1. Introduction

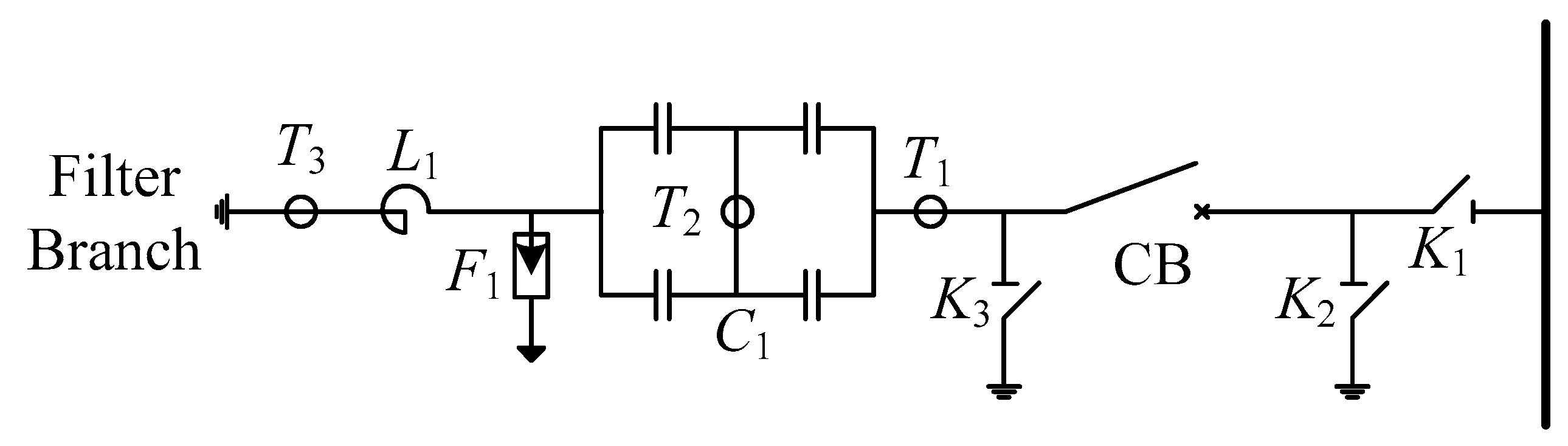

The circuit breaker on the filter branch in the AC bus of the converter station demands frequent operation to regulate the reactive power balance. This frequent operation can potentially lead to performance degradation. As the operation is on capacitive loads, if an abnormal arc occurs during circuit breaker operation, it may result in a discharge explosion, seriously endangering the operational safety of the whole converter station.

In circuit breaker’s frequent operation process, due to arc ablation, high-temperature oxidation, friction contact, and other factors, the contact surface is easy to generate fine particles [

1], leading to the tip discharge effect, which subsequently reduces the insulation margin between circuit breaker contacts. Simultaneously, the frequent operation of the circuit breaker may lead to spring fatigue, and the relaxation of spring stress can slow down the contact operation speed [

2]. As a result, it cannot isolate the fault quickly and effectively. Furthermore, it may also cause significant distortion of the tie rod to make the contact move faster, and the mechanical mechanism may bear overloaded mechanical stress, causing structural damage or deformation and shortening the service life. Thus, it is imperative to carry out research on the early detection of the AC circuit breakers abnormal state.

Previous studies on the online detection of the operating state of AC circuit breakers have mainly focused on detecting contact wear and mechanical deterioration. The crucial element of detecting contact wear lies in effectively extracting characteristic quantities that signify the extent of contact wear, including arc energy [

3,

4], dynamic contact resistance [

5,

6], contact thickness, and mass loss [

7]. Among these, the electrical quantity detection method based on arcing energy, dynamic contact resistance, and other electrical quantities can obtain the contact state without dismantling the arc extinguishing chamber and has the ability of online detection, which has gained more attention in recent years.

