The Effects of Vaporisation Models on the FCC Riser Reactor

Abstract

:1. Introduction

2. Model Description

2.1. Hydrodynamics

2.2. Cracking Reactions

2.3. Simulation Procedure

3. Results and Discussion

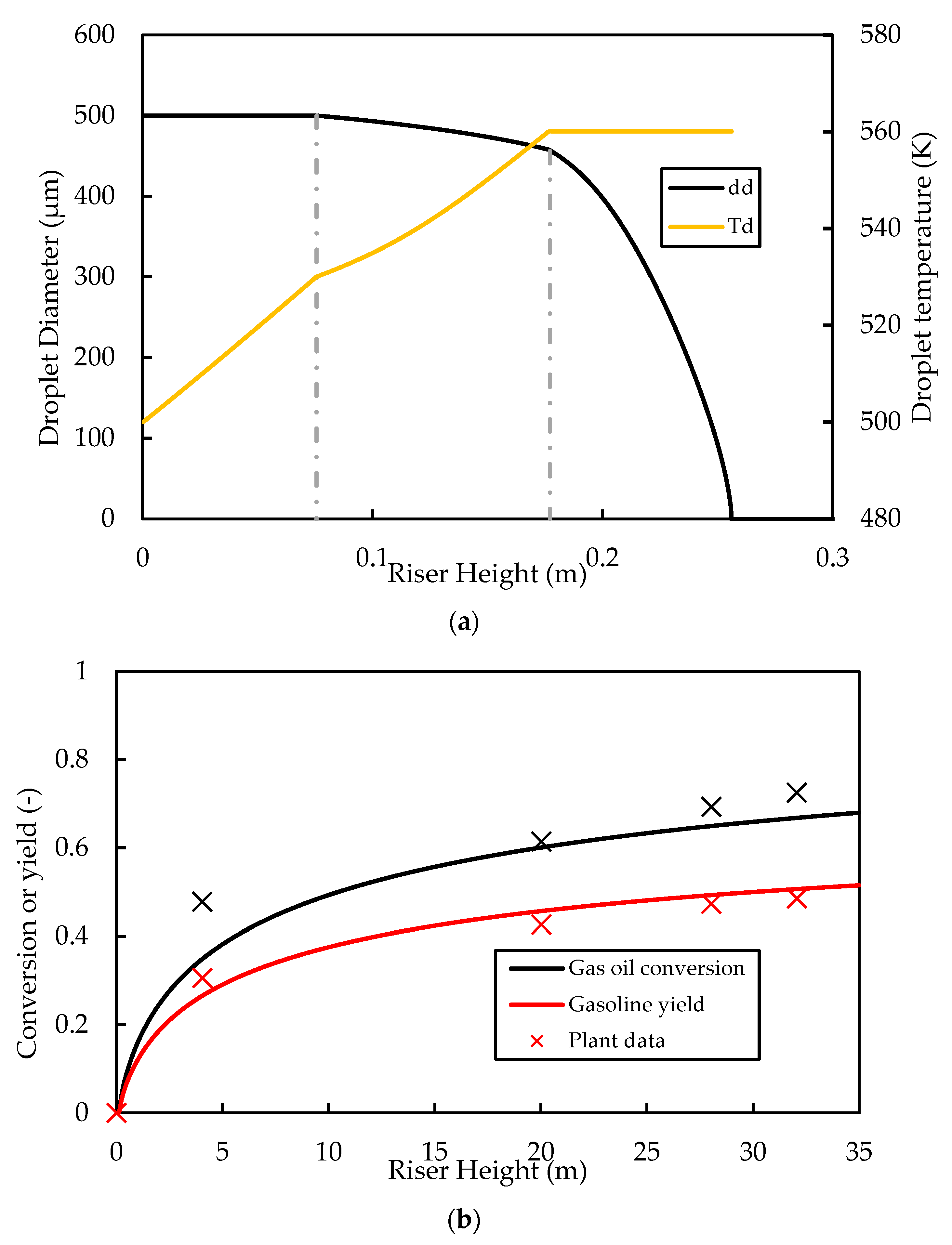

3.1. Derouin Case Study and Model Validation

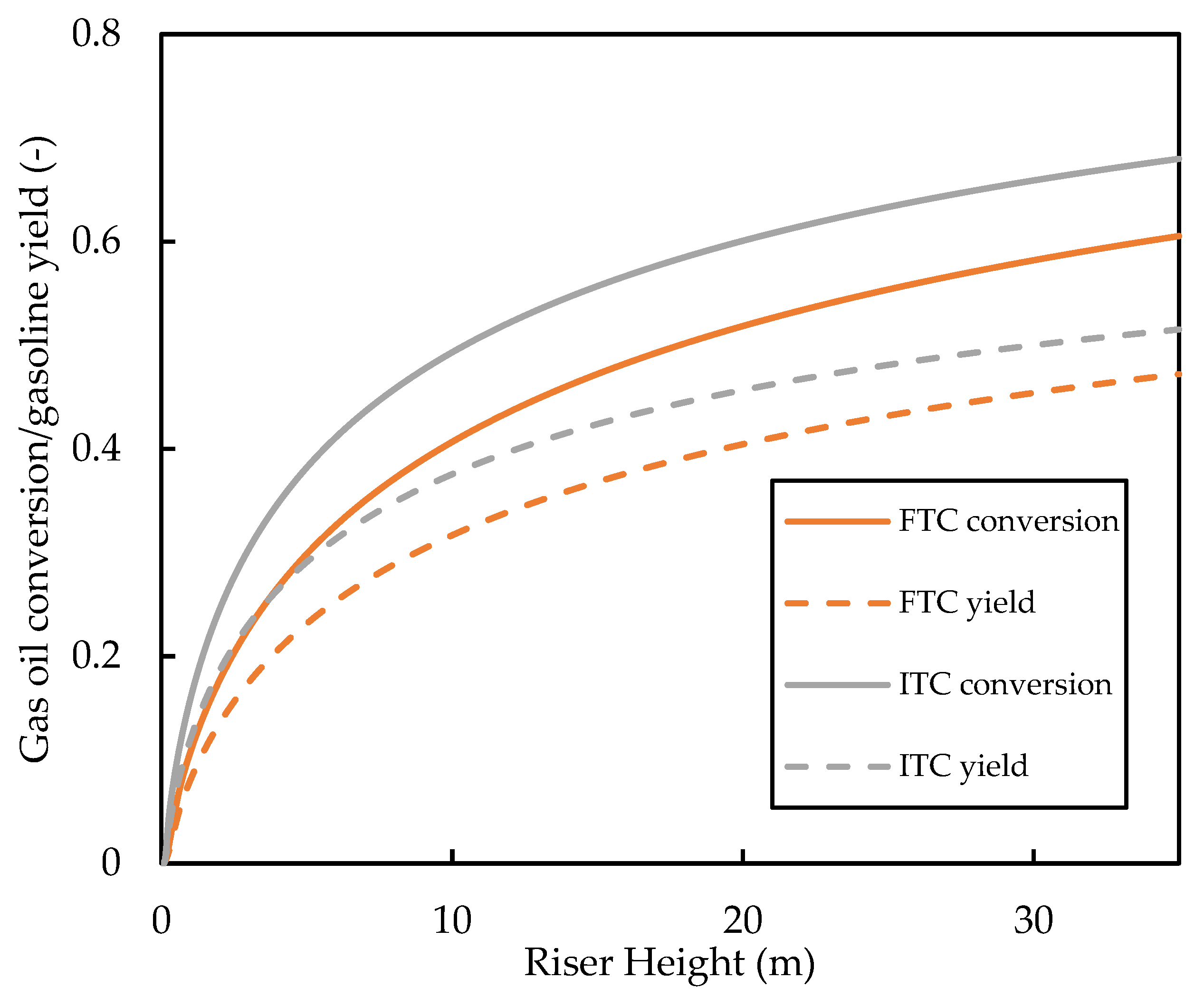

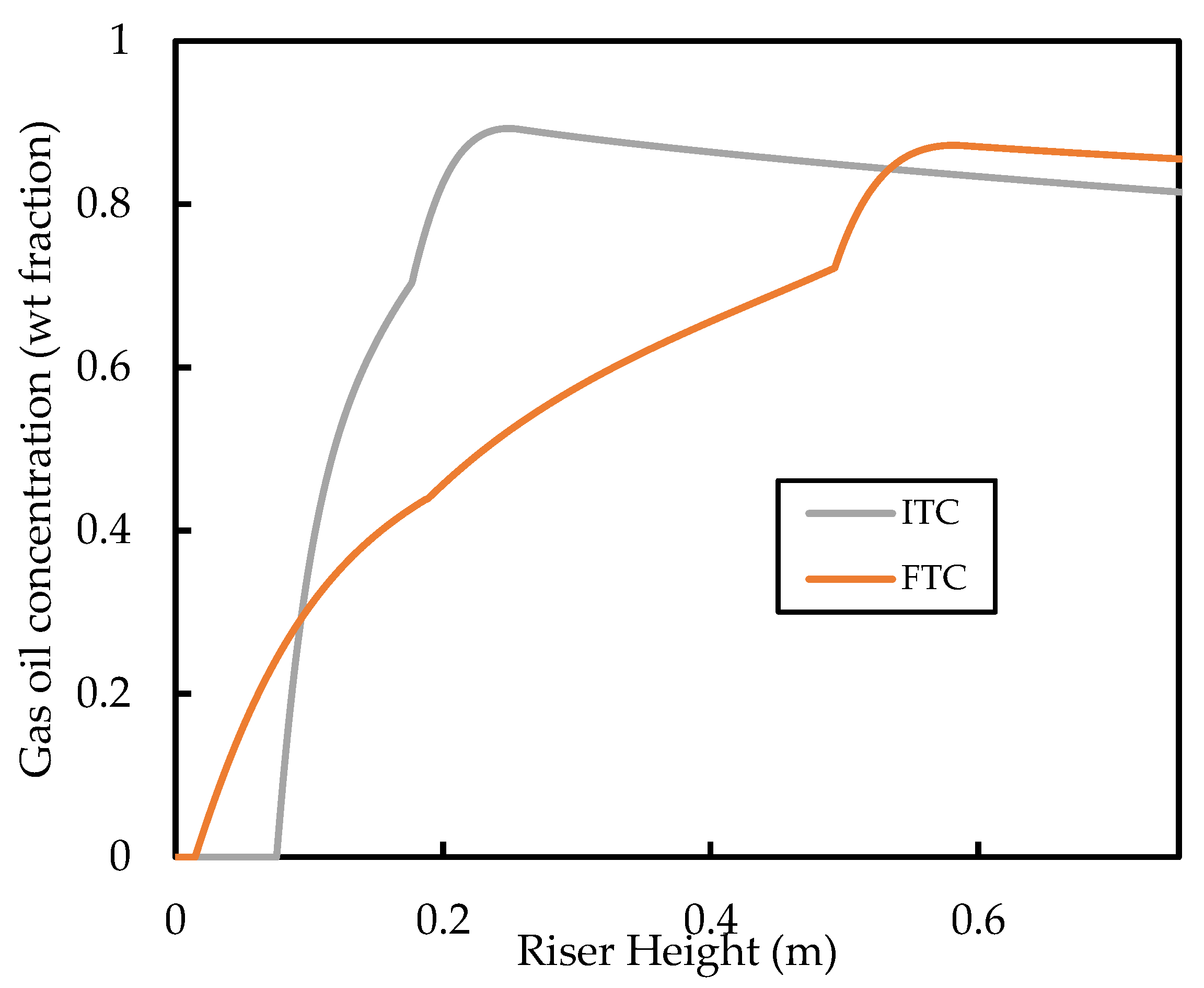

3.2. Base Case Performance Results

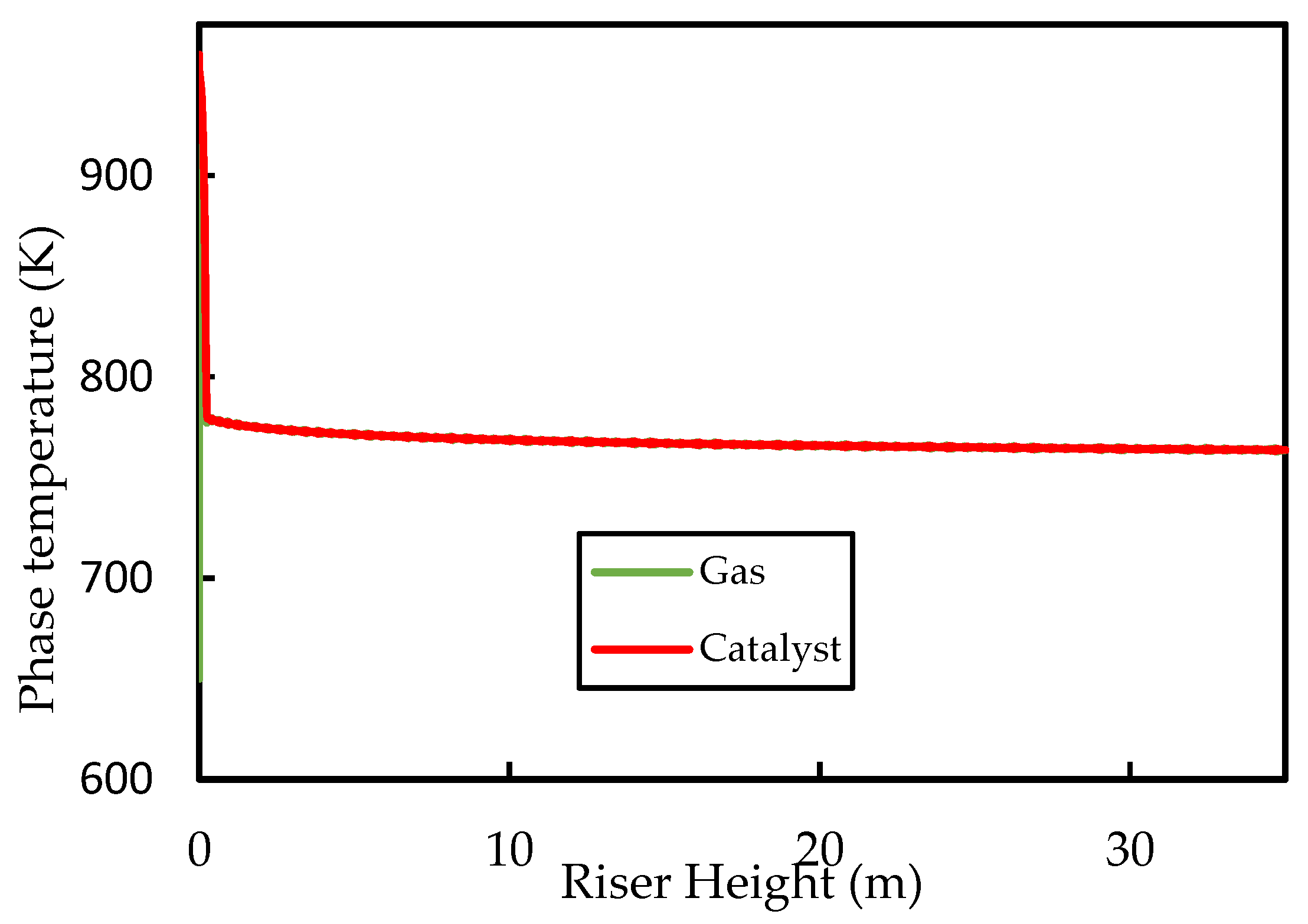

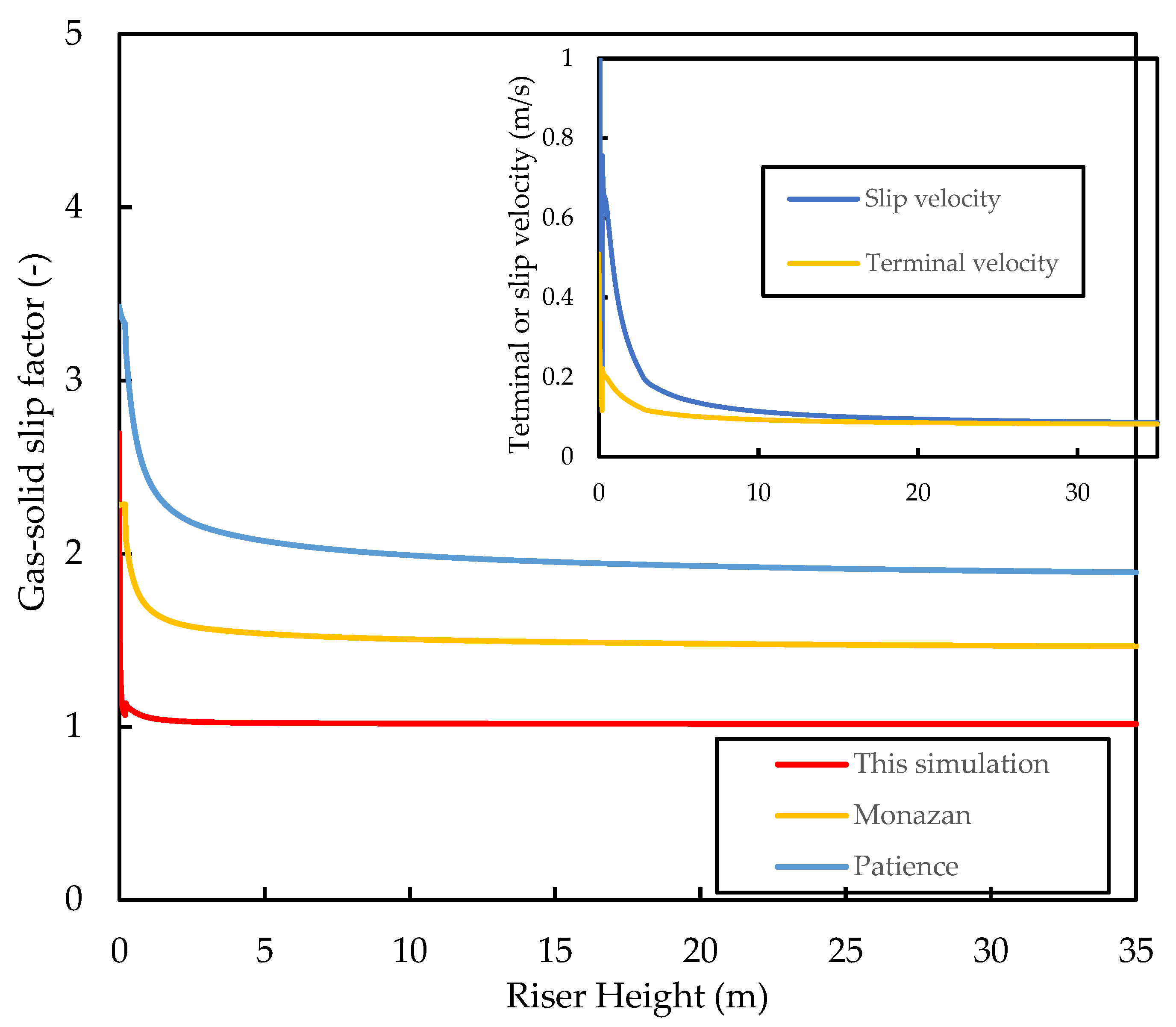

3.3. Hydrodynamics of the Base Case

3.4. Influence of Operating Conditions

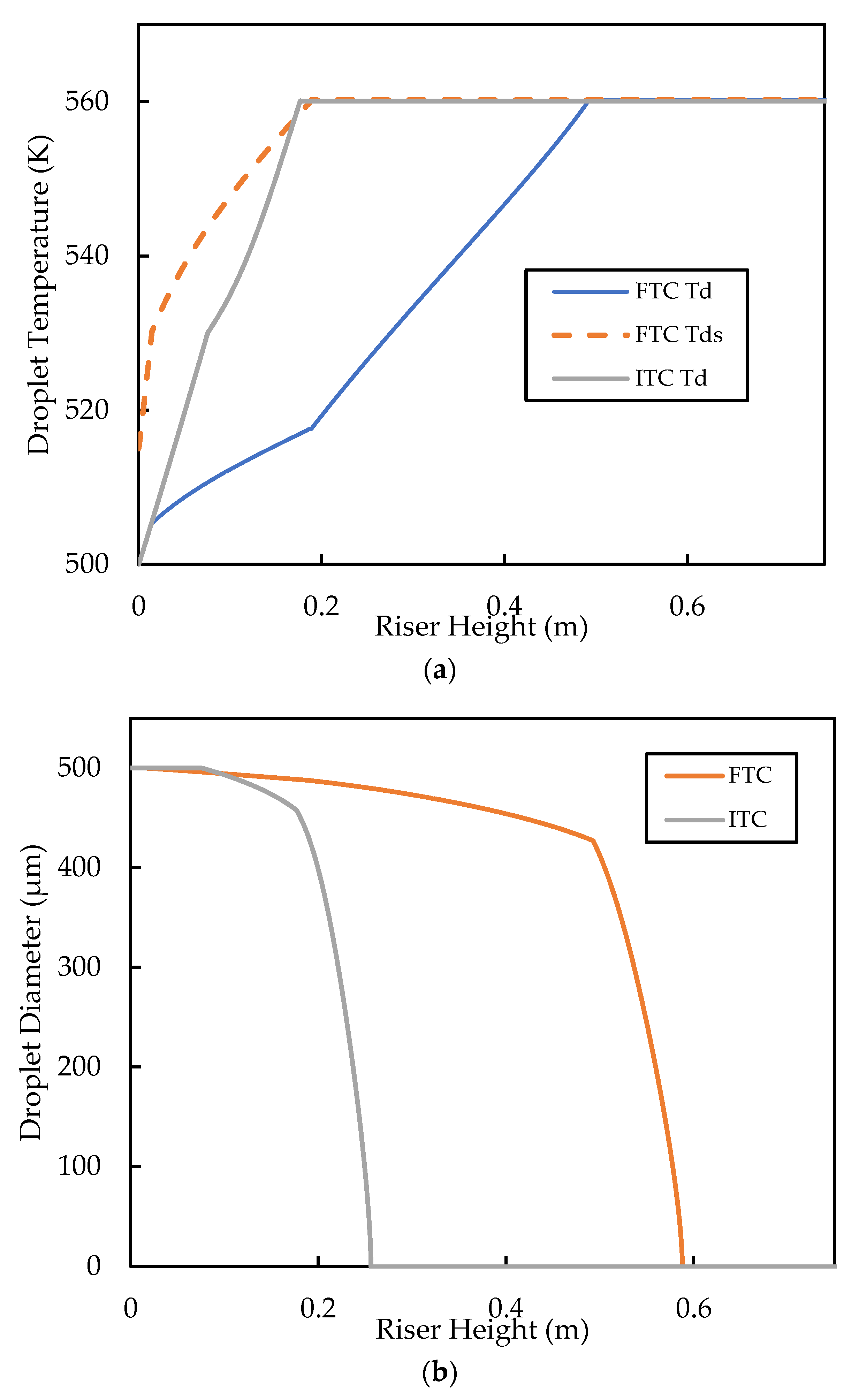

3.5. Influence of Droplet Thermal Conductivity Model

4. Conclusions

