Techno-Economic and Environmental Perspectives of Solar Cell Technologies: A Comprehensive Review

Abstract

1. Introduction

2. Methodology

3. Development of the Generation of Solar Cells

3.1. First-Generation Solar Cells

3.2. Second-Generation Solar Cells

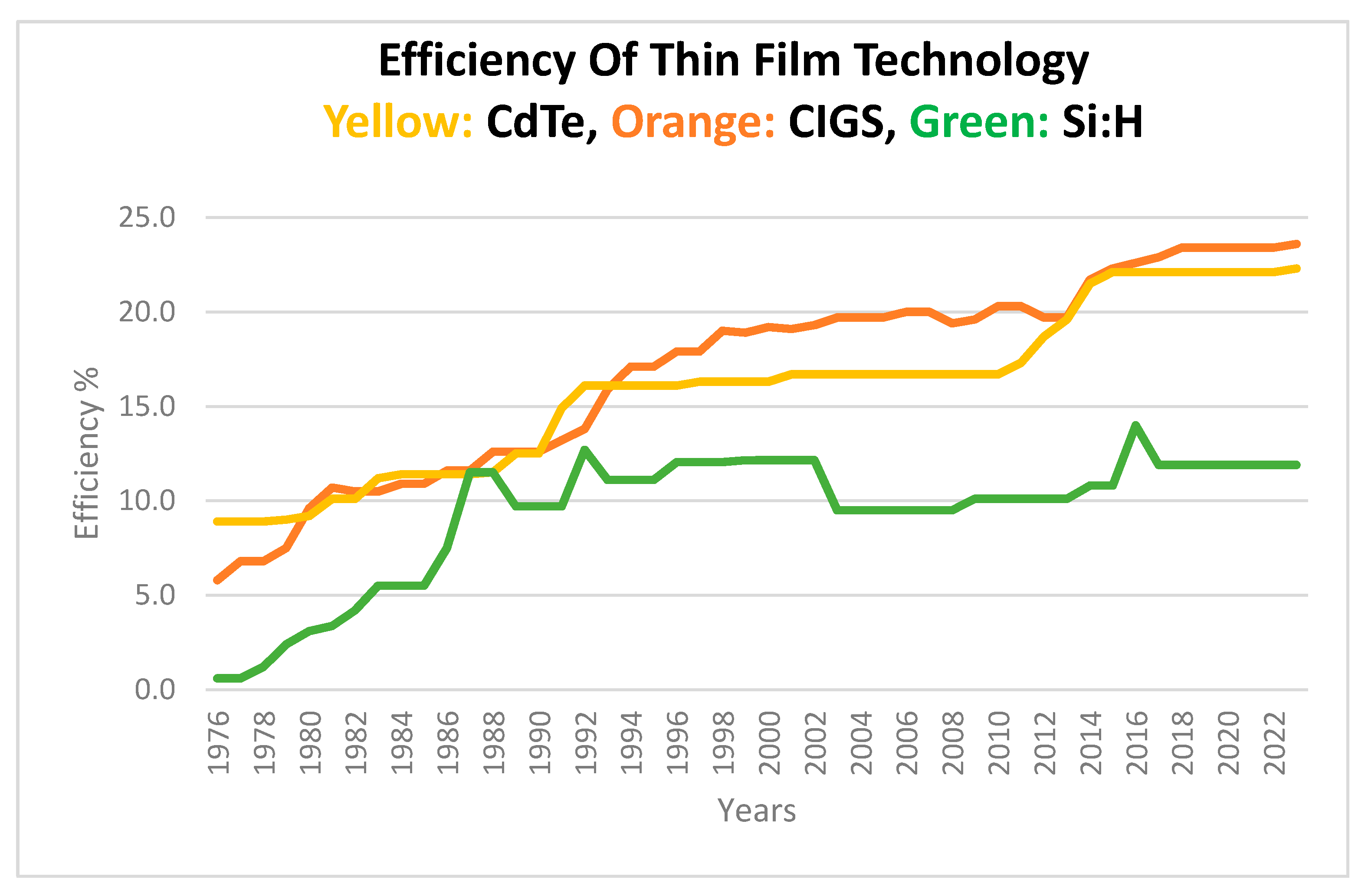

3.2.1. Amorphous Silicon Thin Films

3.2.2. Cadmium Telluride Thin Solar Film (CdTe)

3.2.3. Copper Indium Gallium Di-Selenide (CIGS) Solar Cells

3.3. Third-Generation Solar Cells

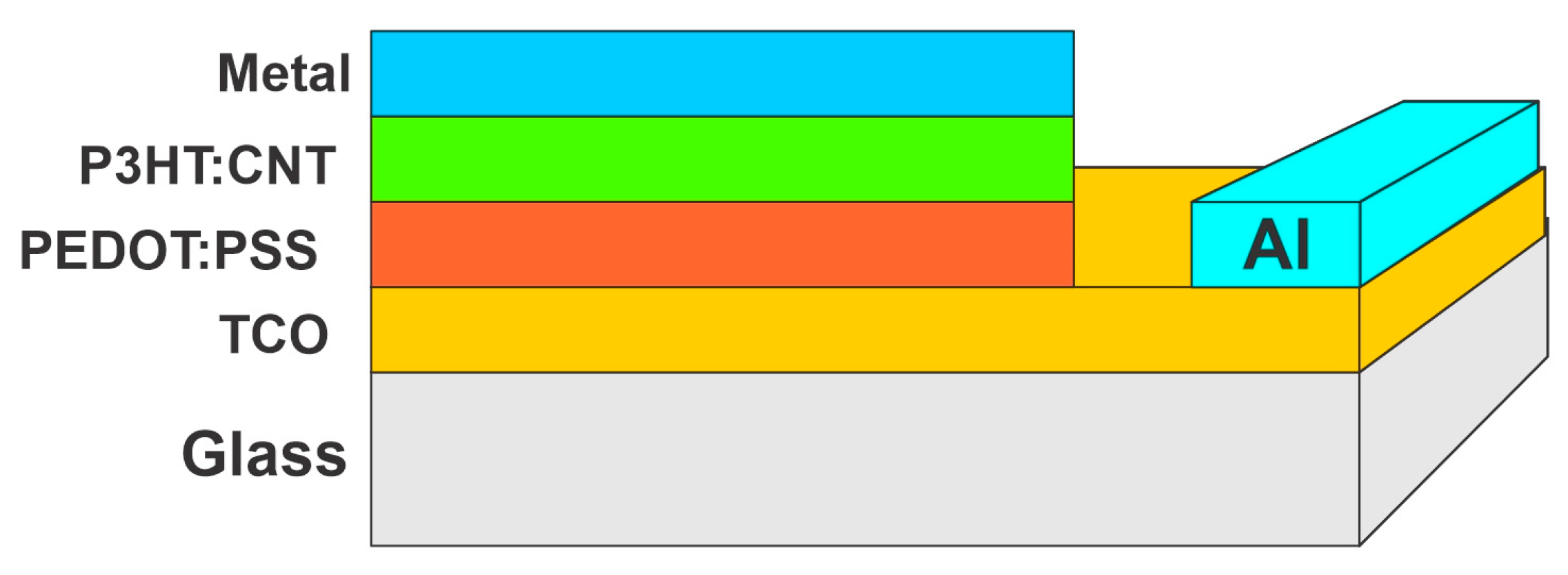

3.3.1. Organic Solar Cells

3.3.2. Dye-Sensitized Solar Cells

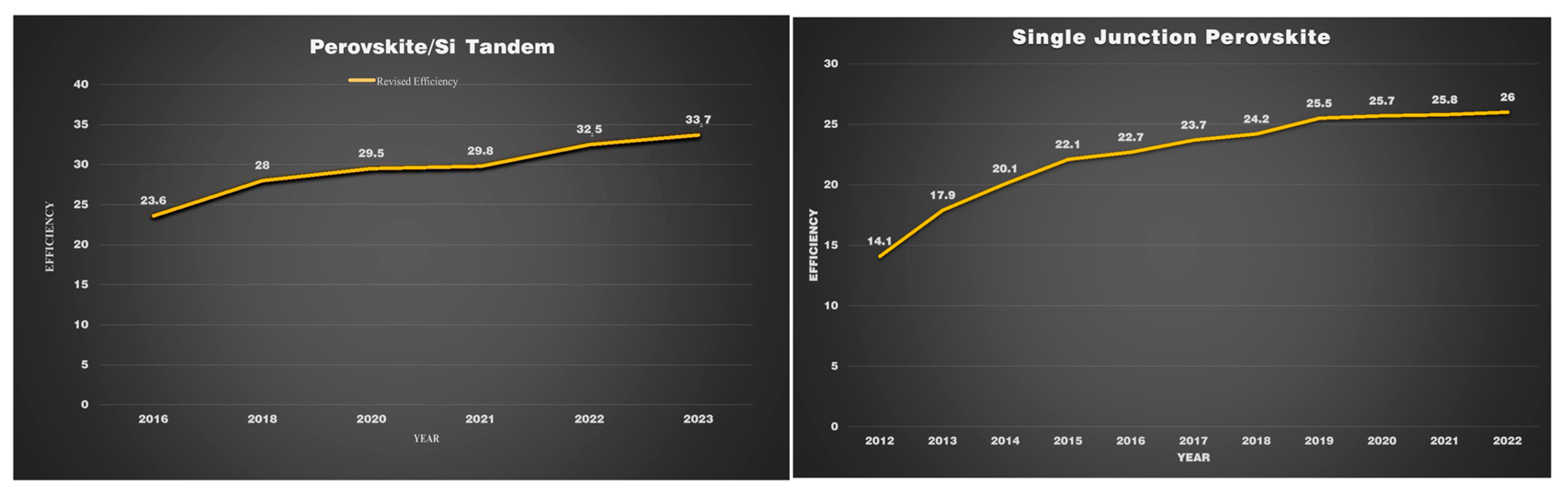

3.3.3. Perovskite Solar Cells

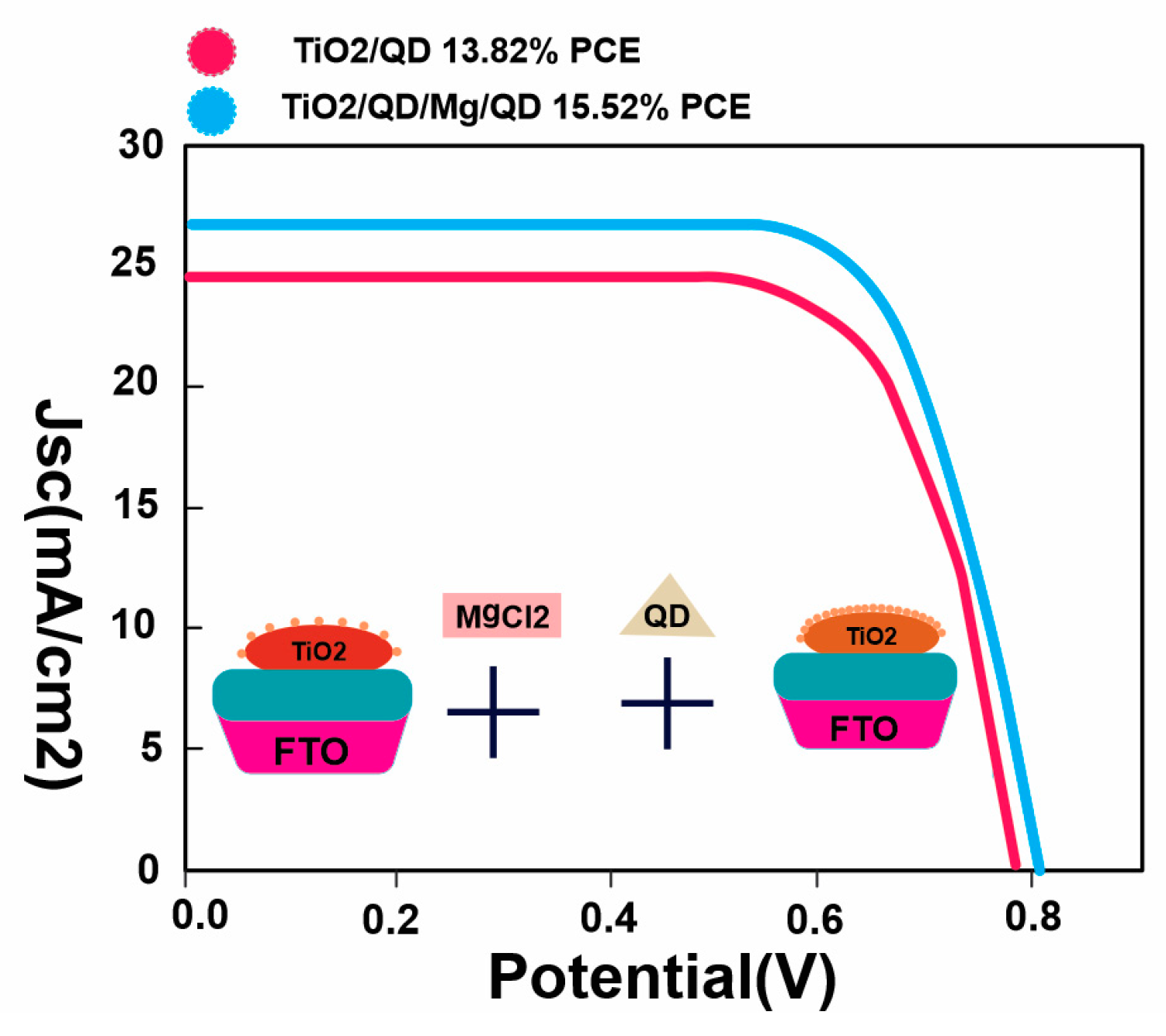

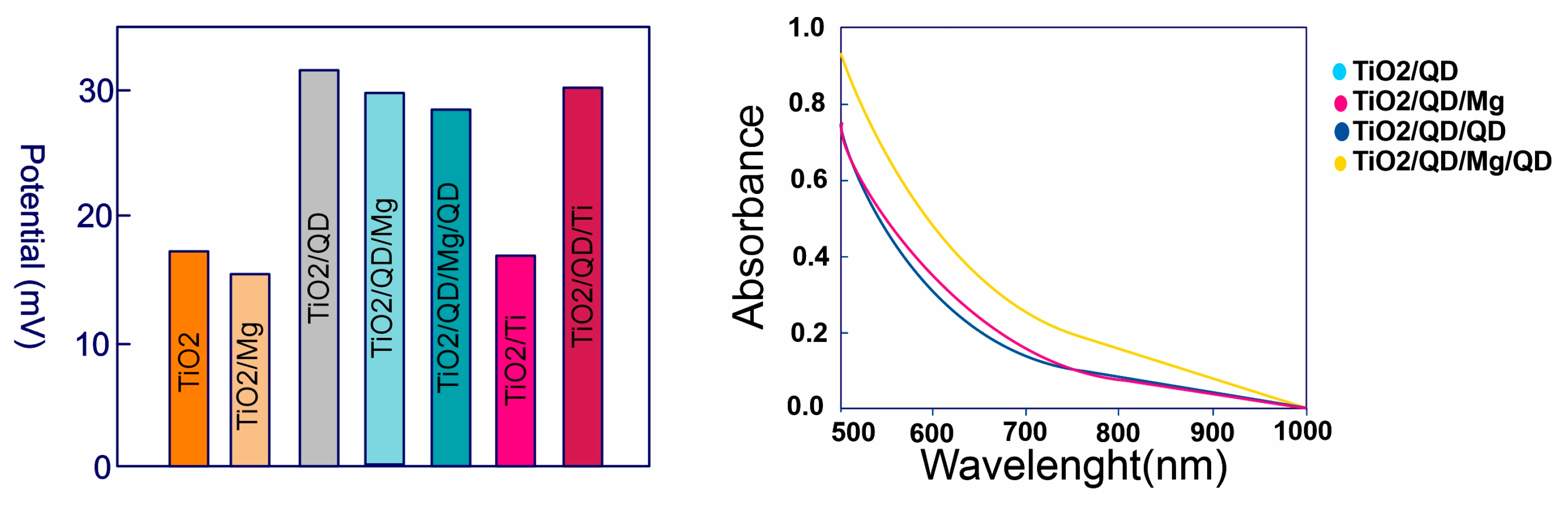

3.3.4. Quantum Dot Solar Cells

3.3.5. Concentrated Solar Cells

4. Comparison of the Efficiency of Disparate PV Cells

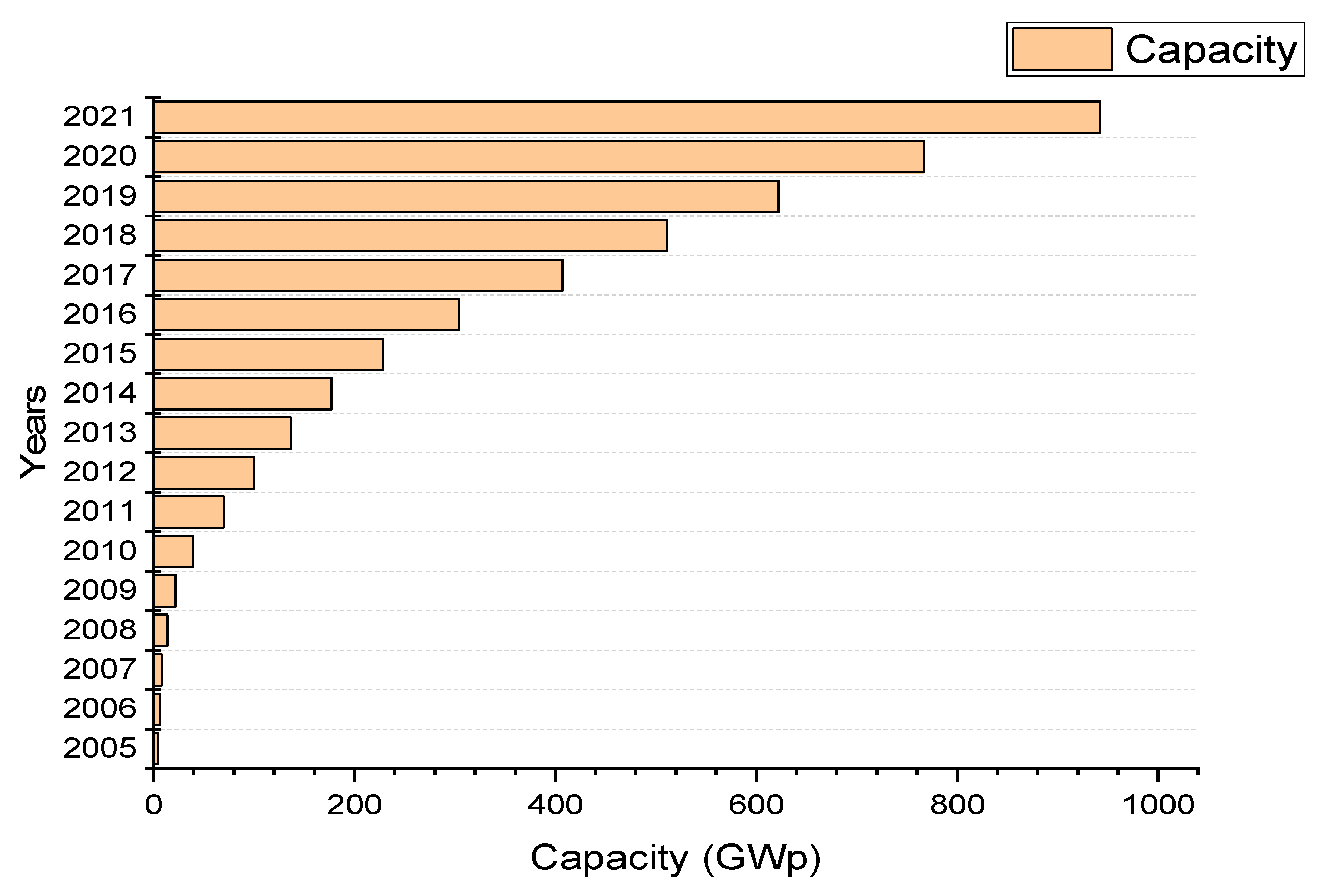

5. Global and Regional Trends in Electrical Energy from PV Cells

6. Characterization of PV Modules

6.1. Safety

6.1.1. Mechanical Safety

6.1.2. Electrical Safety

6.2. Reliability

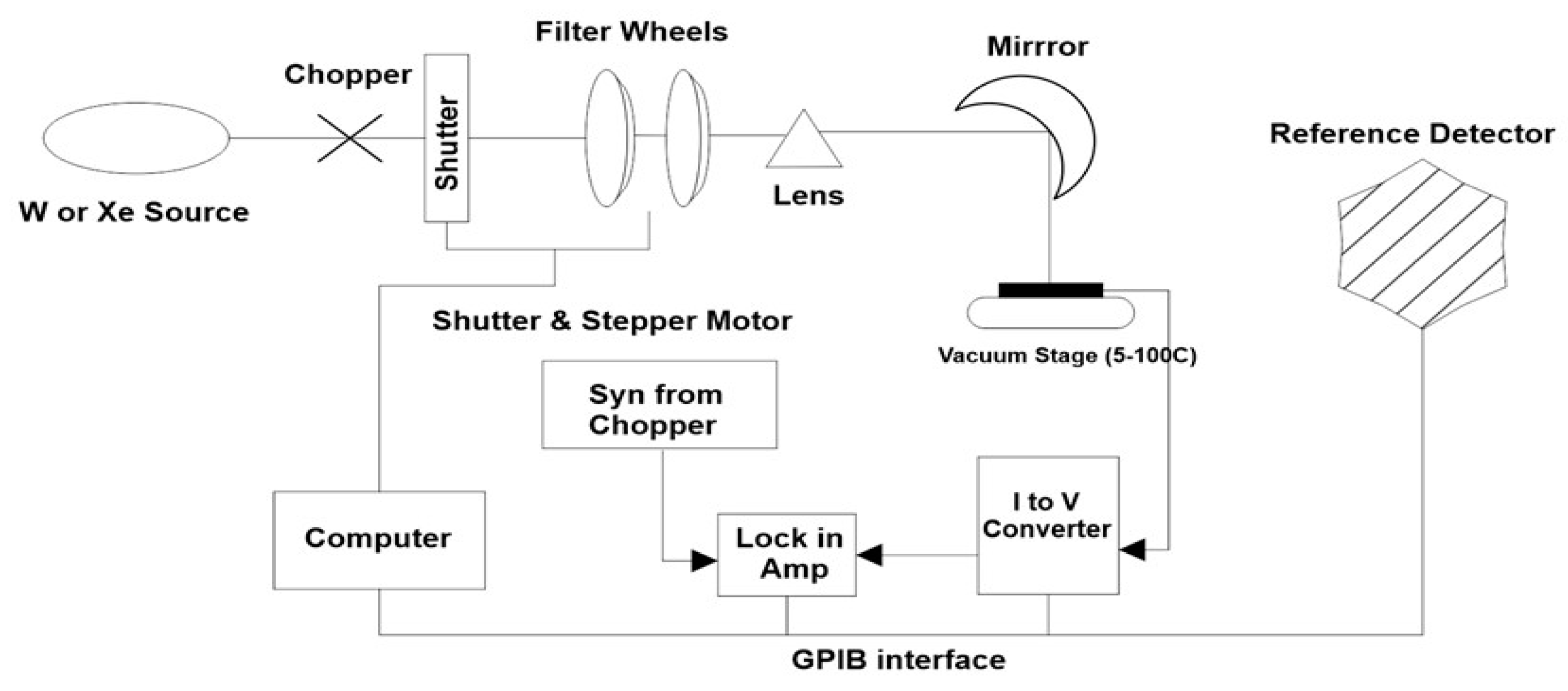

6.3. Spectral Responsivity

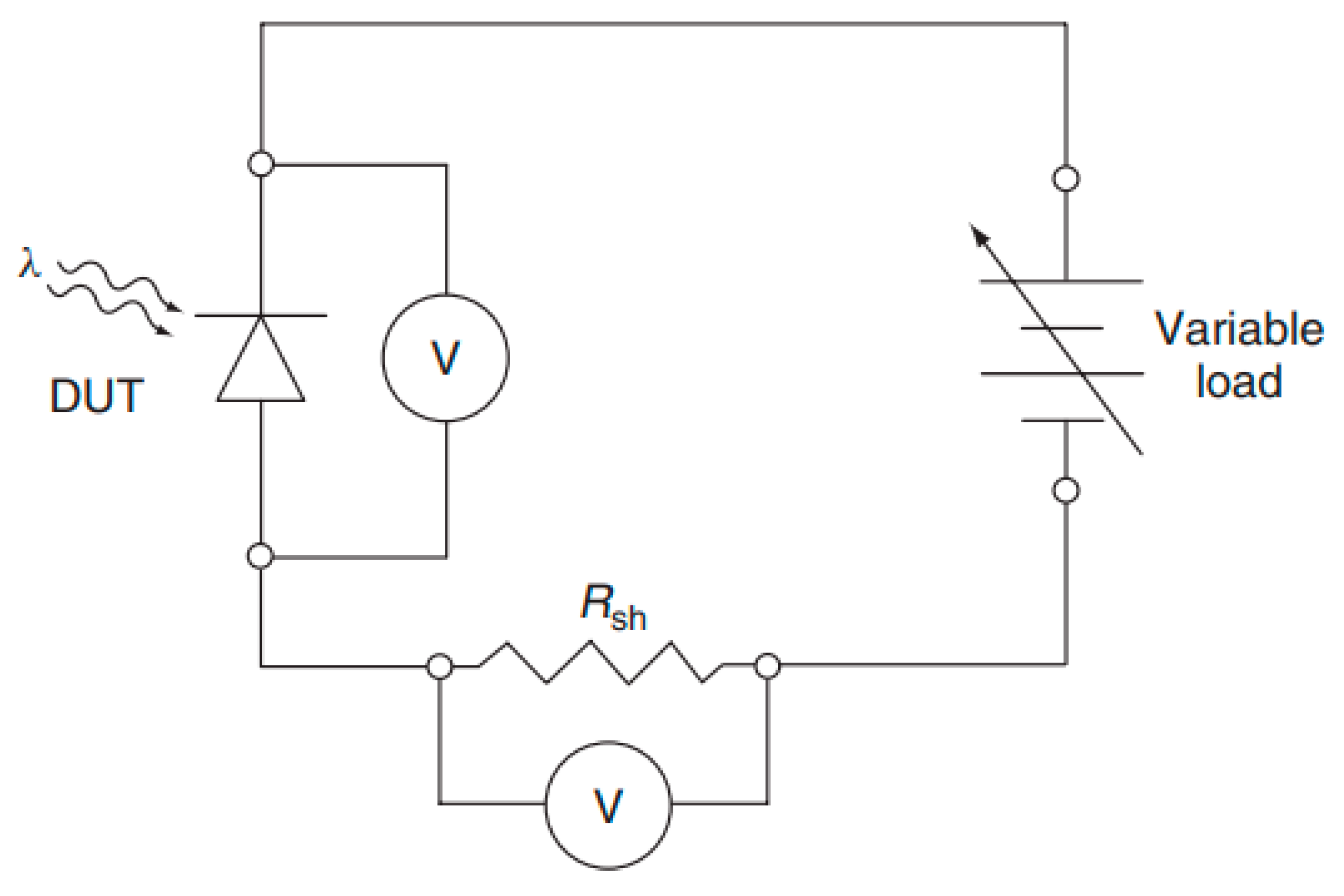

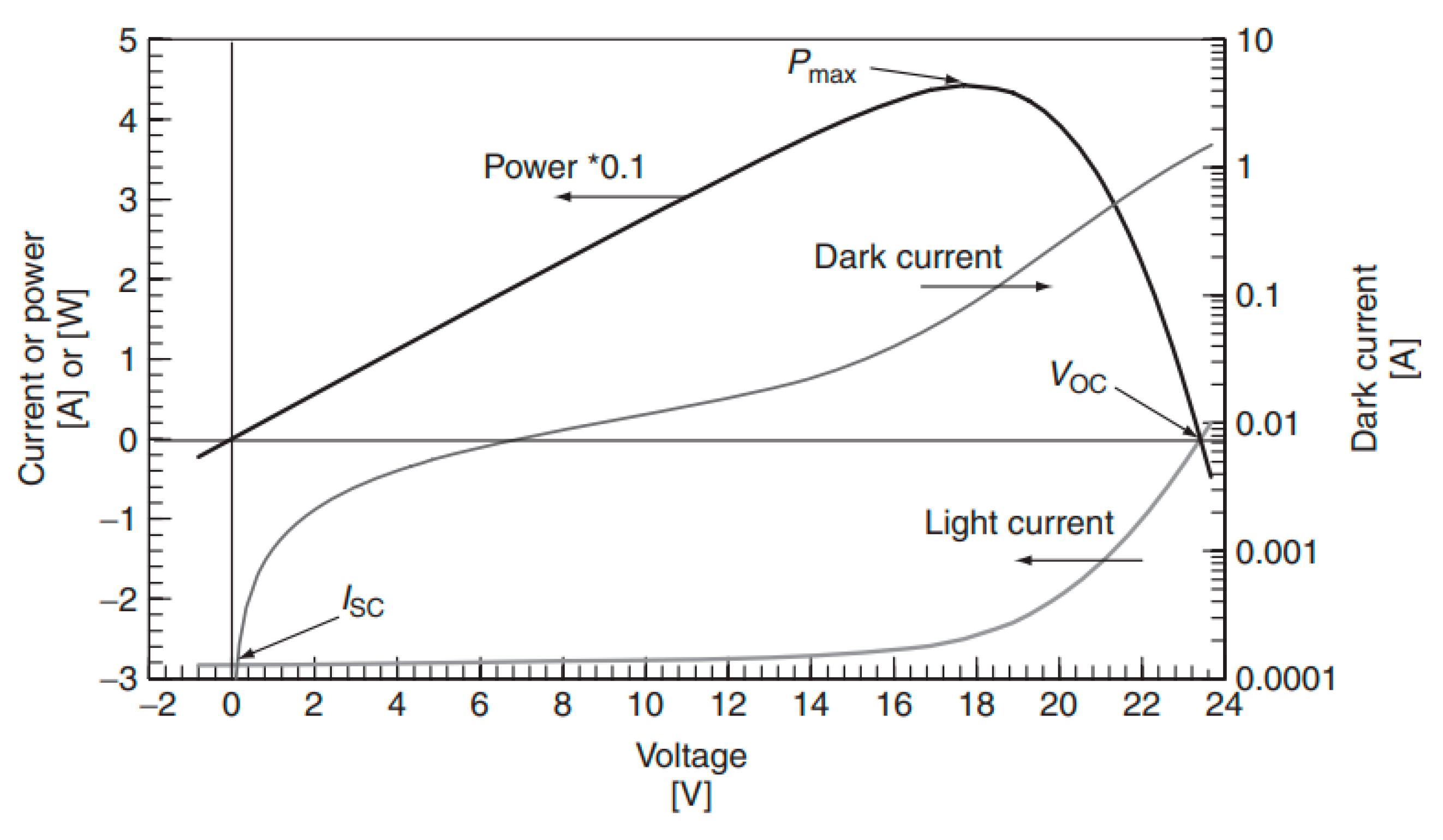

6.4. Current–Voltage Measurement

7. Current and Future Perspectives of PV Technology

7.1. Technical Developments, Challenges, and Impacts

7.2. Economic Developments, Challenges, and Impacts

7.3. Environmental Developments, Challenges, and Impacts

8. Future Suggestions

9. Summary

10. Conclusions