The arcing energy method calculates the integral value of the current in the arcing time, quantitatively reflecting the contact wear of the single operation of the circuit breaker. In Reference [

8], the traditional dynamic contact resistance model was established by analyzing the functional relationship between dynamic conductance G, surface pressure P, and contact surface S, and the indirect calculation of dynamic contact resistance was realized. A hardware measurement device for dynamic contact resistance, combined with software simulation analysis to realize the simulation of dynamic contact resistance was introduce in Ref. [

9], which realized the direct measurement of dynamic contact resistance. However, these methods assume that the arc current value in the arcing time is constant, neglecting the attenuation process of the current, which leads to inaccurate calculation results. On the other hand, the dynamic resistance method employs the measurement circuit to detect the average value of the dynamic resistance value and determines the contact wear by analyzing the stability of the resistance value. Nonetheless, the different types of measurement methods, such as the power supply type, significantly affect the resistance measurement results. The smaller the measurement current, the more imprecise the dynamic resistance measurement results are. Based on the above analysis, it is apparent that the existing detection methods based on electrical quantities are limited by unreasonable assumptions, and the measurement methods are prone to interference and can lead to erroneous detection results.

The current research on the online detection of AC circuit breaker operating states mainly focuses on detecting contact wear and mechanical transmission mechanism abnormalities [

10,

11]. Detecting contact wear involves extracting characteristic quantities that characterize the degree of wear, such as arc energy, dynamic contact resistance, contact thickness, and mass loss. The electrical quantity detection method is a popular approach that can obtain contact state information without dismantling the arc extinguishing chamber and can be carried out online [

12]. However, existing electrical quantity detection methods have limitations due to the assumptions made and measurement methods that can lead to interference and inaccurate results.

Detecting mechanical transmission mechanism abnormalities can be achieved through analyzing the vibration signal of the circuit breaker or using the relationship between mechanical performance and the internal switching-closing coil current signal of the circuit breaker. In reference [

13], the Fourier transform is limited by the window, and the predictive estimated value of the characteristic signal in different states is extracted and identified with the reference value to realize the diagnosis. However, in order to further determine the fault type, the literature [

14] carried out EMD decomposition, and the decomposed different modal signals were used as feature quantities for identification and diagnosis. However, both methods have limitations, such as requiring built-in sensors or being prone to large diagnostic errors due to inaccurate eigenvalue extraction.

To address these limitations, this paper proposes an early detection method that quantitatively analyzes the influence of the deterioration process of the circuit breaker on its performance parameters and identifies its abnormal health state by using different breakdown current ratios. This method has the advantages of fast calculation speed, no sample quality constraints, and no deterioration of the detection threshold over time.

2. Characteristic Analysis of Circuit Breaker Operation State

The process of closing an AC circuit breaker involves using a mechanical transmission mechanism to move the moving contact towards the static contact at a constant speed until they make contact. The control loop receives the closing command, causing the closing spring inside the operating mechanism to release energy and act on the transmission rod inside the pillar. This upward movement drives the transmission shaft indirectly via the insulation rod, which in turn drives the moving contact inside the arc extinguishing chamber at the top of the circuit breaker towards the static contact. A successful closing occurs when the dynamic and static contacts are mechanically connected. However, during the general closing process, an electrical connection is formed in advance due to the arc generated by the breakdown between the fractures before the physical contact of the contacts [

15].

Ideally, the surface of the arc contact is smooth, and the critical breakdown field strength

Eset of the surface is fixed [

16]. However, due to the high temperature burning of the arc and friction contact, the critical breakdown field strength

Eset changes, and the abnormal mechanical transmission mechanism means that the contact spacing changes at the same time as the moving contact movement. Therefore, whether it is to characterize the electrical or mechanical life of the circuit breaker, it can be characterized by the critical breakdown field strength

Eset and the degree of contact spacing d change. Considering that the health status of the circuit breaker is a degradation process, when the cumulative wear of the contact and the abnormality of the operating mechanism cause the critical breakdown field strength

Eset and the contact spacing

d to change to a certain extent, an alarm or shutdown should be issued. Therefore, the mathematical description of the operating state of the circuit breaker is given as follows:

where

E0 and

d0 are the critical breakdown field strength and the corresponding contact spacing value in the ideal state, respectively. The breakdown field strength at the first breakdown is

E0, and the corresponding contact spacing is

d0.

Eth and

dth are the alarm thresholds when the contact wears and the mechanical mechanism deteriorates to a certain extent.

It can be seen from (1) that the key to the detection of circuit breaker health abnormalities is to accurately obtain the real-time changes of

Eset and

d values. However, due to the obvious uncertainty of the field enhancement factor

β generated by the tip effect of fine particles on the electrode surface, the change of

Eset is random [

17], so the change of

Eset is difficult to measure directly. To find a new characteristic quantity instead of

Eset to characterize the wear degree of circuit breaker contacts, the following analyzes the closing and arc development processes of the circuit breaker.

