5.1. Main Features of the Battery Replacement System for Electric Buses

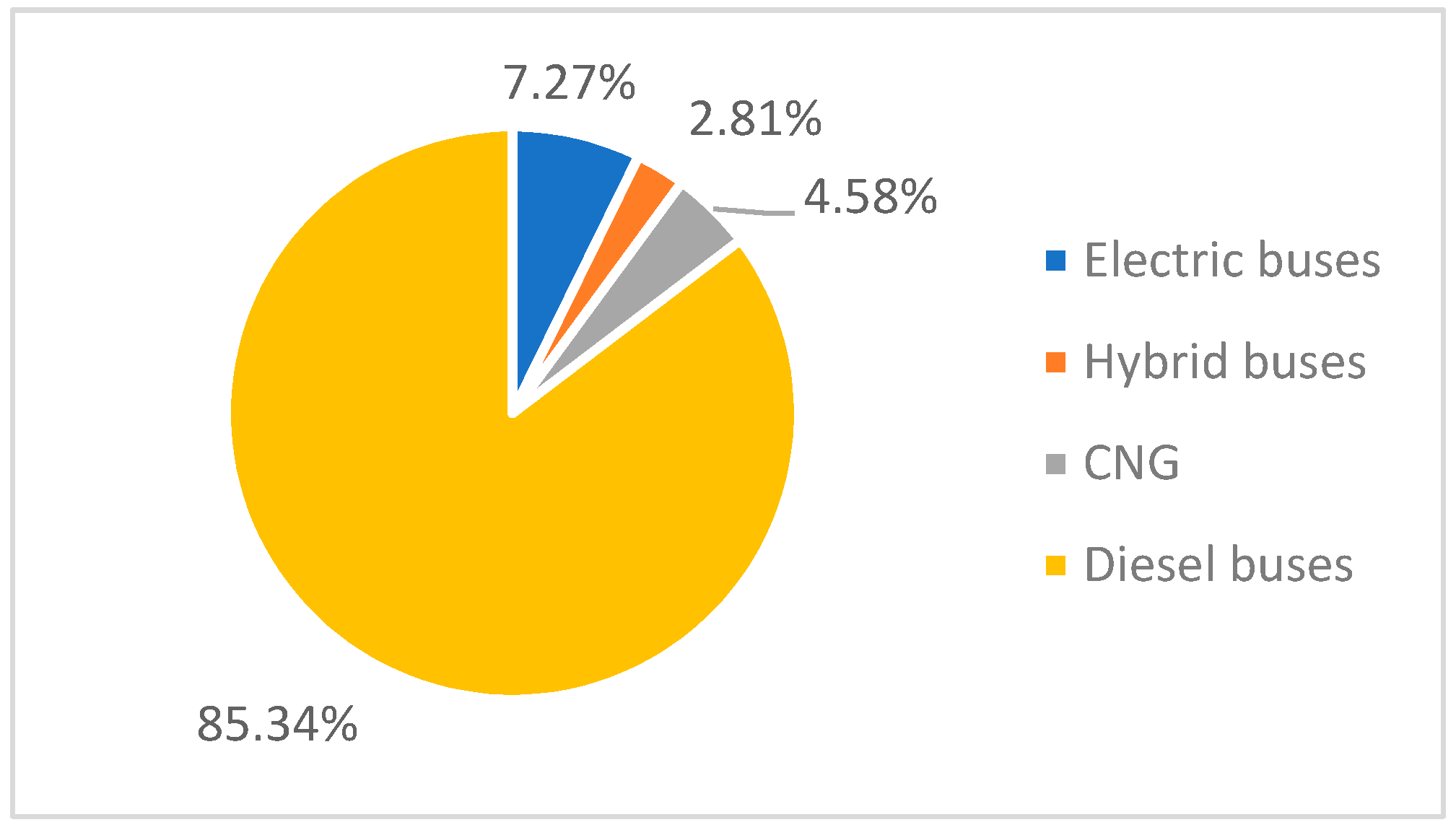

Currently, public transport in Polish cities is mainly based on diesel-powered vehicles, as shown by the studies on the state of the fleet presented above. A small proportion of city buses are hybrid or electric. Another problem facing today’s cities and the people living in them is air pollution, which far exceeds standards and is much higher than in non-urban areas. Combustion-powered buses play a major role in this pollution. Consequently, bus manufacturers are focusing on the development of emission-free technology. These are largely battery-powered electric vehicles. Such vehicles also have their disadvantages, which make it virtually impossible for them to dominate the urban bus fleet. The disadvantage of such solutions is mainly charging, which immobilizes the vehicle for some time. Of course, manufacturers also use rapid recharging capabilities with pantographs, but this forces additional costs and downtime during the day. Space is also needed for a suitable car park or a place to mount the pantograph. Another complication is the high load on the grid from fast chargers, as they emit a high current. The current allows fast charging; however, it is a burden on the existing electrical networks. Charging the bus at the depot, on the other hand, may not be sufficient. As the mileage driven by the buses of the cities studied shows, the number of kilometers driven necessitates charging during the day, making the vehicle immobile. Thus, if the fleet of public transport companies is to be modernized and only electric vehicles are used, current solutions are not able to meet the transport requirements of the cities. Moreover, they generate additional costs in terms of infrastructure, space, and the need to purchase additional electric vehicles. The purchase of additional vehicles is necessary to fill the gap created by daytime charging vehicles. An additional aspect of arguing for the impracticality of the current solutions is the range. In Poland, there is no shortage of days during the year with difficult conditions. The conditions that are difficult for the endurance of the batteries and thus reduce the range. These are cold winter days requiring heating of the bus interior or hot summer days, which are also not lacking, and the use of air conditioning inside is necessary. The change of seasons and the associated temperature fluctuations mean that, in practice, the vehicle may need to be recharged more often than anticipated. This introduces major difficulties in meeting the requirements. The answer to the difficulties caused by current solutions will be a replaceable battery on the bus.

The concept is only the authors’ vision for bringing the solution to market. The solution is currently being submitted to the patent office for later application in real-world conditions. The vision contains conceptual issues to show the applicability of the solution. All details of modeling, economic aspects, and electrical design will be presented in the authors’ subsequent work.

