The Acoustic Characteristics of Tectonically Deformed Coal in Huaibei Coalfield

Abstract

1. Introduction

2. Geological Background

2.1. Geological Setting

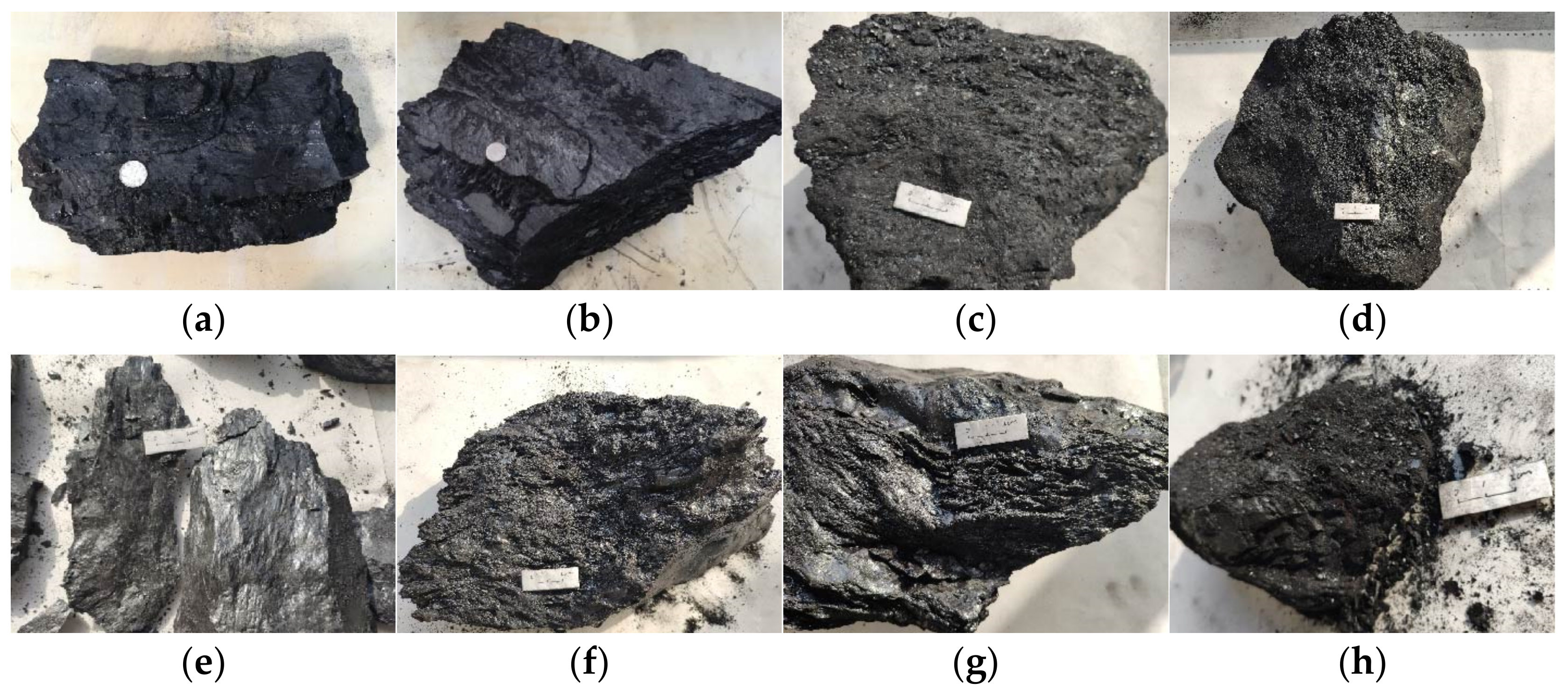

2.2. Core Sampling and Preparation

3. Core Testing

3.1. Testing Method

3.2. Testing Result

4. Discussion

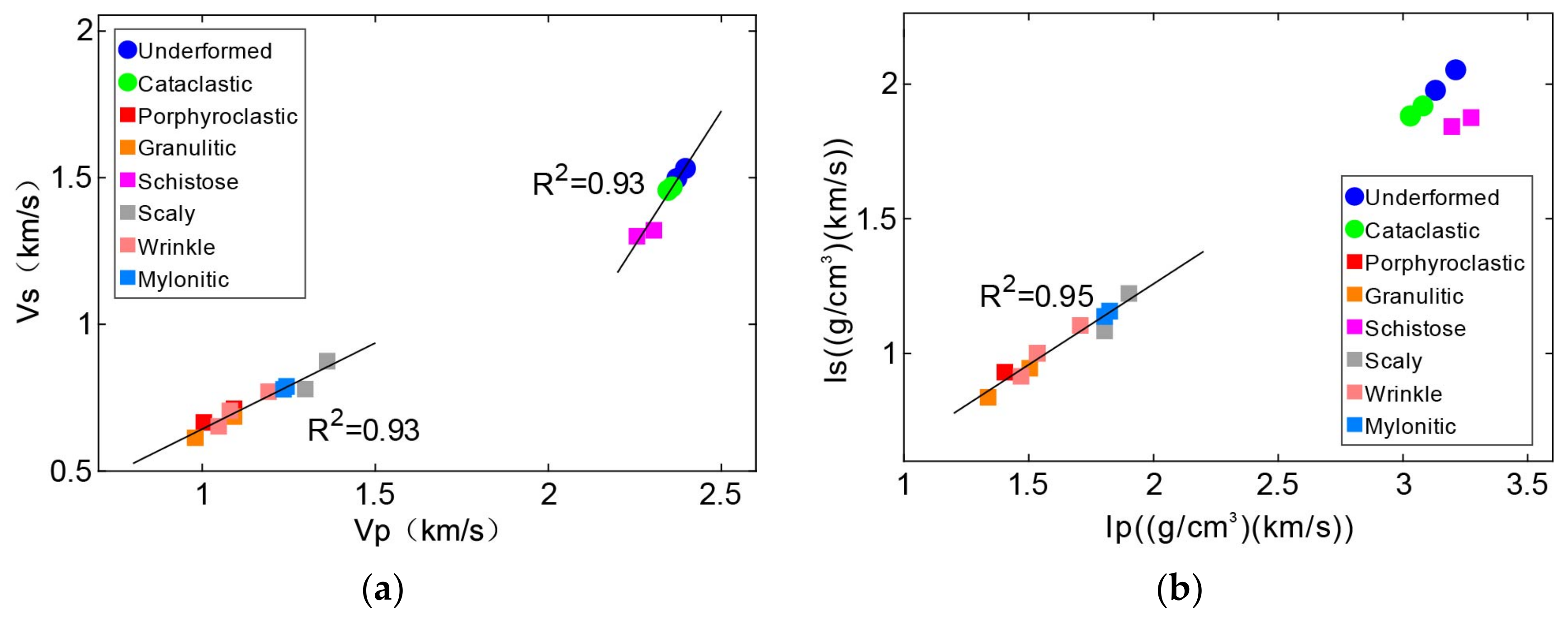

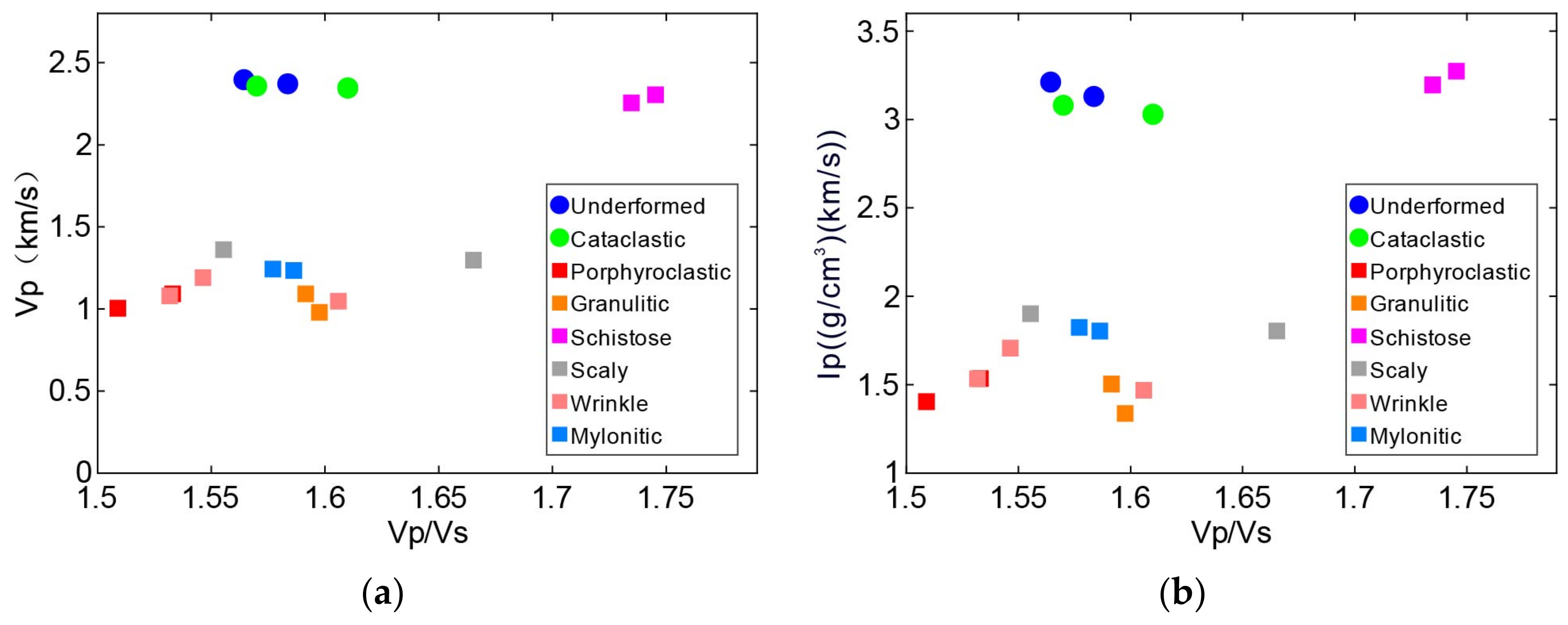

4.1. Regularity in Cross Plots

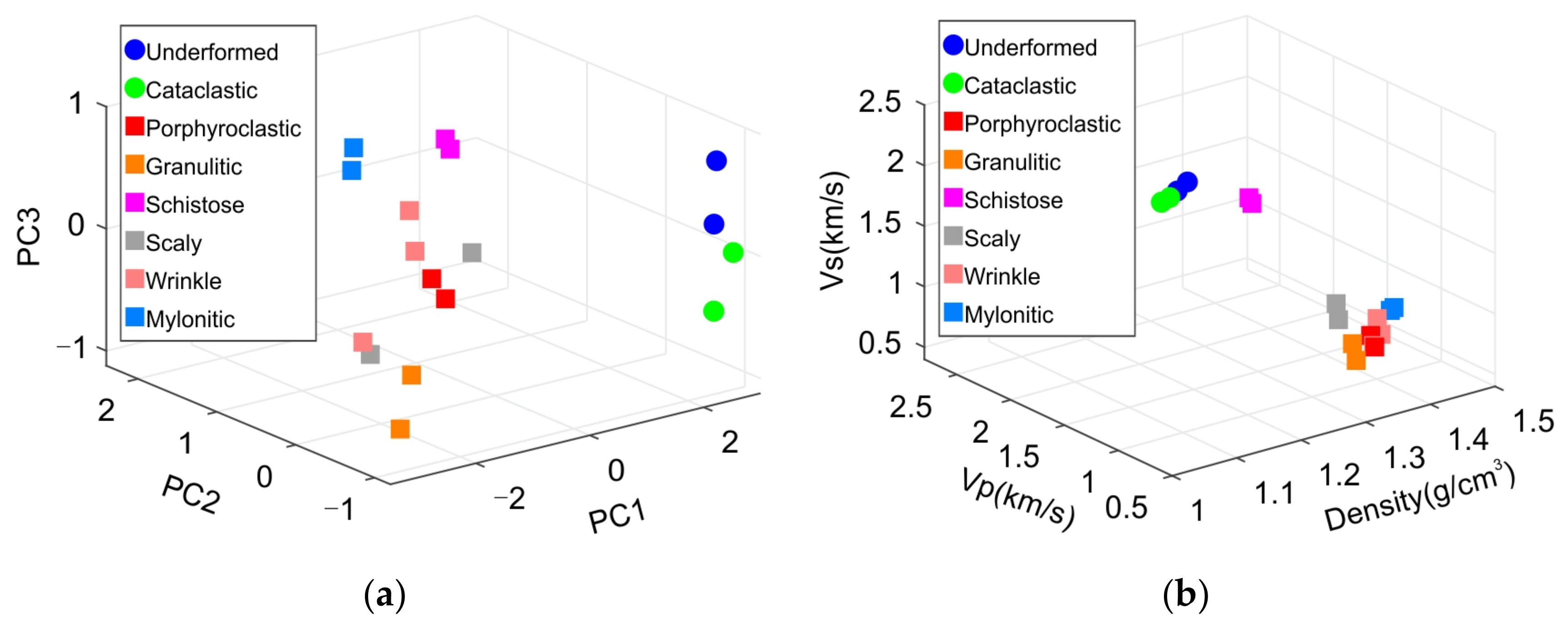

4.2. Information Redundancy among Petrophysical Parameters

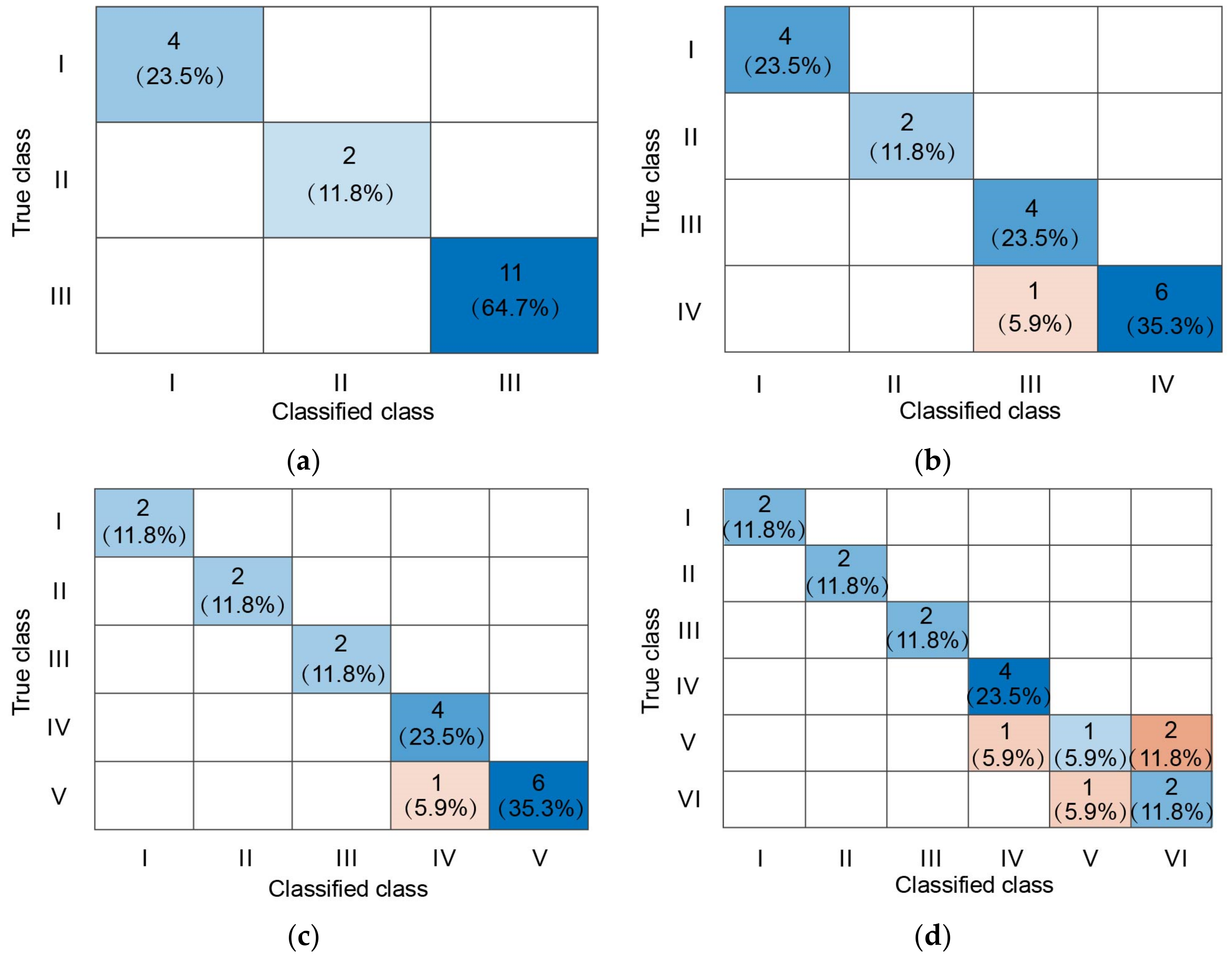

4.3. Identification and Classification for TDCs

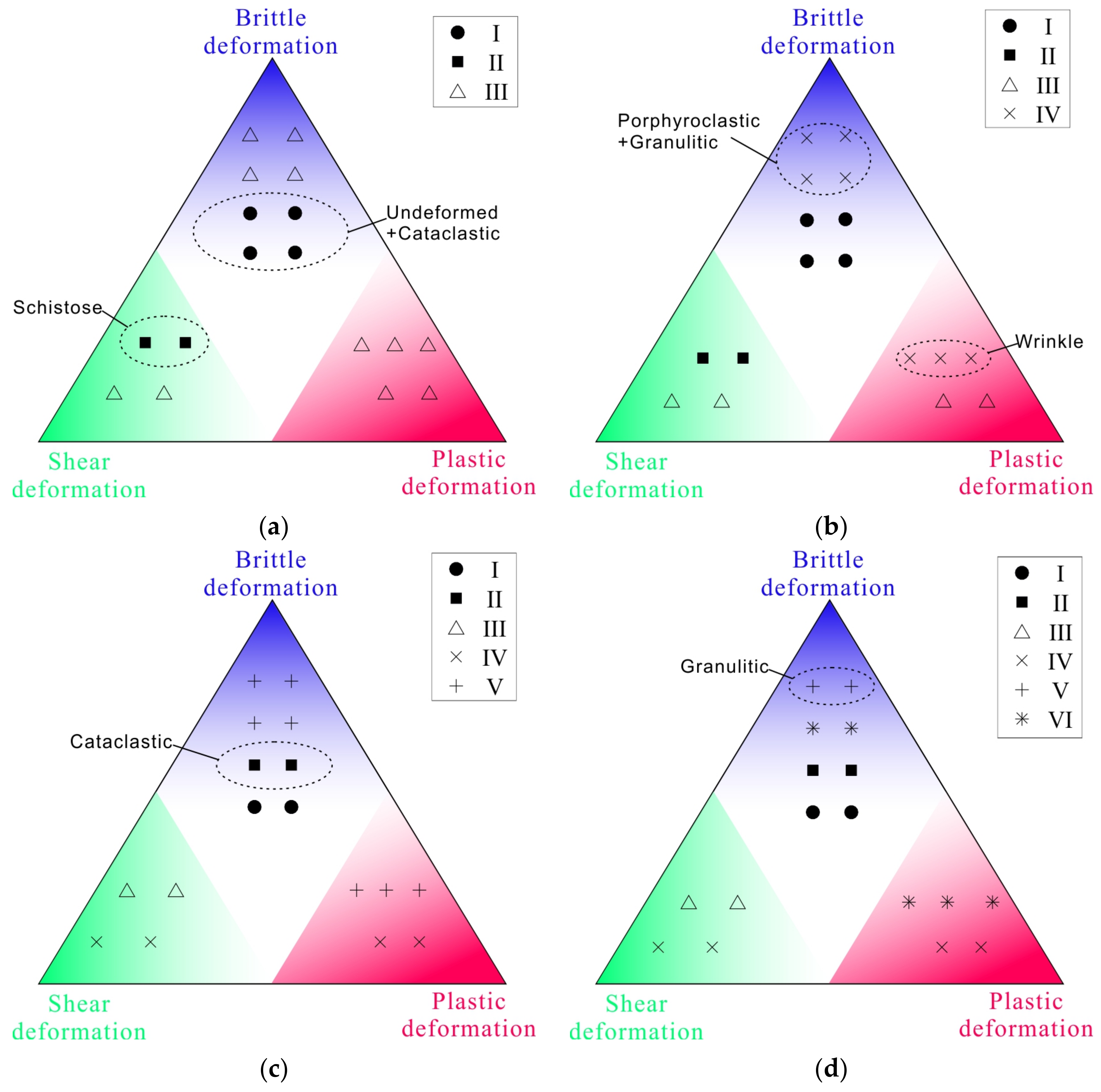

4.4. Correlations between TDC Classifications and Deformation Environments

5. Conclusions

- (1)

