Modelling and Analysis of Inter-Turn Short-Circuit Faults for Large-Power SPM Wind Generators

Abstract

1. Introduction

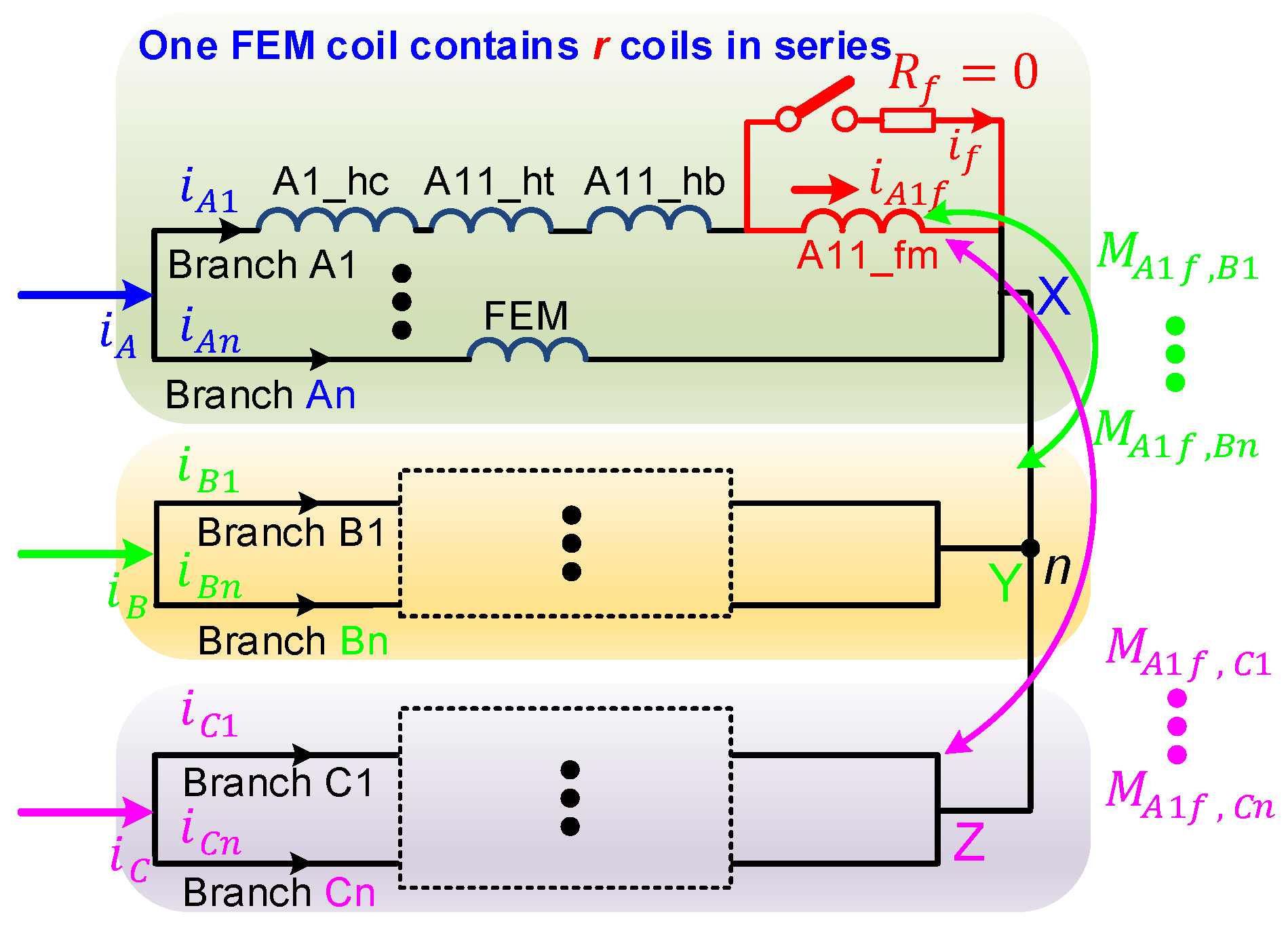

2. Analytical Modelling of ITSC Faults of SPM Wind Generators

- (1)

- All branch-to-neutral voltages such as to of the same phase are equal and the branch back-EMFs of the same phase such as to are equal.