The concept is to equip the bus with a battery that, when discharged, can be quickly removed and replaced with a charged battery, so the vehicle can continue to operate without unnecessary downtime. The discharged battery would be deposited in a place where it would be fully charged and ready for the next replacement. The whole replacement cycle would happen in a circle. The number of batteries would be sized so that the vehicle could pick up a charged battery at any time. The bus would have to have this exchange capability as soon as its energy level was approaching a low state. In addition, swap locations are to be placed at strategic points in the city at the end and start stops where a large number of bus lines arrive. Bus loops are also to be equipped with battery exchange stations similar to those at the depot. The concept is for the entire replacement process to take place automatically, using appropriate equipment. The kit, equipped with appropriate technological solutions, will replace the battery without human intervention. The driver would only have to pull over to a suitable location and start the whole procedure by pressing a button. The advantage of the concept is that the battery-changing equipment can be located underground. The second solution is to enable the exchange in places where it is not possible to build above-ground infrastructure or where it is not advisable for the aesthetics of the city. There are many such places in cities, such as larger bus stops and bus terminals. The premise is to allow batteries to be replaced where necessary without driving halfway across the city to the depot. All the equipment to be replaced would, once the procedure had been initiated, slide out of the appropriate location, and the battery would be replaced in less than two minutes, after which the discharged battery would be placed in a charging point underground. There would be a battery room underground where the robot would pick up the charged batteries and deposit the discharged batteries in empty docks. The whole thing does not require a large underground extension, as it would be operated by robots taking up minimal space, and the number of batteries would be chosen so as not to generate additional, unnecessary costs. For simplicity’s sake, the points have been given the name ‘New Energy Point’, NEP for short. The whole idea is based on the swap-it-out principle. All buses in use in the city would have the same type of battery, so batteries would be standardized into one format. The only difference would be in the range, as articulated buses are much heavier and carry more passengers, so their range would be shorter. However, using one type of battery for all vehicles makes things much easier in daily use and reduces costs. Similarly, in power tools, when the battery is exhausted, the user changes the battery and can continue working without stopping to recharge. Power tool manufacturers, however, have gone a step further and use a single battery system consisting of, for example, three capacities for all their tools. This allows multiple tools to be operated with the same battery. The analogy would be with city buses.

