A Data-Driven Approach for Generator Load Prediction in Shipboard Microgrid: The Chemical Tanker Case Study

Abstract

1. Introduction

- First, this paper attempts to perform load generator prediction for a chemical tanker in two case studies, namely, single load generator prediction for each generator in the ship and total load generator prediction for the total load. The prediction for the single load generator will assist the ship operator with pre-planning for an unexpected event due to the real issues raised by one malfunctioning generator during a voyage. Meanwhile, total load generator prediction can prevent large operational failures that might cause severe disruptions of the voyage and big losses to shipping lines.

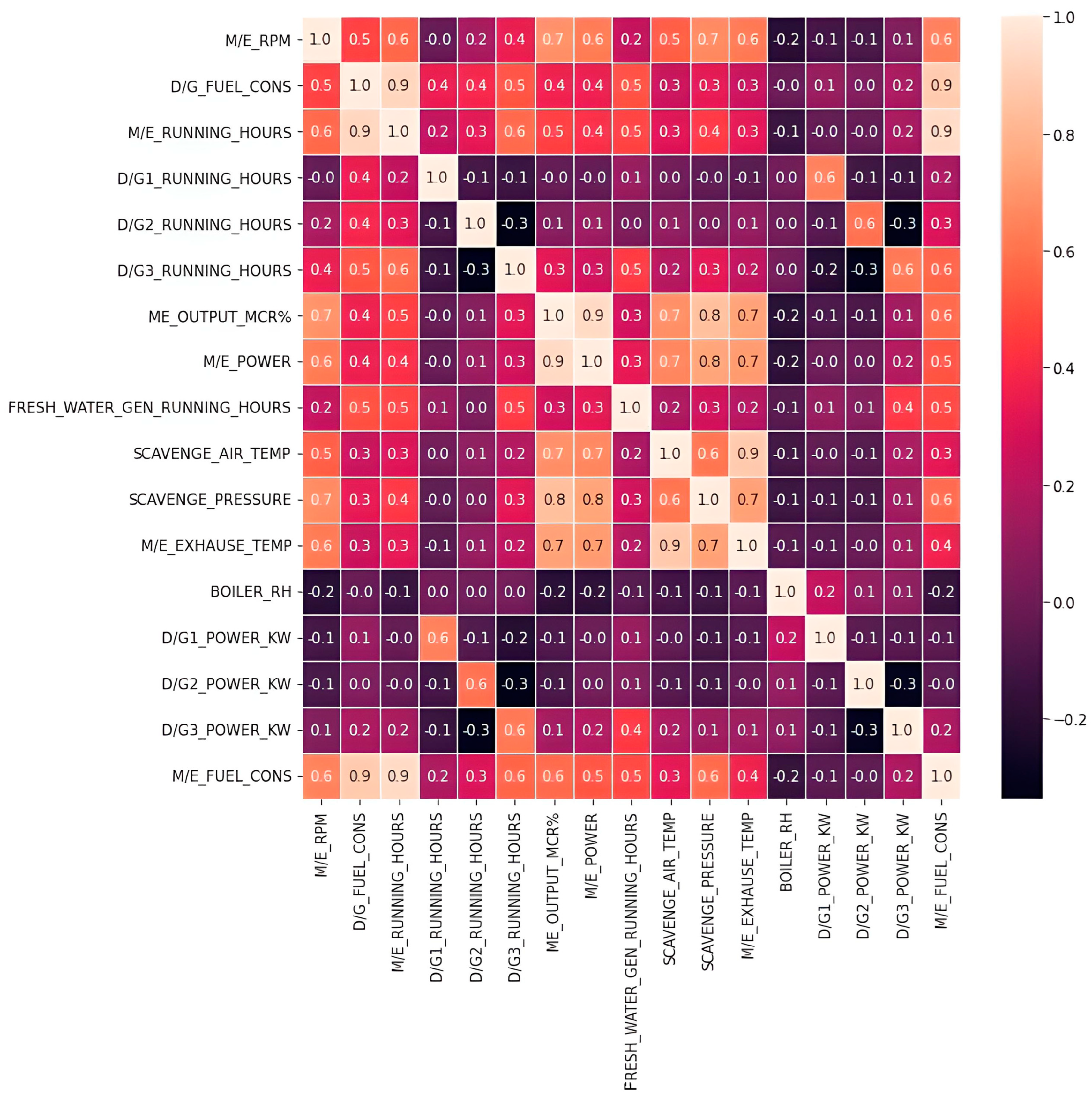

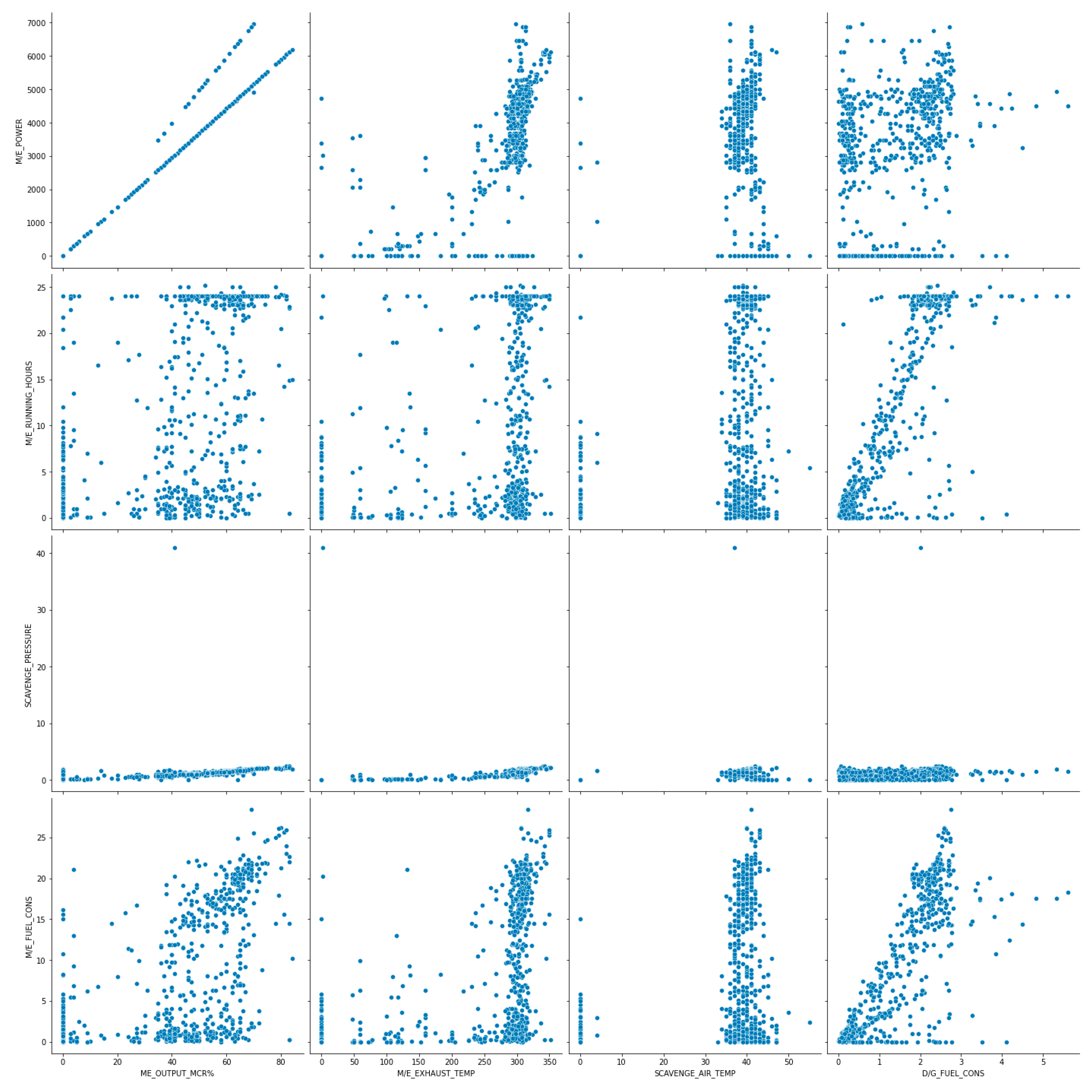

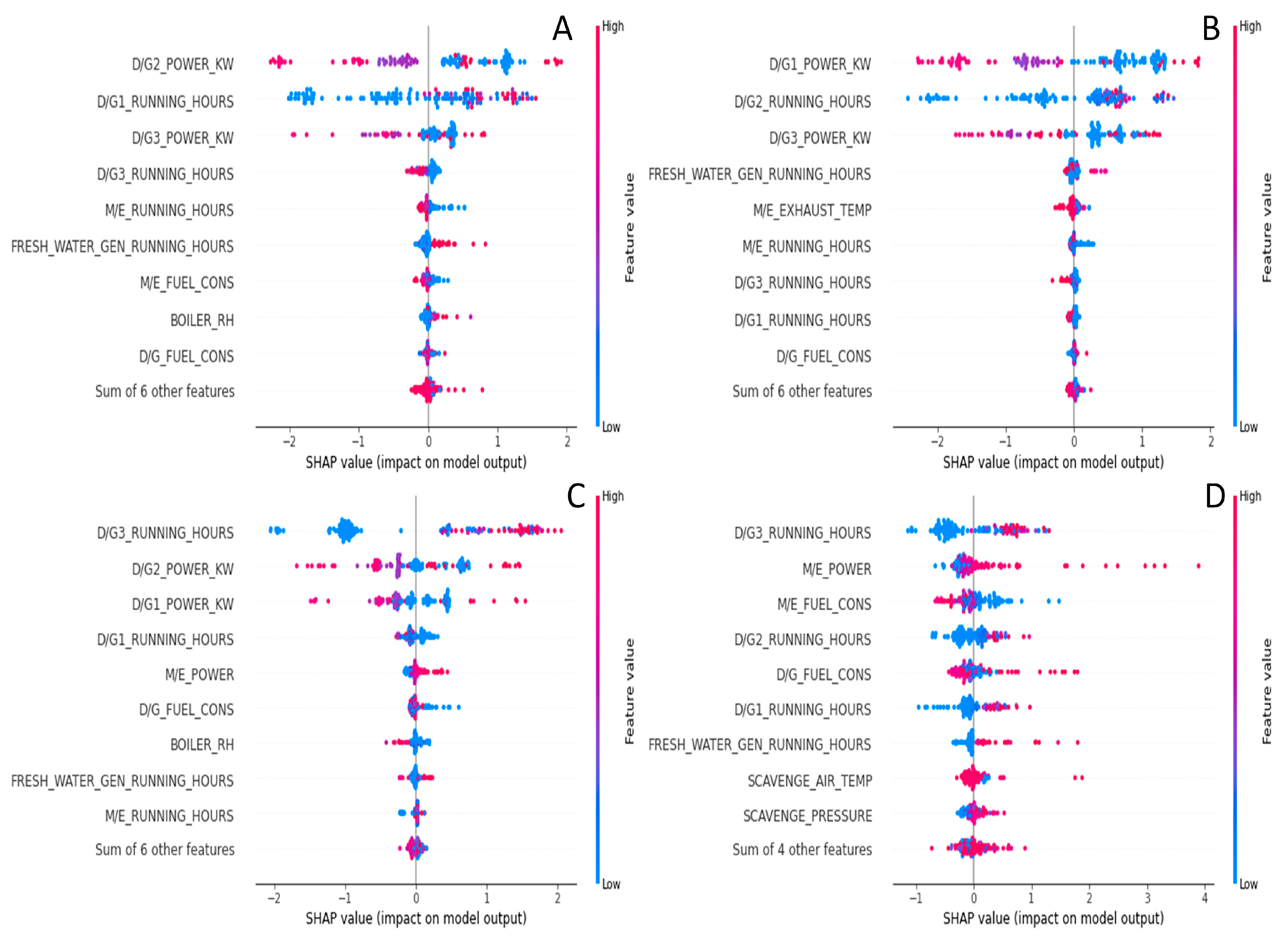

- Second, to address the uncertain number of influence factors that affect the actual reading of the power generator, this paper provides a correlation analysis that demonstrates the strong relationship between the chosen inputs and the varying patterns of output prediction. To make this approach realistic and applicable to new data predictions, it is integrated using 1000 days of a real voyage dataset instead of a dataset generated through software simulation.

- Third, eight different data-driven algorithms were tested in this study, including support vector machine, multiple-linear regression, artificial neural network, deep neural network, k-nearest neighbour, random forest, extreme gradient boosting, and decision tree algorithms. Comparative performance analysis of these approaches will provide the best forecasting model for the ship’s load generator of a chemical tanker ship with minimum error. This model can be used in energy scheduling and power planning to optimize system operations.