- Photovoltaic cells are divided into three major generations: first-, second-, and third-generation solar cells. First-generation solar cells are composed of silicon-based solar cells that are further divided into mono- and polycrystalline solar cells. The highest efficiency achieved by first-generation solar cells for single-crystalline solar cells is 26.1% while multi-crystalline solar cells have an efficiency of around 23.1%. Overall, first-generation solar cells are more developed and are suitable at mediocre temperatures. Second-generation solar cells are based on thin-film solar cells consisting of amorphous silicon cells, cadmium telluride (CdTe), and copper indium gallium selenide (CIGS). Amorphous silicon solar cells have achieved an efficiency of around 14% in the latest research studies. CdTe-based solar cells have achieved an efficiency of around 22.1% recently despite concerns regarding cadmium being toxic and hazardous to the environment. CIGS has recently racked up an efficiency of around 23.6%. Overall, second-generation solar cells operate better at high temperatures. Third-generation solar cells include organic solar cells, dye-sensitized solar cells, quantum dot solar cells, and perovskite cells. Organic solar cells are flexible and lightweight, and the recent efficiency achieved by them is around 19%. Dye-sensitized solar cells have acquired an efficiency of around 30%, and they have a high capacity in achieving higher efficiency. Quantum dot solar cells use nanotechnology, and quantum dots are inexpensive and also use a hybrid design. They recently achieved an efficiency of 18.1%. Perovskite solar cells have good light absorption capabilities, and they have recently achieved an efficiency of 25.8%. Overall, third-generation solar cells have a great capacity for high efficiency and market ingress. Furthermore, third-generation solar cells are more versatile compared to the other two generations. Concentrated solar cells have also demonstrated great potential in achieving high efficiencies. They use fewer materials while concentrating light on a specific area. By utilizing a precise tracking system using these cells, greater amounts of energy can be harnessed.

- It can be observed that in the last two decades that the world has shifted substantially toward solar energy, with Asia providing enormous contributions in the last 7 to 8 years.

- Solar cells are characterized by many factors. Mechanical and electrical safety tests are performed to determine the mechanical strength and electrical insulation properties of materials that are used to fabricate solar cells, respectively. A reliability test is performed to check hot spot formation in solar cells. The formation of hot spots after deployment decreases the efficiency of solar cells. Spectral responsivity elucidates how currents are generated in solar cells and the collection mechanism in PV cells. Via spectral responsivity, how much current would be produced by the incident light that falls on solar cells is determined. The behavior of I-V curves shows the maximum power obtained from solar cells.

