Exergy Analysis and Off-Design Modeling of a Solar-Driven Supercritical CO2 Recompression Brayton Cycle

Abstract

1. Introduction

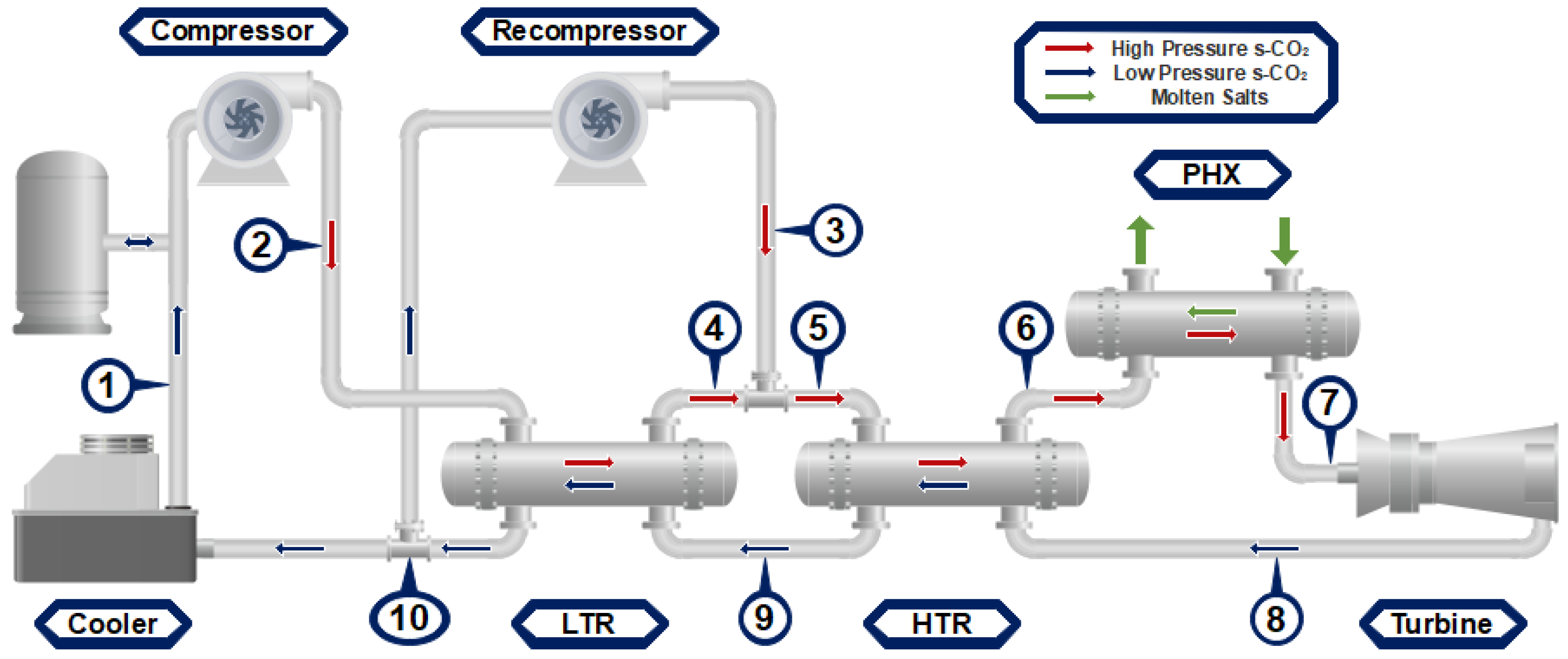

2. Methodology and Modeling

2.1. Cycle Design and Component Sizing

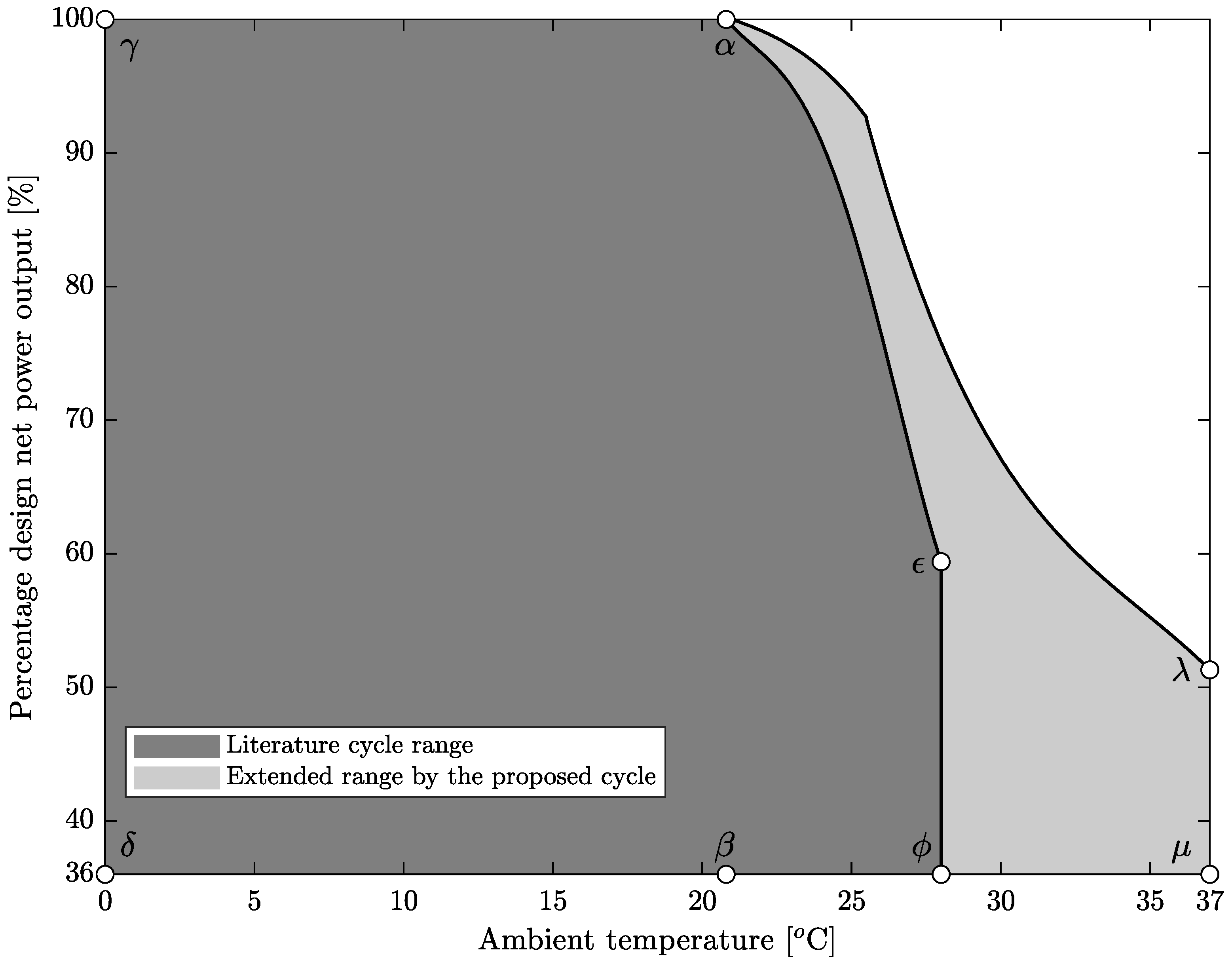

2.2. Literature vs. Proposed Cycle

- The cycle’s mass flow rate is equivalent to or lower than the design mass flow rate;

- The cycle’s high-end pressure is equivalent to or lower than the design high pressure;

- Pressure at any point in the cycle must be equivalent to or lower than the design cycle high pressure;

- Fixed TIT;

- Fixed recompression fraction.