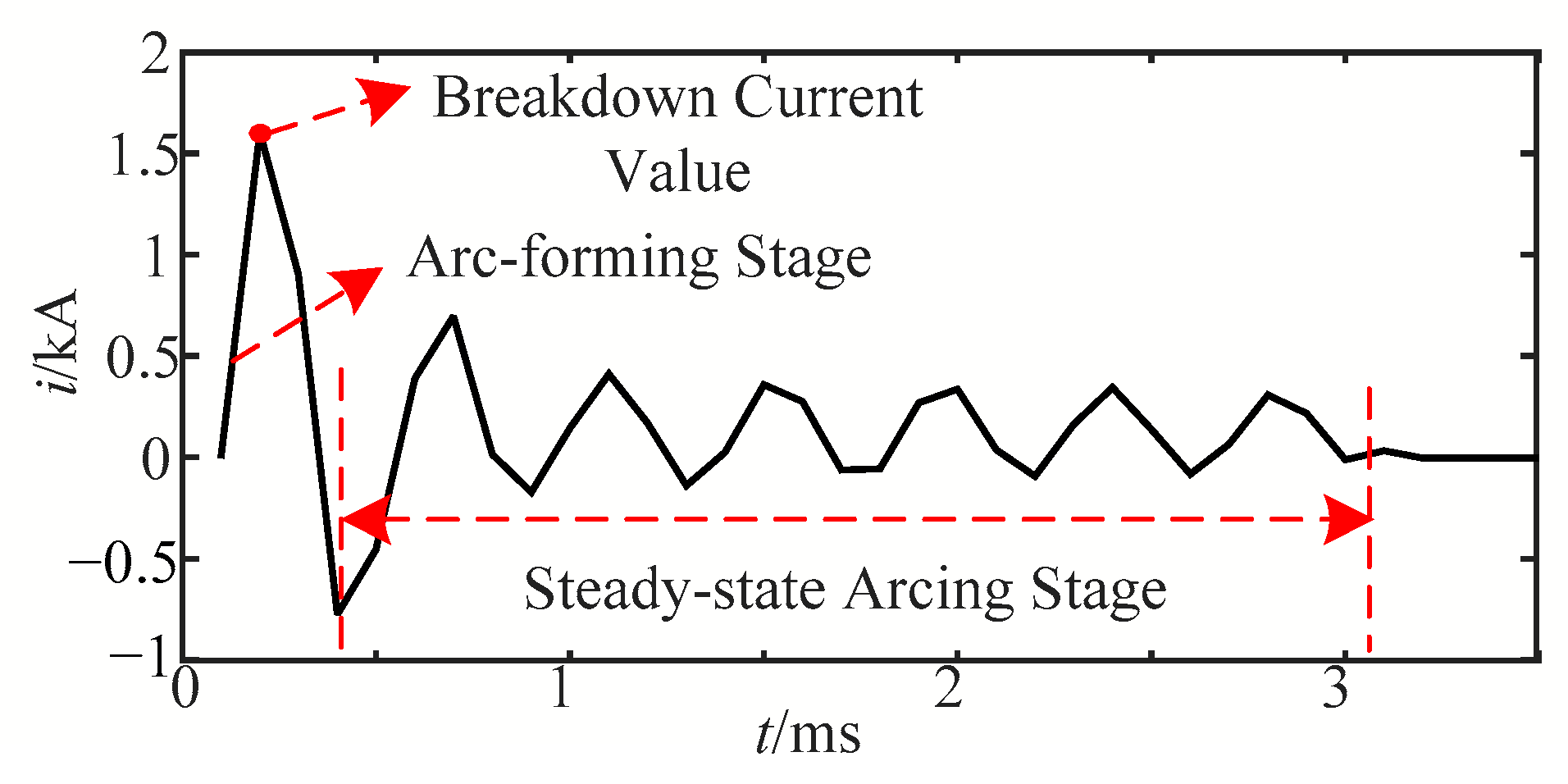

During the closing process, the spacing between the fractures of the circuit breaker gradually reduces. As the closing time is usually greater than 5 ms, the field strength between the fractures undergoes significant dynamic changes during the closing process.