- The vaporisation phenomena and its underlying kinetics are largely less important to the predictions of gas oil conversion and the yield of the product species compared with the cracking kinetics. It is found that both homogeneous and heterogeneous vaporisation heat and mass transfer models predict near identical conversion and gasoline yield profiles, despite predicting significantly different liquid penetration depths. This finding gives validity to the assumption of instantaneous vaporisation that is widely used in the FCC riser modelling literature. Additionally, this observation indicated that, for most operating conditions, the rates of vaporisation predicted by various heat and mass transfer models were faster than the rates of cracking, for the case of the ITC modelling framework. However, when larger droplets are used (), the effect of heat transfer correlations becomes significant. In this case, homogeneous models predict slower vaporisation rates, which limit the progress of cracking, thus resulting in lower conversion. This effect is less significant for heterogeneous vaporisation models as the enhanced heat transfer due to solid–droplet collisions compensates for the reduced interfacial area density from larger droplets. Therefore, for larger droplets, careful consideration is required for the choice of correlation. On the other hand, the FTC model predicts slower vaporisation and thus lower conversion compared with the ITC model. Owing to the lack of experimental data for vaporisation dynamics in the FCC riser, the choice of model becomes difficult in these cases, as validation of the results is not possible. The results in this work suggest that, when the ITC model is used for droplets with initial size smaller than , the choice of the heat transfer model (i.e., homogeneous or heterogeneous) is not important as the conversion and yield are determined by the choice of reaction kinetic model. However, when the FTC model is used, the heat transfer model is as important as the kinetic model in the prediction of conversion and yield. Hence, it is recommended that the FTC is paired with heterogeneous heat transfer models for better prediction of conversion.

