Abstract

Nigeria has the potential to generate 12,522 MW of electricity, but can only dispatch 4000 MW, which is insufficient for a population of over 200 million people as of 2022. Therefore, Nigerians use solid fuels including firewood and charcoal as an alternative to insufficient electricity for domestic use. The consumption of firewood and charcoal in Nigeria is estimated at 23,745,458 tons and 4,828,689 tons, respectively in 2021, by far the most consumed domestic solid fuel sources in Nigeria. Although there are domestic solid fuel alternatives, such as dung, agricultural residues and coal, to firewood and wood charcoal, their sustainable adoption has been slow in Nigeria, indicating that there is insufficient knowledge of domestic solid fuel sources. This requires a review focused on assessing Nigeria’s national sources of solid fuels. This article presents an overview of the sources of domestic solid fuels in Nigeria, an exploration of different types of firewood and charcoal studies, the impact of solid fuels on climate change and the environment, health risks associated with solid fuel and biomass briquettes and pellets as domestic solid fuel alternatives to charcoal and firewood. The continued production and use of firewood and wood charcoal as domestic solid fuel sources encourage deforestation, desertification and greenhouse gas emission, which in turn pose a threat to a sustainable environment and good health. It is necessary to limit the felling of trees for firewood and charcoal production to curtail their negative impacts on the health of users and the environment. This review covered the thermal, mechanical and physical properties of briquette and pellet fuels as substitutions for firewood and charcoal. It was shown that employing briquettes and pellets as a source of solid fuel in the home will lessen the negative impacts that these fuels have on users’ health, the climate and the environment.

1. Introduction

Households are the largest energy-consuming sector in Nigeria, accounting for 62.15% of the country’s GDP in 2021 [1]. Biomass resources, such as firewood and related products, account for 68.6% of Nigeria’s abundant traditional energy resources, while, on the other hand, transition and/or modern energy sources, such as kerosene, liquefied petroleum gas and electricity, accounted for 14.7% in 2018, both domestic uses. Most households use solid and non-solid fuels, of which more than three billion people, or about 50% of the world’s population, rely heavily on solid fuel energy sources (firewood, dung and agricultural residues) and coals to meet their basic energy needs [2,3]. The high reliance on solid fuel is due to the relationship between poverty and energy consumption patterns in terms of energy quality and quantity [4].

According to Barnes and Floor [5], energy issues are pervasive in developing nations and contribute to a population’s extreme poverty. In developing nations such as Nigeria, access to modern energy services is limited as a result of the high poverty level. Another implicit tenet is that since they lack the financial resources required to run the most effective alternative fuel service, the poor typically pay more for each useable unit of unimproved energy consumed. Additionally, because energy merchants must incur significant operational expenses to serve these low-density markets, households in rural locations suffer more from a lack of or an absence of efficient energy services [1].

In Nigeria’s urban and rural areas, solid fuels such as firewood and charcoal made up a large amount of the primary energy consumed in 2018 (67.8%) [1,6]. Charcoal is primarily used in urban areas, according to Ehirm and Osuji’s findings [4], whereas people in rural areas prefer solid fuels such as firewood. Charcoal and firewood, the principal fuel sources in Nigeria, are obtained through the reduction of forest resources (cutting of trees) [7]. Besides firewood and charcoal, agricultural waste provides an energy option, especially in rural communities, accounting for 85.5% in 2018 [1]. The World Health Organization estimates that as of 2002, carbon dioxide emissions from the use of solid fuels were 0.04 metric tons per person. It has been suggested that exposure to health-harming pollutants causes high blood pressure, which raises the risk of kidney disease, cardiovascular disease and stroke [8], as well as pneumonia in young children [9] and early mortality [10,11].

Therefore, to meet the ongoing demand for an energy source that is ecologically friendly, sustainable, affordable and easily accessible, it is necessary to evaluate the quality of domestic solid fuel sources (such as charcoal and firewood). The sources of solid domestic fuels in Nigeria are outlined in this article along with studies on various kinds of firewood and charcoal, the effects of solid fuels on the environment and climate change, the health risks associated with solid fuel and biomass briquettes and pellets as alternatives to charcoal and firewood for domestic use.

2. Sources of Domestic Solid Fuels in Nigeria

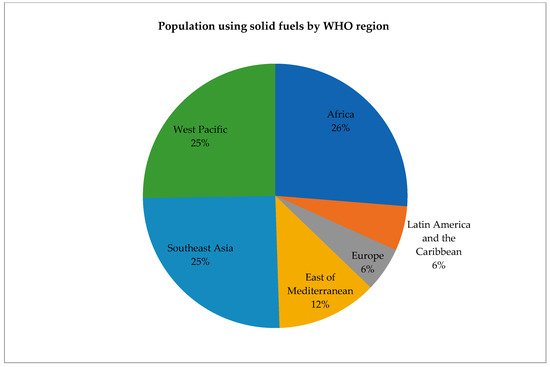

Around 3 billion people (or 40% of the world’s population) depend on burning solid fuels such as coal, biomass, charcoal and firewood [12]. Wood and other solid biomass fuels, including coal, briquettes, dung, farm waste and grass, made up 87.0% of the fuels used for cooking and heating in rural regions in 2018 [1]. These fuels are often obtained from the local community in rural areas and purchased in urban markets [13,14]. Nigerian villagers, who are the guardians of the forest’s resources, rely primarily on firewood and charcoal for their livelihood, making these the country’s most widely used energy sources (Figure 1) [15]. Figure 2 displays the population consuming solid fuels by region according to the World Health Organization.

Figure 1.

The primary domestic solid fuel sources in Nigeria: (a) firewood [16]; (b) wood charcoal [17].

Figure 2.

Population using solid fuels by WHO region [18].

In Nigeria’s rural areas, farmers who raise livestock can use a digester to turn agricultural waste and manure into biogas, which can be used for both heating and lighting. The country’s yearly production of biogas is estimated at 542.5 million tons [19]. However, electricity is not widely used in developing countries, especially in Nigeria. In many underdeveloped countries, the use of raw biomass as an energy source has a negative impact on health and the environment [20]. However, as urbanization advances, waste from these sources may not be disposed of responsibly [21]. At worst, this waste is burned inefficiently, contributing to air pollution [22]; however, if handled well, and depending on the waste, they could be sources of renewable energy.

3. Charcoal and Firewood as Domestic Solid Fuel Sources

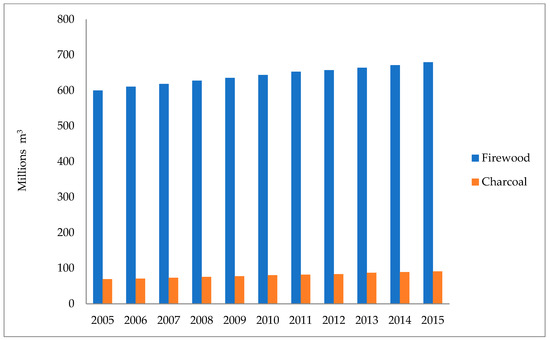

Nigeria produced the most firewood and charcoal in 2014, with 4,828,689 tons and 23,745,458 tons, respectively [23]. Figure 3 shows that the average annual production of charcoal and firewood in Africa has dramatically increased since 2005, rising from 69 million m3 to 91 million m3 for charcoal and from 599 million m3 to 679 million m3 for firewood. Nigeria consumes almost as much solid fuel as it generates, while not being one of the major exporters.

Figure 3.

Solid fuel production (fuelwood and charcoal) in Africa, 2005–2015 [24].

According to Maurice et al. [25], forestry is a source of energy fuel for many farmers and households in rural Nigeria. About 95% of all wood harvested for firewood is used for domestic purposes [26,27]. In the Nigerian metropolis of Kano, Abdul-Hakim and Ibrahim [28] discovered that 66.3% of households utilize firewood as their primary source of energy while only 55% had access to electricity. Additionally, according to Ebenezer et al. [29], 75% of Nigerian households rely on firewood. The growing reliance on firewood is due to rapid urbanization, rural and urban poverty, rising costs of alternative energy and high electricity costs [25,30,31]. The extensive use of firewood in Nigeria has contributed greatly to desert encroachment, climate change and the economic burden on poor households who buy firewood at certain prices or travel long distances to the forest in search of firewood [25,27,30].

Charcoal production is prevalent in wood-rich regions, such as Oyo, Ogun, Edo, Ondo, Cross River, Kwara, Kaduna and Kogi states, and the process involves stacking and arranging cut firewood in conical piles with a small gap at the bottom to allow air circulation and a central shaft to serve as a flue [14]. Then, the entire chimney is lined with moistened clay and a fire is lit at the bottom of the chimney, which spreads throughout the chimney over time, and the whole process depends solely on combustion to be successful. On average, 100 parts of wood yields 25 parts charcoal by weight or 60 parts charcoal by volume. Recently, due to economic hardship, poverty, unemployment and an increment in pump prices in Nigeria, people have had to find another means of making a living in respect to energy [22,32].

