Performance, Emissions, and Combustion Characteristics of a Hydrogen-Fueled Spark-Ignited Engine at Different Compression Ratios: Experimental and Numerical Investigation

Abstract

1. Introduction

2. Experimental Method

2.1. Experimental Setup

2.2. Experimental Conditions

3. Numerical Method

3.1. Chemical Kinetic Model

3.2. CFR Engine Model

4. Results and Discussion

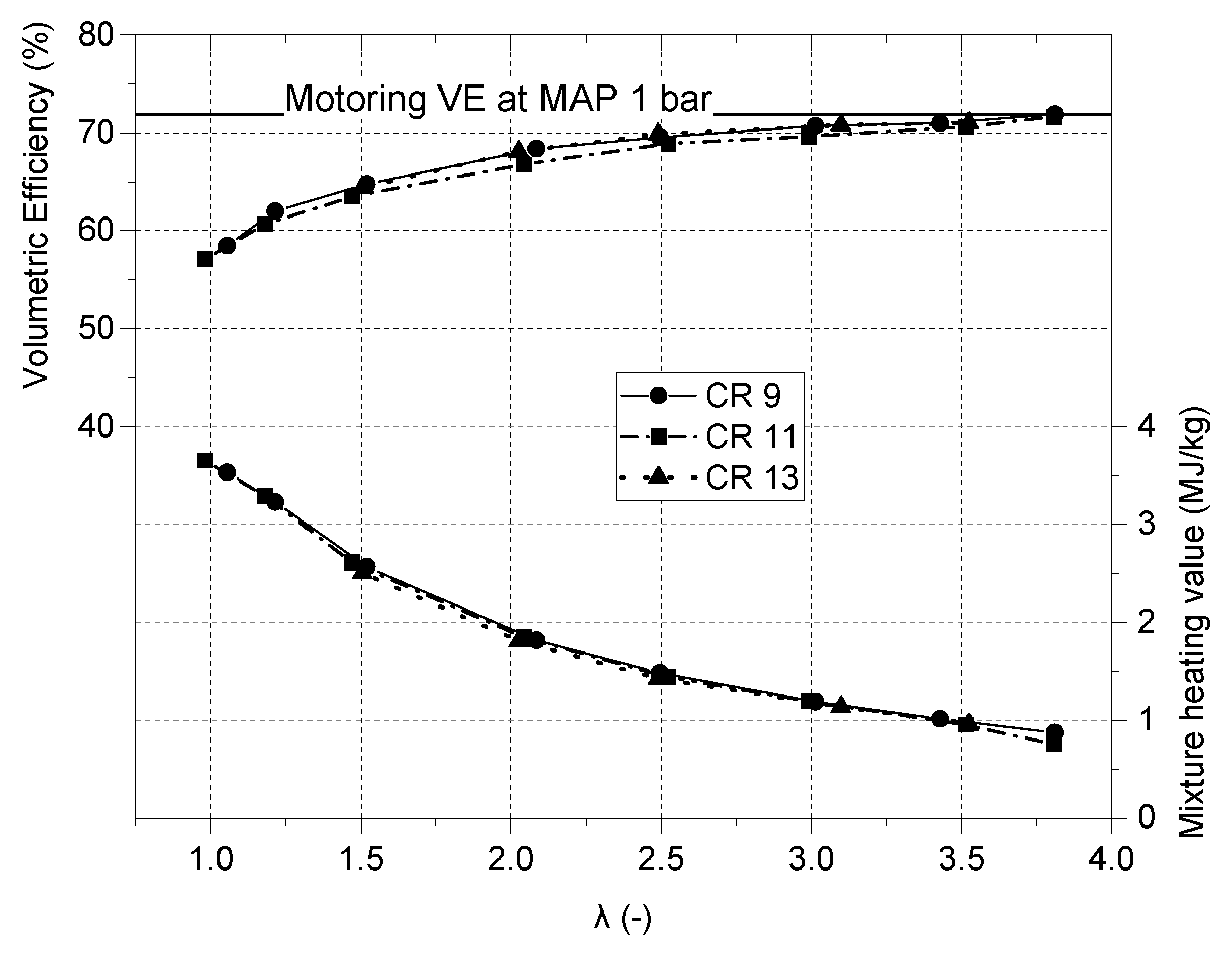

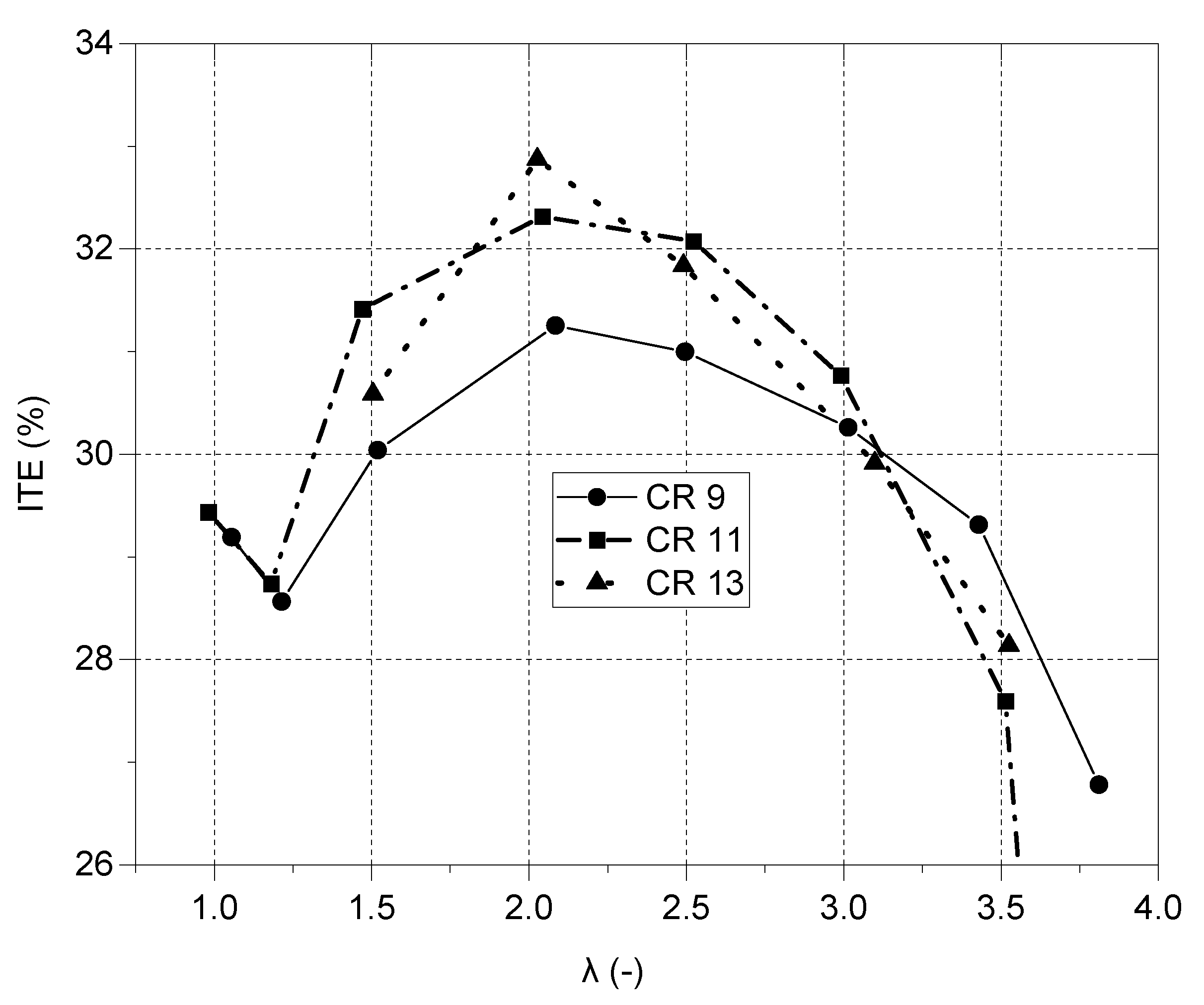

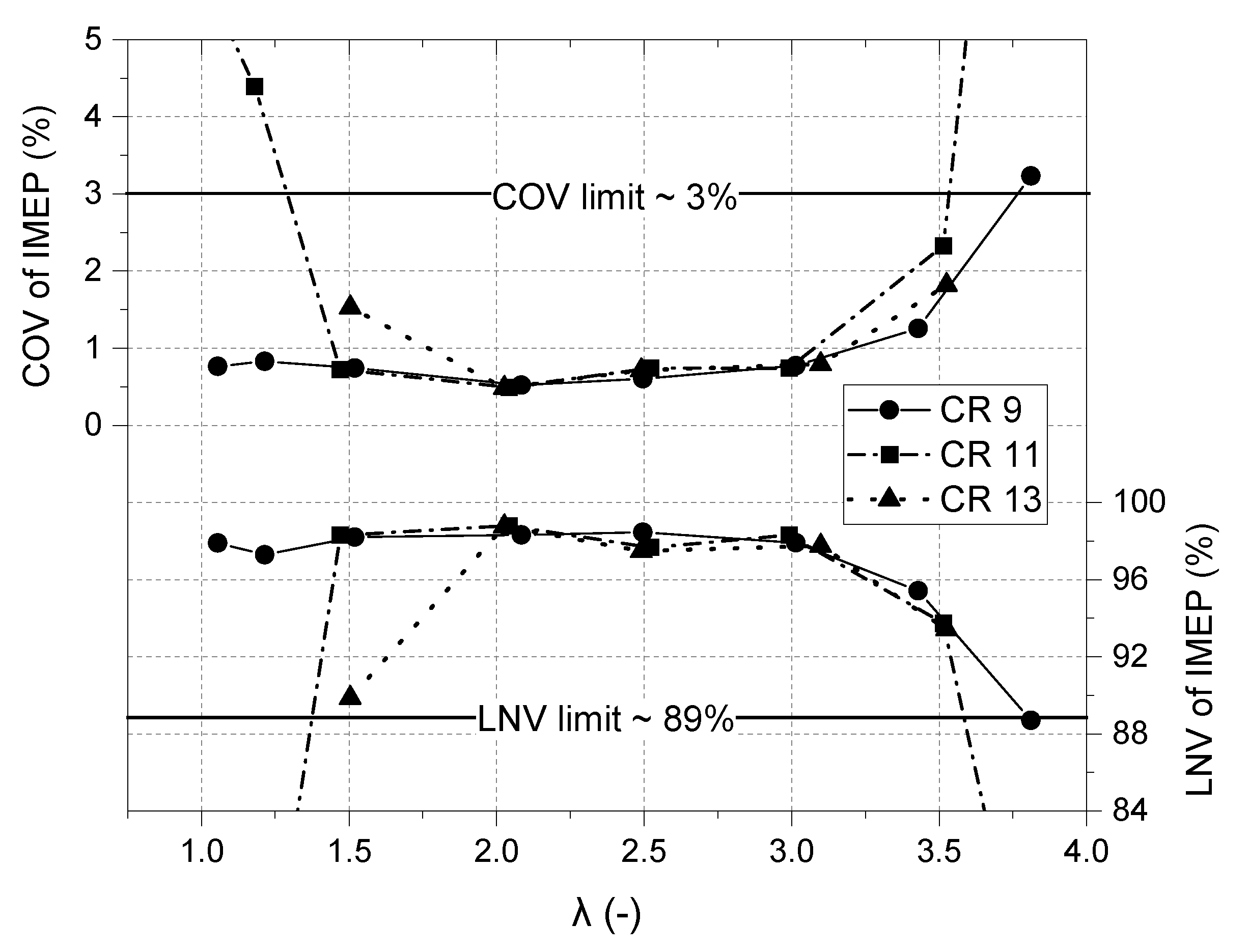

4.1. Engine Performance

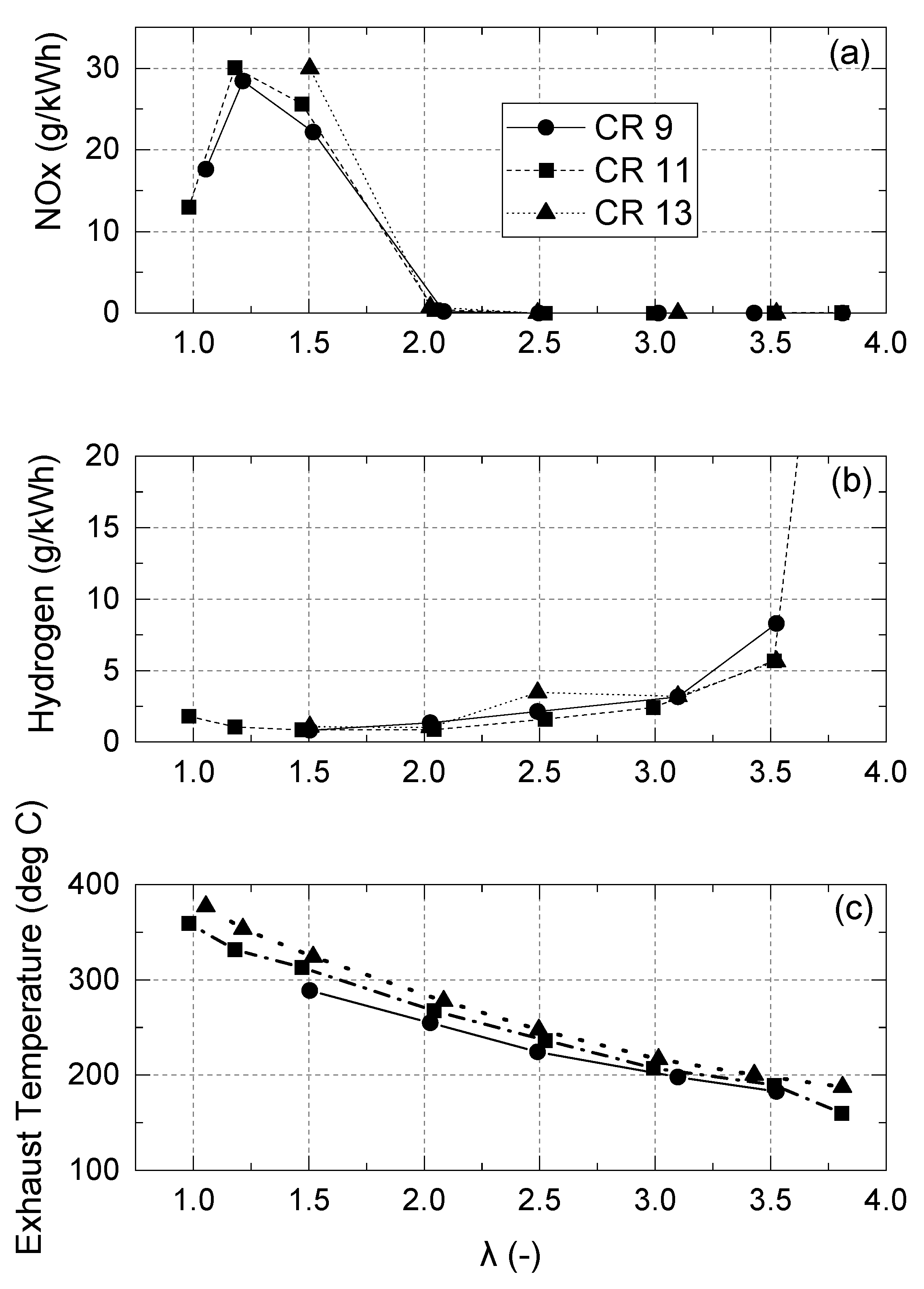

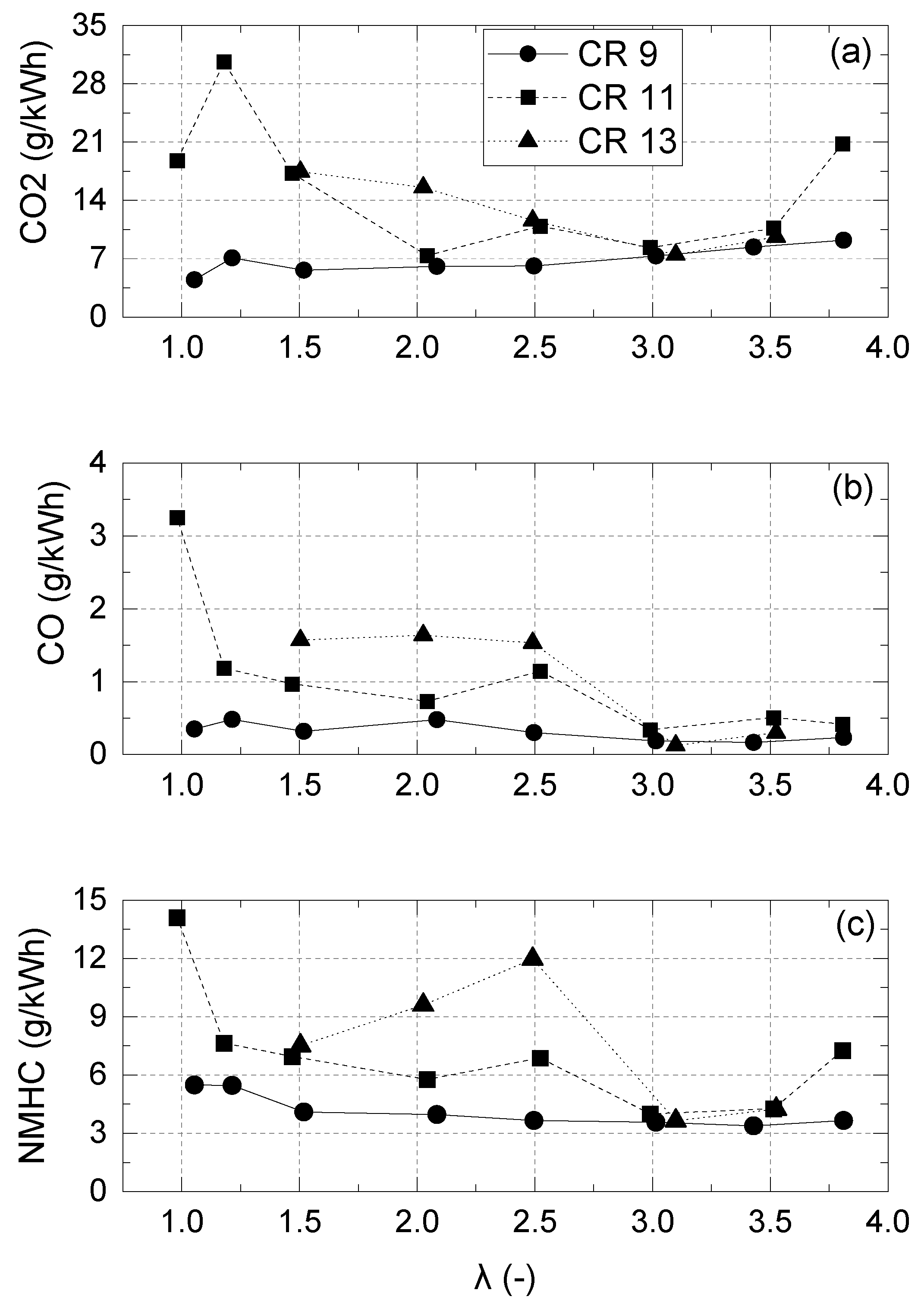

4.2. Engine Emissions