- One-dimensional models for the two-phase gas–solid flow in the fully developed region of the riser tend to overestimate the drag force when the drag is calculated using catalyst particle properties, resulting in the underestimation of the slip factor and thus slip velocity between the gas and solid. Such models predict slip factors of , corresponding to pseudo-homogeneous flow. Evidence from most cold flow pilot scale risers indicates that cluster formations are inherent in FCC risers and are generally understood to result in larger slip factors in the range of . Therefore, 1D models with such determination of drag are unable to predict evidence of this heterogeneity. In view of this, the calculation of drag using cluster properties is imperative for the prediction of the correct slip factors in 1D FCC riser models.

- Future work will focus on studies on vaporisation to provide an implementation for the validation of vaporisation models for larger droplets. Moreover, numerical studies of gas–solid flow using 1D, 2D, and 3D frameworks will be carried out to study the apparent underestimation of the slip factor in the fully developed region of the riser under lower dimensional models. The experimental determination of such slip factors in industrial risers during normal operation will also be an invaluable contribution to the subject.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Phase | Stream | Mass Rate kg s−1 | Diameter | Volume Fraction | Temp (K) |

|---|---|---|---|---|---|

| Solid | Catalyst | 300 | 72 | 0.08 | 960 |

| Gas | Steam | 6 | 0.91 | 650 | |

| Liquid | Feed (GO) | 60 | 500 | 0.01 | 500 |

| Phase | Species | Molar Mass kg kmol−1 | Heat Capacity kJ kg−1 K−1 |

|---|---|---|---|

| Solid | Catalyst | 1.0 | |

| Solid | CK | 371 | 1.0 |

| Gas | GO | 371 | |

| GL | 106 | ||

| LG | 40 | ||

| WV | 18 | ||

| Liquid | GO | 371 |

| Physical Property | Symbol | Reference |

|---|---|---|

| Gas oil heat of vaporisation | Han and Chung [4] | |

| Gas thermal conductivity | Han and Chung [4] | |

| Liquid thermal conductivity | Pachaiyappan, et al. [68] | |

| Gas heat capacity | Lee and Kesler [69] | |

| McKetta Jr [70] | ||

| Liquid heat capacity | Lee and Kesler [69] | |

| Gas viscosity | Han and Chung [4] | |

| Gas diffusivity | Fuller, et al. [71] | |

| Feed critical conditions | Riazi and Al-Sahhaf [72] | |

| Acentric factor | Riazi and Al-Sahhaf [72] |

Appendix B. Notation

| Symbol | Description | Unit |

|---|---|---|

| A | Surface area | m2 |

| CD | Drag coefficient | (-) |

| Cg | Gas molar density | kmol/m3 |

| Cg,i | Species concentration in the gas phase | kmol/m3 |

| cp | Specific heat capacity | kJ/kgK |

| Cs,i | Species concentration at the gas–droplet interphase | kmol/m3 |

| dd | Droplet diameter | m |

| Deff | Effective diffusivity in the gas phase | m2/s |

| dp | Catalyst particle diameter | m |

| Eors | Activation energy | kJ/kmol |

| f | Friction factor | (-) |

| g | Gravitational acceleration | m/s2 |

| h | Heat transfer coefficient | kJ/m2 K |

| k | Thermal diffusivity | kJ/mK |

| kc | Mass transfer coefficient | m/s |

| krs | Rate constant | m6/kgkgcats or m3/kgcats |

| Kors | Frequency factor for rate constant | m6/kgkgcats or m3/kgcats |

| Lv | Heat of vaporisation | kJ/kg |

| md | Droplet mass | kg |

| Mw,i | Species molar mass | kg/kmol |

| Vaporisation rate | kg/s | |

| N | Number density | /m2 |

| Nu | Nusselt number | (-) |

| Nvap | Vaporisation flux at droplet surface | kmol/m2s |

| P | Pressure | kPa |

| Pr | Prandtl number | (-) |

| Psat | Saturation pressure | kPa |

| Qreact | Heat of cracking reactions | kJ/kgcat |

| r | Reaction rate | kg/kgcats |

| R | Ideal gas constant | kJ/K kmol |

| Re | Reynolds number | (-) |

| Rg,i | Species reaction rate | kg/m3s |

| Sc | Schmidt number | (-) |

| Sh | Sherwood number | (-) |

| T | Phase temperature | K |

| v | Velocity | m/s |

References

- Buchanan, J.S. Analysis of Heating and Vaporization of Feed Droplets in Fluidized Catalytic Cracking Risers. Ind. Eng. Chem. Res. 1994, 33, 3104–3111. [Google Scholar] [CrossRef]

- Nayak, S.V.; Joshi, S.L.; Ranade, V.V. Modeling of vaporization and cracking of liquid oil injected in a gas–solid riser. Chem. Eng. Sci. 2005, 60, 6049–6066. [Google Scholar] [CrossRef]

- Güleç, F.; Meredith, W.; Snape, C.E. Progress in the CO2 Capture Technologies for Fluid Catalytic Cracking (FCC) Units—A Review. Front. Energy Res. 2020, 8, 62. [Google Scholar] [CrossRef]

- Han, I.-S.; Chung, C.-B. Dynamic modeling and simulation of a fluidized catalytic cracking process. Part II: Property estimation and simulation. Chem. Eng. Sci. 2001, 56, 1973–1990. [Google Scholar] [CrossRef]

- Selalame, T.W.; Patel, R.; Mujtaba, I.M.; John, Y.M. A Review of Modelling of the FCC Unit—Part I: The Riser. Energies 2022, 15, 308. [Google Scholar] [CrossRef]

- Corma, A.; Orchillés, A. Current views on the mechanism of catalytic cracking. Microporous Mesoporous Mater. 2000, 35, 21–30. [Google Scholar] [CrossRef]