2. Data-Driven Approaches in the Maritime Industry

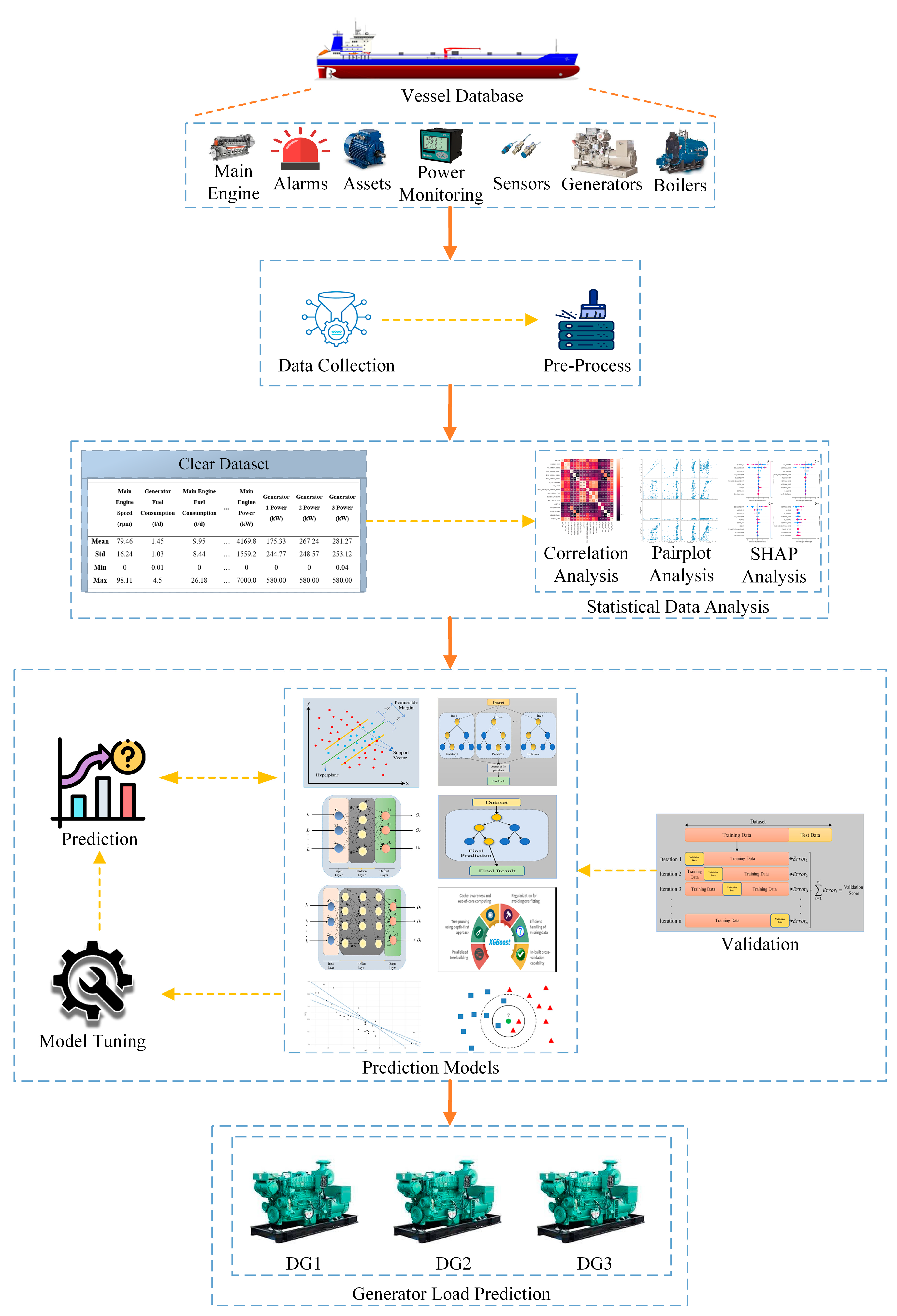

3. Prediction Methodology

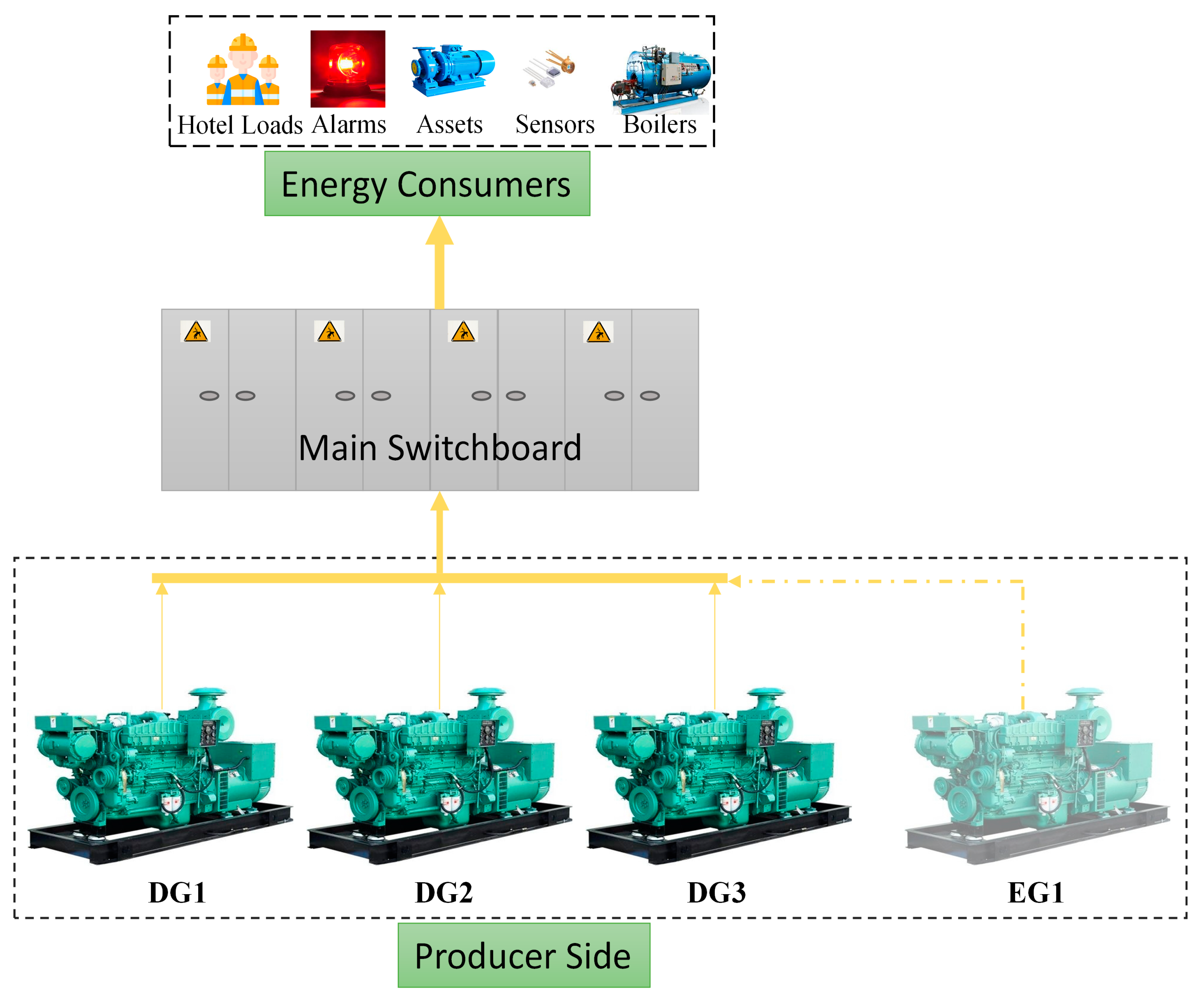

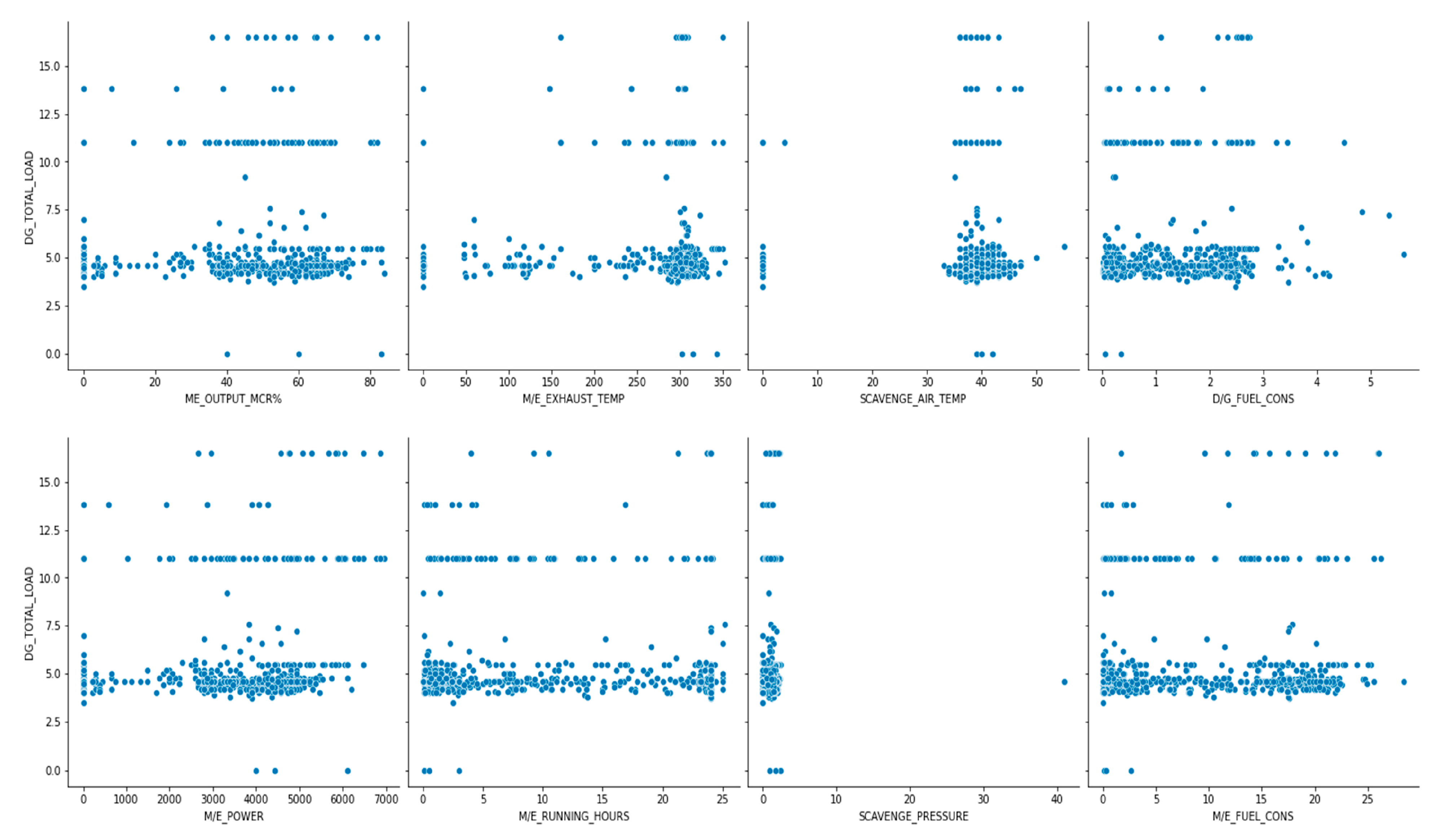

3.1. Data Processing

- Main engine speed (revolutions per minute (rpm)).

- Diesel generator fuel consumption (t/day), power (kW).

- Main engine running hours (h/day).

- Diesel generator running hours (h/day).

- Main engine output maximum continuous rating (%).

- Main engine power (kW), fuel consumption (t/day).

- Fresh water generator running hours (h/day).

- Scavenge air temperature (°C), scavenge pressure (bar).

- Main engine exhaust temperature (°C).

- Boiler running hours (h/day).