According to reports, low-income people and families use charcoal more frequently, with charcoal and firewood making up 75% of all home energy costs [33]. By weight, charcoal is considerably lighter (1 kg of wood gives between 0.16 and 0.30 kg of charcoal) depending on the dry wood weight of the different species used for its production. Because it does not require much storage space and will not be quickly damaged by insects or fungi, charcoal is favored by many households over firewood. Additionally, it is acknowledged to have a calorific value double that of firewood, making it more energy-efficient than the majority of other fuels [34].

Finally, in many societies, solid fuels are used for various household-based activities, such as lighting, cooking and space heating, and various forms of income generation, such as ceramic or food preparation businesses [35].

4. Exploration of Different Types of Firewood and Charcoal Studies

To come up with ideas for producing premium household solid fuels, it is necessary to investigate various types of firewood and charcoal for domestic usage. Because of this, scientists have worked hard to investigate the energy potentials of the two primary domestic solid fuels in Nigeria, and their work has produced a wealth of intriguing results. The following is a summary of studies on the proximate, ultimate analysis and calorific value of various types of firewood and charcoal.

4.1. Proximate, Ultimate Analysis and Energy Potential Study of Different Types of Firewood

The majority of experimental investigations have chosen to evaluate several wood species through immediate and long-term analyses of household solid fuel usage in Nigeria (Table 1). Enyejo et al. [36] investigated the proximate, ultimate analysis and calorific value of Copaiba oliveri, Quassia undulate and Prosopis africana. The experiment results showed that the fixed carbon, which is the primary factor in determining the heating value, ranged from 9.45 to 18.50%. Materials of wood origin are rich in carbon and are characterized by higher combustion heat values than green biomass, i.e., stems, leaves, straw and husks [37,38]. This study reported that the volatile matter composition of wood is typically high and above 80%. The ash content (˂5%) and moisture contents (˂10%) are desirable as they enhance the thermo-chemical conversion process [39].

The moisture content of the fuel is important as a factor in determining the calorific value and pollutant emissions [40,41]. It significantly affects the calorific value of the fuel and plays a significant role in the combustion process, causing an increase in the volume flow of exhaust gases. Combusting fuels with a high moisture content lowers the combustion temperature, adversely affecting the process and making it difficult to burn the fuel. During combustion, significant losses may occur due to incomplete combustion, leading to increased emissions of harmful substances [42]. Shen et al. [43], when burning deciduous wood with a moisture content of 5.3% to 27%, showed that the emission of total dust increased from 1.8 to 4.1 g·kg−1, organic carbon increased from 0.67 to 0.87 g·kg−1 and polycyclic aromatic hydrocarbons (PAH) increased from 13 to 22 g·kg−1. In addition, with the increase in fuel moisture, not only PAH emissions increase but also carbon monoxide emissions [44], as well as benzene, formaldehyde and PM1 emissions [42]. Striugas et al. [45] found the need for a continuous control of fuel moisture to adjust the boiler installation’s operating parameters, as it affects the by-products of burning solid fuels. During the combustion of pure biomass, small amounts of ash are formed (0.5–12.5%), which do not contain harmful substances. Higher ash contents indicate raw material contamination [46,47]. After burning wood, small amounts of ash are produced, compared to ash from burning coal (6–30%). After burning coniferous chips, 0.3% ash is produced, and after burning deciduous wood, 2.2% ash is produced. Larger amounts of ash are usually produced after burning tree bark (5.1%), straw (10.4%), grasses (18.2%) and tobacco stalks (22.5%) [48,49]. It has been shown that there is a weak negative correlation between the ash content and the energy value of the raw material, which means that with the increase in the ash content, the biomass calorific value decreases [50,51,52,53].

The results of the carbon (48.50–59.05%) and hydrogen (5.27–6.50%) content of firewood are desirable on account of their influence in increasing the heating value. Carbon and hydrogen during combustion, through exothermic reactions, are oxidized to carbon dioxide CO2 and water vapor H2O, and their content has a positive effect on the combustion heat of the biofuel and indicates high energy potential. The high content of oxygen (35.13–44.16%) has a negative effect, as it constitutes a ballast in combustion processes [48]. The ratio of oxygen and carbon in biomass correlates negatively with its calorific value, i.e., increasing the O/C ratio from 0.1 to 0.7 causes a decrease in calorific value from 38 to 15 MJ·kg−1 [54]. Chlorine, sulfur and nitrogen are undesirable fuel components due to their negative impact on the environment [54,55]. This study reported that the nitrogen (0.10–0.32%) and sulfur contents (˂0.01–0.03%) are low as expected (Table 1), and are desired since they will ensure a very low emission of NOx and SOx as products of combustion [56,57].

The qualities of several firewood types were examined by Evbuomwam and Okorji [58] to determine which wood species provide better fuels. They investigated the proximate properties and energy potential, including the moisture content, volatile matter, ash content and calorific value of Gmelina arborea and Terminalia catappa (Table 1). It was found that wood properties are greatly dependent on water content; hence, water content affects the choice of wood fuels for domestic application. The higher calorific value of Terminalia catappa (39.74 MJ·kg−1) showed that it tends to slow the burning rate (Table 1).

The qualities of Daniellia oliveri and Tectona grandis for domestic solid fuel use were also explored by Akinlosotu et al. [59]; the ultimate analysis was performed using a CHNSO analyzer. The calorific value is used to determine the energy content of the fuelwood. It is usually affected by ash content, volatile matter, moisture content and elemental composition [59] as shown in Table 1. The fuel-burning rate may be hampered by the increased ash contents indicated. The nutritional and antinutritional composition of tender leaves of Daniellia oliveri was described by Aliyu et al. [60].

Table 1.

Summaries of studies on proximate and ultimate analysis and calorific value of firewood as domestic solid fuel.

Table 1.

Summaries of studies on proximate and ultimate analysis and calorific value of firewood as domestic solid fuel.

| Firewood | Proximate Analysis (% d.b) | Ultimate Analysis (% d.b) | CV (MJ·kg−1 d.b) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AC | FC | VM | MC | C | H | N | O | S | ||

| Daniellia oliveri [59] | 3.55 | 11.50 | 76.00 | 8.71 | 50.50 | 6.10 | 0.10 | 44.00 | 0.01 | 20.24 |

| Tectona grandis [59] | 7.25 | 18.50 | 73.33 | 6.67 | 52.00 | 6.00 | 0.10 | 40.00 | 0.01 | 17.17 |

| Copaiba oliveri [36] | 14.83 | 16.20 | 64.00 | 4.97 | 40.80 | 4.46 | 0.52 | 38.01 | 0.03 | 18.68 |

| Quassia undulate [36] | 14.79 | 9.45 | 64.23 | 3.01 | 34.70 | 3.11 | 0.36 | 42.99 | 0.03 | 18.42 |

| Prosopis africana [36] | 6.79 | 21.30 | 66.25 | 5.66 | 46.07 | 5.56 | 0.65 | 40.69 | 0.04 | 18.68 |

| Gmelina arborea [58] | 2.50 | - | 68.00 | 5.77 | - | - | - | - | - | 10.83 |

| Terminalia catappa [58] | 4.00 | - | 65.00 | 22.65 | - | - | - | - | - | 39.74 |

Abbreviations: AC: ash content, FC: fixed carbon, VM: volatile matter, MC: moisture content, C: carbon, H: hydrogen, N: nitrogen, O: oxygen, S: sulfur, CV: calorific value, d.b: dry base.

4.2. Proximate, Ultimate Analysis and Energy Potential Study of Different Types of Charcoal

There is growing interest among Nigerians in the use of charcoal as a domestic solid fuel source. Although many studies have been carried out on the proximate, ultimate and energy potential of various charcoal types in Africa, these data are still limited. Therefore, some effort should be made to assess domestic solid fuel sources in Nigeria. A few studies which involved the proximate and ultimate analysis and energy potential of charcoal as domestic solid fuel are summarized in Table 2, and they were collected from experiments on different wood species. According to the research presented by Akinlosotu et al. [59], charcoal was produced from three different types of wood: Albizia pediallaris, Tectona grandis and Daniellia oliveri. The charcoal samples were subjected to proximate and ultimate analysis and energy content determination. The analysis showed that charcoal from Daniellia oliveri had the highest range of calorific value (30.18 MJ·kg−1), carbon content (70.70%) and fixed carbon (47.70%), making it more suitable for domestic use as solid fuel. The reason Daniellia oliveri charcoal has a higher ash content than firewood is that water and volatile matter are released during the pyrolysis process, leaving a large portion of the ash in the solid fuel [61]. This suggests that the ash content must inevitably rise with rising temperature and carbonization time. Charcoal has a higher percentage of ash content than the matching wood sample; the higher the heating value, the lower the ash content.

