Co-Combustion of Hydrogen with Diesel and Biodiesel (RME) in a Dual-Fuel Compression-Ignition Engine

Abstract

1. Introduction

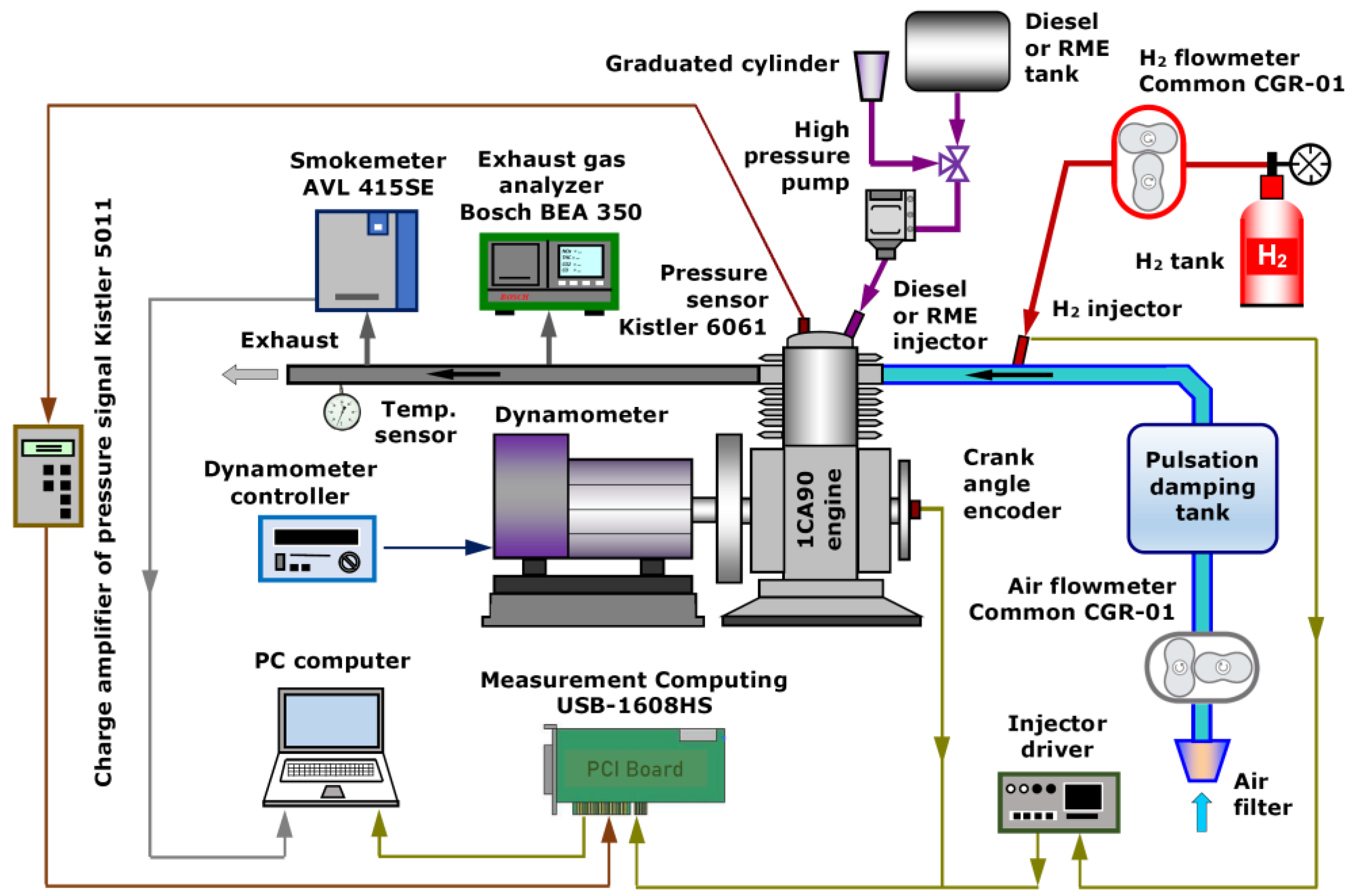

2. Materials and Methods

- -

- pressure sensor Kistler 6061, range 0 … 250 bar, linearity < ±0.5% FS,

- -

- charge amplifier Kistler 511, range ±10 … ±999,000 pC for 10 V FS, error < ±3%, linearity < ±0.05% FS,

- -

- data acquisition module, Measurement Computing USB-1608HS-16 bits resolution, sampling frequency 20 kHz with software,

- -

- air rotor flowmeter Common CGR-01 G40 DN50, measuring range 0.65 … 65 m3/h, accuracy class 1,

- -

- CNG rotor flowmeter Common CGR-01 G10 DN50, measuring range 0.25 … 25 m3/h, accuracy class 1,

- -

- Bosch BEA 350 analyzer.

