Using Central Composite Design to Improve Methane Production from Anaerobic Digestion of Tomato Plant Waste

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrate

2.2. Inoculum

2.3. Experimental Desing and Statistic Analysis

2.4. Batch Assays for Methane Production

2.5. Analytical Methods

3. Results and Discussions

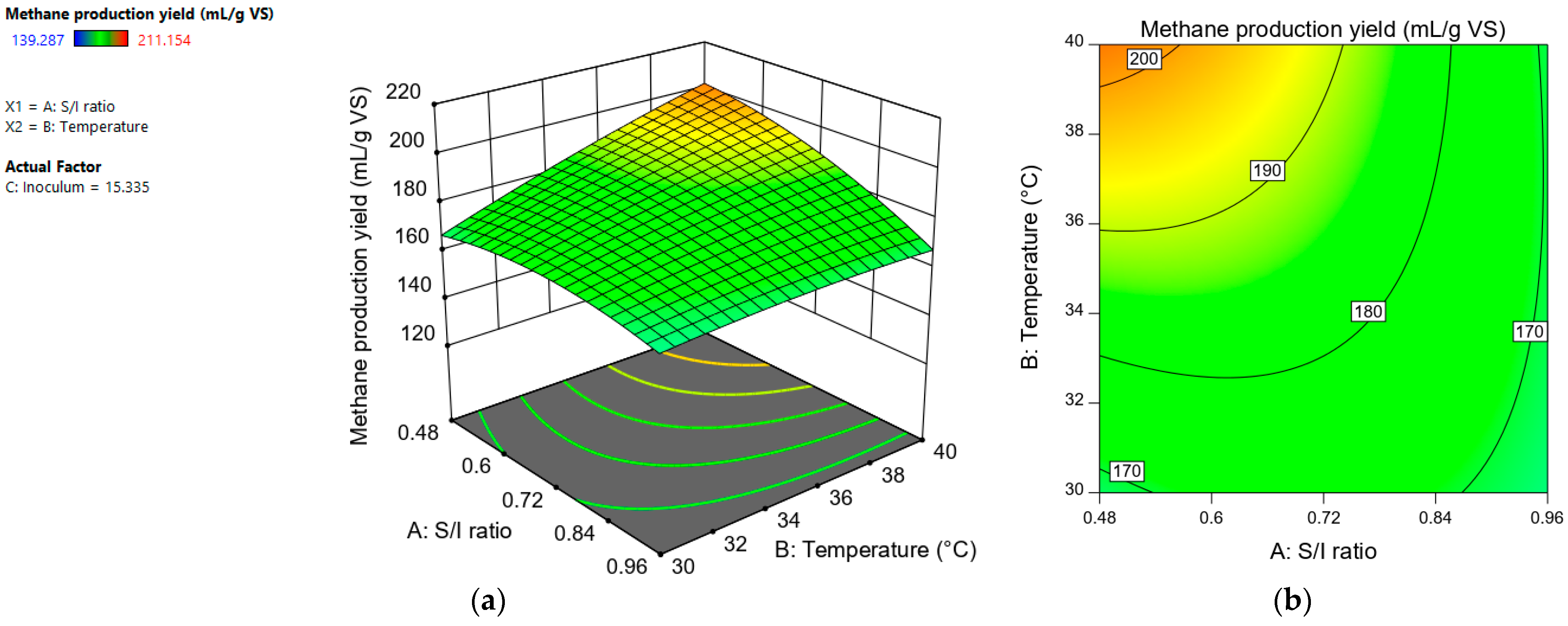

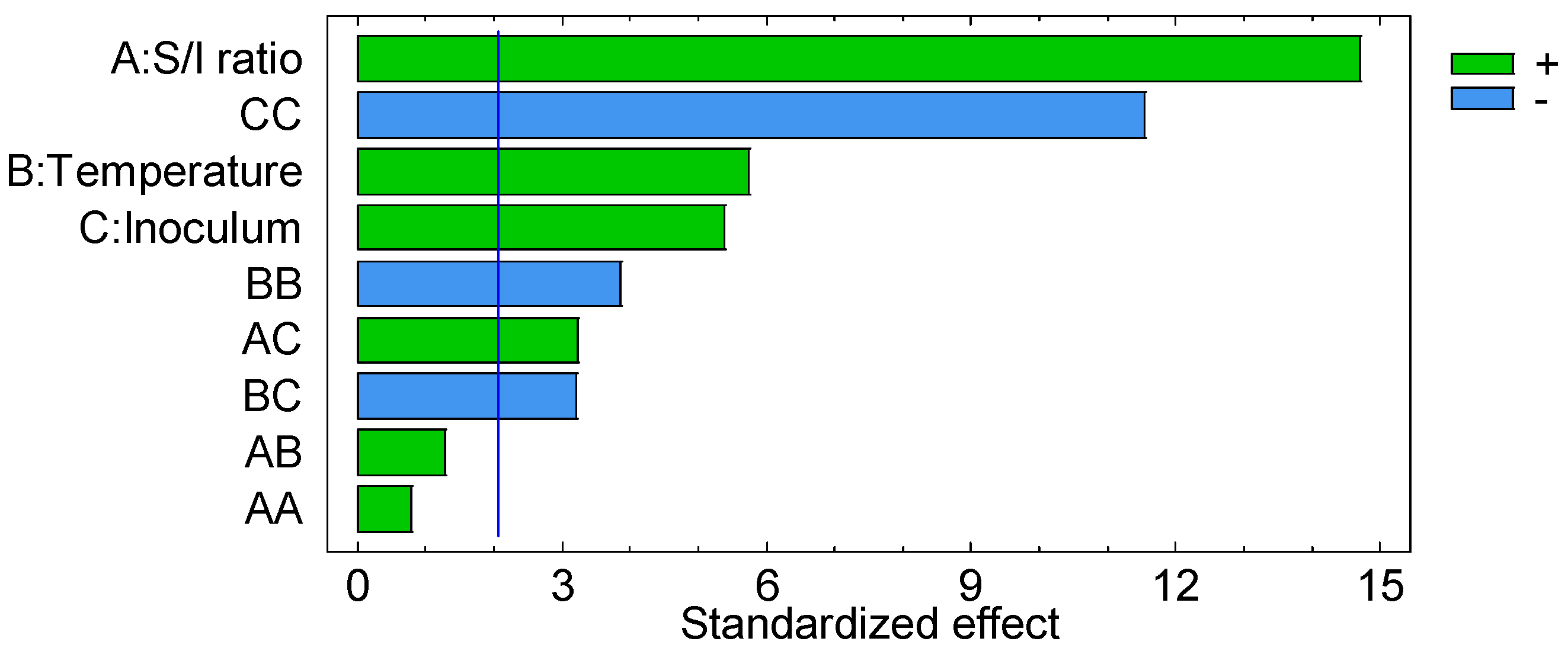

3.1. Regression Analysis and Response Surfaces for Methane Production Yield

0.2413(BC) − 5.77(A2) − 1.83(B2) − 5.83(C2)