- (2)

- All branch inductance matrices are circulant matrices (see Appendix A).

- (3)

- The sum of three phase currents is zero.

3. Inductance Calculation

3.1. Analytical Approach

3.2. FEM Modelling

3.3. Some Results of Inductance Calculations

4. Model Simplification Using Multiphase Clarke Transformation

5. Simulation Results

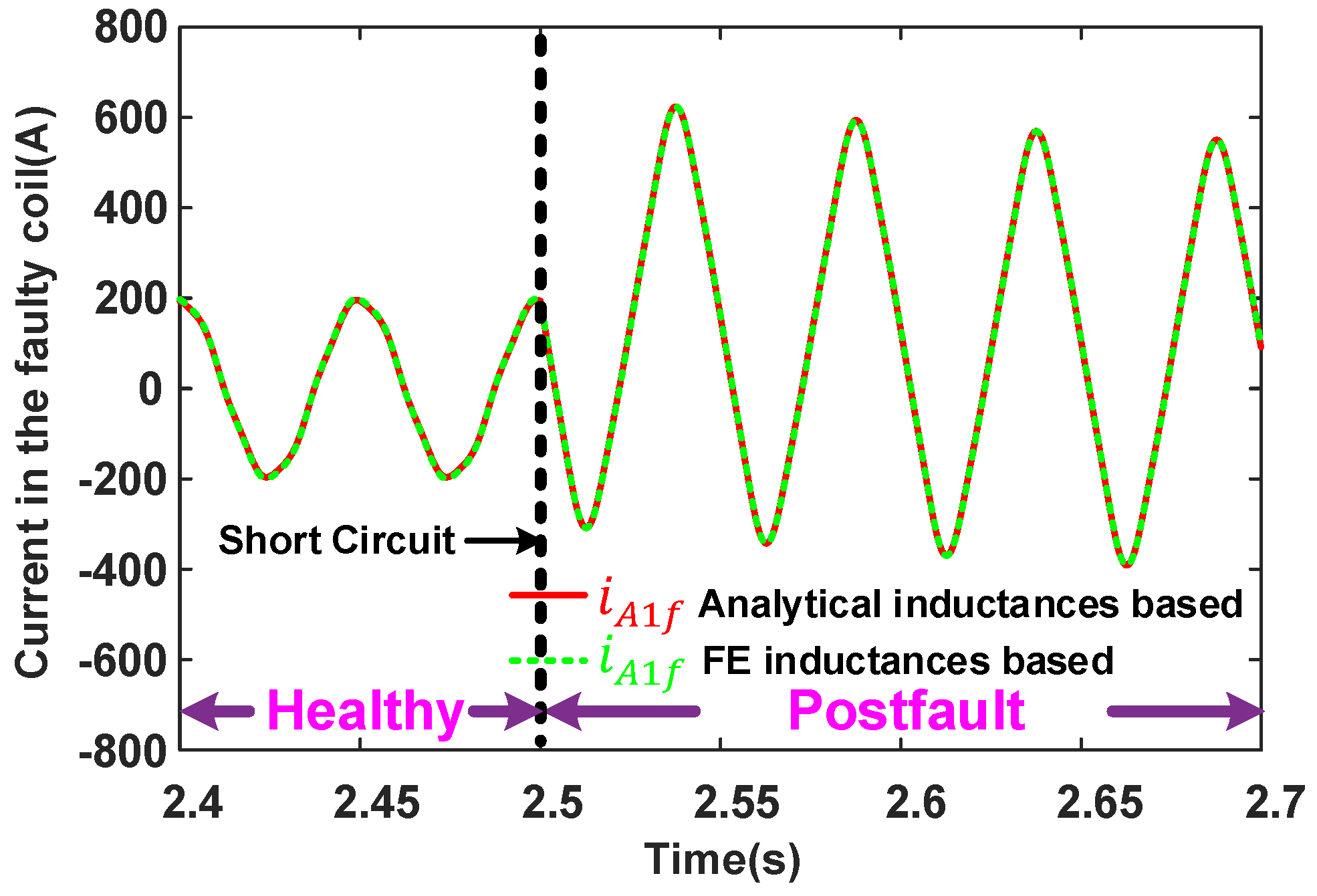

5.1. Fault Simulations with Linear Inductances

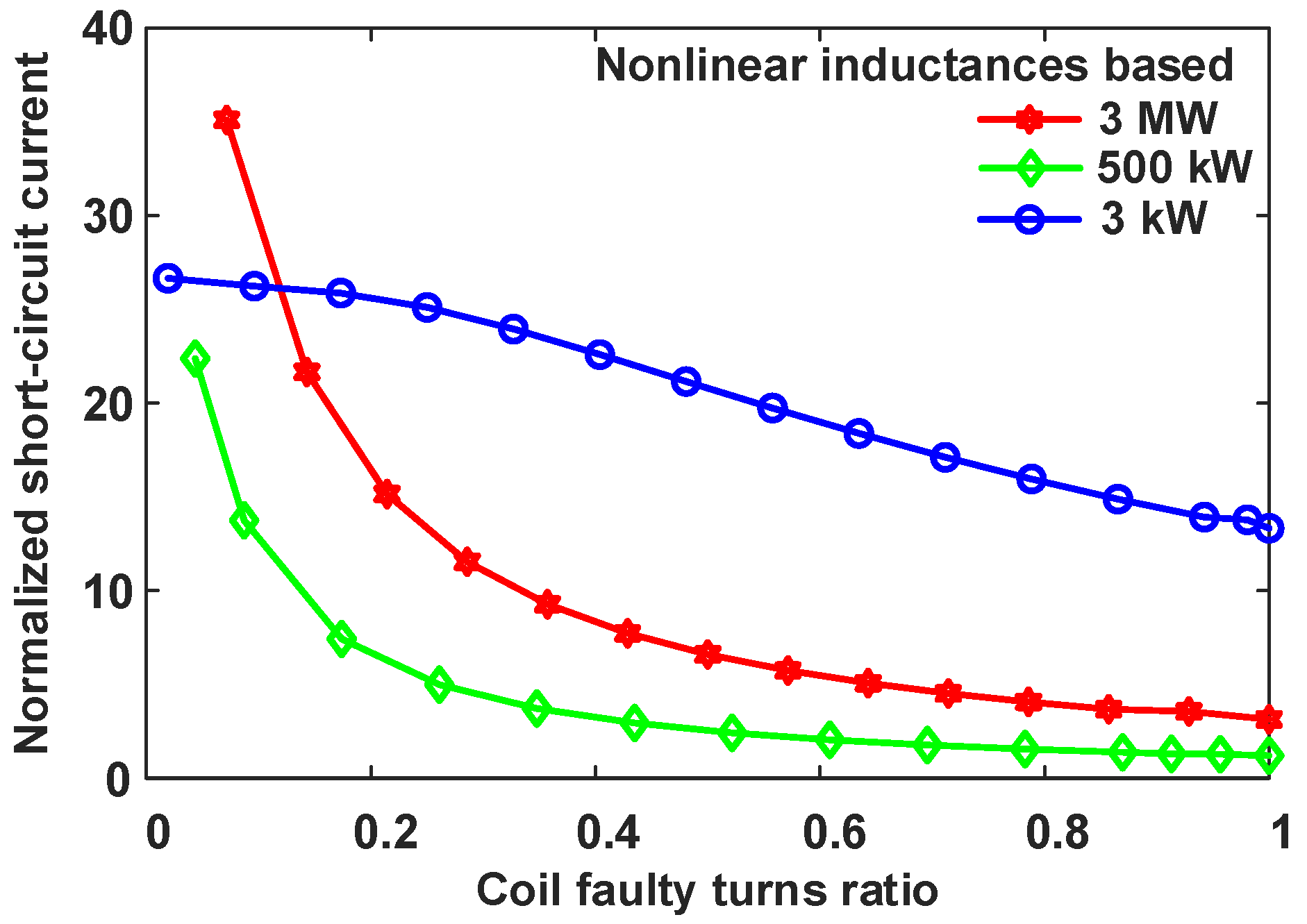

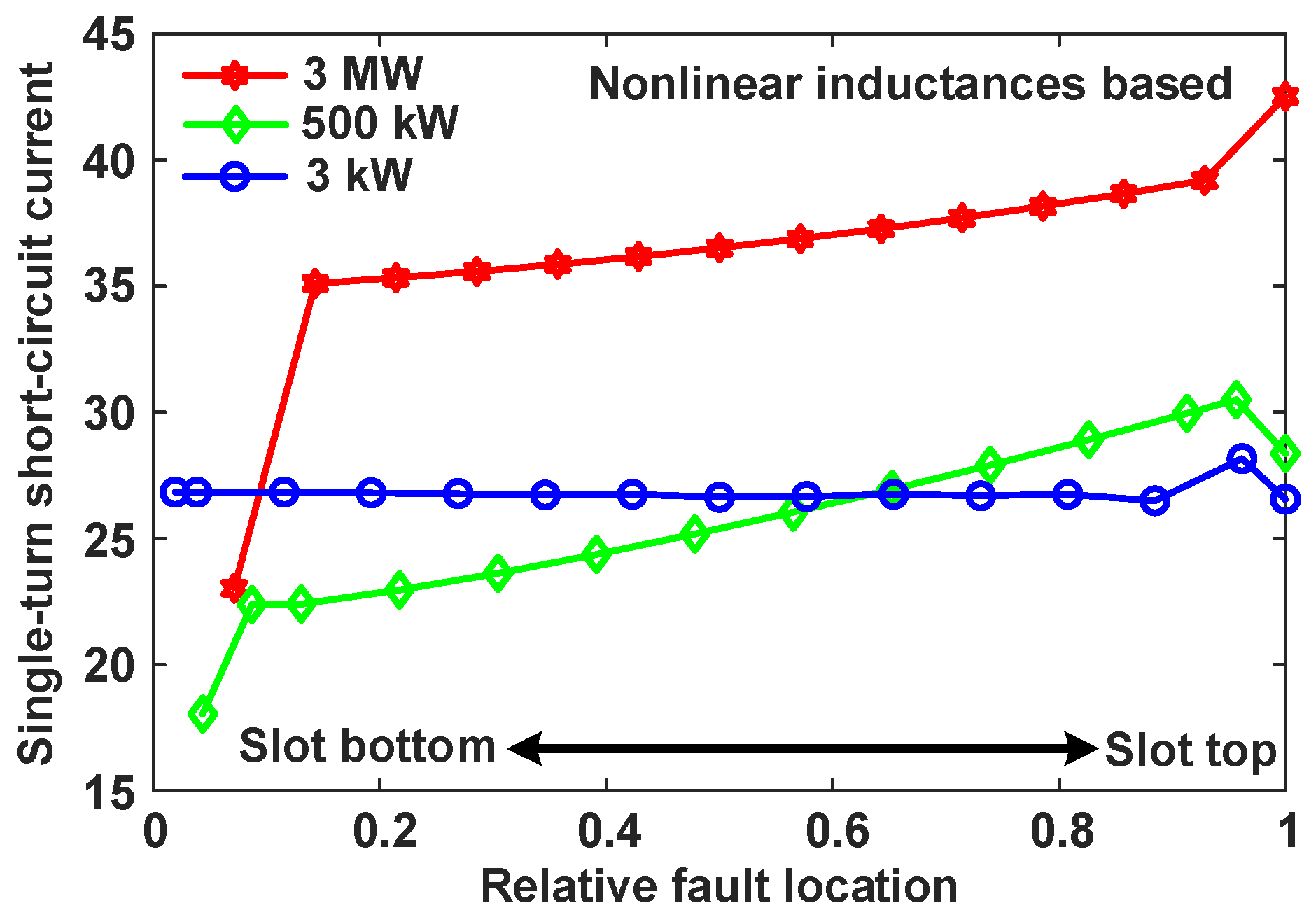

5.2. Fault Simulations with Nonlinear Inductances

5.2.1. Scaling Effect

5.2.2. Influence of Fault Location

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

References

- Yaramasu, V.; Wu, B.; Sen, P.C.; Kouro, S.; Narimani, M. High-power wind energy conversion systems: State-of-the-art and emerging technologies. Proc. IEEE 2015, 103, 740–788. [Google Scholar] [CrossRef]