2.1. Methodology

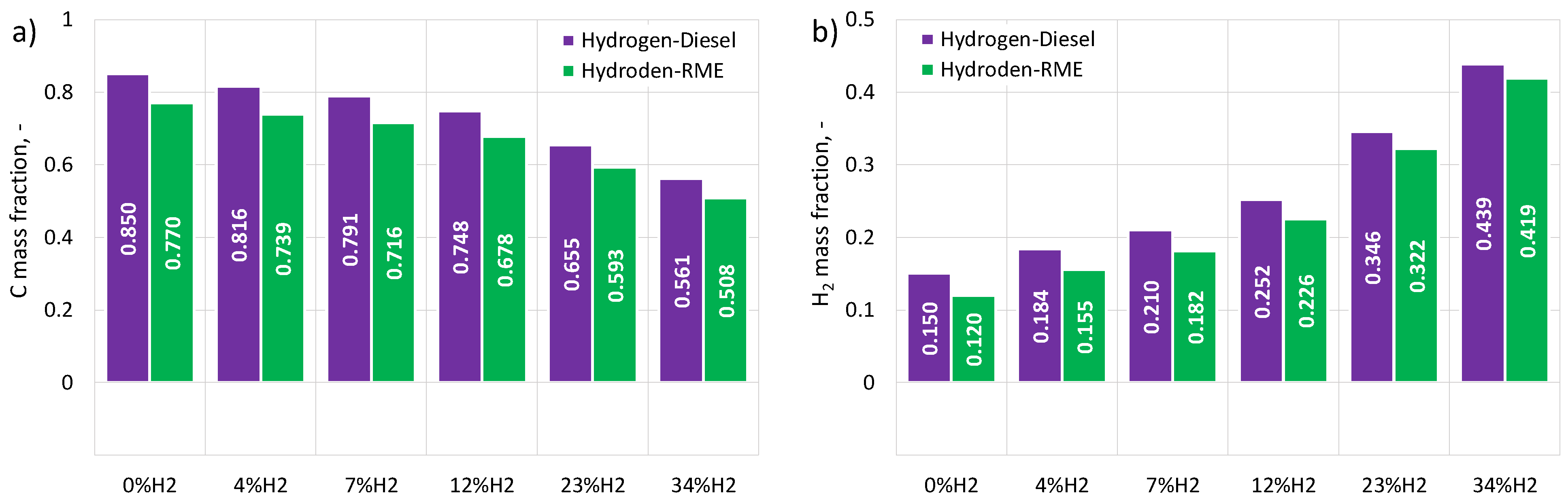

2.2. Fuels Characteristics

3. Results

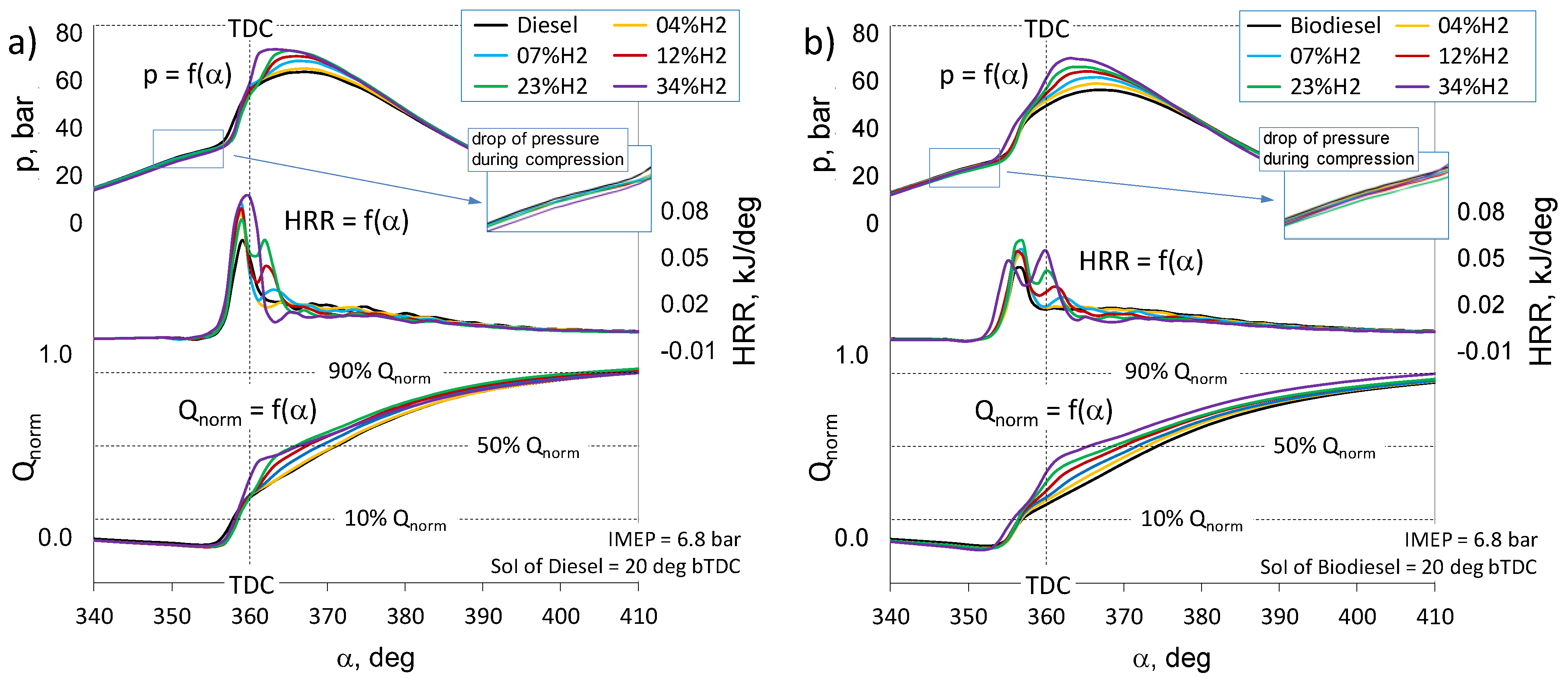

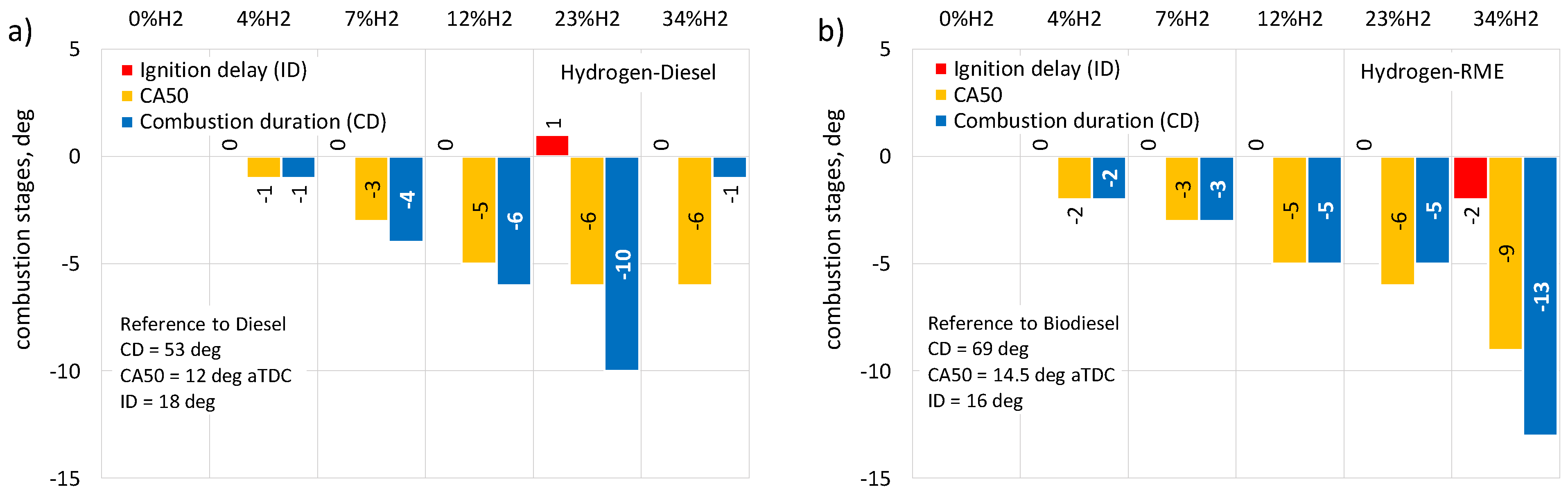

3.1. Combustion Characteristics

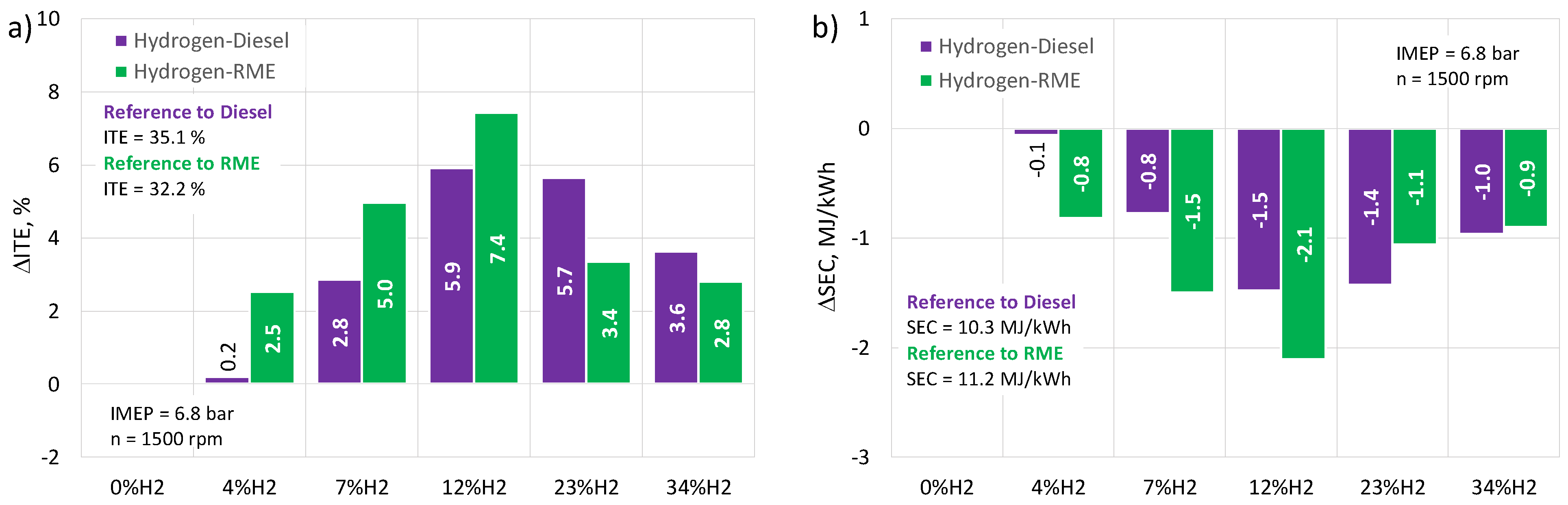

3.2. Performance Characteristics