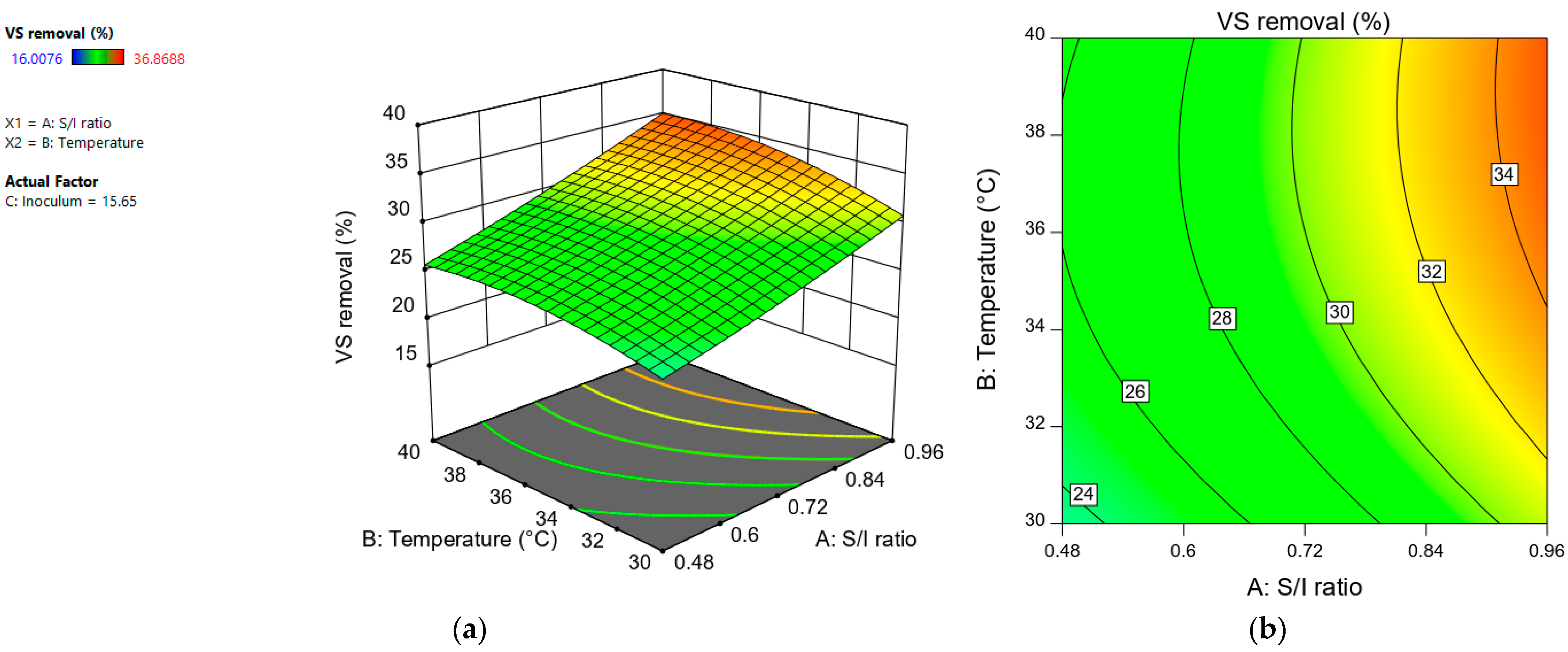

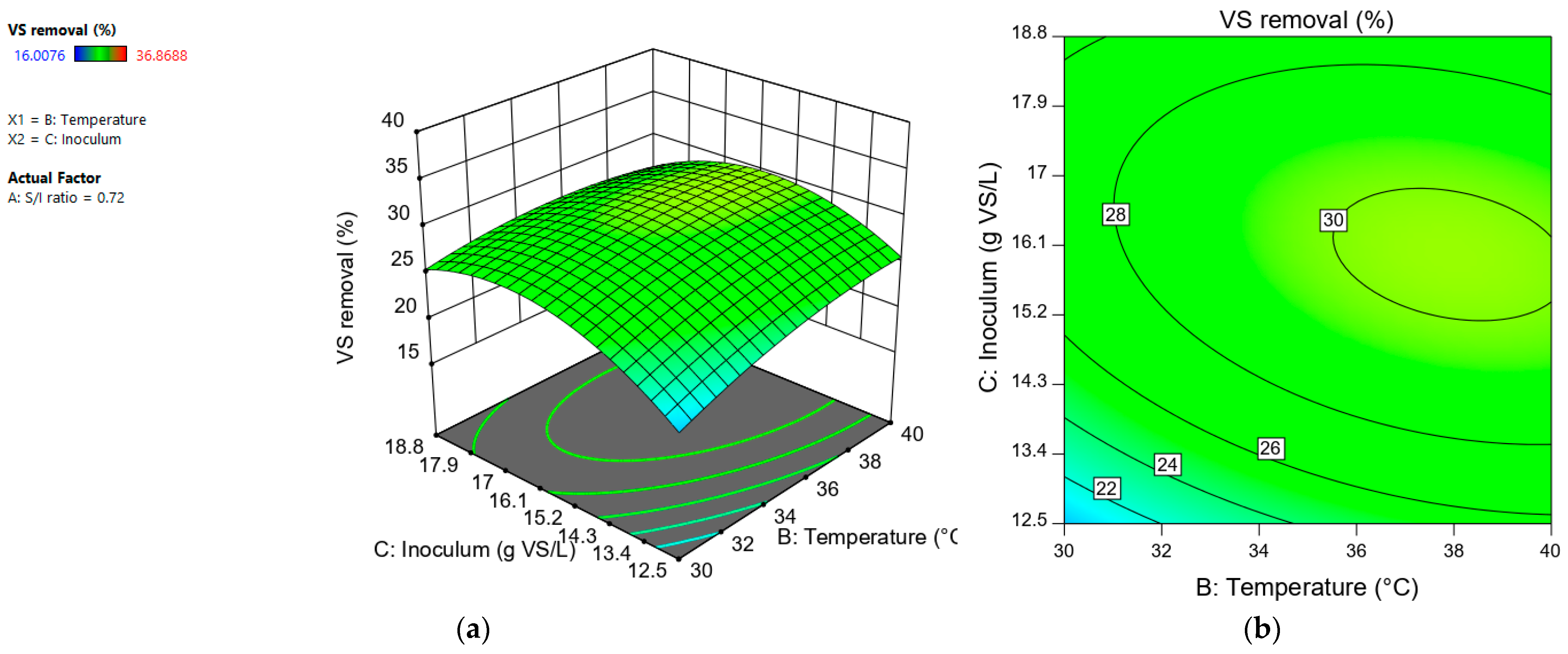

3.2. Regression Analysis and Response Surfaces for Volatil Solids Removal

1.19(BC) − 0.3321(A2) − 1.28(B2) − 4.02 (C2)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khanal, S.K. Anaerobic Biotechnology for Bioenergy Production: Principles and Applications; Wiley: Blackwell, UK, 2008. [Google Scholar]

- Rao, P.R.V.; Baral, S.S.; Dey, R.; Mutnuri, S. Biogas generation potential by anaerobic digestion for sustainable energy development in India. Renew. Sustain. Energy Rev. 2010, 14, 2086–2094. [Google Scholar] [CrossRef]

- Lopez, M.J.; Masaguer, A.; Paredes, C.; Roca, L.; Ros, M.; Salas, M.C.; Boluda, R. Residuos orgánicos y agricultura intensive III. In Red Española de Compostaje; Ediciones Peaninfo SA: Madrid, Spain, 2015; Volume 45, p. 58. [Google Scholar]

- Li, Y.; Xu, F.; Li, Y.Y.; Lu, J.; Li, S.; Shah, A.M.; Zhang, X.; Zhang, H.; Gong, X.; Li, G. Reactor performance and energy analysis of solid state anaerobic co-digestion of dairy manure with corn stover and tomato residues. Waste Manag. 2018, 73, 130–139. [Google Scholar] [CrossRef] [PubMed]

- Almeida, P.A.; Rodrigues, R.M.; Teixeira, L.; Santos, A.; Martins, R.P.; Quina, M.J. Bioenergy Production through Mono and Co-Digestion of Tomato Residues. Energies 2021, 14, 5563. [Google Scholar] [CrossRef]

- Ruiz-Aguilar, G.M.L.; Nuñez-Palenius, H.G.; Lovanh, N.; Camarena-Martínez, S. Comparative Study of Methane Production in a One-Stage vs. Two-Stage Anaerobic Digestion Process from Raw Tomato Plant Waste. Energies 2022, 15, 9137. [Google Scholar] [CrossRef]

