Drilling Conditions Classification Based on Improved Stacking Ensemble Learning

Abstract

1. Introduction

2. Methodology

2.1. Data Processing

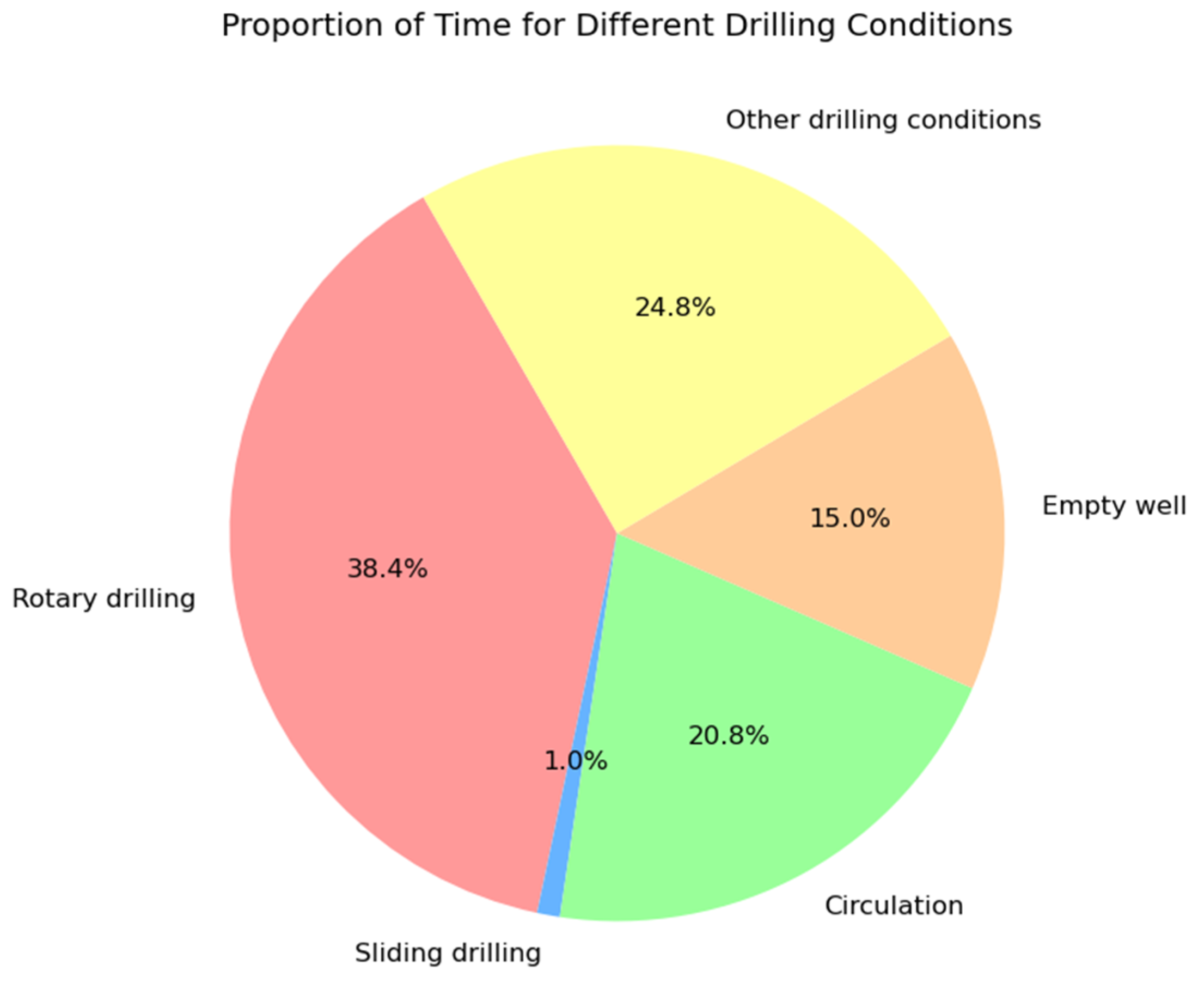

2.1.1. Dataset Description

2.1.2. Feature Selection