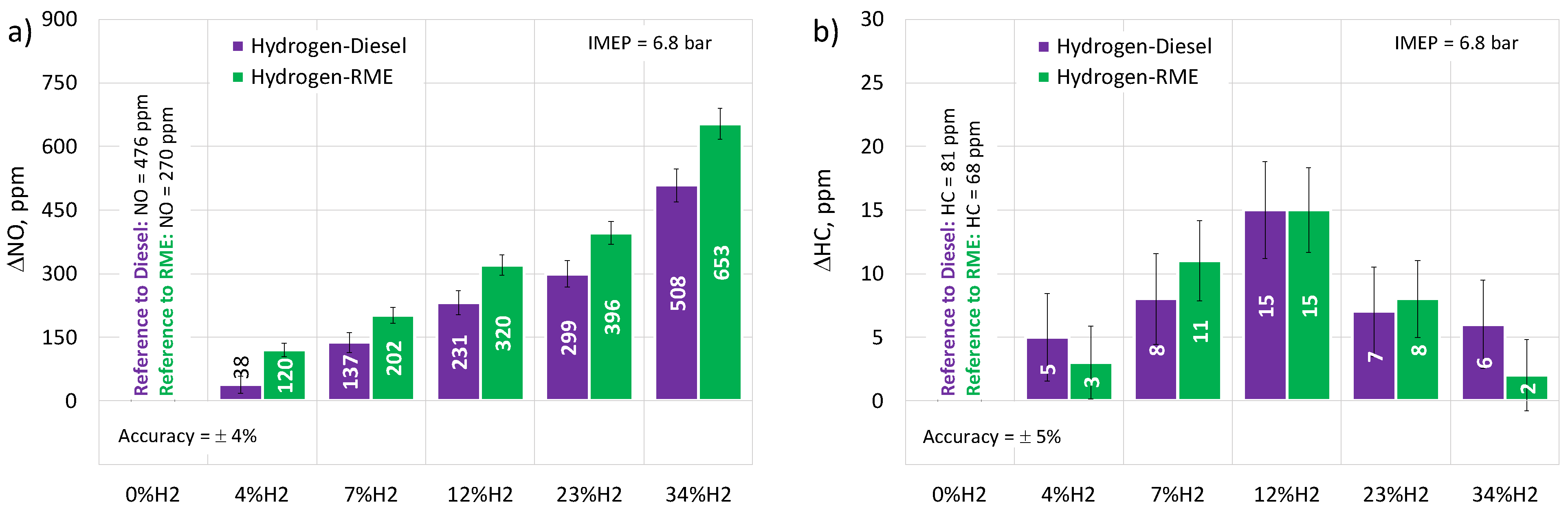

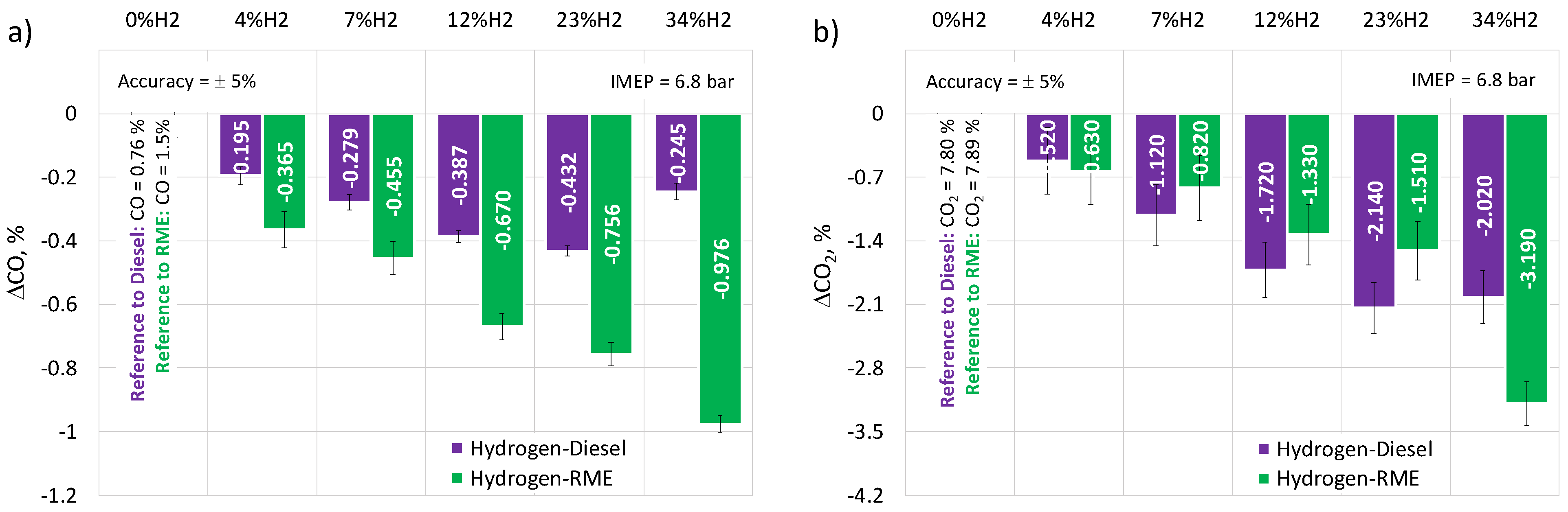

3.3. Emission Characteristics

4. Conclusions

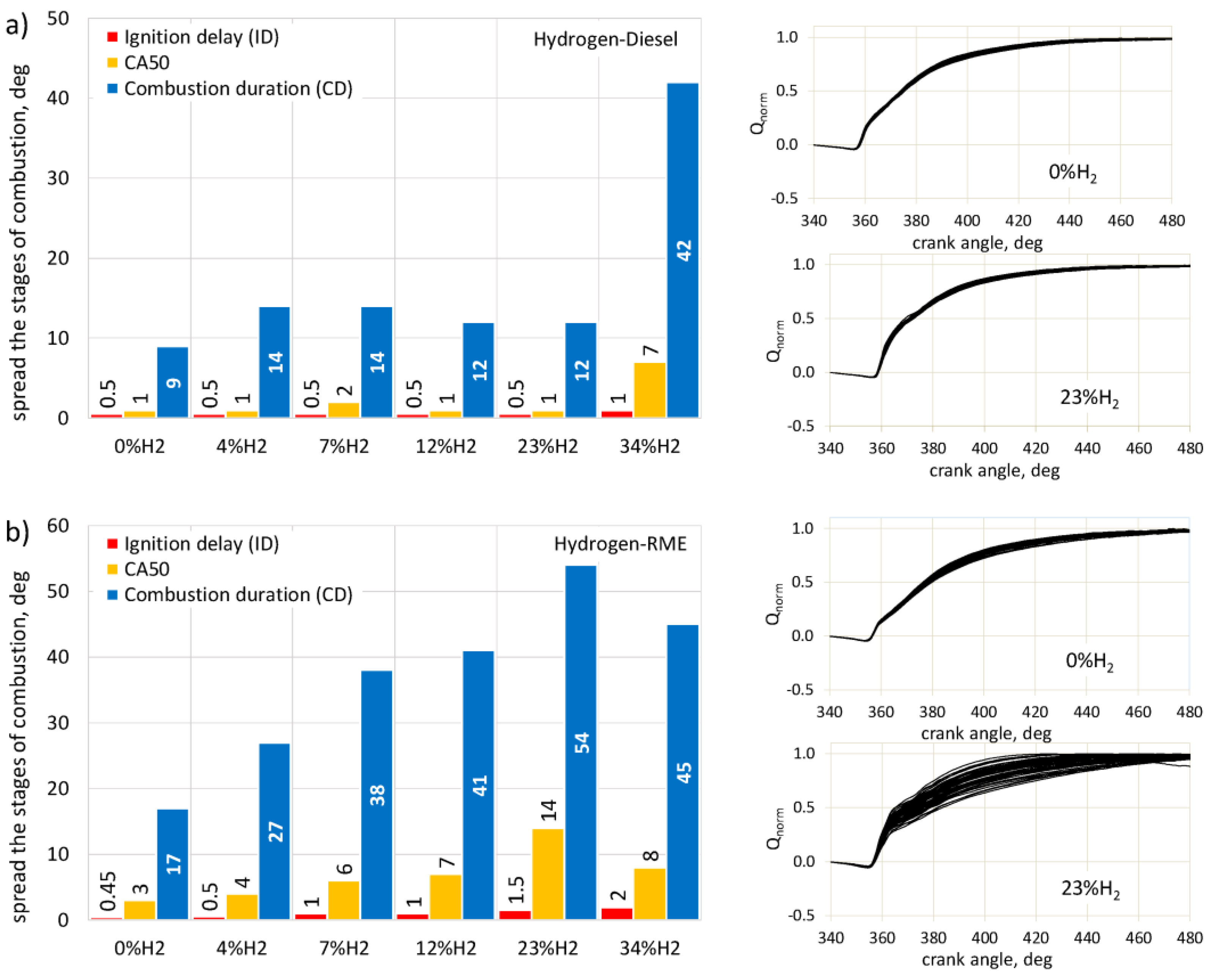

- – Biodiesel (RME) co-combusted with hydrogen exhibits a milder combustion process, characterized by smaller pressure and heat release rate increments compared to diesel fuel, a shorter ignition delay and longer combustion duration in comparison to an engine fueled solely by diesel fuel. Both Hydrogen-Diesel and Hydrogen-RME combinations result in the CA50 angle shifting closer to top dead center (TDC) as the hydrogen share increases.