2.3. Turbine

2.4. Compressors

2.5. Compressors Partial Utilization (M out of N Systems)

2.6. Low- and High-Temperature Recuperators

2.7. PHX and Cooler

2.8. Cooler

2.9. PHX

2.10. Exergy Accounting

2.11. Meteorological Conditions

2.12. Dispatch Matrix and Annual Simulation

2.13. Seasonal Efficiencies

3. Results and Discussion

3.1. SNL Test Loop Benchmarking

3.2. Cycle Design

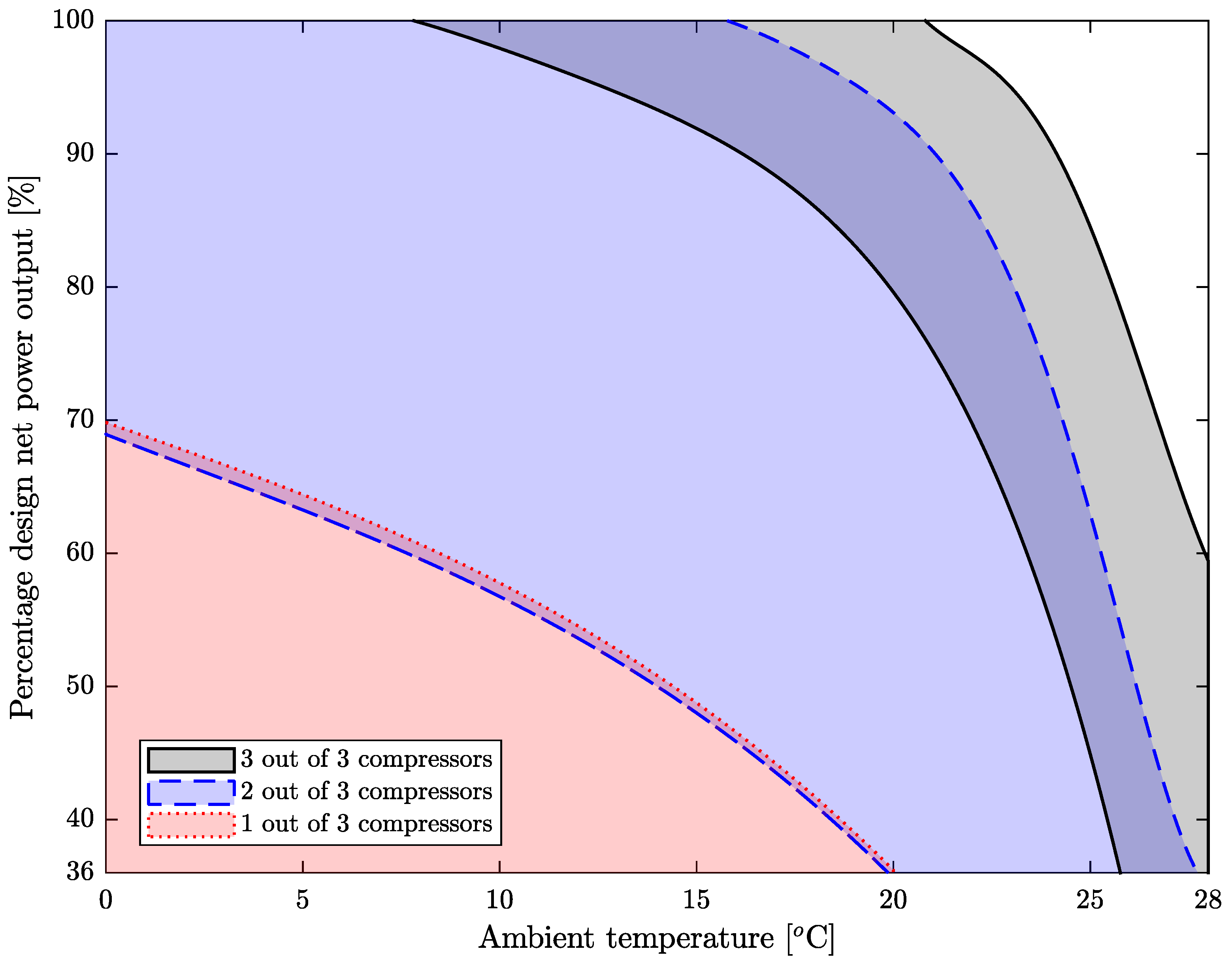

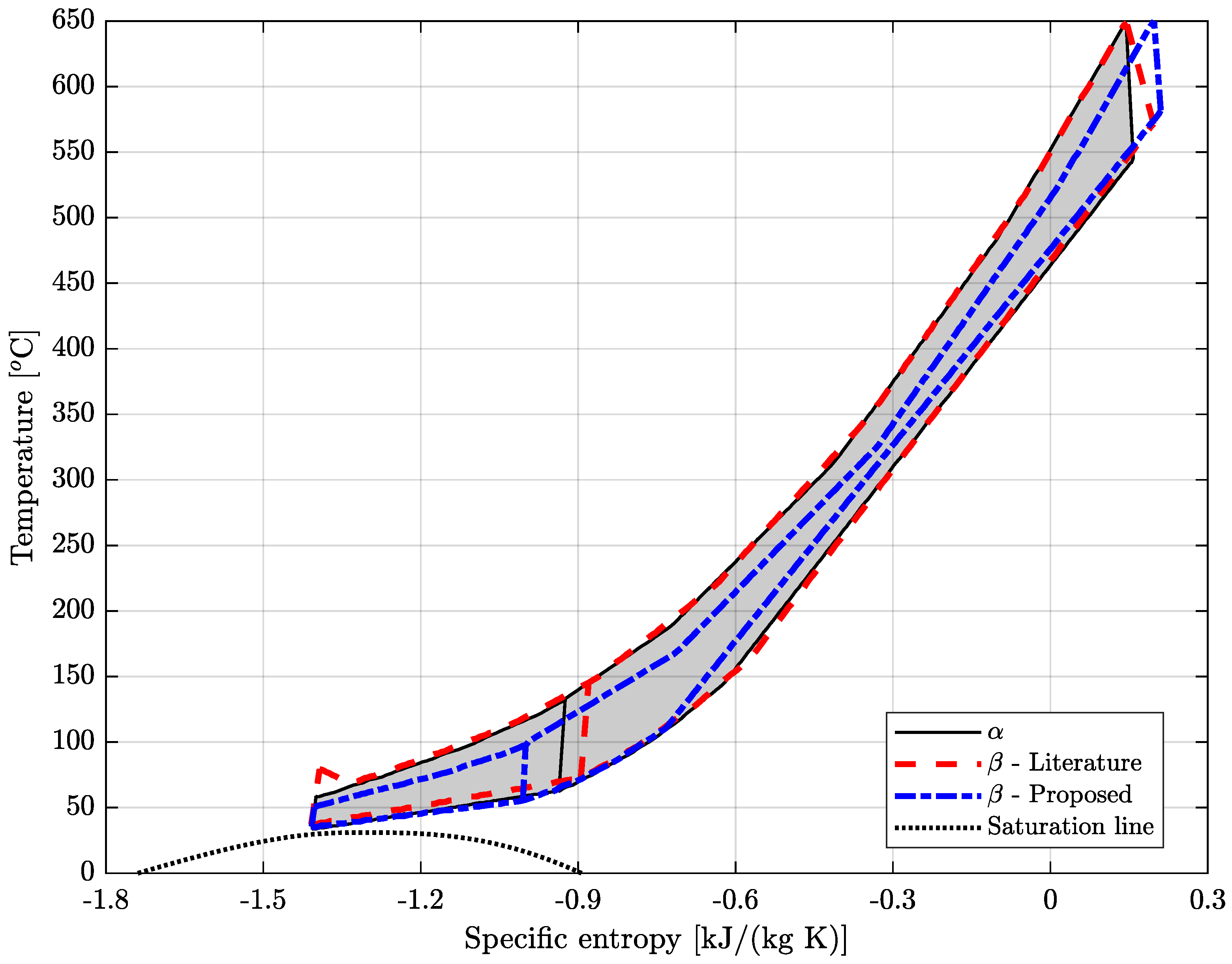

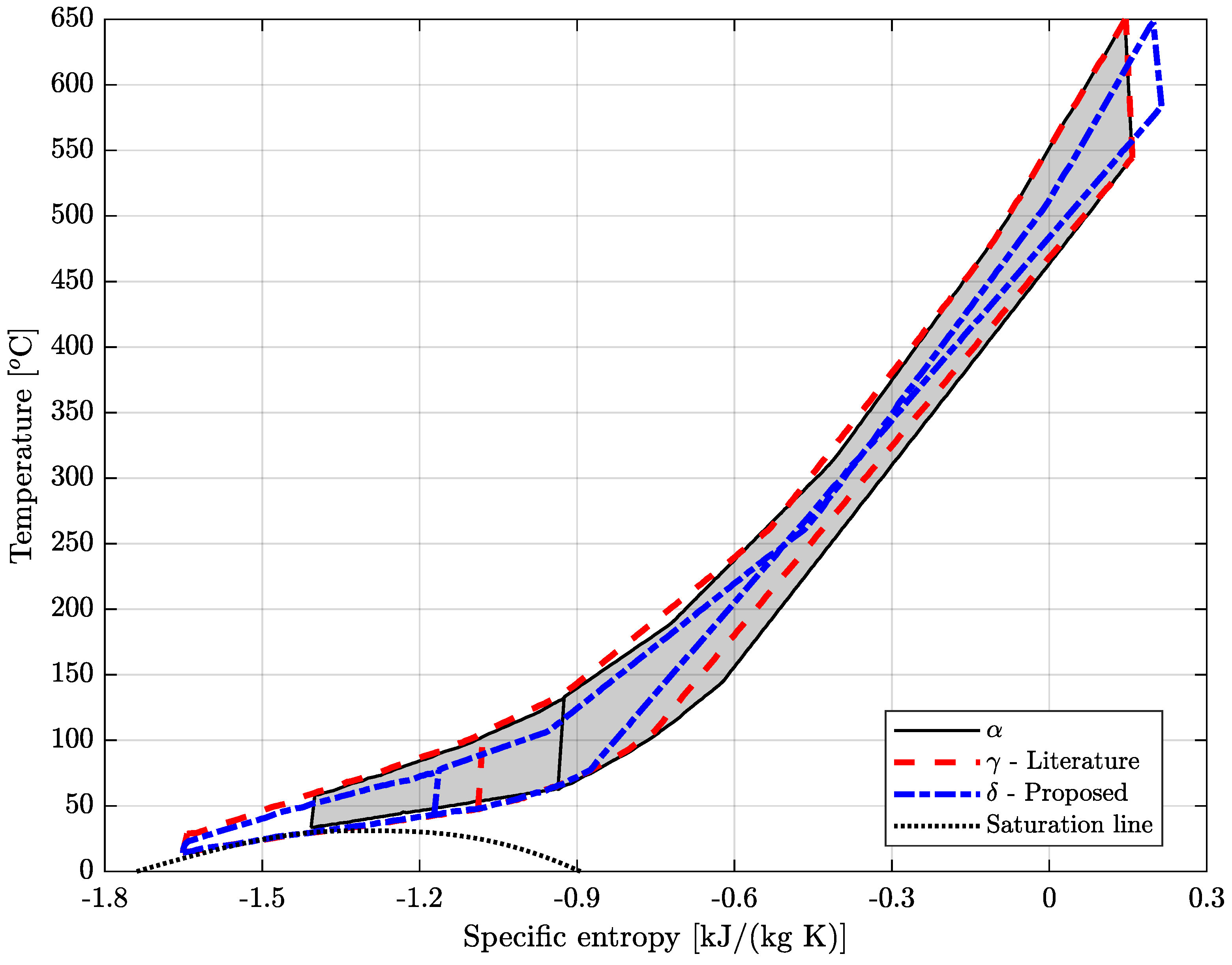

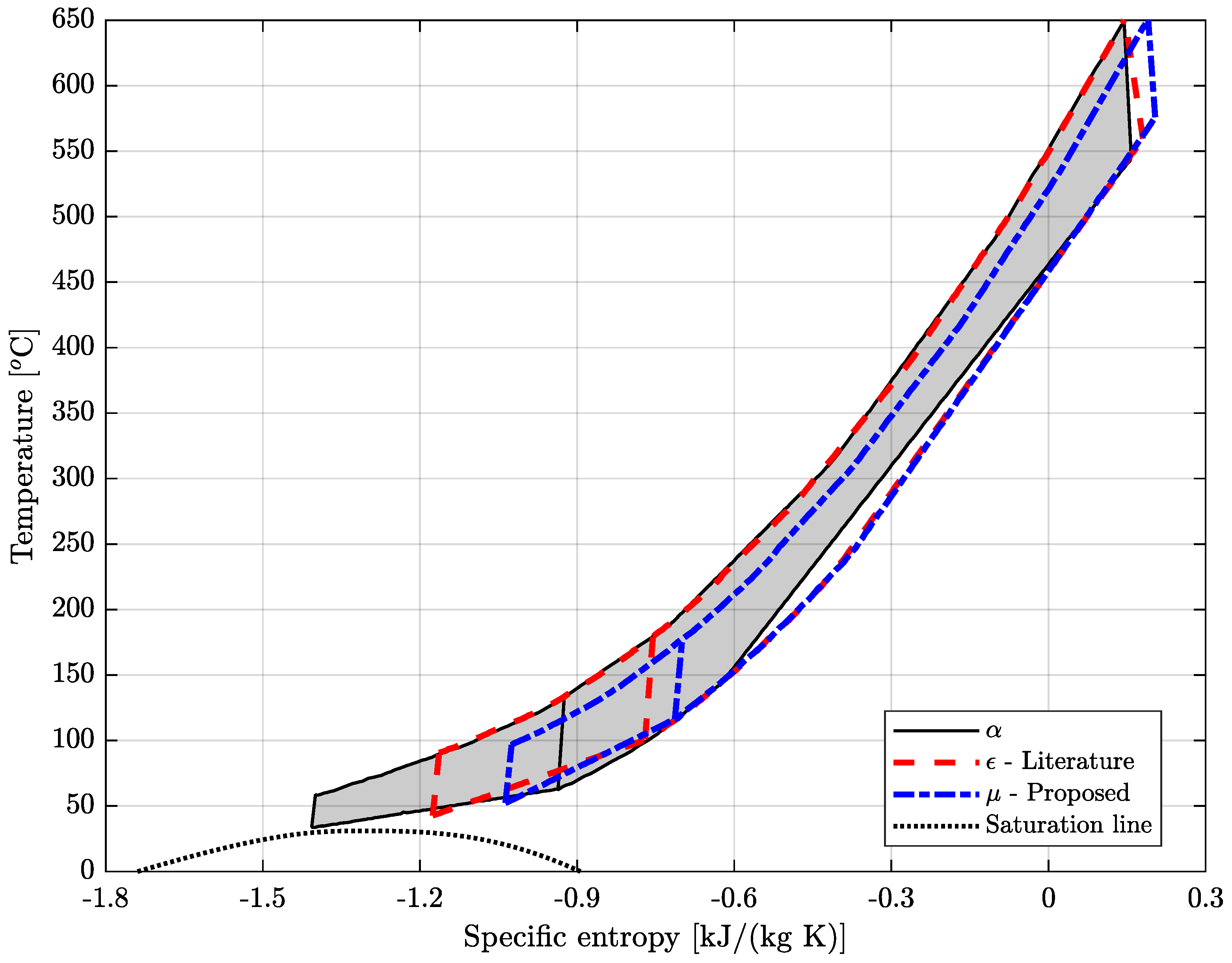

3.3. Literature Cycle

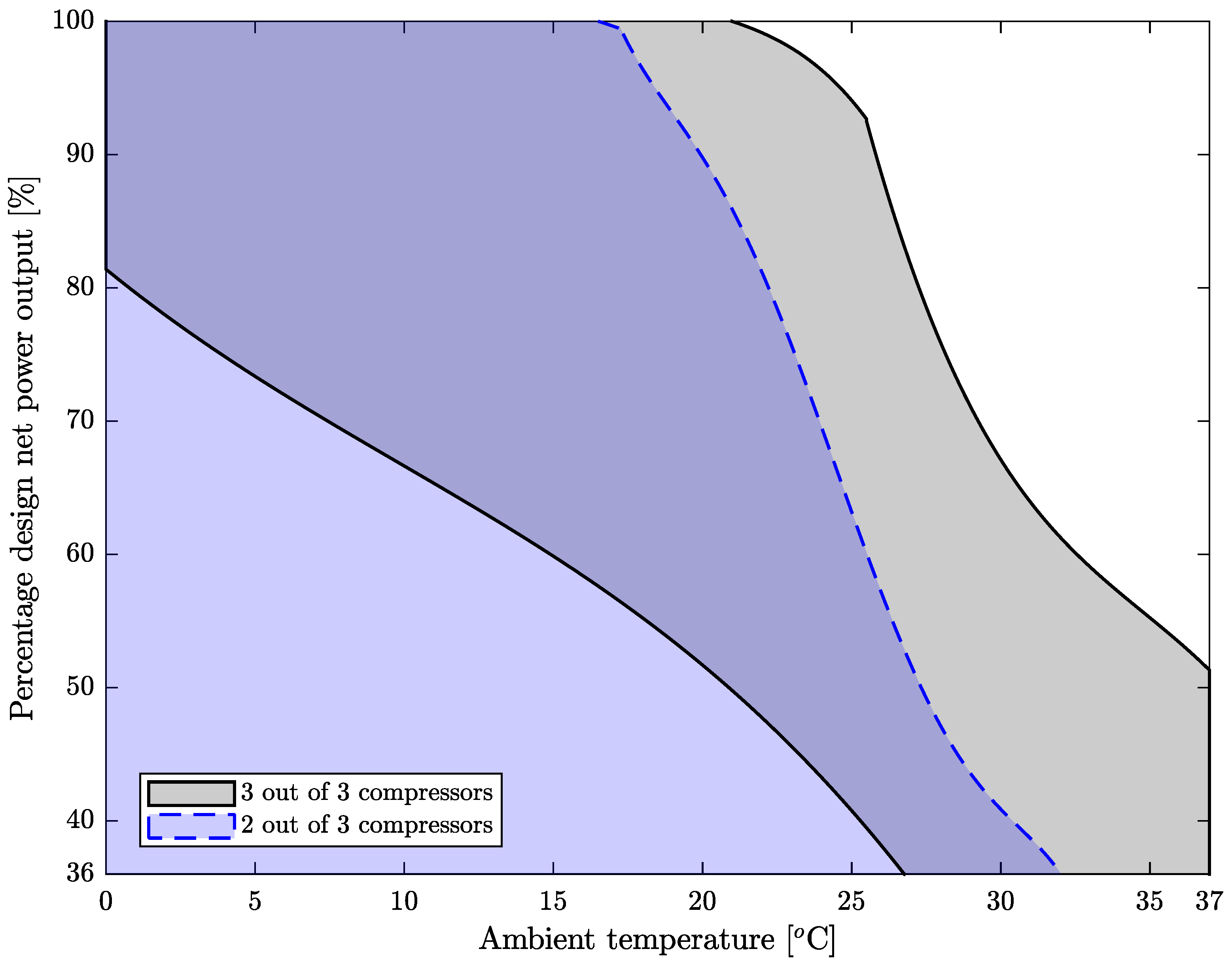

3.4. Proposed Cycle

3.5. Influence of the Ambient Temperature and Net Power Output on the Cycle’s Performance

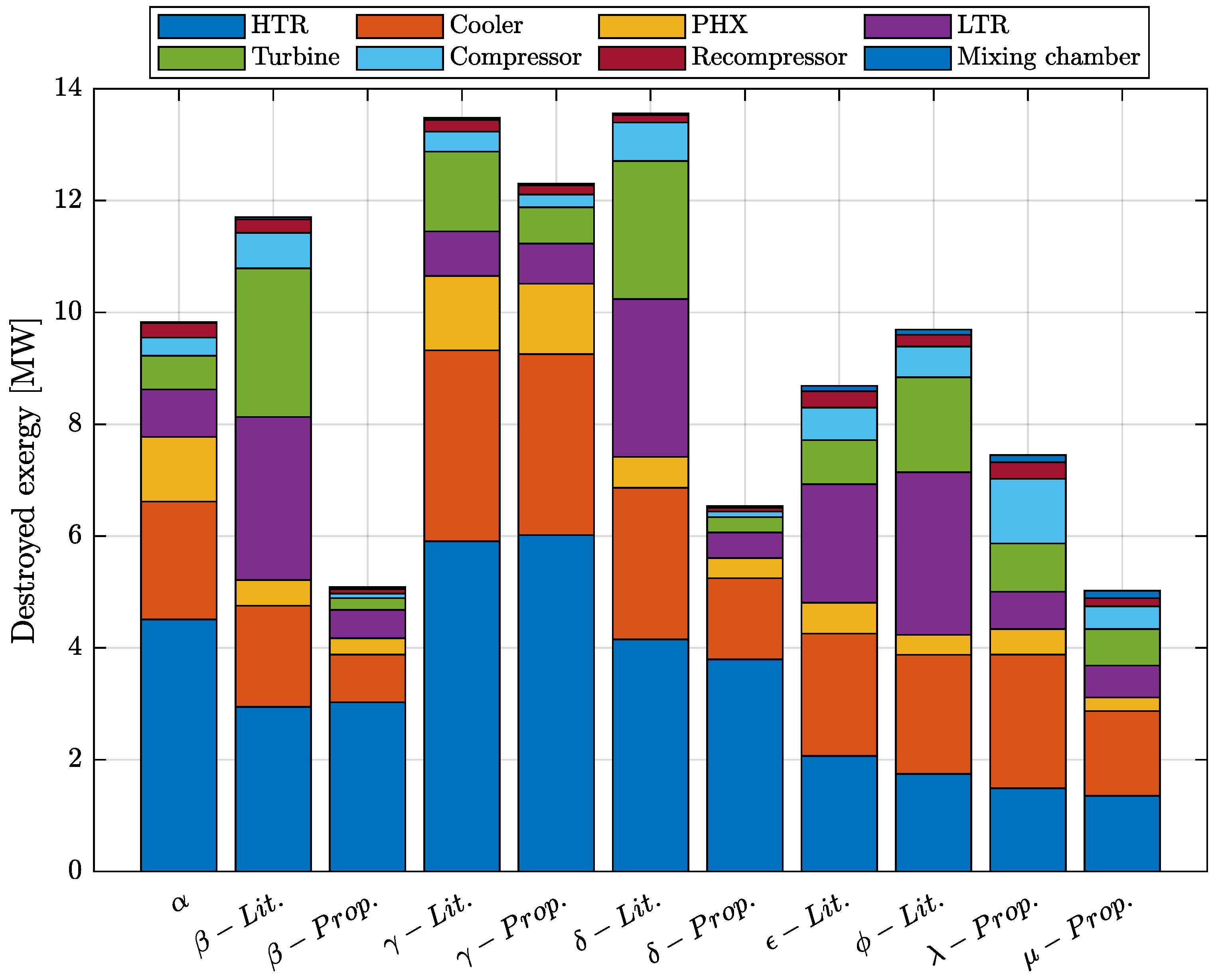

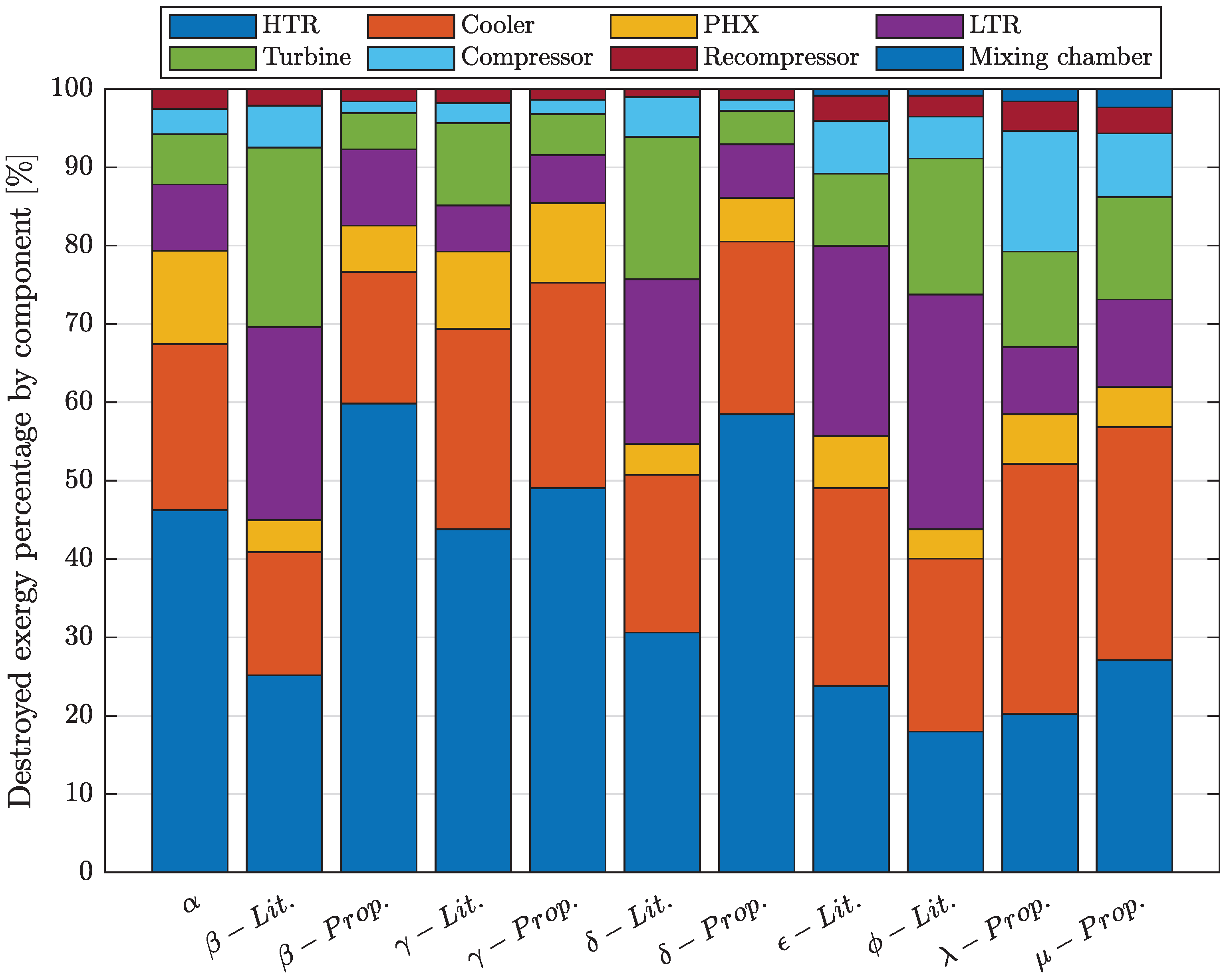

3.6. Exergy Destruction

3.7. Yearly Simulation

4. Conclusions

