Stator ITSC Fault Diagnosis of EMU Asynchronous Traction Motor Based on apFFT Time-Shift Phase Difference Spectrum Correction and SVM

Abstract

1. Introduction

2. Calculation of Signals’ Fundamental Components

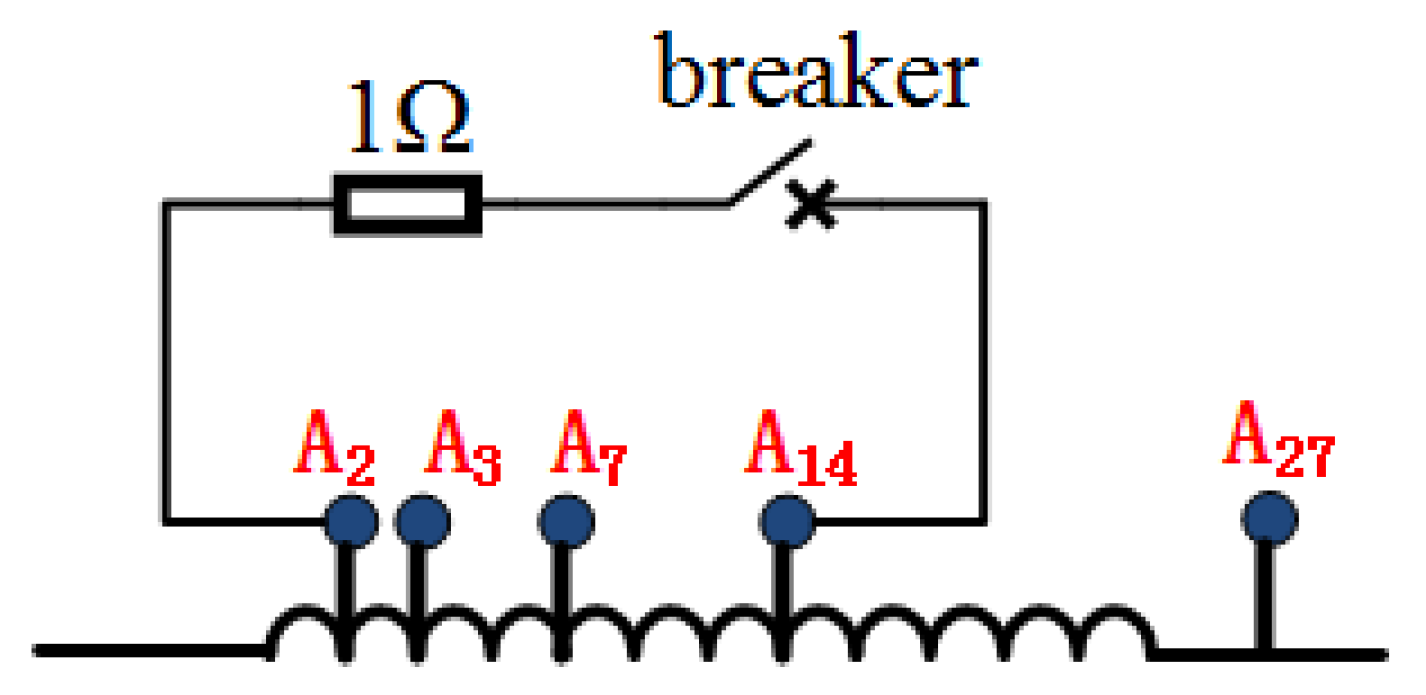

2.1. ZSVC Measurement Method

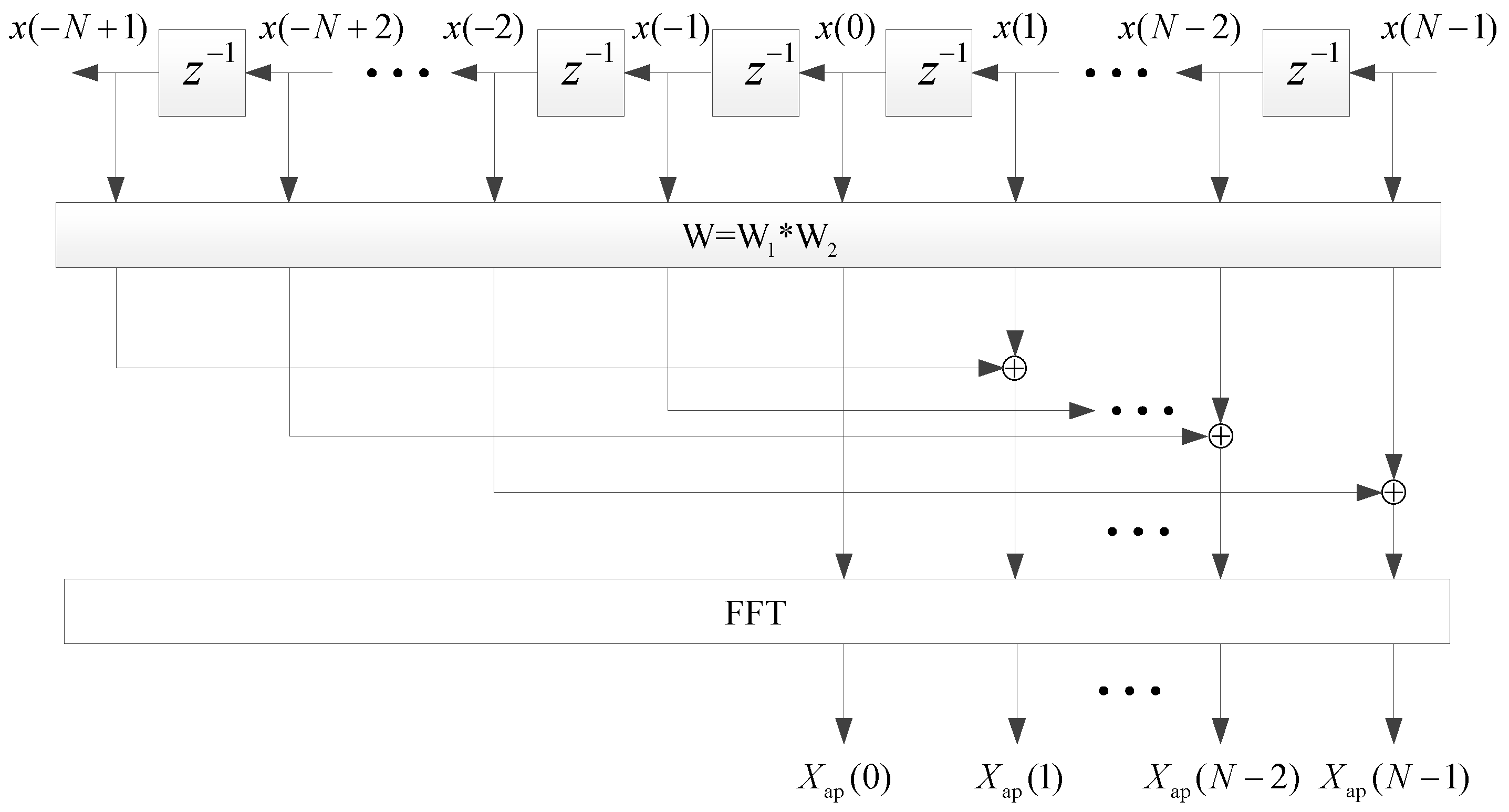

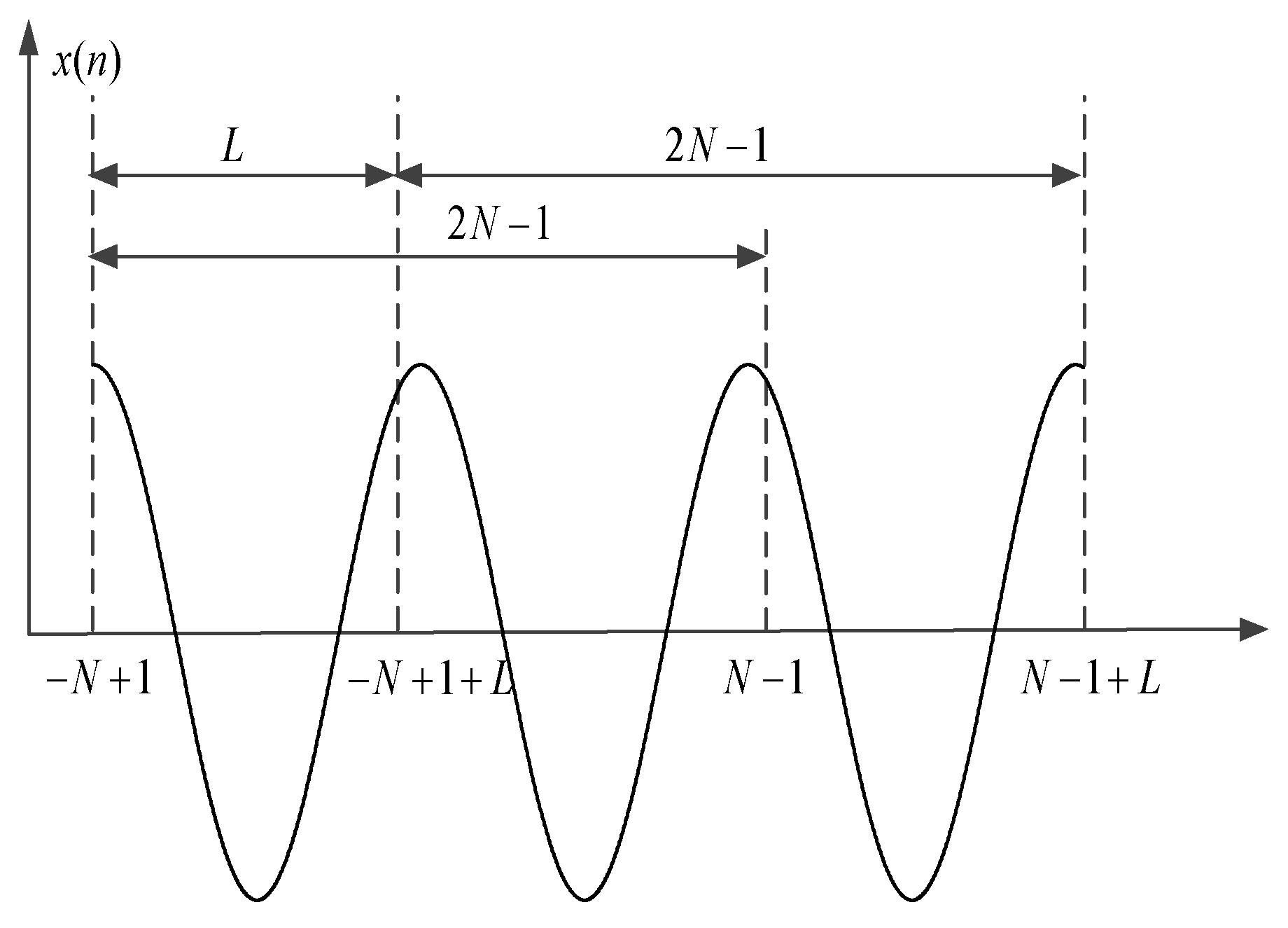

2.2. ApFFT Time-Shift Phase Difference Correction Algorithm

3. Fault Diagnosis Method for Stator ITSC Fault of Traction Motor

3.1. Stator ITSC Fault Extent Index

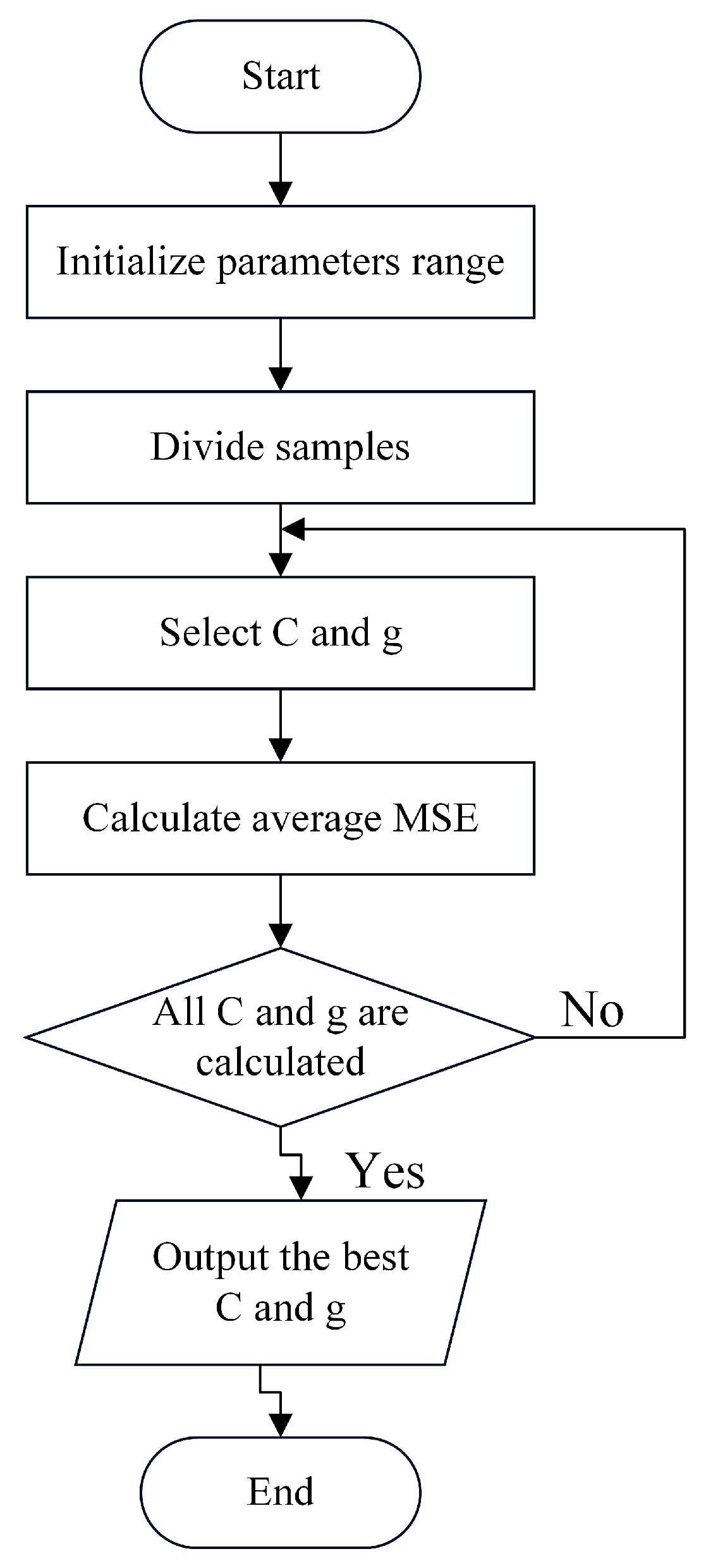

3.2. SVM Model for Diagnosis of ITSC Fault

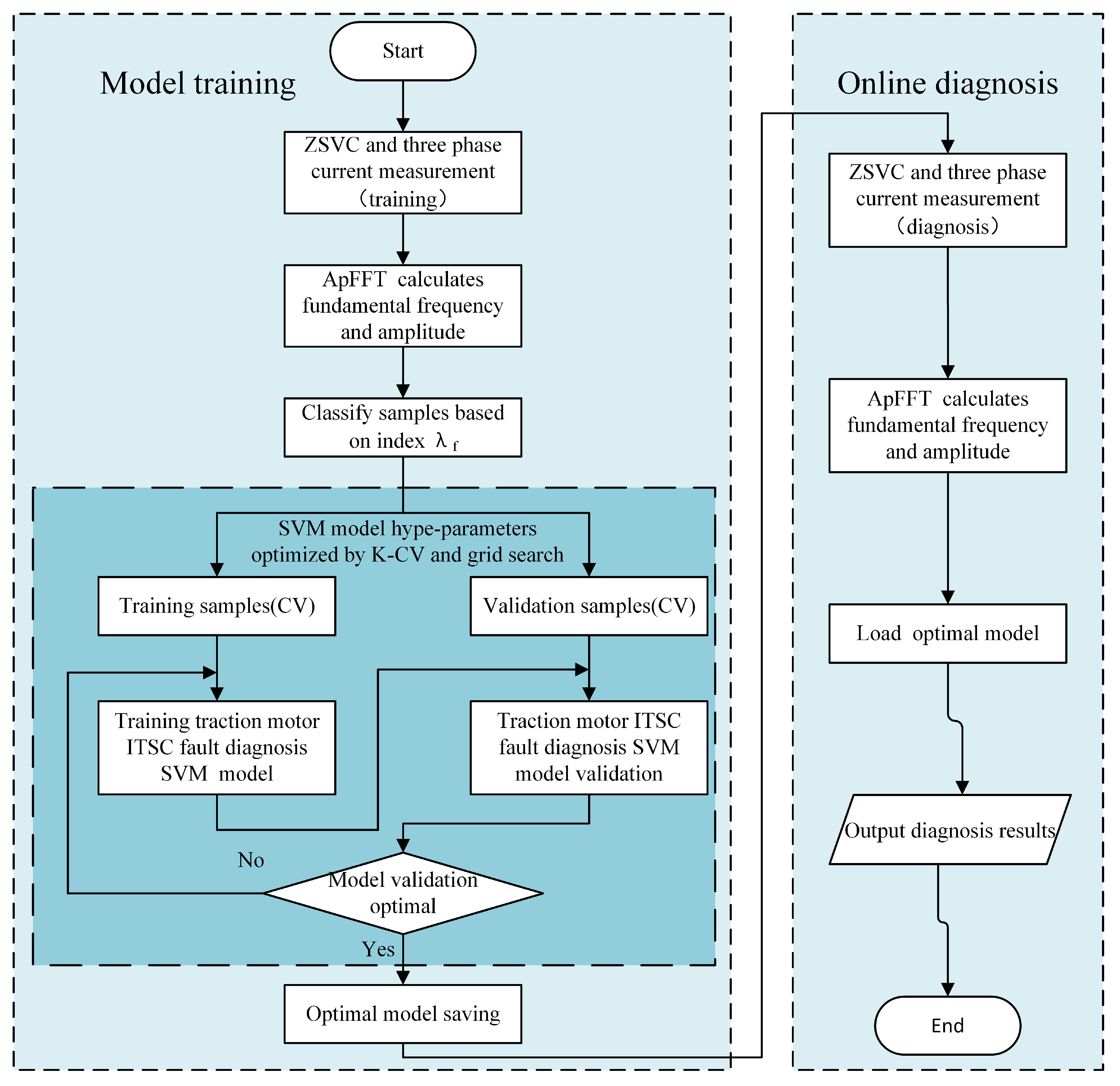