2.1.3. Evaluation Indicators

2.2. Model Building

2.2.1. Multi-Layer Perceptron

2.2.2. Random Forest

2.2.3. K-Nearest Neighbors

2.2.4. Support Vector Machine

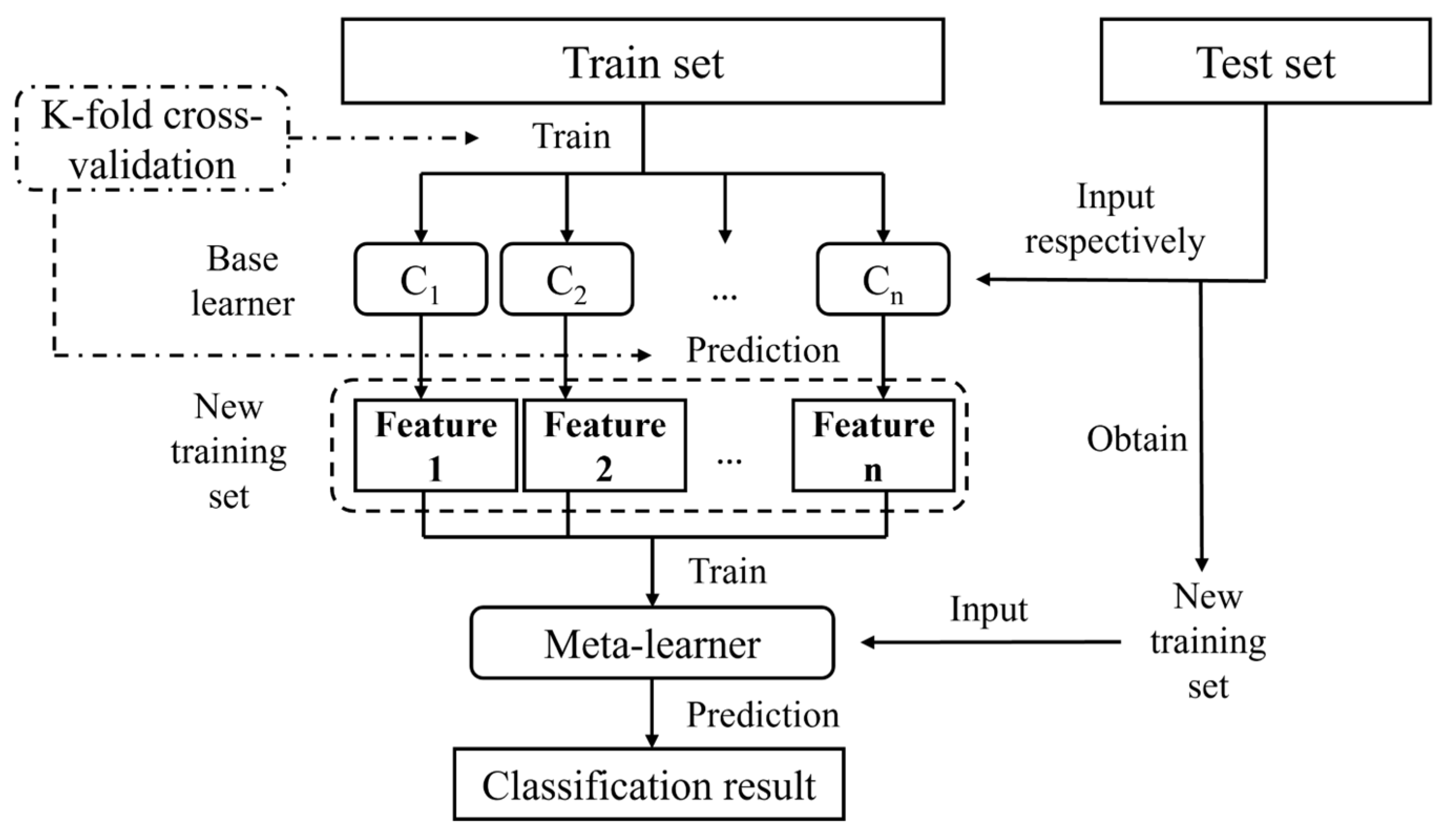

2.2.5. Stacking Ensemble Learning (SEL)

