1. Introduction

As economic development has been leaping forward, the conflict between energy and the environment has become increasingly acute. The rising living standards of residents have prompted a surge in energy consumption intensity, particularly in the construction sector [

1,

2]. Current data indicate that building energy consumption in developed nations accounts for 40% of total social energy consumption, and this proportion is on the rise with the deepening of urbanization [

3]. Natural gas, with its high hydrogen–carbon ratio and calorific value, possesses the advantages of being a cleaner and more efficient fuel compared to other fossil fuels. The exploitation of clean energy natural gas and the vigorous development of urban gas have been identified as effective methods for balancing resources and environmental challenges.

In light of the low-carbon trend and energy security, the production and trade of liquefied natural gas (LNG) have garnered increasing attention in recent times [

4]. Considering the abundance of marine natural resources, natural gas development has emerged as the next frontier in the natural gas industry. However, due to geographical and spatial constraints, floating liquefied natural gas (FLNG) plants have become the primary option for offshore natural gas development [

5]. FLNG is a mobile composite equipment that enables the production, refining, storage, loading, and unloading of LNG at sea. As a self-contained production device from drilling to liquefaction, FLNG obviates the need for land storage equipment or submarine pipelines, thereby offering the advantage of protecting the submarine ecosystem. The spiral tube heat exchanger (SHE) is the core component of natural gas liquefaction, and the liquefaction process is completed internally. Because the internal two-phase flow heat transfer process is complex and variable and the mechanism is still unclear, SHE is the highest cost and the most difficult section in the FLNG system. The small footprint, high heat transfer efficiency, and ability to facilitate cross heat transfer of multiple streams have rendered the SHE a popular choice for use in large-scale liquefaction plants [

6]. The SHE comprises several groups of spiral tubes. During the natural gas liquefaction process, the hot fluid (hydrocarbon refrigerant) flows from bottom to top within the tubes, while the cold fluid on the shell side flows from top to bottom between the respective layers of spiral tubes, allowing for countercurrent heat transfer. Typically, during the flow process in the tube side of SHE, the condensation of hydrocarbon refrigerant will occur. Additionally, in the typical flow process of phase transition in the tube, notably for the non-azeotropic mixed working fluids, the temperature slip results in the complexity of the heat transfer [

7].

