1. Introduction

Due to the continuous depletion of traditional energy sources, the pollution produced by fossil fuels, and excessive CO

2 emissions, the proportion of renewable resources such as wind and solar energy used has been rising rapidly in recent years and so has the scale of power generation [

1]. However, due to seasonal fluctuation and unpredictability, it is difficult to artificially ensure providing high power at all times, which is one of the important reasons for the difficulty in replacing traditional energy [

2]. In recent years, with the continuous reduction of battery costs, the emergence of battery energy storage systems (BESS) has largely alleviated the problems caused by the defects of renewable resources. To balance the supply and demand sides, BESS can absorb excess electric energy or make up for the lack during peak power consumption periods. Therefore, with the advent of the smart grid era, the BESS has been increasingly integrated into all aspects of the modern power grid system operation. Due to attractive high energy and power density properties, Lithium-ion batteries are currently the most suitable energy storage system for powering portable electronic equipment and smart grid systems [

3]. Despite the advantages of BESS, managing BESS remains a challenging problem [

4].

In the management of BESS, the most basic problem is SOC balancing. Even if the manufacturer and batch of batteries are the same, due to uncontrollable small errors in manufacturing, the initial SOC of battery cells will be different. This will lead to over-charging and over-discharging, which is very dangerous. Therefore, the management of BESS has become an important research issue. Based on the multi-agent system (MAS), the SOC balancing scheme was adopted [

5,

6,

7,

8,

9,

10,

11,

12,

13]. MAS is a typical distributed control system. Compared with the centralized control system, MAS provides the advantages of less dependence on nodes, low communication cost, and low individual computing burden, which is widely used in the management of distributed battery energy storage systems [

14,

15,

16,

17,

18,

19]. In the MAS, each battery unit is regarded as an independent individual, which can only communicate with its neighbors in the graph relationship, and sends information to its neighbors. Then, each individual will adjust its power in the next cycle period, and the overall BESS will achieve SOC equalization asymptotically. In [

12], the combination of droop control and proportional-integral controller (PI) was used to change its power and adjust individual decision-making in the next step. Simultaneously, to ensure the frequency of droop control can be quickly restored under the premise of the consistency of battery SOC, a combination of frequency control and SOC control scheme was presented in [

9,

10]. From the perspective of communication delay and nonlinear properties of batteries, the mixture of multiple batteries and the transient nature of loads and energy sources on both sides of the grid were considered in [

6,

11]. Fuzzy control was adopted to achieve SOC balance and prolong battery life based on satisfying grid supply and demand balance in [

5,

7]. For large power grids, in [

13], an adaptive multi-agent power distribution method was used according to the maximum capacity of the agent.

However, in practical applications, the internal electrochemical condition of batteries and the external environment, such as ambient temperature, charge–discharge depth, etc., should be considered. These elements will cause the battery state-of-health (SOH) to decay at different aging speeds (SOH is an important indicator of battery health, which stands for aging degrees here). The distinction of SOH among battery units will significantly reduce the overall life of BESS, but the active SOC cannot quickly balance such large charge and discharge currents. Consequently, it is hard for BESS to achieve the purpose of managing batteries by just relying on SOC consistency control. Moreover, these two balancing control (SOC balance and SOH balance) have an opposite relationship in power adjustment. When a battery unit needs to increase power due to low SOC, it will further accelerate the aging of the battery cell. To slow the aging, SOH balance control needs to reduce power instead. To alleviate this problem, reference [

19] considered the priority of SOC and SOH equalization by ranking the severity of the disproportion degree of SOC and aging rate, which would be a given, which could achieve the dual goals of mixed equalization control.

The aging properties of various lithium-ion batteries also have discrepancies, which should be noticed when considering specific SOC and SOH balancing control. Up to now, LiFePO

4 batteries are regarded as the most promising lithium batteries in the power grid due to their high rate discharge capability, good thermal stability, and easy access to raw materials [

20]. Although the aging of the battery was considered in [

21,

22], the aging model of the lithium manganate battery was referred to instead of the LiFePO

4 battery. Furthermore, LiFePO

4 batteries can be subdivided into 18650 LiFePO

4 batteries and 26650 LiFePO

4 batteries. 26650 batteries have longer battery life and larger rated capacity and volume than 18650 batteries, often used in energy storage stations, etc. [

