Stator ITSC Fault Diagnosis for EMU Induction Traction Motor Based on Goertzel Algorithm and Random Forest

Abstract

1. Introduction

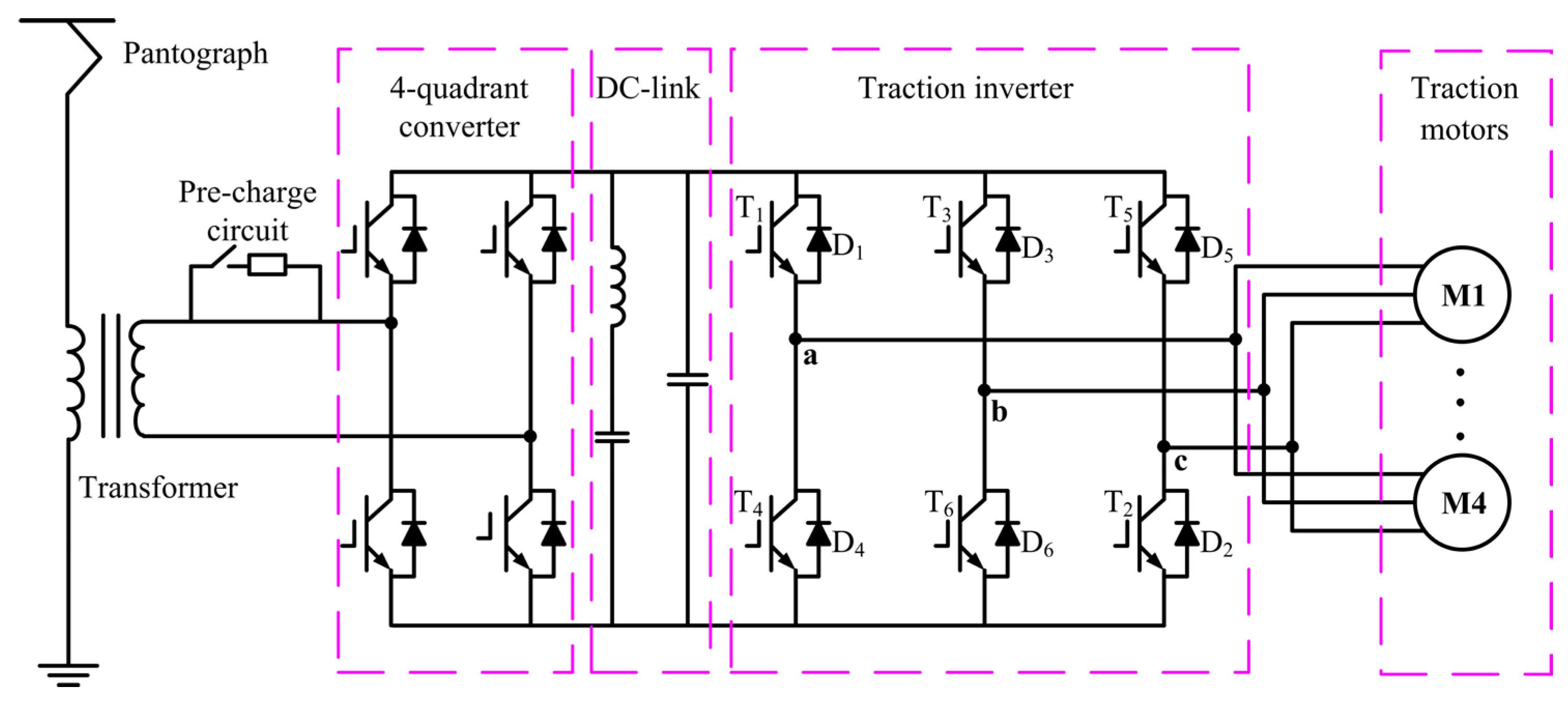

2. Traction Motor Stator ITSC Fault Diagnostic Condition Control

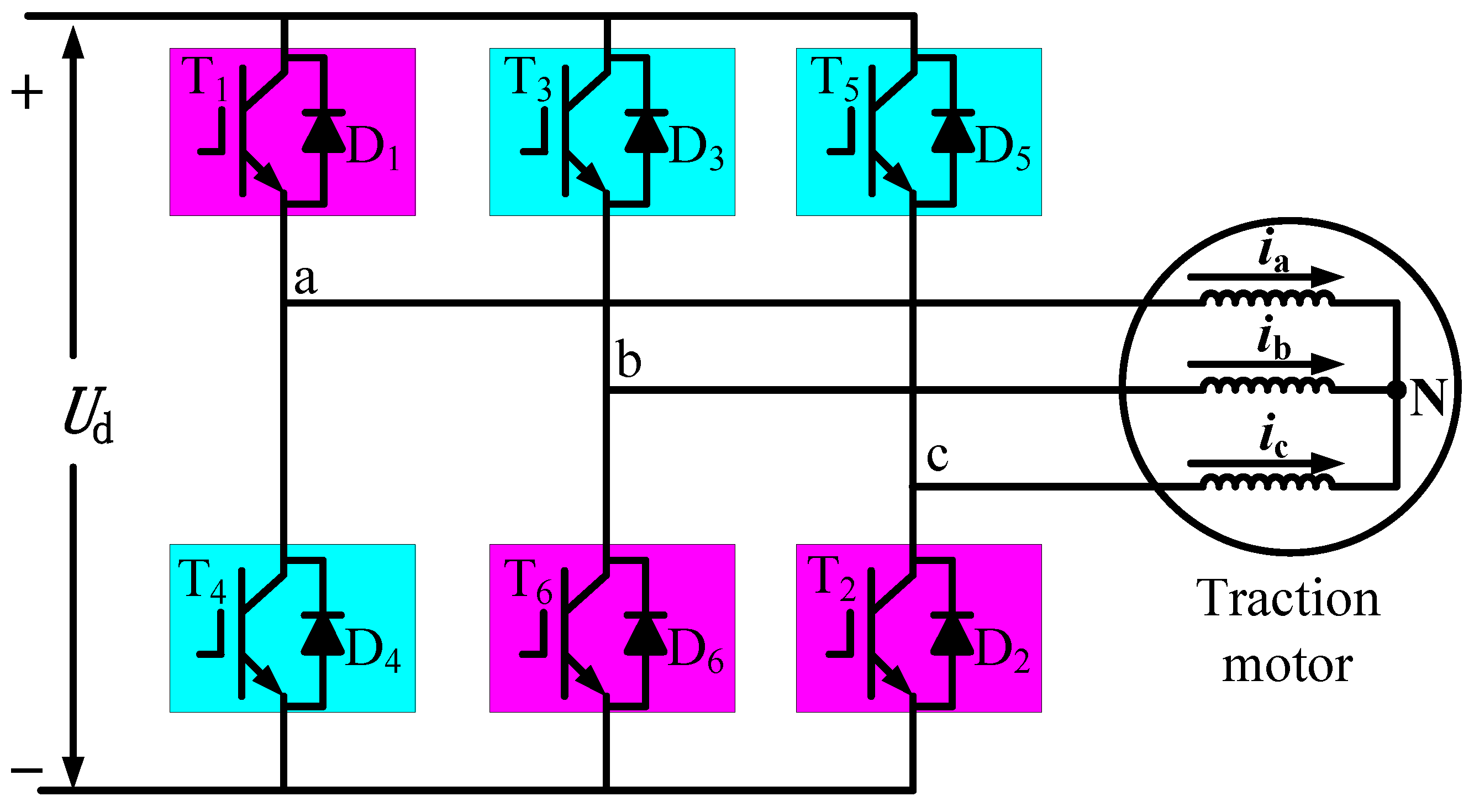

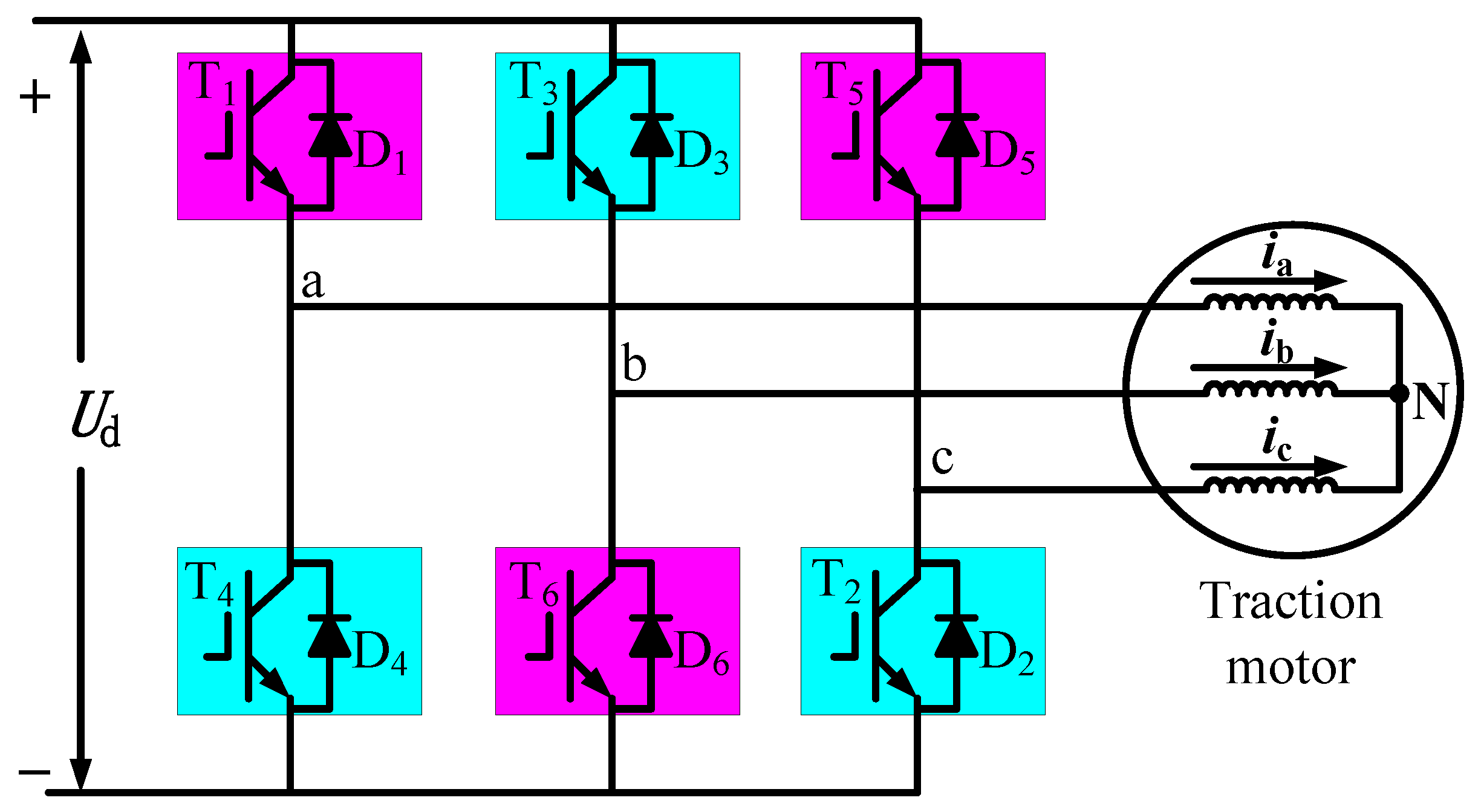

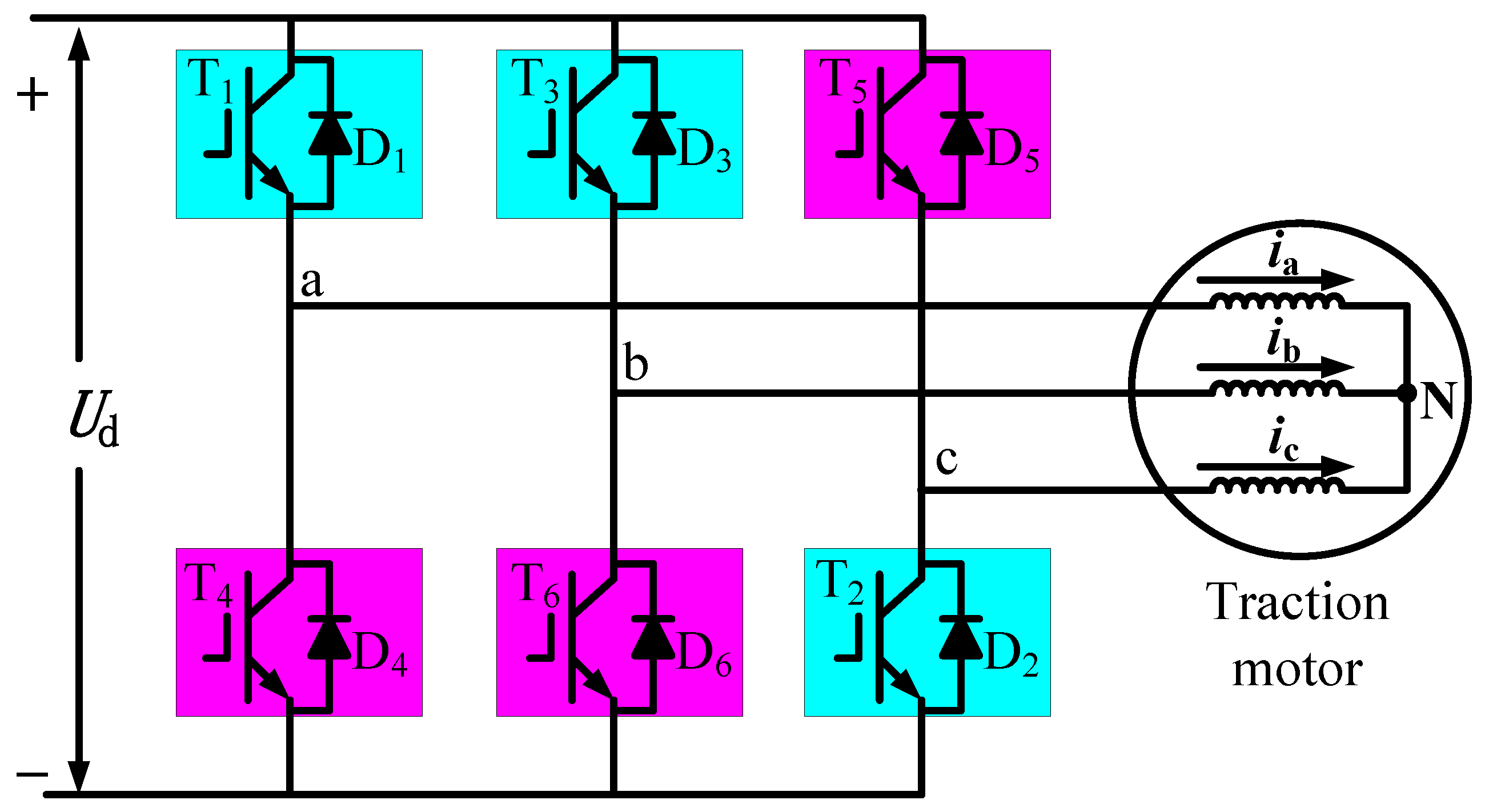

2.1. Working Status of Two-Level Traction Inverter

2.2. ITSC Fault Diagnostic Condition Control

2.3. Traction Motor Magnetomotive Force Analysis under Diagnostic Condition

3. SPWM Excitation Voltage and Goertzel Algorithm