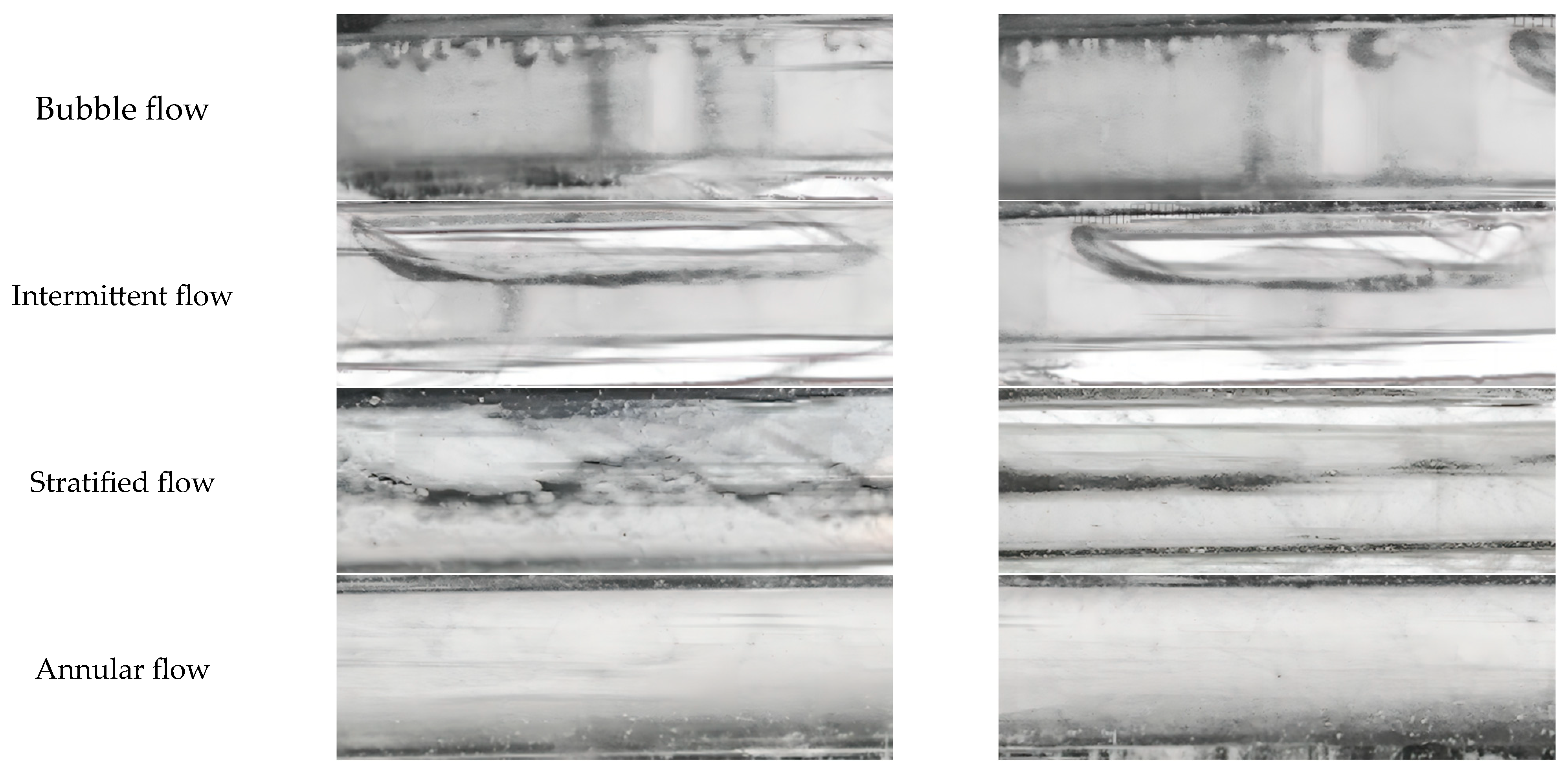

During two-phase flow in a tube, the gas–liquid interface undergoes shape changes that result in distinct flow patterns. These patterns are influenced by momentum and heat transfer during the condensation process, and the two-phase flow exhibits significant chaotic characteristics [

8,

9]. To define these flow patterns conveniently, the flow pattern map method is commonly employed. In 1954, Baker et al. [

10] introduced a flow pattern map for two-phase flow in a horizontal tube, which categorized the flow regimes into bubble flow, slug flow, stratified flow, wavy flow, and mist flow. Mandhane [

11] expanded on the work of Govier and Aziz [

12] by using the gas–liquid phase superficial velocity as the coordinate system for the flow pattern map. Moreover, the researcher also proposed a presently extensively used flow pattern map. A flow pattern map was also proposed by the researcher, which has become extensively utilized at present. This map effectively elucidated the impact of flow velocity and pipe size on the flow pattern. However, it cannot account for the influence of fluid physical properties. To address this limitation, Weisman [

13] conducted a study on the effect of physical parameters and pipe diameter on the flow pattern. He employed a combination of observation method and pressure signal to distinguish the flow pattern and selected a modified gas–liquid phase superficial velocity as the coordinate. Subsequently, Taitel [

14] introduced a theoretical criterion based on the actual transition physical mechanism of the flow pattern. Barnea [

15] then conducted experiments to verify the flow pattern map proposed by Taitel. In comparison to the horizontal tube, the study of flow patterns in the spiral tube had been relatively delayed. Whalley et al. [

16] conducted research on stratified and annular flow in air–water two-phase flow in the spiral tube. However, they did not consider the secondary flow in the spiral tube, resulting in significant differences between the pressure drop data and experimental data. Mujawar [