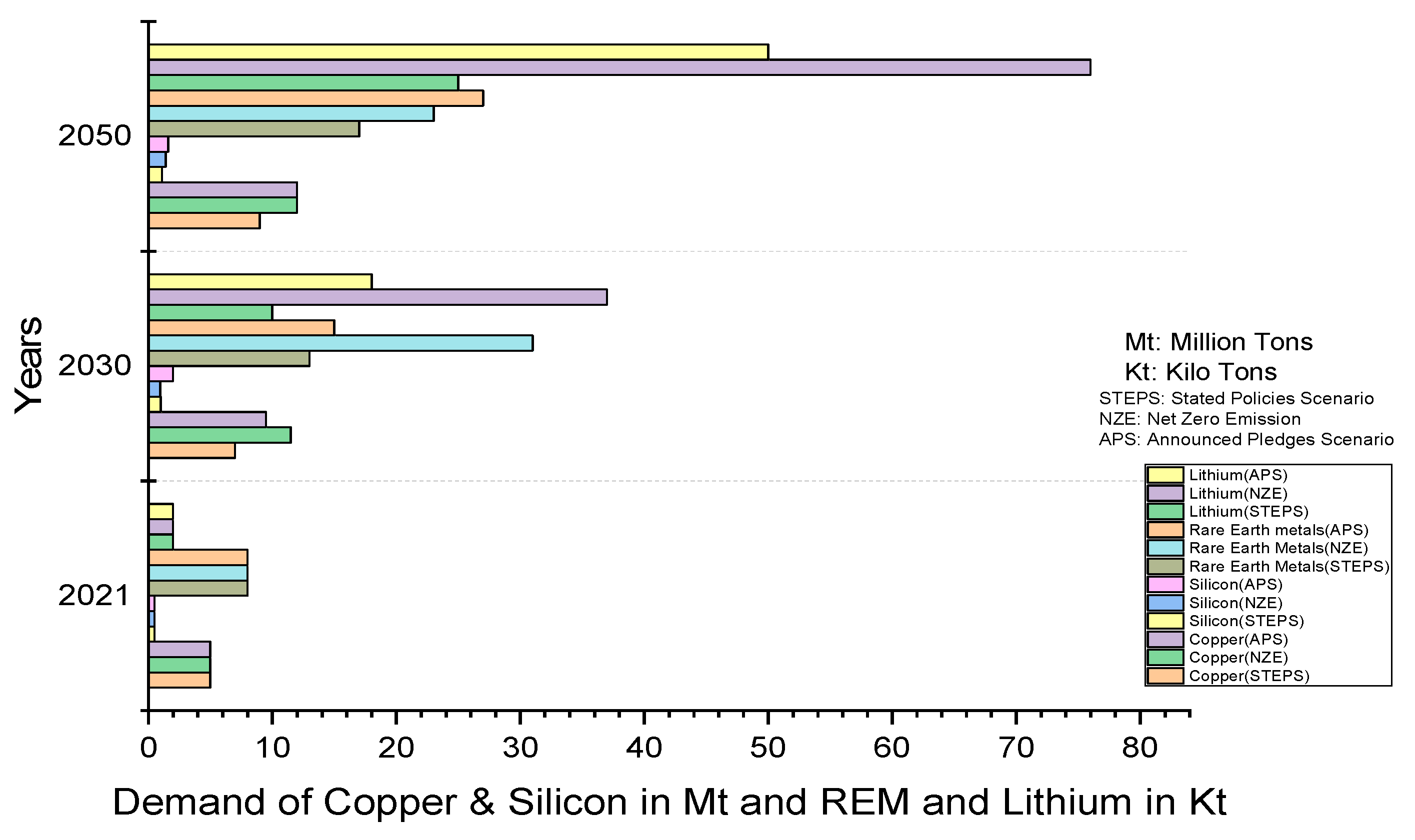

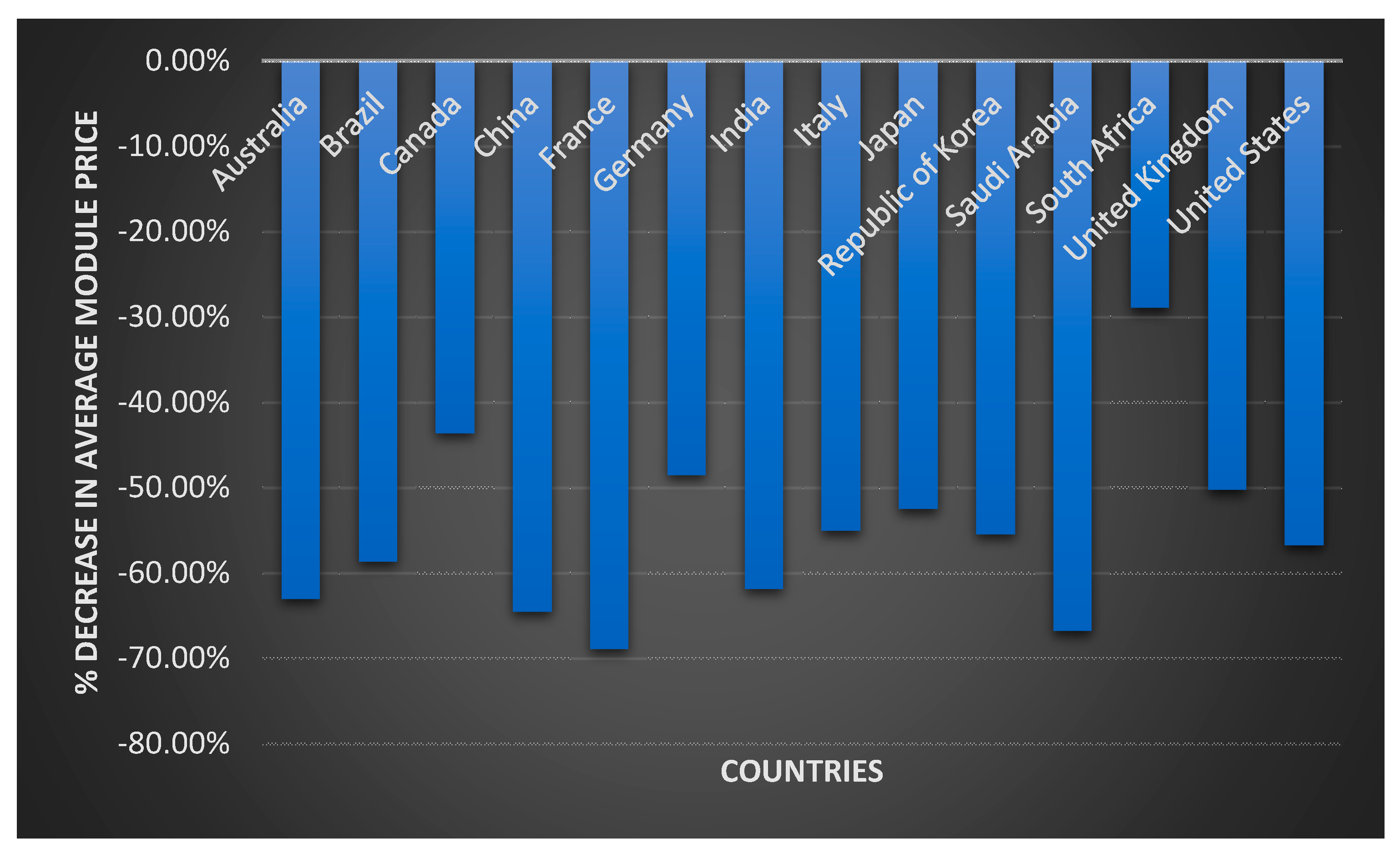

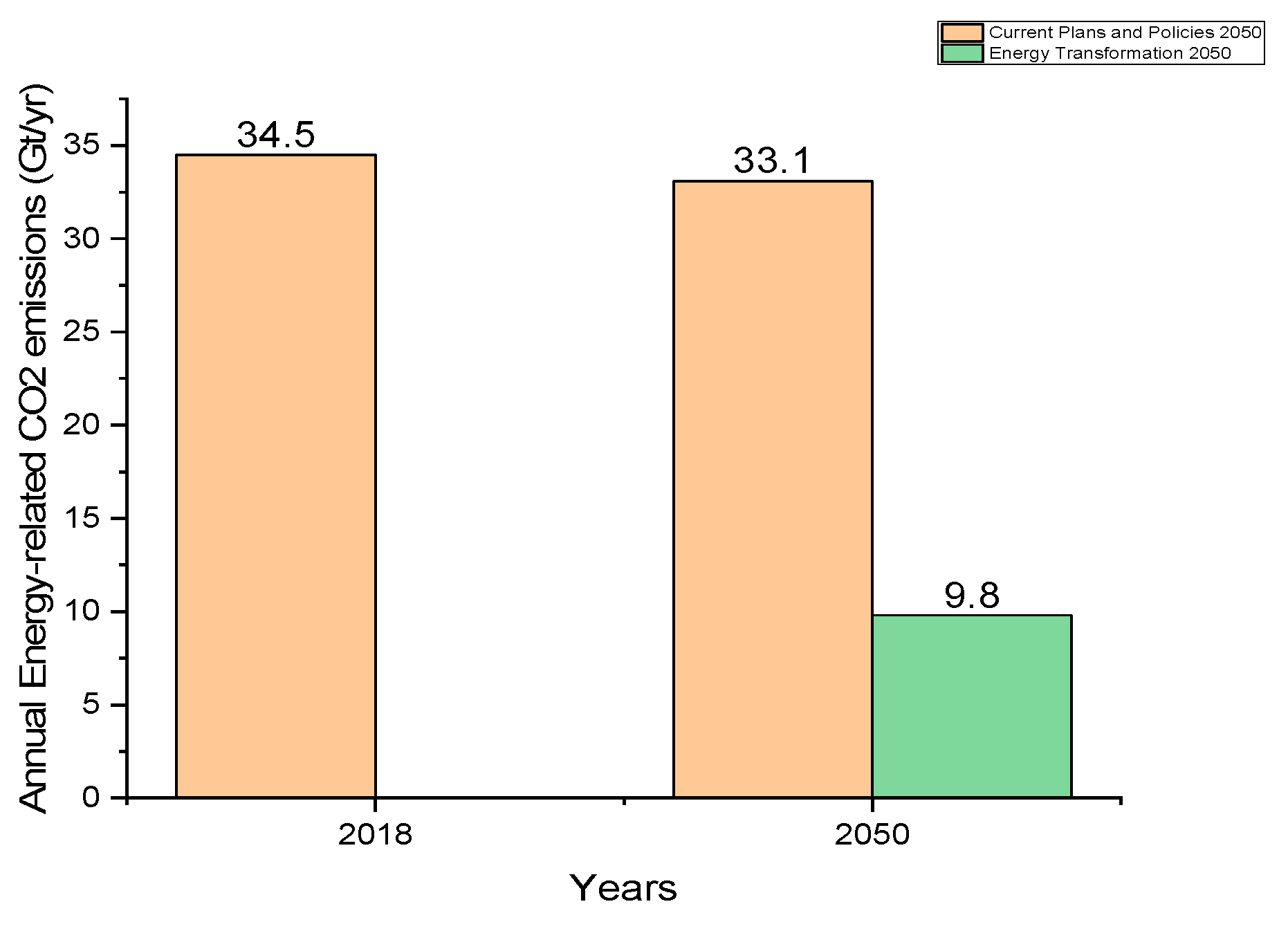

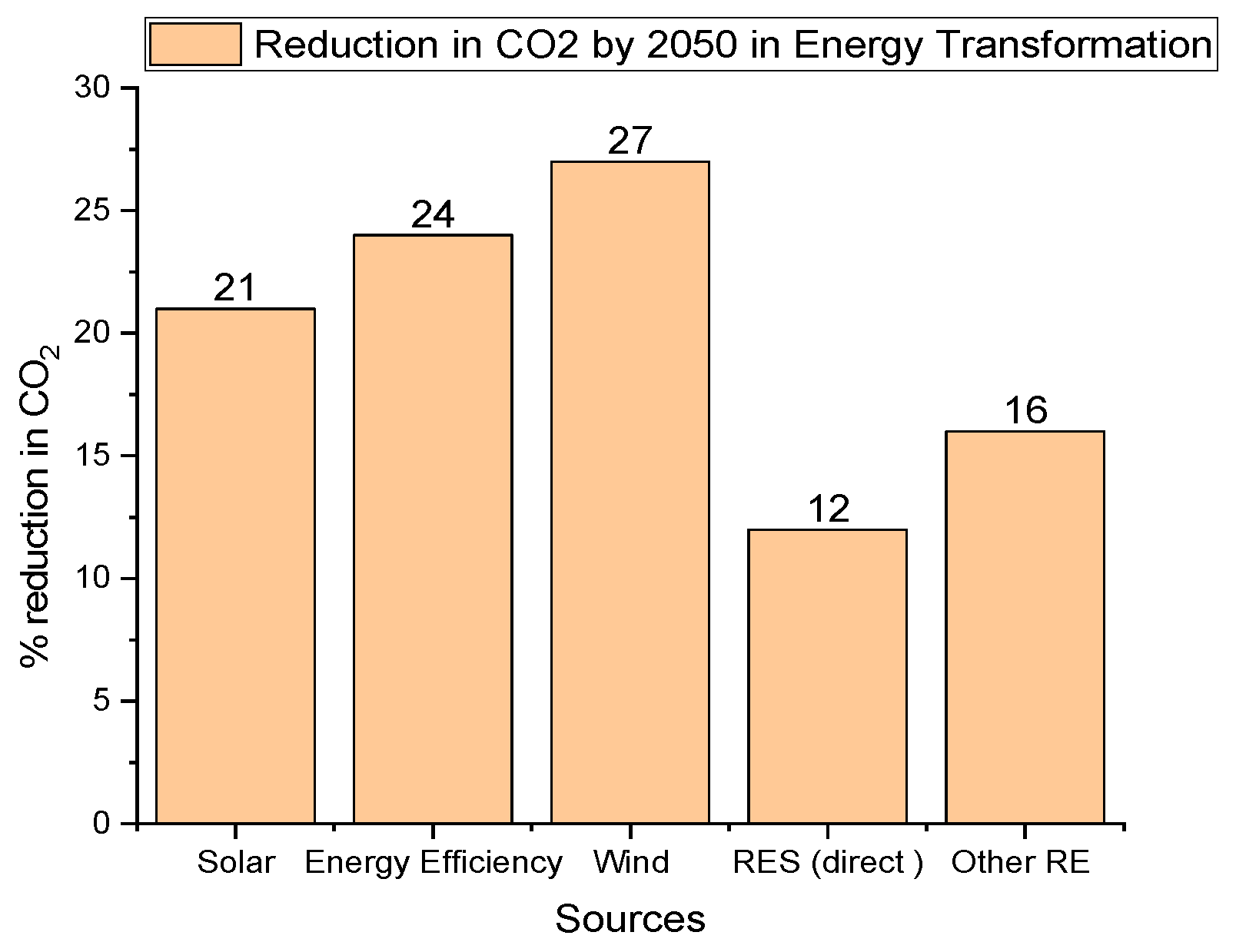

- There are some technical, environmental, and economic challenges that hamper the overall integration of solar energy in the power sector. Technical challenges are related to the efficiency of solar cells and the storage of energy after sunlight goes away. Because the PV industry is supposed to develop explosively in the few next years, the availability of materials to fabricate both solar cells and batteries that store energy is crucial. Research and development on a broader scale are required to decrease the price of batteries and to manufacture efficient and sustainable storage systems. Economic issues are related to the per unit price of energy obtained from solar cells and the overall price of PV panels. In the last decade, overall, the prices of solar cells have declined by around 77%. Massive investments in solar energy have also been observed in the last decade, which have created job opportunities for people in the solar industry. In the next three decades, as this industry grows even further, more jobs will be available. The major environmental problem is the uncontrolled and enormous emissions of CO2, which have decimated the environment considerably in the last 50 years. PV cells can play a pivotal role in decarbonization. It is speculated that around 21% of CO2 could be reduced by solar PV cells in the next three decades.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Singh, B.P.; Goyal, S.K.; Kumar, P. Solar PV cell materials and technologies: Analyzing the recent developments. Mater. Today Proc. 2021, 43, 2843–2849. [Google Scholar] [CrossRef]

- Ge, L.; Du, T.; Li, C.; Li, Y.; Yan, J.; Rafiq, M.U. Virtual Collection for Distributed Photovoltaic Data: Challenges, Methodologies, and Applications. Energies 2022, 15, 8783. [Google Scholar] [CrossRef]

- Bin, L.; Shahzad, M.; Javed, H.; Muqeet, H.A.; Akhter, M.N.; Liaqat, R.; Hussain, M.M. Scheduling and Sizing of Campus Microgrid Considering Demand Response and Economic Analysis. Sensors 2022, 22, 6150. [Google Scholar] [CrossRef]

- Olabi, A.G.; Abdelkareem, M.A. Renewable energy and climate change. Renew. Sustain. Energy Rev. 2022, 158, 112111. [Google Scholar] [CrossRef]

- Muqeet, H.A.U.; Ahmad, A. Optimal scheduling for campus prosumer microgrid considering price based demand response. IEEE Access 2020, 8, 71378–71394. [Google Scholar] [CrossRef]

- Sharma, P.; Goyal, P. Evolution of PV technology from conventional to nano-materials. Mater. Today Proc. 2020, 28, 1593–1597. [Google Scholar] [CrossRef]

- Muqeet, H.A.; Munir, H.M.; Javed, H.; Shahzad, M.; Jamil, M.; Guerrero, J.M. An energy management system of campus microgrids: State-of-the-art and future challenges. Energies 2021, 14, 6525. [Google Scholar] [CrossRef]

- Goetzberger, A.; Hebling, C.; Schock, H.W. Photovoltaic materials, history, status and outlook. Mater. Sci. Eng. R Rep. 2003, 40, 1–46. [Google Scholar] [CrossRef]

- Sethi, V.K.; Pandey, M.; Shukla, P. Cost Boundary in Silicon Solar Panel. Int. J. Chem. Eng. Appl. 2011, 2, 372–375. [Google Scholar] [CrossRef]

- Mercaldo, L.V.; Veneri, P.D. Silicon solar cells: Materials, technologies, architectures. Sol. Cells Light Manag. Mater. Strateg. Sustain. 2020, 1, 35–57. [Google Scholar] [CrossRef]

- Wȩgierek, P.; Billewicz, P. Research on mechanisms of electric conduction in the p-type silicon implanted with Ne+ ions. Acta Phys. Pol. A 2013, 123, 948–951. [Google Scholar] [CrossRef]

- Janani, M.; Nair, S.V.; Nair, A.S. Photovoltaics: Role of Nanotechnology in Dye-Sensitized Solar Cells. Nanotechnol. Energy Sustain. 2017, 1, 101–132. [Google Scholar] [CrossRef]

- Mittal, V. Al-Jamal, Nanotechnology, Fundamentals and Applications, 1st ed.; Dreamtech Press: New Delhi, India, 2020. [Google Scholar]