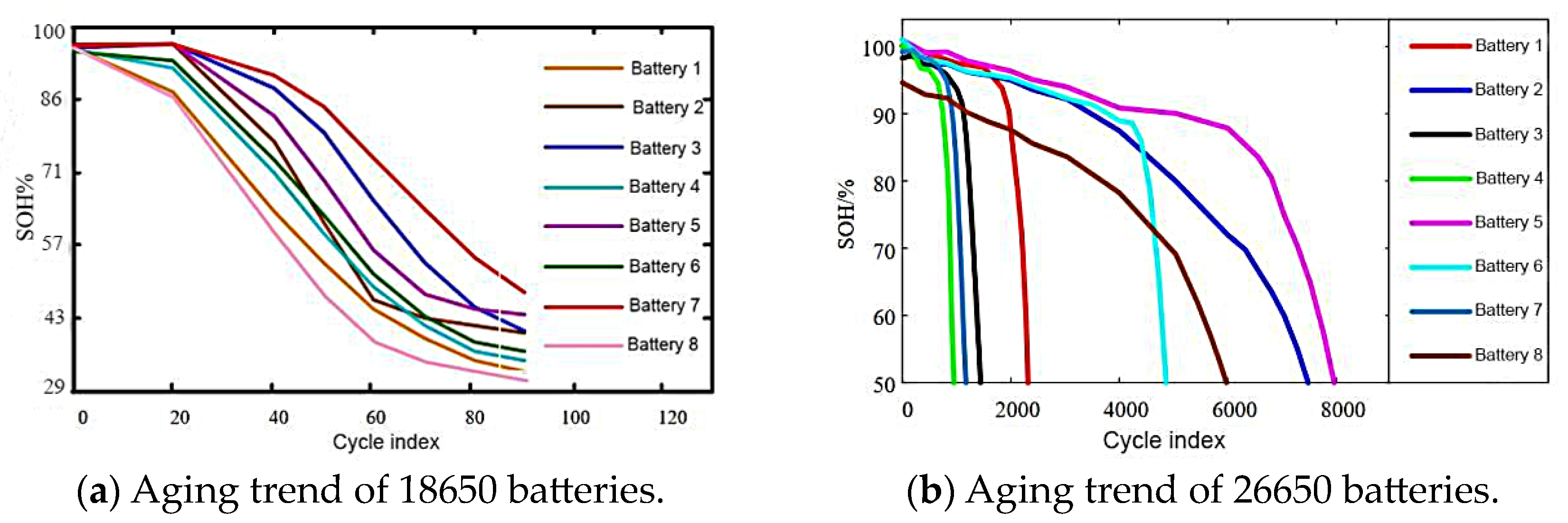

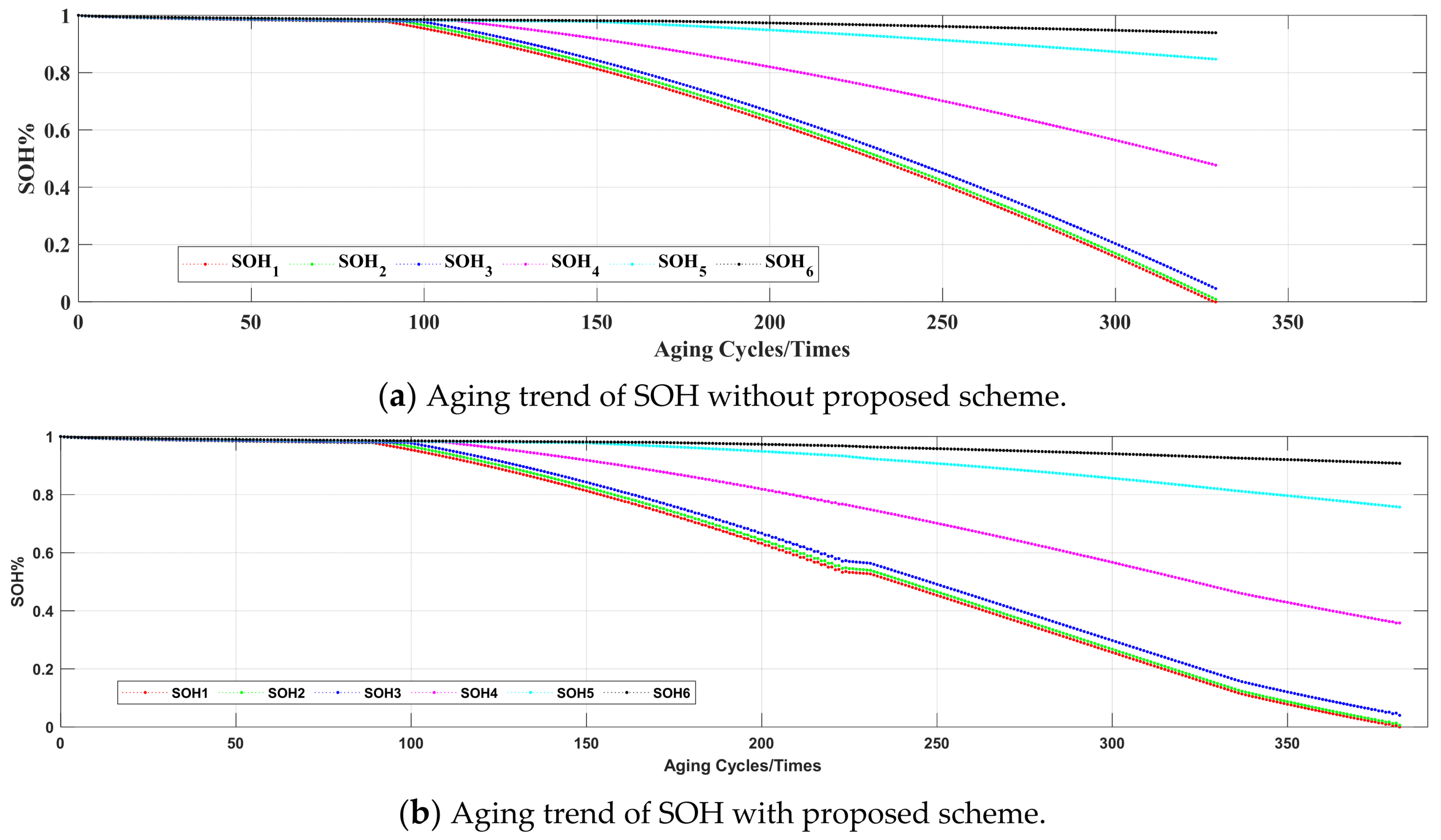

23]. Therefore, aiming at the smart grid system battery storage system, improving the 26650 battery system life is emphasized in this paper. As shown in

Figure 1, the aging trend is quite different. The aging trend of 18650 batteries is relatively concentrated, while the 26650 batteries are extremely scattered, which is one of the reasons for accelerating the aging of the 26650 battery system [

24,

25].

However, it can be found from (b) of

Figure 1 that although 26650 LiFePO

4 batteries show a large aging trend, they also exhibit obvious grouping characteristics. Therefore, to make full use of this characteristic, flexible communication and cooperation between battery units are crucial. The traditional communication and cooperation relationship in a distributed control system was fixed, but the MABS with a suitable structure can solve distributed problems by building a global knowledge base. Thus agents can cooperate and communicate flexibly [

26], which is beneficial to realize the equalization control of 26650 battery units.

In summary, increasing the 26650 battery system life is essential. However, the existing research on SOC and SOH dual balancing control mainly focus on batteries with concentrated aging trends such as 18650, few studies focus on batteries with extremely scattered aging trends such as 26650. Since the aging trend of 26650 batteries shows the characteristics of grouping, a dual-layer equalization control of SOC and SOH based on MABS for the 26650 battery is presented by using such characteristics in this paper.

The rest of this paper is organized as follows: in

Section 2, the mathematical model of the 26650 battery aging process is established; in

Section 3, the battery balancing control strategy is elaborated from the blackboard system design, intra-group SOC balancing control, and inter-group SOH balancing control; in

Section 4, the balancing control scheme proposed is validated using MATLAB simulation; and

Section 5 concludes the paper.