- Wang, X.; Yang, G.; Li, F.; Feng, Y.; Yang, G.; Han, X. Evaluation of two statistical methods for optimizing the feeding composition in anaerobic co-digestion: Mixture design and central composite design. Bioresour. Technol. 2013, 131, 172–178. [Google Scholar] [CrossRef]

- Sathish, S.; Vivekanandan, S. Parametric optimization for floating drum anaerobic bio-digester using Response Surface Methodology and Artificial Neural Network. Alex. Eng. J. 2016, 55, 3297–3307. [Google Scholar] [CrossRef] [Green Version]

- Kainthola, J.; Kalamdhad, A.S.; Goud, V.V. Optimization of methane production during anaerobic co-digestion of rice straw and hydrilla verticillata using response surface methodology. Fuel 2019, 235, 92–99. [Google Scholar] [CrossRef]

- Kainthola, J.; Kalamdhad, A.S.; Goud, V.V. Optimization of process parameters for accelerated methane yield from anaerobic co-digestion of rice straw and food waste. Renew. Energy 2020, 149, 1352–1359. [Google Scholar] [CrossRef]

- Zhang, H.; Khalid, H.; Li, W.; He, Y.; Liu, G.; Chen, C.W. Employing response surface methodology (RSM) to improve methane production from cotton stalk. Environ. Sci. Pollut. Res. 2017, 25, 7618–7624. [Google Scholar] [CrossRef]

- Wang, X.; Yang, G.; Li, F.; Feng, Y.; Ren, G. Response surface optimization of methane potentials in anaerobic co-digestion of multiple substrates: Dairy, chicken manure and wheat straw. Waste Manag. Res. 2012, 31, 60–66. [Google Scholar] [CrossRef]