- – The highest engine efficiency is achieved with a 12% energy share of hydrogen, but the engine fueled by biodiesel exhibits a more substantial efficiency increase for this hydrogen share.

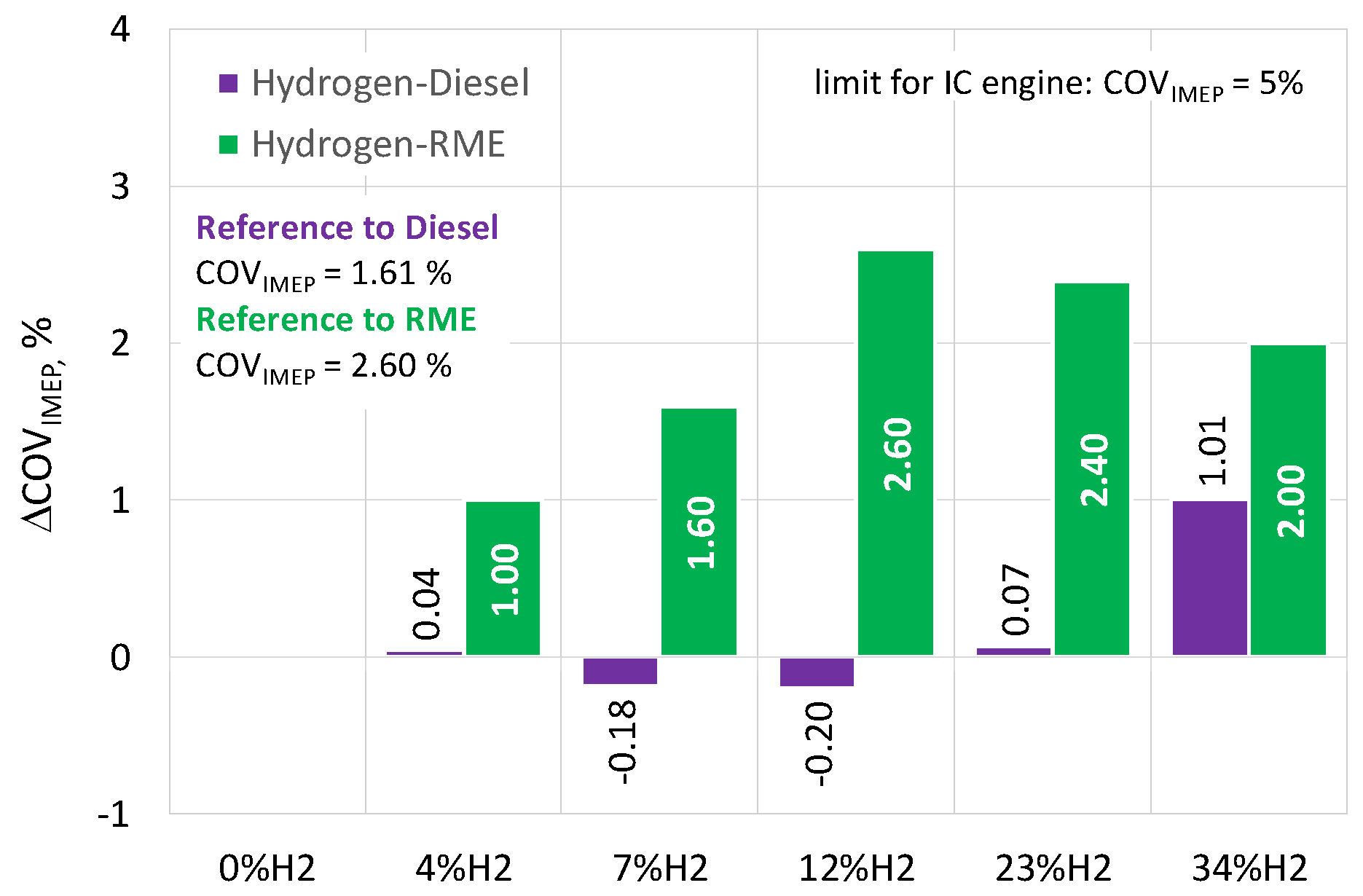

- – An engine powered by biodiesel slightly exhibits poorer work stability, as measured by the COVIMEP value. Hydrogen-RME combustion with a 12% hydrogen share leads to a 2.6% increase in variability.