- Arguably due to the experimental nature of the SNL test loop, Petukhov’s and other correlations proposed in the literature underestimate the pressure drop. Moreover, the model accurately describes the power cycle under nominal conditions when adjusted for the pressure drop. Additionally, Gnielinksi’s correlation accurately describes the heat transfer problem in the s-CO2 RcBC working at a low pressure of 90 bar;

- The s-CO2 RcBC with a two-shaft configuration cannot achieve the required flexibility when considering the off-design operation of the literature cycle subjected to the Crucero meteorological data and the dispatch curves. The operational range of the literature is highly limited, especially because of the effect of the shaft blockage phenomenon. Thus, the M out of N system dramatically extended the operational range of both the literature and proposed cycles by delaying the onset of the surge in the compressors. Extending the cycles’ operational ranges to higher ambient temperatures while generating the design net power output still requires further work;

- The 20-point decrease between nominal and seasonal first-law efficiencies reflects the literature cycle’s performance shortcomings. The proposed cycle’s three-shaft system is flexible, which can be appreciated through the greater operational range and seasonal first-law efficiency. The latter is 10 points greater for the proposed cycle than the literature. The synergistic effects of decreasing the cycle’s high-end pressure alongside its mass flow rates as a turndown strategy are demonstrated and quantified. Similar to the literature cycle, the surge and supersonic flow phenomena also limit the proposed cycle’s operational range;

- The exergy analysis finds the HTR component to be the greatest source of irreversibility under design conditions. This evidences improper HTR and LTR sizing.

- The description of the cooler and PHX at off-design conditions;

- The techno-economic feasibility of an M out of N system for the s-CO2 RcBC;