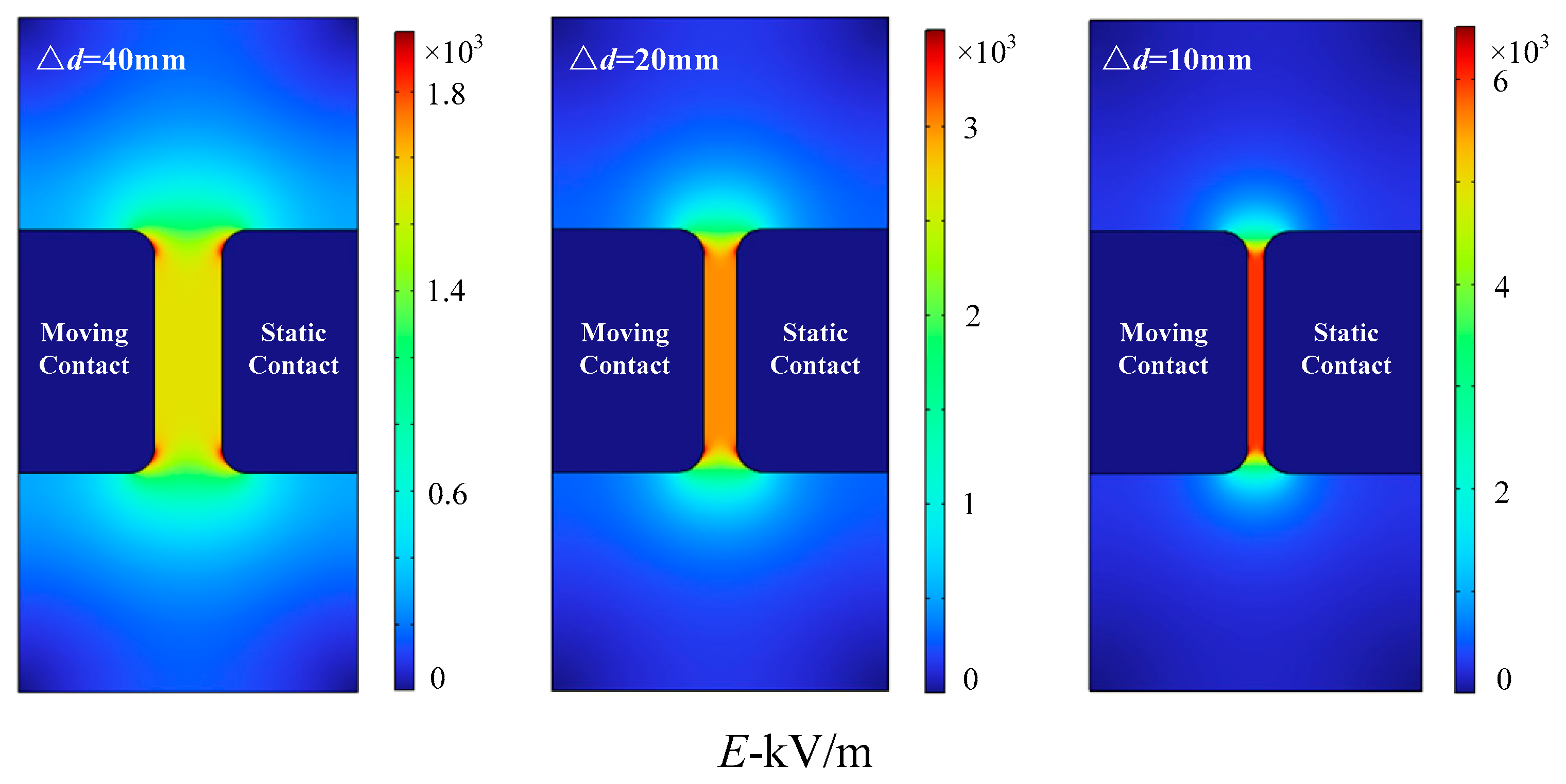

Figure 1 displays the simulation results of the multi-physical field software (based on COMSOL Multiphysics simulation software V5.6, Stockholm, Sweden, COMSOL Co.) of the voltage level of the 220 kV power supply side at the contact bus of the moving contact end and the no-load grounding of the static contact end, the mechanical closing operation of the circuit breaker, and the gradual reduction of the arc chamber fracture spacing with the moving speed of 10 mm/ms [

18], where the electrode is made of copper material.