3.2. Estimation Models

3.2.1. Support Vector Machines (SVM)

3.2.2. Multiple Linear Regression (MLR)

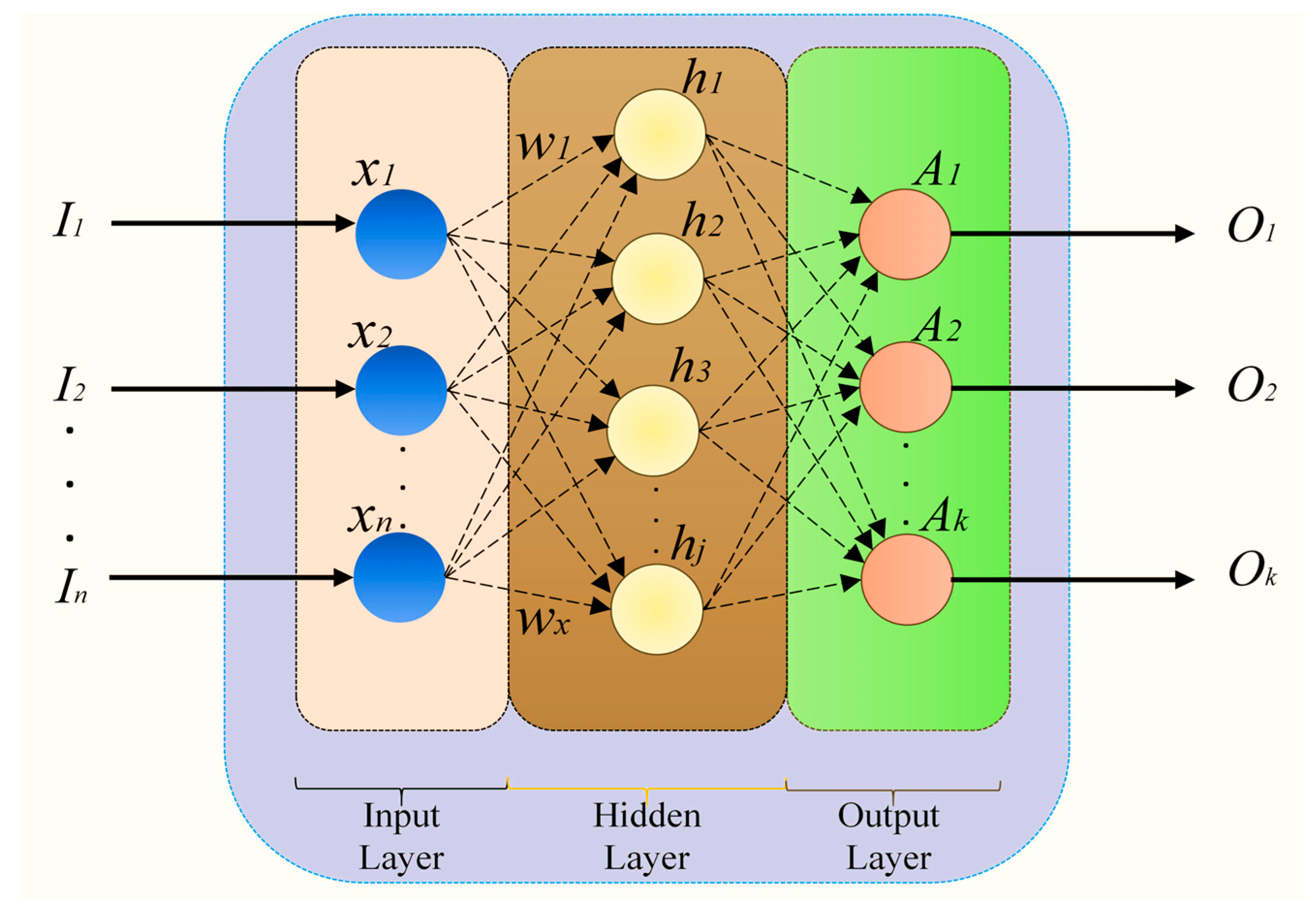

3.2.3. Artificial Neural Network (ANN)

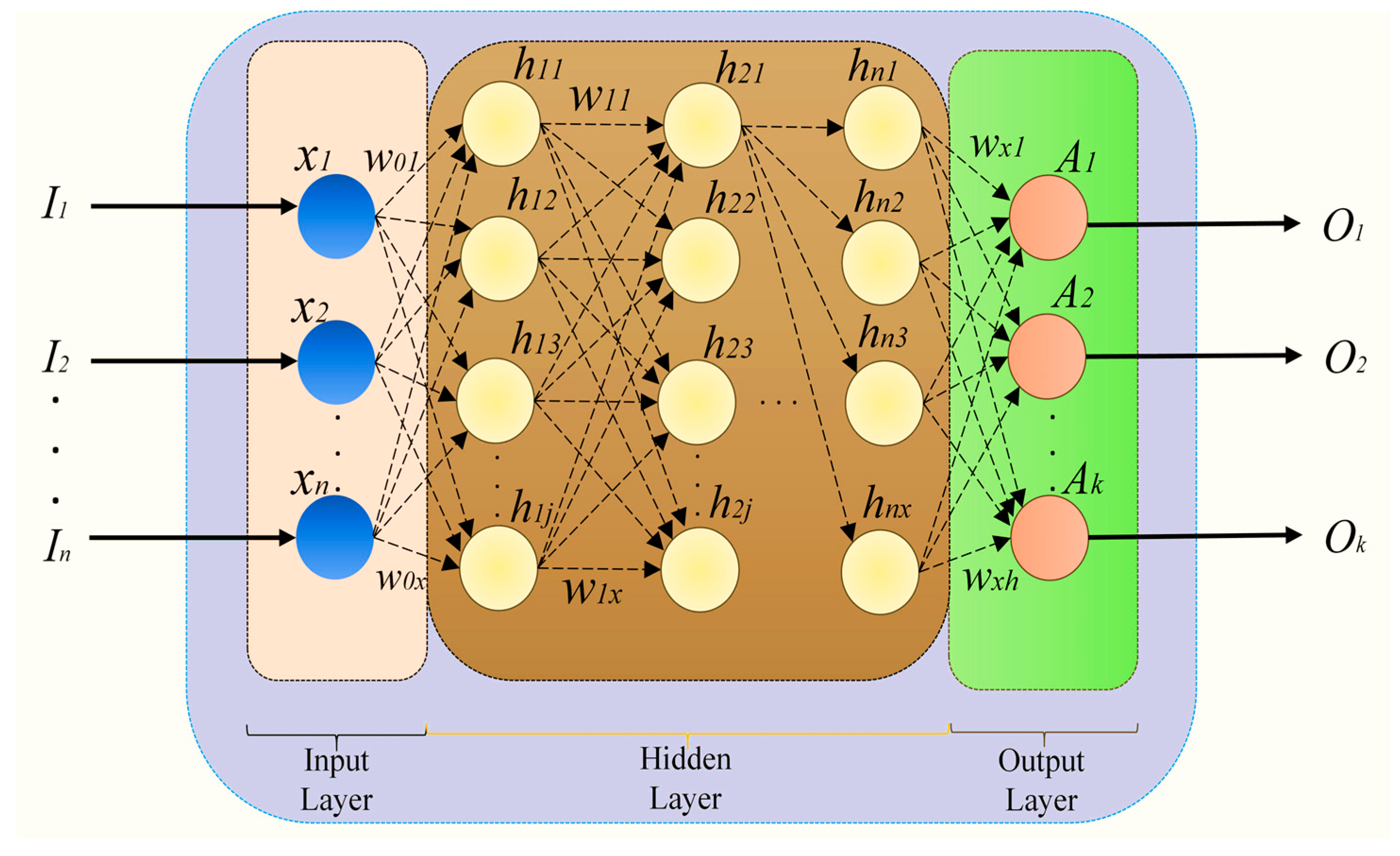

3.2.4. Deep Neural Network (DNN)

3.2.5. K-Nearest Neighbours (KNN)

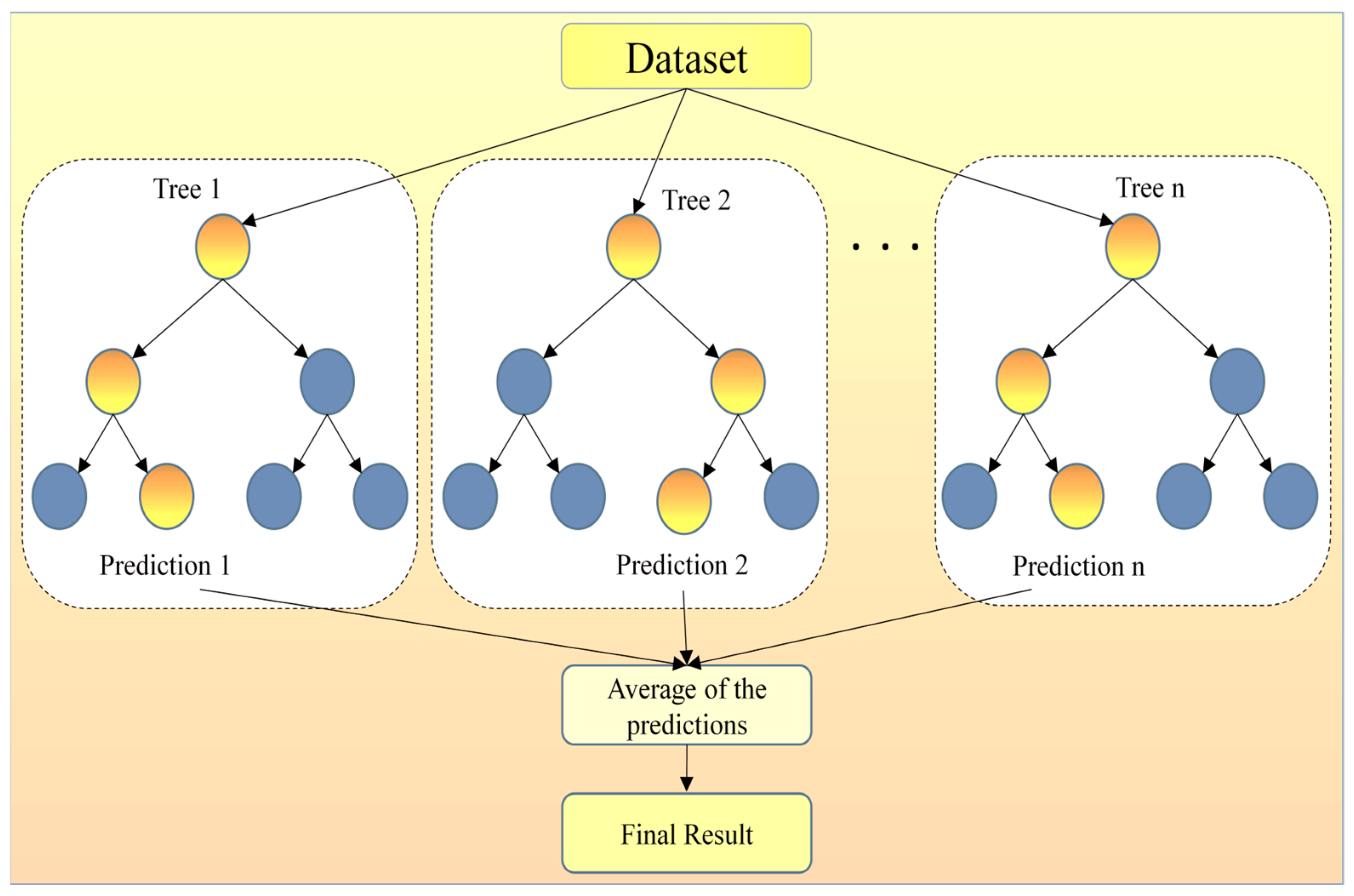

3.2.6. Random Forest (RF)

3.2.7. Extreme Gradient Boosting (XGBoost)

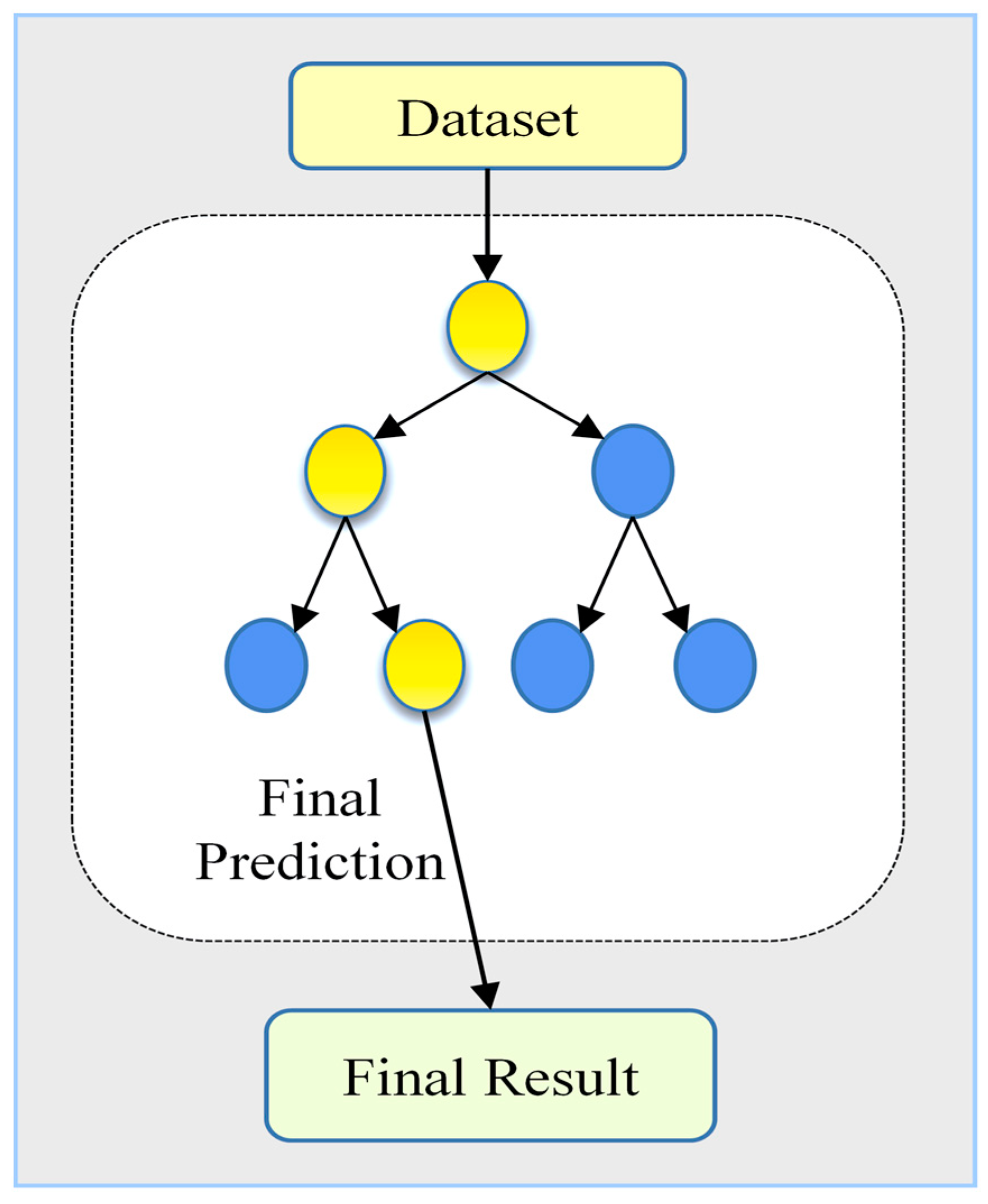

3.2.8. Decision Tree Regressor (DTree)

3.3. Validation and Evaluation

3.3.1. Mean Absolute Error (MAE)

3.3.2. Root Mean Square Error (RMSE)

3.3.3. Mean Absolute Percentage Error (MAPE)

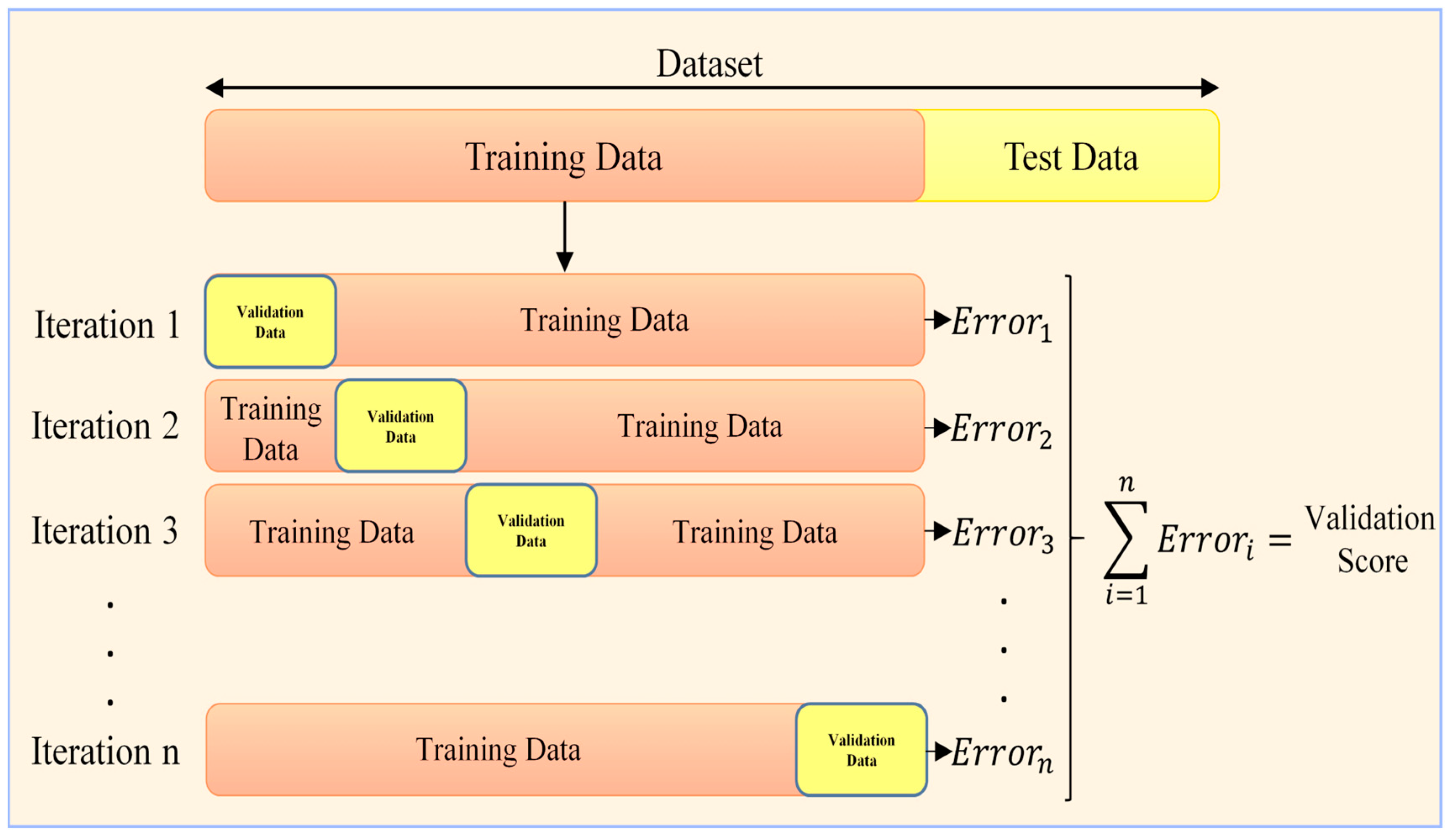

3.3.4. K-Fold Cross-Validation

4. Simulation Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sáez Álvarez, P. From Maritime Salvage to IMO 2020 Strategy: Two Actions to Protect the Environment. Mar. Pollut. Bull. 2021, 170, 112590. [Google Scholar] [CrossRef] [PubMed]

- Ammar, N.R.; Seddiek, I.S. Enhancing Energy Efficiency for New Generations of Containerized Shipping. Ocean Eng. 2020, 215, 107887. [Google Scholar] [CrossRef]

- Bakar, N.N.A.; Bazmohammadi, N.; Çimen, H.; Uyanik, T.; Vasquez, J.C.; Guerrero, J.M. Data-Driven Ship Berthing Forecasting for Cold Ironing in Maritime Transportation. Appl. Energy 2022, 326, 119947. [Google Scholar] [CrossRef]

- Gan, M.; Hou, H.; Wu, X.; Liu, B.; Yang, Y.; Xie, C. Machine Learning Algorithm Selection for Real-Time Energy Management of Hybrid Energy Ship. Energy Rep. 2022, 8, 1096–1102. [Google Scholar] [CrossRef]

- Pagoropoulos, A.; Møller, A.H.; McAloone, T.C. Applying Multi-Class Support Vector Machines for Performance Assessment of Shipping Operations: The Case of Tanker Vessels. Ocean Eng. 2017, 140, 1–6. [Google Scholar] [CrossRef]

- Planakis, N.; Papalambrou, G.; Kyrtatos, N. Ship Energy Management System Development and Experimental Evaluation Utilizing Marine Loading Cycles Based on Machine Learning Techniques. Appl. Energy 2022, 307, 118085. [Google Scholar] [CrossRef]