3.1. Traction Motor SPWM Excitation Voltage Control

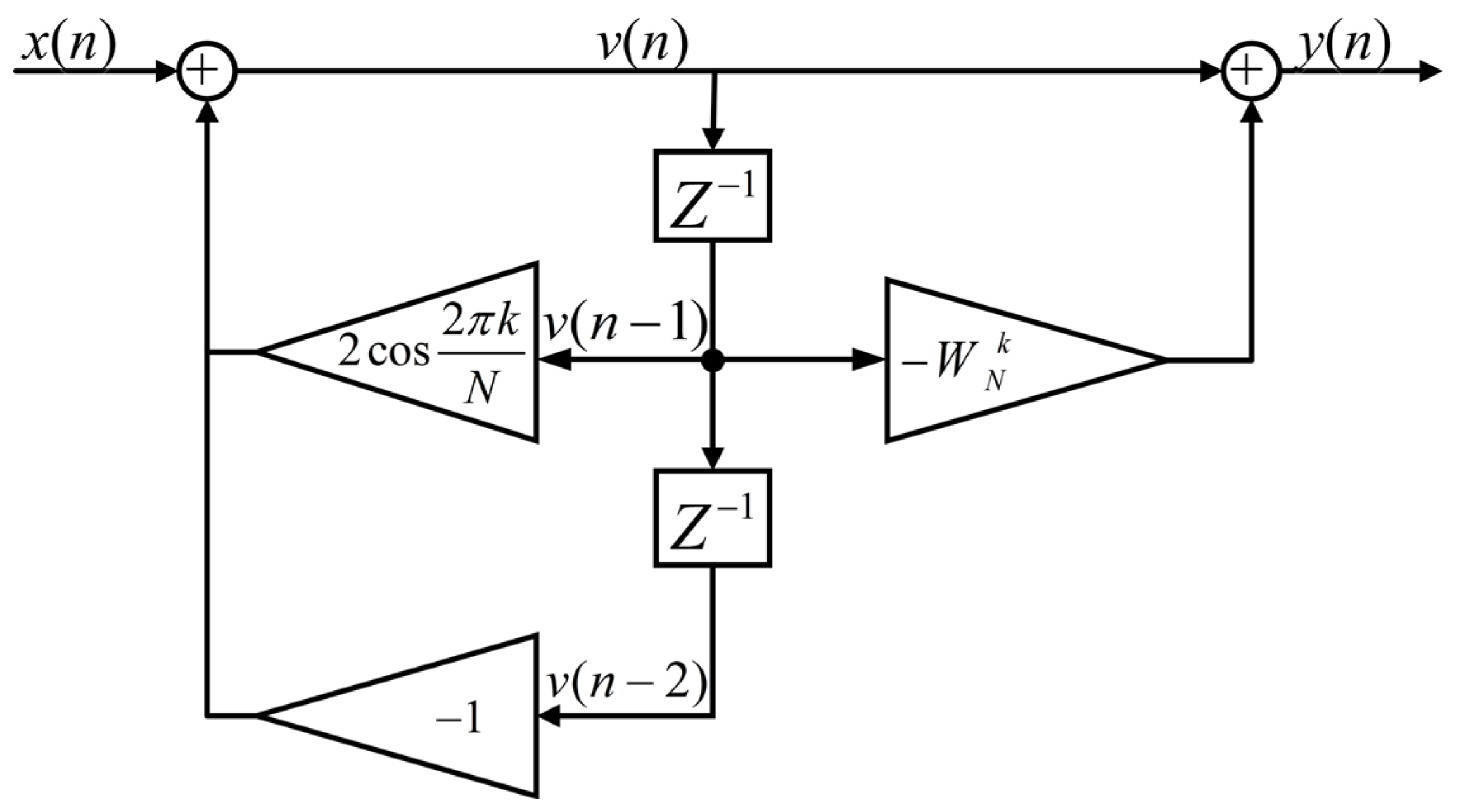

3.2. Calculation of Current Fundamental Component Using Goertzel Algorithm

4. Fault Features and Diagnostic Model of Traction Motor ITSC Faults

4.1. Fault Features of Traction Motor ITSC Diagnostic Conditions

4.2. Random Forest Fault Diagnosis Model

- (1)

- The Bootstrap method is used to resample and randomly select m samples from the original dataset with M samples and generate T train subsets, S1, S2, …, ST. The number of train subset samples m should not be greater than M.

- (2)

- The T train sets are used to generate T corresponding decision trees C1, C2, …, CT; before selecting features on each non-leaf node, s features are randomly selected from the S features as the split feature set for the current node and the node is split using the best splitting method among these s features.

- (3)

- There is no restriction on the growth of each decision tree and no pruning.

- (4)

- A random forest consisting of T decision trees is used to identify and classify the new data set, and the voting method is adopted. The final result is determined by the number of votes.

