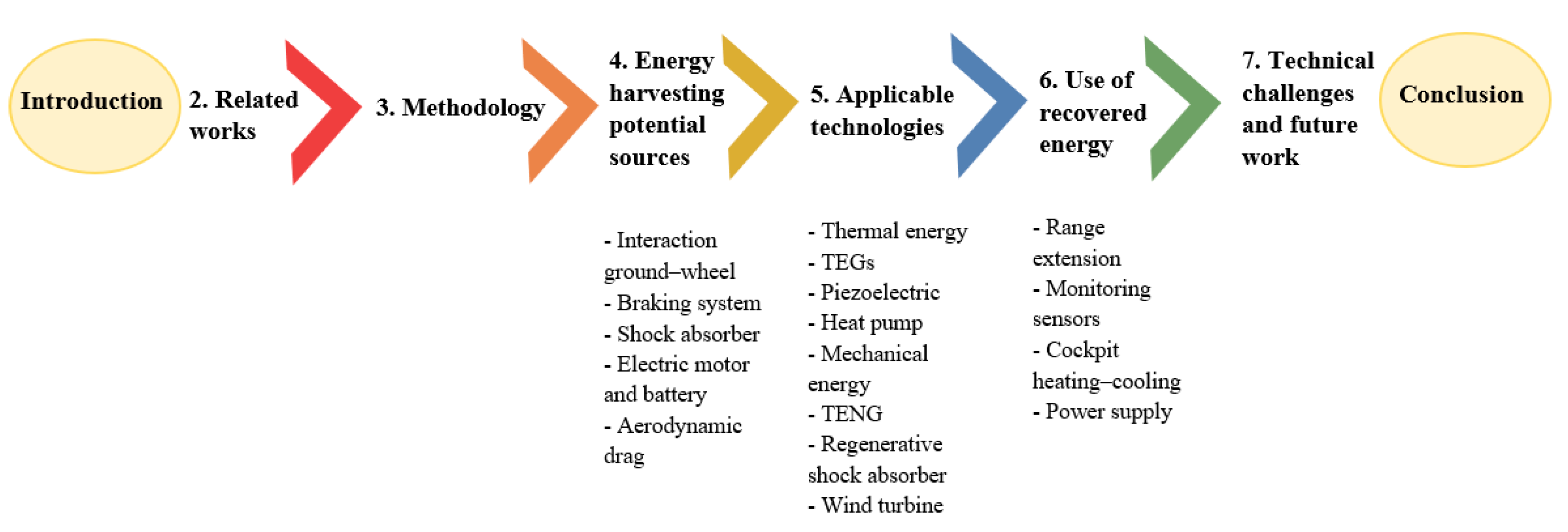

Overview of the Potential of Energy Harvesting Sources in Electric Vehicles

Abstract

1. Introduction

- Regenerative braking, suspension, and rolling energy generated during braking can be captured and stored in the vehicle’s battery.

- Kinetic energy recovery: energy from the motion of the vehicle which can be captured and stored.

- Waste heat recovery: energy from the heat generated by the vehicle powertrain and other systems which can be captured and reused to generate power.