- Hou, J.; Sun, J.; Hofmann, H. Adaptive Model Predictive Control with Propulsion Load Estimation and Prediction for All-Electric Ship Energy Management. Energy 2018, 150, 877–889. [Google Scholar] [CrossRef]

- Hardan, F.; Norman, R. Balancing Loads of Rotating Generators Utilizing VSC Direct Power Controllers in a Ship AC/DC Smartgrid. Electr. Power Syst. Res. 2020, 182, 106200. [Google Scholar] [CrossRef]

- Omer, H.A.; Mahjoub, K.O.; Karrar, A.A. On the Stability of Generators Load Sharing; IFAC: New York, NY, USA, 2014; Volume 19, ISBN 9783902823625. [Google Scholar]

- Roy, N.B.; Das, D. Optimal Allocation of Active and Reactive Power of Dispatchable Distributed Generators in a Droop Controlled Islanded Microgrid Considering Renewable Generation and Load Demand Uncertainties. Sustain. Energy Grids Netw. 2021, 27, 100482. [Google Scholar] [CrossRef]

- Kusakana, K. Optimal Peer-to-Peer Energy Sharing between Prosumers Using Hydrokinetic, Diesel Generator and Pumped Hydro Storage. J. Energy Storage 2019, 26, 101048. [Google Scholar] [CrossRef]

- Li, X.; Sun, B.; Jin, J.; Ding, J. Speed Optimization of Container Ship Considering Route Segmentation and Weather Data Loading: Turning Point-Time Segmentation Method. J. Mar. Sci. Eng. 2022, 10, 1835. [Google Scholar] [CrossRef]

- Uyanık, T.; Yalman, Y.; Kalenderli, Ö.; Arslanoğlu, Y.; Terriche, Y.; Su, C.-L.; Guerrero, J.M. Data-Driven Approach for Estimating Power and Fuel Consumption of Ship: A Case of Container Vessel. Mathematics 2022, 10, 4167. [Google Scholar] [CrossRef]

- Bassam, A.M.; Phillips, A.B.; Turnock, S.R.; Wilson, P.A. Ship Speed Prediction Based on Machine Learning for Efficient Shipping Operation. Ocean Eng. 2022, 245, 110449. [Google Scholar] [CrossRef]

- Murray, B.; Perera, L.P. Proactive Collision Avoidance for Autonomous Ships: Leveraging Machine Learning to Emulate Situation Awareness. IFAC Pap. 2021, 54, 16–23. [Google Scholar] [CrossRef]

- Rawson, A.; Brito, M.; Sabeur, Z.; Tran-Thanh, L. A Machine Learning Approach for Monitoring Ship Safety in Extreme Weather Events. Saf. Sci. 2021, 141, 105336. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, H.; Li, X.; Huang, J.; Wang, W. Machine Learning Method for Energy Consumption Prediction of Ships in Port Considering Green Ports. J. Clean. Prod. 2020, 264, 121564. [Google Scholar] [CrossRef]

