnet offset length | 3 | mm |

| Magnet width | 14 | mm |

| Magnet thickness | 3.5 | mm |

| Shaft diameter | 80 | mm |

| Magnet material | N40SH | - |

| Iron material | M400-50A | - |

| Number of coil turns | 8 | - |

| Slot filling | 0.6 | - |

| Current density | 6 | A/mm2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, Z.; Jiang, D.; Fu, W. A Universal Parametric Modeling Framework for Electric Machine Design. Energies 2023, 16, 5897. https://doi.org/10.3390/en16165897

Qiao Z, Jiang D, Fu W. A Universal Parametric Modeling Framework for Electric Machine Design. Energies. 2023; 16(16):5897. https://doi.org/10.3390/en16165897

Chicago/Turabian StyleQiao, Zhenyang, Dongdong Jiang, and Weinong Fu. 2023. "A Universal Parametric Modeling Framework for Electric Machine Design" Energies 16, no. 16: 5897. https://doi.org/10.3390/en16165897

APA StyleQiao, Z., Jiang, D., & Fu, W. (2023). A Universal Parametric Modeling Framework for Electric Machine Design. Energies, 16(16), 5897. https://doi.org/10.3390/en16165897