- Chopra, K.L.; Paulson, P.D.; Dutta, V. Thin-film solar cells: An overview. Prog. Photovolt. Res. Appl. 2004, 12, 69–92. [Google Scholar] [CrossRef]

- Zhang, J.; Chaker, M.; Ma, D. Pulsed laser ablation based synthesis of colloidal metal nanoparticles for catalytic applications. J. Colloid Interface Sci. 2017, 489, 138–149. [Google Scholar] [CrossRef]

- Matsumoto, R.; Adachi, S.; Sadki, E.H.S.; Yamamoto, S.; Tanaka, H.; Takeya, H.; Takano, Y. Maskless patterning of gallium-irradiated superconducting silicon using focused ion beam. ACS Appl. Electron. Mater. 2020, 2, 677–682. [Google Scholar] [CrossRef]

- Xie, Y.; Yu, H.; Deng, L.; Amin, R.S.; Yu, D.; Fetohi, A.E.; Maximov, M.Y.; Li, L.; El-Khatib, K.M.; Peng, S. Anchoring stable FeS2nanoparticles on MXene nanosheets: Via interface engineering for efficient water splitting. Inorg. Chem. Front. 2022, 9, 662–669. [Google Scholar] [CrossRef]

- Han, C.X.; Zhi, J.Q.; Zeng, Z.; Wang, Y.S.; Zhou, B.; Gao, J.; Wu, Y.X.; He, Z.Y.; Wang, X.M.; Yu, S.W. Synthesis and characterization of nano-polycrystal diamonds on refractory high entropy alloys by chemical vapour deposition. Appl. Surf. Sci. 2023, 623, 157108. [Google Scholar] [CrossRef]

- Baig, N.; Kammakakam, I.; Falath, W.; Kammakakam, I. Nanomaterials: A review of synthesis methods, properties, recent progress, and challenges. Mater. Adv. 2021, 2, 1821–1871. [Google Scholar] [CrossRef]

- Yamauchi, Y.; Kuroda, K. Rational design of mesoporous metals and related nanomaterials by a soft-template approach. Chem.—An Asian J. 2008, 3, 664–676. [Google Scholar] [CrossRef]

- Hameed, J.; Saeed, A. Applications of Nanotechnology in Solar Energy and Energy Storage Sectors; Scientific Research Publishing: Irvine, CA, USA, 2019. [Google Scholar]

- Jayakumar, P. Solar Energy Resource Assessment Handbook; Asian and Pacific Centre for Transfer of Technology: Delhi, India, 2009; pp. 1–117. [Google Scholar]

- Balaji, N.; Hussain, S.Q.; Park, C.; Raja, J.; Yi, J.; Jeyakumar, R. Surface passivation schemes for high-efficiency c-Si solar cells—A review. Trans. Electr. Electron. Mater. 2015, 16, 227–233. [Google Scholar] [CrossRef]

- Kiefer, F.; Ulzhöfer, C.; Brendemühl, T.; Harder, N.P.; Brendel, R.; Mertens, V.; Bordihn, S.; Peters, C.; Müller, J.W. High efficiency N-type emitter-wrap-through silicon solar cells. IEEE J. Photovolt. 2011, 1, 49–53. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory (NREL). Best Research-Cell Efficiencies Best Research-Cell Efficiency Chart Photovoltaic Research; NREL: Golden, CO, USA, 2021. [Google Scholar]

- Al-Ezzi, A.S.; Ansari, M.N.M. Photovoltaic Solar Cells: A Review. Appl. Syst. Innov. 2022, 5, 67. [Google Scholar] [CrossRef]

- Salve, R.V. State of Art of Thin Film Photovoltic Cell: A Review. Int. J. Sci. Res. Sci. Technol. 2020, 7, 157–163. [Google Scholar] [CrossRef]

- Imamzai, M.; Aghaei, M.; Thayoob, Y.H. A Review on Comparison between Traditional Silicon Solar Cells and Thin-Film CdTe Solar Cell. Proc. Natl. Grad. Conf. 2011, 2012, 8–10. [Google Scholar]

- Sharma, S.; Jain, K.K.; Sharma, A. Solar Cells: In Research and Applications—A Review. Mater. Sci. Appl. 2015, 06, 1145–1155. [Google Scholar] [CrossRef]

- Kang, H. Crystalline Silicon vs. Amorphous Silicon: The Significance of Structural Differences in Photovoltaic Applications. IOP Conf. Ser. Earth Environ. Sci. 2021, 726, 6–11. [Google Scholar] [CrossRef]

- Osayemwenre, G.O.; Meyer, E.L. Confirmation of the Degradation of Single Junction Amorphous Silicon Modules (a-Si:H). Int. J. Photoenergy 2019, 2019, 3452180. [Google Scholar] [CrossRef]

- Efaz1, E.T.; Rhaman, M.M.; Al Imam, S.; Bashar, K.L.; Kabir, F.; Mourtaza, M.E.; Sakib, S.N.; Mozahid, F.A. A review of primary technologies of thin-film solar cells. Eng. Res. Express 2021, 3, 032001. [Google Scholar] [CrossRef]

- Report: INFORME Assessment of Performance, Environmental, Health and Safety Aspects of First Solar’s CdTe PV Technology; CENER: Blyth, UK, 2016; pp. 1–105.