2. Related Works

3. Methodology

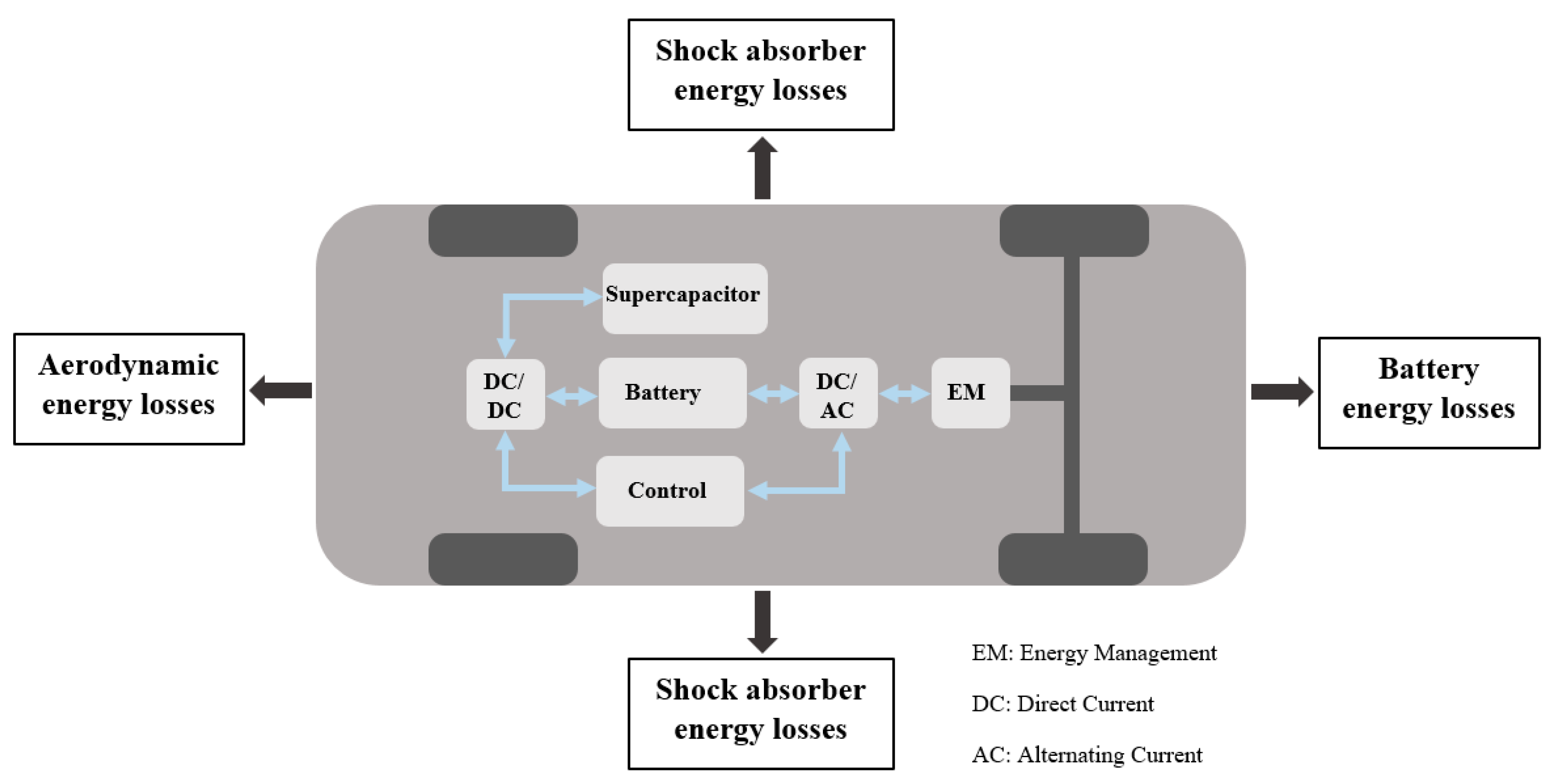

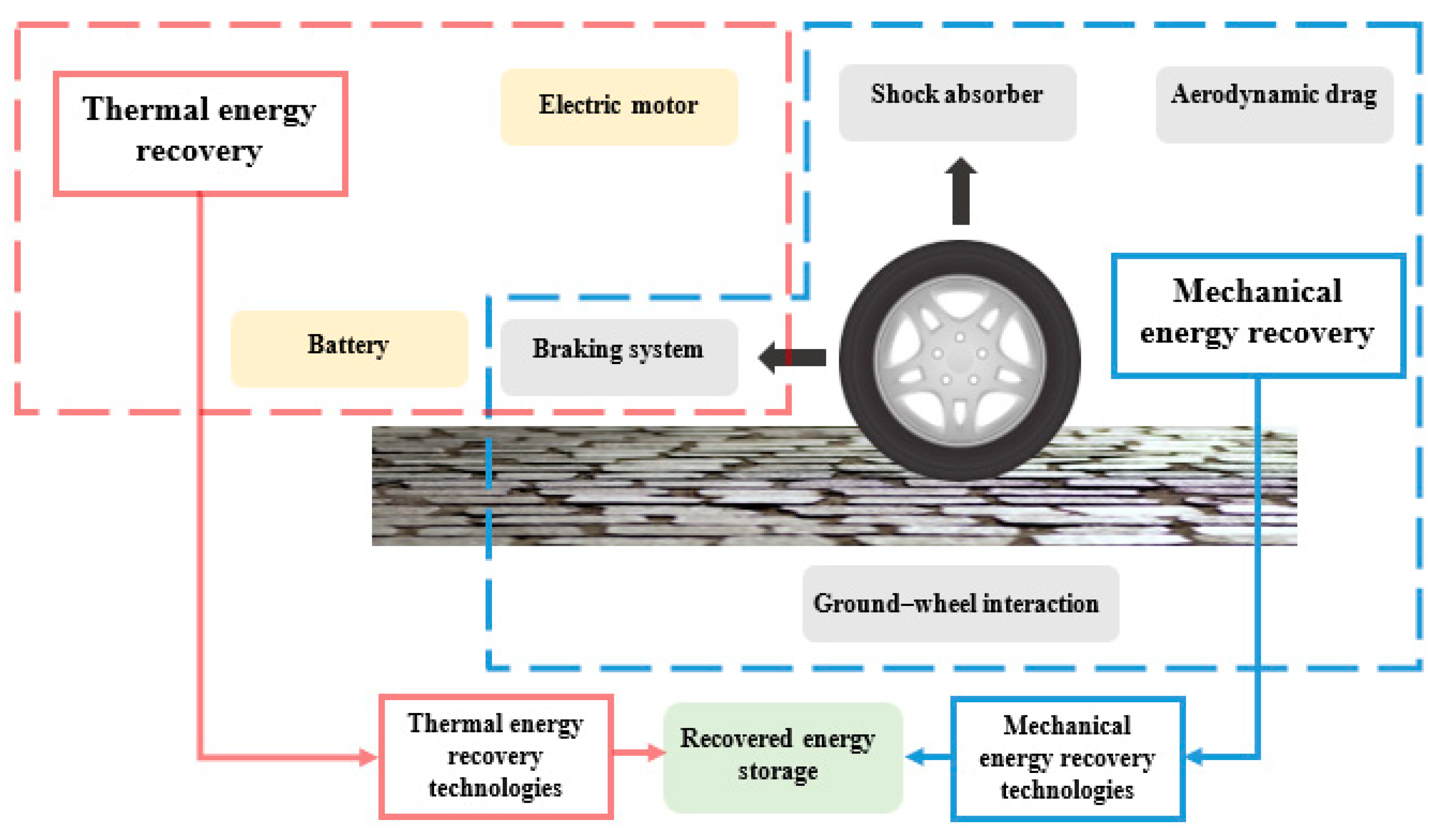

4. Potential Energy Sources

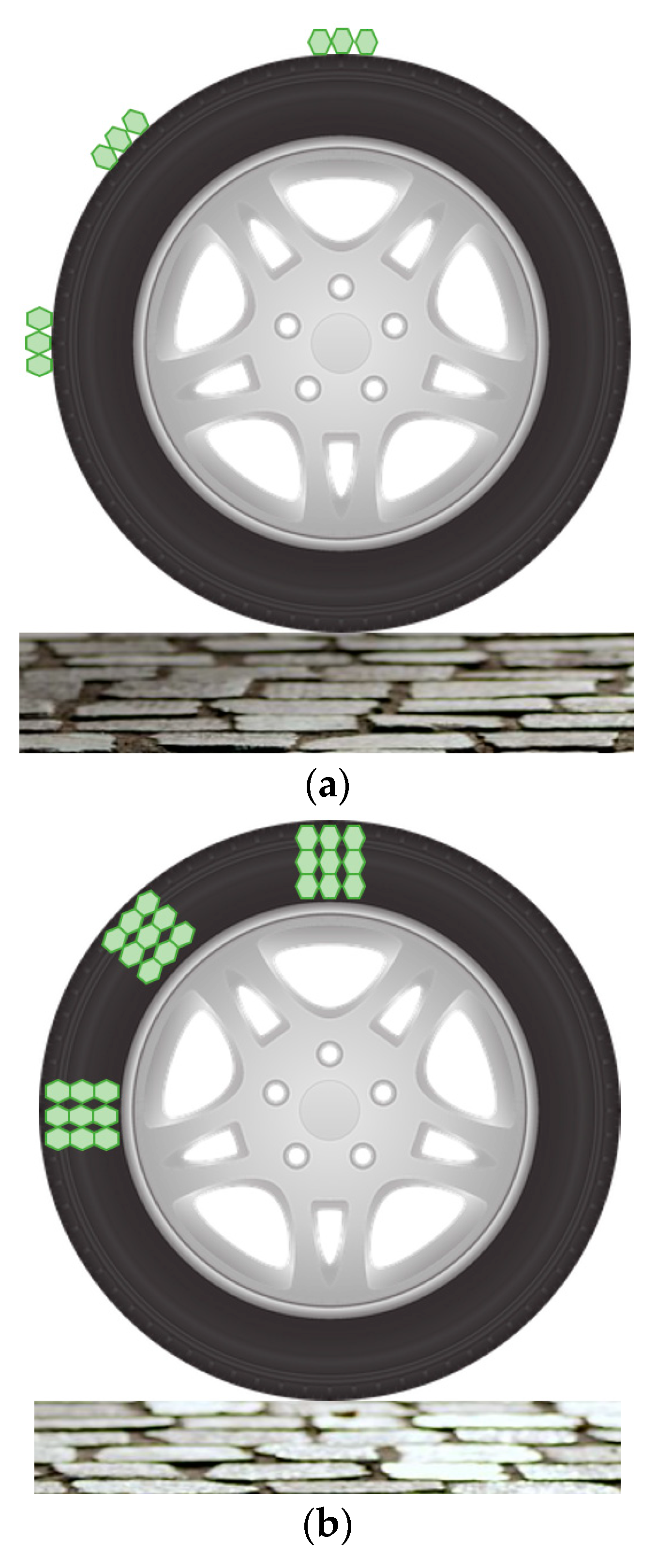

4.1. Interaction Ground–Wheel

4.2. Braking System

4.3. Shock Absorber

4.4. Electric Motor and Battery

4.5. Aerodynamic Drag Source

5. Applicable Technologies

5.1. Thermal Energy Recovery

5.2. Thermoelectric Generator Module (TEG)