2. 26650 Battery Aging Process Mathematical Model

Based on Tongwei’s accelerated aging experiment results of 26650 batteries [

25], a mathematical model of the aging process of 26650 battery cells can be established by introducing the semi-empirical formula of LiFePO

4 battery aging by John Wang et al. [

27].

However, it is tough to predict the battery’s available capacity during the battery cycle. To estimate the battery’s available capacity, John Wang et al. [

27] conducted a large number of charge–discharge experiments on LiFePO

4 batteries and obtained a semi-empirical formula of the capacity degradation percentage on ambient temperature, discharge capacity, and discharge rate as:

where

is the pre-exponent factor;

is the percentage of capacity loss;

is the battery discharge rate;

is the gas constant, which can take

;

the absolute temperature, which is equal to

;

is the total discharge capacity during operation, and the calculation of

is demonstrated as:

Zheng Yuejiu’s team [

27] simplified the parameters

in formula (1) through in-depth research and obtained Formula (3):

By introducing the model of capacity loss percentage, each battery’s actual capacity at the next moment under discrete time can be expressed as:

where

represents the real capacity of a battery unit viewed as agent

in MABS at the moment of

;

is the capacity life loss percentage of the agent

at the moment of

;

is a constant parameter for distinguishing different aging processes of battery units; and

represents the initial capacity of the agent. As shown in

Figure 1, the aging trend of LiFePO

4 batteries can be divided into two stages with a less obvious “inflection point” [

25]:

The first stage is the slow aging stage. The battery inside is stable at this stage; thus the decay speed is low, which makes the aging process present strong consistency.

The second stage is the rapid aging stage. At this stage, the battery’s internal structure is destroyed, which causes the available capacity to fade rapidly, and the decay rate is increased. Therefore, the aging trend becomes highly dispersed and irreversible.

A less obvious “inflection point” between the above stages also exists. For most batteries, the aging rate after the point is significantly different from before. But for others, the point is less obvious, and the overall aging rate is relatively low.

The result of the accelerated aging cycle of LiFePO

4 batteries obtained by Tongwei is shown in

Figure 1b, in which agent 8 deviates greatly from others at the initial state, and agent 6 is a special individual. Therefore, this paper mainly focuses on normal batteries except agents 8 and 6. Moreover, in order to depict the overall aging trend of 26650 batteries and reflect the differences in aging trends among batteries, we could set the “inflection point” of each agent as

, and the overall aging rate of the agent

can be expressed as:

where

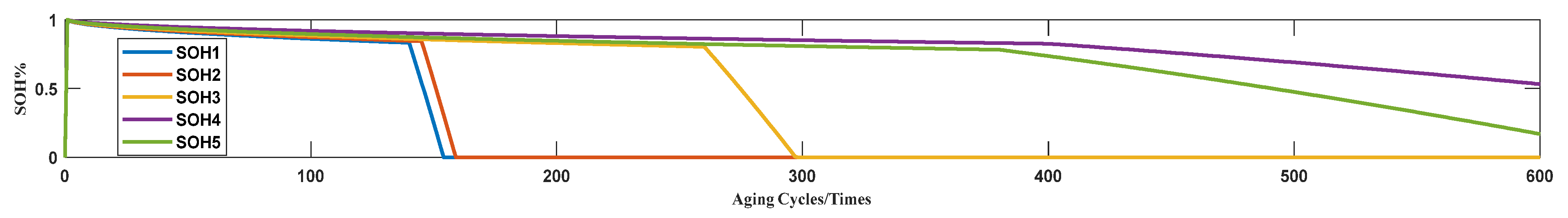

is the aging growth rate of the agent after the “reflection point”, and the result of the model established is shown in

Figure 2:

What needs illustrating is that the aging trend of the 26650 battery is nonlinear in practice, but because of the huge SOH difference among batteries, which is much larger than the sum of the error depicting the aging trend with the linear model and the error of inaccuracy of SOH estimation, these errors will not affect the result of the algorithm proposed in this paper.

3. Balancing Control Scheme

Denote a graph

composed of

nodes and their edges, where let

denote the set of nodes above, and let

denote the set of edges in which an order pair

means there is an edge form

to

.

is the weighted adjacent matrix with non-negative elements. If

,

, otherwise

(We assume that there is no self-loop). Define the total number of edges pointing to

as in-degree, and the total number of edges starting from

as out-degree. Especially, for undirected topology,

, which means the in-degree is equal to the out-degree. The degree of an undirected graph can be expressed as

, and the degree matrix can be expressed as

. The Laplacian Matrix

is defined as:

which can be calculated by adjacent matrix

and degree matrix

:

In this paper, it is assumed the undirected graph is connected.

3.1. SOC Equalization Control Considering Aging

The BESS’s initial SOC of each battery unit is usually different after manufacturing. And during long-term use, battery units will exhibit varying degrees of aging because of the slight discrepancy in manufacturing and different external factors. Therefore, this section introduces the LiFePO

4 battery aging model [

27] and sets different parameters to simulate the aging difference between batteries. Finally, the SOC of all battery units will converge to the same value asymptotically.

The SOC of BESS can be calculated by [

28]:

where

denotes the initial SOC of each battery unit; if the battery is on dis-charging,

, otherwise,

;

satisfies the following equations:

where

and

denote the converter conversion efficiencies during discharging and charging operation;

is the output power;

denotes the output voltage, which is assumed as 220 V in this paper. Then, Formula (8) was discretized and simplified by Ting Yang [

29]:

where

denotes the sampling interval, and since the battery parameter

,

, for

,

and

, where

is a constant. Let

,

, and Formula (10) can be expressed as:

During the operation of batteries, the individual battery unit in the group will automatically allocate the output power based on the inter-group power after grouping by tracking the SOC difference from the adjacent individual, and the SOC consistency within the group will finally be achieved. The output power of the agent

in the group can be calculated by:

where

denotes the inter-group power, which will be specified in

Section 3.4.