- Britt, J.; Ferekides, C. Thin-film CdS/CdTe solar cell with 15.8% efficiency. Appl. Phys. Lett. 1993, 62, 2851–2852. [Google Scholar] [CrossRef]

- De Vos (UGent), A.; Parrott, J.; Baruch, P.; Bandgap, P.L. Bandgap effects in thin-film heterojunction solar cells. In Proceedings of the 12th European Photovoltaic Solar Energy Conference, H.S. Stephens & Associates, Amsterdam, The Netherlands, 11–15 April 1994; pp. 1315–1318. Available online: http://hdl.handle.net/1854/LU-246033 (accessed on 10 March 2023).

- The U.S. Department of Energy (DOE). Cadmium Telluride Solar Energy Technologies Office. Available online: https://www.energy.gov/eere/solar/cadmium-telluride (accessed on 12 March 2023).

- Information, E.C.A.S. Cadmium and Cadmium Compounds. 2023. Available online: https://echa.europa.eu/substance-information/-/substanceinfo/100.318.702 (accessed on 20 March 2023).

- Liu, R.S.; Zhang, L.; Sun, X.; Liu, H.; Zhang, J. Lithium Ion Rechargeable Batteries High Energy Density Lithium Batteries Nanostructured Materials in Electrochemistry Electrocatalysis of Direct Methanol Fuel Cells Advanced Lithium-Ion Batteries; Wiley-VCH: Hoboken, NJ, USA, 2011; ISBN 9783527326952. [Google Scholar]

- Moradi, M.; Teimouri, R.; Saadat, M.; Zahedifar, M. Buffer layer replacement: A method for increasing the conversion efficiency of CIGS thin film solar cells. Optik (Stuttg) 2017, 136, 222–227. [Google Scholar] [CrossRef]

- Hegedus, S.; Luque, A. Handbook of Photovoltaic Science and Engineering; Wiley: Hoboken, NJ, USA, 2011; ISBN 9780470721698. [Google Scholar]

- Zhou, H.; Hsu, W.C.; Duan, H.S.; Bob, B.; Yang, W.; Bin Song, T.; Hsu, C.J.; Yang, Y. CZTS nanocrystals: A promising approach for next generation thin film photovoltaics. Energy Environ. Sci. 2013, 6, 2822–2838. [Google Scholar] [CrossRef]

- Stanbery, B.J.; Abou-Ras, D.; Yamada, A.; Mansfield, L. CIGS photovoltaics: Reviewing an evolving paradigm. J. Phys. D Appl. Phys. 2021, 55, 173001. [Google Scholar] [CrossRef]

- Mufti, N.; Amrillah, T.; Taufiq, A.; Sunaryono; Aripriharta; Diantoro, M.; Zulhadjri; Nur, H. Review of CIGS-based solar cells manufacturing by structural engineering. Sol. Energy 2020, 207, 1146–1157. [Google Scholar] [CrossRef]

- Feurer, T.; Reinhard, P.; Avancini, E.; Bissig, B.; Löckinger, J.; Fuchs, P.; Carron, R.; Weiss, T.P.; Perrenoud, J.; Stutterheim, S.; et al. Progress in thin film CIGS photovoltaics—Research and development, manufacturing, and applications. Prog. Photovolt. Res. Appl. 2017, 25, 645–667. [Google Scholar] [CrossRef]

- Isabela, C.B.; Lameirinhas, R.A.M.; Torres, J.P.N.; Fernandes, C.A. Comparative study of the copper indium gallium selenide (CIGS) solar cell with other solar technologies. Sustain. Energy Fuels 2021, 5, 2273–2283. [Google Scholar] [CrossRef]

- Srinivas, B.; Balaji, S.; Nagendra Babu, M.; Reddy, Y.S. Review on Present and Advance Materials for Solar Cells. Int. J. Eng. Res. 2015, 3, 178–182. [Google Scholar]

- Razykov, T.M.; Ferekides, C.S.; Morel, D.; Stefanakos, E.; Ullal, H.S.; Upadhyaya, H.M. Solar photovoltaic electricity: Current status and future prospects. Sol. Energy 2011, 85, 1580–1608. [Google Scholar] [CrossRef]

- Theelen, M.; Barreau, N.; Daume, F.; Steijvers, H.; Hans, V.; Liakopoulou, A.; Vroon, Z.; Zeman, M. Accelerated performance degradation of CIGS solar cell determined by in-situ monitoring. In Proceedings of the Reliability of Photovoltaic Cells, Modules, Components, and Systems VII, San Diego, CA, USA, 17–21 August 2014; Volume 9179, p. 91790I. [Google Scholar] [CrossRef]

- Ramanujam, J.; Singh, U.P. Copper indium gallium selenide based solar cells—A review. Energy Environ. Sci. 2017, 10, 1306–1319. [Google Scholar] [CrossRef]

- Abdulrazzaq, O.A.; Saini, V.; Bourdo, S.; Dervishi, E.; Biris, A.S. Organic solar cells: A review of materials, limitations, and possibilities for improvement. Part. Sci. Technol. 2013, 31, 427–442. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Bi, P.; Chen, Z.; Qiao, J.; Li, J.; Wang, W.; Zheng, Z.; Zhang, S.; Hao, X.; et al. Binary Organic Solar Cells with 19.2% Efficiency Enabled by Solid Additive. Adv. Mater. 2023, 35, 202301583. [Google Scholar] [CrossRef]

- Fusella, M.A. Handbook of Organic Materials for Electronic and Photonic Devices, 2nd ed.; Ostroverkhova, O., Ed.; Woodhead Publishing: Duxford, UK, 2019; ISBN 978-0-08-102284-9. [Google Scholar]

- Dyer-Smith, C.; Nelson, J.; Li, Y. Organic Solar Cells. In McEvoy’s Handb. Photovoltaics; Fundamentals and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 567–597. [Google Scholar] [CrossRef]

- Chandra Sil, M.; Chen, L.S.; Lai, C.W.; Lee, Y.H.; Chang, C.C.; Chen, C.M. Enhancement of power conversion efficiency of dye-sensitized solar cells for indoor applications by using a highly responsive organic dye and tailoring the thickness of photoactive layer. J. Power Sources 2020, 479, 229095. [Google Scholar] [CrossRef]

- Kokkonen, M.; Talebi, P.; Zhou, J.; Asgari, S.; Soomro, S.A.; Elsehrawy, F.; Halme, J.; Ahmad, S.; Hagfeldt, A.; Hashmi, S.G. Advanced research trends in dye-sensitized solar cells. J. Mater. Chem. A 2021, 9, 10527–10545. [Google Scholar] [CrossRef] [PubMed]

- Sugathan, V.; John, E.; Sudhakar, K. Recent improvements in dye sensitized solar cells: A review. Renew. Sustain. Energy Rev. 2015, 52, 54–64. [Google Scholar] [CrossRef]

- Sharma, K.; Sharma, V.; Sharma, S.S. Dye-Sensitized Solar Cells: Fundamentals and Current Status. Nanoscale Res. Lett. 2018, 13, 1–46. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Zhang, D.; Suo, J.; Cao, Y.; Eickemeyer, F.T.; Vlachopoulos, N.; Zakeeruddin, S.M.; Hagfeldt, A.; Grätzel, M. Hydroxamic acid pre-adsorption raises the efficiency of cosensitized solar cells. Nature 2023, 613, 60–65. [Google Scholar] [CrossRef]

- Akhil, S.; Akash, S.; Pasha, A.; Kulkarni, B.; Jalalah, M.; Alsaiari, M.; Harraz, F.A.; Balakrishna, R.G. Review on perovskite silicon tandem solar cells: Status and prospects 2T, 3T and 4T for real world conditions. Mater. Des. 2021, 211, 110138. [Google Scholar] [CrossRef]

- Li, H.; Zhang, W. Perovskite Tandem Solar Cells: From Fundamentals to Commercial Deployment. Chem. Rev. 2020, 120, 9835–9950. [Google Scholar] [CrossRef]

- Salem, M.S.; Shaker, A.; Abouelatta, M.; Saeed, A. Full Optoelectronic Simulation of Lead-Free Perovskite/Organic Tandem Solar Cells. Polymers 2023, 15, 784. [Google Scholar] [CrossRef]

- Cacovich, S.; Ciná, L.; Matteocci, F.; Divitini, G.; Midgley, P.A.; Di Carlo, A.; Ducati, C. Gold and iodine diffusion in large area perovskite solar cells under illumination. Nanoscale 2017, 9, 4700–4706. [Google Scholar] [CrossRef]

- Yang, J.; Siempelkamp, B.D.; Liu, D.; Kelly, T.L. Investigation of CH3NH3PbI3degradation rates and mechanisms in controlled humidity environments using in situ techniques. ACS Nano 2015, 9, 1955–1963. [Google Scholar] [CrossRef]

- Misra, R.K.; Aharon, S.; Li, B.; Mogilyansky, D.; Visoly-Fisher, I.; Etgar, L.; Katz, E.A. Temperature- and component-dependent degradation of perovskite photovoltaic materials under concentrated sunlight. J. Phys. Chem. Lett. 2015, 6, 326–330. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Brandl, M.; May, B.; Levchuk, I.; Hou, Y.; Richter, M.; Chen, H.; Chen, S.; Kahmann, S.; Osvet, A.; et al. Photoinduced degradation of methylammonium lead triiodide perovskite semiconductors. J. Mater. Chem. A 2016, 4, 15896–15903. [Google Scholar] [CrossRef]

- The U.S. Department of Energy (DOE). Solar Energy Technologies Office (SETO) Solar Energy Research Areas, Photovoltaics Pervoskite Solar Cells. 2022. Available online: https://www.energy.gov/eere/solar/perovskite-solar-cells (accessed on 2 June 2023).

- Köhnen, E.; Wagner, P.; Lang, F.; Cruz, A.; Li, B.; Roß, M.; Jošt, M.; Morales-Vilches, A.B.; Topič, M.; Stolterfoht, M.; et al. 27.9% Efficient Monolithic Perovskite/Silicon Tandem Solar Cells on Industry Compatible Bottom Cells. Sol. RRL 2021, 5, 2100244. [Google Scholar] [CrossRef]

- Shockley, W.; Queisser, H.J. Detailed balance limit of efficiency of p-n junction solar cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- Ahmed, I.; Shi, L.; Pasanen, H.; Vivo, P.; Maity, P.; Hatamvand, M.; Zhan, Y. There is plenty of room at the top: Generation of hot charge carriers and their applications in perovskite and other semiconductor-based optoelectronic devices. Light Sci. Appl. 2021, 10, 174. [Google Scholar] [CrossRef]

- Tvrdy, K.; Kamat, P.V. Quantum Dot Solar Cells. Compr. Nanosci. Technol. 2011, 1–5, 257–275. [Google Scholar] [CrossRef]

- Liu, S.; Li, M.Y.; Xiong, K.; Gao, J.; Lan, X.; Zhang, D.; Gao, L.; Zhang, J.; Tang, J. Efficient quantum dot infrared solar cells with enhanced low-energy photon conversion via optical engineering. Nano Res. 2023, 16, 2392–2398. [Google Scholar] [CrossRef]

- NREL. Best Research-Cell Efficiencies, Quantum Dot Cells (Various Types). 2023. Available online: https://www.nrel.gov/ (accessed on 2 March 2023).