- Freire, N.M.A.; Cardoso, A.J.M. Fault detection and condition monitoring of PMSGs in offshore wind turbines. Machines 2021, 9, 260. [Google Scholar] [CrossRef]

- Badihi, H.; Zhang, Y.; Jiang, B.; Pillay, P.; Rakheja, S. A comprehensive review on signal-based and model-based condition monitoring of wind turbines: Fault diagnosis and lifetime prognosis. Proc. IEEE 2022, 110, 754–806. [Google Scholar] [CrossRef]

- Blaabjerg, F.; Liserre, M.; Ma, K. Power electronics converters for wind turbine systems. IEEE Trans. Ind. Appl. 2012, 48, 708–719. [Google Scholar] [CrossRef]

- Yaramasu, V.; Wu, B. Model Predictive Control of Wind Energy Conversion Systems; IEEE Press Series on Power Engineering; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Palangar, M.F.; Soong, W.L.; Bianchi, N.; Wang, R.-J. Design and optimization techniques in performance improvement of line-start permanent magnet synchronous motors: A review. IEEE Trans. Magn. 2021, 57, 900214. [Google Scholar] [CrossRef]

- Faramarzi Palangar, M.; Mahmoudi, A.; Kahourzade, S.; Soong, W.L. Simultaneous efficiency and starting torque optimization of a line-start permanent-magnet synchronous motor using two different optimization approaches. Arab. J. Sci. Eng. 2021, 46, 9953–9964. [Google Scholar] [CrossRef]

- Alewine, K.; Chen, W. A review of electrical winding failures in wind turbine generators. IEEE Electr. Insul. Mag. 2012, 28, 8–13. [Google Scholar] [CrossRef]

- Bonnett, A.H.; Soukup, G.C. Cause and analysis of stator and rotor failures in three-phase squirrel-cage induction motors. IEEE Trans. Ind. Appl. 1992, 28, 921–937. [Google Scholar] [CrossRef]

- Toliyat, H.A.; Lipo, T.A. Transient analysis of cage induction machines under stator, rotor bar and end ring faults. IEEE Trans. Energy Convers. 1995, 10, 241–247. [Google Scholar] [CrossRef]

- Reichmeider, P.P.; Gross, C.A.; Querrey, D.; Novosel, D.; Salon, S. Internal faults in synchronous machines. I. the machine model. IEEE Trans. Energy Convers. 2000, 15, 376–379. [Google Scholar] [CrossRef]

- Gandhi, A.; Corrigan, T.; Parsa, L. Recent advances in modeling and online detection of stator interturn faults in electrical motors. IEEE Trans. Ind. Electron. 2011, 58, 1564–1575. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Capolino, G. Advances in electrical machine, power electronic, and drive condition monitoring and fault detection: State of the art. IEEE Trans. Ind. Electron. 2015, 62, 1746–1759. [Google Scholar] [CrossRef]

- Kim, H.; Kong, T.; Lee, S.B.; Kang, T.; Oh, N.; Kim, Y.; Park, S.; Lim, C.; Stone, G.C. Experience with stator insulation testing and turn/phase insulation failures in the power generation industry. IEEE Trans. Ind. Appl. 2018, 54, 2225–2236. [Google Scholar] [CrossRef]