3.2. Design of MABS

3.2.1. Design of Blackboard Area

The blackboard system generally consists of three parts: blackboard, knowledge source, and controller [

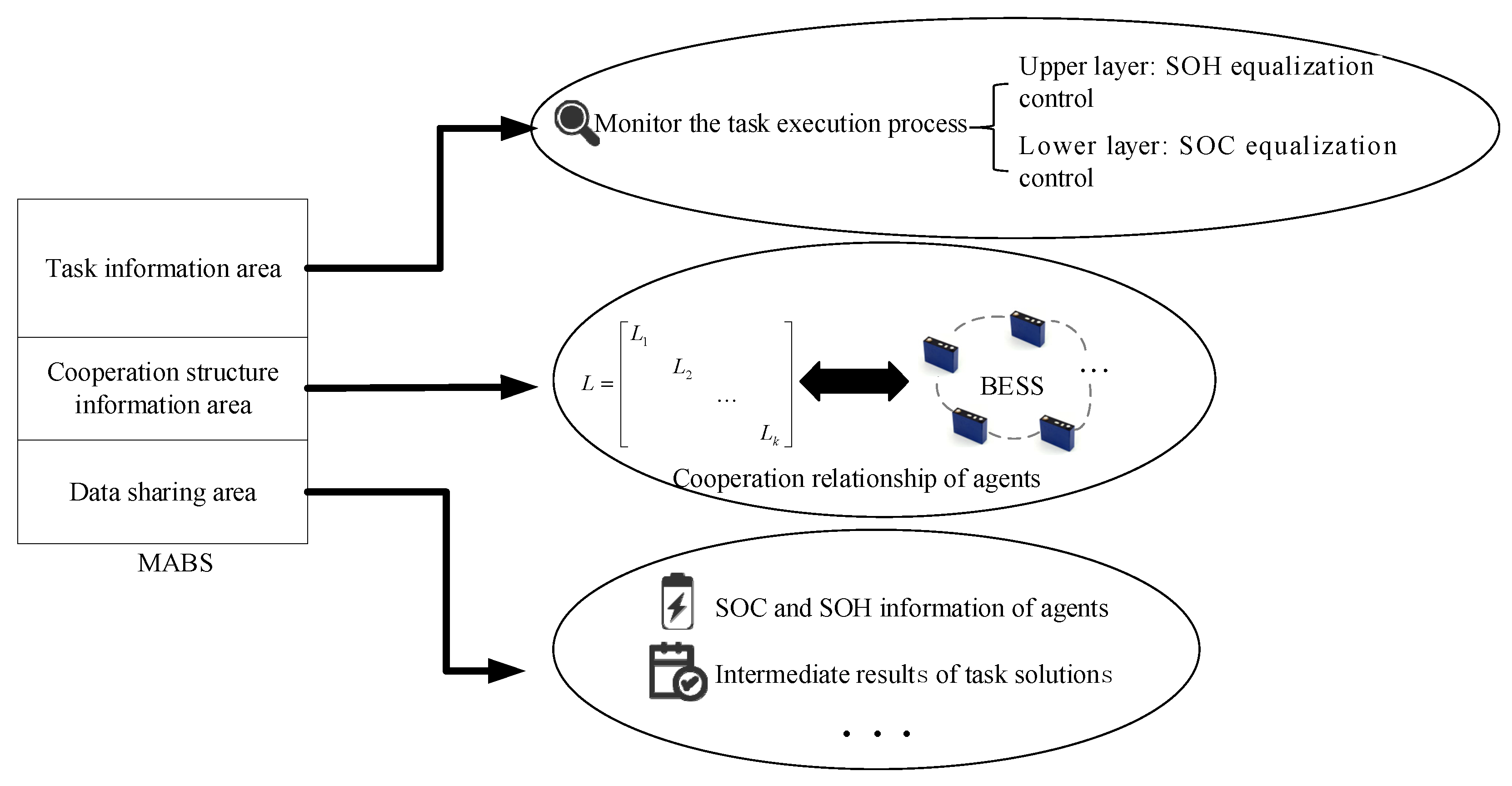

30]. As shown in

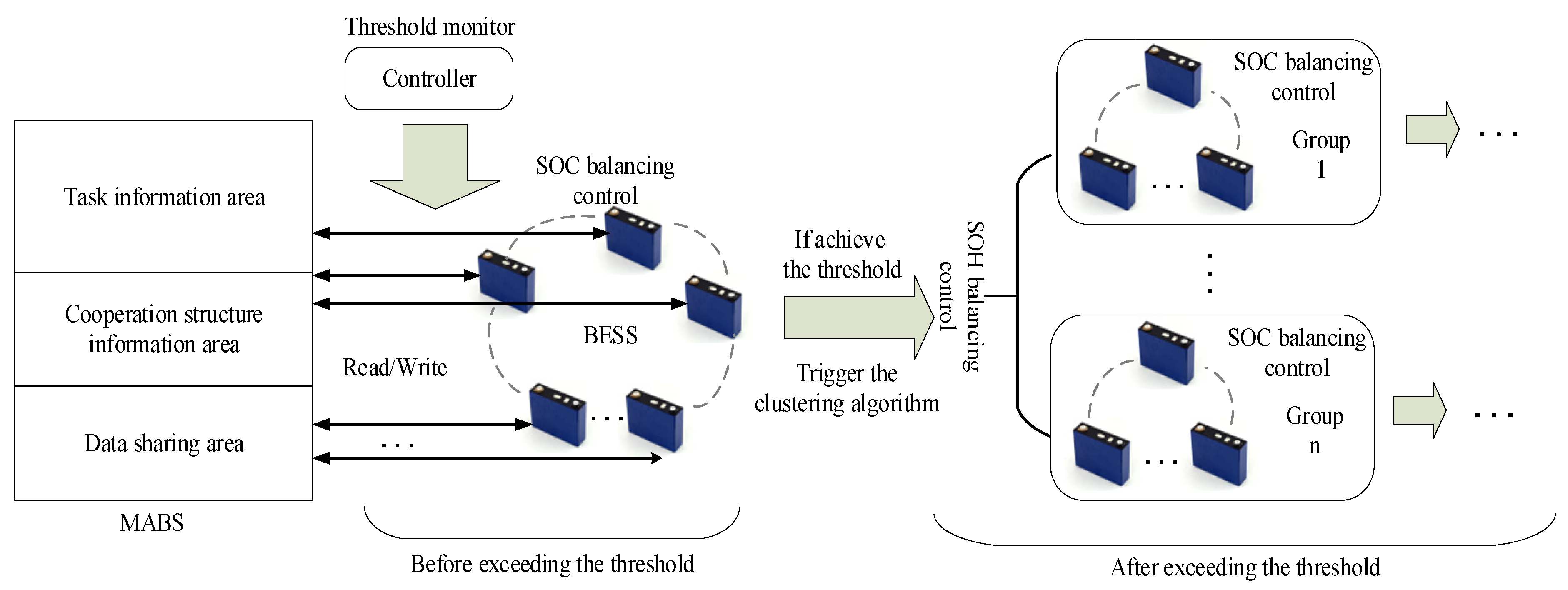

Figure 3, in this paper, the blackboard area is roughly divided into three parts: task information area, data sharing area, and cooperation structure information area.

The task information area is a tree-like structure containing information after task decomposition, which is utilized to monitor the task execution process. According to the level of task, the task information area can be divided into two layers: (1) The upper layer is the inter-group SOH equalization control after grouping under SOH dispersion between batteries; (2) The lower layer is the intra-group SOC equalization control (before the first occurrence of clustering, all units are considered as one group).

The data sharing area mainly stores the data shared by knowledge sources and the intermediate results of task solutions, such as SOC and SOH information, where a battery unit is viewed as a knowledge source here.

The cooperation structure area mainly stores information on cooperation structure among agents. The cooperation structure in BESS is usually a ring topology [

9,