4.3. Combustion Characteristics

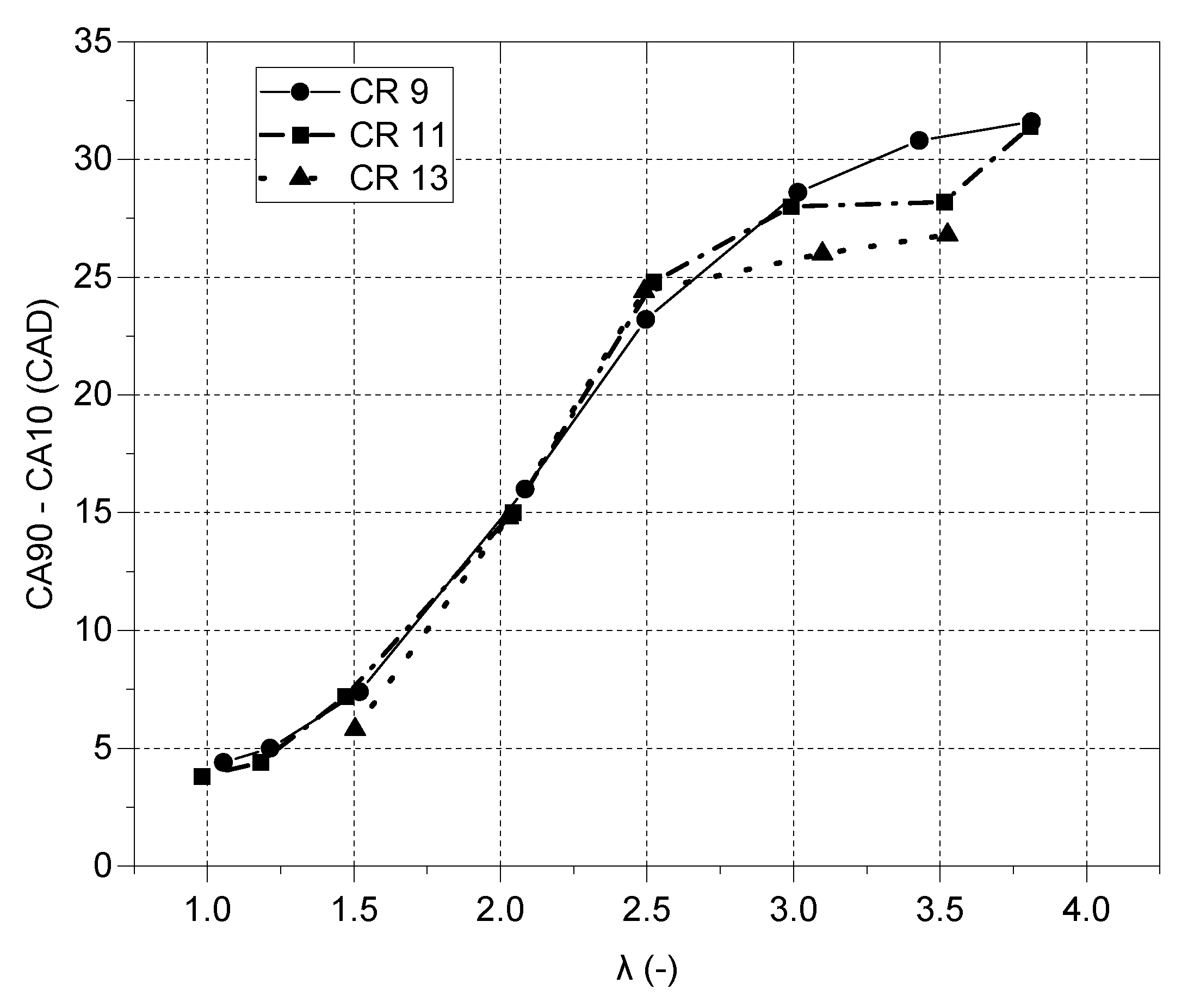

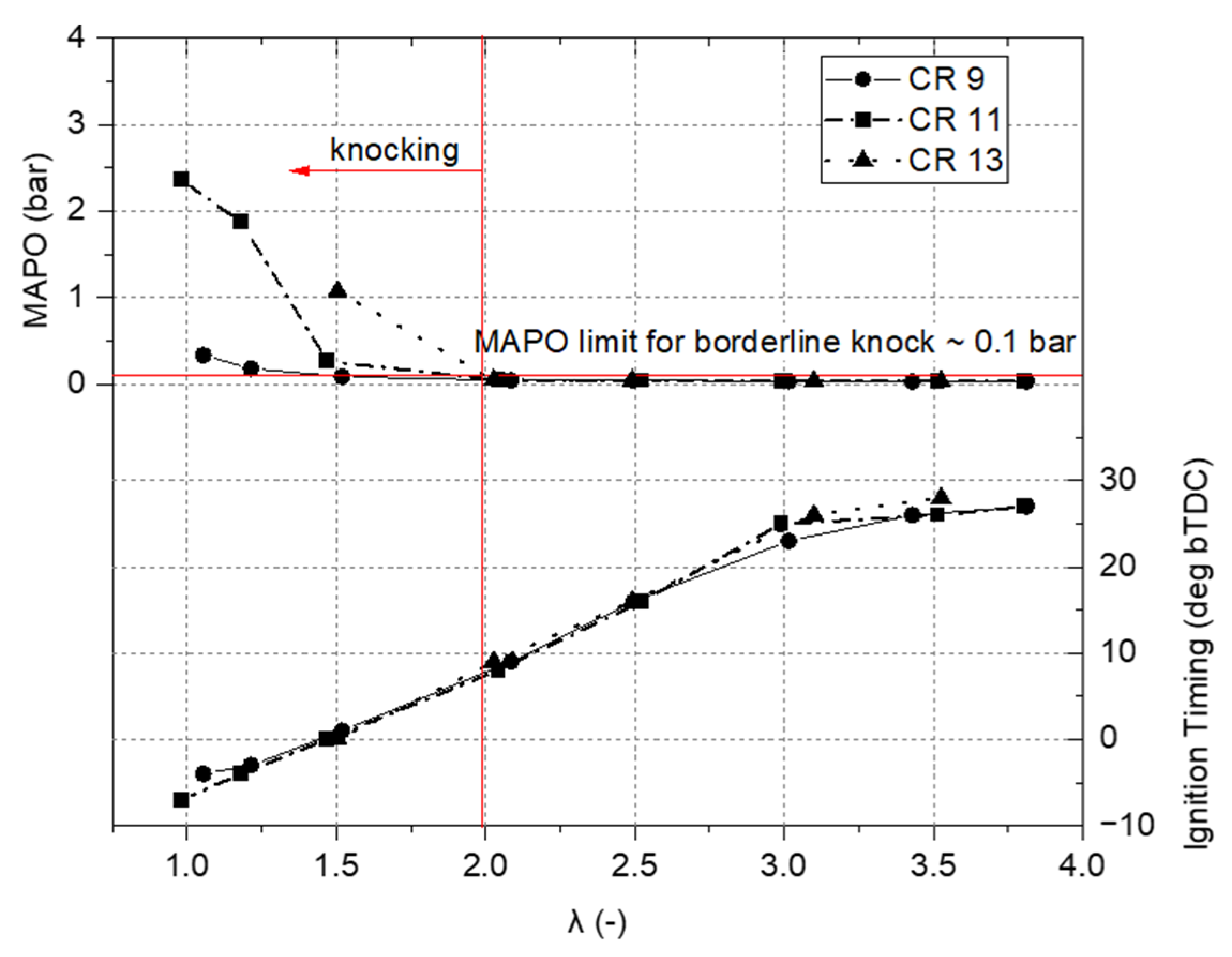

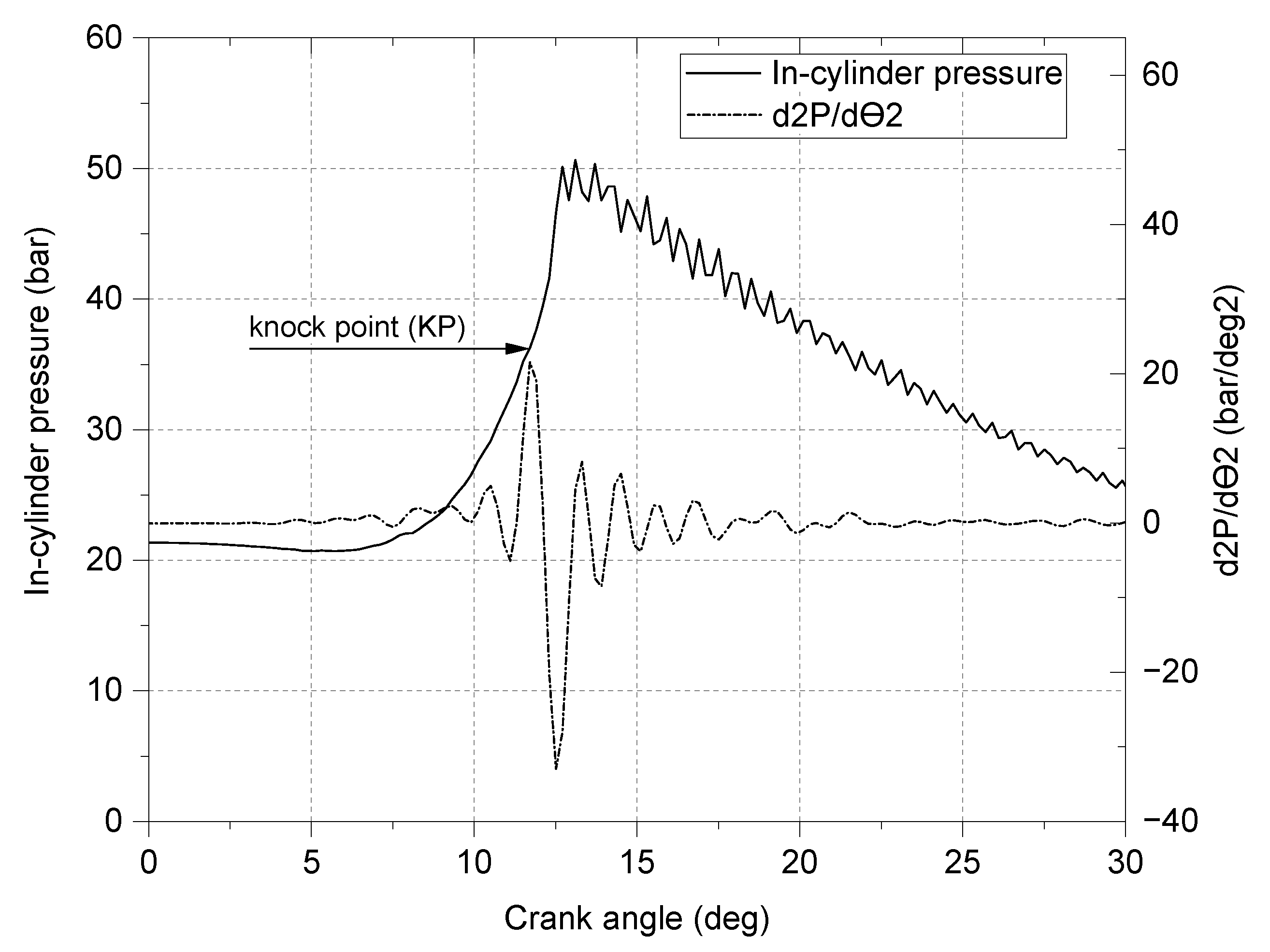

4.3.1. Combustion Characteristics

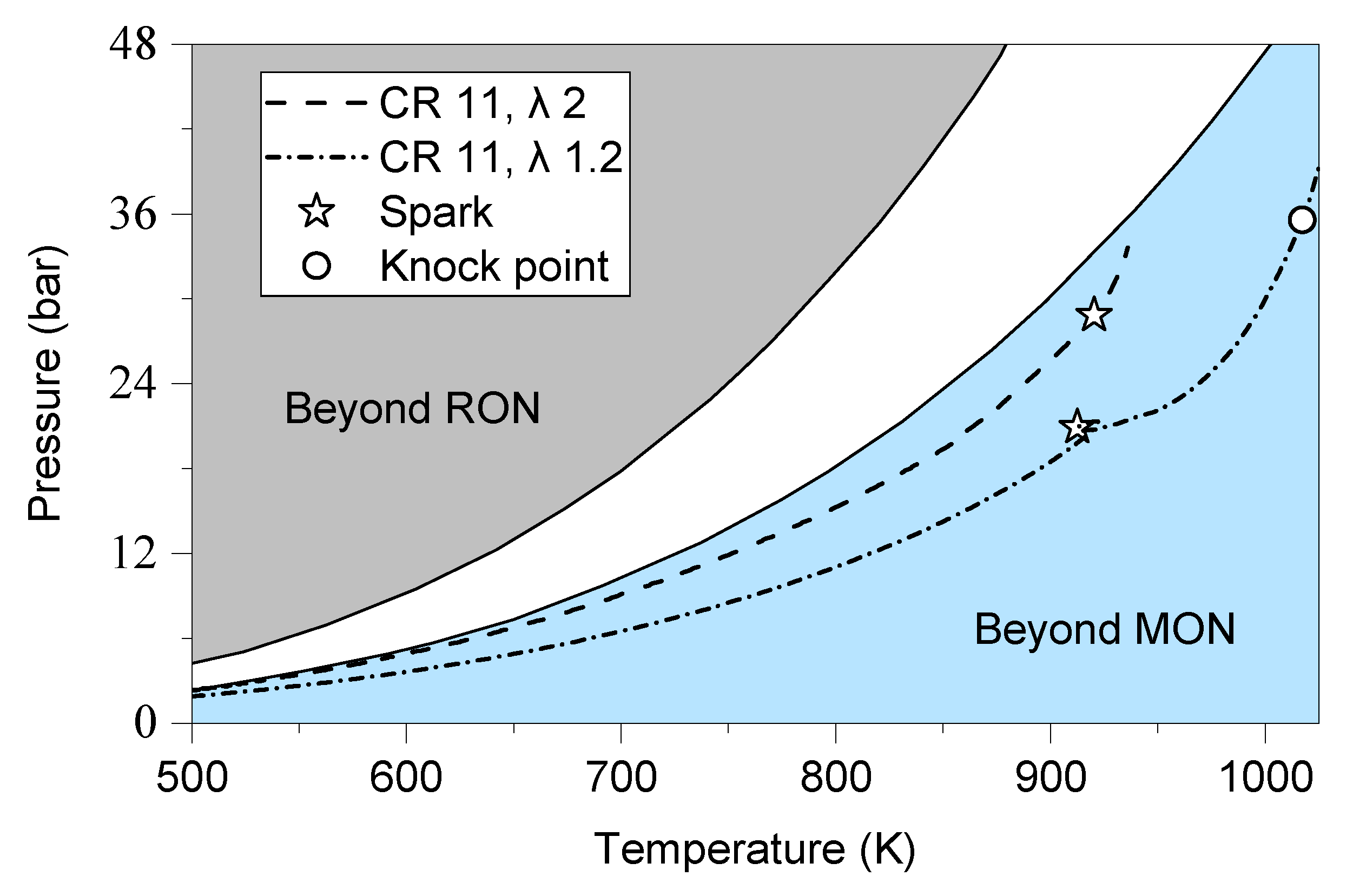

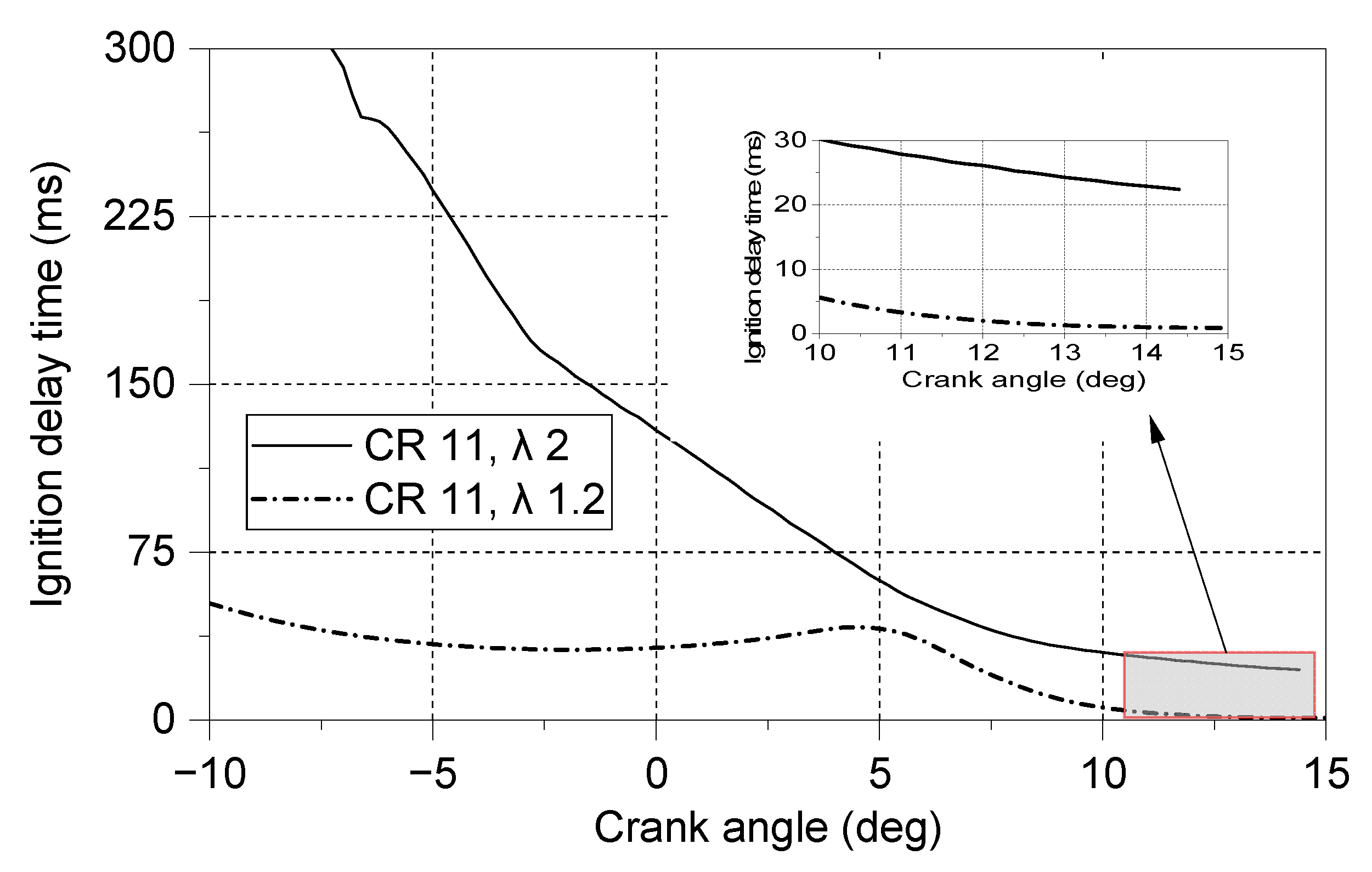

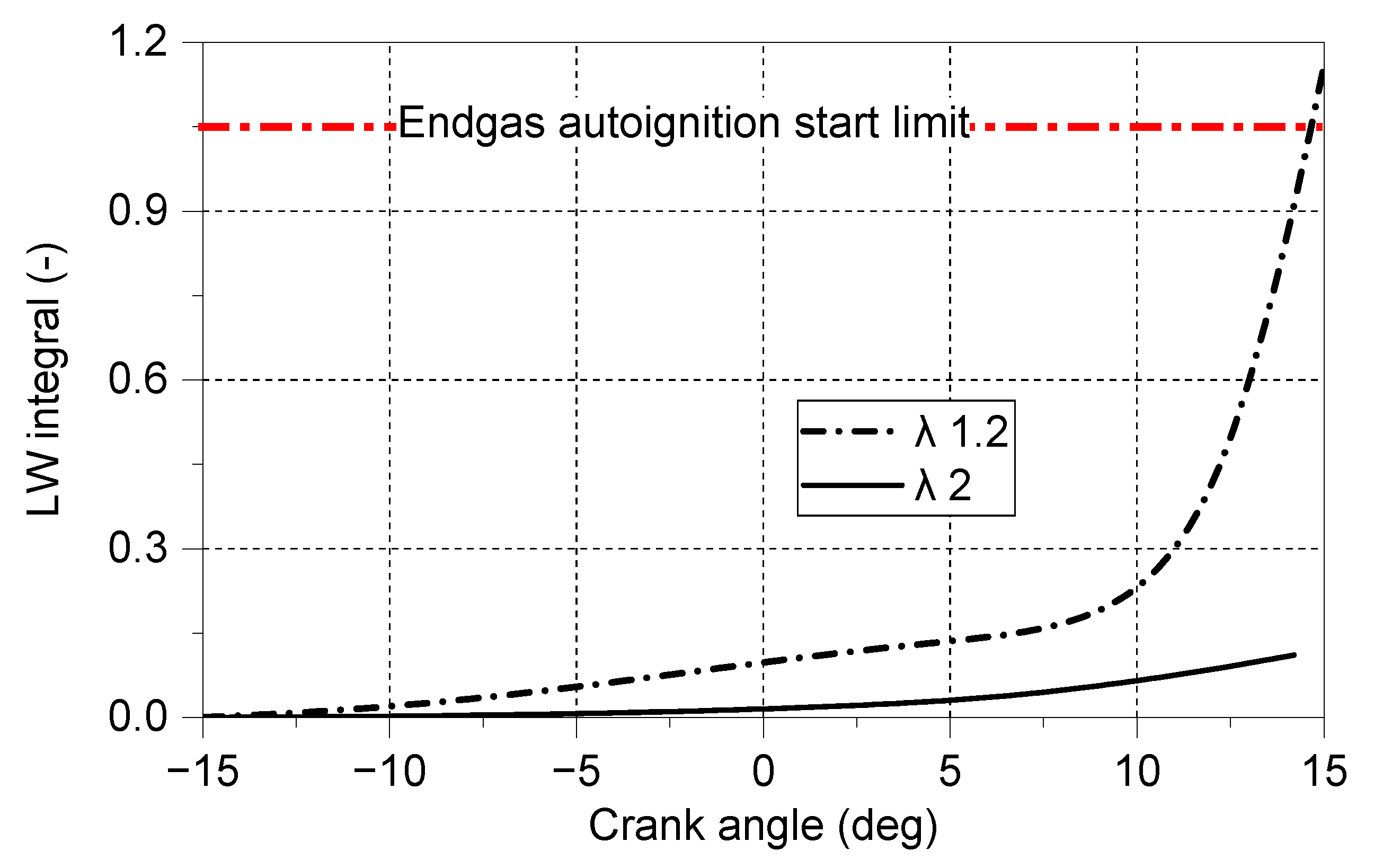