The sulfur content recorded for Daniellia oliveri of less than 0.01% is evidence of the eco-friendly property of the charcoal produced. The calorific value is calculated as a function of the heat of combustion and substrate moisture [62]. The calorific value can be calculated based on the elemental composition of the fuel [63,64], exhaust gas composition [65] or near-infrared (FTIR) spectroscopy [66,67]. The calorific value of biomass depends strictly on its moisture, where it ranges from 6 to 8 MJ·kg−1 for 50–60% moisture to 15 to 17 MJ·kg−1 for dried biomass with 10–20% moisture, and up to 19 MJ·kg−1 for completely dried biomass [68]. The calorific value depends mainly on the degree of coalification of the burnt material, i.e., on its chemical composition and the content of combustible elements in its composition [69]. The calorific value is also correlated with the ash content. Biomass with ash content below 1% has a calorific value of about 20 MJ·kg−1, and after exceeding this ash content, the calorific value decreases by 0.2 MJ·kg−1 with each 1% of ash content. The elemental carbon content also affects the calorific value of biomass—an increase in this content by 1% gives an increase in the calorific value by 0.39 MJ·kg−1 [64,67].

Oke et al. [70] carried out a proximate analysis of Anogeissus lelocarpa and Afzelia africana wood charcoals, in which the study samples had high-volatility content (of 4.60–6.73%, respectively). The moisture content (5.90–6.01%) and ash content (4.02–4.40%) recorded for Anogeissus lelocarpa and Afzelia africana are considerable and make them suitable as domestic solid fuel sources (Table 2). This means that the lower the ash and moisture contents, the higher the calorific value. Adamu et al. [71] investigated the influence of chemical composition on the combustion and calorific value of wood charcoals from Anogeissus lelocarpa and Pokia biglobosa, commonly used in Nigeria (Table 2). Pokia biglobosa had the lowest moisture content (5.10%). The presence of moisture in solid fuel influences its behavior during combustion [72], and this affects the physical properties and quality of the solid fuel produced. The combustion and energy content of the wood charcoals examined was found to be influenced by the chemical composition of the parent woods used for their production. Finally, the assessment of different charcoal woods uncovered the importance of holistic consideration in the appropriate selection of wood species for charcoal production. This may also reduce the rate of forest destruction, thereby maintaining and expanding ecosystem services and forest health.

Table 2.

Summaries of studies on proximate and ultimate analysis and calorific value of charcoal as domestic solid fuel.

Table 2.

Summaries of studies on proximate and ultimate analysis and calorific value of charcoal as domestic solid fuel.

| Charcoal | Proximate Analysis (% d.b) | Ultimate Analysis (% d.b) | CV (MJ·kg−1 d.b) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AC | FC | VM | MC | C | H | N | O | S | ||

| Daniellia oliveri [59] | 4.25 | 47.70 | 40.50 | 6.30 | 70.70 | 1.15 | 0.14 | 17.50 | ˂0.01 | 30.18 |

| Tectona grandis [59] | 18.74 | 22.30 | 53.00 | 5.96 | 72.20 | 1.25 | 0.16 | 16.00 | 0.02 | 25.07 |

| Albizia pediallaris [59] | 3.50 | 43.13 | 24.75 | 6.73 | 75.00 | 1.20 | 0.15 | 14.50 | 0.01 | 27.77 |

| Afzelia africana [70] | 4.40 | 72.00 | 10.10 | 5.90 | - | - | - | - | - | 29.00 |

| Pokia biglobosa [71] | 16.91 | 43.40 | 34.59 | 5.10 | 64.38 | 2.83 | 0.32 | 12.38 | ˂0.01 | 16.88 |

| Anogeissus lelocarpa [70] | 4.02 | 83.00 | 3.00 | 6.01 | - | - | - | - | - | 31.00 |

| Anogeissus Lelocarpa [71] | 6.51 | 71.10 | 17.79 | 4.60 | 76.13 | 3.55 | 0.43 | 18.90 | ˂0.01 | 33.58 |

Abbreviations: AC: ash content, FC: fixed carbon, VM: volatile matter, MC: moisture content, C: carbon, H: hydrogen, N: nitrogen, O: oxygen, S: sulfur, CV: calorific value, d.b: dry base.

5. Effects of Domestic Solid Fuels on Climatic Change and Environment

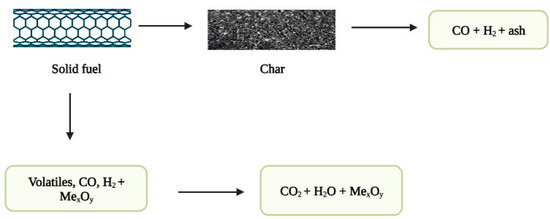

The use of solid fuels can have a number of significant environmental consequences. About 2.4 billion people rely on firewood and charcoal to cook food, resulting in an estimated daily combustion of 2 million tons [35]. Figure 4 provides a summary of the procedure a solid fuel goes through during burning. Currently, charcoal in Nigeria is mostly produced in traditional kilns with less than optimal conversion efficiency and no conversion controls. According to Akinbami [73], when coupled with an unsustainable fuel supply, this can severely stress forests and have significant, albeit poorly understood, effects on soil fertility and biodiversity, which includes 47,158 species of higher plants, 285 mammals, 203 reptiles, 117 amphibians, 864 species of birds and 285 species of fish.

According to the WHO database with information from more than 70 published studies in developing countries, the average 24 h PM10 concentrations in homes that use solid fuels range between 300 and 3000 µgm−3. During cooking, levels of indoor air pollution can be as high as 30,000 µgm−3 [35]. The climate impacts of firewood and charcoal are due to GHG emissions caused by unsustainable wood harvesting (mainly CO2) and incomplete combustion (methane—CH4 and black carbon) [74].

Figure 4.

Solid fuel combustion process [75].

In 2020, Nigeria had a growing stock of 2166.16 million m3 and a total land area of 923,763 km2 (or roughly 21.63 million hectares), with less than 8% of that comprising forests [76]. The overall forest land area consists of more than 1000 gazetted reserves, seven national parks, 32 game reserves and 1 strict natural reserve, and is distributed across the five primary ecological zones of freshwater/mangrove, low land rainforest, derived savannah, Sudan, and Sahel savannah [76]. Nigeria produced 66.21 million m3 of firewood in 2019 compared to 50.92 million m3 in 1990, a 23% increase [77]. The depletion of Nigeria’s forest resources is due to the increased production of firewood and charcoal as well as other activities, including logging, urbanization and agricultural expansion. Nigeria’s deforestation rate is 3.5% per annum (about 350,000 ha to 400,000 ha) [78].

According to Chomini et al. [79], cutting down trees has a negative effect on the environment. Deforestation is also believed to be responsible for 87% of the nation’s overall carbon emissions [80] because the trees that would absorb this carbon are being felled daily, contributing to the problem of global warming [80,81,82,83,84]. Additionally, habitat damage may result in a dearth of animals in the forest (affected areas) [85,86,87,88,89]. Food insecurity is implied as a result of this. Otu-Danquah [90] reported that charcoal and fuel wood production cause severe environmental degradation and deforestation. The degraded hotspots to restore include Imeko Game Reserve (95,488 ha), Aworo Forest Reserve (21,299 ha), Saki (66.29 ha), Ilesha Ibaruba (47.33 ha), Ejeba (85.22 ha), Oroma-Etiti (94.48 ha), Orishaeze (170.31 ha), IfiangNsung (104.03 ha), Badoko (18.73 ha), Amba (337.96 ha) and Banaga (65.27 ha) [91].

6. Health Risks Associated with Domestic Solid Fuels

The majority of the 1.5 million deaths each year from respiratory illnesses due to smoke inhalation are women and children, according to the World Health Organization in 2016. High amounts of indoor air pollution are produced by the use of biomass fuels such as firewood and charcoal, especially when they are burned indoors on conventional stoves or open flames. Review studies showed that the usage of household solid fuels can have a negative impact on women’s and children’s health [92]. As a result, babies spend many hours inhaling indoor smoke during their first year of life, when their still-developing lungs make them especially vulnerable to dangerous pollutants. Fifty-six percent of all deaths related to indoor air occur in children under the age of five [93].

The inefficient combustion of solid fuels in an open fire or traditional indoor stove creates a dangerous mixture of hundreds of pollutants, primarily carbon monoxide and fine particulate matter, but also nitrogen oxides, benzene, butadiene, formaldehyde, polyaromatic hydrocarbons and many other health-damaging chemicals as presented in Table 3 [94]. The consequences of this include shortness of breath, runny eyes, runny nose, throat irritation, coughing, breathing difficulties, wheezing, chest pains, dizziness and nausea [91,95].

Table 3.

Pollutants from solid fuels and their health effects [96].