- Joly, J.F.; de Oliveira, L.P.; Hudebine, D.; Guillaume, D.; Verstraete, J.J. A Review of Kinetic Modeling Methodologies for Complex Processes. Oil Gas Sci. Technol. 2016, 71, 45. [Google Scholar]

- Weekman, V.W., Jr.; Nace, D.M. Kinetics of catalytic cracking selectivity in fixed, moving, and fluid bed reactors. AIChE J. 1970, 16, 397–404. [Google Scholar] [CrossRef]

- Ancheytajuarez, J.; Lopezisunza, F.; Aguilarrodriguez, E. A Strategy for Kinetic Parameter Estimation in the Fluid Catalytic Cracking Process. Ind. Eng. Chem. Res. 1997, 36, 5170–5174. [Google Scholar] [CrossRef]

- Ancheyta-Juárez, J.; López-Isunza, F.; Aguilar-Rodrıguez, E. 5-Lump kinetic model for gas oil catalytic cracking. Appl. Catal. A Gen. 1999, 177, 227–235. [Google Scholar] [CrossRef]

- Ancheyta-Juárez, J.; Sotelo-Boyás, R. Estimation of Kinetic Constants of a Five-Lump Model for Fluid Catalytic Cracking Process Using Simpler Sub-models. Energy Fuels 2000, 14, 1226–1231. [Google Scholar] [CrossRef]

- Bollas, G.M.; Lappas, A.A.; Iatridis, D.K.; Vasalos, I.A. Five-lump kinetic model with selective catalyst deactivation for the prediction of the product selectivity in the fluid catalytic cracking process. Catal. Today 2007, 127, 31–43. [Google Scholar] [CrossRef]

- Chen, C.; Yang, B.; Yuan, J.; Wang, Z.; Wang, L. Establishment and solution of eight-lump kinetic model for FCC gasoline secondary reaction using particle swarm optimization. Fuel 2007, 86, 2325–2332. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, W.; Wang, Z.; Hou, K.; Ouyang, F.; Li, D. A 12-lump kinetic model for heavy oil fluid catalytic cracking for cleaning gasoline and enhancing light olefins yield. Pet. Sci. Technol. 2020, 38, 912–921. [Google Scholar] [CrossRef]

- Gao, H.; Wang, G.; Xu, C.; Gao, J. Eight-Lump Kinetic Modeling of Vacuum Residue Catalytic Cracking in an Independent Fluid Bed Reactor. Energy Fuels 2014, 28, 6554–6562. [Google Scholar] [CrossRef]

- John, Y.M.; Mustafa, M.A.; Patel, R.; Mujtaba, I.M. Parameter estimation of a six-lump kinetic model of an industrial fluid catalytic cracking unit. Fuel 2019, 235, 1436–1454. [Google Scholar] [CrossRef] [Green Version]

- Jacob, S.M.; Gross, B.; Voltz, S.E.; Weekman, V.W., Jr. A lumping and reaction scheme for catalytic cracking. AIChE J. 1976, 22, 701–713. [Google Scholar] [CrossRef]

- Shah, M.T.; Utikar, R.P.; Pareek, V.K.; Evans, G.M.; Joshi, J.B. Computational fluid dynamic modelling of FCC riser: A review. Chem. Eng. Res. Des. 2016, 111, 403–448. [Google Scholar] [CrossRef]

- Feng, W.; Vynckier, E.; Froment, G.F. Single event kinetics of catalytic cracking. Ind. Eng. Chem. Res. 1993, 32, 2997–3005. [Google Scholar] [CrossRef]

- Dewachtere, N.V.; Santaella, F.; Froment, G.F. Application of a single-event kinetic model in the simulation of an industrial riser reactor for the catalytic cracking of vacuum gas oil. Chem. Eng. Sci. 1999, 54, 3653–3660. [Google Scholar] [CrossRef]

- Froment, G.F. Single Event Kinetic Modeling of Complex Catalytic Processes. Catal. Rev. Sci. Eng. 2005, 47, 83–124. [Google Scholar] [CrossRef]

- Quintana-Solórzano, R.; Thybaut, J.W.; Marin, G.B.; Lødeng, R.; Holmen, A. Single-Event MicroKinetics for coke formation in catalytic cracking. Catal. Today 2005, 107, 619–629. [Google Scholar] [CrossRef]

- Sundberg, J.; Standl, S.; von Aretin, T.; Tonigold, M.; Rehfeldt, S.; Hinrichsen, O.; Klein, H. Optimal process for catalytic cracking of higher olefins on ZSM-5. Chem. Eng. J. 2018, 348, 84–94. [Google Scholar] [CrossRef]

- Standl, S.; Tonigold, M.; Hinrichsen, O. Single-Event Kinetic Modeling of Olefin Cracking on ZSM-5: Proof of Feed Independence. Ind. Eng. Chem. Res. 2017, 56, 13096–13108. [Google Scholar] [CrossRef]

- Louge, M.; Chang, H. Pressure and voidage gradients in vertical gas-solid risers. Powder Technol. 1990, 60, 197–201. [Google Scholar] [CrossRef]

- Rhodes, M.J.; Geldart, D. A model for the circulating fluidized bed. Powder Technol. 1987, 53, 155–162. [Google Scholar] [CrossRef]

- Miller, A.; Gidaspow, D. Dense, vertical gas-solid flow in a pipe. AIChE J. 1992, 38, 1801–1815. [Google Scholar] [CrossRef]

- Bhusarapu, S.; Al-Dahhan, M.H.; Duduković, M.P.; Trujillo, S.; O’Hern, T.J. Experimental Study of the Solids Velocity Field in Gas−Solid Risers. Ind. Eng. Chem. Res. 2005, 44, 9739–9749. [Google Scholar] [CrossRef]

- Bhusarapu, S.; Al-Dahhan, M.H.; Duduković, M.P. Solids flow mapping in a gas–solid riser: Mean holdup and velocity fields. Powder Technol. 2006, 163, 98–123. [Google Scholar] [CrossRef]

- Horio, M.; Kuroki, H. Three-dimensional flow visualization of dilutely dispersed solids in bubbling and circulating fluidized beds. Chem. Eng. Sci. 1994, 49, 2413–2421. [Google Scholar] [CrossRef]