- A total of 17 samples of full types of coal (undeformed coal and seven of TDCs) were collected from the Huaibei coalfield, and their petrophysical parameters, including velocities, VP/VS ratio, density, and impedances, were measured accordingly in the laboratory. The VP and VS of dry samples show a small frequency effect, and the experimental results of ultrasonic testing can be comparable to the results of the seismic frequency range. The research results can provide physical parameter guidance for the geophysical exploration of TDCs;

- (2)

- The scatter points of coal samples in the cross plots of VP vs. VS and IP vs. IS have the characteristics of regular partition distributions. Undeformed coal and weak-deformed TDCs have higher velocities/impedances, but strong-deformed TDCs have lower velocities/impedances. P-wave velocity and S-wave velocity show good correlation associations in both regions;

- (3)

- Undeformed coal and TDCs with different deformation types (brittle, shear, and plastic deformations) show significant differences in their petrophysical parameters, and one can differentiate them with cross-plot analysis. Instead of direct classification, this paper proposed a method incorporating principal component and cluster analysis to classify coal samples. The method can accurately distinguish coal samples into at least five types. From the clustering results, different deformation environments and the intensity of deformation can help distinguish different coal deformation types. It provides a theoretical basis for the classification of coal deformation types;

- (4)

- For the strong-deformed TDCs, the proposed method can only roughly classify the coal samples into two classes due to their similar petrophysical parameters. Namely, scaly and mylonite coals belong to one class, and granulitic, porphyroclastic, and wrinkle coals belong to another;

- (5)

- As coal mining in many parts of the world is gradually moving to structurally complex areas, the risks of TDC-related coal-and-gas outbursts occur increasingly. Therefore, this classification schema can be a reference for distinguishing and classifying undeformed coal and TDCs in the future. Moreover, this work will be important for coal mining safety and coalbed methane production.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, B.; Ju, Y.W. Tectonic coal structure and its petrophysical features. Nat. Gas Ind. 2004, 24, 27–29. [Google Scholar]

- Frodsham, K.; Gayer, R.A. The impact of tectonic deformation upon coal seams in the South Wales coalfield, UK. Int. J. Coal Geol. 1999, 38, 297–332. [Google Scholar] [CrossRef]