5.3. Piezoelectric Transducer

5.4. Heat Pump (HP) and Positive Temperature Coefficient (PTC)

5.5. Mechanical Energy Recovery

5.6. Triboelectric Nanogenerator (TENG)

5.7. Regenerative Shock Absorber

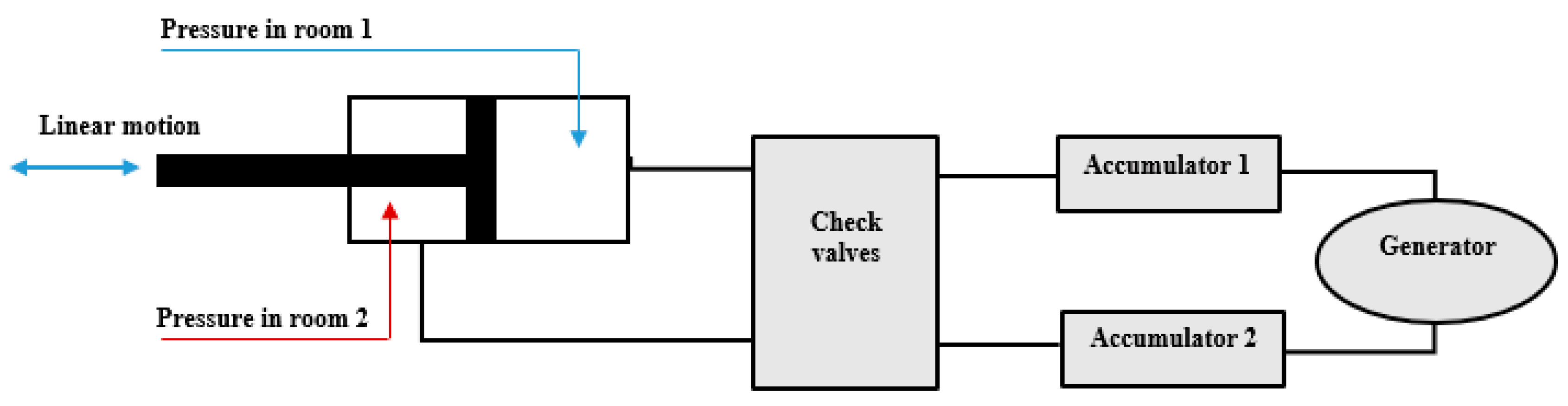

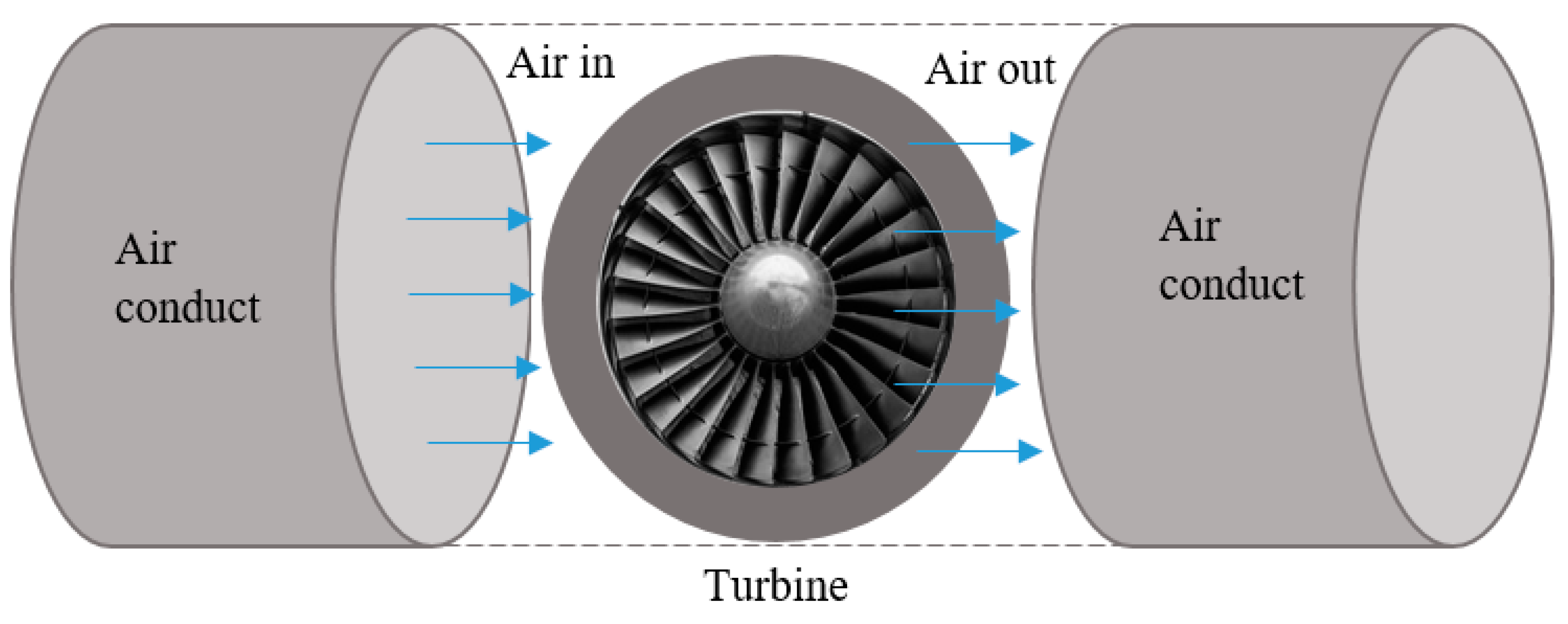

5.8. Wind Turbine

| References | Sources | Type of Energy | Harvesting Technologies | Efficiency Measurement | Experimental/Simulation |