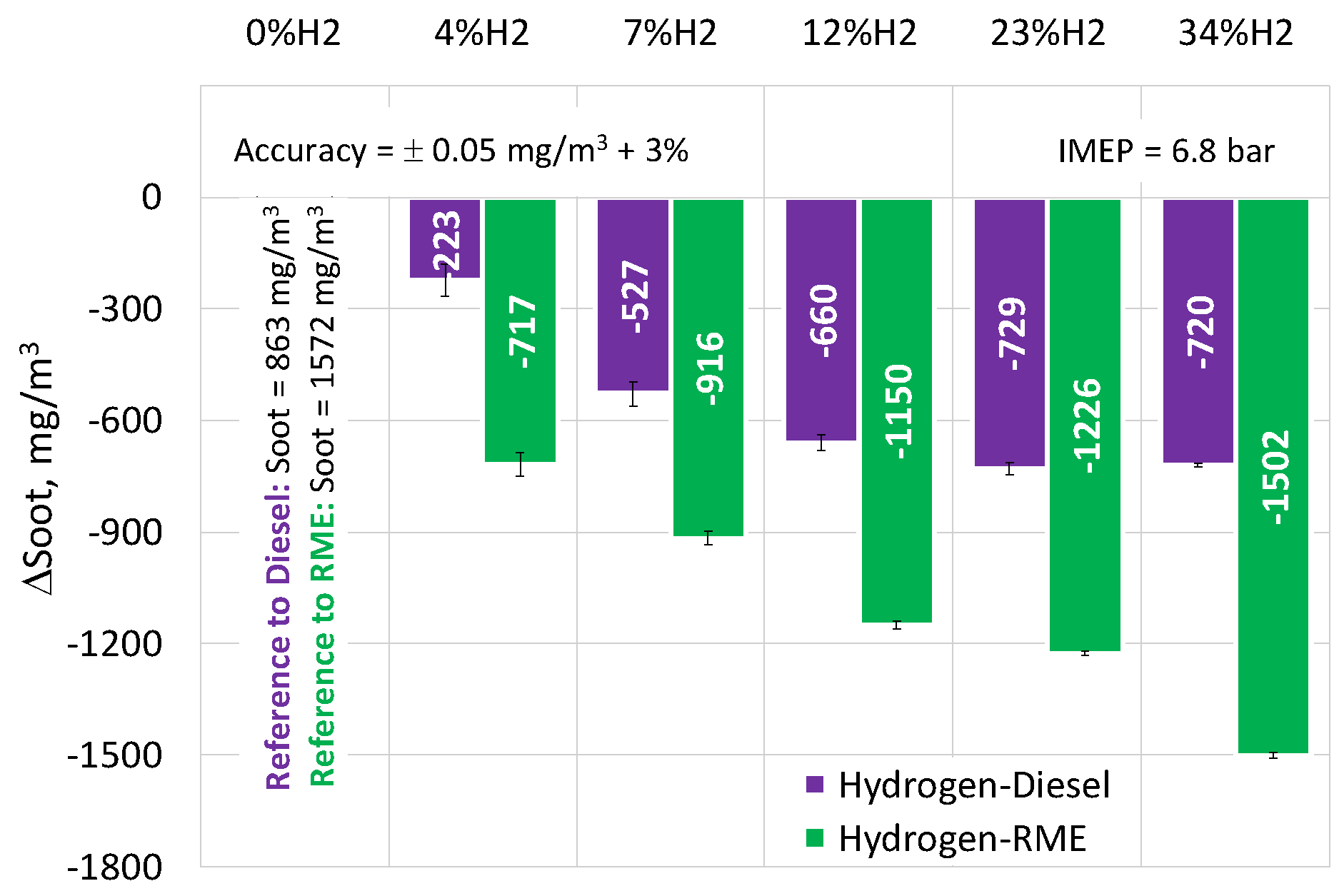

- – Hydrogen demonstrates a positive influence on soot emissions in a compression-ignition engine, both during its co-combustion with diesel fuel and biodiesel. The beneficial effect of using hydrogen is more notable in the Hydrogen-RME configuration.

- – Hydrogen demonstrates a positive influence on soot emissions in a compression-ignition engine, both during its co-combustion with diesel fuel and biodiesel. The beneficial effect of using hydrogen is more notable in the Hydrogen-RME con-figuration.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akal, D.; Öztuna, S.; Büyükakın, M.K. A review of hydrogen usage in internal combustion engines (gasoline-Lpg-diesel) from combustion performance aspect. Int. J. Hydrog. Energy 2020, 45, 35257–35268. [Google Scholar] [CrossRef]

- Arbab, M.I.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Imtenan, S.; Sajjad, H. Fuel properties, engine performance and emission characteristic of common biodiesels as a renewable and sustainable source of fuel. Renew. Sustain. Energy Rev. 2013, 22, 133–147. [Google Scholar] [CrossRef]

- Farhan, S.M.; Wang, P. Post-injection strategies for performance improvement and emissions reduction in DI diesel engines—A review. Fuel Process. Technol. 2022, 228, 107145. [Google Scholar] [CrossRef]

- Shinde, B.J.; Karunamurthy, K. Recent progress in hydrogen fuelled internal combustion engine (H2ICE)—A comprehensive outlook. Mater. Today Proc. 2022, 51, 1568–1579. [Google Scholar] [CrossRef]

- Şanlı, A.; Yılmaz, I.T. Cycle-to-cycle combustion analysis in hydrogen fumigated common-rail diesel engine. Fuel 2022, 320, 123887. [Google Scholar] [CrossRef]

- Sharma, P.; Dhar, A. Effect of hydrogen fumigation on combustion stability and unregulated emissions in a diesel fuelled compression ignition engine. Appl. Energy 2019, 253, 113620. [Google Scholar] [CrossRef]

- Zhou, S.; Luo, Z.; Wang, T.; He, M.; Li, R.; Su, B. Research progress on the self-ignition of high-pressure hydrogen discharge: A review. Int. J. Hydrog. Energy 2022, 47, 9460–9476. [Google Scholar] [CrossRef]

- Zhang, K.; Luo, T.; Li, Y.; Zhang, T.; Li, X.; Zhang, Z.; Shang, S.; Zhou, Y.; Zhang, C.; Chen, X.; et al. Effect of ignition, initial pressure and temperature on the lower flammability limit of hydrogen/air mixture. Int. J. Hydrog. Energy 2022, 47, 15107–15119. [Google Scholar] [CrossRef]

- Seelam, N.; Gugulothu, S.K.; Reddy, S.K.; Bhasker, B.; Panda, J.K. Exploration of engine characteristics in a CRDI diesel engine enriched with hydrogen in dual fuel mode using toroidal combustion chamber. Int. J. Hydrog. Energy 2022, 47, 13157–13167. [Google Scholar] [CrossRef]

- Gerpen, J.V. Biodiesel processing and production. Fuel Process. Technol. 2005, 86, 1097–1107. [Google Scholar] [CrossRef]

- Bukkarapu, K.R.; Krishnasamy, A. A critical review on available models to predict engine fuel properties of biodiesel. Renew. Sustain. Energy Rev. 2022, 155, 111925. [Google Scholar] [CrossRef]

- Kanth, S.; Debbarma, S. Comparative performance analysis of diesel engine fuelled with hydrogen enriched edible and non-edible biodiesel. Int. J. Hydrog. Energy 2021, 46, 10478–10493. [Google Scholar] [CrossRef]

- Gomes Antunes, J.M.; Mikalsen, R.; Roskilly, A.P. An experimental study of a direct injection compression ignition hydrogen engine. Int. J. Hydrog. Energy 2009, 34, 6516–6522. [Google Scholar] [CrossRef]

- Liu, X.; Srna, A.; Yip, H.L.; Kook, S.; Chan, Q.N.; Hawkes, E.R. Performance and emissions of hydrogen-diesel dual direct injection (H2DDI) in a single-cylinder compression-ignition engine. Int. J. Hydrog. Energy 2021, 46, 1302–1314. [Google Scholar] [CrossRef]

- Muralidhara, D.M.; Banapurmath, N.R.; Udayaravi, M.; Prabhakar Reddy, C.; Harari, P.A.; Karthik, T. Effect of hydrogen flow rates on the performance of two biodiesels fuelled dual fuel engine. Mater. Today Proc. 2022, 49, 2189–2196. [Google Scholar] [CrossRef]