17] extended Lockhart and Martinelli’s correlations to spiral tubes. The findings indicated that slug flow was the most common flow pattern in the spiral tube, and the flow pattern in the tube was consistent with the one in the horizontal tube. Chen et al. [

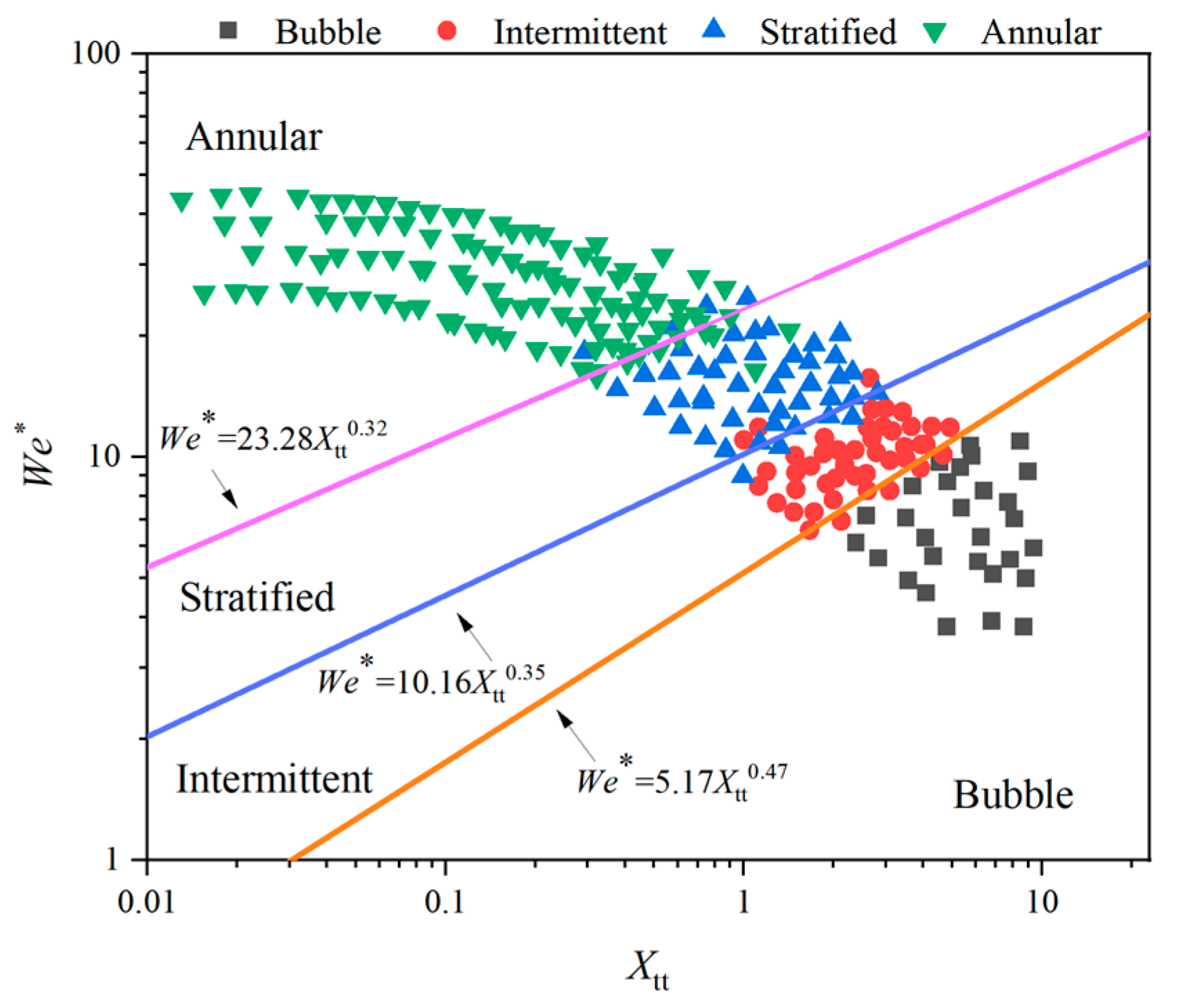

18,

19] conducted a systematic analysis of the flow pattern in the spiral tube and developed a flow pattern map. Simultaneously, the Weber number and liquid Dean number were introduced to characterize the effect of surface tension and secondary flow. Yan [