|---|---|---|---|---|---|

| [17] | Ground–wheel interaction | Vibration | Triboelectric nanogenerator |

| Simulation |

| [66] | Ground–wheel interaction | Vibration | Triboelectric nanogenerator |

| Experimental |

| [67] | Ground–wheel interaction | Vibration | Triboelectric nanogenerator |

| Simulation and experimental |

| [68,69] | Aerodynamic drag | Vibration | Wind turbine |

| Simulation |

| [70] | Aerodynamic drag | Vibration | Piezoelectric transducer |

| Simulation and experimental |

| [74] | Shock absorber | Vibration | Piezoelectric transducer |

| Simulation |

| [72] | Shock absorber | Vibration | Mechanical type shock absorber |

| Experimental |

| [73] | Shock absorber | Vibration | Linear motor type shock absorber |

| Experimental |

| [76] | Braking system | Thermal | Pyroelectric material PZT |

| Simulation |

| [87] | Braking system | Electromagnetic | Faraday disc | Simulation | |

| [77] | Braking system | Thermal | Thermoelectric generator |

| Simulation |

| [31] | Braking system | Vibration | Triboelectric nanogenerator |

| Experimental |

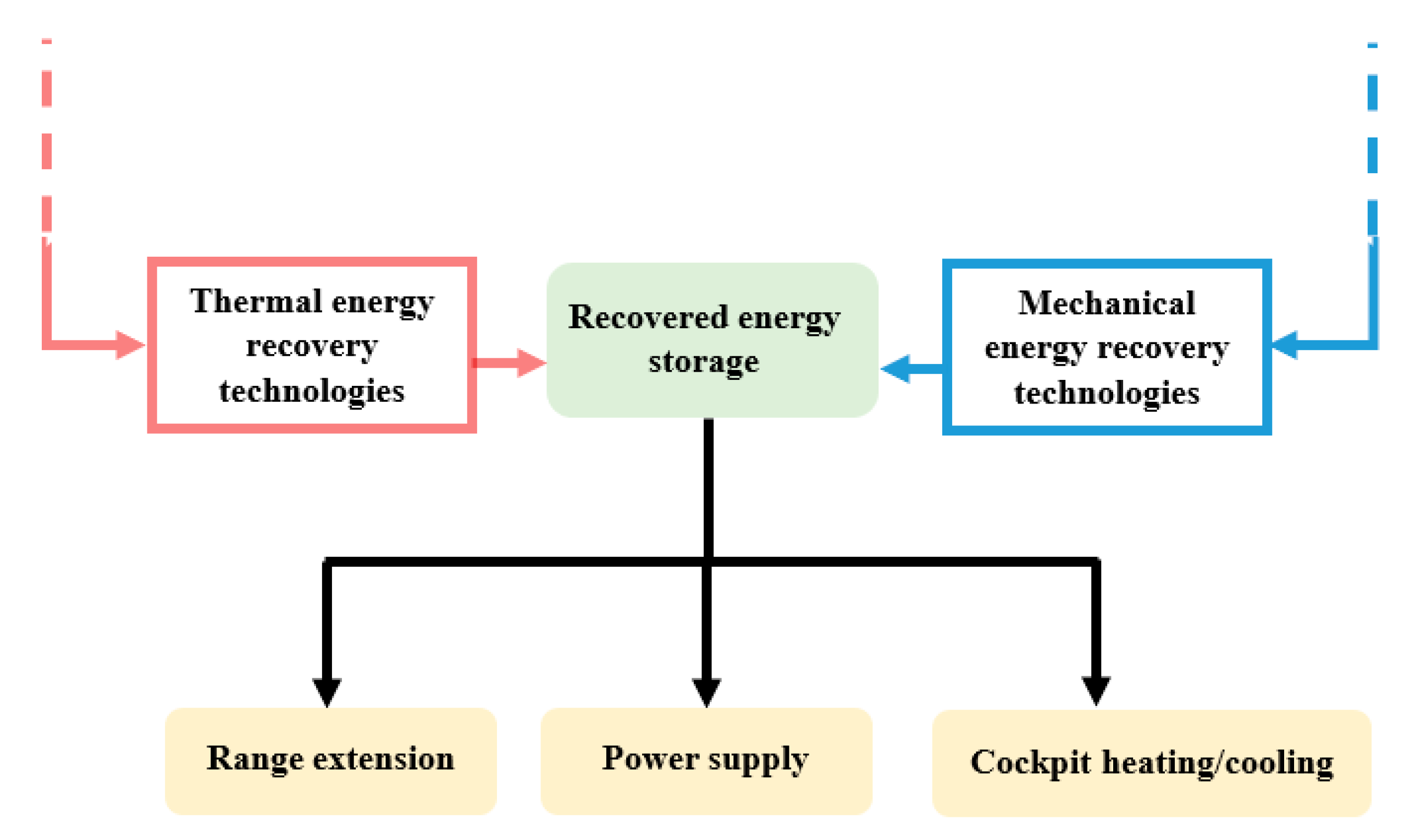

6. Use of Recovered Energy

- Increasing car kilometric range: Recovered energy can be used to extend the range of electric vehicles. This is especially helpful when the battery power is low and a boost is required.

- Battery recharge: The recovered energy can be used to fill the electric vehicle battery. This increases not only the range but also the battery lifespan.

- Improving car performance: The recovered energy can also be used to boost the performance of an electric vehicle. This involves boosting acceleration power and increasing maximum speed as well as reducing vehicle weight.

- Fuel efficiency: The recovered energy can be used to enhance the vehicle’s fuel efficiency. The use of fossil fuels is reduced by using recovered energy to power the car, resulting in lower emissions and a more sustainable future. The energy recovered from different sources in electric vehicles can be used in a variety of ways to improve vehicle overall efficiency and performance.

6.1. Range Extension

6.2. Monitoring Sensors

6.3. Cockpit Heating/Cooling

6.4. Power Supply for Low-Power Devices

7. Technical Challenges and Future Work

8. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alvarez-Diazcomas, A.; Estévez-Bén, A.A.; Rodríguez-Reséndiz, J.; Martínez-Prado, M.A.; Carrillo-Serrano, R.V.; Thenozhi, S. A Review of Battery Equalizer Circuits for Electric Vehicle Applications. Energies 2020, 13, 5688. [Google Scholar] [CrossRef]

- Alvarez-Diazcomas, A.; Rodríguez-Reséndiz, J.; Carrillo-Serrano, R.V. An Improved Battery Equalizer with Reduced Number of Components Applied to Electric Vehicles. Batteries 2023, 9, 65. [Google Scholar] [CrossRef]

- Bai, S.; Liu, C. Overview of energy harvesting and emission reduction technologies in hybrid electric vehicles. Renew. Sustain. Energy Rev. 2021, 147, 111188. [Google Scholar] [CrossRef]

- Hamada, A.T.; Orhan, M.F. An overview of regenerative braking systems. J. Energy Storage 2022, 52 Pt C, 105033. [Google Scholar] [CrossRef]

- US. Department of Energy. Where the Energy Goes: Electric Cars; Office of Energy Efficiency and Renewable Energy: Washington DC, USA, 2020.