Such a solution considerably simplifies the use of the bus in the city without interruptions for charging or the need for pantograph forests. In large cities like Krakow, for example, with a fleet of around 600, this can prove very cumbersome. Replacement batteries have another huge advantage. This is the ability to regenerate a partially used battery by replacing the most worn-out cells. One lump created so that it can be reconditioned significantly reduces costs and makes the task easier. In addition, it is easy to replace the battery when it is completely worn out, return it to the recycler, and buy a new battery instead. The process of caring for the fleet has been significantly improved, eliminating additional costs. This is also because one vehicle can have a lifespan of two or three batteries. To put it in perspective, if a battery lasts five years in such a system for an electric vehicle with a non-replaceable battery, it requires the vehicle to be returned to the manufacturer for a replacement cell. This takes time, causes inconvenience for the transport company, and is costly. With a replaceable battery, on the other hand, the vehicle does not have to leave the operating environment, as there will always be more batteries in use than vehicles. It would be the task of the communications company to purchase a new battery and keep it in circulation. The next step would be to return the used battery to a suitable location. The use of such a solution and technology enables a new approach to zero-emission transport in cities, where it matters most. The public transport system is concentrated in a relatively small area and has a high frequency of movement in a limited circle. This emits large amounts of pollutants into the atmosphere, polluting the air for residents every day. Using only electric buses in the city can make a real difference to air quality in the most vulnerable areas. The vision of a modern city with adapted emission-free public transport could become a reality with the NEP.