- Anh Tran, T. Comparative Analysis on the Fuel Consumption Prediction Model for Bulk Carriers from Ship Launching to Current States Based on Sea Trial Data and Machine Learning Technique. J. Ocean Eng. Sci. 2021, 6, 317–339. [Google Scholar] [CrossRef]

- Ahlgren, F.; Mondejar, M.E.; Thern, M. Predicting Dynamic Fuel Oil Consumption on Ships with Automated Machine Learning. Energy Procedia 2019, 158, 6126–6131. [Google Scholar] [CrossRef]

- Uyanık, T.; Karatuğ, Ç.; Arslanoğlu, Y. Machine Learning Approach to Ship Fuel Consumption: A Case of Container Vessel. Transp. Res. Part D Transp. Environ. 2020, 84, 102389. [Google Scholar] [CrossRef]

- Kong, M.C.; Roh, M.-I.; Kim, K.S.; Lee, J.; Kim, J.; Lee, G. Object Detection Method for Ship Safety Plans Using Deep Learning. Ocean Eng. 2022, 246, 110587. [Google Scholar] [CrossRef]

- Laurie, A.; Anderlini, E.; Dietz, J.; Thomas, G. Machine Learning for Shaft Power Prediction and Analysis of Fouling Related Performance Deterioration. Ocean Eng. 2021, 234, 108886. [Google Scholar] [CrossRef]

- Saettone, S.; Tavakoli, S.; Taskar, B.; Jensen, M.V.; Pedersen, E.; Schramm, J.; Steen, S.; Andersen, P. The Importance of the Engine-Propeller Model Accuracy on the Performance Prediction of a Marine Propulsion System in the Presence of Waves. Appl. Ocean Res. 2020, 103, 102320. [Google Scholar] [CrossRef]

- Wen, H.; Khan, F.; Amin, M.T.; Halim, S.Z. Myths and Misconceptions of Data-Driven Methods: Applications to Process Safety Analysis. Comput. Chem. Eng. 2021, 158, 107639. [Google Scholar] [CrossRef]

- Lang, X.; Wu, D.; Mao, W. Comparison of Supervised Machine Learning Methods to Predict Ship Propulsion Power at Sea. Ocean Eng. 2022, 245, 110387. [Google Scholar] [CrossRef]

- Zhou, T.; Hu, Q.; Hu, Z.; Zhen, R. An Adaptive Hyper Parameter Tuning Model for Ship Fuel Consumption Prediction under Complex Maritime Environments. J. Ocean Eng. Sci. 2021, 7, 255–263. [Google Scholar] [CrossRef]