7. Biomass Briquette and Pellet as an Alternative to Firewood and Charcoal

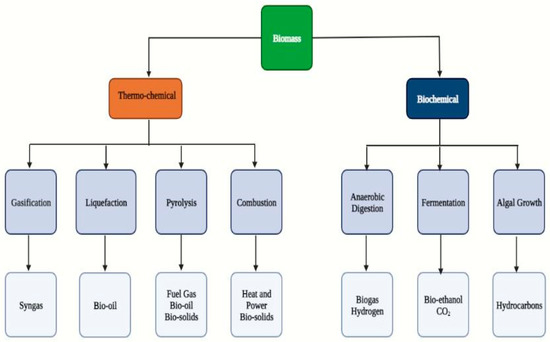

Residues from forests and agriculture are mismanaged and misused as they decay or are incinerated, leading to pollution and degradation [97]. The most significant biomass sources (Figure 5) include sewage, algae, aquatic crops, agricultural and forestry leftovers, animal residues (from livestock farms) and waste products from the wood-processing industry. Only if they cannot be reused in further processing do municipal solid waste (MSW) and waste streams from anthropogenic operations also fall under the biomass category [98]. However, studies have shown that this waste contains a lot of potential energy and can be used to generate heat for domestic and industrial use [99,100]. Biomass fuels are a potential source of renewable energy and can be easily obtained from agricultural waste [101]. Biomass technology can be converted into fuel through different processes, including solid fuel combustion, digestion, pyrolysis, fermentation and catalyzed reactions (Figure 6) [102]. There are many types of biomass, but sawdust and agricultural residues have proven to be one of the best options, with some agricultural residues even able to be used directly as fuels. Because most of them are bulky and uneven and have a low energy density, most of them are unsuitable [101]. These properties make them difficult to handle, store, transport and use in their raw state [103].

Figure 5.

Biomass sources in Nigeria.

Figure 6.

Bio-energy conversion technologies [104].

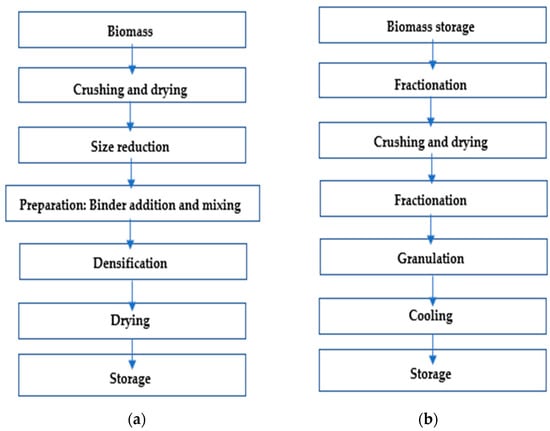

It is therefore necessary to convert them to solve these problems. One of the processes by which this waste can be converted into biomass energy is briquetting and pelleting (Figure 7) [105,106]. The biomass densification process is complex and consists of four phases: grinding, drying, pressing and cooling. As a result, the water content of the raw materials used is reduced and the concentration of mass and energy per volume unit increases, as does the comfort of distribution and use [107]. Briquettes are rectangular or cylindrical in shape, 10–30 cm long and 6–12 cm in diameter. Pellets are granules of cylindrical shape, about 5–40 mm long and 8–12 mm wide (diameter). The uniform size of briquettes and pellets facilitates their transport. The density of briquettes and pellets depends mainly on the moisture content of the biomass, the size and form of fuel particles and the lignin and starch content in the plant. Wood-based waste has a structure that is susceptible to compaction because it contains an internal binder in the form of lignin. Agricultural waste is mostly difficult to compact because it is a compressive material [107]. The granulate production process is carried out in several stages (Figure 7b).

Figure 7.

Production process: (a) briquette; (b) pellet from biomass.

Various types of promising briquette fuels have been studied, such as groundnut shells, sugarcane bagasse, castor seed shells, sawdust, cotton stalks, bamboo dust, coffee husk, tobacco waste tea, paddy straw, mustard straw, mustard shell and watermelon peels [101]. The process of the compaction or densification of wastes (Figure 7a) into a product with a higher density than the raw materials, known as briquetting, produces briquettes [108]. The method [109,110] transforms low-bulk-density biomass into high-density, energy-concentrated fuel, and it mostly entails drying, grinding, screening, compacting and cooling activities. Materials with moisture content in the range of 15–17% are typically used in equipment for the production of briquettes and pellets. Therefore, the material to be granulated is often pre-dried. The raw material is ground into particles of a size of 2 to 4 mm and fed to the press, where it is forced through the holes of the die, resulting in granulates (briquettes, pellets). Then, after leaving the press, the hot granules, at a temperature of 90–95 °C, are cooled. This process helps to stabilize, harden and form granulates [111,112]. Therefore, biomass briquettes are intended to replace firewood and charcoal in households to reduce deforestation and mitigate environmental degradation due to overexploitation [16].

7.1. Characteristics of Biomass Briquettes

The characteristics of briquettes are categorized into three groups based on the criteria that were evaluated (Table 4). These groups are production, physicochemical analysis and combustion properties. These traits illustrate how well briquettes can be handled, transported, stored and burned. These standards are used to evaluate produced briquettes and eventually define their quality. The quality of the briquettes, which also influences how well they can sustain particular impacts, can be used to gauge the success of the densification process. In end-user applications, the qualitative properties of the densified biomass are critical [113].

Table 4.

Summaries of briquette production and other analyses by authors.

However, the nature of the feedstock and briquetting machine used to create them largely determines these characteristics [126]. The success of the densification process can be determined by the briquettes’ quality, which also affects how well they can withstand specific impacts. Ige et al. [101] state that a good briquette should have low moisture content (<20%), high compressive strength (>0.372), high density (1.200 g/cm3) and high calorific value (38–42 MJ·kg−1). This report held up well in comparison to the outcomes of the various findings shown in Table 5. The calorific values reported by Bamisaye and Ige [127] are more than those previously reported from earlier results, such as groundnut shell briquettes, which have a calorific value of 11.99 MJ·kg−1 [128], and soybeans, which have a calorific value of 12.95 MJ·kg−1 [129]. However, this can be linked to the high density, lower volatile matter and high fixed carbon.

Table 5.

Characteristics of briquettes from previous studies.

7.2. Characteristics of Biomass Pellets

Based on the parameters that were assessed, the characteristics of pellets are divided into three categories: physical, mechanical and thermal properties (Table 6). These qualities serve as a reflection of how well the pellets can be handled, moved, stored and burned. Quality varies among pellets. The most crucial characteristic of wood pellets is their calorific value; a higher calorific value translates into higher energy efficiency for a given amount of the product and, as a result, a lower cost for the consumer [133]. The calorific value of pellets composed of wood biomass and straw ranges from 16.5 to 20.5 MJ·kg−1; that of pellets produced from sewage sludge is lower, at about 11.37 MJ·kg−1 [134]; and Nazemi et al. [135] also recorded 12.84–19.84 MJ·kg−1 for seaweed pellets. The quantities of carbon, hydrogen, oxygen, sulfur, nitrogen and ash in a sample are connected to the calorific value (MJ·kg−1) [133]. Durability is a crucial characteristic of pellets; it is thought that durability is high for pellets if the corresponding value exceeds 80%, moderate for pellets if the corresponding value is between 70% and 80% and low for pellets if the corresponding value is less than 70% [136]. High-quality biofuels are defined as pellets with durability above 97.5%, as determined by a specific tumble testing method [137,138].

Table 6.

Characteristics of pellets from previous studies.

The following are the requirements for wood pellets’ quality classes according to the international standard (EN ISO): length (6 or 8 +/− 1 mm), calorific value (≥16.5 MJ·kg−1), bulk density (0.6 g/cm3), moisture (10%) and ash (2%). The following are the briquettes’ quality class requirements: diameter (≥30 mm), length (≥60 mm), bulk density (≥0.9 g/cm3), calorific value (≥14.9 MJ·kg−1), moisture (≤15%) and ash (≤3%) are all acceptable specifications [141].

Even though it has been observed in the literature that numerous studies have been undertaken on the production of briquettes from waste material as fuel in Nigeria, there have been few studies on the development of pellet fuels. Briquettes and pellets have several advantages over firewood. When used with a contemporary stove, they burn more cleanly. Despite being produced under high pressure and being denser than briquettes, pellets have less ash and moisture than briquettes and may be more economical to transport over greater distances [142]. However, Nigeria has not yet embraced briquette and pellet fuels for residential usage. However, as the need for solid fuel grows, it becomes increasingly important to develop briquette and pellet fuels from wood and agricultural waste and use them in Nigerian households, due to the numerous problems associated with using traditional biomass (firewood and charcoal) as the primary source of energy.

8. Conclusions

There has been an over-reliance on firewood and charcoal as a source of domestic fuel in both urban and rural areas of Nigeria. The main problem is that the trees fall out of balance to achieve this purpose. This review has shown the richness and potential of exploring different types of firewood and wood charcoal as domestic solid fuels. This review highlights the importance of understanding and considering firewood and wood charcoal as domestic solid fuels from a social health and environmental perspective. Therefore, the use of firewood and wood charcoal as domestic solid fuel poses a threat to the user’s health, as well as the climate and environment. This paper described the physical, mechanical and thermal properties of briquette and pellet fuels as alternatives to firewood and charcoal. According to the findings, using briquettes and pellets as a household solid fuel source will lessen the negative effects that firewood and wood charcoal have on the climate, environment and the health of their users. To decide on the use of the tested biomass as a solid biofuel, it is necessary to analyze the physicochemical properties of the biomass and ash from its combustion, the emission of flue gas composition and the risk of chloride corrosion in boilers.