3.3. ITSC Fault Diagnosis Procedure Based on SVM Model

4. EMU Electric Traction Simulation Experimental Platform

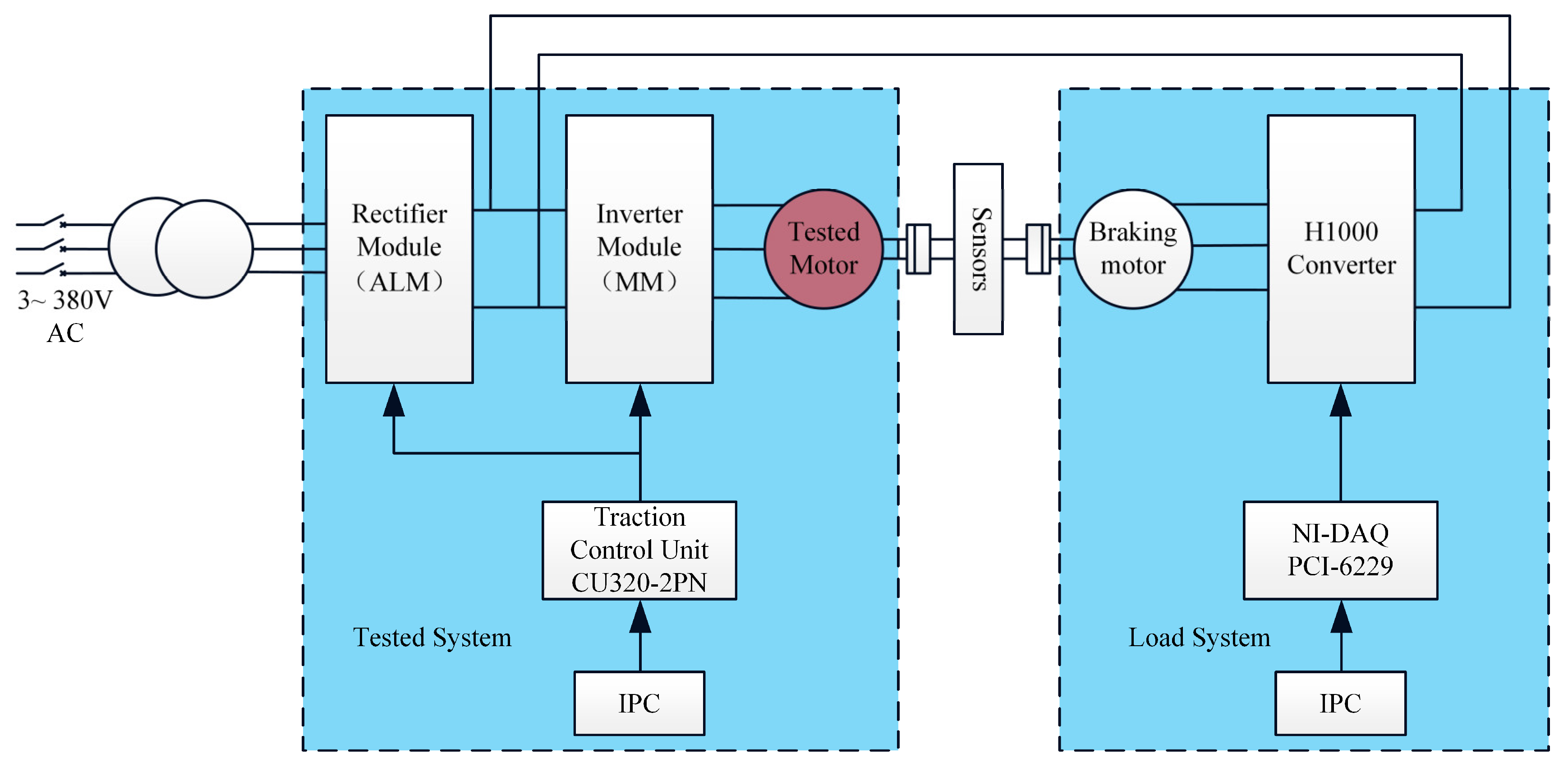

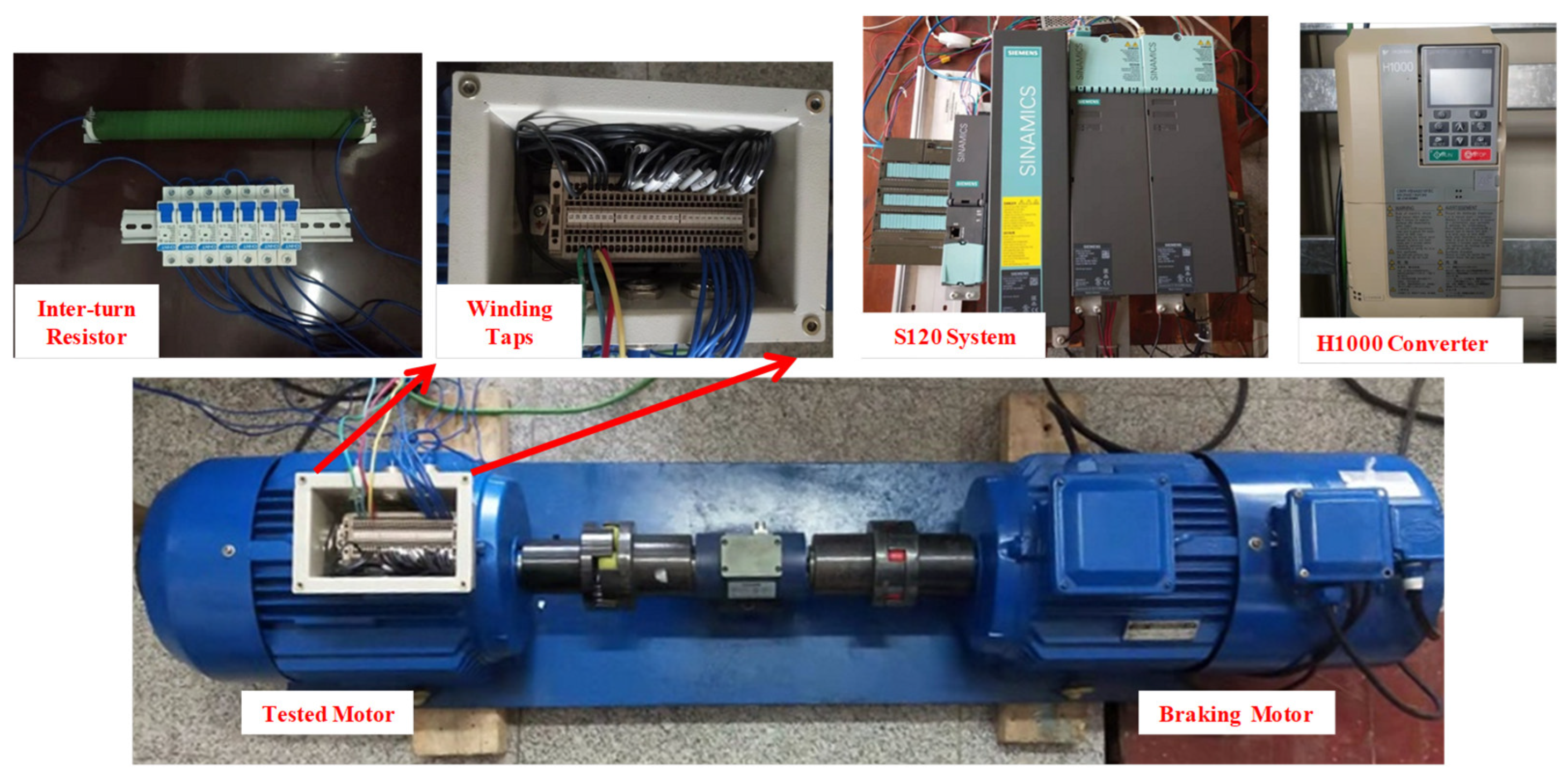

4.1. Overall Design of the Experimental Platform

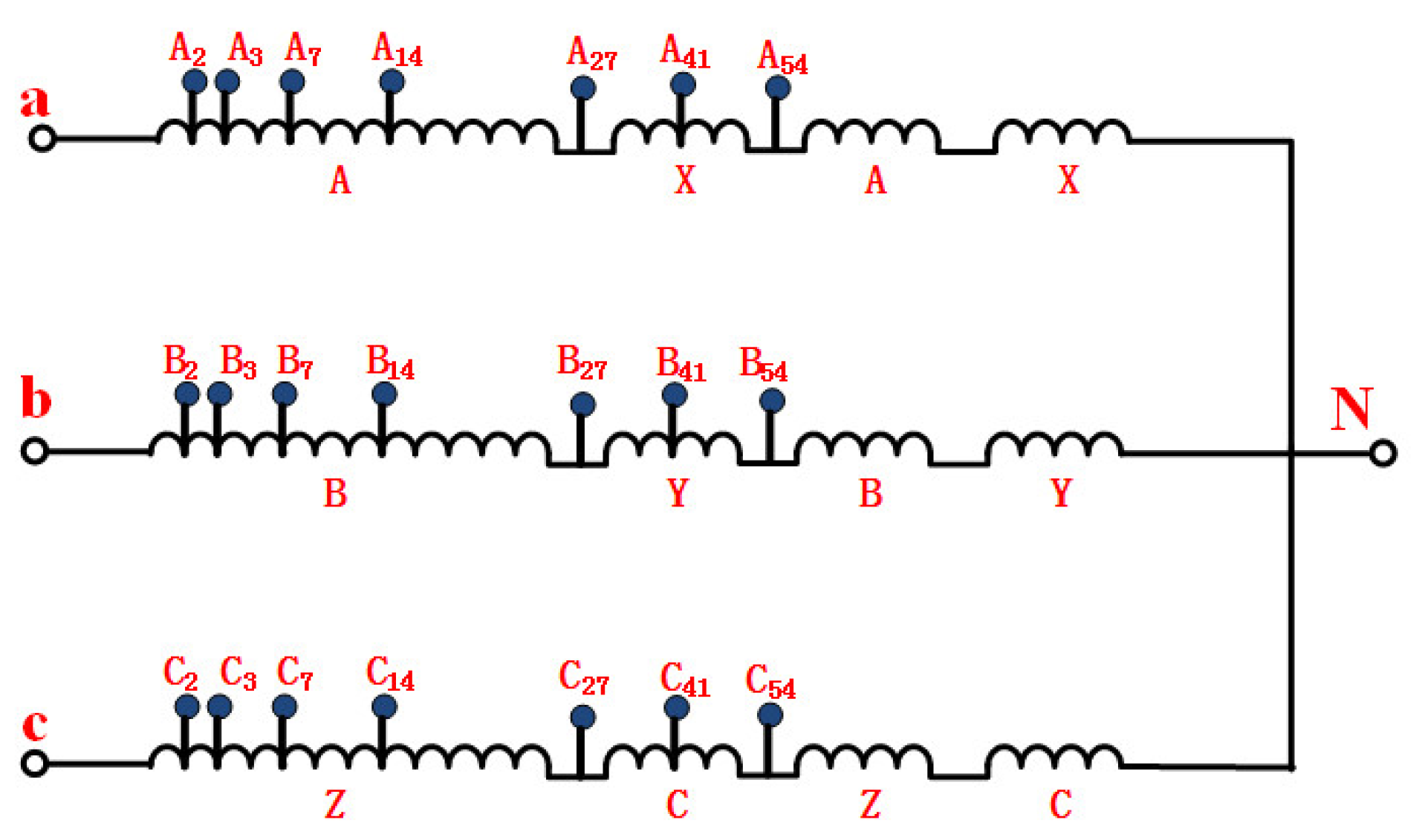

4.2. Setting ITSC Faults on Tested Motor

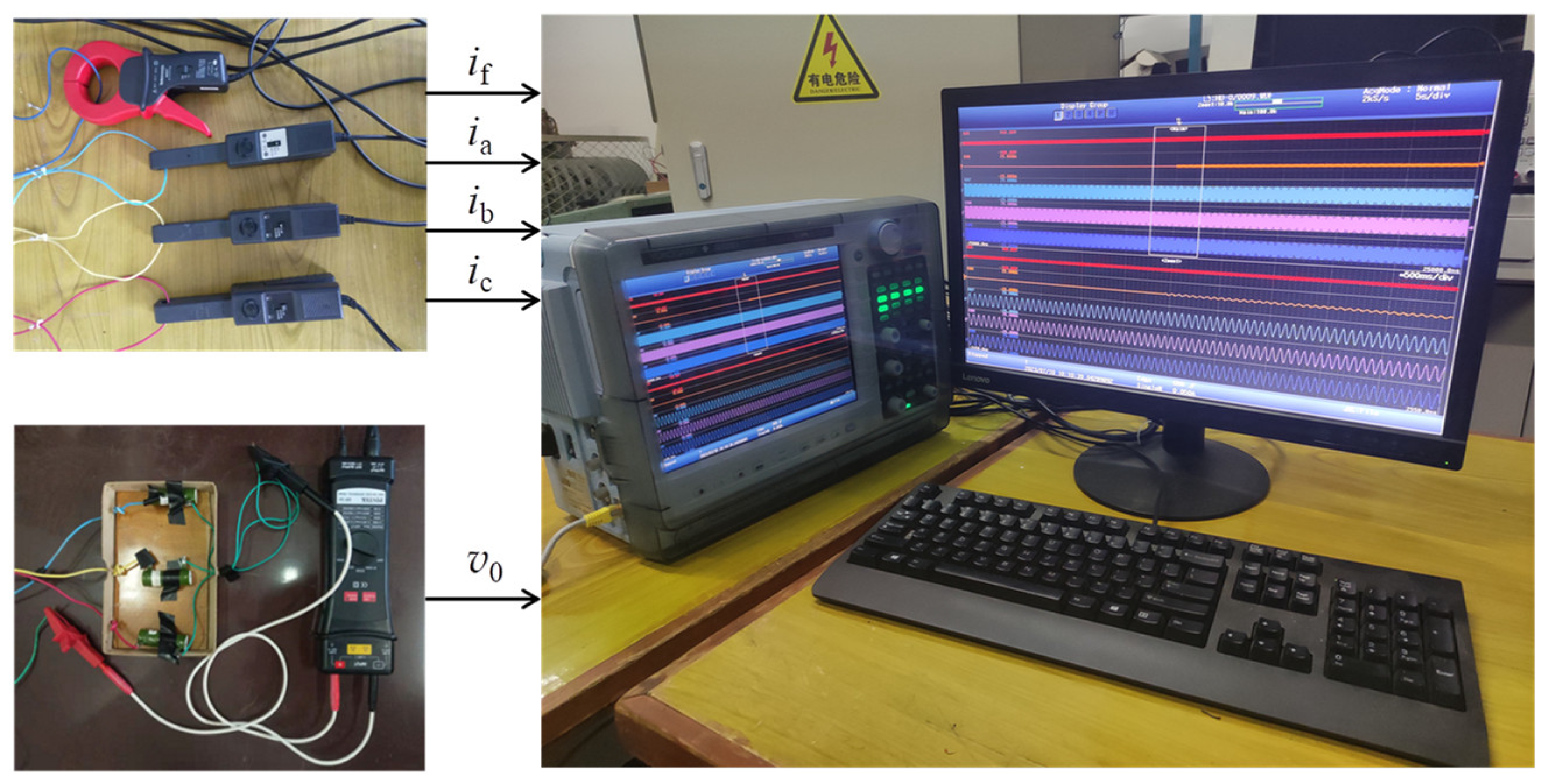

4.3. Signal Measurement of the Experimental Platform

5. Analysis of ITSC Fault Diagnosis Model Based on Experimental Samples

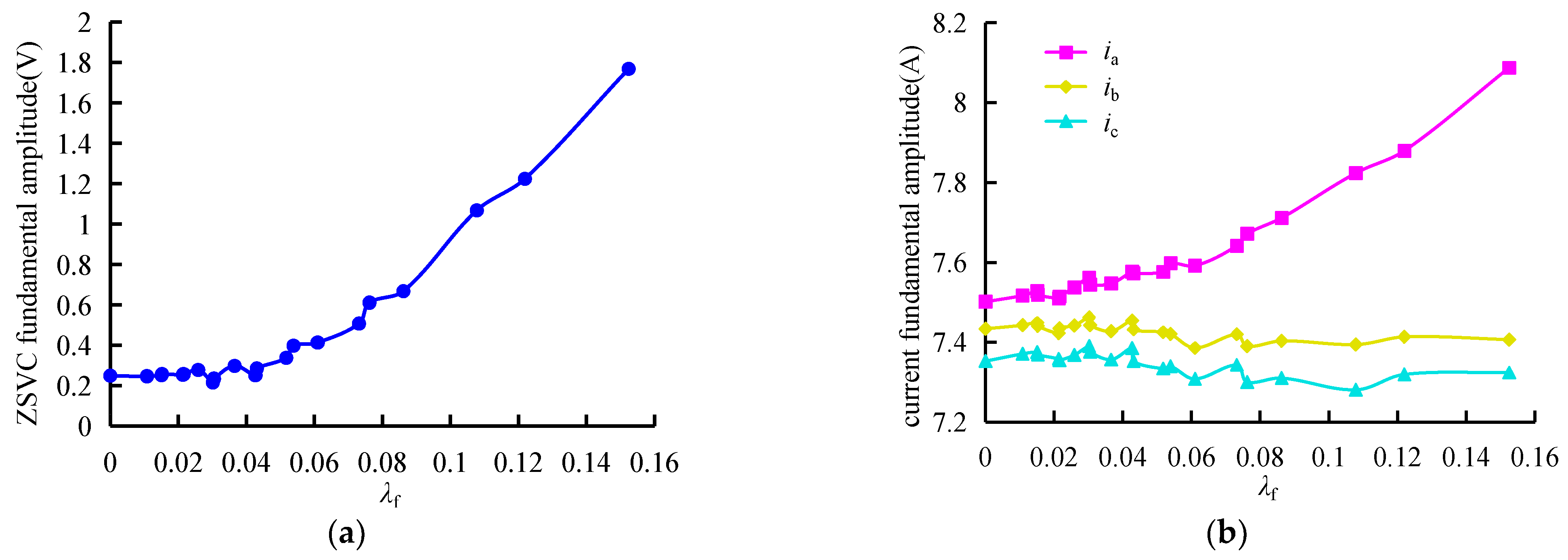

5.1. Analysis of Motor Signals with ITSC Fault

5.2. Analysis of ITSC Fault Features

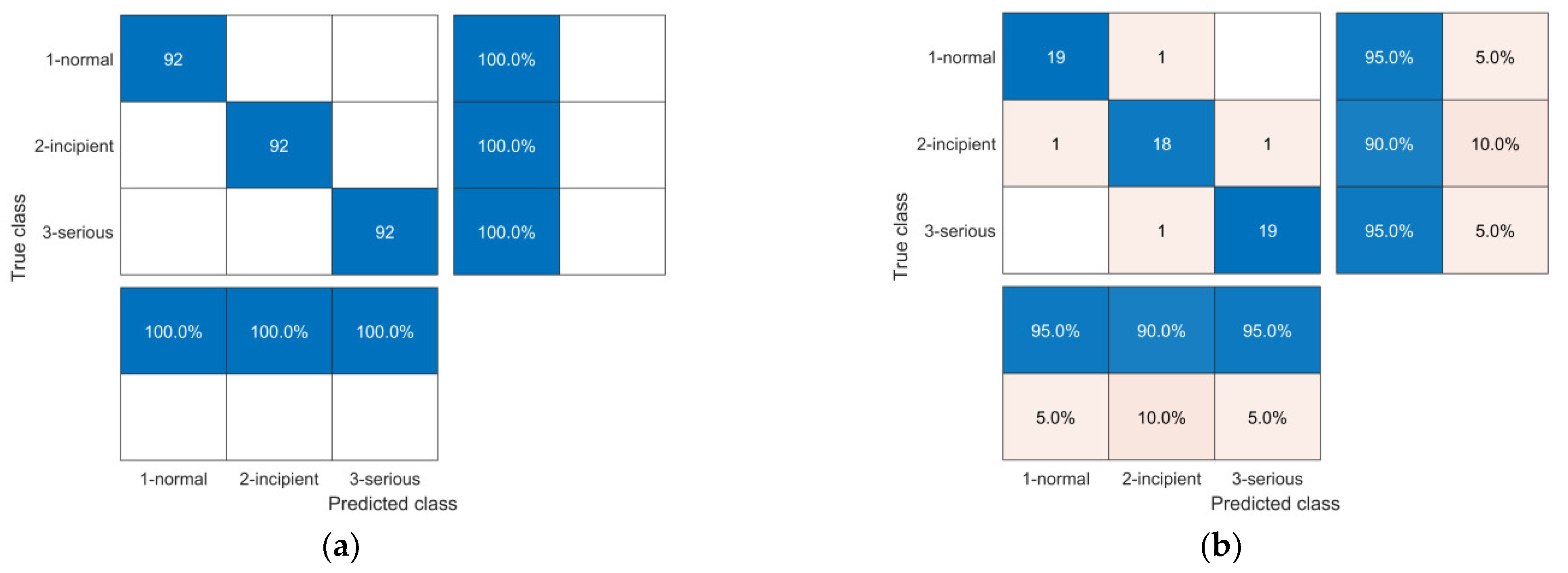