- Yan, R.; Wang, S.; Du, Y. Development of a Two-Stage Ship Fuel Consumption Prediction and Reduction Model for a Dry Bulk Ship. Transp. Res. Part E Logist. Transp. Rev. 2020, 138, 101930. [Google Scholar] [CrossRef]

- Yuan, Z.; Liu, J.; Zhang, Q.; Liu, Y.; Yuan, Y.; Li, Z. Prediction and Optimisation of Fuel Consumption for Inland Ships Considering Real-Time Status and Environmental Factors. Ocean Eng. 2021, 221, 108530. [Google Scholar] [CrossRef]

- Schäfers, P.; Mütze, A.; Nyhuis, P. Integrated Concept for Acquisition and Utilization of Production Feedback Data to Support Production Planning and Control in the Age of Digitalization. Procedia Manuf. 2019, 31, 225–231. [Google Scholar] [CrossRef]

- Ellingsen, O.; Aasland, K.E. Digitalizing the Maritime Industry: A Case Study of Technology Acquisition and Enabling Advanced Manufacturing Technology. J. Eng. Technol. Manag. JETM 2019, 54, 12–27. [Google Scholar] [CrossRef]

- Futagami, K.; Fukazawa, Y.; Kapoor, N.; Kito, T. ScienceDirect Pairwise Acquisition Prediction with SHAP Value Interpretation. J. Financ. Data Sci. 2021, 7, 22–44. [Google Scholar] [CrossRef]

- Wang, D.; Thun, S.; Lindberg, U.; Jiang, L.; Trygg, J.; Tysklind, M. Towards Better Process Management in Wastewater Treatment Plants: Process Analytics Based on SHAP Values for Tree-Based Machine Learning Methods. J. Environ. Manag. 2022, 301, 113941. [Google Scholar] [CrossRef]

- Corinna, C.; Vladimir, V. Support-Vector Networks. IEEE Expert Syst. Appl. 1992, 7, 63–72. [Google Scholar] [CrossRef]

- Luíza da Costa, N.; Dias de Lima, M.; Barbosa, R. Evaluation of Feature Selection Methods Based on Artificial Neural Network Weights. Expert Syst. Appl. 2021, 168, 114312. [Google Scholar] [CrossRef]

- Liu, M.; Zhou, Q.; Wang, X.; Yu, C.; Kang, M. Voyage Performance Evaluation Based on a Digital Twin Model. IOP Conf. Ser. Mater. Sci. Eng. 2020, 929, 012027. [Google Scholar] [CrossRef]

- Xie, X.; Wu, T.; Zhu, M.; Jiang, G.; Xu, Y.; Wang, X.; Pu, L. Comparison of Random Forest and Multiple Linear Regression Models for Estimation of Soil Extracellular Enzyme Activities in Agricultural Reclaimed Coastal Saline Land. Ecol. Indic. 2021, 120, 106925. [Google Scholar] [CrossRef]

- Caravaggi, P.; Leardini, A.; Giacomozzi, C. Multiple Linear Regression Approach for the Analysis of the Relationships between Joints Mobility and Regional Pressure-Based Parameters in the Normal-Arched Foot. J. Biomech. 2016, 49, 3485–3491. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, S.A.; Shirani, A.S.; Lotfi, M.; Menhaj, M.B. Design and Application of Supervisory Control Based on Neural Network PID Controllers for Pressurizer System. Prog. Nucl. Energy 2020, 130, 103570. [Google Scholar] [CrossRef]

- Jeon, M.; Noh, Y.; Shin, Y.; Lim, O.K.; Lee, I.; Cho, D. Prediction of Ship Fuel Consumption by Using an Artificial Neural Network. J. Mech. Sci. Technol. 2018, 32, 5785–5796. [Google Scholar] [CrossRef]

- Maepa, F.; Smith, R.S.; Tessema, A. Support Vector Machine and Artificial Neural Network Modelling of Orogenic Gold Prospectivity Mapping in the Swayze Greenstone Belt, Ontario, Canada. Ore Geol. Rev. 2021, 130, 103968. [Google Scholar] [CrossRef]

- Lazakis, I.; Raptodimos, Y.; Varelas, T. Predicting Ship Machinery System Condition through Analytical Reliability Tools and Artificial Neural Networks. Ocean Eng. 2018, 152, 404–415. [Google Scholar] [CrossRef]

- Choi, S.; Kim, Y.J. Artificial Neural Network Models for Airport Capacity Prediction. J. Air Transp. Manag. 2021, 97, 102146. [Google Scholar] [CrossRef]

- Son, S.; Oh, K.-Y. Integrated Framework for Estimating Remaining Useful Lifetime through a Deep Neural Network. Appl. Soft Comput. 2022, 122, 108879. [Google Scholar] [CrossRef]

- Lyu, S.-H.; Wang, L.; Zhou, Z.-H. Improving Generalization of Deep Neural Networks by Leveraging Margin Distribution. Neural Netw. 2022, 151, 48–60. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, T.; Inui, T.; Kawai, S.; Kuwabara, S.; Nishizawa, H. Monitoring and Diagnostic Technologies Usingdeep Neural Networks for Predictive Optical Network Maintenance [Invited]. J. Opt. Commun. Netw. 2021, 13, 13–22. [Google Scholar] [CrossRef]

- Kong, N.C.L.; Kaneshiro, B.; Yamins, D.L.K.; Norcia, A.M. Time-Resolved Correspondences between Deep Neural Network Layers and EEG Measurements in Object Processing. Vis. Res. 2020, 172, 27–45. [Google Scholar] [CrossRef] [PubMed]

- ArunKumar, K.E.; Kalaga, D.V.; Kumar, C.M.S.; Kawaji, M.; Brenza, T.M. Forecasting of COVID-19 Using Deep Layer Recurrent Neural Networks (RNNs) with Gated Recurrent Units (GRUs) and Long Short-Term Memory (LSTM) Cells. Chaos Solitons Fractals 2021, 146, 110861. [Google Scholar] [CrossRef]

- Su, T.J.; Pan, T.S.; Chang, Y.L.; Lin, S.S.; Hao, M.J. A Hybrid Fuzzy and K-Nearest Neighbor Approach for Debris Flow Disaster Prevention. IEEE Access 2022, 10, 21787–21797. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, X.; Li, Y. Unsupervised Outlier Detection for Mixed-Valued Dataset Based on the Adaptive k-Nearest Neighbor Global Network. IEEE Access 2022, 10, 32093–32103. [Google Scholar] [CrossRef]

- Zhao, W.L.; Wang, H.; Ngo, C.W. Approximate K-NN Graph Construction: A Generic Online Approach. IEEE Trans. Multimed. 2021, 24, 1909–1921. [Google Scholar] [CrossRef]

- Naimi, A.; Deng, J.; Shimjith, S.R.; Arul, A.J. Fault Detection and Isolation of a Pressurized Water Reactor Based on Neural Network and K-Nearest Neighbor. IEEE Access 2022, 10, 17113–17121. [Google Scholar] [CrossRef]

- Gupta, R.; Pierdzioch, C.; Salisu, A.A. Oil-Price Uncertainty and the U.K. Unemployment Rate: A Forecasting Experiment with Random Forests Using 150 Years of Data. Resour. Policy 2022, 77, 102662. [Google Scholar] [CrossRef]

- Zheng, J.; Liu, Y.; Ge, Z. Dynamic Ensemble Selection Based Improved Random Forests for Fault Classification in Industrial Processes. IFAC J. Syst. Control 2022, 20, 100189. [Google Scholar] [CrossRef]

- Zhang, N.; Qian, H.; He, Y.; Li, L.; Sun, C. A Data-Driven Method for Power System Transient Instability Mode Identification Based on Knowledge Discovery and XGBoost Algorithm. IEEE Access 2021, 9, 154172–154182. [Google Scholar] [CrossRef]

- Gu, X.; Han, Y.; Yu, J. A Novel Lane-Changing Decision Model for Autonomous Vehicles Based on Deep Autoencoder Network and XGBoost. IEEE Access 2020, 8, 9846–9863. [Google Scholar] [CrossRef]

- Friedman, J.H. Greedy Function Approximation: A Gradient Boosting Machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Saroj, R.K.; Anand, M. Environmental Factors Prediction in Preterm Birth Using Comparison between Logistic Regression and Decision Tree Methods: An Exploratory Analysis. Soc. Sci. Humanit. Open 2021, 4, 100216. [Google Scholar] [CrossRef]

- Choi, J.; Gu, B.; Chin, S.; Lee, J. Automation in Construction Machine Learning Predictive Model Based on National Data for Fatal Accidents of Construction Workers. Autom. Constr. 2020, 110, 102974. [Google Scholar] [CrossRef]