- Harris, B.J.; Davidson, J.F. Modeling options for circulating fluidized beds: A core/annulus deposition model. In Circulating Fluidized Bed Technology IV; Avidan, A.A., Ed.; American Institute of Chemical Engineers (AIChE): New York, NY, USA, 1994; pp. 32–39. [Google Scholar]

- Berruti, F.; Pugsley, T.S.; Godfroy, L.; Chaouki, J.; Patience, G.S. Hydrodynamics of circulating fluidized bed risers: A review. Can. J. Chem. Eng. 1995, 73, 579–602. [Google Scholar] [CrossRef]

- Han, I.-S.; Chung, C.-B. Dynamic modeling and simulation of a fluidized catalytic cracking process. Part I: Process modeling. Chem. Eng. Sci. 2001, 56, 1951–1971. [Google Scholar] [CrossRef]

- Ahari, J.S.; Farshi, A.; Forsat, K. A mathematical modeling of the riser reactor in industrial FCC unit. Pet. Coal 2008, 50, 15–24. [Google Scholar]

- Heydari, M.; Ebrahim, H.A.; Dabir, B. Modeling of an Industrial Riser in the Fluid Catalytic Cracking Unit. Am. J. Appl. Sci. 2010, 7, 221–226. [Google Scholar] [CrossRef] [Green Version]

- Arya, D.; Gupta, R.K. Simulation Studies on Variable Cluster Size in FCC Riser Reactor. Part. Sci. Technol. 2014, 32, 144–150. [Google Scholar] [CrossRef]

- John, Y.M.; Patel, R.; Mujtaba, I.M. Maximization of propylene in an industrial FCC unit. Appl. Petrochem. Res. 2018, 8, 79–95. [Google Scholar] [CrossRef] [Green Version]

- Ali, H.; Rohani, S.; Corriou, J.P. Modelling and Control of a Riser Type Fluid Catalytic Cracking (FCC) Unit. Chem. Eng. Res. Des. 1997, 75, 401–412. [Google Scholar] [CrossRef]

- Nguyen, T.T.B.; Mitra, S.; Pareek, V.; Joshi, J.B.; Evans, G. Comparison of vaporization models for feed droplet in fluid catalytic cracking risers. Chem. Eng. Res. Des. 2015, 101, 82–97. [Google Scholar] [CrossRef]

- Miller, R.S.; Harstad, K.; Bellan, J. Evaluation of equilibrium and non-equilibrium evaporation models for many-droplet gas-liquid flow simulations. Int. J. Multiph. Flow 1998, 24, 1025–1055. [Google Scholar] [CrossRef]

- Finneran, J. On the evaluation of transport properties for droplet evaporation problems. Int. J. Heat Mass Transf. 2021, 181, 121858. [Google Scholar] [CrossRef]

- Finneran, J.; Garner, C.P.; Nadal, F. Deviations from classical droplet evaporation theory. Proc. R. Soc. A 2021, 477, 20210078. [Google Scholar] [CrossRef] [PubMed]

- Lupo, G. Detailed Simulations of Droplet Evaporation; KTH Royal Institute of Technology: Stockholm, Sweden, 2017. [Google Scholar]

- Bellan, J.; Harstad, K. Analysis of the convective evaporation of nondilute clusters of drops. Int. J. Heat Mass Transf. 1987, 30, 125–136. [Google Scholar] [CrossRef]

- Ranz, W.E. Evaporation from drops, Parts I & II. Chem. Eng. Prog. 1952, 48, 141–146. [Google Scholar]

- Faeth, G. Current status of droplet and liquid combustion. In Energy and Combustion Science; Elsevier: Amsterdam, The Netherlands, 1979; pp. 149–182. [Google Scholar]

- Sazhin, S.S. Advanced models of fuel droplet heating and evaporation. Prog. Energy Combust. Sci. 2006, 32, 162–214. [Google Scholar] [CrossRef]

- Abramzon, B.; Sirignano, W.A. Droplet vaporization model for spray combustion calculations. Int. J. Heat Mass Transf. 1989, 32, 1605–1618. [Google Scholar] [CrossRef]

- Fernandes, J.L.; Verstraete, J.J.; Pinheiro, C.I.C.; Oliveira, N.M.C.; Ribeiro, F.R. Dynamic modelling of an industrial R2R FCC unit. Chem. Eng. Sci. 2007, 62, 1184–1198. [Google Scholar] [CrossRef]

- Tsuo, Y.P.; Gidaspow, D. Computation of flow patterns in circulating fluidized beds. AIChE J. 1990, 36, 885–896. [Google Scholar] [CrossRef]

- Arastoopour, H.; Gidaspow, D. Vertical Pneumatic Conveying Using Four Hydrodynamic Models. Ind. Eng. Chem. Fundam. 1979, 18, 123–130. [Google Scholar] [CrossRef]

- Selalame, T.W.; Patel, R.; Mujtaba, I.M.; John, Y.M. A Review of Modelling of the FCC Unit—Part II: The Regenerator. Energies 2022, 15, 388. [Google Scholar] [CrossRef]

- Fernandes, J.L.; Pinheiro, C.I.C.; Oliveira, N.; Ribeiro, F.R. Modeling and simulation of an operating industrial fluidized catalytic cracking (FCC) riser. In Proceedings of the 2nd Mercosur Congress on chemical Engineering, 4th Mercosur Congress on Process Systems Engineering, Costa Verde, Brazil, 14–18 August 2005; pp. 1–4. [Google Scholar]

- Gupta, R.K.; Kumar, V.; Srivastava, V.K. A new generic approach for the modeling of fluid catalytic cracking (FCC) riser reactor. Chem. Eng. Sci. 2007, 62, 4510–4528. [Google Scholar] [CrossRef]

- Pitault, I.; Forissier, M.; Bernard, J.-R. Détermination de constantes cinétiques du craquage catalytique par la modélisation du test de microactivité (MAT). Can. J. Chem. Eng. 1995, 73, 498–504. [Google Scholar] [CrossRef]

- Shampine, L.F.; Reichelt, M.W. The matlab ode suite. SIAM J. Sci. Comput. 1997, 18, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Derouin, C.; Nevicato, D.; Forissier, M.; Wild, G.; Bernard, J.-R. Hydrodynamics of Riser Units and Their Impact on FCC Operation. Ind. Eng. Chem. Res. 1997, 36, 4504–4515. [Google Scholar] [CrossRef]