- Song, H.; Lin, Y.; Zhang, Z.; Rao, H.; Wang, W.; Fang, Y.; Pan, Z.; Zhong, X. Improving the Efficiency of Quantum Dot Sensitized Solar Cells beyond 15% via Secondary Deposition. J. Am. Chem. Soc. 2021, 143, 4790–4800. [Google Scholar] [CrossRef]

- Palomares, E.; Clifford, J.N.; Haque, S.A.; Lutz, T.; Durrant, J.R. Control of charge recombination dynamics in dye sensitized solar cells by the use of conformally deposited metal oxide blocking layers. J. Am. Chem. Soc. 2003, 125, 475–482. [Google Scholar] [CrossRef]

- Son, H.J.; Wang, X.; Prasittichai, C.; Jeong, N.C.; Aaltonen, T.; Gordon, R.G.; Hupp, J.T. Glass-encapsulated light harvesters: More efficient dye-sensitized solar cells by deposition of self-aligned, conformal, and self-limited silica layers. J. Am. Chem. Soc. 2012, 134, 9537–9540. [Google Scholar] [CrossRef]

- Coffey, V.C. Solar Concentrators: Using Optics to Boost Photovoltaics. Opt. Photonics News 2011, 22, 22. [Google Scholar] [CrossRef]

- Imran Khan, M.; Asfand, F.; Al-Ghamdi, S.G. Progress in technology advancements for next generation concentrated solar power using solid particle receivers. Sustain. Energy Technol. Assess. 2022, 54, 102813. [Google Scholar] [CrossRef]

- Unger, B. Concentrated Photovoltaics. Opt. Photonics News 2009, 20, 26. [Google Scholar] [CrossRef]

- Apostoleris, H.; Stefancich, M.; Chiesa, M. Tracking-integrated systems for concentrating photovoltaics. Nat. Energy 2016, 1, 16018. [Google Scholar] [CrossRef]

- Farahat, M.A. Improvement the thermal electric performance of a photovoltaic cells by cooling and concentration techniques. 39th Int. Univ. Power Eng. Conf. UPEC 2004—Conf. Proc. 2004, 2, 623–628. [Google Scholar]

- Zheng, S.; Shahzad, M.; Asif, H.M.; Gao, J.; Muqeet, H.A. Advanced optimizer for maximum power point tracking of photovoltaic systems in smart grid: A roadmap towards clean energy technologies. Renew. Energy 2023, 206, 1326–1335. [Google Scholar] [CrossRef]

- Pitz-Paal, R. Concentrating Solar Power; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; ISBN 9780081028865. [Google Scholar]

- Green, M.A.; Dunlop, E.D.; Siefer, G.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Hao, X. Solar cell efficiency tables (Version 61). Prog. Photovoltaics Res. Appl. 2023, 31, 3–16. [Google Scholar] [CrossRef]

- Chomać-Pierzecka, E.; Kokiel, A.; Rogozińska-Mitrut, J.; Sobczak, A.; Soboń, D.; Stasiak, J. Analysis and Evaluation of the Photovoltaic Market in Poland and the Baltic States. Energies 2022, 15, 669. [Google Scholar] [CrossRef]

- Masson, G.; Bosch, E.; Kaizuka, I.; Jäger-Waldau, A.; Donoso, J. Snapshot of Global PV Markets 2022 Task 1 Strategic PV Analysis and Outreach PVPS; IEA PVPS: Paris, France, 2022; Volume 44. [Google Scholar]

- Kurtz, S. Reliability and Durability of PV Modules. Photovolt. Sol. Energy 2017, 61730, 491–501. [Google Scholar] [CrossRef]

- Hacke, P.; Terwilliger, K.; Smith, R.; Glick, S.; Pankow, J.; Kempe, M.; Bennett, S.K.I.; Kloos, M. System voltage potential-induced degradation mechanisms in PV modules and methods for test. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 000814–000820. [Google Scholar] [CrossRef]

- Roy, J.N.; Bose, D.N. Characterization, Testing and Reliability of Solar PV Module; Cambridge University Press: Cambridge, UK, 2018; ISBN 9781108231718. [Google Scholar] [CrossRef]

- Nahar Myyas, R.; Al-Dabbasa, M.; Tostado-Véliz, M.; Jurado, F. A novel solar panel cleaning mechanism to improve performance and harvesting rainwater. Sol. Energy 2022, 237, 19–28. [Google Scholar] [CrossRef]

- Anderson, P.M. Semiconductor Memories Technology, Testing, and Reliability; IEEE Press: Piscataway, NJ, USA, 2002. [Google Scholar] [CrossRef]

- Emery, K.; Dunlavy, D.; Field, H.; Moriarty, T. Photovoltaic Spectral Responsivity Measurements. In Proceedings of the 2nd World Conference on Photovoltaic Solar Energy Conversion, Vienna, Austria, 6–10 July 1998; pp. 2298–2301. [Google Scholar]

- Chen, H.; Cong, T.N.; Yang, W.; Tan, C.; Li, Y.; Ding, Y. Progress in electrical energy storage system: A critical review. Prog. Nat. Sci. 2009, 19, 291–312. [Google Scholar] [CrossRef]

- He, Y.; Wang, F.; Du, G.; Pan, L.; Wang, K.; Gerhard, R.; Plath, R.; Rozga, P.; Trnka, P. Revisiting the thermal ageing on the metallised polypropylene film capacitor: From device to dielectric film. High Volt. 2022, 8, 305–314. [Google Scholar] [CrossRef]

- Javed, H.; Muqeet, H.A.; Shehzad, M.; Jamil, M.; Khan, A.A.; Guerrero, J.M. Optimal energy management of a campus microgrid considering financial and economic analysis with demand response strategies. Energies 2021, 14, 8501. [Google Scholar] [CrossRef]

- International Energy Agency International Energy Agency (IEA) World Energy Outlook. 2022. Available online: https://www.iea.org/reports/world-energy-outlook-2022 (accessed on 1 April 2023).

- Ren, R.; Lai, F.; Lang, X.; Li, L.; Yao, C.; Cai, K. Efficient sulfur host based on Sn doping to construct Fe2O3 nanospheres with high active interface structure for lithium-sulfur batteries. Appl. Surf. Sci. 2023, 613, 156003. [Google Scholar] [CrossRef]

- World Trade Organization. Trading into a Bright Energy Future; World Trade Organization: Geneva, Switzerland, 2021. [Google Scholar] [CrossRef]

- IRENA. Future of Solar Photovoltaic: Deployment, Investment, Technology, Grid Integration and Socio-Economic Aspects (A Global Energy Transformation: Paper). 2019. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Oct/IRENA_Future_of_wind_2019.pdf (accessed on 2 April 2023).

- IEA. CO2 Emissions in 2022. Glob. Energy 2022, 62, 20–21. Available online: https://www.iea.org/news/global-co2-emissions-rebounded-to-their-highest-level-in-history-in-2021 (accessed on 2 April 2023).

- Chen, J.; Sun, B.; Li, Y.; Jing, R.; Zeng, Y.; Li, M. Credible capacity calculation method of distributed generation based on equal power supply reliability criterion. Renew. Energy 2022, 201, 534–547. [Google Scholar] [CrossRef]

- IPCC. Summary for Policymakers. In Global Warming of 1.5°C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to; World Meteorological Organization: Geneva, Switzerland, 2018; Volume os8, p. 1969. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, Y.; Zhang, F.; Lee, C.S. A Novel Aluminum–Graphite Dual-Ion Battery. Adv. Energy Mater. 2016, 6, 1502588. [Google Scholar] [CrossRef]

- Mu, S.; Liu, Q.; Kidkhunthod, P.; Zhou, X.; Wang, W.; Tang, Y. Molecular grafting towards high-fraction active nanodots implanted in N-doped carbon for sodium dual-ion batteries. Natl. Sci. Rev. 2021, 8, nwaa178. [Google Scholar] [CrossRef]

- Chen, C.; Lee, C.S.; Tang, Y. Fundamental Understanding and Optimization Strategies for Dual-Ion Batteries: A Review. Nano-Micro Lett. 2023, 15, 121. [Google Scholar] [CrossRef]

- Nasir, T.; Bukhari, S.S.H.; Raza, S.; Munir, H.M.; Abrar, M.; Muqeet, H.A.U.; Bhatti, K.L.; Ro, J.-S.; Masroor, R. Recent Challenges and Methodologies in Smart Grid Demand Side Management: State-of-the-Art Literature Review. Math. Probl. Eng. 2021, 2021, 5821301. [Google Scholar] [CrossRef]

| Sr. No | Selection Criteria | Cited Papers |

|---|---|---|

| 1 | First-Generation Solar Cells | [10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26] |

| 2 | Second-Generation Solar Cells | [27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48] |

| 3 | Third-Generation Solar Cells | [49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76] |

| 4 | Concentrated Solar Cells | [77,78,79,80,81,82,83] |

| 5 | Comparison of Efficiency of solar cells | [84] |

| 6 | Global and regional Trends | [85,86] |

| 7 | Characterization of PV modules | [87,88,89,90,91,92,93] |

| 8 | Current and Future Perspectives of PV technology | [94,95,96,97,98,99,100,101,102,103] |

| Photo Anode | Jsc (mA/cm2) | Voc (V) | Fill Factor | PCE (%) |

|---|---|---|---|---|

| TiO2/QD | 24.69 ± 0.27 | 0.634 ± 0.003 | 0.640 ± 0.001 | 10.03 ± 0.07 |

| TiO2/QD/QD | 24.56 ± 0.57 | 0.631 ± 0.002 | 0.639 ± 0.005 | 9.90± 0.19 |

| TiO2/QD/Mg/QD | 26.79 ± 0.16 | 0.644 ± 0.003 | 0.652 ± 0.001 | 11.25 ± 0.10 |

| TiO2/QD | 25.03 | 0.632 | 0.637 | 10.11 |

| TiO2/QD/QD | 25.19 | 0.634 | 0.634 | 10.12 |

| TiO2/QD/Mg/QD | 27.03 | 0.645 | 0.651 | 11.35 |

| Classification | Efficiency (%) | Area (cm2) | Voc (v) | Isc (mA/Cm2) | FF (%) | Test CDate | Description |

|---|---|---|---|---|---|---|---|

| Silicon | |||||||

| Si (Crystalline Solar) | 26.8 ± 0.4 | 274.4 | 0.7514 | 41.45 | 86.1 | ISHF (8/22) | LONGI, n-type HJT |

| Si (DS wafer cell) | 24.4 ± 0.3 | 267.5 | 0.7132 | 41.47 | 82.5 | ISFH (8/20) | Jinko Solar, n-type |

| Si (thin transfer submodule) | 21.2 ± 0.4 | 239.7 | 0.687 | 38.5 | 80.3 | NREL (4/14) | Solexel (35 μm thick) |

| Si (thin-film module) | 10.5 ± 0.3 | 94 | 0.492 | 29.7 | 72.1 | FhG-ISE (8/07) | CSG Solar (<2 μm on glass) |

| III–V Cells | |||||||

| GaAs (thin-film cell) | 29.1 ± 0.6 | 0.998 | 1.1272 | 29.788 | 86.7 | FhG-ISE (10/18) | Alta Devices |