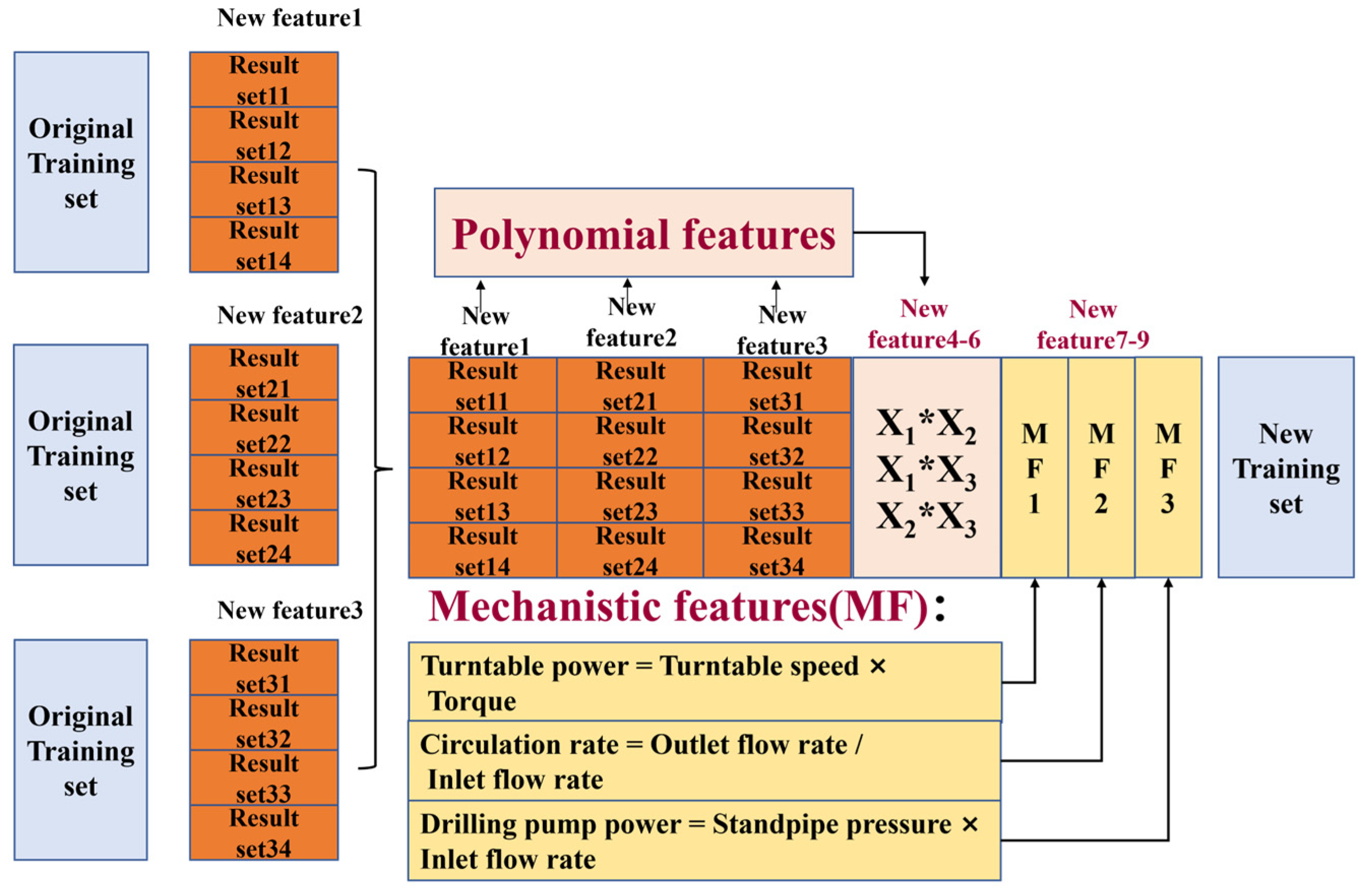

2.2.6. Improved Stacking Ensemble Learning (ISEL)

- (1)

- Feature construction using polynomial cross-combination;

- (2)

- Feature construction based on the integration of mechanistic knowledge.