- Schweinfurth, S.P. Coal: A complex natural resource: An overview of factors affecting coal quality and use in the United States. US Geol. Surv. Circ. 2002, 1–39. [Google Scholar] [CrossRef]

- Ju, Y.W.; Jiang, B.; Hou, Q.L.; Wang, G.L. New structure-genetic classification system in tectonically deformed coals and its geological significance. Meitan Xuebao/J. China Coal Soc. 2004, 29, 513. [Google Scholar]

- Draper, J.J.; Boreham, C.J. Geological controls on exploitable coal seam gas distribution in Queensland. Appea J. 2006, 46, 343–366. [Google Scholar] [CrossRef]

- Cheng, Y.; Pan, Z. Reservoir properties of Chinese tectonic coal: A review. Fuel 2020, 260, 116350. [Google Scholar] [CrossRef]

- Lu, J.; Wang, Y.; Chen, J.Y. Detection of Tectonically Deformed Coal Using Model-Based Joint Inversion of Multi-Component Seismic Data. Energies 2018, 11, 17. [Google Scholar] [CrossRef]

- Chen, L. Effects of tectonic stress environment on tectonophysical features of deformed coal. Int. J. Green Energy 2019, 16, 185–199. [Google Scholar] [CrossRef]

- Jiang, B.; Qu, Z.; Wang, G.G.X.; Li, M. Effects of structural deformation on formation of coalbed methane reservoirs in Huaibei coalfield, China. Int. J. Coal Geol. 2010, 82, 175–183. [Google Scholar] [CrossRef]

- Qu, Z.; Wang, G.G.X.; Jiang, B.; Rudolph, V.; Dou, X.; Li, M. Experimental Study on the Porous Structure and Compressibility of Tectonized Coals. Energy Fuels 2010, 24, 2964–2973. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.D. Modelling of anisotropic coal swelling and its impact on permeability behaviour for primary and enhanced coalbed methane recovery. Int. J. Coal Geol. 2011, 85, 257–267. [Google Scholar] [CrossRef]

- Song, Y.; Jiang, B.; Li, M.; Hou, C.; Xu, S. A review on pore-fractures in tectonically deformed coals. Fuel 2020, 278, 118248. [Google Scholar] [CrossRef]

- Song, Y.; Jiang, B.; Han, Y. Macromolecular response to tectonic deformation in low-rank tectonically deformed coals (TDCs). Fuel 2018, 219, 279–287. [Google Scholar] [CrossRef]

- Jiang, B.; Qin, Y.; Ju, Y.W.; Wang, J.Y. Research on tectonic stress field of generate and reservoir of coalbed methane. Zhongguo Kuangye Daxue Xuebao/J. China Univ. Min. Technol. 2005, 34, 564–569. [Google Scholar]

- Meng, Z.; Zhang, J.; Wang, R. In-situ stress, pore pressure and stress-dependent permeability in the Southern Qinshui Basin. Int. J. Rock Mech. Min. Sci. 2011, 48, 122–131. [Google Scholar] [CrossRef]

- Mosher, K.; He, J.; Liu, Y.; Rupp, E.; Wilcox, J. Molecular simulation of methane adsorption in micro- and mesoporous carbons with applications to coal and gas shale systems. Int. J. Coal Geol. 2013, 109–110, 36–44. [Google Scholar] [CrossRef]

- Li, W.; Jiang, B.; Zhu, Y.-M. Impact of tectonic deformation on coal methane adsorption capacity. Adsorpt. Sci. Technol. 2019, 37, 698–708. [Google Scholar] [CrossRef]

- Lu, G.; Wei, C.; Wang, J.; Meng, R.; Soh Tamehe, L. Influence of pore structure and surface free energy on the contents of adsorbed and free methane in tectonically deformed coal. Fuel 2021, 285, 119087. [Google Scholar] [CrossRef]

- Pan, J.; Zhu, H.; Hou, Q.; Wang, H.; Wang, S. Macromolecular and pore structures of Chinese tectonically deformed coal studied by atomic force microscopy. Fuel 2015, 139, 94–101. [Google Scholar] [CrossRef]

- Fengli, L.; Bo, J.; Guoxi, C.; Yu, S.; Zheng, T. Structural and evolutionary characteristics of pores-microfractures and their influence on coalbed methane exploitation in high-rank brittle tectonically deformed coals of the Yangquan mining area, northeastern Qinshui basin, China. J. Pet. Sci. Eng. 2019, 174, 1290–1302. [Google Scholar] [CrossRef]

- Cheng, G.; Jiang, B.; Li, M.; Li, F.; Song, Y. Effects of pore-fracture structure of ductile tectonically deformed coals on their permeability: An experimental study based on raw coal cores. J. Pet. Sci. Eng. 2020, 193, 107371. [Google Scholar] [CrossRef]

- Ren, J.; Song, Z.; Li, B.; Liu, J.; Lv, R.; Liu, G. Structure feature and evolution mechanism of pores in different metamorphism and deformation coals. Fuel 2021, 283, 119292. [Google Scholar] [CrossRef]

- Hou, X.; Zhou, X.; Pan, J. Similar Material Proportioning and Preparation of Ductile Surrounding Rocks for Simulating In Situ Coalbed methane Production from Tectonically Deformed Coals. Rock Mech. Rock Eng. 2022, 55, 5377–5392. [Google Scholar] [CrossRef]

- Avseth, P.; Mukerji, T.; Mavko, G. Quantitative Seismic Interpretation: Applying Rock Physics Tools to Reduce Interpretation Risk; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2005. [Google Scholar]

- Mavko, G.; Mukerji, T.; Dvorkin, J. The Rock Physics Handbook: Tools for Seismic Analysis of Porous Media; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Bosch, M.; Mukerji, T.; Gonzalez, E.F. Seismic inversion for reservoir properties combining statistical rock physics and geostatistics: A review. Geophysics 2010, 75, A165–A176. [Google Scholar] [CrossRef]