- Paraskos, J.A.; Shah, Y.T.; McKinney, J.D.; Carr, N.L. A Kinematic Model for Catalytic Cracking in a Transfer Line Reactor. Ind. Eng. Chem. Process Des. Dev. 1976, 15, 165–169. [Google Scholar] [CrossRef]

- Blasetti, A.; de Lasa, H. FCC Riser Unit Operated in the Heat-Transfer Mode: Kinetic Modeling. Ind. Eng. Chem. Res. 1997, 36, 3223–3229. [Google Scholar] [CrossRef]

- Ahmadi Motlagh, A.H.; Grace, J.R.; Briens, C.; Berruti, F.; Farkhondehkavaki, M.; Hamidi, M. Experimental analysis of volatile liquid injection into a fluidized bed. Particuology 2017, 34, 39–47. [Google Scholar] [CrossRef]

- Leclère, K.; Briens, C.; Gauthier, T.; Bayle, J.; Guigon, P.; Bergougnou, M. Experimental measurement of droplet vaporization kinetics in a fluidized bed. Chem. Eng. Process. 2004, 43, 693–699. [Google Scholar] [CrossRef]

- Theologos, K.N.; Nikou, I.D.; Lygeros, A.I.; Markatos, N.C. Simulation and design of fluid catalytic-cracking riser-type reactors. AIChE J. 1997, 43, 486–494. [Google Scholar] [CrossRef]

- Wu, C.; Cheng, Y.; Jin, Y. Understanding Riser and Downer Based Fluid Catalytic Cracking Processes by a Comprehensive Two-Dimensional Reactor Model. Ind. Eng. Chem. Res. 2009, 48, 12–26. [Google Scholar] [CrossRef]

- Patience, G.S.; Chaouki, J.; Berruti, F.; Wong, R. Scaling considerations for circulating fluidized bed risers. Powder Technol. 1992, 72, 31–37. [Google Scholar] [CrossRef]

- Monazam, E.R.; Shadle, L.J. Analysis of the Acceleration Region in a Circulating Fluidized Bed Riser Operating above Fast Fluidization Velocities. Ind. Eng. Chem. Res. 2008, 47, 8423–8429. [Google Scholar] [CrossRef]

- Matsen, J.M. Some characteristics of large solids circulation systems. Fluid. Technol. 1976, 2, 135–149. [Google Scholar]

- Das, A.K.; Baudrez, E.; Marin, G.B.; Heynderickx, G.J. Three-Dimensional Simulation of a Fluid Catalytic Cracking Riser Reactor. Ind. Eng. Chem. Res. 2003, 42, 2602–2617. [Google Scholar] [CrossRef]

- Pachaiyappan, V.; Ibrahim, S.; Kuloor, N. Simple correlation for determining viscosity of organic liquids. Chem. Eng. 1967, 74, 193–196. [Google Scholar]

- Lee, B.; Kesler, M. Isobaric teat capacity of petroleum fraction liquids/vapors. In Technical Data Book-Petroleum Refining; American Petroleum Institute: Tulsa, OK, USA, 1988. [Google Scholar]

- McKetta, J.J., Jr. Encyclopedia of Chemical Processing and Design; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Fuller, E.N.; Schettler, P.D.; Giddings, J.C. New method for prediction of binary gas-phase diffusion coefficients. Ind. Eng. Chem. 1966, 58, 18–27. [Google Scholar] [CrossRef]

- Riazi, M.R.; Al-Sahhaf, T.A. Physical properties of heavy petroleum fractions and crude oils. Fluid Phase Equilibria 1996, 117, 217–224. [Google Scholar] [CrossRef]

| Cracking Reaction 1 | kors 2 | Eors (kJ kmol−1) | |

|---|---|---|---|

| GL | 0.045 m6 kg−1 kgcat−1 s−1 | 68,316 | 195 |

| LG | 0.011 m6 kg−1 kgcat−1 s−1 | 89,303 | 670 |

| CK | 0.00154 m6 kg−1 kgcat−1 s−1 | 64,639 | 745 |

| LG | 1.33 × 10−4 m3 kgcat−1 s−1 | 52,769 | 530 |

| CK | 3.67 × 10−4 m3 kgcat−1 s−1 | 115,566 | 690 |

| Cracking Reaction |

|---|

| Gas continuity Gas momentum Gas energy equation Solid continuity Solid or droplet momentum Solid energy equation Droplet phase continuity Droplet diameter reduction Droplet energy balance Species Continuity |

| Cracking Reaction |

|---|

| Drag coefficient Wall–fluid friction coefficients Pressure gradient Gas phase density Heat transfer coefficient Gas–droplet: Mass transfer coefficient |

| Parameter | Derouin, et al. [57] | Base Case |

|---|---|---|

| CTO 1 | 5.5 | 6 |

| GO feed rate (kg s−1) | 85 | 60 |

| Feed temperature (K) | 650 | 500 |

| Catalyst inlet temperature (K) | 900 | 960 |

| Riser diameter (m) | 1.0 | 1.1 |

| Riser height (m) | 35 | 35 |

| Droplet inlet diameter (m) | 350 | 500 |

| Steam rate (wt%) | 5 | 6.5 |

| Inlet pressure (kPa) | 315 | 250 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selalame, T.W.; Patel, R.; Mujtaba, I.M.; John, Y.M. The Effects of Vaporisation Models on the FCC Riser Reactor. Energies 2023, 16, 4831. https://doi.org/10.3390/en16124831

Selalame TW, Patel R, Mujtaba IM, John YM. The Effects of Vaporisation Models on the FCC Riser Reactor. Energies. 2023; 16(12):4831. https://doi.org/10.3390/en16124831

Chicago/Turabian StyleSelalame, Thabang W., Raj Patel, Iqbal Mohammed Mujtaba, and Yakubu Mandafiya John. 2023. "The Effects of Vaporisation Models on the FCC Riser Reactor" Energies 16, no. 12: 4831. https://doi.org/10.3390/en16124831

APA StyleSelalame, T. W., Patel, R., Mujtaba, I. M., & John, Y. M. (2023). The Effects of Vaporisation Models on the FCC Riser Reactor. Energies, 16(12), 4831. https://doi.org/10.3390/en16124831