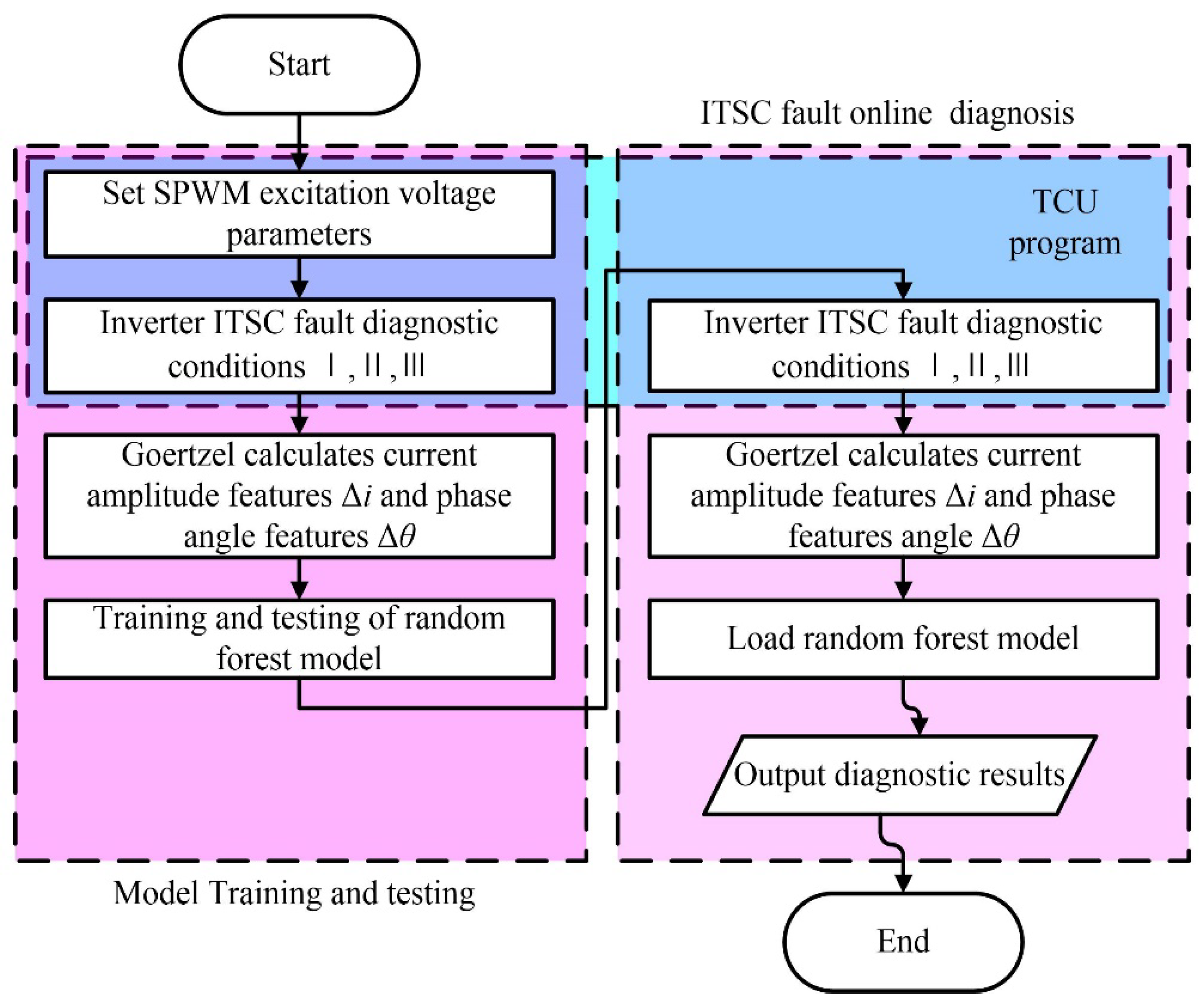

4.3. Fault Diagnosis of Traction Motor ITSC Faults

5. Diagnosis for Traction Motor ITSC Fault Simulation Experimental Platform

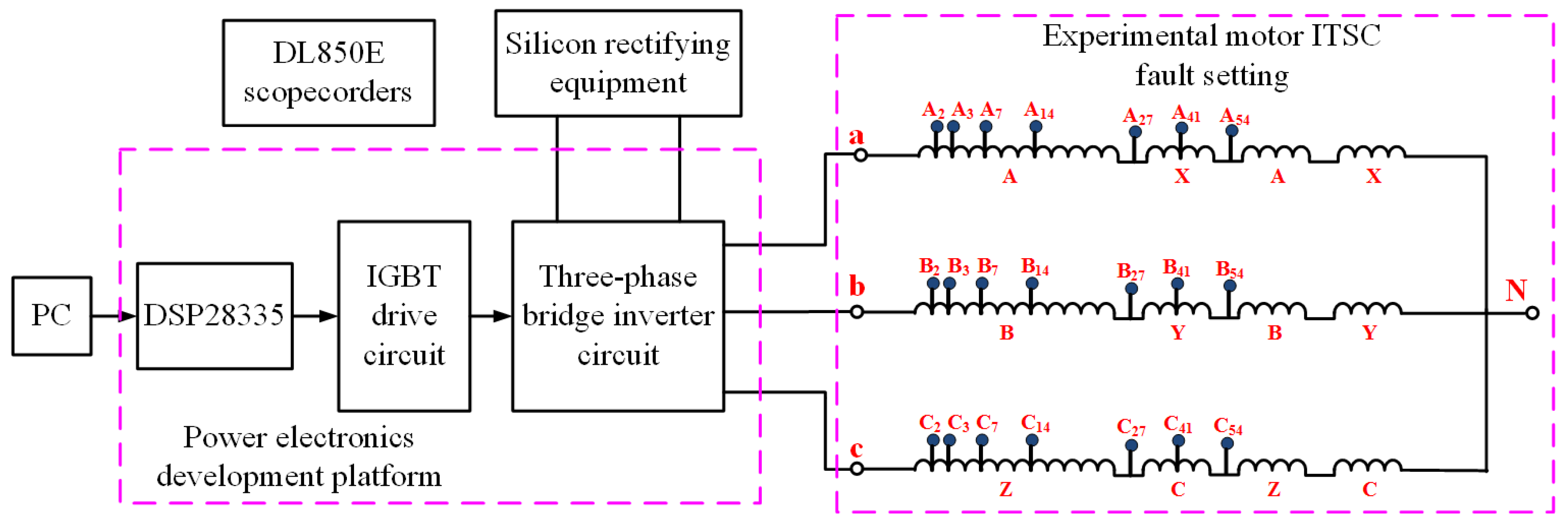

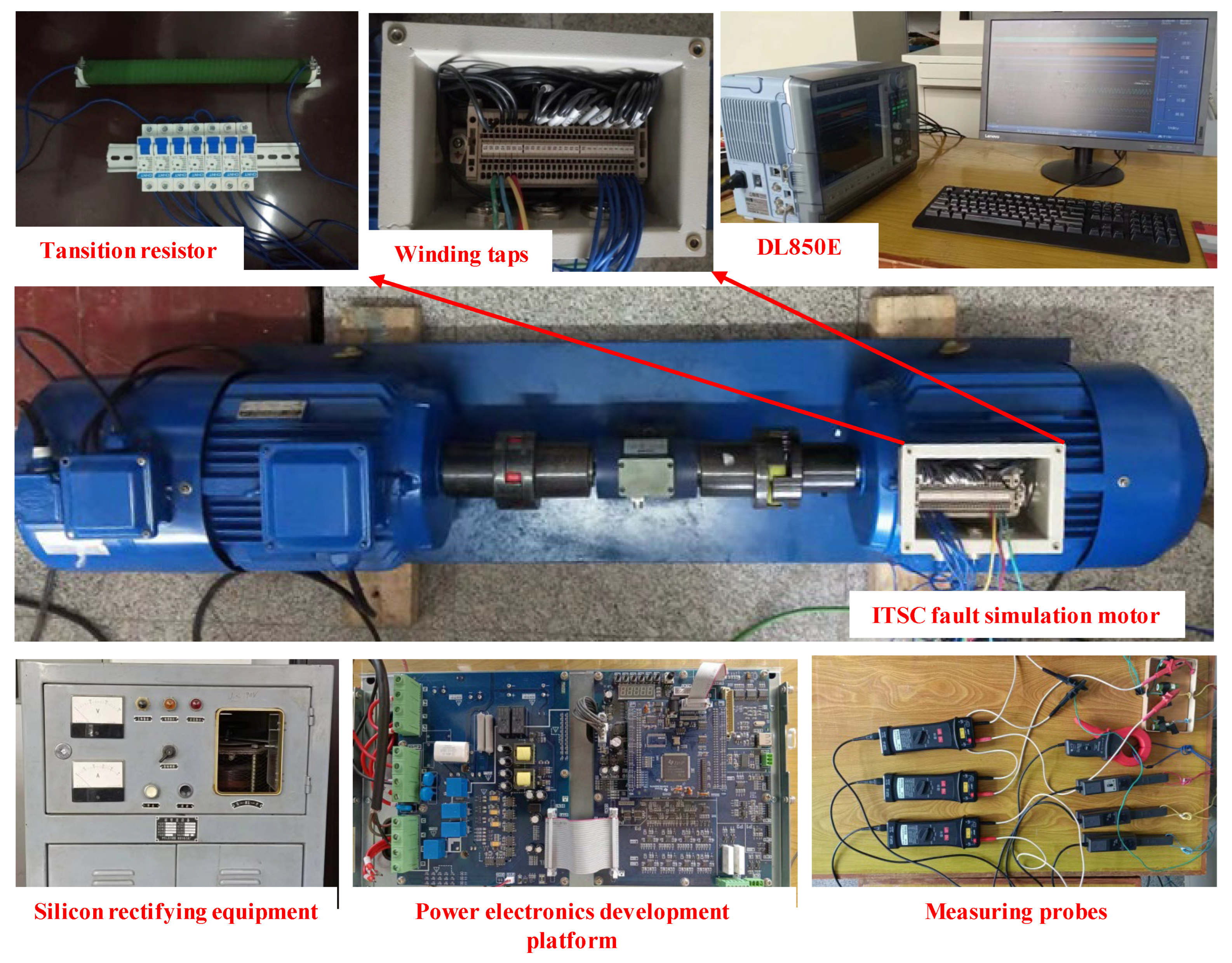

5.1. Description of the Experimental Platform

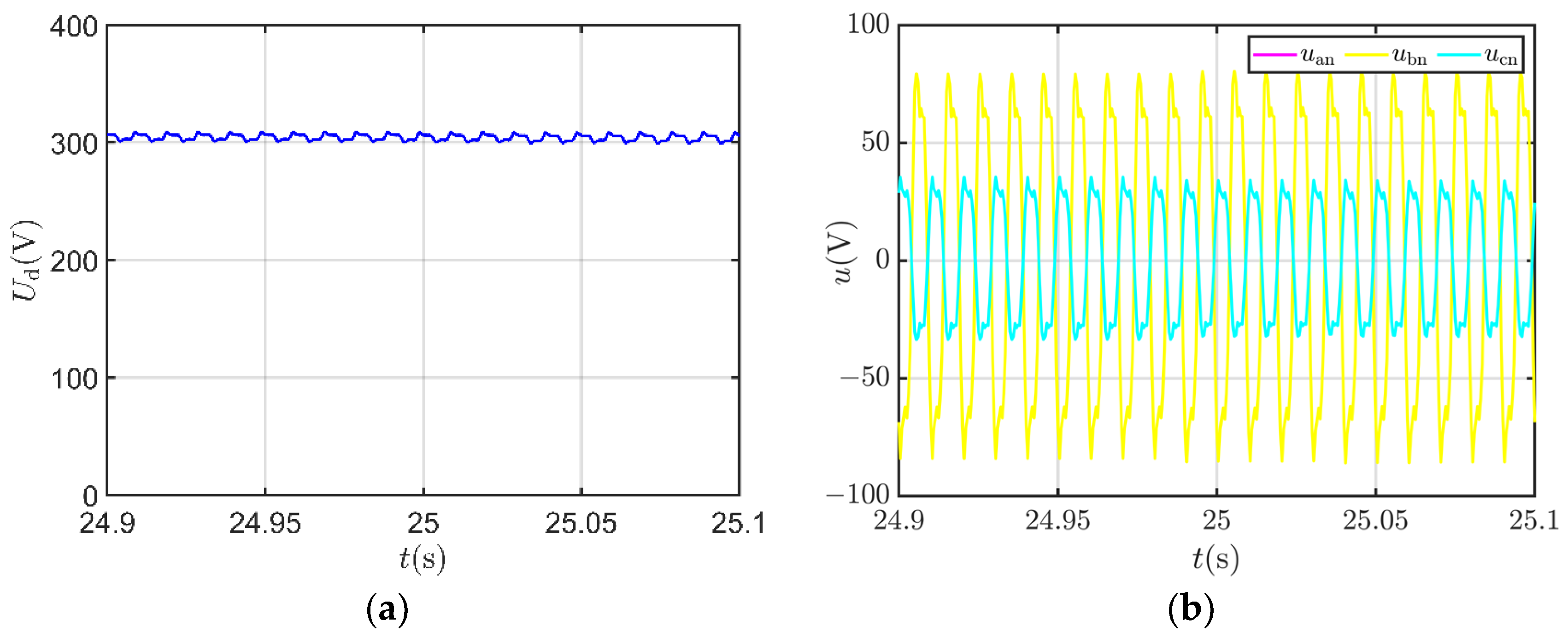

5.2. SPWM Excitation Parameters of the Experimental Platform

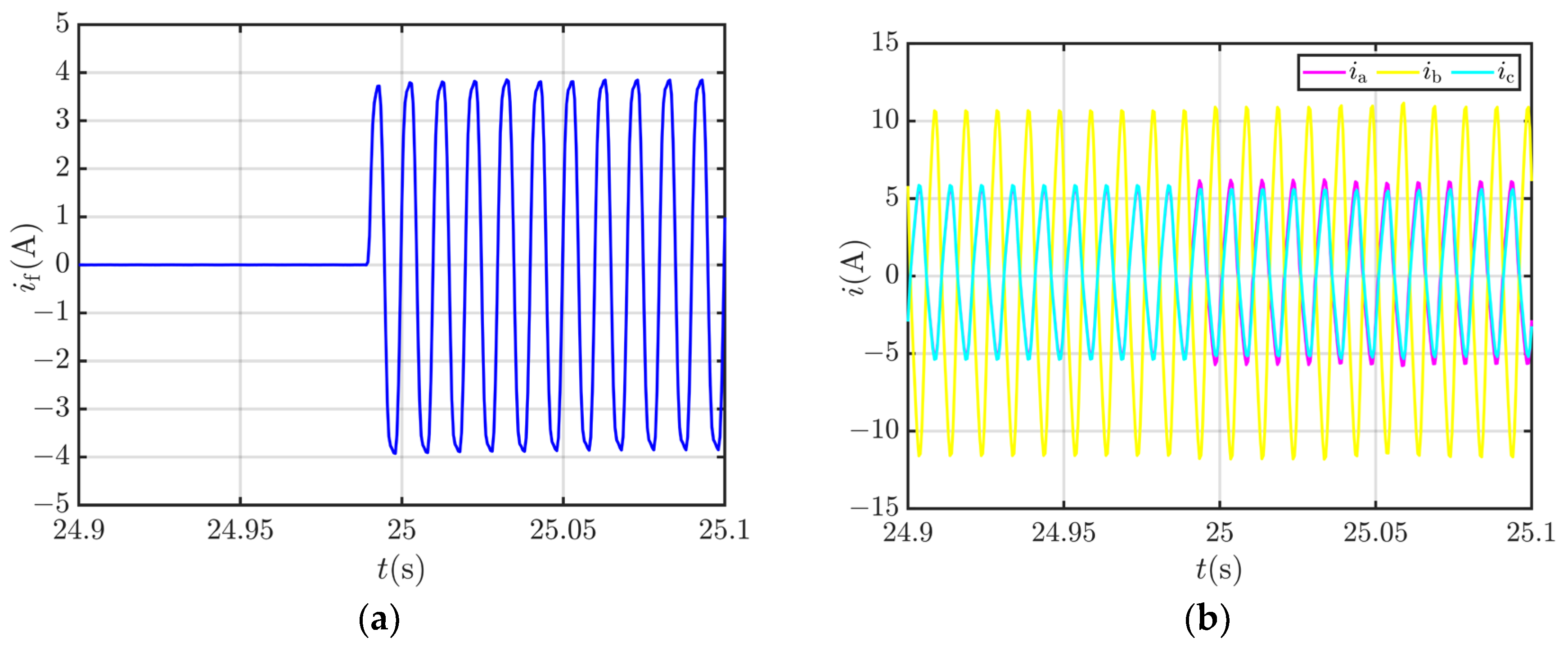