- Li, H.; Lin, B.; Yang, W.; Zheng, C.; Hong, Y.; Gao, Y.; Liu, T.; Wu, S. Experimental study on the petrophysical variation of different rank coals with microwave treatment. Int. J. Coal Geol. 2016, 154–155, 82–91. [Google Scholar] [CrossRef]

- Li, J.J.; Pan, D.M.; Cui, R.F.; Ding, E.J.; Zhang, W.; Hu, M.S. Prediction of tectonically deformed coal based on lithologic seismic information. J. Geophys. Eng. 2016, 13, 116–122. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, D.; Cai, Y.; Li, X. Variation of petrophysical properties and adsorption capacity in different rank coals: An experimental study of coals from the Junggar, Ordos and Qinshui Basins in China. Energies 2019, 12, 986. [Google Scholar] [CrossRef]

- Jia, Q.; Liu, D.; Cai, Y.; Fang, X.; Li, L. Petrophysics characteristics of coalbed methane reservoir: A comprehensive review. Front. Earth Sci. 2021, 15, 202–223. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, D.; Yin, J.; Zhou, X.; Li, Y.; Chi, P.; Han, Y.; Ansari, U.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-bearing Sediment in Northern South China Sea by Horizontal Wellbore: Evolution and Mechanism. Nat. Resour. Res. 2023, 32, 1595–1620. [Google Scholar] [CrossRef]

- Wang, F.; Liu, X.; Jiang, B.; Zhuo, H.; Chen, W.; Chen, Y.; Li, X. Low-loading Pt nanoparticles combined with the atomically dispersed FeN4 sites supported by FeSA-N-C for improved activity and stability towards oxygen reduction reaction/hydrogen evolution reaction in acid and alkaline media. J. Colloid Interface Sci. 2023, 635, 514–523. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, C.; Yang, Y.; Ansari, U.; Han, Y.; Li, X.; Cheng, Y. Preliminary experimental investigation on long-term fracture conductivity for evaluating the feasibility and efficiency of fracturing operation in offshore hydrate-bearing sediments. Ocean. Eng. 2023, 281, 114949. [Google Scholar] [CrossRef]

- Morcote, A.; Mavko, G.; Prasad, M. Dynamic elastic properties of coal. Geophysics 2010, 75, E227–E234. [Google Scholar] [CrossRef]

- Lwin, M.J. The effect of different gases on the ultrasonic response of coal. Geophysics 2011, 76, E155–E163. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, X.; Yang, D. Ultrasonic elastic characteristics of five kinds of metamorphic deformed coals under room temperature and pressure conditions. Sci. China Earth Sci. 2014, 57, 2208–2216. [Google Scholar] [CrossRef]

- Wu, H.; Dong, S.; Li, D.; Huang, Y.; Qi, X. Experimental study on dynamic elastic parameters of coal samples. Int. J. Min. Sci. Technol. 2015, 25, 447–452. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, B.; Chen, T.; Xu, S.; Zhu, G. Experimental study on ultrasonic velocity and anisotropy of tectonically deformed coal. Int. J. Coal Geol. 2017, 179, 242–252. [Google Scholar] [CrossRef]

- Cai, W.; Dou, L.M.; Cao, A.Y.; Gong, S.Y.; Li, Z.L. Application of seismic velocity tomography in underground coal mines: A case study of Yima mining area, Henan, China. J. Appl. Geophys. 2014, 109, 140–149. [Google Scholar] [CrossRef]

- Barrash, W.; Morin, R.H. Recognition of units in coarse, unconsolidated braided-stream deposits from geophysical log data with principal components analysis. Geology 1997, 25, 687–690. [Google Scholar] [CrossRef]

- Ren, P.; Xu, H.; Tang, D.; Li, Y.; Sun, C.; Tao, S.; Li, S.; Xin, F.; Cao, L. The identification of coal texture in different rank coal reservoirs by using geophysical logging data in northwest Guizhou, China: Investigation by principal component analysis. Fuel 2018, 230, 258–265. [Google Scholar] [CrossRef]

- Li, W.; Chen, T.; Song, X.; Gong, T.; Liu, M. Reconstruction of critical coalbed methane logs with principal component regression model: A case study. Energy Explor. Exploit. 2020, 38, 1178–1193. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Xue, S.; Zhang, K.; Xu, H.; Fang, H.; Jia, J. Insight into difference in high-pressure adsorption-desorption of CO2 and CH4 from low permeability coal seam of Huainan-Huaibei coalfield, China. J. Environ. Chem. Eng. 2022, 10, 108846. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, B.; Qu, Z. Controls on migration and aggregation for tectonically sensitive elements in tectonically deformed coal: An example from the Haizi mine, Huaibei coalfield, China. Sci. China Earth Sci. 2014, 57, 1180–1191. [Google Scholar] [CrossRef]

- Lu, G.; Wei, C.; Wang, J.; Zhang, J.; Quan, F.; Tamehe, L.S. Variation of surface free energy in the process of methane adsorption in the nanopores of tectonically deformed coals: A case study of middle-rank tectonically deformed coals in the huaibei coalfield. Energy Fuels 2019, 33, 7155–7165. [Google Scholar] [CrossRef]

- Dong, J.; Cheng, Y.-P.; Chang, T.-Y.; Zhang, J.-J.; Guo, S.-F. Coal mine methane control cost and full cost: The case of the Luling Coal Mine, Huaibei coalfield, China. J. Nat. Gas Sci. Eng. 2015, 26, 290–302. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, G.; Wang, L.; Chou, C.-L. Composition and quality of coals in the Huaibei Coalfield, Anhui, China. J. Geochem. Explor. 2008, 97, 59–68. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, G.; Qi, C.; Zhang, Y.; Wong, M. The use of sequential extraction to determine the distribution and modes of occurrence of mercury in Permian Huaibei coal, Anhui Province, China. Int. J. Coal Geol. 2008, 73, 139–155. [Google Scholar] [CrossRef]

- GB482-1995; Sampling of Coal in Seam. China State Bureau of Technical Supervision: Beijing, China, 1995.