19], which can be depicted clearly through Laplace matrix L. And the method of rewriting the L matrix according to the grouping result will be elaborated on later in

Section 3.3.2. The controller supervises the SOH difference between battery units and triggers the clustering control when exceeding a certain threshold.

3.2.2. The Threshold Selection of the MABS Controller

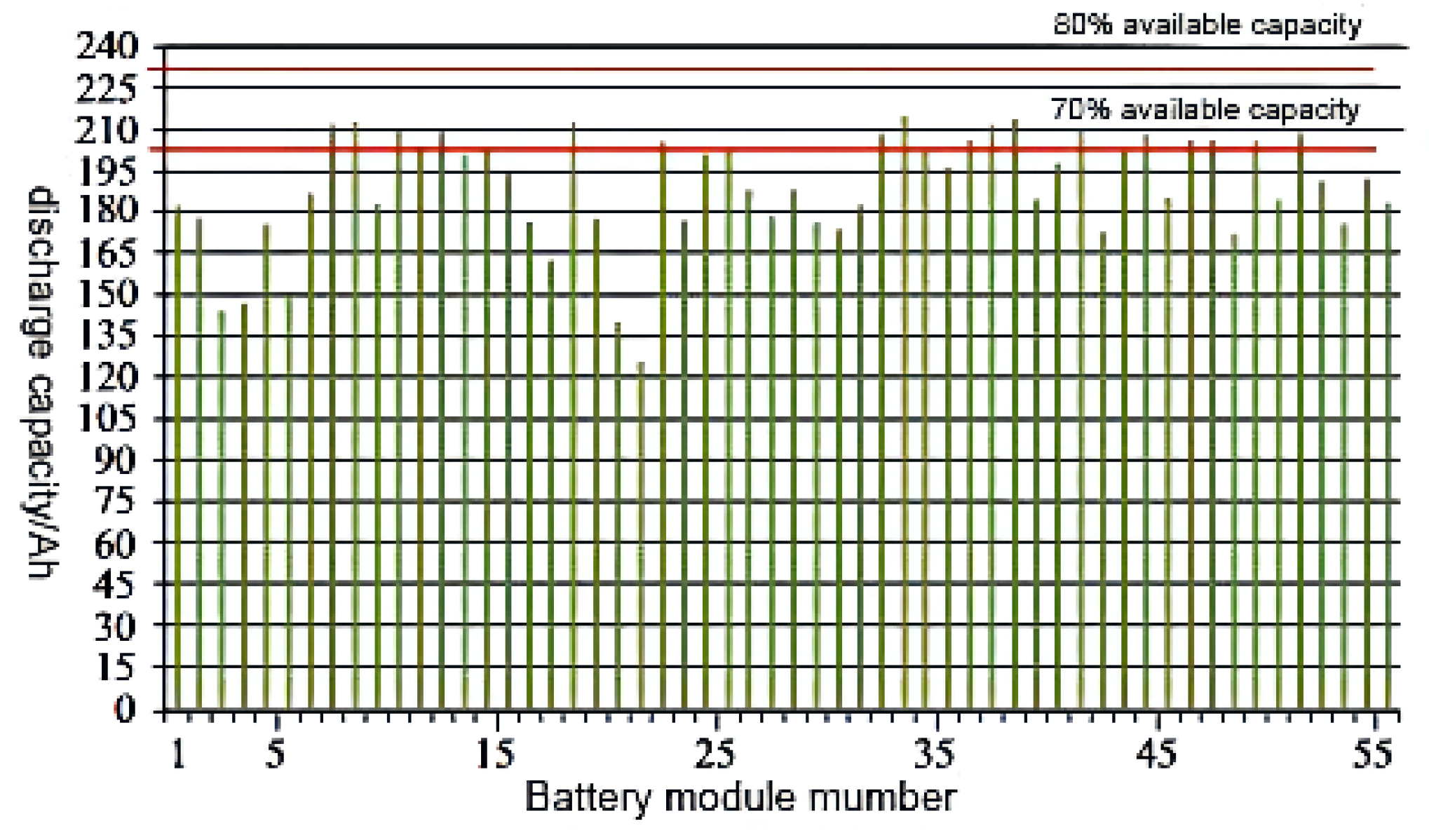

A proper threshold is critical to whether the blackboard system controller can work. When SOH dispersion between batteries exceeds the threshold, the system will trigger clustering and allocate more DOD to the battery unit with less aging trend. Although there is no clear definition for the severity of SOH dispersion in previous studies, we can set the dispersion of retired LiFePO

4 batteries as the lowest limit so that the threshold value can be selected. Zhao Guang-Jian et al. [

31] conducted a study on the capacity distribution of retired LiFePO

4 batteries, as shown in

Figure 4. From the figure, we can find that the difference between the worst and the best capacity of batteries is about 30%; thus, 30% can be set as the lowest limit of the threshold. It is noticed that if the chosen threshold is too lenient, it will reduce battery aging, and if the threshold is set too strict, the frequent clustering triggers will reduce system efficiency. Therefore, 20% is selected as the threshold of battery SOH dispersion in this paper.