5.2. Battery Replacement Procedure with a Description of Individual Components

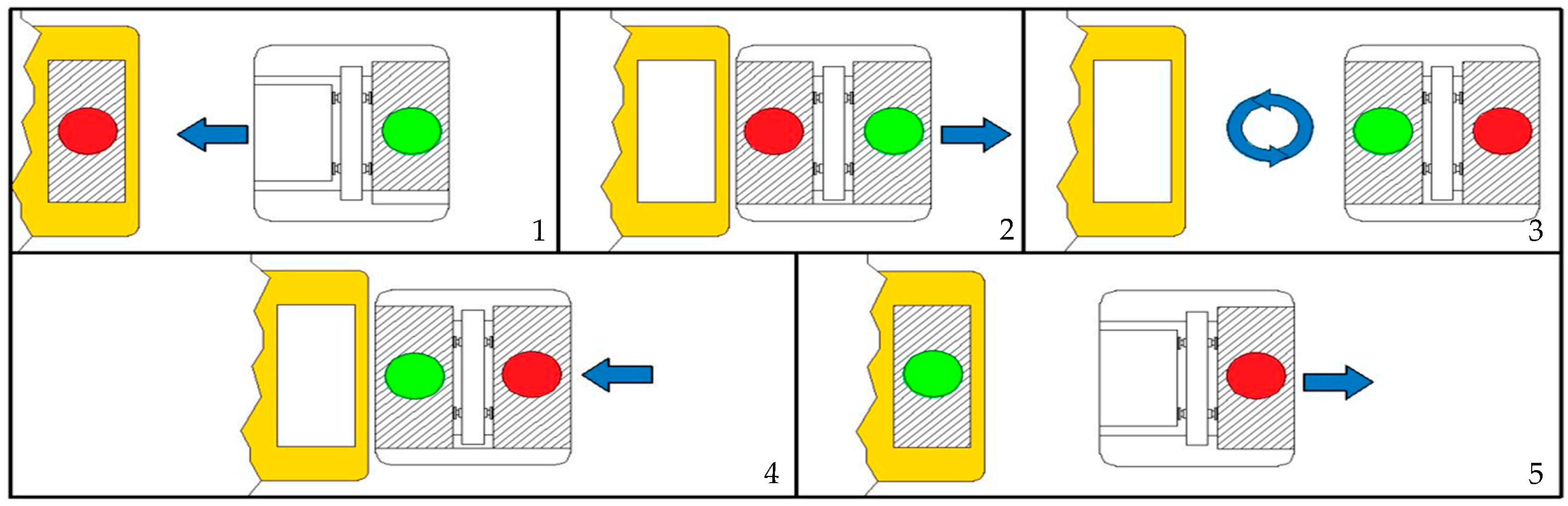

The procedure for replacing the batteries in the vehicle is carried out automatically using a special trolley capable of transporting two batteries at the same time. The trolley is designed to minimize the time it takes to replace the batteries. When the bus arrives at the designated location and the procedure begins, the battery trolley will wait with the charged battery for the replacement. Once the procedure has started, the trolley will remove the discharged battery from the bus and move away to the necessary distance from the vehicle; its upper platform will rotate 180°, and then the trolley will insert the charged battery in place of the discharged one. The diagram shows the rear of the bus in yellow. The hatched rectangles represent the batteries. There is a green or red point in each of them. Green represents a charged battery, and red represents a discharged battery. The arrows show the direction of movement of the trolley. The replacement of the battery in five stages and the top view are shown in

Figure 4.