20] analyzed air–water and R113 gas–liquid two-phase flow in a spiral tube using a high-speed framing camera and identified plug flow, slug flow, and annular flow in the tube. According to Yan’s findings, the stratified flow was unlikely to occur in the spiral rising tube, and the slug flow occupied the original region in the flow pattern map. Murai [

21] conducted a study on two-phase flow in the helical tube using two high-speed framing cameras (front and vertical). The results showed that the stratified flow did not appear in the spiral tube, and the bubble flow region became narrower with a decrease in the spiral diameter. However, it should be noted that the range of gas velocity was limited in Murai’s experiment, and the wavy flow and annular flow were not considered.

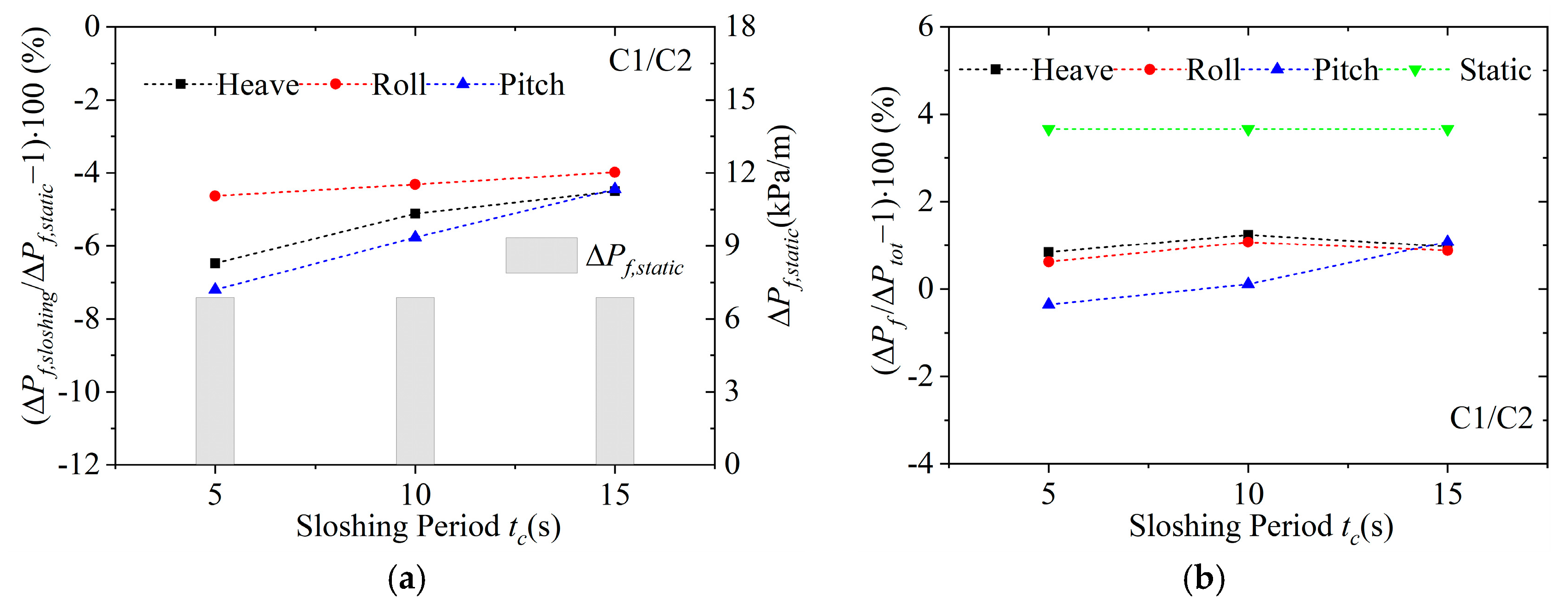