- Ghaleb, A.; Kutty, S.R.M.; Ho, Y.; Hayder, G.; Noor, A.; Al-Sabaeei, A.M.; Almahbashi, N. Response Surface Methodology to Optimize Methane Production from Mesophilic Anaerobic Co-Digestion of Oily-Biological Sludge and Sugarcane Bagasse. Sustainability 2020, 12, 2116. [Google Scholar] [CrossRef] [Green Version]

- Saleh, A.F.; Kamarudin, E.; Yaacob, A.B.; Yussof, A.W.; Abdullah, M.Z. Optimization of biomethane production by anaerobic digestion of palm oil mill effluent using response surface methodology. Asia-Pac. J. Chem. Eng. 2011, 7, 353–360. [Google Scholar] [CrossRef]

- Rasouli, M.; Ajabshirchi, Y.; Mousavi, S.M.; Nosrati, M.; Yaghmaei, S. Process Optimization and Modeling of Anaerobic Digestion of Cow Manure for Enhanced Biogas Yield in a Mixed Plug-flow Reactor using Response Surface Methodology. Biosci. Biotechnol. Res. Asia 2015, 12, 2333–2344. [Google Scholar] [CrossRef] [Green Version]

- Sajeena, B.B.; Jose, P.P.; Madhu, G. Optimization of process parameters affecting biogas production from organic fraction of municipal solid waste via anaerobic digestion. Int. J. Bioeng. Life Sci. 2014, 8, 43–48. [Google Scholar] [CrossRef]

- Safari, M.; Abdi, R.; Adl, M.; Kafashan, J. Optimization of biogas productivity in lab-scale by response surface methodology. Renew. Energy 2018, 118, 368–375. [Google Scholar] [CrossRef]

- Camarena-Martínez, S.; Martínez-Martínez, J.M.; Saldaña-Robles, A.; Nuñez-Palenius, H.G.; Costilla-Salazar, R.; Valdez-Vazquez, I.; Lovanh, N.; Ruiz-Aguilar, G.M.L. Effects of experimental parameters on methane production and volatile solids removal from tomato and pepper plant wastes. Bioresources 2020, 15, 4763–4780. [Google Scholar] [CrossRef]

- Lara-Vázquez, A.R.; Sánchez, A.B.; Valdez-Vazquez, I. Hydration treatments increase the biodegradability of native wheat straw for hydrogen production by a microbial consortium. Int. J. Hydrogen Energy 2014, 39, 19899–19904. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association/American Water Works Association/Water Environment Federation: Washington, DC, USA, 2005. [Google Scholar]

- Kang, J.; Kim, K.; Oh, G.; Rhee, S. Analysis on biochemical methane potential of agricultural byproducts with different types of silage storage. J. Mater. Cycles Waste Manag. 2013, 16, 468–474. [Google Scholar] [CrossRef]

- Drosg, B.; Braun, R.; Bochmann, G.; Al Saedi, T. Analysis and characterisation of biogas feedstocks. In The Biogas Handbook; Elsevier: Amsterdam, The Netherlands, 2013; pp. 52–84. [Google Scholar] [CrossRef]

- Reungsang, A.; Pattra, S.; Reungsang, A. Optimization of Key Factors Affecting Methane Production from Acidic Effluent Coming from the Sugarcane Juice Hydrogen Fermentation Process. Energies 2012, 5, 4746–4757. [Google Scholar] [CrossRef] [Green Version]

- Abbasi, S.A.; Tauseef, S.M.; Abbasi, S.A. Biogas Energy; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Rodriguez-Chiang, L.; Dahl, O. Effect of Inoculum to Substrate Ratio on the Methane Potential of Microcrystalline Cellulose Production Wastewater. Bioresources 2014, 10, 898–911. [Google Scholar] [CrossRef]

- Budiyono, I.N.; Widiasa, S.; Seno, J. The Influence of Total Solid Contents on Biogas Yield from Cattle Manure Using Rumen Fluid Inoculum. Energy Res. J. 2010, 1, 6–11. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; Zhu, J. Modeling Kinetics of Anaerobic Co-Digestion of Poultry Litter and Wheat Straw Mixed with Municipal Wastewater in a Continuously Mixed Digester with Biological Solid Recycle Using Batch Experimental Data. Chem. Eng. Commun. 2017, 204, 501–511. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Z.; Nakamoto, T.; Li, Y.; Yang, Y.; Utsumi, M.; Sugiura, N. Influence of substrate-to-inoculum ratio on the batch anaerobic digestion of bean curd refuse-okara under mesophilic conditions. Biomass Bioenergy 2011, 35, 3251–3256. [Google Scholar] [CrossRef]