5.3. Analysis of SVM ITSC Fault Diagnosis Model Performance

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, S.-G. A Study on Traction Motor Characteristic in EMU Train. In Proceedings of the 13th International Conference on Control, Automation and Systems, Gyeonggi-do, Republic of Korea, 22–25 October 2014. [Google Scholar]

- Zhang, K.; Jiang, B.; Chen, F. Multiple-Model-Based Diagnosis of Multiple Faults With High-Speed Train Applications Using Second-Level Adaptation. IEEE Trans. Ind. Electron. 2021, 68, 6257–6266. [Google Scholar] [CrossRef]

- Chen, Z.P.; Wang, Z.; Jia, L.M.; Cai, G.Q. Analysis and Comparison of Locomotive Traction Motor Intelligent Fault Diagnosis Methods. Appl. Mech. Mater. 2011, 97–98, 994–1002. [Google Scholar] [CrossRef]

- Al-Ameri, S.M.; Alawady, A.A.; Yousof, M.F.M.; Kamarudin, M.S.; Salem, A.A.; Abu-Siada, A.; Mosaad, M.I. Application of Frequency Response Analysis Method to Detect Short-Circuit Faults in Three-Phase Induction Motors. Appl. Sci. 2022, 12, 2046. [Google Scholar] [CrossRef]

- Chao, C.; Wang, W.; Chen, H.; Zhang, B.; Shao, J.; Teng, W. Enhanced Fault Diagnosis Using Broad Learning for Traction Systems in High-Speed Trains. IEEE Trans. Power Electron. 2020, 36, 7461–7469. [Google Scholar] [CrossRef]