3.3. Consistent Group Control of MAS Based on the Blackboard System

The process is mainly divided into two steps. First, when the controller detects the battery dispersion has reached a threshold, the controller will trigger the max–min K-means distributed clustering algorithm, and each battery unit will be put into different clusters based on the proximity degree of SOH; then, the intelligent agent will reconstruct the cooperation relationship based on the results after grouping.

3.3.1. Multi-Agent Distributed Clustering Algorithm

The algorithm is a classical clustering algorithm. Its basic idea is to select the largest and smallest objects among batteries set as initial clustering centers respectively, calculate the distance from each point to objects , and divide each object into specified clusters according to the minimum distance. Then, recalculate the center of each cluster utilized as the new clustering center, and iterate the above process until the data in each cluster does not change. The specific calculation steps are as follows:

① Let overall SOH values in BESS be the sample space . When the threshold is triggered, select max and mini values in the sample space as the first clustering center, and the corresponding group is noted as .

② Calculate the Euclidean distance from for all clustering centers, and the max distance is recorded as .

③ Determine whether is less than , where is the distance between and , . If exceeds , the point is recorded as the third clustering center, and repeat the above steps until .

④ After obtaining the number of groups and the center of each cluster , assign each agent to the class with the smallest Euclidean distance, then record each group as .

⑤ Calculate the center value of each cluster , and then, define these new centers as group centers and repeat the above steps. Finally, we can get new clusters, the number of elements in each cluster , , and the center of each cluster , where is the number of these clusters.

⑥ Recalculate the center value of each group in each cycle before the controller triggers the clustering algorithm next time.

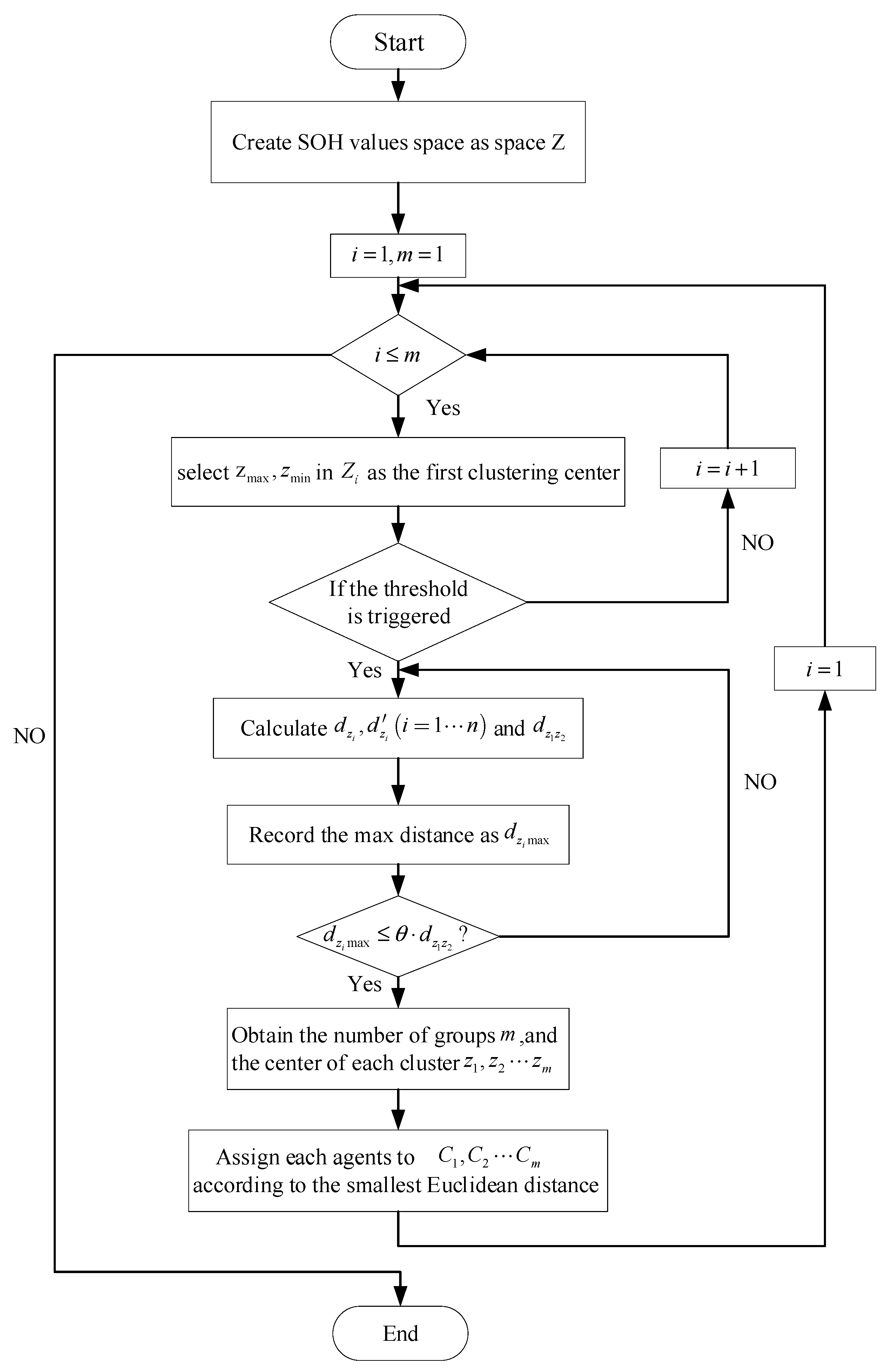

Figure 5 shows the flowchart of the multi-agent distributed clustering algorithm.