Author Contributions

Conceptualization, G.Ł.; formal analysis, G.Ł. and A.R.I.; investigation, G.Ł. and A.R.I.; resources, A.R.I.; data curation, A.R.I.; writing—original draft preparation, G.Ł. and A.R.I.; writing—review and editing, G.Ł.; visualization, G.Ł. and A.R.I.; supervision, G.Ł.; project administration, G.Ł.; funding acquisition, G.Ł. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Education and Science of Poland, grant number WZ/WB-IIS/4/2023.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nnaji, M.; Eze, A.A.; Uzoma, C.C. Addressing Household Cooking Fuel Options in Nigeria. IOP Conf. Ser. Earth Environ. Sci. 2021, 730, 012038. [Google Scholar] [CrossRef]

- Staton, D.M.; Harding, M.H. Health and Environmental Effects of Cooking Stoves in Developing Countries. Available online: http://www.bioenergylists.org/stovesdoc/Environment/staton.pdf (accessed on 22 April 2023).

- Desalu, O.O.; Ojo, O.O.; Ariyibi, A.E.; Kolawole, T.F.; Ogunleye, A.I. Community Survey of the Pattern and Determinants of Household Sources of Energy for Cooking in Rural and Urban South-Western. Pan Afr. Med. J. 2012, 12, 12–17. [Google Scholar]

- Ehirm, C.N.; Osuji, E.E. Demand Analysis for Solid Fuel and Its Substitutes as Domestic Energy in Imo State, Nigeria: Application of Quadratic Almost Ideal Demand System (QUAIDS). Rev. Financ. Econ. 2020, 2, 39–54. [Google Scholar] [CrossRef]

- Barnes, D.F.; Floor, W.M. Rural energy in developing economies: A challenge for economic development. Annu. Rev. Energy Environ. 1996, 21, 497–530. [Google Scholar] [CrossRef]

- Tunde, A.M.; Adeleke, E.A.; Adeniyi, E.E. Impact of charcoal production on the sustainable development of Asa local government area, Kwara State, Nigeria. Ethiop. Int. J. Multidiscip. Res. 2013, 7, 1–5. [Google Scholar] [CrossRef]

- Sunday, Y.K.; Mohammed, F.Z. Briquettes from Agricultural Residues; An Alternative Clean and Sustainable Fuel for Domestic Cooking in Nasarawa State, Nigeria. Energy Power 2020, 10, 40–47. [Google Scholar] [CrossRef]

- Weinhold, B. Indoor PM pollution and elevated blood pressure: Cardiovascular impact of indoor biomass burning. Environ. Health Perspect. 2011, 119, A442. [Google Scholar] [CrossRef]

- Barnes, B.R. Behavioural Change, Indoor Air Pollution and Child Respiratory Health in Developing Countries: A Review. Int. J. Environ. Res. Public. Health 2014, 11, 4607–4618. [Google Scholar] [CrossRef]

- Smith, K.R.; Mehta, S. The burden of disease from indoor air pollution in developing countries: Comparison of estimates. Int. J. Hyg. Environ. Health 2003, 206, 279–289. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. Indoor Air Pollution—Our World in Data. 2019. Available online: https://ourworldindata.org/indoor-air-pollution (accessed on 22 November 2019).

- Frostard, J.J.; Nguyen, Q.P.; Baumann, M.M.; Blacker, B.F.; Marczak, L.B.; Deshpande, A.; Wiens, K.E.; Legrand, K.E.; Johnson, K.B.; Abbasi-Kangevari, M.; et al. Mapping development and health effects of solid fuels in low-income countries, 2000–2018: A geospatial modeling study. Lancet Glob. Health 2022, 10, e1395–e1411. [Google Scholar]

- Osano, A.; Maghanga, J.; Munyeza, C.; Chaka, B.; Olal, W.; Forbes, P. Insights into household fuel use in Kenyan communities. Sustain. Cities Soc. 2020, 55, 102039. [Google Scholar] [CrossRef]

- Lackner, M.; Palotás, Á.; Winter, F. Combustion: From Basics to Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013; Volume 1, p. 4. [Google Scholar]

- Rotowa, J.A.; Egbwole, Z.T.; Adeagbo, A.A.; Blessing, O.M. Effect of Indiscriminate Charcoal Production on Nigeria Forest Estate. Int. J. Environ. Protec. Policy 2019, 7, 134–139. [Google Scholar]

- Ogunsanwo, O.Y.; Attah, V.I.; Adenaiya, O.; Umar, M. Sustainable Utilization of Firewood as a Form of Energy in Nigeria. In Proceedings of the 37th Annual Conference of the Forestry Association of Nigeria held in Minna, Minna, Nigeria, 9–14 November 2018. [Google Scholar]

- Ibrahim, M.S.; Bello, S.; Ibrahim, A. Biomass briquettes as an alternative source of cooking fuel towards green recovery post-COVID-19. Saudi J. Engin. Technol. 2020, 5, 285–290. [Google Scholar]

- Bensch, G.; Jeuland, M.; Peters, J. Efficient biomass cooking in Africa for climate change mitigation and development. One Earth 2021, 4, 879–890. [Google Scholar] [CrossRef]

- Okoro, E.E.; Igwilo, K.C.; Sanni, E.S.; Orodu, K. A review on waste to biogas and its potential in Nigeria. Int. J. Eng. Technol. 2018, 7, 5960–5966. [Google Scholar]

- Tripathi, N.; Hills, C.D.; Singh, R.S.; Atkinson, C.J. Biomass Waste Utilisation in Low-Carbon Products: Harnessing a major potential resource. NPJ Clim. Atmos. Sci. 2019, 2, 35. [Google Scholar] [CrossRef]

- Asmare, M.; Alelign, B. Bahir Dar City Municipal Solid Waste Potential Assessment for Clean Energy. Am. J. Energy Eng. 2019, 7, 28–38. [Google Scholar] [CrossRef]

- Munyeza, C.F.; Osano, A.M.; Maghanga, J.K.; Forbes, P.B. Polycyclic aromatic hydrocarbon Gaseous Emissions from Household Cooking Devices: A Kenyan case study. Environ. Toxicol. Chem. 2020, 39, 538–547. [Google Scholar] [CrossRef] [PubMed]

- Food and Agricultural Organization (FAO). State of the World’s Forests Report; United Nations Food and Agriculture Organization: Rome, Italy, 2014. [Google Scholar]

- FAO. FAOSTAT (Dataset). Available online: http://faostat3.fao.org/ (accessed on 21 December 2016).

- Maurice, D.C.; Umar, Y.; Zubairu, E. Analysis of Factors Influencing Fuelwood Consumption in Some Selected Local Government Areas of Taraba State, Nigeria. J. Agric. Econ. Environ. Soc. Sci. 2017, 10, 163–168. [Google Scholar]

- Ebe, F.E. Socio-Economic Factors Influencing the Use of Fuelwood in Urban Areas of Enugu State, Nigeria. IOSR J. Bus. Manag. 2014, 16, 147–151. [Google Scholar] [CrossRef]

- Danlami, A.H. Assessment of factors influencing firewood consumption in Bauchi state, Nigeria. J. Sustain. Sci. Manag. 2019, 14, 99–109. [Google Scholar]

- Abdul-Hakim, I.K.; Ibrahim, Y. Socio-economic Factors Influencing Household Energy Choices in Kano Metropolis, Nigeria. Am. J. Energy 2018, 3, 10–17. [Google Scholar]

- Ebenezer, M.; Mukarumbwa, P.; Ojo, S.; Olalekan, O.S. Household Cooking Energy Situation in Nigeria: Insight from Nigeria Malaria Indicator Survey 2015. Int. J. Energy Econ. Policy 2018, 8, 284–291. [Google Scholar] [CrossRef]

- Gatama, M.N. Factors Influencing Household Energy Consumption: The Case of Biomass Fuels in Kikuyu District of Kiambu County, Kenya. Master’s Thesis, University of Nairobi, Nairobi, Kenya, 2014. [Google Scholar]

- Orimoogunje, O.I.; Asifat, J. Fuel Wood Consumption and Species Degradation in South-Western Nigeria: The Ecological Relevance. J. Landsc. Ecol. 2015, 8, 56–68. [Google Scholar] [CrossRef]

- Egbewole, Z.T.; Rotowa, O.J. Hike in Pump Price: Major Doom to Nigerian Forest. J. Energy Environ. Chem. Eng. 2018, 3, 19–26. [Google Scholar] [CrossRef]

- Kambewa, P.; Mataya, B.; Sichinga, K.; Johnson, T. Charcoal: The Reality—A Study of Charcoal Consumption, Trade and Production in Malawi; Small and Medium Forestry Enterprise Series No 21; International Institute for Environment and Development: London, UK, 2007. [Google Scholar]