5.3. Analysis of ITSC Fault Diagnosis Signals

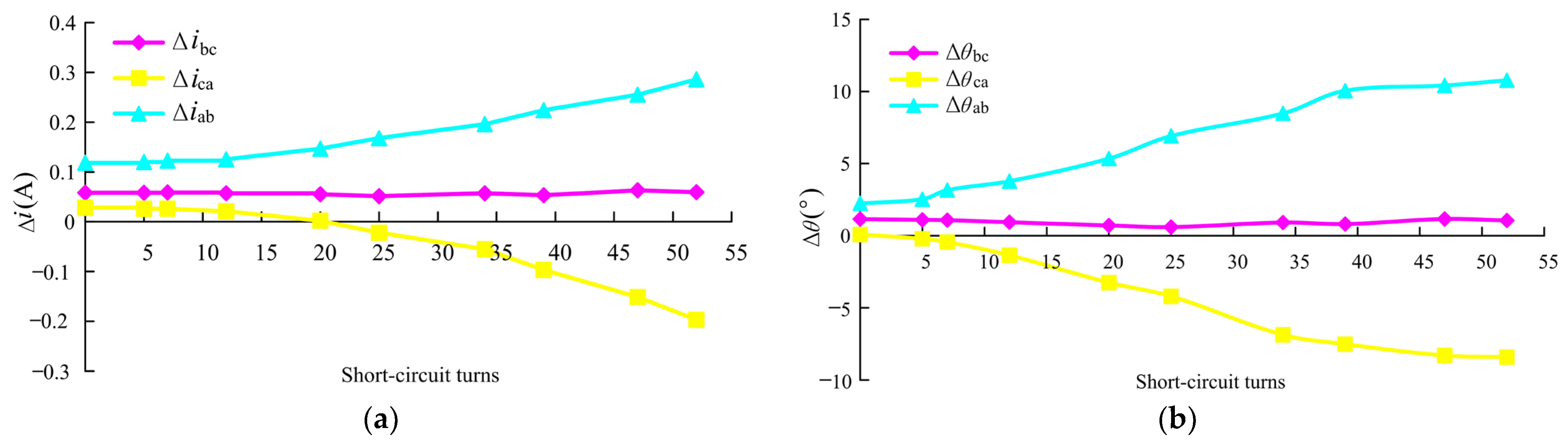

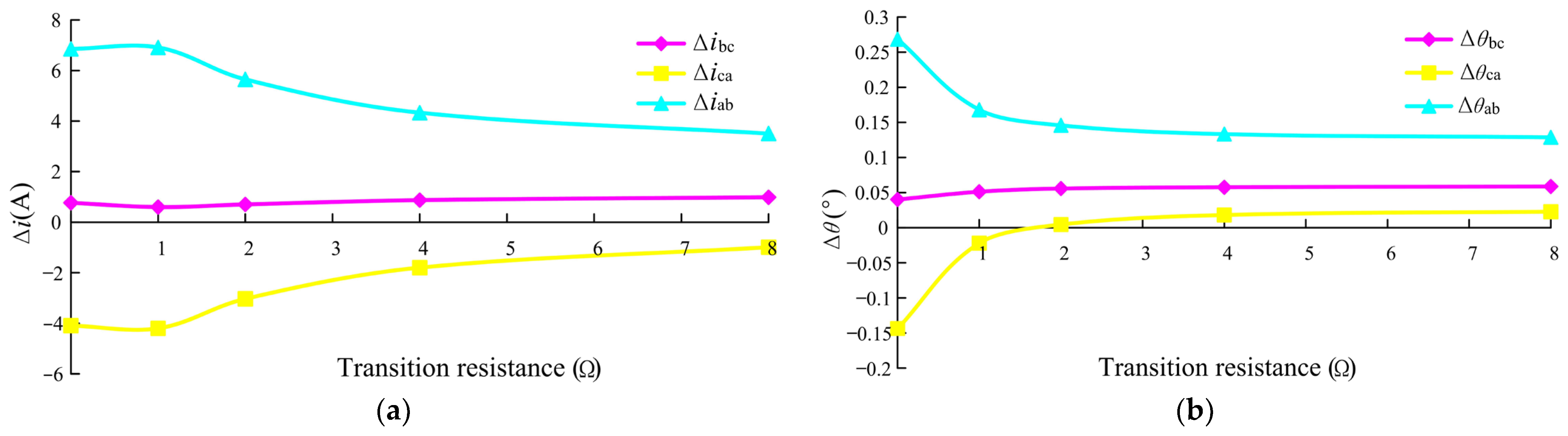

5.4. The Impact of ITSC Fault Extent on Features

5.5. Fault Detection and Location Based on Random Forest Model

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, S.-G. A Study on Traction Motor Characteristic in EMU Train. In Proceedings of the 13th International Conference on Control, Automation and Systems, Gyeonggi-do, Republic of Korea, 22–25 October 2014. [Google Scholar]

- Chen, Z.P.; Wang, Z.; Jia, L.M.; Cai, G.Q. Analysis and Comparison of Locomotive Traction Motor Intelligent Fault Diagnosis Methods. Appl. Mech. Mater. 2011, 97–98, 994–1002. [Google Scholar] [CrossRef]

- Chao, C.; Wang, W.; Chen, H.; Zhang, B.; Shao, J.; Teng, W. Enhanced Fault Diagnosis Using Broad Learning for Traction Systems in High-Speed Trains. IEEE Trans. Power Electron. 2020, 36, 7461–7469. [Google Scholar] [CrossRef]