- (1)

- Feature construction using polynomial cross-combination

- (2)

- Feature construction based on the integration of mechanistic knowledge

2.3. Model Parameter

3. Results and Discussion

- Strong feature combination capability: The embedded mechanism model can automatically learn and discover complex relationships and interactions between features. By embedding mechanisms such as nonlinear transformations, cross-features, and high-order feature combinations in the model, it enhances the modeling capability for complex data patterns;

- Strong adaptability: The embedded mechanism model can automatically adjust the model’s complexity and flexibility based on the characteristics of the data. It can select appropriate feature embedding methods and parameter settings automatically, thereby improving the model’s adaptability and performance;

- Strong interpretability: Compared to some black-box models, the embedded mechanism model often has better interpretability. Due to its explicit feature embedding process and model parameters, it becomes easier to understand how the model processes input features, thus providing better explanations for the model’s predictions;

- Strong generalization capability: The embedded mechanism model learns and extracts the intrinsic feature representation of the data, enabling it to capture the underlying patterns and distribution characteristics of the data, resulting in strong generalization ability. It can effectively handle new unseen samples and maintain good performance across different datasets.

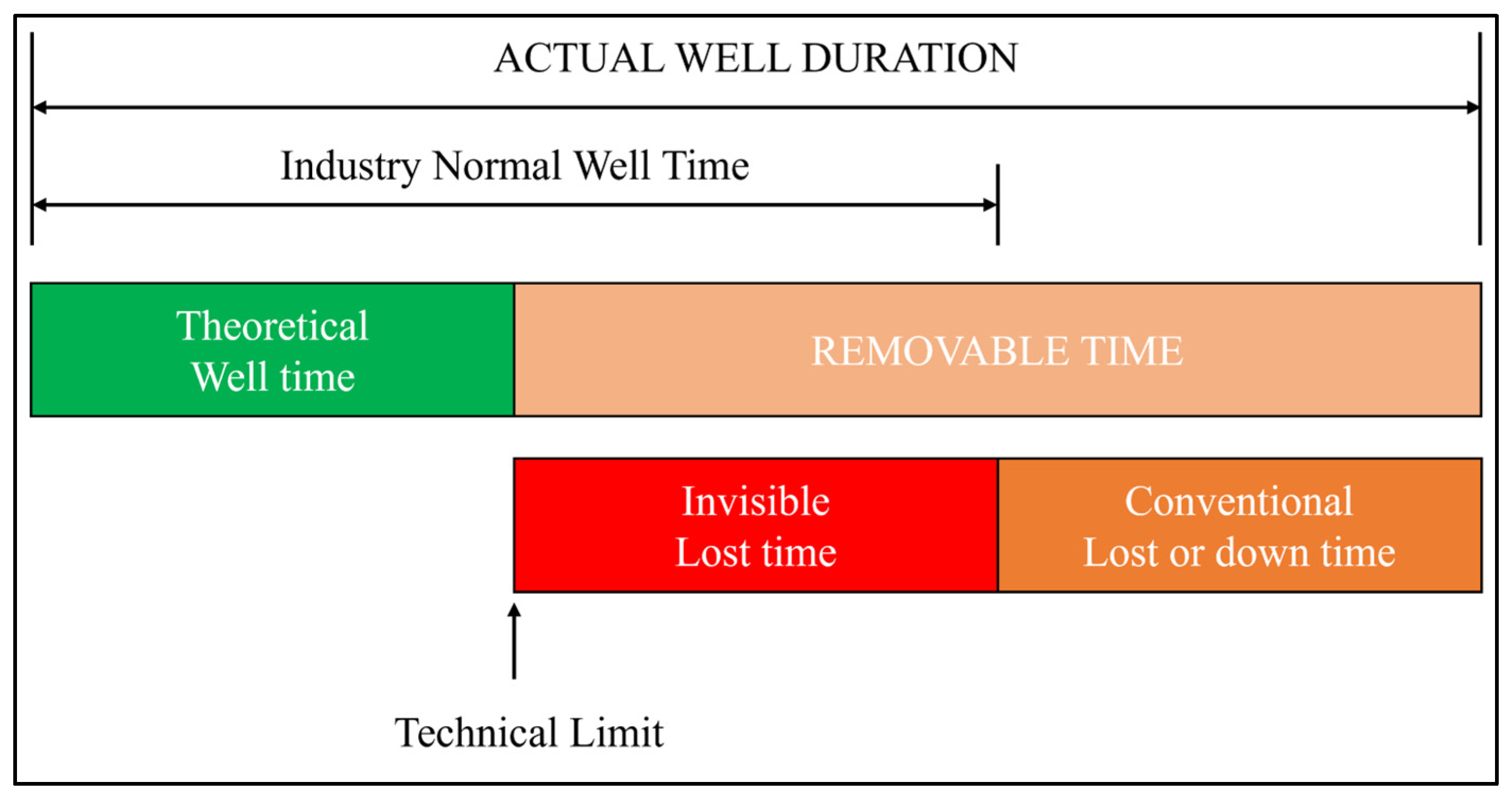

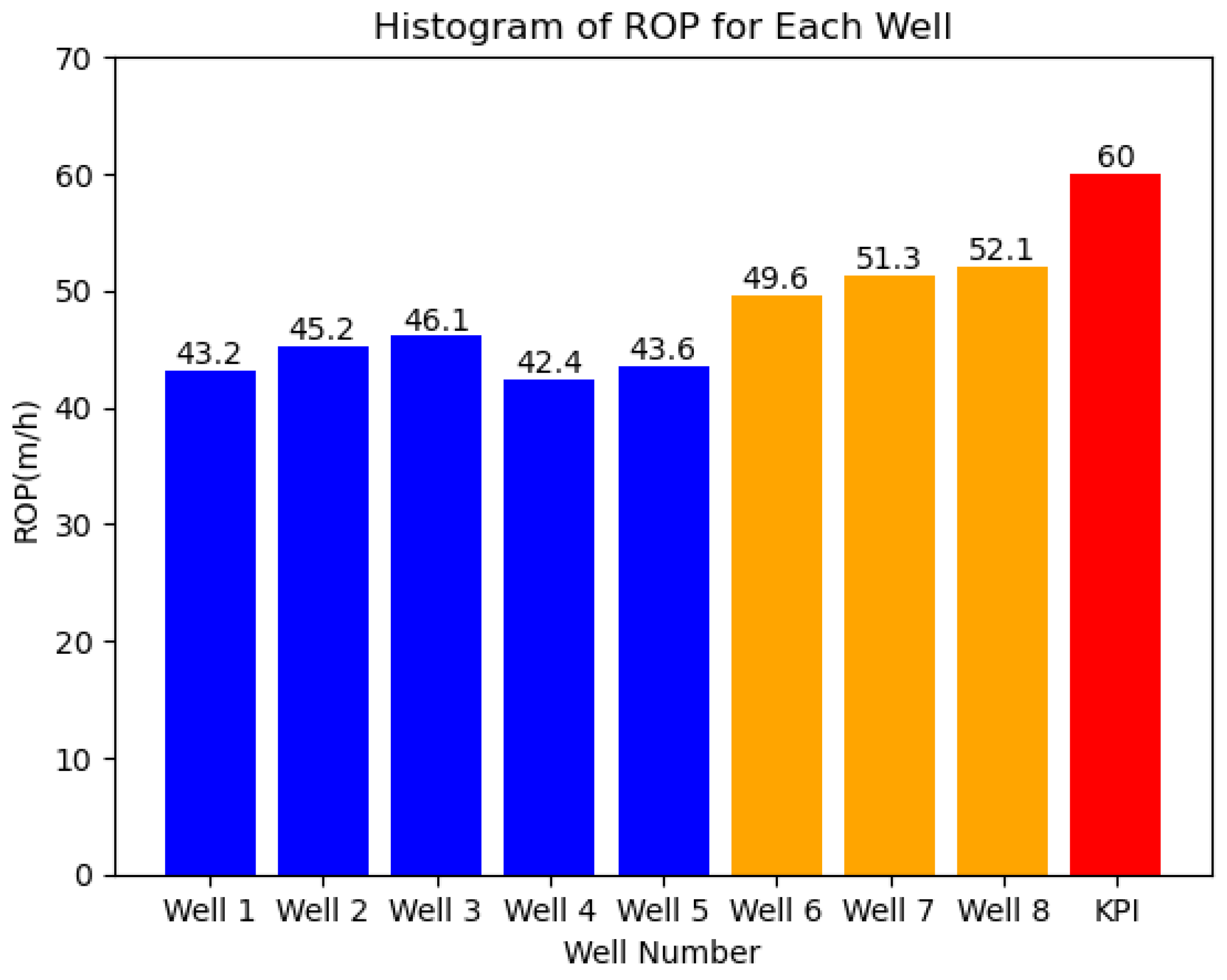

4. Drilling Time Efficiency Statistics and Enhancement

4.1. Invisible Lost Time

4.2. Drilling Time Efficiency Statistics

4.3. Enhancing Drilling Efficiency

4.4. Engineering Applications

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Golitsyna, M.; Semenikhin, A.; Chebuniaev, I.; Vasilyev, V.; Koryabkin, V.; Makarov, V.; Simon, I.; Baybolov, T.; Osmonalieva, O. Automatic Method for Anomaly Detection while Drilling. In Proceedings of the First EAGE Digitalization Conference and Exhibition, Vienna, Austria, 30 November–3 December 2020; EAGE Publications BV: Bunnik, The Netherlands, 2020; pp. 1–5. [Google Scholar]

- Yin, Q.; Yang, J.; Zhou, B.; Jiang, M.; Chen, X.; Fu, C.; Yan, L.; Li, L.; Li, Y.; Liu, Z. Improve the Drilling Operations Efficiency by the Big Data Mining of Real-Time Logging. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Abu Dhabi, United Arab Emirates, 29–31 January 2018; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- van Oort, E.; Taylor, E.; Thonhauser, G.; Maidla, E. Real-time rig-activity detection helps identify and minimize invisible lost time: Drilling technology. World Oil 2008, 229, 39–47. [Google Scholar]

- Maidla, E.; Maidla, W. Rigorous Drilling Nonproductive-Time Determination and Elimination of Invisible Lost Time: Theory and Case Histories. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Lima, Peru, 1–3 December 2010. [Google Scholar]