- Kaale, B.K. Baseline Study on Biomass Energy Conservation in Tanzania; SADC Programme for Biomass Energy Conservation (ProBEC) Report: 55; Ministry of Energy and Minerals Report: Gaborone, Botswana, 2005. [Google Scholar]

- Rehfuess, E.A.; Bruce, N.G.; Smith, K.R. Solid Fuel Use: Health Effect; Elsevier B.V: Amsterdam, The Netherlands, 2011; pp. 151–161. [Google Scholar]

- Enyejo, L.A.; Kwaghger, A.; Nyior, G.B. Investigation of Combustion Properties of Some Selected Fuelwood Species in Nigeria. Elixir Mech. Eng. 2018, 114, 49587–49593. [Google Scholar]

- Abbasi, T.; Abbasi, S.A. Biomass energy and the environmental impacts associated with its production and utilization. Renew. Sustain. Energy Rev. 2010, 14, 919–937. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Huhtinen, M. Wood Energy: Wood as a Fuel; Materials for 5 EURES Training Sessions, NCP; Emerald Group Publishing Limited: Bingley, UK, 2009. [Google Scholar]

- Yang, Y.B.; Sharifi, V.N.; Swithenbank, J. Effect of air flow rate and fuel moisture on the burning behaviours of biomass and simulated municipal solid wastes in packed beds. Fuel 2004, 83, 1553–1562. [Google Scholar] [CrossRef]

- Meng, X.; Sun, R.; Ismail, T.M.; Zhou, W.; Ren, X.; Zhang, R. Parametric studies on corn straw combustion characteristics in a fixed bed: Ash and moisture content. Energy 2018, 158, 192–203. [Google Scholar] [CrossRef]

- Price-Allison, A.; Lea-Langton, A.R.; Mitchell, E.J.S.; Gudka, B.; Jones, J.M.; Mason, P.E.; Williams, A. Emissions performance of high moisture wood fuels burned in a residential stove. Fuel 2019, 239, 1038–1045. [Google Scholar] [CrossRef]

- Shen, G.; Xue, M.; Wei, S.; Chen, Y.; Zhao, Q.; Li, B.; Wu, H.; Tao, S. Influence of fuel moisture, charge size, feeding rate and air ventilation conditions on the emissions of PM, OC, EC, parent PAHs, and their derivatives from residential wood combustion. J. Environ. Sci. 2013, 25, 1808–1816. [Google Scholar] [CrossRef]

- Bignal, K.T.; Langridge, S.; Zhou, J.L. Release of polycyclic aromatic hydrocarbons, carbon monoxide and particulate matter from biomass combustion in a wood-fired boiler under varying boiler conditions. Atmos. Environ. 2008, 42, 8863–8871. [Google Scholar] [CrossRef]

- Striugas, N.; Vorotinskiene, L.; Paulauskas, R.; Navakas, R.; Dziugys, A.; Narbutas, L. Estimating the fuel moisture content to control the reciprocating grate furnace firing wet woody biomass. Energy Convers. Manag. 2017, 149, 937–949. [Google Scholar] [CrossRef]

- Vassilev, S.; Baxter, D.; Andersen, L.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Baxter, D. Trace element concentrations and associations in some biomass ashes. Fuel 2014, 129, 292–313. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Barnthaler, G. Chemical properties of solid biofuels significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Song, Y.C.; Li, W.Y.; Feng, J. Ash contents and ash-forming elements of biomass and their significance for solid biofuel combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash. Part 1. Phase–mineral and chemical composition and classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Vassilev, V.S. Advantages and disadvantages of composition and properties of biomass in comparison with coal. Fuel 2015, 158, 330–350. [Google Scholar] [CrossRef]

- Zając, G.; Maj, G.; Szyszlak-Bargłowicz, J.; Słowik, T.; Krzaczek, P.; Gołębiowski, W.; Dębowski, M. Evaluation of the properties and usefulness of ashes from the corn grain drying process biomass. Energies 2020, 13, 1290. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical characteristics of biomass ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef]

- Khan, A.A.; de Jong, W.; Jansens, P.J.; Spliethoff, H. Biomass combustion in fluidized bed boilers: Potential problems and remedies. Fuel Process. Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- Ren, X.; Sun, R.; Chi, H.H.; Meng, X.; Li, Y.; Levendis, Y.A. Hydrogen chloride emissions from combustion of raw and torrefied biomass. Fuel 2017, 200, 37–46. [Google Scholar] [CrossRef]

- Yanik, J.; Duman, G.; Karlström, O.; Brink, A. NO and SO2 emissions from combustion of raw and torrefied biomasses and their blends with lignite. J. Environ. Manag. 2018, 227, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Fan, W.; Wu, X.; Zhang, X. Chlorine-induced high-temperature corrosion of boiler steels combusting sha erhu coal compared to biomass. Energy Fuel 2018, 32, 4237–4247. [Google Scholar] [CrossRef]

- Evbuomwan, B.O.; Okorji, C.J. Determination of the Fuel Wood Properties of Selected Nigerian Wood Trees. GSJ 2018, 6, 1019–1033. [Google Scholar]

- Akinlosotu, O.L.O.; Balogun, B.A.O.; Abdulkarim, R.; Osueke, C. Thermal and Physico-Chemical Characterization of Charcoal Produced in Kwara State, Nigeria. Int. J. Mech. Eng. Technol. 2019, 10, 883–889. [Google Scholar]

- Aliyu, M.; Birnin-Yauri, A.U.; Elinge, C.M.; Ige, A.R. Proximate, Minerals and Anti-nutritional Composition of Daniellia oliveri tender leaves. Int. J. Adv. Chem. 2022, 10, 24–28. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Motghare, K.A.; Rathod, A.P.; Wasewar, K.L.; Labhsetwar, N.K. Comparative study of different waste biomass for energy application. Waste Manag. 2016, 47, 40–45. [Google Scholar] [CrossRef]

- Ozyuguran, A.; Yaman, S. Prediction of Calorific Value of Biomass from Proximate Analysis. Energy Procedia 2017, 107, 130–136. [Google Scholar] [CrossRef]

- Ozyuguran, A.; Akturk, A.; Yaman, S. Optimal use of condensed parameters of ultimate analysis to predict the calorific value of biomass. Fuel 2018, 214, 640–646. [Google Scholar] [CrossRef]

- Tabakaev, R.; Shanenkov, I.; Kazakov, A.; Zavorin, A. Thermal processing of biomass into high-calorific solid composite fuel. J. Anal. Appl. Pyrolysis 2017, 124, 94–102. [Google Scholar] [CrossRef]

- Gillespie, G.D.; Everard, C.D.; McDonnell, K.P. Prediction of biomass pellet quality indices using near-infrared spectroscopy. Energy 2015, 80, 582–588. [Google Scholar] [CrossRef]

- Mancini, M.; Rinnan, Å.; Pizzi, A.; Toscano, G. Prediction of gross calorific value and ash content of woodchip samples by means of FT-NIR spectroscopy. Fuel Process. Technol. 2018, 169, 77–83. [Google Scholar] [CrossRef]

- Mustafa, B.G.; Kiah, M.H.M.; Irshad, A.; Andrews, G.E.; Phylaktou, H.N.; Li, H.; Gibbs, B.M. Rich biomass combustion: Gaseous and particle number emissions. Fuel 2019, 248, 221–231. [Google Scholar] [CrossRef]

- Mółka, J.; Łapczyńska-Kordon, B. Energy properties of selected biomass species. Agric. Eng. 2011, 15, 141–147. [Google Scholar]

- Oke, M.A.; Sonibare, J.A.; Onakpohor, A.; Odunlami, O.A.; Akeredolu, F.A.; Elehinafe, F.B. Proximate analysis of some common charcoal in Southwestern Nigeria. Res. Eng. 2022, 15, 100454. [Google Scholar] [CrossRef]

- Adamu, H.; Sabo, A.; Chinade, A.A.; Lame, F.A. Exploration of Influence of Chemical Composition on Combustion and Fuel Characteristics of Wood- Charcoals Commonly Used in Bauchi State, Nigeria. Int. J. Renew. Energy Res. 2018, 8, 1508–1519. [Google Scholar]

- Demirbas, A. Relationships between heating value and lignin, moisture, ash and extractive contents of biomass fuels. Energy Explor. Exploit. 2002, 20, 105–111. [Google Scholar] [CrossRef]

- Akinbami, J. An integrated strategy for sustainable forest-energy-environment interactions in Nigeria. J. Environ. Manag. 2003, 6, 115–280. [Google Scholar] [CrossRef]

- IEA. Africa Energy Outlook: A Focus on Energy Prospects in Sub-Saharan Africa; International Energy Agency (IEA): Paris, France, 2014. [Google Scholar]

- Lyngfelt, A.; Brink, A.; Langørgen, Ø.; Mattisson, T.; Rydén, M.; Linderholm, C. 11,000 h of Chemical-Looping Combustion Operation—Where Are We and Where Do We Want to Go? Int. J. Greenh. Gas Control 2019, 88, 38–56. [Google Scholar] [CrossRef]

- FAO. Global Forest Resources Assessment Report 2020, Nigeria. 2020. Available online: https://www.fao.org/3/cb0037en/cb0037en.pdf (accessed on 8 May 2023).