- Guo, X.; Tang, Y.; Wu, M.; Zhang, Z.; Yuan, J. FPGA-Based Hardware-in-the-Loop Real-Time Simulation Implementation for High-Speed Train Electrical Traction System. IET Electr. Power Appl. 2020, 14, 850–858. [Google Scholar] [CrossRef]

- Elbouchikhi, E.; Amirat, Y.; Feld, G.; Benbouzid, M. Generalized Likelihood Ratio Test Based Approach for Stator-Fault Detection in a PWM Inverter-Fed Induction Motor Drive. IEEE Trans. Ind. Electron. 2019, 66, 6343–6353. [Google Scholar] [CrossRef]

- Al-Ameri, S.M.; Alawady, A.A.; Yousof, M.F.M.; Kamarudin, M.S.; Salem, A.A.; Abu-Siada, A.; Mosaad, M.I. Application of Frequency Response Analysis Method to Detect Short-Circuit Faults in Three-Phase Induction Motors. Appl. Sci. 2022, 12, 2046. [Google Scholar] [CrossRef]

- Tallam, R.M.; Habetler, T.G.; Harley, R.G. Transient Model for Induction Machines with Stator Winding Turn Faults. IEEE Trans. Ind. Appl. 2002, 38, 632–637. [Google Scholar] [CrossRef]

- Kallesoe, C.S.; Vadstrup, P.; Rasmussen, H.; Izadi-Zamanabadi, R. Observer Based Estimation of Stator Winding Faults in Delta-Connected Induction Motors, a LMI Approach. In Proceedings of the IAS Annual Meeting, Tampa, FL, USA, 8–12 October 2006. [Google Scholar] [CrossRef]

- Angelo, C.; Bossio, G.R.; Gi Ac Cone, S.J.; Valla, M.I.; Garcia, G.O. Online Model-Based Stator-Fault Detection and Identification in Induction Motors. IEEE Trans. Ind. Electron. 2009, 56, 4671–4680. [Google Scholar] [CrossRef]

- Nguyen, V.; Wang, D.; Seshadrinath, J.; Ukil, A.; Krishna, M.S.; Nadarajan, S.; Vaiyapuri, V. A Method for Incipient Interturn Fault Detection and Severity Estimation of Induction Motors Under Inherent Asymmetry and Voltage Imbalance. IEEE Trans. Transp. Electrif. 2017, 3, 703–715. [Google Scholar] [CrossRef]

- Abdallah, H.; Benatman, K. Stator Winding Inter-turn Short-circuit Detection in Induction Motors by Parameter Identification. IET Electr. Power Appl. 2017, 11, 272–288. [Google Scholar] [CrossRef]

- Bachir, S.; Tnani, S.; Trigeassou, J.-C.; Champenois, G. Diagnosis by Parameter Estimation of Stator and Rotor Faults Occurring in Induction Machines. IEEE Trans. Ind. Electron. 2006, 53, 963–973. [Google Scholar] [CrossRef]

- Bazine, I.B.A.; Tnani, S.; Poinot, T.; Champenois, G.; Jelassi, K. On-Line Detection of Stator and Rotor Faults Occurring in Induction Machine Diagnosis by Parameters Estimation. In Proceedings of the 8th IEEE Symposium on Diagnostics for Electrical Machines, Power Electronics & Drives, Bologna, Italy, 5–8 September 2011. [Google Scholar] [CrossRef]

- Aswad, R.A.K.; Jassim, B.M.H. Detection and Localization of the Stator Winding Inter-Turn Fault in Induction Motors Based on Parameters Estimation Using Genetic Algorithm. J. Inst. Eng. India Ser. B 2022, 103, 405–414. [Google Scholar] [CrossRef]

- Nandi, S. Stator Fault Detection in Induction Machines Using Triplen Harmonics at Motor Terminal Voltage after Switch-Off. In Proceedings of the IEEE Power Engineering Society General Meeting, San Francisco, CA, USA, 12–16 June 2005. [Google Scholar]

- Qing, W.; Nandi, S. Fast Single-Turn Sensitive Stator Interturn Fault Detection of Induction Machines Based on Positive- and Negative-Sequence Third Harmonic Components of Line Currents. IEEE Trans. Ind. Appl. 2010, 46, 974–983. [Google Scholar] [CrossRef]

- El Bouchikhi, E.H.; Choqueuse, V.; Benbouzid, M. Induction Machine Faults Detection Using Stator Current Parametric Spectral Estimation. Mech. Syst. Signal Process. 2015, 52–53, 447–464. [Google Scholar] [CrossRef]

- Ghanbari, T.; Samet, H. A Kalman Filter Based Technique for Stator Turn-Fault Detection of the Induction Motors. Int. J. Emerg. Electr. Power Syst. 2017, 18, 20170071. [Google Scholar] [CrossRef]

- Nazemi, M.H.; Gallehdar, D.; Haghjoo, F.; Cruz, S. A Secure and Sensitive Wavelet Transform Based Technique for Stator Fault Detection in the Cases of Line-connected and Inverter-fed Induction Machines. IET Electr. Power Appl. 2021, 15, 1138–1153. [Google Scholar] [CrossRef]

- Almounajjed, A.; Sahoo, A.K.; Kumar, M.K. Diagnosis of Stator Fault Severity in Induction Motor Based on Discrete Wavelet Analysis. Measurement 2021, 182, 109780. [Google Scholar] [CrossRef]

- Lee, S.; Wang, Y.; Song, J. Fourier and Wavelet Transformations Application to Fault Detection of Induction Motor with Stator Current. J. Cent. South Univ. Technol. 2010, 17, 93–101. [Google Scholar] [CrossRef]

- Vinayak, B.A.; Varma, S.; Jagadanand, G. Precise Wavelet Selection for Condition Monitoring of Inverter-Fed Induction Machine. In Proceedings of the 2017 IEEE International Conference on Signal Processing, Informatics, Communication and Energy Systems (SPICES), Kollam, India, 8–10 August 2017. [Google Scholar] [CrossRef]

- Seshadrinath, J.; Singh, B.; Panigrahi, B.K. Single-Turn Fault Detection in Induction Machine Using Complex-Wavelet-Based Method. IEEE Trans. Ind. Appl. 2012, 48, 1846–1854. [Google Scholar] [CrossRef]

- Akhil Vinayak, B.; Anjali Anand, K.; Jagadanand, G. Wavelet-based Real-time Stator Fault Detection of Inverter-fed Induction Motor. IET Electr. Power Appl. 2020, 14, 82–90. [Google Scholar] [CrossRef]

- Yang, J.; Huang, J.; Liu, T. Diagnosis of Stator Faults in Induction Motor Based on Zero Sequence Voltage after Switch-Off. J. Zhejiang Univ. Sci. A 2008, 9, 165–172. [Google Scholar] [CrossRef]

- Dash, R.N.; Subudhi, B.; Das, S. A comparison between MLP NN and RBF NN techniques for the detection of stator inter-turn fault of an induction motor. In Proceedings of the 2010 International Conference on Industrial Electronics, Control and Robotics, Rourkela, India, 27–29 December 2010. [Google Scholar] [CrossRef]