- Haider, M.S.; Zeshan Yousaf, S.; Malik, R.N.; Visvanathan, C. Effect of mixing ratio of food waste and rice husk co-digestion and substrate to inoculum ratio on biogas production. Bioresour. Technol. 2015, 190, 451–457. [Google Scholar] [CrossRef]

- Xu, S.; Karthikeyan, O.P.; Selvam, A.; Wong, J.W.C. Effect of inoculum to substrate ratio on the hydrolysis and acidification of food waste in leach bed reactor. Bioresour. Technol. 2012, 126, 425–430. [Google Scholar] [CrossRef] [PubMed]

- Córdoba, V.; Fernández, M.J.; Santalla, E. The effect of substrate/inoculum ratio on the kinetics of methane production in swine wastewater anaerobic digestion. Environ. Sci. Pollut. Res. 2017, 25, 21308–21317. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.Y.; Zhang, D.; Li, G.; Lu, J.; Li, S. Solid state anaerobic co-digestion of tomato residues with dairy manure and corn stover for biogas production. Bioresour. Technol. 2016, 217, 50–55. [Google Scholar] [CrossRef]

- Valdez-Vazquez, I.; Torres-Aguirre, G.A.; Molina, C.A.; Ruiz-Aguilar, G.M.L. Characterization of a Lignocellulolytic Consortium and Methane Production from Untreated Wheat Straw: Dependence on Nitrogen and Phosphorous Content. Bioresources 2016, 11, 4237–4251. [Google Scholar] [CrossRef] [Green Version]

- Fang, H.H.P.; Liu, H. Effect of pH on hydrogen production from glucose by a mixed culture. Bioresour. Technol. 2002, 82, 87–93. [Google Scholar] [CrossRef]