- FAO. Forestry Production and Trade. Food and Agricultural Organization of the United Nations. FAOstat. 2020. Available online: http://www.fao.org/faostat/en/#data/FO (accessed on 8 May 2023).

- The Federal Republic of Nigeria; National Forest Policy; Federal Ministry of Environment: Abuja, Nigeria, 2006.

- Chomini, E.A.; Henry, M.U.; Daspan, A.J.; Agbaje, I.O.; Ameh, M.A.; Osasebor, F.O.; Vihi, S.K.; Chomini, M.S. Perception of the Impact of Fuel Wood and Charcoal Productions on the Environment: A Case Study of Toro L.G.A of Bauchi State, Nigeria. J. Appl. Sci. Environ. Manag. 2022, 26, 1665–1668. [Google Scholar] [CrossRef]

- Deforestation Statistics for Nigeria (Dataset). 2021. Available online: https://rainforests.mongabay.com/deforestation/archive/Nigeria.htm (accessed on 14 May 2021).

- Allen, M.R.; Gillett, N.P.; Kettleborough, J.A. Quantifying anthropogenic influence on recent near-surface temperature change. Surv. Geophys. 2006, 27, 491–544. [Google Scholar] [CrossRef]

- Lorenz, K.; Lal, R. Carbon Sequestration in Forest Ecosystems; Springer: New York, NY, USA, 2010; p. 277. [Google Scholar]

- Gupta, R.B.; Demirbas, A. GDE Gasoline, Diesel and Ethanol Biofuels from Grasses and Plants; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Molcan, P.; Lu, B.; Bris, T.; Le, Y.Y.; Taupin, B.; Caillat, S. Characterisation of biomass and coal co-firing on a 3 MWth Combustion Test Facility using flame imaging and gas/ash sampling techniques. Fuel 2009, 88, 2328–2334. [Google Scholar] [CrossRef]

- Avila, C.; Pang, C.H.; Wu, T.; Lester, E. Morphology and reactivity characteristics of char biomass particles. Bioresour. Technol. 2011, 102, 5237–5243. [Google Scholar] [CrossRef] [PubMed]

- Turkenburg, W.C. Renewable energy technologies. In World Energy Assessment: Energy and the Challenge of Sustainability an Overview, 1st ed.; Goldemberg, J., Ed.; United Nations Development Programme: New York, NY, USA, 2000; pp. 219–224. [Google Scholar]

- Hoogwij, M.M.; Faaij, A.P.C.; van den Broek, R.; Berndes, G.; Gielen, D.; Turkenburg, W.C. Exploration of the ranges of the global potential of biomass for energy. Biomass Bioenergy 2003, 25, 119–133. [Google Scholar] [CrossRef]

- Faaij, A.P.C. Bio-energy in Europe: Changing technology choices. Energy Policy 2006, 34, 322–342. [Google Scholar] [CrossRef]

- Hamelinck, C.N.; Faaij, A.P.C. Outlook for advanced biofuels. Energy Policy 2006, 34, 3268–3283. [Google Scholar] [CrossRef]

- Otu-Danquah, K.A. Current status of charcoal demand and supply and initiation on improved cook stoves. In Proceedings of the A Presentation Made during the Kick-Off Meeting for TEC/ESMAP Survey on Energy Access and Productive Uses for the Urban Poor Was Held in the SSNIT Guest House Conference Room, Accra Ghana, Africa, 11 August 2010. [Google Scholar]

- UNCCD. Land Degradation Neutrality Resilience at Local, National and Reional Levels; United Nations Convention to Combact Desertification: Bonn, Germany, 2015. [Google Scholar]

- McCarron, A.; Unyb, I.; Caesc, L.; Lucasd, S.E.; Sempleb, S.; Ardreye, J.; Price, H. Solid fuel users’ perceptions of household solid fuel use in low- and middle-income countries: A scoping review. J. Environ. Inter. 2020, 143, 105991. [Google Scholar] [CrossRef]

- World Health Organization. Burning Opportunity: Clean Household Energy for Health, Sustainable Development and Well-Being of Women and Children; Word Health Organization: Geneve, Switzerland, 2016. [Google Scholar]

- Sufiyan, I.; Muhammad, K.D.; Umar Musa, U. Appraisal of Per Capita Consumption of Charcoal and Firewood as an Alternative Energy Sources for Domestic Usage in Keffi Nasarawa State Nigeria. J. Wastes Biomass Manag. 2021, 3, 22–26. [Google Scholar] [CrossRef]

- Adegoke, I.A.; Ogunsanwo, O.Y. Impact of Charcoal Production on Environmental Sustainability in the Derived Savannah Belt of South West Nigeria. In Proceedings of the 34th Forestry Association Nigeria Conference (FAN), Nigeria, Africa, 5–10 December 2011; pp. 453–460. [Google Scholar]

- Gustavo, B. Burning Firewood and Charcoal Indoors. Air Pollution and Risks. 2017, pp. 1–45. Available online: http://www.conceito-online.com.br (accessed on 15 April 2023).

- Jekayinfa, S.O.; Omisakin, O.O. The Energy Potentials of Some Agricultural Wastes as Local Fuel Materials in Nigeria. Agricultural Engineering International. CIGR E-J. Sci. Res. Dev. 2005, 3, 1–10. [Google Scholar]

- Kaltschmitt, M. Renewable energy from biomass, Introduction. In Renewable Energy Systems; Kaltschmitt, M., Themelis, N.J., Bronicki, L.Y., Söder, L., Vega, L.A., Eds.; Springer: New York, NY, USA, 2013. [Google Scholar]

- Jekayinfa, S.O.; Scholz, V. Potential Availability of Energetically Usable Crop Residues in Nigeria. Energy Sources 2009, 31, 687–697. [Google Scholar] [CrossRef]

- Oladeji, J.T.; Enweremadu, C.C.; Olafimihan, E.O. Conversion of Agricultural Wastes into Biomass Briquettes. IJAAAR 2009, 5, 116–123. [Google Scholar]

- Ige, A.R.; Elinge, C.M.; Hassan, L.G.; Adegoke, I.A.; Ogala, H. Effect of Binder on Physico-chemical Properties of Fuel Briquettes Produced from Watermelon Peels. AASCIT J. Energy 2018, 5, 23–27. [Google Scholar]

- Hakizimana, E.; Wali, U.G.; Sandoval, D.; Venant, K. Environmental Impacts of Biomass Energy Sources in Rwanda. Energy Environ. Eng. 2020, 7, 62–71. [Google Scholar] [CrossRef]

- El-Saeidy, E.A. Technological Fundamentals of Briquetting Cotton Stalks as a Bio-Fuel. An Unpublished. Ph.D. Thesis, Faculty of Agriculture and Horticulture, Humboldt University, Humboldt, Germany, 2014. [Google Scholar]

- Jiang, L.; Liang, J.; Yuan, X.; Li, H.; Li, C.; Xiao, Z. Co-pelletization of sewage sludge and biomass: The density and hardness of pellet. Bioresour Technol 2014, 166, 435–443. [Google Scholar] [CrossRef]

- Okello, C.; Pindozzi, S.; Faugna, S.; Boccia, L. Development of Bioenergy Technologies in Uganda: A Review of Progress. Renew. Sust. Energy Rev. 2013, 18, 55–63. [Google Scholar] [CrossRef]

- Santana, D.A.R.; Scatolino, M.V.; Lima, M.D.R.; de Oliveira Barros, U., Jr.; Garcia, D.P.; Andrade, C.R.; de Cassia Oliveira Carneiro, A.; Trugilho, P.F.; de Paula Protásio, T. Pelletizing of lignocellulosic wastes as an environmentally friendly solution for the energy supply: Insights on the properties of pellets from Brazilian biomasses. Environ. Sci. Pollut. Res. 2021, 28, 11598–11617. [Google Scholar] [CrossRef]

- Szymajda, A.; Łaska, G.; Joka, M. Assessment of Cow Dung Pellets as a Renewable Solid Fuel in Direct Combustion Technologies. Energies 2021, 14, 1192. [Google Scholar] [CrossRef]

- Kaur, A.; Roy, M.; Kundu, K. Densification of Biomass by Briquetting: A Review. Int. J. Recent. Sci. Res. 2017, 8, 20561–20568. [Google Scholar]

- Surendra, K.C.; Khanal, S.K.; Shrestha, P.; Lamsal, B. Current status of renewable energy in Nepal: Opportunities and challenges. Renew. Sustain. Energy Rev. 2011, 15, 4107–4117. [Google Scholar]

- Mwampamba, T.H.; Owen, M.; Pigaht, M. Opportunities, challenges and way forward for the charcoal briquette industry in Sub-Saharan Africa. Energy Sustain. Dev. 2013, 17, 158–170. [Google Scholar] [CrossRef]