- Gurusamy, V.; Capolino, G.-A.; Akin, B.; Henao, H.; Romary, R.; Pusca, R. Recent trends in magnetic sensors and flux based condition monitoring of electromagnetic devices. IEEE Trans. Ind. Appl. 2022, 58, 4668–4684. [Google Scholar] [CrossRef]

- Zafarani, M.; Bostanci, E.; Qi, Y.; Goktas, T.; Akin, B. Interturn short-circuit faults in permanent magnet synchronous machines: An extended review and comprehensive analysis. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 2173–2191. [Google Scholar] [CrossRef]

- Lee, S.B.; Stone, G.C.; Antonino-Daviu, J.; Gyftakis, K.N.; Strangas, E.G.; Maussion, P.; Platero, C.A. Condition monitoring of industrial electric machines: State of the art and future challenges. IEEE Ind. Electron. Mag. 2020, 14, 158–167. [Google Scholar] [CrossRef]

- Mostafaei, M.; Faiz, J. An overview of various faults detection methods in synchronous generators. IET Electr. Power Appl. 2021, 15, 391–404. [Google Scholar] [CrossRef]

- Tu, X.; Dessaint, L.; Kahel, M.E.; Barry, A.O. A new model of synchronous machine internal faults based on winding distribution. IEEE Trans. Ind. Electron. 2006, 53, 1818–1828. [Google Scholar] [CrossRef]

- Tu, X.; Dessaint, L.; Fallati, N.; Kelper, B.D. Modeling and real-time simulation of internal faults in synchronous generators with parallel-connected windings. IEEE Trans. Ind. Electron. 2007, 54, 1400–1409. [Google Scholar] [CrossRef]

- Gu, B.; Choi, J.; Jung, I. Development and analysis of interturn short fault model of PMSMs with series and parallel winding connections. IEEE Trans. Power Electron. 2014, 29, 2016–2026. [Google Scholar] [CrossRef]

- Qian, H.; Guo, H.; Ding, X. Modeling and analysis of interturn short fault in permanent magnet synchronous motors with multistrands windings. IEEE Trans. Power Electron. 2016, 31, 2496–2509. [Google Scholar] [CrossRef]

- Naderi, P. Magnetic-equivalent-circuit approach for inter-turn and demagnetisation faults analysis in surface mounted permanent-magnet synchronous machines using pole specific search-coil technique. IET Electr. Power Appl. 2018, 12, 916–928. [Google Scholar] [CrossRef]

- Forstner, G.; Kugi, A.; Kemmetmüller, W. A magnetic equivalent circuit based modeling framework for electric motors applied to a PMSM with winding short circuit. IEEE Trans. Power Electron. 2020, 35, 12285–12295. [Google Scholar] [CrossRef]

- Gao, C.; Lv, K.; Si, J.; Feng, H.; Hu, Y. Research on interturn short-circuit fault indicators for direct-drive permanent magnet synchronous motor. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 1902–1914. [Google Scholar] [CrossRef]

- Bouzid, M.B.K.; Champenois, G.; Maalaoui, A.; Tnani, S. Efficient simplified physical faulty model of a permanent magnet synchronous generator dedicated to the stator fault diagnosis part I: Faulty model conception. IEEE Trans. Ind. Appl. 2017, 53, 2752–2761. [Google Scholar] [CrossRef]

- Gao, C.; Lv, K.; Si, J.; Su, P.; Gan, C. A physical faulty model based on coil sub-element for direct-drive permanent magnet synchronous motor with stator winding short-circuit faults. IEEE Access 2019, 7, 151307–151319. [Google Scholar] [CrossRef]

- Mei, Z.T.; Li, G.J.; Zhu, Z.Q.; Clark, R.; Thomas, A.; Azar, Z. Scaling Effect on inter-turn short-circuit fault of pm machines for wind power application. IEEE Trans. Ind. Appl. 2023, 59, 789–800. [Google Scholar] [CrossRef]