- The design and optimization of an s-CO2 RcBC with dispatch curves designed primarily to complement solar photovoltaic.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- REN21. Renewable Energy Data in Perspective; Technical Report; REN21: Paris, France, 2022. [Google Scholar]

- IRENA. Innovation Outlook Thermal Energy Storage; Technical Report; International Renewable Energy Agency: Masdar City, United Arab Emirates, 2020. [Google Scholar]

- Bergh, K.V.D.; Delarue, E. Cycling of conventional power plants: Technical limits and actual costs. Energy Convers. Manag. 2015, 97, 70–77. [Google Scholar] [CrossRef]

- Arias, I.; Cardemil, J.; Zarza, E.; Valenzuela, L.; Escobar, R. Latest developments, assessments and research trends for next generation of concentrated solar power plants using liquid heat transfer fluids. Renew. Sustain. Energy Rev. 2022, 168, 112844. [Google Scholar] [CrossRef]

- Angelino, G. Carbon Dioxide Condensation Cycles For Power Production. J. Eng. Power 1968, 90, 287–295. [Google Scholar] [CrossRef]

- Cabeza, L.F.; de Gracia, A.; Fernández, A.I.; Farid, M.M. Supercritical CO2 as heat transfer fluid: A review. Appl. Therm. Eng. 2017, 125, 799–810. [Google Scholar] [CrossRef]

- Dostal, V.; Driscoll, M.J.; Hejzlar, P. A Supercritical Carbon Dioxide Cycle for Next Generation Nuclear Reactors; MIT-ANP-TR-100; MIT Press: Cambridge, MA, USA, 2004. [Google Scholar]

- Wu, P.; Ma, Y.; Gao, C.; Liu, W.; Shan, J.; Huang, Y.; Wang, J.; Zhang, D.; Ran, X. A review of research and development of supercritical carbon dioxide Brayton cycle technology in nuclear engineering applications. Nucl. Eng. Des. 2020, 368, 110767. [Google Scholar] [CrossRef]

- Sarmiento, C.; Cardemil, J.M.; Díaz, A.J.; Barraza, R. Parametrized analysis of a carbon dioxide transcritical Rankine cycle driven by solar energy. Appl. Therm. Eng. 2018, 140, 580–592. [Google Scholar] [CrossRef]