- Guo, X.; Tang, Y.; Wu, M.; Zhang, Z.; Yuan, J. FPGA-Based Hardware-in-the-Loop Real-Time Simulation Implementation for High-Speed Train Electrical Traction System. IET Electr. Power Appl. 2020, 14, 850–858. [Google Scholar] [CrossRef]

- Kaufhold, M.; Aninger, H. Electrical Stress and Failure Mechanism of the Winding Insulation in PWM-Inverter-Fed Low-Voltage Induction Motors. IEEE Trans. Ind. Electron. 2000, 2, 396–402. [Google Scholar] [CrossRef]

- Mbaye, A.; Bellomo, J.P. Electrical Stresses Applied to Stator Insulation in Low-Voltage Induction Motors Fed by PWM Drives. IET Electr. Power Appl. 1997, 144, 191–198. [Google Scholar] [CrossRef]

- Hwang, D.H.; Park, D.Y.; Kim, Y.J.; Lee, Y.H.; Hur, I.G. A Comparison with Insulation System for PWM-Inverter-Fed Induction Motors. In Proceedings of the International Conference on Electrical Machines & Systems, Shenyang, China, 18–20 August 2001. [Google Scholar] [CrossRef]

- Otero, M.; Barrera, P.; Bossio, G.R.; Leidhold, R. Stator Inter-turn Faults Diagnosis in Induction Motors Using Zero-sequence Signal Injection. IET Electr. Power Appl. 2020, 14, 273–2738. [Google Scholar] [CrossRef]

- Singh, M.; Shaik, A.G. Incipient Fault Detection in Stator Windings of an Induction Motor Using Stockwell Transform and SVM. IEEE Trans. Instrum. Meas. 2020, 69, 9496–9504. [Google Scholar] [CrossRef]