- Jackson, E.K.; Roberts, W.; Nelsen, B.; Williams, G.P.; Nelson, E.J.; Ames, D.P. Introductory Overview: Error Metrics for Hydrologic Modelling—A Review of Common Practices and an Open Source Library to Facilitate Use and Adoption. Environ. Model. Softw. 2019, 119, 32–48. [Google Scholar] [CrossRef]

- Saud, S.; Jamil, B.; Upadhyay, Y.; Irshad, K. Performance Improvement of Empirical Models for Estimation of Global Solar Radiation in India: A k-Fold Cross-Validation Approach. Sustain. Energy Technol. Assess. 2020, 40, 100768. [Google Scholar] [CrossRef]

- McKenzie, J. Mean Absolute Percentage Error and Bias in Economic Forecasting. Econ. Lett. 2011, 113, 259–262. [Google Scholar] [CrossRef]

- Wong, T.T. Parametric Methods for Comparing the Performance of Two Classification Algorithms Evaluated by K-Fold Cross Validation on Multiple Datasets. Pattern Recognit. 2017, 65, 97–107. [Google Scholar] [CrossRef]

- Liu, C.; Lin, B.; Lai, J.; Miao, D. An Improved Decision Tree Algorithm Based on Variable Precision Neighborhood Similarity. Inf. Sci. 2022, 615, 152–166. [Google Scholar] [CrossRef]

- Brito, L.C.; Susto, G.A.; Brito, J.N.; Duarte, M.A.V. An Explainable Artificial Intelligence Approach for Unsupervised Fault Detection and Diagnosis in Rotating Machinery. Mech. Syst. Signal Process. 2022, 163, 108105. [Google Scholar] [CrossRef]

- Yiğit, K. Evaluation of Energy Efficiency Potentials from Generator Operations on Vessels. Energy 2022, 257, 124687. [Google Scholar] [CrossRef]

| Item | Specification |

|---|---|

| Vessel Type | Oil/Chemical Tanker |

| Gross Tonnage | 29,590 t |

| Deadweight Tonnage | 49,990 t |

| Length/Breadth | 183/32.3 m |

| Year Built | 2017 |

| Average/Maximum Speed | 13.4/17.3 knots |

| Main Engine Power | 7000 kW |

| Generator Power/Count | 580 kW/3 |

| Draft | 8 m |

| Main Engine Speed (rpm) | Generator Fuel Consumption (t/d) | Main Engine Fuel Consumption (t/d) | … | Main Engine Power (kW) | Generator 1 Power (kW) | Generator 2 Power (kW) | Generator 3 Power (kW) | |

|---|---|---|---|---|---|---|---|---|

| Mean | 79.46 | 1.45 | 9.95 | … | 4169.8 | 175.33 | 267.24 | 281.27 |

| Std | 16.24 | 1.03 | 8.44 | … | 1559.2 | 244.77 | 248.57 | 253.12 |

| Min | 0 | 0.01 | 0 | … | 0 | 0 | 0 | 0.04 |

| Max | 98.11 | 4.5 | 26.18 | … | 7000.0 | 580.00 | 580.00 | 580.00 |

| Model | Hyperparameter |

|---|---|

| SVM | None |

| MLR | None |

| ANN | solver = ‘lbfgs’, alpha = 0.00001, max_iter = 10,000, activation = ‘tanh’, hidden_layer_sizes = (5000), power_t = 0.7, validation_fraction = 0.3, batch_size = 250 |

| DNN | input_dim = 16, hidden_layer_count = 17, input_layer_activation_function = ‘relu’, hidden_layer_activation_function = ‘linear’, output_layer_activation_function = ‘linear’, optimizer = ‘Adam’, epochs = 1500 |

| KNN | n_neighbors = 3, weights = “distance”,algorithm = “kd_tree”, p = 20 |

| RF | n_estimators = 350, max_depth = 150 |

| XGB | None |

| Dtree | None |

| MAE | RMSE | MAPE | |||||||

|---|---|---|---|---|---|---|---|---|---|

| DG1 | DG2 | DG3 | DG1 | DG2 | DG3 | DG1 | DG2 | DG3 | |

| SVR | 1.6736 | 1.9411 | 1.6893 | 6.3752 | 4.8703 | 7.5162 | 30.865 | 33.814 | 36.241 |

| MLR | 1.1652 | 1.3124 | 1.1804 | 2.6701 | 3.1117 | 2.4007 | 29.597 | 28.877 | 31.195 |

| ANN | 0.9589 | 1.0027 | 0.9324 | 1.9204 | 2.1717 | 1.8913 | 34.265 | 24.977 | 29.988 |

| DNN | 0.5783 | 0.4025 | 0.5308 | 1.8067 | 1.4948 | 1.8733 | 31.714 | 36.591 | 33.773 |

| KNN | 1.4294 | 1.5561 | 1.2901 | 4.4118 | 4.4908 | 4.0399 | 34.652 | 32.794 | 35.763 |

| RF | 0.3413 | 0.2252 | 0.2892 | 0.4733 | 0.2662 | 0.4714 | 31.879 | 8.1517 | 9.9462 |

| XGB | 0.2817 | 0.1424 | 0.2926 | 0.4212 | 0.2431 | 0.5093 | 29.547 | 6.1015 | 11.184 |

| DTree | 0.2364 | 0.1306 | 0.1532 | 0.2455 | 0.2069 | 0.2182 | 17.493 | 5.1139 | 7.7481 |

| Total Load Prediction | |||

|---|---|---|---|

| MAE | RMSE | MAPE | |

| SVR | 1.3520 | 8.3232 | 15.966 |

| MLR | 1.5283 | 5.6608 | 23.302 |

| ANN | 1.6575 | 6.1073 | 25.048 |

| DNN | 1.0866 | 2.6049 | 14.728 |

| KNN | 1.8220 | 9.6310 | 27.184 |

| RF | 1.3146 | 4.9486 | 14.513 |

| XGB | 1.4152 | 5.7916 | 16.805 |

| DTree | 1.4452 | 9.0413 | 19.748 |

| Model | ||||||||

|---|---|---|---|---|---|---|---|---|

| SVR | MLR | ANN | DNN | KNN | RF | XGB | DTree | |

| Fold 1 | 1.4235 | 1.5813 | 1.7434 | 1.1517 | 1.9589 | 1.4257 | 1.4789 | 1.4925 |

| Fold 2 | 1.4387 | 1.5975 | 1.6928 | 1.2146 | 1.9827 | 1.3952 | 1.4912 | 1.5014 |

| Fold 3 | 1.4291 | 1.6124 | 1.7126 | 1.1738 | 1.9186 | 1.3573 | 1.4671 | 1.4874 |

| Fold 4 | 1.4413 | 1.5731 | 1.6891 | 1.1513 | 1.8917 | 1.3841 | 1.4397 | 1.4731 |

| Fold 5 | 1.4275 | 1.5629 | 1.6973 | 1.1725 | 1.9226 | 1.3619 | 1.4515 | 1.4667 |

| Mean Score | 1.4320 | 1.5854 | 1.7070 | 1.1727 | 1.9349 | 1.3848 | 1.4656 | 1.4842 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uyanık, T.; Bakar, N.N.A.; Kalenderli, Ö.; Arslanoğlu, Y.; Guerrero, J.M.; Lashab, A. A Data-Driven Approach for Generator Load Prediction in Shipboard Microgrid: The Chemical Tanker Case Study. Energies 2023, 16, 5092. https://doi.org/10.3390/en16135092

Uyanık T, Bakar NNA, Kalenderli Ö, Arslanoğlu Y, Guerrero JM, Lashab A. A Data-Driven Approach for Generator Load Prediction in Shipboard Microgrid: The Chemical Tanker Case Study. Energies. 2023; 16(13):5092. https://doi.org/10.3390/en16135092

Chicago/Turabian StyleUyanık, Tayfun, Nur Najihah Abu Bakar, Özcan Kalenderli, Yasin Arslanoğlu, Josep M. Guerrero, and Abderezak Lashab. 2023. "A Data-Driven Approach for Generator Load Prediction in Shipboard Microgrid: The Chemical Tanker Case Study" Energies 16, no. 13: 5092. https://doi.org/10.3390/en16135092

APA StyleUyanık, T., Bakar, N. N. A., Kalenderli, Ö., Arslanoğlu, Y., Guerrero, J. M., & Lashab, A. (2023). A Data-Driven Approach for Generator Load Prediction in Shipboard Microgrid: The Chemical Tanker Case Study. Energies, 16(13), 5092. https://doi.org/10.3390/en16135092