- Sun, T.; Zhao, Y.; Yang, J.; Yin, Q.; Wang, W.; Chen, Y. Real-Time Intelligent Identification Method under Drilling Conditions Based on Support Vector Machine. Pet. Drill. Tech. 2019, 47, 28–33. [Google Scholar]

- Ben, Y.; James, C.; Cao, D. Development and application of a real-time drilling state classification algorithm with machine learning. In Proceedings of the Unconventional Resources Technology Conference, Unconventional Resources Technology Conference (URTeC), Denver, CO, USA, 22–24 July 2019; pp. 3053–3066. [Google Scholar]

- de Oliveira, G.L.; Zank, C.A.; Costa, A.F.; Mendes, H.M.; Henriques, L.F.; Mocelin, M.R.; de Oliveira Neto, J. Offshore Drilling Improvement through Automating the Rig State Detection Process-Implementation Process History and Proven Success. In Proceedings of the IADC/SPE Drilling Conference and Exhibition, Forth Worth, TX, USA, 1–3 March 2016; OnePetro: Richardson, TX, USA, 2016. [Google Scholar]

- Coley, C. Building a Rig State Classifier Using Supervised Machine Learning to Support Invisible Lost Time Analysis. In Proceedings of the SPE/IADC International Drilling Conference and Exhibition, Hague, The Netherlands, 5–7 March 2019; OnePetro: Richardson, TX, USA, 2019. [Google Scholar]

- Qiao, Y.; Lin, H.; Zhou, W. Intelligent identification of drilling conditions based on CNN-BiGRU parallel hybrid network. In Proceedings of the 5th Petroleum and Petrochemical Artificial Intelligence High-End Forum and the 8th Intelligent Digital Oilfield Open Forum, Beijing, China, 15 September 2022. [Google Scholar]