- Sonje, D.M.; Kundu, P.; Chowdhury, A. A Novel Approach for Sensitive Inter-turn Fault Detection in Induction Motor Under Various Operating Conditions. Arab. J. Sci. Eng. 2019, 44, 6887–6900. [Google Scholar] [CrossRef]

- Namdar, A. A robust principal component analysis-based approach for detection of a stator inter-turn fault in induction motors. Prot. Control. Mod. Power Syst. 2022, 7, 48. [Google Scholar] [CrossRef]

- Mejia-Barron, A.; Tapia-Tinoco, G.; Razo-Hernandez, J.R.; Valtierra-Rodriguez, M.; Granados-Lieberman, D. A neural network-based model for MCSA of ITSC faults in induction motors and its power hardware in the loop simulation. Comput. Electr. Eng. 2021, 93, 107234. [Google Scholar] [CrossRef]

- Tallam, R.; Habetler, T.; Harley, R. Transient model for induction machines with stator winding turn faults. IEEE Trans. Ind. Appl. 2002, 38, 632–637. [Google Scholar] [CrossRef]

- Zhao, Z.; Fan, F.; Wang, W.; Liu, Y.; See, K.Y. Detection of Stator Interturn Short-Circuit Faults in Inverter-Fed Induction Motors by Online Common-Mode Impedance Monitoring. IEEE Trans. Instrum. Meas. 2021, 70, 3513110. [Google Scholar] [CrossRef]

- Duan, F.; Zivanovic, R. Induction Motor Stator Fault Detection by a Condition Monitoring Scheme Based on Parameter Estimation Algorithms. Electr. Power Compon. Syst. 2016, 44, 1138–1148. [Google Scholar] [CrossRef][Green Version]

- Bazine, I.B.A.; Tnani, S.; Poinot, T.; Champenois, G.; Jelassi, K. On-Line Detection of Stator and Rotor Faults Occurring in In-duction Machine Diagnosis by Parameters Estimation. In Proceedings of the 8th IEEE Symposium on Diagnostics for Electrical Machines, Power Electronics & Drives, Bologna, Italy, 5–8 September 2011. [Google Scholar] [CrossRef]

- Abdallah, H.; Benatman, K. Stator winding inter-turn short-circuit detection in induction motors by parameter identification. IET Electr. Power Appl. 2017, 11, 272–288. [Google Scholar] [CrossRef]

- Nguyen, V.; Seshadrinath, J.; Wang, D.; Nadarajan, S.; Vaiyapuri, V. Model-Based Diagnosis and RUL Estimation of Induction Machines Under Interturn Fault. IEEE Trans. Ind. Appl. 2017, 53, 2690–2701. [Google Scholar] [CrossRef]

- Kallesoe, C.S.; Vadstrup, P.; Rasmussen, H.; Izadi-Zamanabadi, R. Observer Based Estimation of Stator Winding Faults in Delta-Connected Induction Motors, a LMI Approach. In Proceedings of the IAS Annual Meeting, Tampa, FL, USA, 8–12 October 2006. [Google Scholar] [CrossRef]

- De Angelo, C.H.; Bossio, G.R.; Giaccone, S.J.; Valla, M.I.; Solsona, J.A.; Garcia, G.O. Online Model-Based Stator-Fault Detection and Identification in Induction Motors. IEEE Trans. Ind. Electron. 2009, 56, 4671–4680. [Google Scholar] [CrossRef]

- Guezmil, A.; Berriri, H.; Pusca, R.; Sakly, A.; Romary, R.; Mimouni, M.F. Detecting Inter-Turn Short-Circuit Fault in Induction Machine Using High-Order Sliding Mode Observer: Simulation and Experimental Verification. J. Control. Autom. Electr. Syst. 2017, 28, 532–540. [Google Scholar] [CrossRef]

- Kia, M.Y.; Khedri, M.; Najafi, H.R.; Nejad, M.A.S. Hybrid modelling of doubly fed induction generators with inter-turn stator fault and its detection method using wavelet analysis. IET Gener. Transm. Distrib. 2013, 7, 982–990. [Google Scholar] [CrossRef]

- Kumar, P.S.; Xie, L.; Halick, M.S.M.; Vaiyapuri, V. Stator End-Winding Thermal and Magnetic Sensor Arrays for Online Stator Inter-Turn Fault Detection. IEEE Sens. J. 2020, 21, 5312–5321. [Google Scholar] [CrossRef]

- Chen, P.; Xie, Y.; Hu, S. Electromagnetic Performance and Diagnosis of Induction Motors With Stator Interturn Fault. IEEE Trans. Ind. Appl. 2020, 57, 1354–1364. [Google Scholar] [CrossRef]

- Lee, S.-H.; Wang, Y.-Q.; Song, J.-I. Fourier and wavelet transformations application to fault detection of induction motor with stator current. J. Cent. S. Univ. Technol. 2010, 17, 93–101. [Google Scholar] [CrossRef]

- Liu, H.; Huang, J.; Hou, Z.; Yang, J.; Ye, M. Stator inter-turn fault detection in closed-loop controlled drive based on switching sideband harmonics in CMV. IET Electr. Power Appl. 2017, 11, 178–186. [Google Scholar] [CrossRef]

- Sadeghi, R.; Samet, H.; Ghanbari, T. Detection of Stator Short-Circuit Faults in Induction Motors Using the Concept of Instantaneous Frequency. IEEE Trans. Ind. Inform. 2018, 15, 4506–4515. [Google Scholar] [CrossRef]

- Vinayak, B.A.; Anand, K.A.; Jagadanand, G. Wavelet-based real-time stator fault detection of inverter-fed induction motor. IET Electr. Power Appl. 2019, 14, 82–90. [Google Scholar] [CrossRef]

- Almounajjed, A.; Sahoo, A.K.; Kumar, M.K. Diagnosis of stator fault severity in induction motor based on discrete wavelet analysis. Measurement 2021, 182, 109780. [Google Scholar] [CrossRef]

- Tian, R.; Chen, F.; Dong, S. Compound Fault Diagnosis of Stator Interturn Short Circuit and Air Gap Eccentricity Based on Random Forest and XGBoost. Math. Probl. Eng. 2021, 42, 2149048. [Google Scholar] [CrossRef]

- Xu, Z.; Hu, C.; Yang, F.; Kuo, S.-H.; Goh, C.-K.; Gupta, A.; Nadarajan, S. Data-Driven Inter-Turn Short Circuit Fault Detection in Induction Machines. IEEE Access 2017, 5, 25055–25068. [Google Scholar] [CrossRef]

- Husari, F.; Seshadrinath, J. Incipient Interturn Fault Detection and Severity Evaluation in Electric Drive System Using Hybrid HCNN-SVM Based Model. IEEE Trans. Ind. Inform. 2021, 18, 1823–1832. [Google Scholar] [CrossRef]

- Rajamany, G.; Srinivasan, S.; Rajamany, K.; Natarajan, R.K. Induction Motor Stator Interturn Short Circuit Fault Detection in Accordance with Line Current Sequence Components Using Artificial Neural Network. J. Electr. Comput. Eng. 2019, 1, 4825787. [Google Scholar] [CrossRef]