- Akar, M.A.; Kekilli, E.; Bas, O.; Yildizhan, S.; Serin, H.; Ozcanli, M. Hydrogen enriched waste oil biodiesel usage in compression ignition engine. Int. J. Hydrog. Energy 2018, 43, 18046–18052. [Google Scholar] [CrossRef]

- Köse, H.; Acaroğlu, M. The effect of hydrogen addition to Cynara biodiesel on engine performance and emissions in diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–20. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Grab-Rogaliński, K. Effect of natural gas enrichment with hydrogen on combustion process and emission characteristic of a dual fuel diesel engine. Int. J. Hydrog. Energy 2020, 45, 9088–9097. [Google Scholar] [CrossRef]

- Tuccar, G.; Uludamar, E. Emission and engine performance analysis of a diesel engine using hydrogen enriched pomegranate seed oil biodiesel. Int. J. Hydrog. Energy 2018, 43, 18014–18019. [Google Scholar] [CrossRef]

- Dimitriou, P.; Kumar, M.; Tsujimura, T.; Suzuki, Y. Combustion and emission characteristics of a hydrogen-diesel dual-fuel engine. Int. J. Hydrog. Energy 2018, 43, 13605–13617. [Google Scholar] [CrossRef]

- Köse, H.; Ciniviz, M. An experimental investigation of effect on diesel engine performance and exhaust emissions of addition at dual fuel mode of hydrogen. Fuel Process. Technol. 2013, 114, 26–34. [Google Scholar] [CrossRef]

- Xia, C.; Brindhadevi, K.; Elfasakhany, A.; Alsehli, M.; Tola, S. Performance, combustion and emission analysis of castor oil biodiesel blends enriched with nanoadditives and hydrogen fuel using CI engine. Fuel 2021, 306, 121541. [Google Scholar] [CrossRef]

- Kanth, S.; Ananad, T.; Debbarma, S.; Das, B. Effect of fuel opening injection pressure and injection timing of hydrogen enriched rice bran biodiesel fuelled in CI engine. Int. J. Hydrog. Energy 2021, 46, 28789–28800. [Google Scholar] [CrossRef]

- Das, S.; Kanth, S.; Das, B.; Debbarma, S. Experimental evaluation of hydrogen enrichment in a dual-fueled CRDI diesel engine. Int. J. Hydrog. Energy 2022, 47, 11039–11051. [Google Scholar] [CrossRef]

- Stępień, Z.A. Comprehensive overview of hydrogen-fueled internal combustion engines: Achievements and future challenges. Energies 2021, 14, 6504. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Butler, B. An overview of development and challenges in hydrogen powered vehicles. Int. J. Green Energy 2020, 17, 13–37. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- Clapp, L.J.; Jenkin, M.E. Analysis of the relationship between ambient levels of O3, NO2 and NO as a function of NOx in the UK. Atmos. Environ. 2001, 35, 6391–6405. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Grab-Rogaliński, K. An experimental study on the performance and emission of the diesel/CNG dual-fuel combustion mode in a stationary CI engine. Energies 2019, 12, 3857. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Grab-Rogaliński, K. The effect of RME-1-butanol blends on combustion, performance and emission of a direct injection diesel engine. Energies 2021, 14, 2941. [Google Scholar] [CrossRef]

| Ref. | Engine Type | Fuelling Type | Operating Parameters | Emission |

|---|---|---|---|---|

| [6] | 1-cylinder, 4-stroke, water cooled engine, constant speed 1500 rpm | diesel fuelling, dose of hydrogen into engine manifolds, hydrogen energy share: 0%, 5%, 10%, 20% | load (25, 50 and 75%), increase of COVIMEP at 25% load, stabilization and increase of COVIMEP at 50 and 75% load | decrease of unregulated emissions (formaldehyde and acetaldehyde), (propylene, ethylene and aromatic hydrocarbons) |

| [9] | 1-cylinder (normally aspirated, air-cooled). engine speed at 1500 rpm | hydrogen into the intake manifold, hydrogen energy share (HES): 0% (100% diesel), 6%, 12%, 18% and 24% | 5.2% decrease at 24% HES in the BSEC, BTE increase (by 7.85% with 24% HES) | NOx increase (3.42%), CO2 (3.61%), CO (2.84%), and smoke (4.85%) decrease |

| [12] | 1-cylinder, 4-stroke, naturally aspired, constant speed 1500 rpm | diesel and biodiesel, hydrogen at a fixed flow rate of 7 lpm through the intake manifold, hydrogen-enriched diesel (D + H2), hydrogen-enriched 10, and 20% rice bran biodiesel blend (RB10 + H2) | engine load: 30%, 50%, 70%, 80%, 90%, 100%, 1.6% increase in the brake thermal efficiency, 6.35% decrease in fuel consumption | 4–38% lower CO emissions, 6–14% lower UHC emission, 6–13% higher NOx emission |

| [13] | single cylinder, constant engine speed, four-stroke, direct injection, naturally aspirated, air-cooled | conventional diesel, direct injection hydrogen-fuelled mode, varying the excess air ratio | higher power to weight ratio, 14% higher peak power, 43% fuel efficiency (28% for diesel engine) | 20% reduction in NOx emission |

| [14] | automotive-size, 1-cylinder, common-rail | hydrogen-diesel dual-fuel engine with dual direct injection, hydrogen energy fractions (0–50%) | intermediate fixed load of about 7.8 bar IMEP, indicated efficiency of 47% at 50% hydrogen substitution ratio | NOx emission below11 g/kWh |

| [15] | 1-cylinder, water cooled engine, constant speed 1500 rpm | B100 + hydrogen (variable ratio) hydrogen into the intake manifold, hydrogen-enriched biodiesels, flow rates of H₂ from 0.1 to 0.25 kg/h | 80% and 100% load reduction of brake thermal efficiency (BTE) | reduction of smoke, CO and HC emissions, increase NOx |

| [16] | naturally aspirated, water cooled, four stroke, 1-cylinder | B100 blended with diesel: 10 and 20%, pure hydrogen to intake manifold | B100 fraction deteriorated performance, Hydrogen improved performance | B100 fraction deteriorated emission, decrease CO and CO2, increase of NOx |