- Wang, Z.; Wang, Z.; Ning, A. Research on Blockchain Anomaly Transaction Detection Technology Based on Stacking Ensemble Learning. J. Inf. Secur. Res. 2023, 9, 98–108. [Google Scholar]

- Su, F.; Luo, H. A fingerprint recognition algorithm based on improved Stacking ensemble learning. Comput. Eng. Sci. 2022, 44, 2153–2161. [Google Scholar]

- Shao, W. Heart Disease Diagnosis Method Based on Stacking Ensemble Learning. Mod. Informationn Technol. 2022, 6, 97–99, 103. [Google Scholar]

- Cao, M.; Gong, W.; Gao, Z. Research on Lithology Identification Based on Stacking Integrated Learning. Comput. Technol. Dev. 2022, 32, 161–166. [Google Scholar]

- Pu, Y.; Liu, X. Application of Stacking Integrated Learning in Sales Volume Forecasting. Softw. Guide 2022, 21, 103–108. [Google Scholar]

- Li, Y.; Zhou, X.; Gao, W.; Bo, Z.; Geng, N. Emergency Patient Arrival Forecast Based on Stacking Ensemble Learning. Ind. Eng. Manag. 2019, 6, 16–22. [Google Scholar]

- Myers, L.; Sirois, M.J. Spearman correlation coefficients, differences between. Encycl. Stat. Sci. 2004, 12, 7901. [Google Scholar] [CrossRef]

- Ruuska, S.; Hämäläinen, W.; Kajava, S.; Mughal, M.; Matilainen, P.; Mononen, J. Evaluation of the confusion matrix method in the validation of an automated system for measuring feeding behaviour of cattle. Behav. Process. 2018, 148, 56–62. [Google Scholar] [CrossRef] [PubMed]

- Taud, H.; Mas, J.F. Multilayer perceptron (MLP). In Geomatic Approaches for Modeling Land Change Scenarios; Springer: Cham, Switzerland, 2018; pp. 451–455. [Google Scholar]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Peterson, L.E. K-nearest neighbor. Scholarpedia 2009, 4, 1883. [Google Scholar] [CrossRef]

- Suthaharan, S.; Suthaharan, S. Support vector machine. Machine learning models and algorithms for big data classification: Thinking with examples for effective learning. Integr. Ser. Inf. Syst. 2016, 36, 207–235. [Google Scholar]

- Naimi, A.I.; Balzer, L.B. Stacked generalization: An introduction to super learning. Eur. J. Epidemiol. 2018, 33, 459–464. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Wang, S.; Cao, Z. An ensemble classifier based on stacked generalization for predicting membrane protein types. In Proceedings of the 2017 10th International Congress on Image and Signal Processing, BioMedical Engineering and Informatics (CISP-BMEI), Shanghai, China, 14–16 October 2017; pp. 1–6. [Google Scholar]

- Anguita, D.; Ghelardoni, L.; Ghio, A.; Oneto, L.; Ridella, S. The ‘K’ in K-Fold Cross Validation; ESANN: Bruges, Belgium, 2012; pp. 441–446. [Google Scholar]

- Li, C.; Miu, J.; Shen, B. Operational Effectiveness Prediction of Equipment System based on improved Stacking-Ensemble-Learning Method. Acta Armamentarii 2022. [Google Scholar] [CrossRef]

- de Wardt, J.P.; Rushmore, P.H.; Scott, P.W. True Lies: Measuring Drilling and Completion Efficiency. In Proceedings of the IADC/SPE Drilling Conference and Exhibition, Fort Worth, Texas, USA, 1–3 March 2016; OnePetro: Richardson, TX, USA, 2016. [Google Scholar]