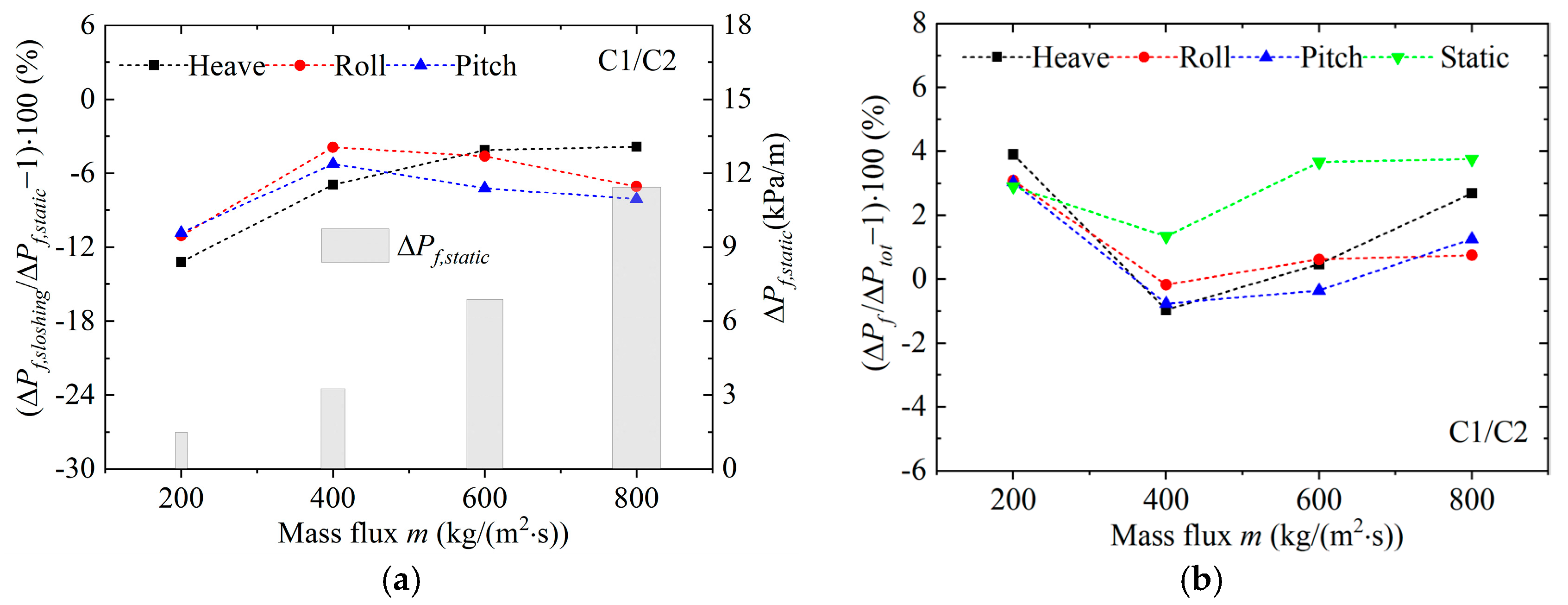

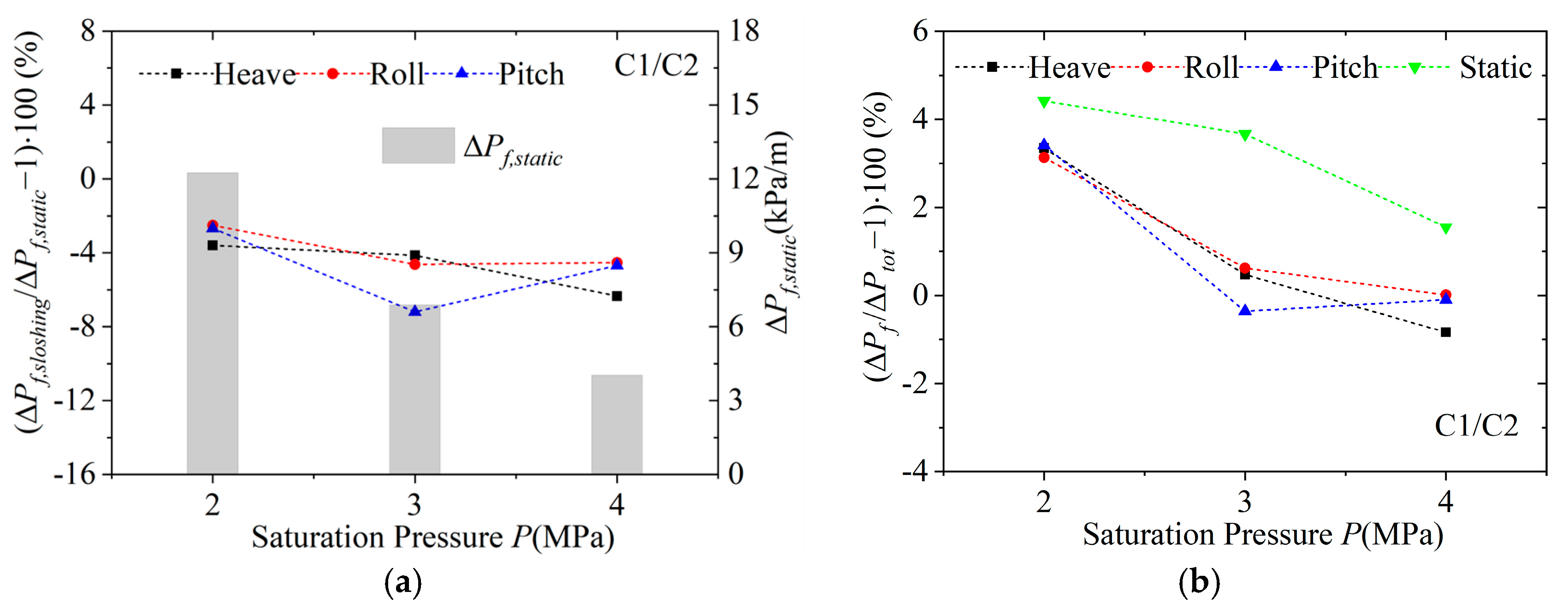

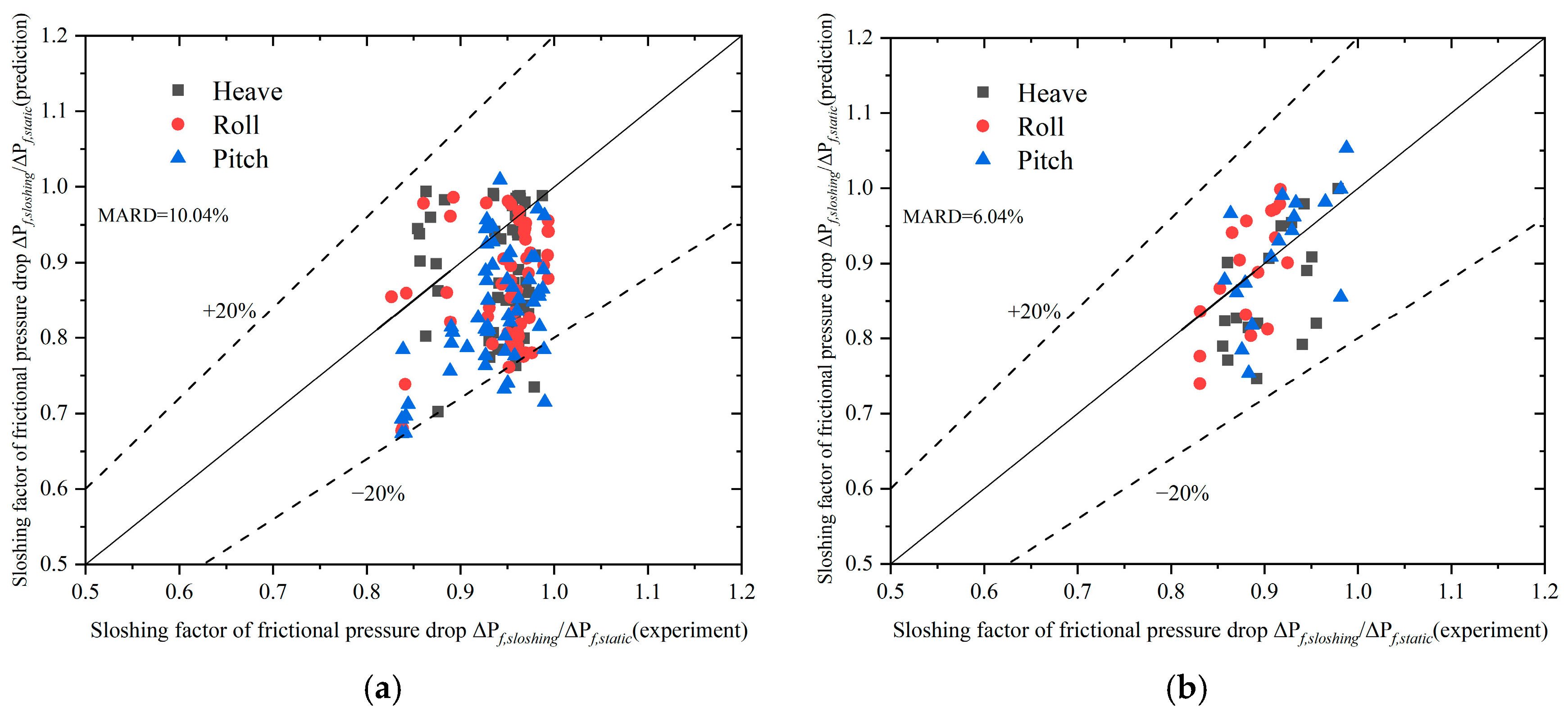

When SHE is utilized in the FLNG industry, the heat exchanger is subject to tilting, swaying, and fluctuation due to the influence of oceanic conditions. This can have a significant impact on the stability and internal flow of SHE, and the existing correlations of frictional pressure drop are inadequate in predicting the frictional pressure drop in the tube [

22]. To ensure the proper functioning of the equipment, it is necessary to conduct research on the two-phase flow characteristics under offshore conditions. Currently, there is limited research on the effect of offshore sloshing on the frictional pressure drop of two-phase flow in a spiral tube. Zhu et al. [