- de Araujo Passos, L.; de Abreu, S.; da Silva, A. A short-and long-term demand based analysis of a CO2 concentrated solar power system with backup heating. Appl. Therm. Eng. 2019, 160, 114003. [Google Scholar] [CrossRef]

- Sakalis, G. Investigation of supercritical CO2 cycles potential for marine Diesel engine waste heat recovery applications. Appl. Therm. Eng. 2021, 195, 117201. [Google Scholar] [CrossRef]

- Duvenhage, D.F.; Brent, A.C.; Stafford, W.H. The need to strategically manage CSP fleet development and water resources: A structured review and way forward. Renew. Energy 2019, 132, 813–825. [Google Scholar] [CrossRef]

- Atif, M.; Al-Sulaiman, F.A. Energy and exergy analyses of solar tower power plant driven supercritical carbon dioxide recompression cycles for six different locations. Renew. Sustain. Energy Rev. 2017, 68, 153–167. [Google Scholar] [CrossRef]

- Biencinto, M.; González, L.; Valenzuela, L.; Zarza, E. A new concept of solar thermal power plants with large-aperture parabolic-trough collectors and sCO2 as working fluid. Energy Convers. Manag. 2019, 199, 112030. [Google Scholar] [CrossRef]

- Battisti, F.; de Araujo Passos, L.; da Silva, A. Performance mapping of packed-bed thermal energy storage systems for concentrating solar-powered plants using supercritical carbon dioxide. Appl. Therm. Eng. 2021, 183, 116032. [Google Scholar] [CrossRef]

- Battisti, F.; de Araujo Passos, L.; da Silva, A. Economic and environmental assessment of a CO2 solar-powered plant with packed-bed thermal energy storage. Appl. Energy 2022, 314, 118913. [Google Scholar] [CrossRef]

- Clementoni, E.M.; Held, T.; Pasch, J.; Moore, J. Test Facilities; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 393–414. [Google Scholar] [CrossRef]

- Dyreby, J. Modeling the Supercritical Carbon Dioxide Brayton Cycle with Recompression. Master’s Thesis, University of Wisconsin–Madison, Madison, WI, USA, 2014. [Google Scholar]

- Fuller, R.; Eisemann, K. Supercritical CO2 Power Cycle Symposium Centrifugal Compressor Off-Design Performance for Super-Critical CO2. In Presentation, Supercritical CO2 Power Cycle Symposium; Barber Nichols, Inc.: Arvada, CO, USA, 2011. [Google Scholar]

- Pasch, J.J.; Conboy, T.M.; Fleming, D.D.; Rochau, G.E. Supercritical CO2 Recompression Brayton Cycle: Completed Assembly Description; Technical Report October; Sandia National Laboratories: Albuquerque, NM, USA, 2012. [Google Scholar] [CrossRef]

- Jahn, I.; Keep, J. On the off-design performance of supercritical carbon dioxide power cycles. In Proceedings of the Shanghai 2017 Global Power and Propulsion Forum, Shanghai, China, 10–12 July 2017; Global Power and Propulsion Society: Zug, Switzerland, 2017; pp. 1–10. [Google Scholar]

- Correa, F.; Barraza, R.; Too, Y.C.S.; Padilla, R.V.; Cardemil, J.M. Optimized operation of recompression sCO2 Brayton cycle based on adjustable recompression fraction under variable conditions. Energy 2021, 227, 120334. [Google Scholar] [CrossRef]

- Delsoto, G.; Battisti, F.; da Silva, A. Dynamic modeling and control of a solar-powered Brayton cycle using supercritical CO2 and optimization of its thermal energy storage. Renew. Energy 2023, 206, 336–356. [Google Scholar] [CrossRef]

- Liu, M.; Tay, N.S.; Bell, S.; Belusko, M.; Jacob, R.; Will, G.; Saman, W.; Bruno, F. Review on concentrating solar power plants and new developments in high temperature thermal energy storage technologies. Renew. Sustain. Energy Rev. 2016, 53, 1411–1432. [Google Scholar] [CrossRef]

- de Araujo Passos, L.; de Abreu, S.; da Silva, A. Time-dependent behavior of a recompression cycle with direct CO2 heating through a parabolic collector array. Appl. Therm. Eng. 2018, 140, 593–603. [Google Scholar] [CrossRef]

- Glassman, A. Miscellaneous Losses. In Turbine Design and Application; NASA: Washington, DC, USA, 1972; p. 390. [Google Scholar]

- Stodola. Modelling of off-design multistage turbine pressures by stodola’s ellipse. In Proceedings of the Energy Incorporated PEPSE User’s Group Meeting, Richmond, VA, USA, 2–3 November 1983. [Google Scholar]

- Bravo, C. Optimización de Parámetros de Diseño de una Planta Solar de Concentración para Generación Eléctrica Considerando Distintos Escenarios de Despacho. Master’s Thesis, University of Wisconsin–Madison, Madison, WI, USA, 2018. [Google Scholar]

- Petukhov, B.S. Heat Transfer and Friction in Turbulent Pipe Flow with Variable Physical Properties. Adv. Heat Transf. 1970, 6, 503–564. [Google Scholar] [CrossRef]

- Blasius, H. Das Aehnlichkeitsgesetz bei Reibungsvorgängen in Flüssigkeiten. In Mitteilungen über Forschungsarbeiten auf dem Gebiete des Ingenieurwesens; Springer: Berlin/Heidelberg, Germany, 1913; pp. 1–41. [Google Scholar] [CrossRef]

- Jiang, Y.; Liese, E.; Zitney, S.E.; Bhattacharyya, D. Design and dynamic modeling of printed circuit heat exchangers for supercritical carbon dioxide Brayton power cycles. Appl. Energy 2018, 231, 1019–1032. [Google Scholar] [CrossRef]