| Factors | Levels | ||||

|---|---|---|---|---|---|

| −2 | −1 | 0 | +1 | +2 | |

| A: Substrate/inoculum ratio | 0.32 | 0.48 | 0.72 | 0.96 | 1.12 |

| B: Temperature (°C) | 27.00 | 30.00 | 35.00 | 40.00 | 43.00 |

| C: Inoculum (g VS/L) | 10.35 | 12.50 | 15.65 | 18.80 | 20.95 |

| Run | A | B | C | Methane Production Yield (mL/g VS) | VS Removal (%) | ||

|---|---|---|---|---|---|---|---|

| Experimental | Predicted | Experimental | Predicted | ||||

| 1 | 0.96 | 40 | 12.50 | 158.1 ± 1.6 | 152.7 | 31.0 ± 0.2 | 29.5 |

| 2 | 0.96 | 30 | 12.50 | 158.0 ± 1.9 | 149.5 | 21.9 ± 0.6 | 22.9 |

| 3 | 0.48 | 40 | 18.80 | 210.8 ± 0.5 | 203.5 | 22.6 ± 1.9 | 20.9 |

| 4 | 0.48 | 30 | 18.80 | 179.4 ± 0.7 | 169.1 | 20.2 ± 1.6 | 21.0 |

| 5 | 0.48 | 30 | 12.50 | 161.7 ± 3.7 | 154.8 | 18.4 ± 1.6 | 17.9 |

| 6 | 0.96 | 40 | 18.80 | 182.2 ± 1.0 | 173.3 | 32.8 ± 0.1 | 32.6 |

| 7 | 0.72 | 35 | 15.65 | 188.1 ± 2.5 | 183.9 | 29.9 ± 1.8 | 29.7 |

| 8 | 0.72 | 35 | 15.65 | 176.4 ± 14.0 | 183.9 | 31.2 ± 1.8 | 29.7 |

| 9 | 0.96 | 30 | 18.80 | 172.2 ± 7.8 | 171.1 | 32.4 ± 1.2 | 30.8 |

| 10 | 0.48 | 40 | 12.50 | 204.8 ± 3.3 | 190.2 | 21.6 ± 0.6 | 22.6 |

| 11 | 0.72 | 43 | 15.65 | 183.7 ± 1.6 | 194.6 | 28.0 ± 0.6 | 28.8 |

| 12 | 0.72 | 35 | 10.35 | 142.4 ± 4.4 | 152.8 | 16.3 ± 0.4 | 15.8 |

| 13 | 0.72 | 35 | 15.65 | 188.2 ± 1.2 | 183.9 | 28.9 ± 2.5 | 29.7 |

| 14 | 0.72 | 35 | 15.65 | 175.5 ± 6.4 | 183.9 | 28.8 ± 2.9 | 29.7 |

| 15 | 0.32 | 35 | 15.65 | 169.9 ± 11.0 | 182.6 | 23.9 ± 0.4 | 23.6 |

| 16 | 1.12 | 35 | 15.65 | 149.2 ± 2.8 | 152.7 | 36.9 ± 0.1 | 37.7 |

| 17 | 0.72 | 35 | 20.95 | 176.3 ± 1.3 | 182.1 | 19.9 ± 2.6 | 20.9 |

| 18 | 0.72 | 27 | 15.65 | 157.6 ± 3.3 | 163.0 | 23.6 ± 0.4 | 23.4 |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 8661.58 | 9 | 962.40 | 25.23 * | <0.0001 |

| A: S/I ratio | 2150.58 | 1 | 2150.58 | 56.38 | <0.0001 |

| B: Temperature | 2414.72 | 1 | 2414.72 | 63.31 | <0.0001 |

| C: Inoculum | 2076.21 | 1 | 2076.21 | 54.43 | <0.0001 |

| AB | 1034.90 | 1 | 1034.90 | 27.13 | <0.0001 |

| AC | 53.38 | 1 | 53.38 | 1.40 | 0.2501 |

| BC | 0.9313 | 1 | 0.9313 | 0.0244 | 0.8773 |

| A2 | 610.49 | 1 | 610.49 | 16.00 | 0.0006 |

| B2 | 61.32 | 1 | 61.32 | 1.61 | 0.2187 |

| C2 | 622.98 | 1 | 622.98 | 16.33 | 0.0006 |

| Residual | 801.02 | 21 | 38.14 | ||

| Lack of fit | 463.71 | 5 | 92.74 | 4.40 ** | 0.0104 |

| Pure error | 337.31 | 16 | 21.08 | ||

| Cor total | 10,886.00 | 31 |

| Standard deviation = 6.18 | Mean = 173.39 | CV = 3.56 |

| R2 = 0.9153 | Adj R2 = 0.8791 | Pred R2 = 0.8075 |

| SCRP = 1821.66 | Adequate precision = 18.037 |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 1055.27 | 9 | 117.25 | 54.10 * | <0.0001 |

| A: S/I ratio | 478.57 | 1 | 478.57 | 220.82 | <0.0001 |

| B: Temperature | 71.96 | 1 | 71.96 | 33.20 | <0.0001 |

| C: Inoculum | 64.64 | 1 | 64.64 | 29.83 | <0.0001 |

| AB | 3.86 | 1 | 3.86 | 1.78 | 0.1962 |

| AC | 23.11 | 1 | 23.11 | 10.66 | 0.0037 |

| BC | 22.52 | 1 | 22.52 | 10.39 | 0.0041 |

| A2 | 2.02 | 1 | 2.02 | 0.9339 | 0.3448 |

| B2 | 30.08 | 1 | 30.08 | 13.88 | 0.0013 |

| C2 | 296.02 | 1 | 296.02 | 136.59 | <0.0001 |

| Residual | 45.51 | 21 | 2.17 | ||

| Lack of fit | 25.39 | 5 | 5.08 | 4.04 ** | 0.0147 |

| Pure error | 20.13 | 16 | 1.26 | ||

| Cor total | 1101.93 | 31 |

| Standard deviation = 1.47 | Mean = 25.53 | CV = 5.77 |

| R2 = 0.9587 | Adj R2 = 0.9409 | Pred R2 = 0.9017 |

| SCRP = 108.19 | Adequate precision = 25.4024 |

| Substrate | Variables Evaluated (Levels) | Optimal Conditions | Yield | Ref. |

|---|---|---|---|---|

| Palm oil mill effluent and fruit bunches as co-substrate | Temperature (20–50 °C) Co-substrate (0–6 g) Substrate (50–100 mL) | 47.8 °C, 50.4 mL substrate, 5.7 g co-substrate | 57.4 mL biogas/g COD | [14] |