| GaAs (multi-crystalline) | 18.4 ± 0.5 | 4.011 | 0.994 | 23.2 | 79.7 | NREL (11/95) | RTI, Ge substrate |

| InP (crystalline cell) | 24.2 ± 0.5 | 1.008 | 0.939 | 31.15 | 82.6 | NREL (3/13) | NREL |

| Thin Film Chalcogenide | |||||||

| CIGS (cell) (Cd-free) | 23.35 ± 0.5 | 1.043 | 0.734 | 39.58 | 80.4 | AIST (11/18) | Solar Frontier |

| CIGSSe (submodule) | 19.8 ± 0.5 | 665.4 | 0.688 | 37.96 | 75.9 | NREL (12/21) | Avancis, 110 cells |

| CdTe (cell) | 21.0 ± 0.4 | 1.0623 | 0.8759 | 30.25 | 79.4 | Newport (8/14) | First Solar, on glass |

| CZTSSe (cell) | 11.3 + 0.3 | 1.1761 | 0.5333 | 3357.00% | 63 | Newport (10/18) | DGIST, Korea |

| CZTS (cell) | 10.0 + 0.2 | 1.113 | 0.7083 | 21.77 | 65.1 | NREL (3/17) | UNSW |

| Amorphous/Microcrystalline | |||||||

| Si (amorphous cell) | 10.2 ± 0.3 | 1.001 | 0.896 | 16.36 | 69.8 | AIST (7/14) | AIST |

| Si (microcrystalline cell) | 11.9 ± 0.3 | 1.044 | 0.55 | 29.72 | 75 | AIST (2/17) | AIST |

| Perovskite | |||||||

| Perovskite (cell) | 23.7 ± 0.5 | 1.062 | 1.213 | 24.99 | 78.4 | NPVM (5/22) | U.Sci.Tech., Hefei |

| Perovskite (minimodule) | 22.4 ± 0.5 | 26.02 | 1.127 | 25.61 | 77.6 | NPVM (7/22) | EPFLSion/NCEPU, 8 cells |

| Dye-sensitized | |||||||

| Dye (cell) | 11.9 ± 0.4 | 1.005 | 0.744 | 22.47 | 71.2 | AIST (9/12) | Sharp |

| Dye (minimodule) | 10.7 ± 0.4 | 26.55 | 0.754 | 20.19 | 69.9 | AIST (2/15) | Sharp, 7 serial cells |

| Dye (submodule) | 8.8 ± 0.3 | 398.8 | 0.697 | 18.42 | 68.7 | AIST (9/12) | Sharp, 26 serial cells |

| Organic | |||||||

| Organic (cell) | 15.2 ± 0.2 | 1.015 | 0.8467 | 24.24 | 74.3 | FhG-ISE (10/20) | Fraunhofer ISE |

| Organic (minimodule) | 14.5 ± 0.3 | 19.31 | 0.8518 | 23.51 | 72.5 | JET (12/21) | ZJU/Microquanta, 7 cells |

| Organic (submodule) | 11.7 ± 0.2 | 203.98 | 0.8177 | 20.68 | 69.3 | FhG-ISE (10/19) | ZAE Bayern, 33 cells |

| Classification | Efficiency (%) | Area (cm2) | Voc (v) | Isc (mA/Cm2) | FF (%) | Test Centre/Date | Description |

|---|---|---|---|---|---|---|---|

| III–V Multijunction | |||||||

| 5 junction cells (bonded) (2.17/1.68/1.40/1.06/0.73 eV) | 38.8 + 1.2 | 1.021 | 4.767 | 9.564 | 85.2 | NREL (7/13) | Spectrolab,2-terminal |

| InGaP/GaAs/InGaAs | 37.9 ± 1.2 | 1.047 | 3.065 | 14.27 | 86.7 | AIST (2/13) | Sharp, 2 term. |

| GaInP/GaAs (monolithic) | 32.8 ± 1.4 | 1 | 2.568 | 14.56 | 87.7 | NREL (9/17) | LG Electronics, 2 term. |

| Multijunction with c-Si | |||||||

| GaInP/GalnAsP/Si (wafer bonded) | 35.9 ± 1.3 | 3.987 | 3.248 | 13.11 | 84.3 | FhG-ISE (4/20) | Fraunhofer ISE, 2 term |

| GaInP/GaAs/Si (mech. stack) | 35.9 ± 0.5 | 1.002 | 2.52/0.681 | 13.6/11.0 | 87.5/78.5 | NREL (2/17) | NREL/CSEM/EPFL, 4-term |

| GaAsP/Si (monolithic) | 23.4 ± 0.3 | 1.026 | 1.732 | 17.341 | 77.7 | NREL (5/20) | OSU/UNSW/SolAero, 2-term |

| GaAs/Si (mech. stack) | 32.8 ± 0.5 | 1.003 | 1.09/0.683 | 28.9/11.1 | 85.0/79.2 | NREL (12/16) | NREL/CSEM/EPFL, 4-term |

| Perovskite/Si | 31.3 ± 0.3 | 1.1677 | 1.9131 | 20.47 | 79.8 | NREL (6/22) | CSEM/ EPFL, 2-term |

| GaInP/GalnAs/Ge; Si (spectral split) | 34.5 ± 2.0 | 27.83 | 2.66/0.65 | 13.1/9.3 | 85.6/79.0 | NREL (4/16) | UNSW/Azur/Trina, 4-term |

| GaInP/GaAs/Si (monolithic) | 25.9 ± 0.9 | 3.987 | 2.647 | 12.21 | 80.2 | FhG-ISE (6/20) | Fraunhofer ISE, 2-term. |

| Other Multijunction | |||||||

| Perovskite/CIGS | 24.2 ± 0.7 | 1.045 | 1.768 | 19.24 | 72.9 | FhG-ISE (1/20) | HZB, 2-terminal |

| Perovskite/perovskite | 26.4 ± 0.7 | 1.044 | 2.118 | 15.22 | 82.6 | JET (3/22) | SichuanU/EMPA, 2-term |

| Perovskite/perovskite(minimodule) | 24.5 + 0.6 | 20.25 | 2.157 | 14.86 | 77.5 | JET (6/22) | Nanjing/Renshine, 2-term. |

| a-Si/nc-Si/nc-Si (thin-film) | 14.0 ± 0.4 | 1.045 | 1.922 | 9.9 | 73.4 | AIST (5/16) | AIST, 2-term |

| a-Si/nc-Si (thin-film cell) | 12.7 ± 0.4 | 1 | 1.342 | 13.45 | 70.2 | AIST (10/14) | AIST, 2-term. |

| Notable Exceptions | |||||||

| GaInP/GaAs (mqw) | 32.9 ± 0.5 | 0.25 | 2.5 | 15.36 | 85.7 | NREL (1/20) | NREL/UNSW.multiple QW |

| GaInP/GaAs (mqw)/GaAs | 39.5 ± 0.5 | 0.242 | 2.997 | 15.44 | 85.3 | NREL (9/21) | NREL multiple QW |

| GaInP/GaAs/GalnAs | 37.8 ± 1.4 | 0.998 | 3.013 | 14.6 | 85.8 | NREL (1/18) | Microlink (ELO) |

| 6 junctions (monolithic) (2.19/1.76/1.45/1.19/0.97/0.7 eV) | 39.2±3.2 | 0.247 | 5.549 | 8.457 | 83.5 | NREL (11/18) | NREL, inv. Metamorphic |

| Perovskite/Si (large) | 26.8 ± 1.2 | 274.22 | 1.891 | 17.84 | 79.4 | FhG-ISE (11/21) | Oxford PV, |

| Perovskite/perovskite | 28.0±0.6 | 0.0495 | 2.125 | 16.42 | 80.3 | JET (12/21) | Nanjing U, 2-term. |

| Perovskite/organic | 23.4 ± 0.8 | 0.0552 | 2.136 | 14.56 | 75.6 | JET (3/22) | NUS/SERIS |

| GaInP/GaInAs; GaInAsP/GaInAs | 47.6 ± 2.6 | 0.0452 | FhG-ISE (5/22 | hG-ISE 4J bonded |

| Capital Cost USD/KW | Levelised Cost of Electricity USD/MWh | |||||

|---|---|---|---|---|---|---|

| United States | 2021 | 2030 | 2050 | 2021 | 2030 | 2050 |

| Wind offshore | 4040 | 2200 | 1500 | 120 | 60 | 40 |

| Wind onshore | 1380 | 1270 | 1190 | 35 | 30 | 30 |

| Solar PV | 1090 | 620 | 430 | 50 | 30 | 25 |

| Gas CCGT | 1000 | 1000 | 1000 | 80 | 130 | n.a. |

| Coal | 2100 | 2100 | 2100 | 165 | n.a. | n.a. |

| Nuclear | 5000 | 4800 | 4500 | 100 | 100 | 100 |

| European Union | ||||||

| Wind offshore | 3040 | 1800 | 1240 | 60 | 35 | 25 |

| Wind onshore | 1590 | 1470 | 1380 | 55 | 50 | 45 |

| Solar PV | 810 | 470 | 340 | 50 | 35 | 25 |

| Gas CCGT | 1000 | 1000 | 1000 | 145 | 195 | n.a. |

| Coal | 2000 | 2000 | 2000 | 230 | n.a. | n.a. |

| Nuclear | 6600 | 5100 | 4500 | 140 | 115 | 115 |

| China | ||||||

| Wind offshore | 2860 | 1640 | 1120 | 100 | 50 | 35 |

| Wind onshore | 1160 | 1060 | 1000 | 45 | 40 | 35 |

| Solar PV | 630 | 360 | 250 | 35 | 20 | 15 |

| Gas CCGT | 560 | 560 | 560 | 105 | 130 | n.a. |

| Coal | 800 | 800 | 800 | 100 | n.a. | n.a. |

| Nuclear | 2800 | 2800 | 2500 | 65 | 65 | 65 |

| India | ||||||

| Wind offshore | 2780 | 1560 | 1080 | 120 | 65 | 45 |

| Wind onshore | 930 | 840 | 790 | 45 | 35 | 35 |

| Solar PV | 590 | 320 | 210 | 35 | 20 | 15 |

| Gas CCGT | 700 | 700 | 700 | 75 | 100 | n.a. |

| Coal | 1200 | 1200 | 1200 | 60 | n.a. | n.a. |

| Nuclear | 2800 | 2800 | 2800 | 75 | 65 | 65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nazir, S.; Ali, A.; Aftab, A.; Muqeet, H.A.; Mirsaeidi, S.; Zhang, J.-M. Techno-Economic and Environmental Perspectives of Solar Cell Technologies: A Comprehensive Review. Energies 2023, 16, 4959. https://doi.org/10.3390/en16134959

Nazir S, Ali A, Aftab A, Muqeet HA, Mirsaeidi S, Zhang J-M. Techno-Economic and Environmental Perspectives of Solar Cell Technologies: A Comprehensive Review. Energies. 2023; 16(13):4959. https://doi.org/10.3390/en16134959

Chicago/Turabian StyleNazir, Shoaib, Asjad Ali, Abdullah Aftab, Hafiz Abdul Muqeet, Sohrab Mirsaeidi, and Jian-Min Zhang. 2023. "Techno-Economic and Environmental Perspectives of Solar Cell Technologies: A Comprehensive Review" Energies 16, no. 13: 4959. https://doi.org/10.3390/en16134959

APA StyleNazir, S., Ali, A., Aftab, A., Muqeet, H. A., Mirsaeidi, S., & Zhang, J.-M. (2023). Techno-Economic and Environmental Perspectives of Solar Cell Technologies: A Comprehensive Review. Energies, 16(13), 4959. https://doi.org/10.3390/en16134959