- Mylavarapu, S.K.; Sun, X.; Christensen, R.N.; Unocic, R.R.; Glosup, R.E.; Patterson, M.W. Fabrication and design aspects of high-temperature compact diffusion bonded heat exchangers. Nucl. Eng. Des. 2012, 249, 49–56. [Google Scholar] [CrossRef]

| Configuration | Literature | Proposed | ||

|---|---|---|---|---|

| Comp. | Recomp. | Comp. | Recomp. | |

| I | 3 | 3 | 3 | 3 |

| II | 2 | 3 | 2 | 2 |

| III | 1 | 2 | - | - |

| Scaled f | ||||||

|---|---|---|---|---|---|---|

| Variable | SNL | EES | Error [%] | SNL | EES | Error [%] |

| [kW] | 455 | 498.4 | 9.538 | 455 | 497 | 9.231 |

| [kW] | 662 | 738.4 | 11.541 | 662 | 699 | 5.589 |

| [kW] | 515 | 542.7 | 5.379 | 515 | 529.5 | 2.816 |

| [kW] | 2202 | 2100 | 4.632 | 2202 | 2154 | 2.180 |

| [kW] | 47.8 | 50.45 | 5.544 | 47.8 | 50.45 | 5.544 |

| [kW] | 85.1 | 79.59 | 6.475 | 85.1 | 79.65 | 6.404 |

| [kW] | 331.1 | 370 | 11.749 | 331.1 | 332.1 | 0.302 |

| [kW] | 198.2 | 240 | 21.090 | 198.2 | 202 | 1.917 |

| [bar] | 64.22 | 63.58 | 0.997 | 64.22 | 63.58 | 0.997 |

| [bar] | 62.89 | 61.96 | 1.479 | 62.89 | 62.18 | 1.129 |

| [bar] | 52.95 | 58.18 | 9.877 | 52.95 | 52.96 | 0.019 |

| [bar] | 0.79 | 0.08972 | 88.643 | 0.79 | 0.79 | 0.000 |

| [bar] | 3.03 | 0.5643 | 81.376 | 3.03 | 3.03 | 0.000 |

| [bar] | 0.86 | 0.2516 | 70.744 | 0.86 | 0.86 | 0.000 |

| [bar] | 0.88 | 0.6989 | 20.580 | 0.88 | 0.88 | 0.000 |

| [-] | 1.84 | 1.827 | 0.707 | 1.84 | 1.827 | 0.707 |

| [-] | 1.81 | 1.796 | 0.773 | 1.81 | 1.799 | 0.608 |

| [-] | 1.64 | 1.736 | 6.144 | 1.64 | 1.636 | 0.030 |

| [%] | 67.3 | 66.36 | 1.397 | 67.3 | 66.36 | 1.397 |

| [%] | 70.2 | 69.78 | 0.598 | 70.2 | 69.77 | 0.613 |

| [%] | 84.7 | 84.77 | 0.083 | 84.7 | 84.81 | 0.130 |

| [%] | 29.9 | 32.5 | 8.552 | 29.9 | 28.9 | 3.472 |

| State | P [bar] | T [°C] | h [kJ/kg] | s [kJ/(kg K)] |

|---|---|---|---|---|

| 1 | 90.000 | 35.80 | −202.928 | −1.407 |

| 2 | 200.277 | 58.89 | −185.118 | −1.401 |

| 3 | 200.254 | 134.25 | −10.676 | −0.9248 |

| 4 | 200.227 | 129.94 | −18.509 | −0.9441 |

| 5 | 200.227 | 131.22 | −16.156 | −0.9383 |

| 6 | 200.100 | 486.59 | 449.974 | −0.09712 |

| 7 | 200.020 | 650.00 | 653.311 | 0.1453 |

| 8 | 90.789 | 544.29 | 530.044 | 0.1565 |

| 9 | 90.352 | 145.01 | 63.910 | −0.6244 |

| 10 | 90.100 | 65.15 | −52.716 | −0.9362 |

| Variable | Unit | Magnitude |

|---|---|---|

| D | [m] | 0.2245 |

| D | [m] | 0.2027 |

| D | [m] | 0.4637 |

| N | [rev/min] | 15,760 |

| N | [rev/min] | 26,817 |

| N | [rev/min] | 15,760 |

| A | [m] | 3393 |

| A | [m] | 2962 |

| N | [-] | 550,000 |

| N | [-] | 600,000 |

| L | [m] | 1.5 |

| L | [m] | 1.2 |

| a | [mm] | 0.8 |

| b | [mm] | 0.8 |

| a | [mm] | 0.8 |

| b | [mm] | 0.8 |

| D | [mm] | 0.9776 |

| D | [mm] | 0.9776 |

| Variable | Unit | Magnitude |

|---|---|---|

| [-] | 0.89 | |

| [-] | 0.89 | |

| [-] | 0.93 | |

| [bar] | 110.3 | |

| [bar] | 110.2 | |

| [bar] | 109.2 | |

| [bar] | 0.05013 | |

| [bar] | 0.2523 | |

| [bar] | 0.1265 | |

| [bar] | 0.4366 | |

| [bar] | 0.1 | |

| [bar] | 0.08 | |

| P | [bar] | 200 |

| P | [bar] | 90 |

| T | [°C] | 650 |

| T | [°C] | 35.8 |

| [MW] | 29.740 | |

| [MW] | 118.864 | |

| [MW] | 51.851 | |

| [MW] | 26.813 | |

| [MW] | 3.179 | |

| [MW] | 3.216 | |

| [MW] | 31.433 | |

| [-] | 0.3 | |

| [kg/s] | 255 | |

| [kg/s] | 224.6 | |

| [MW] | 25 | |

| [-] | 0.483 |

| Metric | Literature | Proposed |

|---|---|---|

| Availability [%] | 76.45 | 93.45 |

| [%] | 29 | 39 |

| [%] | 48 | 65 |

| Time 3 out of 3 [%] | 0.76 | 36.24 |

| Time 2 out of 3 [%] | 49.93 | 57.20 |

| Time 1 out of 3 [%] | 25.75 | 0.00 |

| Time unavailable [%] | 23.55 | 6.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Battisti, F.G.; Klein, C.F.; Escobar, R.A.; Cardemil, J.M. Exergy Analysis and Off-Design Modeling of a Solar-Driven Supercritical CO2 Recompression Brayton Cycle. Energies 2023, 16, 4755. https://doi.org/10.3390/en16124755

Battisti FG, Klein CF, Escobar RA, Cardemil JM. Exergy Analysis and Off-Design Modeling of a Solar-Driven Supercritical CO2 Recompression Brayton Cycle. Energies. 2023; 16(12):4755. https://doi.org/10.3390/en16124755

Chicago/Turabian StyleBattisti, Felipe G., Carlos F. Klein, Rodrigo A. Escobar, and José M. Cardemil. 2023. "Exergy Analysis and Off-Design Modeling of a Solar-Driven Supercritical CO2 Recompression Brayton Cycle" Energies 16, no. 12: 4755. https://doi.org/10.3390/en16124755

APA StyleBattisti, F. G., Klein, C. F., Escobar, R. A., & Cardemil, J. M. (2023). Exergy Analysis and Off-Design Modeling of a Solar-Driven Supercritical CO2 Recompression Brayton Cycle. Energies, 16(12), 4755. https://doi.org/10.3390/en16124755