As shown in

Figure 1, the color between the fractures gradually darkens, indicating a gradual increase in field strength. This signifies that the electric field force experienced by the particles on the contact surface gradually strengthens. Under the action of an applied electric field, the contact surface is ionized, and the relationship between them is:

where

q is the amount of electron charge,

E is the field strength between the fractures,

x is the electric moving distance, and

Wi is the work function of the metal.

When the electron moving distance

x on the metal surface is constant, there is a minimum breakdown field strength, and the electron escapes after satisfying (2) [

19]. After the electron escapes, it is subjected to the electric field force to collide and ionize between the fractures, eventually leading to gas breakdown. The mathematical description of the breakdown condition is:

where

u is the instantaneous value of the voltage difference between the breaks; that is, the instantaneous value of the breakdown field strength is greater than or equal to

Eset when the contact is broken, so the instantaneous value of the breakdown field strength

E can be considered to replace

Eset. However, it can be seen from (3) that the instantaneous breakdown field strength

E depends on the voltage difference

u between the breaks and the contact spacing

d. The bus-side voltage of the circuit breaker can be measured, but the change of the voltage on the opposite side depends on the residual charge of the connected capacitor bank after discharge, which cannot be measured in real time [

20]. Therefore, it is difficult to accurately obtain the voltage value of the circuit breaker fracture in practice. In addition, considering factors such as cost and reliability, the circuit breaker is generally not equipped with contact displacement sensors, so the real-time change in contact spacing is not easy to know.

4. Method for Early Detection of Circuit Breaker Abnormal State

The deterioration of circuit breakers does not typically occur abruptly or by chance. Instead, it is a gradual process characterized by irreversible changes such as the gradual burning of contacts, spring fatigue, and stress relaxation. In this process, changes in the breakdown field strength or contact spacing follow a certain trend, and the breakdown current sequence displays a monotonic trend, the steepness of which correlates to the extent of degradation. Thus, the shape of the breakdown current sequence can be analyzed to detect the stability of the sequence, which, in turn, can be used to determine whether the circuit breaker has degraded.

4.1. Detection Principle and the Criterion

The breakdown current value sequence is considered an autoregressive model, so this paper uses ADF (Augmented Dickey-Fuller) to check whether the breakdown current sequence is stable in detection step 3 of

Section 4.2. The ADF test is also called the unit root test. Its basic idea is that when there is no unit root in the test sequence, the sequence is stable. Let the breakdown of the current sequence be

Xt =

Xt−1 + Δ

Xt, where

Xt is a random walk process of unknown trend and Δ

Xt is an incremental process of random walk

Xt−1. The ADF test model is:

where

α is the intercept term,

βt is the time trend term,

εt is the white noise with the mean-variance of

σ2,

γ is the parameter to be solved, and

l is the lag order of

Xt.

Under the null hypothesis

H0:

γ = 0, there is at least one unit root; suppose

H1:

γ < 0, there is no unit root. The test process can be completed by

t-testing based on the critical value table [

23].

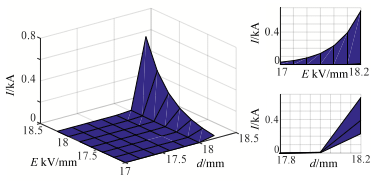

When the test results have a unit root, the sequence is determined to be a non-stationary deteriorating sequence; to further determine whether the mechanical parameter change and contact wear of the circuit breaker have reached the serious defect degree, the analysis is as follows:

Firstly, the relationship between contact spacing, breakdown field strength, and breakdown current can be obtained by the logarithmic transformation of (7):

Subtract the relationship between contact spacing in (9)

Among them, I1 and I2 represent the breakdown of current values when the contact spacing changes and in the ideal state, respectively.

Reference [

24] provides the standard values for the breakdown field strength, approximately 9 kV/mm and 18 kV/mm, respectively, when the gas pressure is 0.1 MPa and 0.2 MPa at 300 K. Currently, the gas theory lacks a unified numerical characterization of the actual breakdown field strength. This paper considers the effects of gas pressure and temperature deviations across various regions. To facilitate numerical calculations, the value of

E in (10) is taken as 12 kV/mm.