- Bensaoucha, S.; Ameur, A.; Bessedik, S.A.; Moati, Y. Artificial Neural Networks Technique to Detect and Locate an Interturn Short-Circuit Fault in Induction Motor. In Renewable Energy for Smart and Sustainable Cities; Hatti, M., Ed.; Lecture Notes in Networks and Systems; Springer International Publishing: Cham, Switzerland, 2019; Volume 62, pp. 103–113. ISBN 978-3-030-04788-7. [Google Scholar]

- Skowron, M.; Orlowska-Kowalska, T.; Wolkiewicz, M.; Kowalski, C.T. Convolutional Neural Network-Based Stator Current Data-Driven Incipient Stator Fault Diagnosis of Inverter-Fed Induction Motor. Energies 2020, 13, 1475. [Google Scholar] [CrossRef]

- Urresty, J.-C.; Riba, J.-R.; Romeral, L. Application of the ZSVC component to detect stator winding inter-turn faults in PMSMs. Electr. Power Syst. Res. 2012, 89, 38–44. [Google Scholar] [CrossRef]

- Hang, J.; Zhang, J.; Cheng, M.; Huang, J. Online Interturn Fault Diagnosis of Permanent Magnet Synchronous Machine Using Zero-Sequence Components. IEEE Trans. Power Electron. 2015, 30, 6731–6741. [Google Scholar] [CrossRef]

- Cash, M.; Habetler, T.; Kliman, G. Insulation failure prediction in AC machines using line-neutral voltages. IEEE Trans. Ind. Appl. 1998, 34, 1234–1239. [Google Scholar] [CrossRef]

- Cash, M.A.; Habetler, T.G. Insulation failure prediction in inverter-fed induction machines using line-neutral voltages. In Proceedings of the IAS Annual Meeting, New Orleans, LA, USA, 5–9 October 1997. [Google Scholar] [CrossRef]

- Garcia, P.; Briz, F.; Degner, M.W.; Diez, A.B. Diagnostics of Induction Machines Using the Zero Sequence Voltage. In Proceedings of the IAS Annual Meeting, Seattle, WA, USA, 3–7 October 2004. [Google Scholar] [CrossRef]

- Wang, Z.H.; Huang, X.D. Principle of Phase Measurement and Its Application Based on All-Phase Spectral Analysis. J. Data Acquis Process 2009, 24, 777–782. [Google Scholar] [CrossRef]

- Huang, X.D.; Wang, Z.H. Anti-noise Performance of All-phase FFT Phase Measuring Method. J. Data Acquis Process 2011, 26, 286–291. [Google Scholar] [CrossRef]

- Huang, K.H.; Wang, D.M.; Zhu, Z.Y.; Wei, H.F.; Jiang, W.U. Power System Harmonic Detection Algorithm Based on Co-sin-Window and Interpolated FFT and APFFT. Comput. Technol. Dev. 2011, 21, 223–230. [Google Scholar]

- Huang, X.; Wang, Y.; Jin, X.; Lü, W. No-Windowed ApFFT/FFT Phase Difference Frequency Estimator Based on Frequency-Shift & Compensation. J. Electron. Inf. 2016, 38, 124–131. [Google Scholar] [CrossRef]

- Qi, G.Q.; Jia, X.L. High-Accuray Frequency and Phase Estimation of single-Tone Based on Phase of DFT. Acta Electron. Sin. 2001, 9, 1164–1167. [Google Scholar] [CrossRef]

- Li, X.F.; Li, L.; Kou, K.; Wu, T.F.; Yang, Y. Analysis and Improvement of Time-Shift Phase Difference Spectral Correction Based on All-Phase FFT. J. Tianjin Univ. Sci. Technol. 2016, 49, 1290–1295. [Google Scholar]

- Li, S. Multi-Sensor Fusion by CWT-PARAFAC-IPSO-SVM for Intelligent Mechanical Fault Diagnosis. Sensors 2022, 22, 367. [Google Scholar] [CrossRef]

- Todkar, S.S.; Baltazart, V.; Ihamouten, A.; Dérobert, X.; Guilbert, D. One-class SVM based outlier detection strategy to detect thin interlayer debondings within pavement structures using Ground Penetrating Radar data. J. Appl. Geophys. 2021, 192, 104392. [Google Scholar] [CrossRef]

- Guan, S.; Wang, X.; Hua, L.; Li, L. Quantitative ultrasonic testing for near-surface defects of large ring forgings using feature extraction and GA-SVM. Appl. Acoust. 2020, 173, 107714. [Google Scholar] [CrossRef]

- Zhao, Y.; Wei, G. Using an Improved PSO-SVM Model to Recognize and Classify the Image Signals. Complexity 2021, 21, 8328532. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Power | 5.5 kW | Frequency | 50 Hz |

| Voltage | 380 V | Speed | 1445 rpm |

| Current | 11.7 A | Turns per phase | 162 |

| Poles | 4 | Connection mode | Y |

| Magnetizing inductance | 205.2 mH | Stator resistance | 1.061 Ω |

| Rotor resistance | 0.6269 Ω | Stator leakage inductance | 3.217 mH |

| Rotor leakage inductance | 7.349 mH | Inertia | 0.1367 kg·m2 |

| Turns | 5 | 7 | 12 | 20 | 25 | |

|---|---|---|---|---|---|---|

| Resistance (Ω) | ||||||

| 1 | 0.03049 | 0.04268 | 0.07317 | 0.12195 | 0.15244 | |

| 2 | 0.02156 | 0.03018 | 0.05174 | 0.08623 | 0.10779 | |

| 4 | 0.01524 | 0.02134 | 0.03659 | 0.06098 | 0.07622 | |

| 8 | 0.01078 | 0.01509 | 0.02587 | 0.04312 | 0.05390 | |

| Speed (rpm) | Torque (Nm) | Turns | Resistance (Ω) |

|---|---|---|---|

| 450, 600, 750, 900 | 2, 10, 18, 26 | 5, 7, 12, 20, 25 | 1, 2, 4, 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Liu, X.; Hu, J.; Fei, J.; Zhao, G.; Zhu, Z. Stator ITSC Fault Diagnosis of EMU Asynchronous Traction Motor Based on apFFT Time-Shift Phase Difference Spectrum Correction and SVM. Energies 2023, 16, 5612. https://doi.org/10.3390/en16155612

Ma J, Liu X, Hu J, Fei J, Zhao G, Zhu Z. Stator ITSC Fault Diagnosis of EMU Asynchronous Traction Motor Based on apFFT Time-Shift Phase Difference Spectrum Correction and SVM. Energies. 2023; 16(15):5612. https://doi.org/10.3390/en16155612

Chicago/Turabian StyleMa, Jie, Xiaodong Liu, Jisheng Hu, Jiyou Fei, Geng Zhao, and Zhonghuan Zhu. 2023. "Stator ITSC Fault Diagnosis of EMU Asynchronous Traction Motor Based on apFFT Time-Shift Phase Difference Spectrum Correction and SVM" Energies 16, no. 15: 5612. https://doi.org/10.3390/en16155612

APA StyleMa, J., Liu, X., Hu, J., Fei, J., Zhao, G., & Zhu, Z. (2023). Stator ITSC Fault Diagnosis of EMU Asynchronous Traction Motor Based on apFFT Time-Shift Phase Difference Spectrum Correction and SVM. Energies, 16(15), 5612. https://doi.org/10.3390/en16155612