23] analyzed the uniform distribution characteristics in the plate-fin heat exchanger during sloshing conditions and found that sloshing reduces the uniform distribution of the flow. Yu et al. [

24] explored the impact of rolling on the flow characteristics of the working medium in a rectangular channel and concluded that the angular velocity of rolling was the most significant factor affecting the flow rate. Zhang et al. [

25] conducted a study on the impact of rolling motion on the frictional pressure drop of single-phase working medium in a horizontal tube, and developed a frictional factor to indicate the effect of rolling motion on the frictional pressure drop. Extensive research has been conducted on the classification of condensing two-phase flow patterns through the study of horizontal tube, inclined tube, and spiral tube, resulting in the development of various dimensionless numbers. While many scholars have studied the distribution [

26,

27,

28], flow pattern division [

29,

30,

31], and transformation criteria [

21,

32] of two-phase flow in the tube, research on the two-phase flow in the helical tube of mixed hydrocarbon refrigerant remains relatively scarce.

At present, the effect of offshore sloshing on the two-phase flow and pressure drop in the SHE for FLNG remains unclear. Given the operation characteristics of the FLNG unit, it is crucial to analyze the effect of operation and sloshing conditions on the condensation pressure drop of mixed hydrocarbon medium in spiral tubes. Through experimental analysis, the effects of operation and sloshing conditions on frictional pressure drop were quantitatively evaluated, providing valuable guidance for the study of condensation flow in this type of spiral tube.