| [17] | 4-cylinder, turbocharged, variable rpm | small dose of hydrogen into intake manifold, D100, B100, (B7 + H2.5), (D + H2.5); D100/B100 blends direct inj. | max power and torque for (B7 + H2.5), highest ITE (B100 + H2.5) | reduction HC; increase NOx, minimum CO for B100 and (B100 + H2.5) |

| [19] | 4-cylinder, water cooled, engine speeds ranging from 1200 to 2800 rpm | hydrogen into the intake manifold hydrogen-enriched pomegranate seed oil biodiesel (POB), hydrogen flow: 5 L/min | full load conditions, positive effects on power output and BSFC | improvement of CO emissions, deterioration of NOx emissions |

| [20] | 4-cylinder, heavy-duty, (EGR) system and a boosting system | H2 energy share ratio of up to 98% | low and medium operating loads | for low load: reduction of CO and NOx emission of over 90%, soot decrease by 85%, for medium load increase NOx emission |

| [21] | four-stroke, water cooled, 4-cylinder, turbocharger, engine speeds 1000 to 2500 rpm | hydrogen into the inlet manifold (2.5%, 5% and 7.5% as volume) | full load, increase in engine torque, power, thermal efficiency, nitrogen oxides (NOx) and exhaust gasses temperatures | increase in NOx and EGT, decrease in HC, CO |

| [22] | 1-cylinder, four-stroke, water cooled, 4-cylinder, 1500 rpm | hydrogen into the inlet manifold (constant fraction 25%) biodiesel | full range of load, small increase in BTE, | decrease in CO, CO2, HC and NOx |

| [23] | 1-cylinder, four-stroke, water cooled, | diesel and biodiesel, hydrogen flow into intake manifold 7 lpm | small increase in BTE, | reduction in HC, CO and smoke, increase in NOx |

| [24] | 1-cylinder, water cooled, 1500 rpm, | diesel and palm biodiesel blend (P20), hydrogen injected into the intake manifold at different flow rates of 7 lpm and 10 lpm, loading condition of 30%, 60%, 80%, 90%, and 100% | increase in BTE and decrease in BSEC, reduction in combustion duration (CD), best improvement achieved for 90% load. | increase in NOx, decrease in CO, CO2 and HC, At 90% load, 10 lpm of H2-decreased HC od 51% and CO of 37%, |

| Item | Title 2 |

|---|---|

| Engine model | Andoria 1CA90 |

| Type of engine | Stationary, four stroke |

| Type of ignition | Compression ignition |

| Rated speed (rpm) | 1500 |

| Engine rated power @1500 rpm (kW) | 7 |

| Technique of cooling | Air cooled |

| Intake system | Naturally aspirates |

| Bore/stroke (mm) | 90/90 |

| Displacement (cc) | 573 |

| No. of cylinders | 1 |

| Injection system | Direct injection |

| Compression ratio | 17 |

| Start of injection (deg bTDC) | 20 |

| Apparatus | Measuring Range | Resolution | Accuracy from Measured Value | Absolute Accuracy |

|---|---|---|---|---|

| CO | 0.000–10.000% vol. | 0.001% vol. | … | … |

| 0.000–5.000% vol. | 0.001% vol. | ±5% | ±0.06% vol. | |

| HC | 0–9999 ppm vol. | 1 ppm vol. | … | … |

| 0–2000 ppm vol. | 1 ppm vol. | ±5% | ±12 ppm vol. | |

| CO2 | 0.00–18.00% vol. | 0.01% vol. | … | … |

| 0.00–16.00% vol. | 0.01% vol. | ±5% | ±0.5% vol. | |

| O2 | 0.00–22.00% vol. | 0.01% vol. | … | … |

| 0.00–21.00% vol. | 0.01% vol. | ±4% | ±0.1% vol. | |

| NO | 0–5000 ppm vol. | 1 ppm vol. | ±4% | ±25 ppm vol. |

| 0–4000 ppm vol. | 1 ppm vol. | ±8% | ±50 ppm vol. | |

| λ | 0.500–9.999 | 0.001 | … | … |

| 0.700–1.300 | 0.001 | ±4% | … |

| Diesel | RME | Hydrogen | |

|---|---|---|---|

| Molecular formula | C14H30 | CH3(CH2)nCOOCH3 | H2 |

| Cetane number | 51 | 54 | 5–10 |

| Octane number | 0–15 | 25 | 130 |

| Molecular weight (kg/kmol) | 170–200 | 296 | 2.02 |

| Density at 15 °C (kg/m3) | 840 | 820–845 | 0.084 |

| Lower heating value (MJ/kg) | 42.7 | 37.3 | 119.93 |

| Autoignition temperature (K) | 503 | 534 | 855 |

| Stoichiometric air-fuel ratio (kg/kg) | 14.53 | 12.3 | 34.4 |

| Kinematic viscosity at 20 °C (mm2/s) | 4 | 7.4 | - |

| Flammability limits in air (at%) | 0.6–5.5 | - | 4–75 |

| Ignition energy in air (mJ) | 0.24 | - | 0.02 |

| Diffusion coefficient in air (cm2/s) | 0.038 | - | 0.61 |

| Oxygen content (wt%) | 0 | 11 | 0 |

| Hydrogen content (wt%) | 15 | 12 | 100 |

| Carbon content (wt%) | 85 | 77 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tutak, W.; Jamrozik, A.; Grab-Rogaliński, K. Co-Combustion of Hydrogen with Diesel and Biodiesel (RME) in a Dual-Fuel Compression-Ignition Engine. Energies 2023, 16, 4892. https://doi.org/10.3390/en16134892

Tutak W, Jamrozik A, Grab-Rogaliński K. Co-Combustion of Hydrogen with Diesel and Biodiesel (RME) in a Dual-Fuel Compression-Ignition Engine. Energies. 2023; 16(13):4892. https://doi.org/10.3390/en16134892

Chicago/Turabian StyleTutak, Wojciech, Arkadiusz Jamrozik, and Karol Grab-Rogaliński. 2023. "Co-Combustion of Hydrogen with Diesel and Biodiesel (RME) in a Dual-Fuel Compression-Ignition Engine" Energies 16, no. 13: 4892. https://doi.org/10.3390/en16134892

APA StyleTutak, W., Jamrozik, A., & Grab-Rogaliński, K. (2023). Co-Combustion of Hydrogen with Diesel and Biodiesel (RME) in a Dual-Fuel Compression-Ignition Engine. Energies, 16(13), 4892. https://doi.org/10.3390/en16134892