- Mei, Z.T.; Li, G.J.; Zhu, Z.Q.; Clark, R.; Thomas, A.; Azar, Z. Modelling and analysis of inter-turn short-circuit fault of pm machines with parallel-connected coils. IEEE Trans. Energy Convers. 2023, 38, 1268–1279. [Google Scholar] [CrossRef]

- Padinharu, D.K.; Li, G.; Zhu, Z.; Foster, M.; Stone, D.; Griffo, A.; Clark, R.; Thomas, A. Scaling effect on electromagnetic performance of surface-mounted permanent-magnet vernier machine. IEEE Trans. Magn. 2020, 56, 8100715. [Google Scholar] [CrossRef]

- Faiz, J.; Nejadi-Koti, H.; Valipour, Z. Comprehensive review on inter-turn fault indexes in permanent magnet motors. IET Electr. Power Appl. 2017, 11, 142–156. [Google Scholar] [CrossRef]

- Zhang, J.; Zhan, W.; Ehsani, M. Diagnosis and fault-tolerant control of permanent magnet synchronous motors with interturn short-circuit fault. IEEE Trans. Control Syst. Technol. 2023, 1–8. [Google Scholar] [CrossRef]

- Mitcham, A.J.; Antonopoulos, G.; Cullen, J.J.A. Implications of shorted turn faults in bar wound pm machines. IEE Proc.-Electr. Power Appl. 2004, 151, 651–657. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, J.; Howe, D.; Jewell, G. Analytical prediction of the short-circuit current in fault-tolerant permanent-magnet machines. IEEE Trans. Ind. Electron. 2008, 55, 4210–4217. [Google Scholar]

- Arumugam, P.; Hamiti, T.; Gerada, C. Modeling of different winding configurations for fault-tolerant permanent magnet machines to restrain interturn short-circuit current. IEEE Trans. Energy Convers. 2012, 27, 351–361. [Google Scholar] [CrossRef]

- Davis, P.J. Circulant Matrices; Monographs and Textbooks in Pure and Applied Mathematics; Wiley: Hoboken, NJ, USA, 1979. [Google Scholar]

| Rated power | 3 kW | 500 kW | 3 MW |

| Rated speed (rpm) | 170 | 32 | 15 |

| Rated voltage (Vrms) | 690 | 690 | 690 |

| Phase current (Arms) | 2.5 | 438.2 | 2790 |

| Series-parallel winding | 16S1P * | 7S7P * | 4S20P * |

| Series turns/coil | 52 | 23 | 14 |

| Numbers of slots/poles | 96/32 | 294/98 | 480/160 |

| Rotor outer diameter (mm) | 426.4 | 2195.5 | 5000 |

| Stack length (mm) | 110 | 550 | 1200 |

| Airgap length (mm) | 2 | 2.15 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mei, Z.; Li, G.; Zhu, Z.; Clark, R.; Thomas, A.; Azar, Z. Modelling and Analysis of Inter-Turn Short-Circuit Faults for Large-Power SPM Wind Generators. Energies 2023, 16, 4723. https://doi.org/10.3390/en16124723

Mei Z, Li G, Zhu Z, Clark R, Thomas A, Azar Z. Modelling and Analysis of Inter-Turn Short-Circuit Faults for Large-Power SPM Wind Generators. Energies. 2023; 16(12):4723. https://doi.org/10.3390/en16124723

Chicago/Turabian StyleMei, Zeting, Guangjin Li, Ziqiang Zhu, Richard Clark, Arwyn Thomas, and Ziad Azar. 2023. "Modelling and Analysis of Inter-Turn Short-Circuit Faults for Large-Power SPM Wind Generators" Energies 16, no. 12: 4723. https://doi.org/10.3390/en16124723

APA StyleMei, Z., Li, G., Zhu, Z., Clark, R., Thomas, A., & Azar, Z. (2023). Modelling and Analysis of Inter-Turn Short-Circuit Faults for Large-Power SPM Wind Generators. Energies, 16(12), 4723. https://doi.org/10.3390/en16124723