Table 1 shows the breakdown of current ratios corresponding to different Δ

d values calculated.

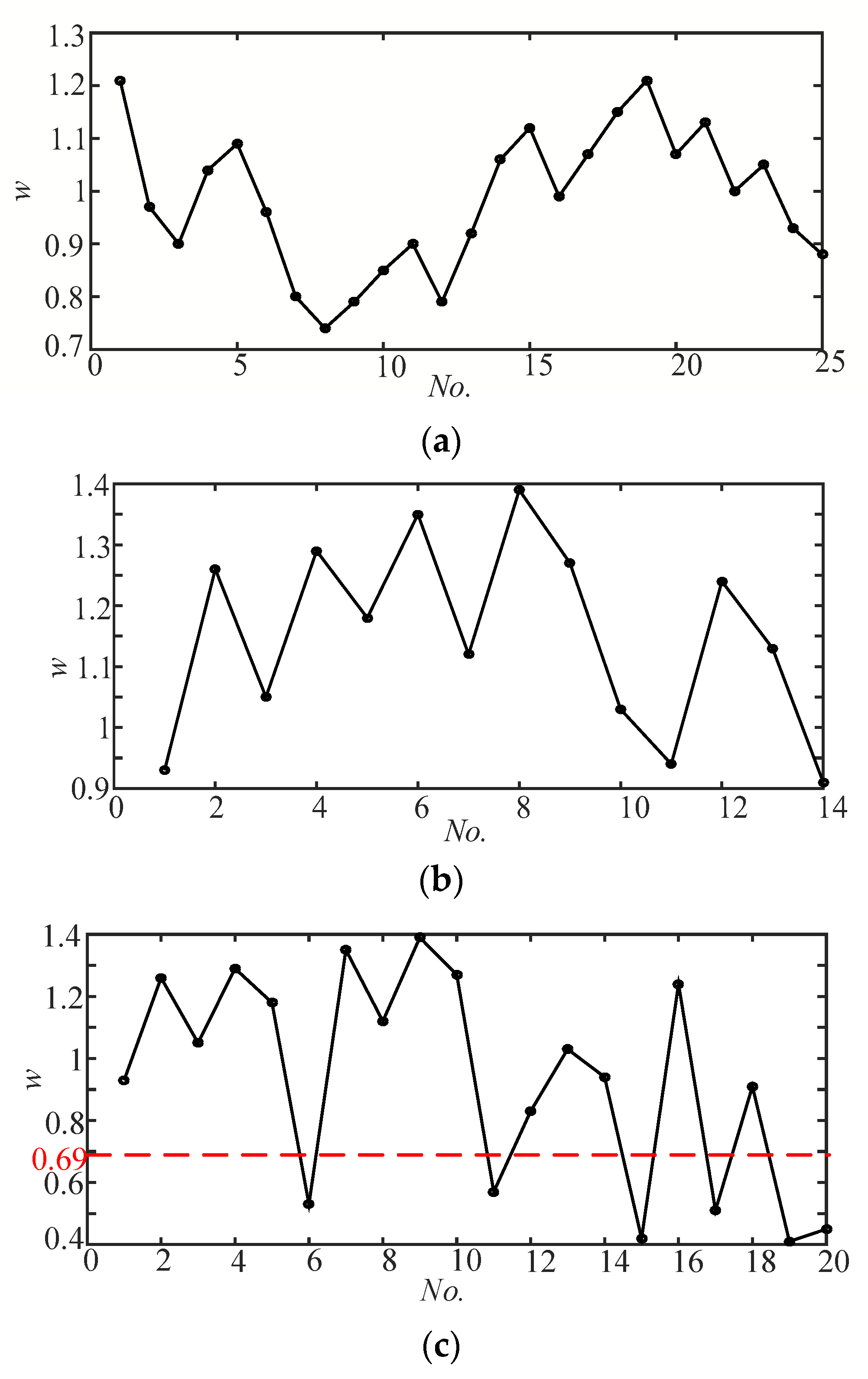

It can be seen from

Table 1 that when Δ

d > 10 mm, the change of the two breakdown current values is about 45%, while when Δ

d > 5 mm, the change of the two breakdown current values is only 18%. Considering the reliability and sensitivity of the detection, the threshold value Δ

d = 10 mm can be taken as the threshold value, corresponding to the ratio of the two breakdown currents equal to 0.69.