| Co-digestion between dairy manure (DM), chicken manure (CM), and wheat straw | C/N (15:1–35:1) DM/CM (100:0–0:100) Initial feed load (9–21 g VS/L) I/S 0.5–3.5) | C/N 26.31, DM/CM 42.96:57.04, Initial feed load 15.90 g VS/L, I/S 2.34 | 394 mL CH4/g VS | [12] |

| Co-digestion between dairy manure (DM), chicken manure (CM), and rice straw (RS) | C/N (15–35), DM/CM (0–100) | 44.5% DM, 35.0% CM, 20.5% RS C/N 24.7 | 343 mL CH4/g VS | [7] |

| Municipal solid waste | Substrate (83.0–115.0 g ST/L), initial pH (6–7), total organic carbon (TOC) (16.8–23.9) | 99 g ST/L substrate, pH 6.5, 20.32 g TOC/L | 53.4 mL biogas/g VS | [16] |

| Cow manure | Organic loading rate (OLR) (0.82–4.2 kg VS/m3-d), temperature (8.1–66.9 °C) Agitation (0–100 rpm) | OLR 3.15 kg VS/m3-d, 37.7 °C, 20.3 rpm/10 min every 2 h | 113 mL CH4/g VS | [15] |

| Rice straw | Temperature (40–60 °C), pH (6.8–7.6), substrate (90–130 kg), shaking time (2–10 s) | 50 °C, pH 7.5, 110.7 kg of substrate, 5 s shaking | 725 mL biogas/g VS | [8] |

| Canola waste with cow manure | Temperature (15–60 °C), substrate (5–11% ST), inoculum (0–50% ST), shaking time (1–5 min/d) | 40.4 °C, 7.4% TS substrate, 3.6 min/d shaking, 26.3% ST inoculum | 376.8 mL CH4/g VS | [17] |

| Cotton stalk (CS) | Organic loading (OL) (5.86–34.14 g VS/L), feed-to-inoculum (F/I) ratio (0.29–1.71) | F/I of 0.79, OL 25.61 g VS/L | 70.2 mL CH4/g VS | [11] |

| Rice straw and Hydrilla verticillata | C/N (14.89–40.11), food/microorganisms (F/M) (0.15–4.35), pH (6.16–7.84) | C/N 29.7, F/M 2.15, pH 7.34 | 287.60 mL CH4/g VS added | [9] |

| Rice straw and food waste | Initial pH (6.43–7.57), F/M ratio (0.48–4.02) | pH 7.32, F/M 1.87 | 323.8 mL CH4/g VS added | [10] |

| Oily biological sludge and sugarcane bagasse | C/N (20–30), VS co-substrate/VS inoculum (0.06–0.18) | C/N ratio of 30, VS co-substrate/VS inoculum 0.18 * | 63.5 mL CH4/g VS removed | [13] |

| Tomato plant waste | Temperature (27–43 °C), S/I ratio (0.32–1.12), inoculum (10.35–20.95 g VS/L) | S/I 0.48, 40 °C, 18.8 g VS/L * | 210.8 mL CH4/g VS * | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz-Aguilar, G.M.L.; Martínez-Martínez, J.H.; Costilla-Salazar, R.; Camarena-Martínez, S. Using Central Composite Design to Improve Methane Production from Anaerobic Digestion of Tomato Plant Waste. Energies 2023, 16, 5412. https://doi.org/10.3390/en16145412

Ruiz-Aguilar GML, Martínez-Martínez JH, Costilla-Salazar R, Camarena-Martínez S. Using Central Composite Design to Improve Methane Production from Anaerobic Digestion of Tomato Plant Waste. Energies. 2023; 16(14):5412. https://doi.org/10.3390/en16145412

Chicago/Turabian StyleRuiz-Aguilar, Graciela M. L., Juan H. Martínez-Martínez, Rogelio Costilla-Salazar, and Sarai Camarena-Martínez. 2023. "Using Central Composite Design to Improve Methane Production from Anaerobic Digestion of Tomato Plant Waste" Energies 16, no. 14: 5412. https://doi.org/10.3390/en16145412

APA StyleRuiz-Aguilar, G. M. L., Martínez-Martínez, J. H., Costilla-Salazar, R., & Camarena-Martínez, S. (2023). Using Central Composite Design to Improve Methane Production from Anaerobic Digestion of Tomato Plant Waste. Energies, 16(14), 5412. https://doi.org/10.3390/en16145412