- Birch, F. The velocity of compressional waves in rocks to 10 kilobars: 1. J. Geophys. Res. (1896–1977) 1960, 65, 1083–1102. [Google Scholar] [CrossRef]

- Greenhalgh, S.A.; Emerson, D.W. Elastic Properties of Coal Measure Rocks New South Wales. Explor. Geophys. 1986, 17, 157–163. [Google Scholar] [CrossRef]

- Tatham, R.H. Vp Vs and lithology. Geophysics 1982, 47, 336–344. [Google Scholar] [CrossRef]

- Dumitrescu, C.C.; Lines, L. Heavy oil reservoir characterization using Vp/Vs ratios from multicomponent data. In Proceedings of the 69th EAGE Conference and Exhibition Incorporating SPE EUROPEC, London, UK, 11–14 June 2007. [Google Scholar]

- Bhowmick, S. Role of Vp/Vs and Poisson’s Ratio in the Assessment of Foundation(s) for Important Civil Structure(s). Geotech. Geol. Eng. 2017, 35, 527–534. [Google Scholar] [CrossRef]

- Li, Y.; Grevemeyer, I.; Huang, H.; Qiu, X.; Murray-Bergquist, L. Crustal Compositional Variations From Continental to Oceanic Domain: A VP/VS Ratio Study Across the Zhongsha Block, South China Sea. J. Geophys. Res. Solid Earth 2022, 127, e2021JB023470. [Google Scholar] [CrossRef]

- Yuan, Y.; Liu, Y.; Zhang, J.; Wei, X.; Chen, T. Reservoir prediction using multi-wave seismic attributes. Earthq. Sci. 2011, 24, 373–389. [Google Scholar] [CrossRef]

- Huang, B.; Xu, R.; Fu, C.; Wang, Y.; Wang, L. Thief Zone Assessment in Sandstone Reservoirs Based on Multi-Layer Weighted Principal Component Analysis. Energies 2018, 11, 1274. [Google Scholar] [CrossRef]

- Machart, P.; Ralaivola, L. Confusion Matrix Stability Bounds for Multiclass Classification. Comput. Sci. 2012. [Google Scholar] [CrossRef]

- Deng, X.; Liu, Q.; Deng, Y.; Mahadevan, S. An improved method to construct basic probability assignment based on the confusion matrix for classification problem. Inf. Sci. 2016, 340–341, 250–261. [Google Scholar] [CrossRef]

- Kalkreuth, W.D.; Marchioni, D.L.; Calder, J.H.; Lamberson, M.N.; Naylor, R.D.; Paul, J. The relationship between coal petrography and depositional environments from selected coal basins in Canada. Int. J. Coal Geol. 1991, 19, 21–76. [Google Scholar] [CrossRef]

- Wang, K.; Pang, X.; Zhang, H.; Hu, T.; Xu, T.; Zheng, T.; Zhang, X. Organic geochemical and petrophysical characteristics of saline lacustrine shale in the Dongpu Depression, Bohai Bay Basin, China: Implications for Es3 hydrocarbon exploration. J. Pet. Sci. Eng. 2020, 184, 106546. [Google Scholar] [CrossRef]

- Burton, Z.F.M.; McHargue, T.; Kremer, C.H.; Bloch, R.B.; Gooley, J.T.; Jaikla, C.; Harrington, J.; Graham, S.A. Peak Cenozoic warmth enabled deep-sea sand deposition. Sci. Rep. 2023, 13, 1276. [Google Scholar] [CrossRef]

- Radke, M.; Schaefer, R.G.; Leythaeuser, D.; Teichmüller, M. Composition of soluble organic matter in coals: Relation to rank and liptinite fluorescence. Geochim. Cosmochim. Acta 1980, 44, 1787–1800. [Google Scholar] [CrossRef]

- Cook, A.C.; Sherwood, N.R. Classification of oil shales, coals and other organic-rich rocks. Org. Geochem. 1991, 17, 211–222. [Google Scholar] [CrossRef]

- Burton, Z.F.M. Sediment Organic Contents Required for Gas Hydrate Formation: A Survey of Published Basin and Hydrocarbon System Models. Fuels 2022, 3, 580–587. [Google Scholar] [CrossRef]

- Song, W.; Yao, J.; Li, Y.; Yang, Y.; Sun, H. New pore size distribution calculation model based on chord length and digital image. J. Nat. Gas Sci. Eng. 2017, 48, 111–118. [Google Scholar] [CrossRef]

- Hou, S.; Wang, X.; Wang, X.; Yuan, Y.; Pan, S.; Wang, X. Pore structure characterizeation of low volatile bituminous coals with different particle size and tectonic deformation using low pressure gas adsorption. Int. J. Coal Geol. 2017, 183, 13. [Google Scholar] [CrossRef]

- Wang, Z. Fundamentals of seismic rock physics. Geophysics 2001, 66, 398–412. [Google Scholar] [CrossRef]

| Coalmine | Deformation Order | Main Deformation | Coal Type | Measurable Cores |

|---|---|---|---|---|

| Luling | Undeformed | Primary | Undeformed coal | 2 |

| Brittle deformation | Brittle deformation environment | Cataclastic coal | 2 | |

| Zhuxianzhuang | Porphyroclastic coal | 2 | ||

| Granulitic coal | 2 | |||

| Shear deformation environment | Schistose coal | 2 | ||

| Brittle–ductile deformation | Scaly coal | 2 | ||

| Ductile deformation | Plastic deformation environment | Wrinkle coal | 3 | |

| Mylonitic coal | 2 |

| No. | TDC Type | VP (km/s) | VS (km/s) | VP/VS Ratio | Density (g/cm3) | IP (g/cm3)(km/s) | IS (g/cm3)(km/s) |