In view of the fact that the change in contact wear can be reflected by the change in critical breakdown field strength, the expression of breakdown field strength in (9) is organized as follows:

When the contact spacing is 7.5~16 mm, the influence of contact structure change on its field strength is the most obvious [

25]. In order to ensure that the two closing spacings Δ

d retain a certain margin,

d takes 10 mm,

E1 takes the breakdown field strength when the contact breakdown occurs after contact wear, and

E2 takes the breakdown field strength when the contact breakdowns occur between good contacts in an ideal state.

After calculation, it is found that the change of E1 in (11) exceeds 5 kV/mm on the basis of the normal value E2, and the value of d/λe(Ui/λΕ1) is small and can be negligible. Then, I1/I2 < 0.69 in (11) is obtained. Therefore, when the breakdown current ratio is less than 0.69 or greater than 1.45, it means that the contact spacing change exceeds 10 mm or the breakdown field strength deviation exceeds 5 kV/mm. At this time, it can be judged that the circuit breaker has a serious defect and should be immediately alarmed for maintenance.

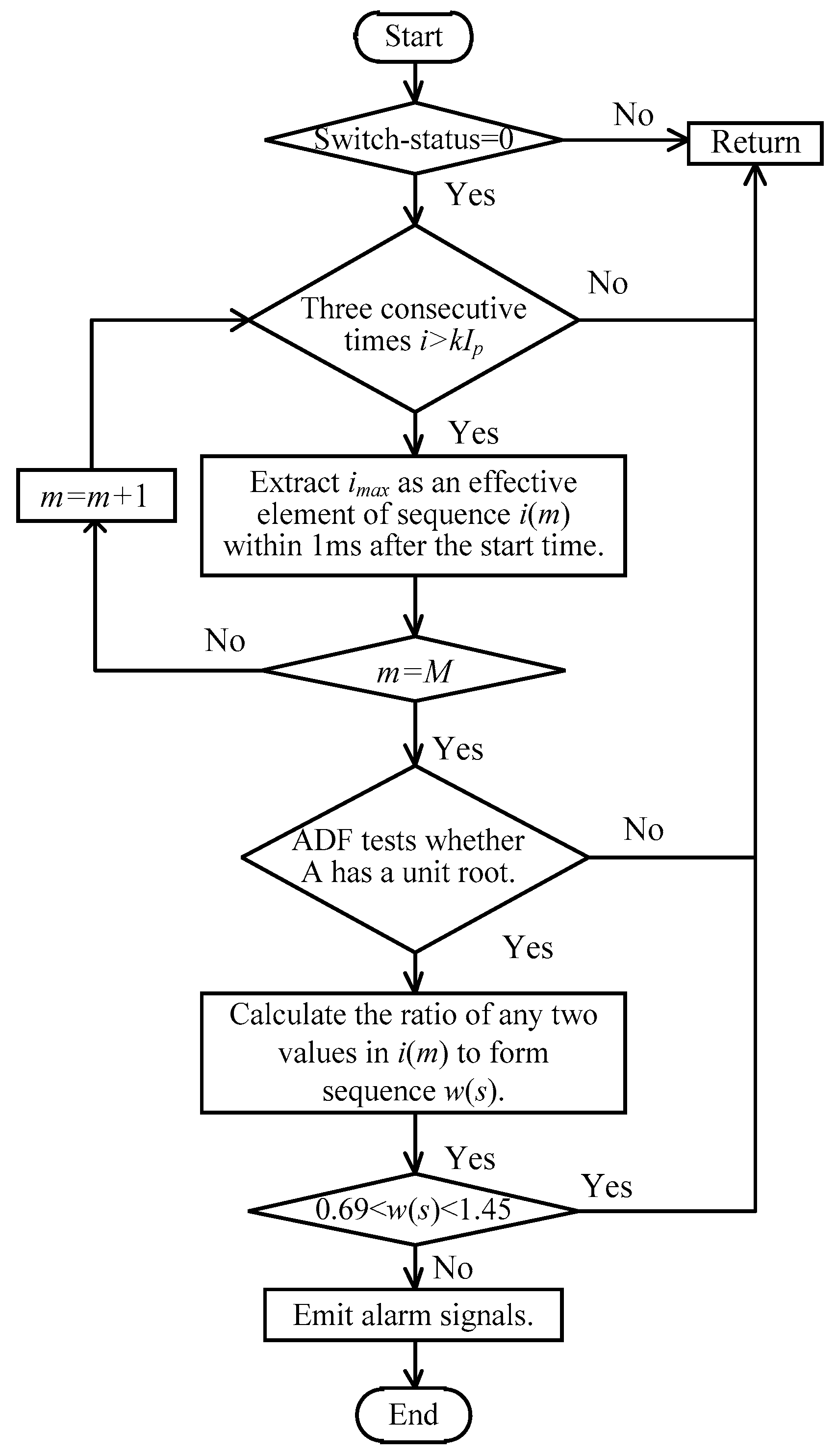

4.2. Detection Process

In this paper, the detection method uses the current transformer to obtain the load-side current of the filter branch. The switching state of the circuit breaker before fully closing is considered the binary value 0, and the switching state after fully closing is considered the binary value 1. The early detection process of the single-phase abnormal state of the AC circuit breaker based on closing electrical quantity monitoring is given as shown in

Figure 3:

Step 1: Set the rated load current amplitude of the closing branch of the circuit breaker as Ip, collect, and monitor the instantaneous current value i when the switching state of the circuit breaker is 0 in real-time. When the continuous three i sampling values are greater than kIp, it is determined that the arc current occurs during the closing process of the circuit breaker, and we go to Step 2. Otherwise, continue to monitor the instantaneous value of the current in real-time; the value of k is less than 1, and in order to ensure sensitivity, the value of k = 1/3 is recommended.

Step 2: The sampling time when the first sampling value is greater than kIp is taken as the reference value, and the pre-breakdown peak can be reached in the subsequent fixed time window (generally 0.1 ms after arcing; the whole arcing process is generally 3–4 ms, so it is recommended that the time window be 1 ms). The current peak imax is recorded as the breakdown current value during the closing process of the circuit breaker, and the breakdown current value imax is used as an element of the continuous monitoring breakdown current sequence i(m), recorded as i(m = 1); then, the breakdown current value waiting for the next circuit breaker closing process is monitored in real-time, recorded as i(m = 2), until a complete breakdown current sequence i(m = M) is formed. In order to minimize the allowable error of the sample, it is recommended to generally take M > 10 and go to Step 3.