- Buenaventura, A.G.; Azzopardi, B. Energy recovery systems for retrofitting in internal combustion engine vehicles: A review of techniques. Renew. Sustain. Energy Rev. 2015, 41, 955–964. [Google Scholar] [CrossRef]

- Zheng, P.; Wang, R.; Gao, J. A Comprehensive Review on Regenerative Shock Absorber Systems. J. Vib. Eng. Technol. 2020, 8, 225–246. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, X.; John, S. A Comprehensive Review of the Techniques on Regenerative Shock Absorber Systems. Energies 2018, 11, 1167. [Google Scholar] [CrossRef]

- Zheng, P.; Gao, J.; Wang, R.; Dong, J.; Diao, J. Review on the Research of Regenerative Shock Absorber. In Proceedings of the 24th International Conference on Automation and Computing (ICAC), Newcastle Upon Tyne, UK, 6–7 September 2018. [Google Scholar]

- Tiwari, S.; Singh, M.K.; Kumar, A. Regenerative Shock Absorber: Research Review. Int. J. Eng. Res. Technol. 2020, 9, 565–569. [Google Scholar]

- Wang, H.; Jasim, A.; Chen, X. Energy harvesting technologies in roadway and bridge for different applications—A comprehensive review. Appl. Energy 2018, 212, 1083–1094. [Google Scholar] [CrossRef]

- Gholikhani, M.; Roshani, H.; Dessouky, S.; Papagiannakis, A. A critical review of roadway energy harvesting technologies. Appl. Energy 2020, 261, 114388. [Google Scholar] [CrossRef]

- Bosso, N.; Magelli, M.; Zampieri, N. Application of low-power energy harvesting solutions in the railway field: A review. Veh. Syst. Dyn. 2020, 59, 841–871. [Google Scholar] [CrossRef]

- Pan, H.; Qi, L.; Zhang, Z.; Yan, J. Kinetic energy harvesting technologies for applications in land transportation: A comprehensive review. Appl. Energy 2021, 286, 116518. [Google Scholar] [CrossRef]

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A Review on Electric Vehicles: Technologies and Challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Farhadi, P.; Golmohammadi, A.; Malvajerdi, A.S.; Shahgholi, G. Tire and soil effects on power loss: Measurement and comparison with finite element model results. J. Terramechanics 2020, 92, 13–22. [Google Scholar] [CrossRef]

- Guo, T.; Liu, G.; Pang, Y.; Wu, B.; Xi, F.; Zhao, J.; Bu, T.; Fu, X.; Li, X.; Zhang, C. Compressible hexagonal-structured triboelectric nanogenerators for harvesting tire rotation energy. Extrem. Mech. Lett. 2018, 18, 1–8. [Google Scholar] [CrossRef]

- Belhocine, A.; Abdullah, O.I. Finite element analysis (FEA) of frictional contact phenomenon on vehicle braking system. Mech. Based Des. Struct. Mach. 2022, 50, 2961–2996. [Google Scholar] [CrossRef]

- Han, M.J.; Lee, C.H.; Park, T.W.; Park, J.M.; Son, S.M. Coupled thermo-mechanical analysis and shape optimization for reducing uneven wear of brake pads. Int. J. Automot. Technol. 2017, 18, 1027–1035. [Google Scholar] [CrossRef]

- Zum Hagen, F.H.F.; Mathissen, M.; Grabiec, T.; Hennicke, T.; Rettig, M.; Grochowicz, J.; Vogt, R.; Benter, T. Study of Brake Wear Particle Emissions: Impact of Braking and Cruising Conditions. Environ. Sci. Technol. 2019, 53, 5143–5150. [Google Scholar] [CrossRef]

- Liu, H.; Wen, C.; Yuen, A.C.Y.; Han, Y.; Cheung, S.C.-P.; Kook, S.; Yeoh, G.H. A novel thermal management system for battery packs in hybrid electrical vehicles utilising waste heat recovery. Int. J. Heat Mass Transf. 2022, 195, 123199. [Google Scholar] [CrossRef]

- Riva, G.; Perricone, G.; Wahlström, J. A Multi-Scale Simulation Approach to Investigate Local Contact Temperatures for Commercial Cu-Full and Cu-Free Brake Pads. Lubricants 2019, 7, 80. [Google Scholar] [CrossRef]

- Borawski, A. Simulation Study of the Process of Friction in the Working Elements of a Car Braking System at Different Degrees of Wear. Acta Mech. Autom. 2018, 12, 221–226. [Google Scholar] [CrossRef]

- Eriksson, M.; Bergman, F.; Jacobson, S. Surface Characterization of Brake Pads after Running Under Silent and Squealing Conditions. Wear 1999, 232, 163–167. [Google Scholar] [CrossRef]

- Ricciardi, V.; Travagliati, A.; Schreiber, V.; Klomp, M.; Ivanov, V.; Augsburg, K.; Faria, C. A Novel Semi-Empirical Dynamic Brake Model for Automotive Applications. Tribol. Int. 2020, 146, 106223. [Google Scholar] [CrossRef]

- Tauviqirrahman, M.; Muchammad, M.; Setiazi, T.; Setiyana, B.; Jamari, J. Analysis of the effect of ventilation hole angle and material variation on thermal behavior for car disc brakes using the finite element method. Results Eng. 2023, 17, 100844. [Google Scholar] [CrossRef]

- Borawski, A. Research in Impact of Cargo Vehicle Load Weight on Braking System Element Heating Process in Single Emergency Stopping. In Proceedings of the 19th International Scientific Conference Engineering for Rural Development, Latvia, Jelgava, 20–22 May 2020; pp. 578–584. [Google Scholar] [CrossRef]

- Polajnar, M.; Kalin, M.; Thorbjornsson, I.; Thorgrimsson, J.; Valle, N.; Botor-Probierz, A. Friction and wear performance of functionally graded ductile iron for brake pads. Wear 2017, 382–383, 85–94. [Google Scholar] [CrossRef]

- Belhocine, A.; Bouchetara, M. Thermomechanical modelling of dry contacts in automotive disc brake. Int. J. Therm. Sci. 2012, 60, 161–170. [Google Scholar] [CrossRef]

- Grzes, P. Maximum temperature of the disc during repeated braking applications. Adv. Mech. Eng. 2019, 11, 1687814019837826. [Google Scholar] [CrossRef]

- Han, C.B.; Du, W.; Zhang, C.; Tang, W.; Zhang, L.; Wang, Z.L. Harvesting energy from automobile brake in contact and non-contact mode by conjunction of triboelectrication and electrostatic-induction processes. Nano Energy 2014, 6, 59–65. [Google Scholar] [CrossRef]