3.3.2. Reconfiguration of the Cooperation Structure between Agents

When the clustering is completed, the system will reconstruct intelligent agents’ cooperative relationships based on the results. Since the graph structure of BESS is a loop topology, all inter-group and intra-group cooperation relations can be expressed by the Laplacian matrix, and for a connected graph [

30], the Laplacian matrix

has at least one eigenvalue

, and the corresponding eigenvector is

,

,

. The clustering results can be classified into three cases based on the number of elements in the group

and the nature of the connected graph:

① , the individual is an isolated node; therefore, its neighboring agent and according to the nature of L-matrix.

② , each individual has only one agent to cooperate with; therefore, its neighboring agent and .

③ , at this moment, the individuals inside the group can form a loop; therefore, the neighboring agent of any agent in the group and .

The specific algorithm for multi-intelligent cooperative relationship reconstruction is demonstrated in Algorithm 1.

| Algorithm 1: Reconstruction steps |

| Input: Group numbers ; Cluster ; Initial Laplace matrix ; Number of elements in each group |

| Output: Matrix after reconstruction |

| trigger ← 0 // This is a global variable |

| |

| if trigger = 1 then // Reconstruct if system triggers clustering |

| Subscript // Record the order of elements in L |

| → do |

| for s: → do |

| Subscript (r, s)← in |

| ← // Reset L as an unit matrix |

| → do |

| = 1 then |

| ←0 |

| = 2 then |

| for s: 1→2 do |

| ←1 // Diagonal elements are 1 |

| ←−1 // Adjacent element is −1 |

|

else |

| for : 1→ do |

| ←−1 |

| ←−1 |

| trigger←0 |

3.4. Inter-Group SOH Equalization Control

Before the first “inflection point”, the overall battery aging trend is concentrated, and the system only requires SOC equalization control. Once an “inflection point” appears, it indicates it is not enough to slow down the battery decay trend for the system only relying on SOC equalization control. Therefore, the group SOH equalization control is particularly essential. In addition, though the 26650LiFePO4 battery aging trend has a highly dispersed degree, it also presents a more obvious grouping characteristic, which is greatly beneficial for SOH equalization control.

Generally, DOD has a tight relationship with battery SOH [

32]. The relationship between SOH, DOD, and the number of aging cycles (

) can be expressed as Formula (13):

where

is the actual SOH after each charge–discharge cycle;

is the initial SOH;

are constants of the battery degradation fitting curve, and for a general Li-ion battery,

. Under the same aging cycles, if two adjacent individuals with different initial SOH (

) will be equal at the same time is guaranteed, the relationship between agents can be expressed as [

33,

34]:

With

increasing, the dispersion of 26650 LiFePO

4 batteries increases rapidly. Furthermore, the regulation of DOD has a range limitation, and the initial state gap (

) of battery SOH is small [

31]. As a result, the equalization effect of Formula (14) is not ideal, and even the system will oscillate due to the DOD regulation restriction. Moreover, Formula (14) is tough for BESS containing three or more agents to express all the regulation relationships, so Formula (14) is difficult to apply in BESS directly.

The essence of the MAS consistency algorithm is to regulate the agent

’s output in the next step by calculating the algebraic sum of the state differences between agent

and its adjacent agents

separately. Consequently, the multi-agent equalization problem can be transformed into an equalization problem between two agents by considering the average value of adjacent individuals as a new agent. Meanwhile, the initial state of SOH is replaced with the SOH of neighboring individuals after each aging cycle to meet the real-time nature of the equalization control. By transforming and discretizing the Formula (14), the following expression can be obtained:

where

denotes DOD of the agent

at

moment;

is the adjustment term,

. Because the 26650 battery aging trend dispersion becomes larger with the aging cycles, we assume the adjustment term is a linear function in this paper so that the current difference value can be appropriately adjusted in the late aging cycle to prevent overshoot. Therefore, as the number of cycles increases, the value of

at the moment of

should be smaller than the value at the moment of

.

Then, regard each group as an agent, and let the central values

calculated from each cycle after clustering represent the average SOH of each group. Substitute them into Formula (12), and the DOD of the group

can be obtained, which is noted as

. After obtaining

of each group,

can be determined. Define the total power offered by BESS as

. When

, BESS is on discharging; when

, BESS is on charging. The power assigned to group

can be expressed as Formula (16):

3.5. Structure of the Equalization Control Scheme

In summary, as shown in

Figure 6, the scheme proposed in this paper is divided into three parts: the blackboard system design, the control strategy before the battery aging dispersion threshold, and the control strategy after the battery aging dispersion threshold.

In this paper, the blackboard area is roughly divided into three parts: task information area, data sharing area, and cooperation structure information area.

Before the dispersion reaches the threshold value, battery units are controlled by SOC equalization under the loop graph topology. After the controller detects the dispersion reaches the threshold value, the system triggers the clustering algorithm to cluster battery units with similar SOH into one group. Then, the SOH equalization is controlled between groups; meanwhile, the SOC equalization is controlled within the group. Finally, the system will repeat the process above until one of the battery units in the BESS cannot work.

4. Simulations and Discussion

This section verifies that the proposed SOC and SOH double-layer equalization control based on MABS can effectively prolong the overall usage life under the condition of ensuring SOC equalization and reduce the aging dispersion of the battery to a certain extent through MATLAB. During the simulation, the aging cycle times are reduced by a certain percentage, referring to the experimental results of the accelerated aging cycle of 26650 LiFePO

4 batteries in [

25].

The initial Laplace matrix

L is shown as:

The experiment assumes that the LiFePO

4 batteries have different initial SOC (

) and the same initial SOH (both are

). The battery voltages are all assumed as 220 V, and the initial value of DOD is 0.6. The simulation experimental parameters are given in

Table 1.