Step 3: ADF test model is established based on (8), and the ADF test is used to judge whether the sequence i(m) is stable. If the original sequence test results accept the null hypothesis, indicating that there is a unit root, that is, the original sequence is a non-stationary sequence, go to Step 4.

Step 4: Calculate the ratio of any two values in the

i(

m) sequence to form a new sequence

w(

s), and determine whether all values in the

w(

s) sequence satisfy:

If any value in the w(s) sequence does not satisfy (12), it indicates that the circuit breaker needs to be alarmed with a serious warning signal immediately.

Figure 3.

Flow chart of circuit breaker single-phase abnormal state early detection.

Figure 3.

Flow chart of circuit breaker single-phase abnormal state early detection.

6. Conclusions

The early detection of abnormal states in circuit breakers is of great significance for ensuring the safety of substations and power supplies. The degradation of circuit breaker performance is generally not accidental or sudden, and there is a clear gradual process, such as irreversible changes such as gradual contact burning, spring fatigue, stress relaxation, etc. During this process, the breakdown field strength or contact spacing changes in a trend, and the breakdown current value sequence shows a monotonic trend, so the monotonic change steepness of the breakdown current is related to the degree of degradation. The paper first analyzed the impact of the changes in critical breakdown field strength and contact spacing on the operating status of the circuit breaker, quantitatively analyzed the characteristic quantities that can characterize the operating status of the high-voltage AC circuit breaker and the arc extinguishing capacity of the arc extinguishing chamber: breakdown current value and arc current trend term, and designed a technical scheme that uses breakdown current value to replace the critical breakdown field strength and contact spacing to comprehensively characterize the operating status of the circuit breaker. A method for early detection of abnormal states in circuit breakers based on sequences of different breakdown current ratio sequences was proposed, and its effectiveness was verified using simulation and on-site actual recorded data. The next step will be to develop an online detection device and carry out practical applications. At the same time, considering the changes in electrical quantities during the opening process of the circuit breaker, further improvements to the monitoring technology for the operating status of the circuit breaker will be researched.