- Mejia-Barron, A.; Tapia-Tinoco, G.; Razo-Hernandez, J.R.; Valtierra-Rodriguez, M.; Granados-Lieberman, D. A Neural Network-Based Model for MCSA of Inter-Turn Short-Circuit Faults in Induction Motors and Its Power Hardware in the Loop Simulation. Comput. Electr. Eng. 2021, 93, 107234. [Google Scholar] [CrossRef]

- Yi, L.; Liu, Y.; Yu, W.; Zhao, J. A Novel Nonlinear Observer for Fault Diagnosis of Induction Motor. J. Algorithms Comput. 2020, 14, 174830262092272. [Google Scholar] [CrossRef]

- Cherif, H.; Benakcha, A.; Laib, I.; Chehaidia, S.E.; Menacer, A.; Soudan, B.; Olabi, A.G. Early Detection and Localization of Stator Inter-Turn Faults Based on Discrete Wavelet Energy Ratio and Neural Networks in Induction Motor. Energy 2020, 212, 118684. [Google Scholar] [CrossRef]

- Husari, F.; Seshadrinath, J. Incipient Interturn Fault Detection and Severity Evaluation in Electric Drive System Using Hybrid HCNN-SVM Based Model. IEEE Trans. Ind. Inf. 2022, 18, 1823–1832. [Google Scholar] [CrossRef]

- Tian, R.; Chen, F.; Dong, S. Compound Fault Diagnosis of Stator Interturn Short Circuit and Air Gap Eccentricity Based on Random Forest and XGBoost. Math. Probl. Eng. 2021, 42, 2149048. [Google Scholar] [CrossRef]

- Zhang, K.; Jiang, B.; Chen, F. Multiple-Model-Based Diagnosis of Multiple Faults With High-Speed Train Applications Using Second-Level Adaptation. IEEE Trans. Ind. Electron. 2021, 68, 6257–6266. [Google Scholar] [CrossRef]

- Koodziejek, P.; Wachowiak, D. Fast Real-Time RDFT- and GDFT-Based Direct Fault Diagnosis of Induction Motor Drive. Energies 2022, 15, 1244. [Google Scholar] [CrossRef]

- Sundararajan, P.; Sathik, M.H.M.; Sasongko, F.; Tan, C.S.; Pou, J.; Blaabjerg, F.; Gupta, A.K. Condition Monitoring of DC-Link Capacitors Using Goertzel Algorithm for Failure Precursor Parameter and Temperature Estimation. IEEE Trans. Power Electron. 2020, 35, 6386–6396. [Google Scholar] [CrossRef]

- Papathanasopoulos, D.A.; Giannousakis, K.N.; Dermatas, E.S.; Mitronikas, E.D. Vibration Monitoring for Position Sensor Fault Diagnosis in Brushless DC Motor Drives. Energies 2021, 14, 2248. [Google Scholar] [CrossRef]

- Pena-Alzola, R.; Sztykiel, M.; Jones, C.E.; Norman, P.J.; Moore, G.; Pou, J.; Burt, G.M. First-Fault Detection in DC Distribution With IT Grounding Based on Sliding Discrete Fourier-Transform. IEEE Trans. Power Electron. 2021, 36, 3649–3654. [Google Scholar] [CrossRef]

- Prasetyo, Y.T. “The Big One” Earthquake Preparedness Assessment among Younger Filipinos Using a Random Forest Classifier and an Artificial Neural Network. Sustainability 2023, 15, 679. [Google Scholar] [CrossRef]

- Guo, G.; Cui, X.; Du, B. Random-Forest Machine Learning Approach for High-Speed Railway Track Slab Deformation Identification Using Track-Side Vibration Monitoring. Appl. Sci. 2021, 11, 4756. [Google Scholar] [CrossRef]

- Liu, J.; Xu, Q.Y.; Chen, W.S. Classification of Bird and Drone Targets Based on Motion Characteristics and Random Forest Model Using Surveillance Radar Data. IEEE Access 2021, 9, 160135–160144. [Google Scholar] [CrossRef]

- Chen, S.; Yang, R.; Zhong, M. Graph-based semi-supervised random forest for rotating machinery gearbox fault diagnosis. Control Eng. Pract. 2021, 117, 104952. [Google Scholar] [CrossRef]

| Mode | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|---|

| SA | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 |

| SB | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 |

| SC | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| Voltage vector |

| Diagnostic Condition Ⅰ | Diagnostic Condition Ⅱ | Diagnostic Condition Ⅲ |

|---|---|---|

| Δibc = ibmax − icmax | Δica = icmax − iamax | Δiab = iamax − ibmax |

| Δθbc = θb − θc | Δθca = θc − θa | Δθab = θa − θb |

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Nominal power | 5.5 kW | Nominal frequency | 50 Hz |

| Nominal voltage | 380 V | Connection mode | Y |

| Nominal current | 11.7 A | Nominal speed | 1445 rpm |

| Poles | 4 | Turns per phase | 162 |

| Magnetizing inductance | 205.2 mH | Stator resistance | 1.061 Ω |

| Rotor resistance | 0.6269 Ω | Stator Leakage inductance | 3.217 mH |

| Rotor Leakage inductance | 7.349 mH | Inertia | 0.1367 kg·m2 |

| Modulation frequency | 100 Hz | Modulation index | 0.4 |

| Carrier frequency | 5000 Hz | DC-link voltage | 300 V |

| Parameters | Values |

|---|---|

| Transition resistance (Ω) | 0, 1, 2, 4, 8 |

| Short-circuit turns | 5, 7, 12, 20, 25, 34, 39, 47, 52 |

| Models | Accuracy of the Train Sets | Accuracy of the Test Sets |

|---|---|---|

| BP neural network | 97.86% | 97.5% |

| KNN | 98.57% | 100% |

| SVM | 95% | 97.5% |

| Naive Bayes | 99.29% | 100% |

| Random Forest | 100% | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Li, Y.; Wang, L.; Hu, J.; Li, H.; Fei, J.; Li, L.; Zhao, G. Stator ITSC Fault Diagnosis for EMU Induction Traction Motor Based on Goertzel Algorithm and Random Forest. Energies 2023, 16, 4949. https://doi.org/10.3390/en16134949

Ma J, Li Y, Wang L, Hu J, Li H, Fei J, Li L, Zhao G. Stator ITSC Fault Diagnosis for EMU Induction Traction Motor Based on Goertzel Algorithm and Random Forest. Energies. 2023; 16(13):4949. https://doi.org/10.3390/en16134949

Chicago/Turabian StyleMa, Jie, Yingxue Li, Liying Wang, Jisheng Hu, Hua Li, Jiyou Fei, Lin Li, and Geng Zhao. 2023. "Stator ITSC Fault Diagnosis for EMU Induction Traction Motor Based on Goertzel Algorithm and Random Forest" Energies 16, no. 13: 4949. https://doi.org/10.3390/en16134949

APA StyleMa, J., Li, Y., Wang, L., Hu, J., Li, H., Fei, J., Li, L., & Zhao, G. (2023). Stator ITSC Fault Diagnosis for EMU Induction Traction Motor Based on Goertzel Algorithm and Random Forest. Energies, 16(13), 4949. https://doi.org/10.3390/en16134949