- Sultana, A.; Kumar, A. Ranking of biomass pellets by integration of economic, environmental and technical factors. Biomass Bioenergy 2012, 39, 344–355. [Google Scholar] [CrossRef]

- Bamisaye, A.; Ige, A.R.; Adegoke, A.I.; Idowu, M.A.; Elinge, C.M. Evaluation and Characterization of the Combustion Properties of Alkaline Pretreated Bio-solid fuel derived from Cabbage Waste. Biomass Convers. Biorefin. 2022, 22, 1–11. [Google Scholar] [CrossRef]

- Adegoke, I.A.; Ige, A.R.; Bamisaye, A.; Elinge, C.M.; Olubunmi, O.A. Effect of Alkaline Delignification on Physico-chemical and Combustion Properties of Bean Chaff Briquette. Asian J. Trop. Biotechnol. 2022, 19, 20–27. [Google Scholar] [CrossRef]

- Ige, A.R.; Bamisaye, A. Production and Characterisation of Briquettes from Maize Stalk and Neem Leaves Admixture. Acta Chem. Malays. 2021, 5, 177–181. [Google Scholar] [CrossRef]

- Ige, A.R.; Ogala, H.; Elinge, C.M.; Abdulrahman, H. The Effect of Binder Ratio on the Physical and Combustion Characteristics of Carbonized Rice Stalk Briquettes. Int. J. Adv. Acad. Res. 2020, 6, 221–229. [Google Scholar] [CrossRef]

- Elinge, C.M.; Oyibo, M.C.; Birnin Yauri, A.U.; Ige, A.R.; Yakubu, Y.; Ogunleye, A.O. Enhancing the Properties of Water Hyacinth Biomass Briquettes by Mercerization Process. Int. Res. J. Pure Appl. Chem. 2020, 21, 43–55. [Google Scholar] [CrossRef]

- Ahmed, M.A.; Elinge, C.M.; Ibrahim, G.W.; Ige, A.R. Production and Characterization of Fuel Briquettes from Bambara Nut Shell and Soya Bean Shell. Int. J. Acad. Res. 2020, 6, 2488–9849. [Google Scholar]

- Ige, A.R.; Elinge, C.M.; Aliyu, M.; Gwani, M.; Ambursa, M.M. Production and Characterization of Bio-briquettes from Biochar Derived Pyrolysis of Rice Husk. Acta Chem. Malays. 2022, 6, 52–57. [Google Scholar] [CrossRef]

- Ige, A.R.; Elinge, C.M.; Aliyu, M.; Gwani, M.; Hassan, L.G.; Birnin-Yauri, A.U. Physico-chemical and Combustion Analysis of Bio-Briquettes from Biochar Produced from Pyrolysis of Groundnut Shell. Int. J. Adv. Chem. 2021, 9, 74–79. [Google Scholar]

- Ige, A.R.; Elinge, C.M.; Hassan, L.G.; Adegoke, I.A.; Ogala, H. Effect of Binder on the Physico-chemical Properties of Fuel Briquettes Produced from Sugarcane Peels at Ambient Temperature and Die Pressure. AASCIT J. Energy 2018, 5, 28–31. [Google Scholar]

- Bamisaye, A.; Ige, A.R.; Adegoke, I.A.; Ogunbiyi, E.O.; Bamidele, M.O.; Adeleke, O.; Adegoke, K.A. Eco-friendly de-lignified and raw Celosia argentea waste solid biofuel: Comparative studies and machine learning modeling. Fuel 2023, 340, 1–12. [Google Scholar] [CrossRef]

- Adegoke, I.A.; Ige, A.R.; Audu, M. Combustion Quality Evaluation of Briquettes Produced from Sesame Hull as Source of Sustainable Energy. Asian J. Energy Trans. Conserv. 2020, 4, 20–39. [Google Scholar] [CrossRef]

- Elinge, C.M.; Birnin-Yauri, A.U.; Senchi, D.S.; Ige, A.R.; Ajakaye, J.; Yusuf, A.; Abubakar, R.K. Studies of the Combustion Profile of Briquettes Produced from Carbonized Rice Husk Using Different Binders at Moderate Temperature and Die Pressure. Int. J. Adv. Acad. Res. 2019, 5, 70–77. [Google Scholar]

- Li, H.; Jiang, L.B.; Li, C.Z.; Liang, J.; Yuan, X.Z.; Xiao, Z.H. Co-pelletization of sewage sludge and biomass: The energy input and properties of pellets. Fuel Process. Technol. 2015, 132, 55–61. [Google Scholar] [CrossRef]

- Tumuluru, S.J.; Christopher, W.T.; Kenny, K.L.; Hess, J.R. A Review on Biomass Densification Technologies for Energy Application. 2010. Available online: https://www.osti.gov/biblio/1016196 (accessed on 3 May 2023).

- Stolarski, M.J.; Szczukowski, S.; Tworkowski, J.; Krzyzaniak, M.; Gulczyński, P.; Mleczek, M. Comparison of quality and production cost of briquettes made from agricultural and forest origin biomass. Renew. Energy 2013, 57, 20–26. [Google Scholar] [CrossRef]

- Bamisaye, A.; Ige, A.R. Effect of binder type on the NaOH-treated briquettes produced from banana leaves. Biomass Convers. Biorefin. 2021, 21, 1–9. [Google Scholar] [CrossRef]

- Olawale, J.O.; Abdulkadir, B.H.; Barakat, J.I. Effect of starch and gum Arabic binders in the combustion characteristics of Briquettes prepared from sawdust. Int. J. Sci. Eng. Res. 2014, 5, 1–10. [Google Scholar]

- Enweremadu, C.C.; Ojediran, J.O.; Oladeji, O.J.; Afolabi, I.O. Evaluation of energy potential of husks from soya beans and cow pea. Sci. Focus. 2004, 8, 18–23. [Google Scholar]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. Production and Characterization of Hybrid Briquettes from Corncobs and Oil Palm Trunk Bark under a Low-Pressure Densification Technique. Sustainability 2020, 12, 2468. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Effect of pellet die diameter on density and durability of pellets made from high moisture woody and herbaceous biomass. Carbon. Resour. Convers. 2018, 1, 44–54. [Google Scholar] [CrossRef]

- Efomah, A.N.; Gbabo, A. The Physical, Proximate and Ultimate Analysis of Rice Husk Briquettes Produced from a Vibratory Block Mould Briquetting Machine. IJISET Int. J. Innov. Sci. Eng. Technol. 2015, 2, 814–822. [Google Scholar]

- Gaur, S.; Reed, T. Thermal Data For Natural and Synthetic Fuels; Marcel Dekker: New York, NY, USA, 1998; 259p. [Google Scholar]

- Greinert, A.; Mrówczyńska, M.; Szefner, W. The Use of Waste Biomass from the Wood Industry and Municipal Sources for Energy Production. Sustainability 2019, 11, 3083. [Google Scholar] [CrossRef]

- Nazemi, M.; Unnthorsson, R.; Richter, C. Seaweed Pellets as a Renewable Fuel Feedstock. Biomass 2023, 3, 78–95. [Google Scholar] [CrossRef]

- Theerarattananoon, K.; Xua, F.; Wilson, J.; Ballardc, R.; Mckinneyb, L.; Staggenborgc, S.; Vadlanib, P.; Peid, Z.J.; Wang, D. Physical properties of pellets made from sorghum stalk, corn stover, wheat straw, and big bluestem. Ind. Crops Prod. 2011, 33, 325–332. [Google Scholar] [CrossRef]

- Oveisi-Fordiie, E. Durability of Wood Pellets; University of British Columbia: Vancouver, BC, Canada, 2011. [Google Scholar]

- Temmerman, M.; Rabier, F.; Jensen, P.D.; Hartmann, H.; Böhm, T. Comparative study of durability test methods for pellets and briquettes. Biomass Bioenergy 2006, 30, 964–972. [Google Scholar] [CrossRef]

- Carroll, J.P.; Finnan, J. Physical and chemical properties of pellets from energy crops and cereal straws. Biosyst. Eng. 2012, 112, 151–159. [Google Scholar] [CrossRef]

- Iftikhar, M.; Sghar, A.; Ramzan, N.; Sajjadi, B.; Chen, W. Biomass densification: Effect of cow dung on the physicochemical properties of wheat straw and rice husk based biomass pellets. Biomass Bioenergy 2019, 122, 1–16. [Google Scholar] [CrossRef]

- Kofman, P.D. Review of Worldwide Standards for Solid Biofuels; Council for Forest Research and Development: Processing/Products, CONFORD Connects Publishing: Dublin, Ireland, 2016. [Google Scholar]

- Japhet, J.A.; Luka, B.S.; Maren, I.B.; Datau, S.G. The Potential of Wood and Agricultural Waste for Pellet Fuel Development in Nigeria—A Technical Review. Int. J. Eng. Appl. Sci. Technol. 2020, 4, 598–607. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).