4.3.2. Simulation Results—Reactivity of Hydrogen

5. Conclusions

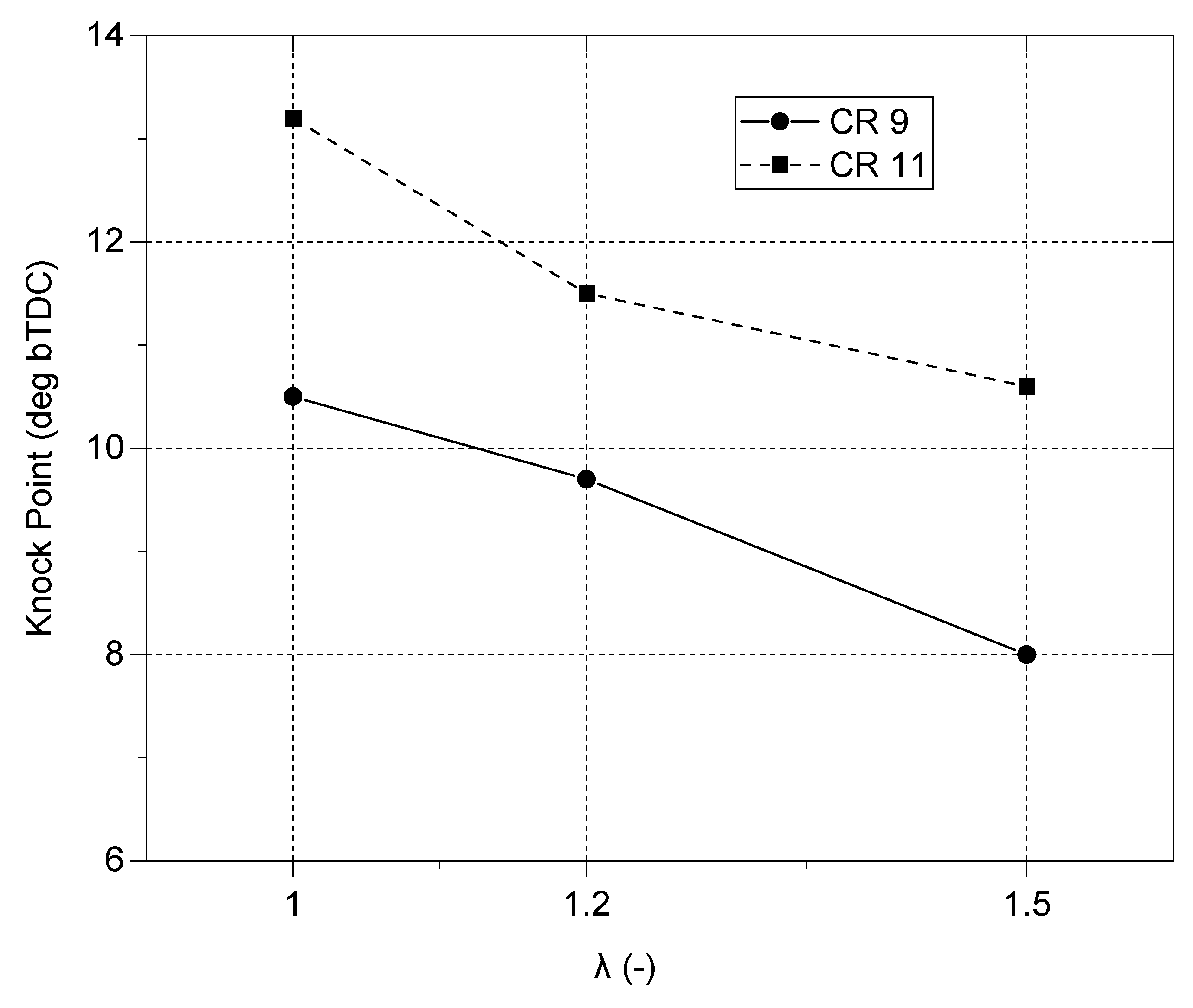

- Increasing the compression ratio of hydrogen engines results in an increase in the peak pressure and advancement in the knock point. However, it also leads to an increase in thermal efficiency, indicating the trade-off between performance and knock propensity.

- The air–fuel ratio (λ) has a significant impact on the performance and emissions of a hydrogen ICE. The results at λ = 2 demonstrated the highest thermal efficiency and low emissions of NOx, CO, and UHC but had a relatively low power output. In contrast, a higher power output but lower thermal efficiency, along with higher emissions, were observed at λ = 1.2.

- Based on the combustion analysis, hydrogen-fueled operation demonstrated normal combustion with the λ ≥ 2 cases but knocking combustion with the λ < 2 cases, irrespective of the tested compression ratios.