- Wu, W.; Zhang, S.; Zhang, Z. Mathematical Simulations and On-Road Experimentations of the Vibration Energy Harvesting from Mining Dump Truck Hydro-Pneumatic Suspension. Shock Vib. 2019, 2019, 4814072. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, K.; Wang, D.; Chen, C.; Li, X. Energy conversion mechanism and regenerative potential of vehicle suspensions. Energy 2017, 119, 961–970. [Google Scholar] [CrossRef]

- Han, X.; Zou, H.; Tian, C.; Tang, M.; Yan, Y. Numerical study on the heating performance of a novel integrated thermal management system for the electric bus. Energy 2019, 186, 115812. [Google Scholar] [CrossRef]

- Ding, P.; Wang, Z.; Wang, Y.; Li, K. A distributed multiple-heat source staged heating method in an electric vehicle. Renew. Energy 2020, 150, 1010–1018. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. Novel thermal management system using boiling cooling for high-powered lithium-ion battery packs for hybrid electric vehicles. J. Power Sources 2017, 363, 291–303. [Google Scholar] [CrossRef]

- Zhang, Y.; Liang, F.; Li, S.; Zhang, C.; Zhang, S.; Liu, X.; Zhao, S.; Yang, S.; Xia, Y.; Lin, J.; et al. A review on battery thermal management and its digital improvement-based cyber hierarchy and interactional network. Int. J. Energy Res. 2022, 46, 11529–11555. [Google Scholar] [CrossRef]

- Ahn, J.H.; Kang, H.; Lee, H.S.; Jung, H.W.; Baek, C.; Kim, Y. Heating performance characteristics of a dual source heat pump using air and waste heat in electric vehicles. Appl. Energy 2014, 119, 1–9. [Google Scholar] [CrossRef]

- Maral, Y.; Aktas, M.; Erol, O.; Ongun, R.; Polat, F. An examination about thermal capacities of thermoelectric coolers in battery cooling systems. J. Eng. Res. 2017, 6, 703–710. [Google Scholar]

- Liu, Y.; Yang, S.; Guo, B.; Deng, C. Numerical analysis and design of thermal management system for lithium ion battery pack using thermoelectric coolers. Adv. Mech. Eng. 2014, 6, 852712. [Google Scholar] [CrossRef]

- Feng, L.; Zhou, S.; Li, Y.; Wang, Y.; Zhao, Q.; Luo, C.; Wang, G.; Yan, K. Experimental investigation of thermal and strain management for lithium-ion battery pack in heat pipe cooling. J. Energy Storage 2018, 16, 84–92. [Google Scholar] [CrossRef]

- Lan, C.; Xu, J.; Qiao, Y.; Ma, Y. Thermal management for high power lithium-ion battery by minichannel aluminum tubes. Appl. Therm. Eng. 2016, 101, 284–292. [Google Scholar] [CrossRef]

- Zou, H.; Wang, W.; Zhang, G.; Qin, F.; Tian, C.; Yan, Y. Experimental investigation on an integrated thermal management system with heat pipe heat exchanger for electric vehicle. Energy Convers. Manag. 2016, 118, 88–95. [Google Scholar] [CrossRef]

- Smith, J.; Hinterberger, M.; Schneider, C.; Koehler, J. Energy savings and increased electric vehicle range through improved battery thermal management. Appl. Therm. Eng. 2016, 101, 647–656. [Google Scholar] [CrossRef]

- Lyu, Y.; Siddique, A.; Majid, S.; Biglarbegian, M.; Gadsden, S.; Mahmud, S. Electric vehicle battery thermal management system with thermoelectric cooling. Energy Rep. 2019, 5, 822–827. [Google Scholar] [CrossRef]

- Wiriyasart, S.; Hommalee, C.; Sirikasemsuk, S.; Prurapark, R.; Naphon, P. Thermal management system with nanofluids for electric vehicle battery cooling modules. Case Stud. Therm. Eng. 2020, 18, 100583. [Google Scholar] [CrossRef]

- Liu, F.; Lan, F.; Chen, J. Dynamic thermal characteristics of heat pipe via segmented thermal resistance model for electric vehicle battery cooling. J. Power Sources 2016, 321, 57–70. [Google Scholar] [CrossRef]

- Hu, C.; Li, H.; Wang, Y.; Hu, X.; Tang, D. Experimental and numerical investigations of lithium-ion battery thermal management using flat heat pipe and phase change material. J. Energy Storage 2022, 55 Pt D, 105743. [Google Scholar] [CrossRef]

- Rao, Z.; Qian, Z.; Kuang, Y.; Li, Y. Thermal performance of liquid cooling based thermal management system for cylindrical lithium-ion battery module with variable contact surface. Appl. Therm. Eng. 2017, 123, 1514–1522. [Google Scholar] [CrossRef]

- Zhao, J.; Rao, Z.; Huo, Y.; Liu, X.; Li, Y. Thermal management of cylindrical power battery module for extending the life of new energy electric vehicles. Appl. Therm. Eng. 2015, 85, 33–43. [Google Scholar] [CrossRef]

- Tian, Z.; Gan, W.; Zhang, X.; Gu, B.; Yang, L. Investigation on an integrated thermal management system with battery cooling and motor waste heat recovery for electric vehicle. Appl. Therm. Eng. 2018, 136, 16–27. [Google Scholar] [CrossRef]

- Tian, Z.; Gu, B.; Gao, W.; Zhang, Y. Performance evaluation of an electric vehicle thermal management system with waste heat recovery. Appl. Therm. Eng. 2020, 169, 114976. [Google Scholar] [CrossRef]

- Huang, J.; Shoai Naini, S.; Miller, R.; Rizzo, D.; Sebeck, K.; Shurin, S.; Wagner, J. A Hybrid Electric Vehicle Motor Cooling System-Design, Model, and Control. IEEE Trans. Veh. Technol. 2019, 68, 4467–4478. [Google Scholar] [CrossRef]

- Sun, B.; Gao, S.; Ma, C.; Li, J. System power loss optimization of electric vehicle driven by front and rear induction motors. Int. J. Automot. Technol. 2018, 19, 121–134. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, C.; Liu, C.; Pong, P.W.T. Experimental Investigation of a Johnson Noise Thermometry Using GMR Sensor for Electric Vehicle Applications. IEEE Sens. J. 2018, 18, 3098–3107. [Google Scholar] [CrossRef]

- Chen, Q.; Yang, X. Calculation analysis of thermal loss and temperature field of in-wheel motor in micro-electric vehicle. J. Mech. Sci. Technol. 2014, 28, 3189–3195. [Google Scholar] [CrossRef]