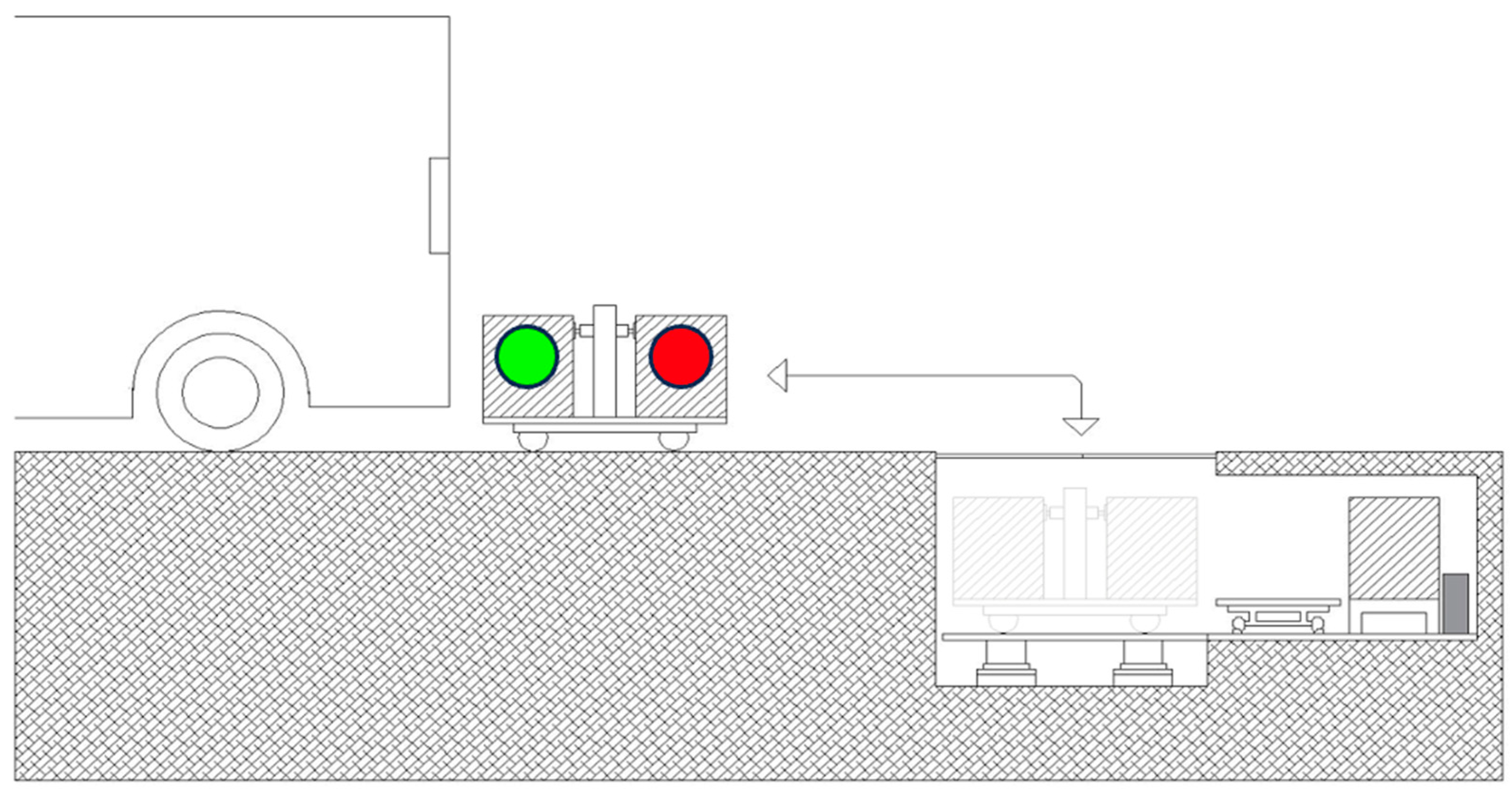

The drawing shows the location of the battery in the vehicle. This location was considered optimal because of the ease of access to the battery and, therefore, easier replacement. In addition, locating the battery low lowers the center of gravity, does not consume interior space, and allows the construction of a low-floor vehicle. The design of the bogie allows the battery to be driven up to the vehicle’s body line and raised to the correct height. The appropriate design of the battery bed on the bus should allow the battery to be changed quickly.

The electric bus in the concept design would be equipped with a main battery (replaceable) and an auxiliary power supply. The auxiliary power supply would be designed to allow a drive of several kilometers in case of need, system failure, or other emergency events. It should also allow basic systems on the bus to operate while its main battery is disconnected and outside the vehicle. Such a solution is intended to avoid emergencies and ensure safety. Current technology allows several different solutions to be used since lithium-ion batteries are constantly being improved. New solutions are also constantly sought. For the project, an existing battery on the market was used as an example, and real data was analyzed. The battery is offered by Impact Clean Power Technology in model UVES Energy Gen 2.0; the detailed battery parameters are shown in

Table 9.

The underground storage and battery charging systems would require an additional lift. According to the concept, an exchange trolley would appear at the exchange site, i.e., at the level of the bus where the exchange takes place. After the exchange, it would enter a specially constructed lift and then descend underground. Once the level is lowered, the swap trolley will transfer the discharged battery to a rack trolley serving the charging docks. At this stage, the batteries would be stacked in a free charging bay, and the trolley would pick up the next charged battery and hand it to the exchange trolley.

When it is necessary to install an underground battery replacement system on a bus loop, there are several emerging issues stemming from the nature of the underground facility. The first and most important is the drainage system. If the device is to operate underground, the question is, “what to do during heavy rainfall or snowfall?”. There is a solution in the form of using a drainage system from where the platform meets the ground or roofing the replacement area. Covering a small area seems to be an effective way, but it requires the exchange trolley to travel a greater distance to the vehicle where the exchange is to take place or reverse the bus. Reversing the bus, however, involves some inconvenience. For the driver to reverse the bus in many cities, it is necessary to be assisted by an MPK employee; he cannot do it himself for safety reasons. This creates a problem, as on a loop where it would take place several times a day, it requires an extra full-time employee to direct the bus driver when reversing to the right place.