- Hou, X. The State Recognition and the Time-Dependent Analysis Based on Mud Logging Data in Drilling Operations; China University of Petroleum: Dongying, China, 2020. [Google Scholar]

| Author | Research Contents |

|---|---|

| Wang et al. [10] | A blockchain anomaly transaction detection method based on stacking ensemble learning, which outperforms individual models. |

| Su et al. [11] | Using DenseNet and the improved AlexNet as two convolutional neural networks for stacking, fingerprints are classified. |

| SHAO Weixi [12] | Ensemble models with significant diversity among base classifiers exhibit better classification performance, achieving an accuracy of 89.78% on the heart disease dataset. |

| Cao et al. [13] | Using the PCA algorithm to calculate the weights for each base model, the accuracy of the ensemble model was improved by 1.85% compared to the traditional stacking ensemble model. |

| You et al. [14] | In sales forecasting, stacking ensemble learning improves prediction accuracy by up to 1.42% compared to individual models. |

| Li et al. [15] | The stacking ensemble method outperforms individual models in predicting multiple indicators of emergency department patient arrivals. |

| Drilling Conditions | Rotary Drilling | Sliding Drilling | Circulation | Empty Well | Other Drilling Conditions |

|---|---|---|---|---|---|

| data volume | 463,260 | 11,508 | 251,501 | 181,770 | 599,860 |

| Input | Output |

|---|---|

| Well depth, Drill bit position, Delayed well depth, Hookload, Hookheight, Weight on bit, Rotary Speed, Torque, Standpipe pressure, Casing pressure, Rate of Penetration, Inlet flow rate, Outlet flow rate, Methane, Total hydrocarbons, Pump Stroke Rate #1/#2/#3 | Drilling conditions |

| True Result | Forecast Result | |

|---|---|---|

| Positive Class | Negative Class | |

| Positive class | TP | FN |

| Negative class | FP | TN |

| Model | Parameter |

|---|---|

| MLP | Hidden layer sizes: (100, 50), Activation function: ReLU, Learning rate: 0.01 |

| Random Forest | Number of trees: 100, Feature subset size: sqrt (total features), Tree depth: None |

| KNN | K value: 5, Distance metric: Euclidean distance, Neighbor selection strategy: Majority voting |

| SVM | Kernel selection: RBF kernel, Regularization parameter C: 1.0, Kernel parameter: gamma = 0.1 |

| SEL/ISEL | Base learner types: Random Forest, KNN, SVM, Number of base learners: 3, Ensemble strategy: Voting |

| Intelligent Model | Evaluation Indicator | |||

|---|---|---|---|---|

| Accuracy | Precision | Recall | F1 Score | |

| MLP | 0.92 | 0.89 | 0.93 | 0.91 |

| RF | 0.96 | 0.95 | 0.96 | 0.95 |

| KNN | 0.97 | 0.95 | 0.94 | 0.94 |

| SVM | 0.96 | 0.92 | 0.93 | 0.92 |

| SEL | 0.96 | 0.96 | 0.97 | 0.96 |

| ISEL | 0.97 | 0.97 | 0.98 | 0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Zhang, Y.; Zhou, D.; Ji, Y.; Song, X.; Li, D.; Zhu, Z.; Wang, Z.; Liu, Z. Drilling Conditions Classification Based on Improved Stacking Ensemble Learning. Energies 2023, 16, 5747. https://doi.org/10.3390/en16155747

Yang X, Zhang Y, Zhou D, Ji Y, Song X, Li D, Zhu Z, Wang Z, Liu Z. Drilling Conditions Classification Based on Improved Stacking Ensemble Learning. Energies. 2023; 16(15):5747. https://doi.org/10.3390/en16155747

Chicago/Turabian StyleYang, Xinyi, Yanlong Zhang, Detao Zhou, Yong Ji, Xianzhi Song, Dayu Li, Zhaopeng Zhu, Zheng Wang, and Zihao Liu. 2023. "Drilling Conditions Classification Based on Improved Stacking Ensemble Learning" Energies 16, no. 15: 5747. https://doi.org/10.3390/en16155747

APA StyleYang, X., Zhang, Y., Zhou, D., Ji, Y., Song, X., Li, D., Zhu, Z., Wang, Z., & Liu, Z. (2023). Drilling Conditions Classification Based on Improved Stacking Ensemble Learning. Energies, 16(15), 5747. https://doi.org/10.3390/en16155747