- Huang, J.L.; Xuan, Y.; Zhang, L.; Liu, T.G. Analysis on the design and temperature field of switched reluctance motor for electric vehicle. J. Phys. Conf. Ser. 2021, 1777, 012001. [Google Scholar] [CrossRef]

- Li, L.; Zhu, G.; Zhao, Y.; Jia, N.; Xue, M.; Li, Y. Design and analysis of different cooling schemes of a flux-modulated permanent magnet in-wheel motor for electric vehicle applications. IET Electr. Power Appl. 2021, 15, 348–358. [Google Scholar] [CrossRef]

- Wang, X.; Li, B.; Gerada, D.; Huang, K.; Stone, I.; Worrall, S.; Yan, Y. A critical review on thermal management technologies for motors in electric cars. Appl. Therm. Eng. 2022, 201. (Part A). [Google Scholar] [CrossRef]

- Putra, N.; Ariantara, B. Electric motor thermal management system using L-shaped flat heat pipes. Appl. Therm. Eng. 2017, 126, 1156–1163. [Google Scholar] [CrossRef]

- Lee, K.-H.; Cha, H.-R.; Kim, Y.-B. Development of an interior permanent magnet motor through rotor cooling for electric vehicles. Appl. Therm. Eng. 2016, 95, 348–356. [Google Scholar] [CrossRef]

- Naini, S.S.; Miller, R.S.; Rizoo, D.; Wagner, J. A Model Reference Adaptive Controller for an Electric Motor Thermal Management System in Autonomous Vehicles. SAE Int. J. Electrified Veh. 2022, 12, 3–16. [Google Scholar] [CrossRef]

- Chen, Q.; Shao, H.; Huang, J.; Sun, H.; Xie, E.J. Analysis of Temperature Field and Water Cooling of Outer Rotor In-Wheel Motor for Electric Vehicle. IEEE Access 2019, 7, 140142–140151. [Google Scholar] [CrossRef]

- Gai, Y.; Kimiabeigi, M.; Chong, Y.C.; Widmer, J.D.; Deng, X.; Popescu, M.; Goss, J.; Staton, D.A.; Steven, A. Cooling of automotive traction motors: Schemes, examples, and computation methods. IEEE Trans. Ind. Electron. 2019, 66, 1681–1692. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, C. Oil-cooling method of the permanent magnet synchronous motor for electric vehicle. Energies 2019, 12, 2984. [Google Scholar] [CrossRef]

- Mao, Y.; Geng, D.; Liang, E.; Wang, X. Single-electrode triboelectric nanogenerator for scavenging friction energy from rolling tires. Nano Energy 2015, 15, 227–234. [Google Scholar] [CrossRef]

- Seung, W.; Yoon, H.; Kim, T.Y.; Kang, M.; Kim, J.; Kim, H.; Kim, S.M.; Kim, S. Dual Friction Mode Textile-Based Tire Cord Triboelectric Nanogenerator. Adv. Funct. Mater. 2020, 30, 2002401. [Google Scholar] [CrossRef]

- Huluka, A.W.; Kim, C.H. Numerical Study on Aerodynamic Drag Reduction and Energy Harvest for Electric Vehicle: A Concept to Extend Driving Range. IOP Conf. Ser. Mater. Sci. Eng. 2019, 700, 012009. [Google Scholar] [CrossRef]

- Jiang, H.; Li, A.; Ma, S.; Chen, L. Design and performance analysis of airflow energy recovery device of electric vehicle. J. Jiangsu Univ. Nat. Sci. Ed. 2017, 38, 125–132. [Google Scholar]

- Li, X.; Li, Z.; Bi, C.; Liu, B.; Su, Y. Study on wind energy harvesting effect of a vehicle-mounted piezo-electromagnetic hybrid energy harvester. IEEE Access 2020, 8, 167631–167646. [Google Scholar] [CrossRef]

- Iqbal, M.Y.; Wu, Z.; Tie, W.; Li, G.; Zhiyong, J.; GuiCheng, H. A High-Efficiency Energy Harvesting by Using Hydraulic Electromagnetic Regenerative Shock Absorber. Mech. Mach. Sci. 2021, 105, 276–294. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, T.; Zhang, Z.; Yuan, Y.; Liu, Y. A high-efficiency regenerative shock absorber considering twin ball screws transmissions for application in range-extended electric vehicles. Energy Built Environ. 2020, 1, 36–49. [Google Scholar] [CrossRef]

- Salman, W.; Qi, L.; Zhu, X.; Pan, H.; Zhang, X.; Bano, S.; Zhang, Z.; Yuan, Y. A high-efficiency energy regenerative shock absorber using helical gears for powering low-wattage electrical device of electric vehicles. Energy 2018, 159, 361–372. [Google Scholar] [CrossRef]

- Lafarge, B.; Grondel, S.; Delebarre, C.; Cattan, E. A validated simulation of energy harvesting with piezoelectric cantilever beams on a vehicle suspension using Bond Graph approach. Mechatronics 2018, 53, 202–214. [Google Scholar] [CrossRef]

- Morangueira, Y.L.; Pereira, J.C.D.C. Energy harvesting assessment with a coupled full car and piezoelectric model. Energy 2020, 210, 118668. [Google Scholar] [CrossRef]

- Tabbai, Y.; Alaoui-Belghiti, A.; El Moznine, R.; Belhora, F.; Hajjaji, A.; El Ballouti, A. Friction and wear performance of disc brake pads and pyroelectric energy harvesting. Int. J. Precis. Eng. Manuf. Technol. 2021, 8, 487–500. [Google Scholar] [CrossRef]

- Saqr, K.M.; Mansour, M.K.; Musa, M.N. Thermal design of automobile exhaust based thermoelectric generators: Objectives and challenges. Int. J. Automot. Technol. 2008, 9, 155–160. [Google Scholar] [CrossRef]

- Zoui, M.A.; Bentouba, S.; Velauthapillai, D.; Zioui, N.; Bourouis, M. Design and characterization of a novel finned tubular thermoelectric generator for waste heat recovery. Energy 2022, 253, 124083. [Google Scholar] [CrossRef]

- Choi, H.S.; Hur, S.; Kumar, A.; Song, H.; Baik, J.M.; Song, H.C.; Ryu, J. Continuous pyroelectric energy generation with cyclic magnetic phase transition for low-grade thermal energy harvesting. Appl. Energy 2023, 344, 121271. [Google Scholar] [CrossRef]

- Coulibaly, A.; Zioui, N.; Bentouba, S.; Kelouwani, S.; Bourouis, M. Use of thermoelectric generators to harvest energy from motor vehicle brake discs. Case Stud. Therm. Eng. 2021, 28, 101379. [Google Scholar] [CrossRef]

- Zioui, N.; Mahmoudi, A. Modal analysis and modelling approach for piezoelectric transducers based energy harvesting applications. Int. J. Model. Identif. Control 2020, 36, 304–314. [Google Scholar] [CrossRef]