- The LW integral approach was used to assess the likelihood of knock, and the results indicated both normal and knocking combustion possibilities, similar to what was observed in the experimental investigations. The knock-free stable combustion from the lean stable operation has limits of up to a λ of 3. However, a significant increase in end-gas autoignition was observed, with a further decrease in λ for all tested CRs.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| aTDC | After top dead center |

| bTDC | Before top dead center |

| CAD | Crank angle degree |

| CFR | Cooperative fuel research |

| COV | Coefficient of variation |

| CR | Compression ratio |

| DI | Direct injection |

| HC | Hydrocarbons |

| ICE | Internal combustion engines |

| IDT | Ignition delay time |

| IMEP | Indicated mean effective pressure |

| ITE | Indicated thermal efficiency |

| KP | Knock point |

| LNV | Lowest normalized value |

| LW | Livengood–Wu |

| MAP | Manifold absolute pressure |

| MAPO | Maximum amplitude of high-frequency pressure oscillation |

| PFI | Port-fuel injection |

| SI | Spark ignition |

| TDC | Top dead center |

| TPA | Three pressure analysis |

| TWC | Three-way catalyst |

References

- Ritchie, H.; Roser, M.; Rosado, P. CO2 and Greenhouse Gas Emissions. Our World Data. 2020. Available online: https://ourworldindata.org/co2-and-greenhouse-gas-emissions (accessed on 4 July 2023).

- Senecal, K.; Leach, F. Racing Toward Zero: The Untold Story of Driving Green; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- Bae, C.; Kim, J. Alternative fuels for internal combustion engines. Proc. Combust. Inst. 2017, 36, 3389–3413. [Google Scholar] [CrossRef]

- Turner, J.W.G.; Leach, F.C.P. 3-Using alternative and renewable liquid fuels to improve the environmental performance of internal combustion engines: Key challenges and blending technologies. In Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance, 2nd ed.; Folkson, R., Sapsford, S., Eds.; Woodhead Publishing: Soston, UK, 2022; pp. 57–92. [Google Scholar]

- Husted, H.; Karl, G.; Schilling, S.; Weber, C. Direct injection of CNG for driving performance with low CO2. In Proceedings of the 23rd Aachen Colloquium Automobile and Engine Technology, Aachen, Germany, 6–8 October 2014; pp. 829–850. [Google Scholar]

- Rengarajan, S.; Liu, Z.; Lerin, C.; Stetter, J.; Narang, V.; Lana, C. LPG Direct Injection Engine for Medium Duty Trucks; Technical Paper 2020-07-5008; SAE: Warrendale, PA, USA, 2020; pp. 1–10. [Google Scholar] [CrossRef]

- Verhelst, S.; Wallner, T. Hydrogen-fueled internal combustion engines. Prog. Energy Combust. Sci. 2009, 35, 490–527. [Google Scholar] [CrossRef]

- Verhelst, S.; Turner, J.W.G.; Sileghem, L.; Vancoillie, J. Methanol as a fuel for internal combustion engines. Prog. Energy Combust. Sci. 2019, 70, 43–88. [Google Scholar] [CrossRef]

- Sopena, C.; Diéguez, P.M.; Sáinz, D.; Urroz, J.C.; Guelbenzu, E.; Gandía, L.M. Conversion of a commercial spark ignition engine to run on hydrogen: Performance comparison using hydrogen and gasoline. Int. J. Hydrog. Energy 2010, 35, 1420–1429. [Google Scholar] [CrossRef]

- Sun, D.; Liu, F. Research on the Performance and Emission of a Port Fuel Injection Hydrogen Internal Combustion Engine. In Proceedings of the 2011 International Conference on Computer Distributed Control and Intelligent Environmental Monitoring, Changcha, China, 19–20 February 2011; pp. 963–966. [Google Scholar]

- Verhelst, S.; Sierens, R.; Verstraeten, S. A Critical Review of Experimental Research on Hydrogen Fueled SI Engines; Technical Paper 2006-01-0430; SAE: Warrendale, PA, USA, 2006; Volume 115, pp. 264–274. [Google Scholar] [CrossRef]

- Stone, R. Introduction to Internal Combustion Engines; Springer: London, UK, 1999; Volume 3, pp. 1–16. [Google Scholar]

- Poursadegh, F.; Brear, M.; Hayward, B.; Yang, Y. Autoignition, knock, detonation and the octane rating of hydrogen. Fuel 2023, 332, 126201. [Google Scholar] [CrossRef]

- Turner, J.W.G.; Popplewell, A.; Patel, R.; Johnson, T.R.; Darnton, N.J.; Richardson, S.; Bredda, S.W.; Tudor, R.J.; Bithell, C.I.; Jackson, R.; et al. Ultra Boost for Economy: Extending the Limits of Extreme Engine Downsizing. SAE Int. J. Engines 2014, 7, 387–417. [Google Scholar] [CrossRef]

- Lee, J.; Park, C.; Kim, Y.; Choi, Y.; Bae, J.; Lim, B. Effect of turbocharger on performance and thermal efficiency of hydrogen-fueled spark ignition engine. Int. J. Hydrog. Energy 2019, 44, 4350–4360. [Google Scholar] [CrossRef]

- Oh, S.; Park, C.; Nguyen, D.; Kim, S.; Kim, Y.; Choi, Y.; Lee, J. Investigation on the operable range and idle condition of hydrogen-fueled spark ignition engine for unmanned aerial vehicle (UAV). Energy 2021, 237, 121645. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- White, C.M.; Steeper, R.R.; Lutz, A.E. The hydrogen-fueled internal combustion engine: A technical review. Int. J. Hydrog. Energy 2006, 31, 1292–1305. [Google Scholar] [CrossRef]

- Gao, J.; Wang, X.; Song, P.; Tian, G.; Ma, C. Review of the backfire occurrences and control strategies for port hydrogen injection internal combustion engines. Fuel 2022, 307, 121553. [Google Scholar] [CrossRef]

- Fischer, M.; Sterlepper, S.; Pischinger, S.; Seibel, J.; Kramer, U.; Lorenz, T. Operation principles for hydrogen spark ignited direct injection engines for passenger car applications. Int. J. Hydrog. Energy 2022, 47, 5638–5649. [Google Scholar] [CrossRef]

- Livengood, J.C.; Wu, P.C. Correlation of autoignition phenomena in internal combustion engines and rapid compression machines. Symp. Int. Combust. 1955, 5, 347–356. [Google Scholar] [CrossRef]

- Khaled, F.; Badra, J.; Farooq, A. Ignition delay time correlation of fuel blends based on Livengood-Wu description. Fuel 2017, 209, 776–786. [Google Scholar] [CrossRef]

- Fagundez, J.L.S.; Sari, R.L.; Garcia, A.; Pereira, F.M.; Martins, M.E.S.; Salau, N.P.G. A chemical kinetics based investigation on laminar burning velocity and knock occurrence in a spark-ignition engine fueled with ethanol–water blends. Fuel 2020, 280, 118587. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Z.; Huang, Y.; Liu, D.; Duan, J.; Guo, S.; Qin, Z. The effect of hydrogen injection parameters on the quality of hydrogen–air mixture formation for a PFI hydrogen internal combustion engine. Int. J. Hydrog. Energy 2017, 42, 23832–23845. [Google Scholar] [CrossRef]

- Sun, B.-G.; Zhang, D.-S.; Liu, F.-S. Cycle variations in a hydrogen internal combustion engine. Int. J. Hydrog. Energy 2013, 38, 3778–3783. [Google Scholar] [CrossRef]

- ASTM D2699-22a; Standard Test Method for Research Octane Number of Spark-Ignition Engine Fuel. ASTM: West Conshohocken, PA, USA, 2023.