|---|---|---|---|---|---|---|---|

| 1 | Underformed | 2.37 | 1.50 | 1.58 | 1.29 | 3.13 | 1.98 |

| 2 | Underformed | 2.40 | 1.53 | 1.56 | 1.34 | 3.21 | 2.05 |

| 3 | Cataclastic | 2.36 | 1.47 | 1.57 | 1.32 | 3.08 | 1.92 |

| 4 | Cataclastic | 2.35 | 1.46 | 1.61 | 1.30 | 3.03 | 1.88 |

| 5 | Porphyroclasticic | 1.00 | 0.67 | 1.51 | 1.33 | 1.40 | 0.93 |

| 6 | Porphyroclastic | 1.09 | 0.71 | 1.53 | 1.30 | 1.53 | 1.00 |

| 7 | Granulitic | 1.09 | 0.69 | 1.59 | 1.30 | 1.50 | 0.95 |

| 8 | Granulitic | 0.98 | 0.61 | 1.60 | 1.29 | 1.34 | 0.84 |

| 9 | Schistose | 2.26 | 1.30 | 1.73 | 1.30 | 3.20 | 1.84 |

| 10 | Schistose | 2.31 | 1.32 | 1.75 | 1.30 | 3.27 | 1.88 |

| 11 | Scaly | 1.36 | 0.87 | 1.56 | 1.40 | 1.90 | 1.22 |

| 12 | Scaly | 1.30 | 0.78 | 1.67 | 1.40 | 1.80 | 1.08 |

| 13 | Wrinkle | 1.05 | 0.65 | 1.61 | 1.38 | 1.47 | 0.91 |

| 14 | Wrinkle | 1.19 | 0.77 | 1.55 | 1.41 | 1.71 | 1.10 |

| 15 | Wrinkle | 1.08 | 0.70 | 1.53 | 1.40 | 1.53 | 1.00 |

| 16 | Mylonitic | 1.24 | 0.79 | 1.58 | 1.40 | 1.82 | 1.16 |

| 17 | Mylonitic | 1.24 | 0.78 | 1.59 | 1.40 | 1.80 | 1.14 |

| Correlation | VP | VS | VP/VS | den | Ip | Is |

|---|---|---|---|---|---|---|

| VP | 1.00 | |||||

| VS | 0.99 | 1.00 | ||||

| VP/VS | 0.45 | 0.35 | 1.00 | |||

| den | −0.63 | −0.67 | 0.03 | 1.00 | ||

| Ip | 0.99 | 0.98 | 0.50 | −0.55 | 1.00 | |

| Is | 1.00 | 0.99 | 0.40 | −0.59 | 0.99 | 1.00 |

| PCs | Eigenvalues | Variance Contributions (%) | Cumulative Contributions (%) |

|---|---|---|---|

| PC1 | 4.589 | 76.48 | 76.48 |

| PC2 | 1.050 | 17.49 | 93.98 |

| PC3 | 0.360 | 6.00 | 99.98 |

| PC4 | 0.001 | 0.02 | 99.99 |

| PC5 | 3.41 × 10−4 | 0.01 | 100.00 |

| PC6 | 1.32 × 10−7 | 0.00 | 100.00 |

| Parameters | PC1 | PC2 | PC3 | PC4 | PC5 | PC6 |

|---|---|---|---|---|---|---|

| VP | 0.47 | 0.01 | 0.12 | 0.30 | 0.65 | −0.51 |

| VS | 0.46 | −0.09 | 0.17 | −0.60 | 0.33 | 0.53 |

| VP/VS | 0.22 | 0.80 | −0.54 | −0.12 | −0.02 | 0.00 |

| Density | −0.31 | 0.58 | 0.74 | −0.05 | 0.11 | 0.00 |

| IP | 0.46 | 0.10 | 0.20 | 0.65 | −0.29 | 0.48 |

| IS | 0.46 | −0.01 | 0.27 | −0.33 | −0.61 | −0.48 |

| Classes | Class Definition | Deformation Environment | Accuracy |

|---|---|---|---|

| 3 | I Undeformed, Cataclastic II Schistose III Scaly, Mylonitic, Granulitic, Porphyroclastic, Wrinkle | Primary and brittle Shear Brittle, shear, and plastic | 100% |

| 4 | I Undeformed, Cataclastic II Schistose III Scaly, Mylonitic IV Granulitic, Porphyroclastic, Wrinkle | Primary and brittle Shear Shear and plastic Brittle and plastic | 94.1% |

| 5 | I Undeformed II Cataclastic III Schistose IV Scaly, Mylonitic V Granulitic, Porphyroclastic, Wrinkle | Primary Brittle Shear Shear and plastic Brittle and plastic | 94.1% |

| 6 | I Undeformed II Cataclastic III Schistose IV Scaly, Mylonitic V Granulitic VI Porphyroclastic, Wrinkle | Primary Brittle Shear Shear and plastic Brittle Brittle and plastic | 76.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, X.; Chen, T.; Zhang, D. The Acoustic Characteristics of Tectonically Deformed Coal in Huaibei Coalfield. Energies 2023, 16, 5179. https://doi.org/10.3390/en16135179

Song X, Chen T, Zhang D. The Acoustic Characteristics of Tectonically Deformed Coal in Huaibei Coalfield. Energies. 2023; 16(13):5179. https://doi.org/10.3390/en16135179

Chicago/Turabian StyleSong, Xiong, Tongjun Chen, and Dengliang Zhang. 2023. "The Acoustic Characteristics of Tectonically Deformed Coal in Huaibei Coalfield" Energies 16, no. 13: 5179. https://doi.org/10.3390/en16135179

APA StyleSong, X., Chen, T., & Zhang, D. (2023). The Acoustic Characteristics of Tectonically Deformed Coal in Huaibei Coalfield. Energies, 16(13), 5179. https://doi.org/10.3390/en16135179