- Zioui, N.; Djabali, A.; Toubal, L. Energy recovery using piezoelectric cells: A comparison of compression and flexure. Int. J. Mech. Mechatron. Eng. 2021, 21. [Google Scholar]

- Zioui, N.; Mahmoudi, A. Recovery of automotive vibrational energy by piezoelectric conversion: Comparison of transducer locations within a vehicle. Int. J. Mech. Mechatron. Eng. 2021, 21. [Google Scholar]

- Liu, C.; Zhang, Y.; Gao, T.; Shi, J.; Chen, J.; Wang, T.; Pan, L. Performance evaluation of propane heat pump system for electric vehicle in cold climate. Int. J. Refrig. 2018, 95, 51–60. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, D.; Zhang, C.; Chen, J. Electric vehicle range extension strategies based on improved AC system in cold climate—A review. Int. J. Refrig. 2018, 88, 141–150. [Google Scholar] [CrossRef]

- Tian, Z.; Gu, B. Analyses of an integrated thermal management system for electric vehicles. Int. J. Energy Res. 2019, 43, 5788–5802. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, S.C. Effects of geometric parameters and operating conditions on the performance of a high-voltage PTC heater for an electric vehicle. Appl. Therm. Eng. 2018, 143, 1023–1033. [Google Scholar] [CrossRef]

- Shin, Y.H.; Ahn, S.K.; Kim, S.C. Performance Characteristics of PTC Elements for an Electric Vehicle Heating System. Energies 2016, 9, 813. [Google Scholar] [CrossRef]

- Yu, B.; Yang, J.; Wang, D.; Shi, J.; Chen, J. Energy consumption and increased EV range evaluation through heat pump scenarios and low GWP refrigerants in the new test procedure WLTP. Int. J. Refrig. 2019, 100, 284–294. [Google Scholar] [CrossRef]

- Heo, D.; Chung, J.; Kim, B.; Yong, H.; Shin, G.; Cho, J.-W.; Kim, D.; Lee, S. Triboelectric speed bump as a self-powered automobile warning and velocity sensor. Nano Energy 2020, 72, 104719. [Google Scholar] [CrossRef]

- Aksu, U.; Halicioglu, R. A review study on energy harvesting systems for vehicles. Teh. Glas. 2018, 12, 251–259. [Google Scholar] [CrossRef]

- Tu, R.; Gai, Y.J.; Farooq, B.; Posen, D.; Hatzopoulou, M. Electric vehicle charging optimization to minimize marginal greenhouse gas emissions from power generation. Appl. Energy 2020, 277, 115517. [Google Scholar] [CrossRef]

- Barcellona, S.; Piegari, L.; Villa, A. Passive hybrid energy storage system for electric vehicles at very low temperatures. J. Energy Storage 2019, 25, 100833. [Google Scholar] [CrossRef]

- Pan, Y.; Zuo, L.; Ahmadian, M. A half-wave electromagnetic energy-harvesting tie towards safe and intelligent rail transportation. Appl. Energy 2022, 313, 118844. [Google Scholar] [CrossRef]

| References | Sources | Temperature or Amount of Energy Available | Energy Type | Experimental/ Simulation | Targeted Application |

|---|---|---|---|---|---|

| [17] | Ground–wheel interaction | Vibration energy | Simulation | Energy harvesting | |

| [66] | Ground–wheel interaction | Vibration energy | Experimental | Energy harvesting | |

| [67] | Ground–wheel interaction | Vibration energy | Simulation and experimental | Energy harvesting | |

| [68,69] | Aerodynamic drag | Vibration energy | Simulation | Energy harvesting | |

| [70] | Aerodynamic drag | Vibration energy | Simulation and experimental | Energy harvesting | |

| [71,72,73,74] | Shock absorber | Vibration energy | Experimental | Energy harvesting | |

| [75] | Shock absorber | Vibration energy | Simulation | Energy harvesting | |

| [76,77] | Braking system | [30 °C; 300 °C] | Thermal energy | Simulation | Energy harvesting |

| [31] | Braking system | Vibration energy | Experimental | Energy harvesting | |

| [34,35] | Battery | <40 °C | Thermal energy | Experimental | Energy management |

| [36,41] | Battery | <40 °C | Thermal energy | Simulation | Energy management |

| [42] | Battery | [40 °C; 60 °C] | Thermal energy | Simulation | Energy management and harvesting |

| [43] | Battery | [40 °C; 60 °C] | Thermal energy | Experimental | Energy management and harvesting |

| [50] | Battery | >60 °C | Thermal energy | Simulation | Energy management and harvesting |

| [51] | Battery | >60 °C | Thermal energy | Experimental | Energy management and harvesting |

| [52] | Electric motor | <50 °C | Thermal energy | Simulation | Energy management and harvesting |

| [53] | Electric motor | [50 °C; 100 °C] | Thermal energy | Simulation | Energy management |

| [54] | Electric motor | [50 °C; 100 °C] | Thermal energy | Experimental | Energy management |

| [60,61] | Electric motor | >100 °C | Thermal energy | Simulation | Energy management |

| Technology | Disadvantages | Advantages |

|---|---|---|

| TEG | Low output performance Conversion efficiency low | Continuous energy recuperation Faster engine warm-up |

| Heat pump and PTC | Performance dependence on outdoor temperatures and the need for additional heating in very cold weather | Rapid heating and low energy consumption |

| Piezoelectric | Transducer array and high cost for high energy output | Use for both energy harvesting and sensors |

| Wind turbine | Installation in the vehicle and dependent on topography, weather, and environment | No power source required and does not degrade air quality |

| Regenerative shock absorber | Easy to retrofit and no space or significant weight added | Best results for heavy and off-road vehicles |

| TENG | Low durability High frictional damage | High efficiency at low frequency; low cost, low density, light weight |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bentouba, S.; Zioui, N.; Breuhaus, P.; Bourouis, M. Overview of the Potential of Energy Harvesting Sources in Electric Vehicles. Energies 2023, 16, 5193. https://doi.org/10.3390/en16135193

Bentouba S, Zioui N, Breuhaus P, Bourouis M. Overview of the Potential of Energy Harvesting Sources in Electric Vehicles. Energies. 2023; 16(13):5193. https://doi.org/10.3390/en16135193

Chicago/Turabian StyleBentouba, Said, Nadjet Zioui, Peter Breuhaus, and Mahmoud Bourouis. 2023. "Overview of the Potential of Energy Harvesting Sources in Electric Vehicles" Energies 16, no. 13: 5193. https://doi.org/10.3390/en16135193

APA StyleBentouba, S., Zioui, N., Breuhaus, P., & Bourouis, M. (2023). Overview of the Potential of Energy Harvesting Sources in Electric Vehicles. Energies, 16(13), 5193. https://doi.org/10.3390/en16135193