Figure 5 shows a single-level model for charging and storing small quantities of batteries. This model could be used for small exchange points where it is not possible to build an above-ground point but where it is necessary to change batteries several times a day. The exchange trolley, after driving underground on a suitable platform, transfers the battery to the rail trolley operating the battery room. The diagram shows the principles of the system. It should be noted that the above exchange system can be freely adapted to the needs of the site. There may be a multi-story battery depot underground if necessary. With such a solution, efficient drainage is necessary to protect the exchange elements from damage.

A bus wishing to replace the batteries would be expected to drive out onto a suitably prepared lane at an elevation relative to the surrounding ground. As a result, excess water would run off immediately from the elevation into the city’s drainage system. The replacement lane would have to be secured properly to ensure the safety of the process. The entire platform covering the elements would be equipped with a drainage system effective enough to prevent the flooding of electrical components. As the exchange trolley is lifted by the lift, the top safety hatch will open, and the exchange trolley will then have a few meters to travel to the bus to replace the battery. Appropriate sensors in the swap trolley will trigger the swap platform at the appropriate moment, initiating the opening.

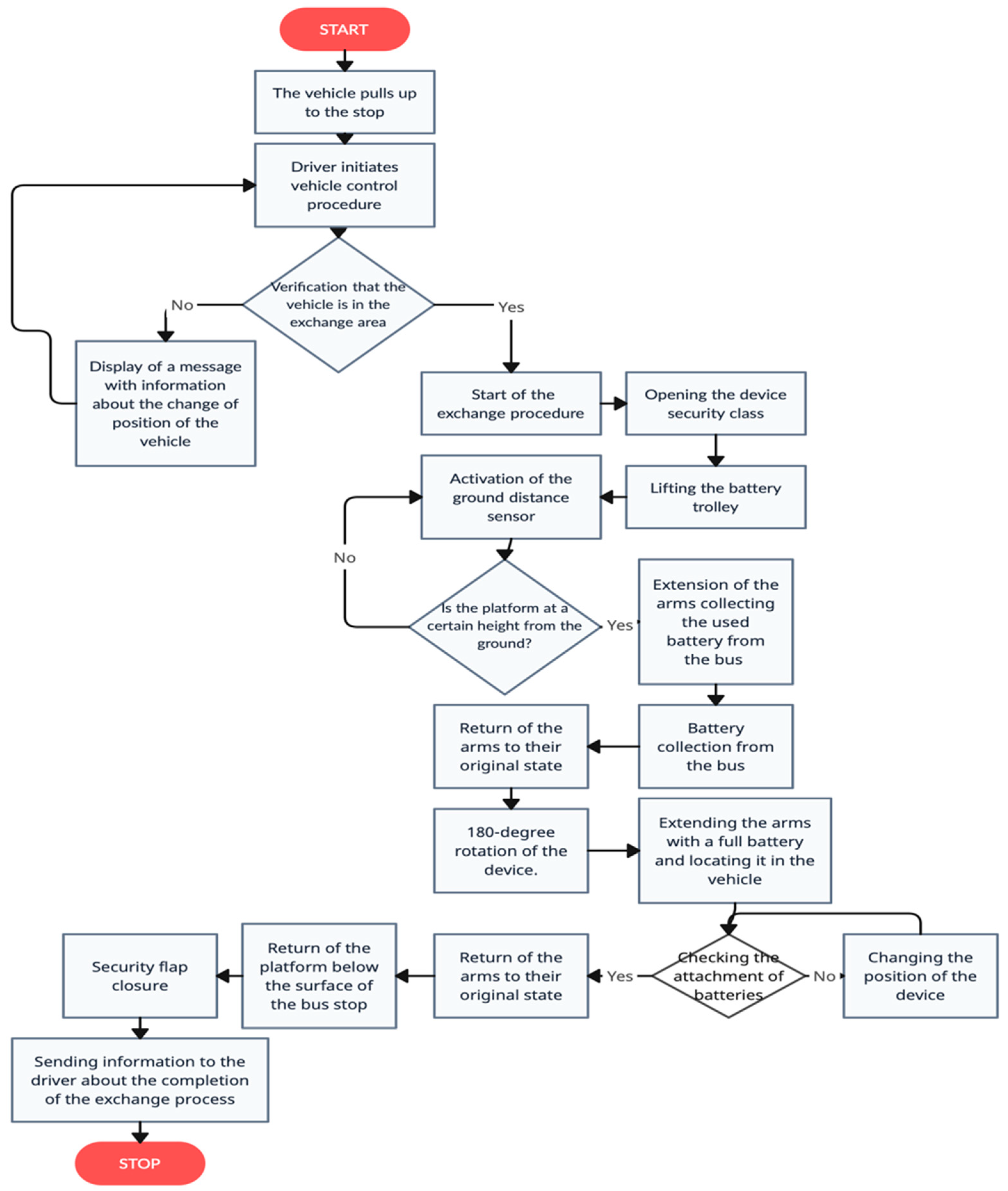

The whole procedure is illustrated in

Figure 6, which shows that the device can operate continuously without the driver or an independent person. In many cases, it is time that determines the solution.

Temporal analysis of the replacement of one battery according to the presented procedure with the assumption that the vehicle approaching the stop is located in the designated place:

- −

Opening of the safety flap:

| 20 s; |

- −

Rejecting the battery platform:

| 25 s; |

- −

Retrieving empty battery:

| 25 s; |

- −

Rotation of the device:

| 20 s; |

- −

Placing the battery in the vehicle:

| 35 s; |

- −

Returning the platform below the surface:

| 25 s; |

- −

Closing the safety flap:

| 20 s. |

The total time to change the battery in the vehicle at one stop is about 170 s, which gives us about 3 min. With the solution, we can charge the battery in the vehicle faster than a full charge using other solutions. Charging the batteries of electric buses by plug-in chargers takes about 4–5 h, while in the case of a special station using a pantograph, it takes about 1 h [

18].