- Millo, F.; Ferraro, C.V. Knock in S.I. Engines: A Comparison between Different Techniques for Detection and Control; Technical Paper 982477; SAE: Warrendale, PA, USA, 1998; Volume 107, pp. 1091–1112. [Google Scholar] [CrossRef]

- Smith, J.R.; Green, R.M.; Westbrook, C.K.; Pitz, W.J. An experimental and modeling study of engine knock. Symp. Int. Combust. 1985, 20, 91–100. [Google Scholar] [CrossRef]

- Hoth, A.; Kolodziej, C.P. Effects of knock intensity measurement technique and fuel chemical composition on the research octane number (RON) of FACE gasolines: Part 1—Lambda and knock characterization. Fuel 2021, 304, 120722. [Google Scholar] [CrossRef]

- Kar, T.; Fosudo, T.; Slunecka, C.; Marchese, A.; Windom, B.; Olsen, D. A Study of Propane Combustion in a Spark-Ignited Cooperative Fuel Research (CFR) Engine; Technical Paper 2022-01-0404; SAE: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Rockstroh, T.; Kolodziej, C.P.; Jespersen, M.C.; Goldsborough, S.S.; Wallner, T. Insights into Engine Knock: Comparison of Knock Metrics across Ranges of Intake Temperature and Pressure in the CFR Engine. SAE Int. J. Fuels Lubr. 2018, 11, 545–561. [Google Scholar] [CrossRef]

- Nguyen, D.; Turner, J.W.G. Effect of nitric oxide on the performance and emissions of a hydrogen-fueled HCCI engine. Fuel 2023, 349, 128611. [Google Scholar] [CrossRef]

- Pal, P.; Kolodziej, C.P.; Choi, S.; Som, S.; Broatch, A.; Gomez-Soriano, J.; Wu, Y.; Lu, T.; See, Y.C. Development of a Virtual CFR Engine Model for Knocking Combustion Analysis. SAE Int. J. Engines 2018, 11, 1069–1082. [Google Scholar] [CrossRef]

- Kar, T.; Zhou, Z.; Brear, M.; Yang, Y.; Khosravi, M.; Lacey, J. A Comparative Study of Directly Injected, Spark Ignition Engine Combustion and Energy Transfer with Natural Gas, Gasoline, and Charge Dilution. SAE Int. J. Fuels Lubr. 2022, 15, 199–220. [Google Scholar] [CrossRef]

- Ansys Chemkin-Pro. Theory Manual; Ansys: Canonsburg, PA, USA, 2021. [Google Scholar]

- Kar, T.; Fosudo, T.; Marchese, A.; Windom, B.; Olsen, D. Effect of fuel composition and EGR on spark-ignited engine combustion with LPG fueling: Experimental and numerical investigation. Fuel 2022, 327, 125221. [Google Scholar] [CrossRef]

- Slunecka, C.J.; Zdanowicz, A.; Bhoite, S.; Vaughan, S.; Windom, B.; Olsen, D.; Marchese, A. Autoignition of Premixed Liquefied Petroleum Gas in a Rapid Compression Machine: Experimental Results and Chemical Kinetic Mechanism Reduction. In Proceedings of the 12th U.S. National Combustion Meeting, College Station, TX, USA, 24–26 May 2021; Colorado State University: Fort Collins, CO, USA, 2021. [Google Scholar]

- GT-Power. Engine Performance Application Manual; Gamma Technologies: Westmont, IL, USA, 2018. [Google Scholar]

- Choi, S.; Kolodziej, C.P.; Hoth, A.; Wallner, T. Development and Validation of a Three Pressure Analysis (TPA) GT-Power Model of the CFR F1/F2 Engine for Estimating Cylinder Conditions; Technical Paper 2018-01-0848; SAE: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Woschni, G.A. Universally Applicable Equation for the Instantaneous Heat Transfer Coefficient in the Internal Combustion Engine; Technical Paper 670931; SAE: Warrendale, PA, USA, 1967. [Google Scholar] [CrossRef]

- Assanis, D.; Wiese, K.; Schwarz, E.; Bryzik, W. The Effects of Ceramic Coatings on Diesel Engine Performance and Exhaust Emissions; Technical Paper 910460; SAE: Warrendale, PA, USA, 1991; Volume 100, pp. 657–665. [Google Scholar] [CrossRef]

- Han, S.B. Cycle-to-cycle variations under cylinder-pressure-based combustion analysis in spark ignition engines. KSME Int. J. 2000, 14, 1151–1158. [Google Scholar] [CrossRef]

- Hoard, J.; Rehagen, L. Relating Subjective Idle Quality to Engine Combustion; Technical Paper 970035; SAE: Warrendale, PA, USA, 1997. [Google Scholar] [CrossRef]

- Han, L.; Cai, S.; Gao, M.; Hasegawa, J.-Y.; Wang, P.; Zhang, J.; Shi, L.; Zhang, D. Selective Catalytic Reduction of NOx with NH3 by Using Novel Catalysts: State of the Art and Future Prospects. Chem. Rev. 2019, 119, 10916–10976. [Google Scholar] [CrossRef]

- Getsoian, A.B.; Theis, J.R.; Lambert, C.K. Sensitivity of Three-Way Catalyst Light-Off Temperature to Air-Fuel Ratio. Emiss. Control Sci. Technol. 2018, 4, 136–142. [Google Scholar] [CrossRef]

- Verhelst, S.; Maesschalck, P.; Rombaut, N.; Sierens, R. Increasing the power output of hydrogen internal combustion engines by means of supercharging and exhaust gas recirculation. Int. J. Hydrog. Energy 2009, 34, 4406–4412. [Google Scholar] [CrossRef]

- Li, H.; Karim, G.A.; Sohrabi, A. Examination of the Oil Combustion in a S.I. Hydrogen Engine; Technical Paper 2004-01-2916; SAE: Warrendale, PA, USA, 2004. [Google Scholar] [CrossRef]

- Szybist, J.P.; Wagnon, S.W.; Splitter, D.; Pitz, W.J.; Mehl, M. The Reduced Effectiveness of EGR to Mitigate Knock at High Loads in Boosted SI Engines. SAE Int. J. Engines 2017, 10, 2305–2318. [Google Scholar] [CrossRef]

- Jain, S.; Li, D.; Aggarwal, S.K. Effect of hydrogen and syngas addition on the ignition of iso-octane/air mixtures. Int. J. Hydrog. Energy 2013, 38, 4163–4176. [Google Scholar] [CrossRef]

| Displacement volume | 611.7 cc |

| Intake system | Naturally aspirated |

| Compression Ratio | 4:1 to 18:1 |

| Bore, Stroke | 82.55 mm, 114.3 mm |

| Number of Valves | 2 |

| Exhaust Valve Open | 140 CAD ATDC |

| Exhaust Valve Close | 345 CAD BTDC |

| Inlet Valve Open | 350 CAD BTDC |

| Inlet Valve Close | 146 CAD BTDC |

| Device | Measuring Range | Accuracy |

|---|---|---|

| Air mass flow controller | 0–1000 SLPM | ±0.5% of the flow rate ±0.1% of the full scale |

| Hydrogen mass flow controller | 0–100 SLPM | ±0.5% of the flow rate ±0.1% of the full scale |

| In-cylinder pressure transducer | Up to 150 bar | ±0.3% of the full scale |

| FTIR analyser | 0–10,000 ppm | ≤2% of the measured value |

| Hydrogen portable analyser | 0–20,000 ppm | ±100 ppm or 5% of the measured value |

| Intake and exhaust pressure transducers | 0–10 bar | ±0.1% of the full scale |

| Thermocouples | −200–1250 °C | ±0.75% of the full scale |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, D.; Kar, T.; Turner, J.W.G. Performance, Emissions, and Combustion Characteristics of a Hydrogen-Fueled Spark-Ignited Engine at Different Compression Ratios: Experimental and Numerical Investigation. Energies 2023, 16, 5730. https://doi.org/10.3390/en16155730

Nguyen D, Kar T, Turner JWG. Performance, Emissions, and Combustion Characteristics of a Hydrogen-Fueled Spark-Ignited Engine at Different Compression Ratios: Experimental and Numerical Investigation. Energies. 2023; 16(15):5730. https://doi.org/10.3390/en16155730

Chicago/Turabian StyleNguyen, Ducduy, Tanmay Kar, and James W. G. Turner. 2023. "Performance, Emissions, and Combustion Characteristics of a Hydrogen-Fueled Spark-Ignited Engine at Different Compression Ratios: Experimental and Numerical Investigation" Energies 16, no. 15: 5730. https://doi.org/10.3390/en16155730

APA StyleNguyen, D., Kar, T., & Turner, J. W. G. (2023). Performance, Emissions, and Combustion Characteristics of a Hydrogen-Fueled Spark-Ignited Engine at Different Compression Ratios: Experimental and Numerical Investigation. Energies, 16(15), 5730. https://doi.org/10.3390/en16155730