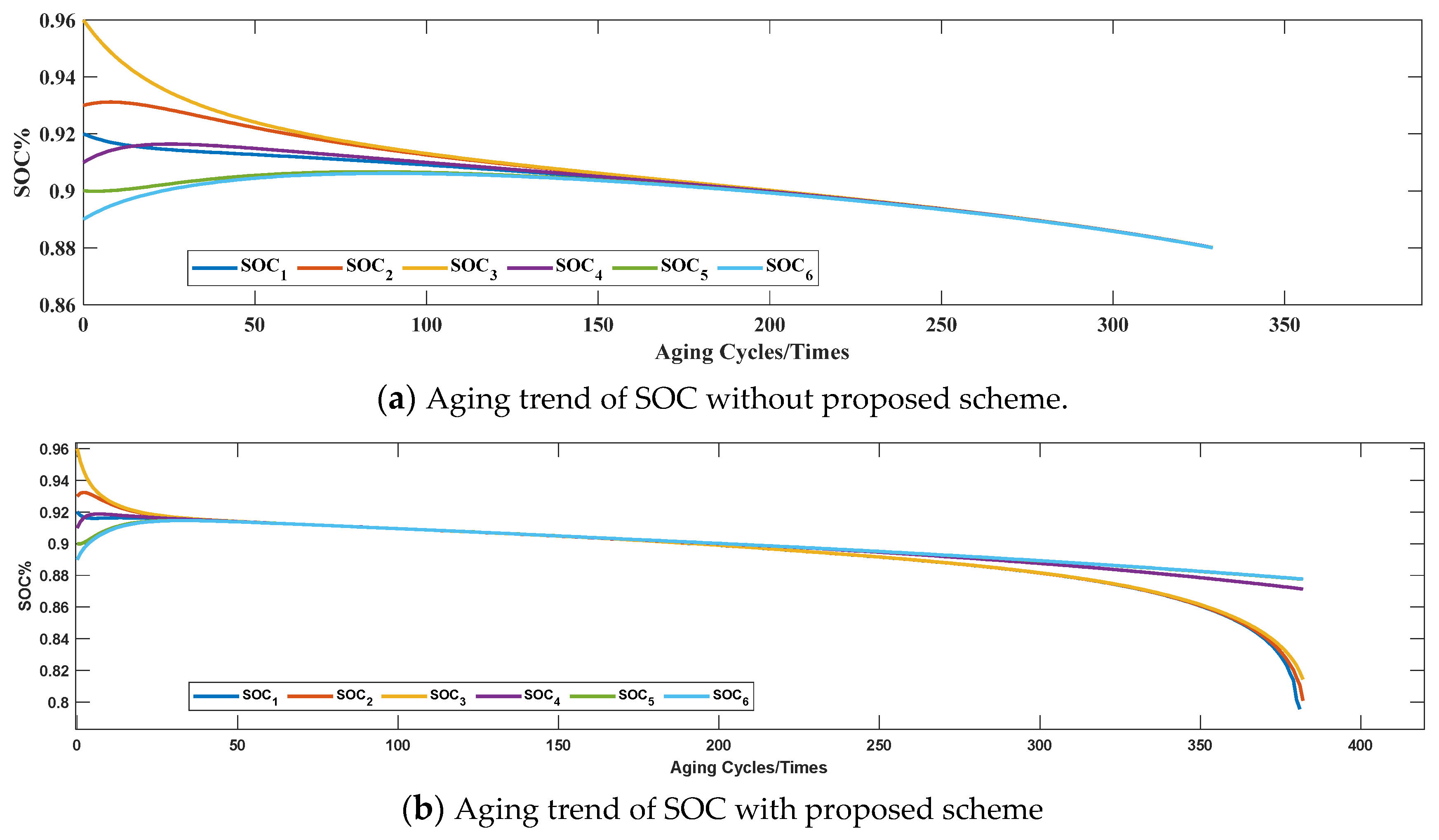

Figure 7 shows the comparison of the process of SOC change. From the overall trend, SOC decreases with aging cycles in the balancing process, which reflects the influence of the aging of batteries on SOC balancing. From the SOC aging degree, the proposed algorithm not only improves the service life of the battery system but also increases the aging degree of batteries, which enables batteries to fully release electric energy.

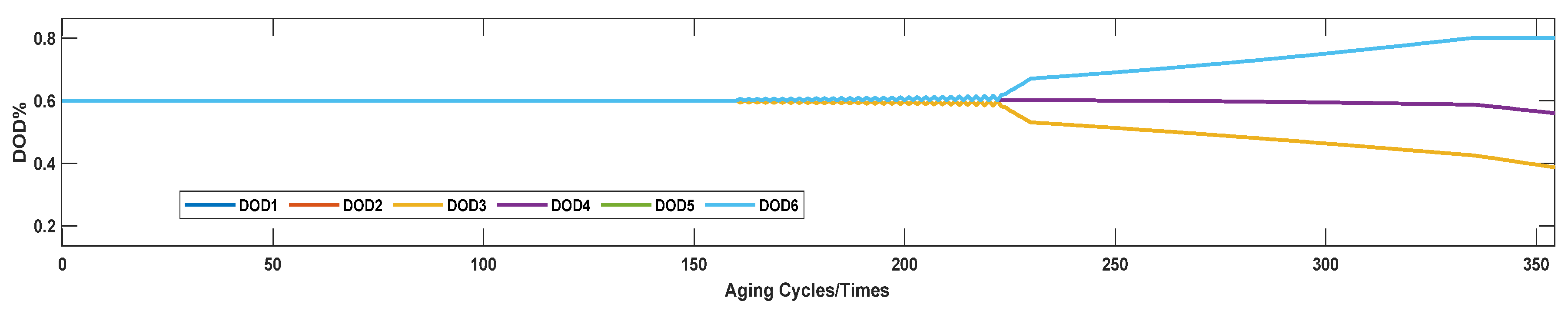

Figure 8 shows the process of DOD change during the simulation process. After the “inflection point”, the SOC gradually shows the grouping trend, and the DOD is also adjusted according to different groups.

As shown in

Figure 9, (a) and (b) show the aging trend of the battery without the proposed scheme and with the proposed scheme, respectively, and (b) clearly shows that compared with (a), the overall aging cycle increases from 330 to nearly 400, and the dispersion between batteries also decreases to some extent, which also proves the effectiveness of the algorithm.