However, as far as costs are concerned, in the case of plug-in chargers, the cost of the design and construction of one fast-charging station for buses, together with the necessary infrastructure and any road system adjustments made by external companies, may amount to approximately EUR 200,000 [

62]. The same is also true for the pantograph. On the other hand, as far as the construction costs of the proposed device are concerned, they will be about 20% higher than the potential construction costs of other solutions due to its technological specificity, although this fact is secondary because the time advantage in the battery filling procedure itself is not comparable and is greater in favor of the proposed solution. The cost of charging one battery directly in this solution and other alternatives is itself the same, as in the concept proposal, the battery residing below the surface would be charged continuously.

A full cost statement, including an econometric model as well as a specification of the device’s operation, will be presented by the authors in future papers, as the article itself is about a review of the various potential solutions available on the market, with only the indication of another alternative possibility.

Test work is currently underway to solve and clarify some of the issues surrounding the device itself.

5.4. Possible Solutions Using Renewable Energy Sources

Sourcing energy for electric vehicles is not insignificant because of the carbon footprint they leave. Electric vehicles used in cities are emission-free only locally, as combustion-based methods are often used to generate electricity to power them. Alternative energy sources can reduce emissions and pollutants. One that, along with the use of emission-free vehicles, can amplify the environmental effect of the change is the Aeromine turbine.

The turbine has no external moving parts. Its design amplifies airflow by generating a vacuum that drives a hidden turbine rotor [

66]. The device is ideally suited for installation on building roofs. It could therefore be successfully installed on buildings in the city or the buildings of a depot or energy storage facility. Its advantage is that it takes up little space, and the unit itself is small compared to traditional wind turbines, which are often impossible to install in cities. The device is capable of operating at a low air speed of approximately 8 km/h [

67]. The solution is also relatively inexpensive, as the device is expected to produce 50% more energy than photovoltaic panels at the same installation cost [

68]. Such a solution would allow some of the energy needed to charge the batteries to be obtained from renewable sources.

The example described above only presents an alternative to the possibility of electric vehicles being used on an ad hoc basis at bus stops.