1. Introduction

The combustion of fossil fuels has severe disadvantages. The oil depletion time is less than 30 years [

1], the Earth’s climate system has likely been affected [

2], and negative health impacts are expressed in the literature [

3]. Part of the solution is to stop running trucks on fossil fuels. Several studies have concluded that battery electric trucks could become a cost-efficient, fossil-free alternative to today’s commercial diesel trucks [

4,

5,

6,

7,

8]. However, the cost-effectiveness of battery electric trucks is sensitive to driving patterns [

4,

9], and relatively uniform driving patterns are best suited to electrification [

4,

10]. Another possible solution is hydrogen trucks, but recently published studies favour battery electric ones [

11,

12]. The feasibility of battery electric trucks seems promising, but fuel cells might be better for heavy-duty trucks on extra long journeys [

13]. Thus, there is no unambiguous answer to the question of which power train results in the lowest total cost of ownership; this will depend on how the vehicle is used [

14]. The literature also highlights other important factors for cost-effective battery electric vehicles, such as the battery price [

15,

16] and size [

4,

17]. Moreover, the price of public fast charging could strongly impact the cost-effectiveness, battery sizing and charging strategy [

5]. The charger utilisation must be high enough for the installation to be worthwhile [

18] and is a prerequisite for cheap public fast charging [

5]. Some advantages of increased fees during rush hours were presented in a previous study [

19], including a better meeting of demand, avoiding queues and increased profit. However, is it possible to achieve high charger utilisation and simultaneously high charger availability? This question was highlighted as important to future research in a recently published study [

5] and will be investigated in the present one.

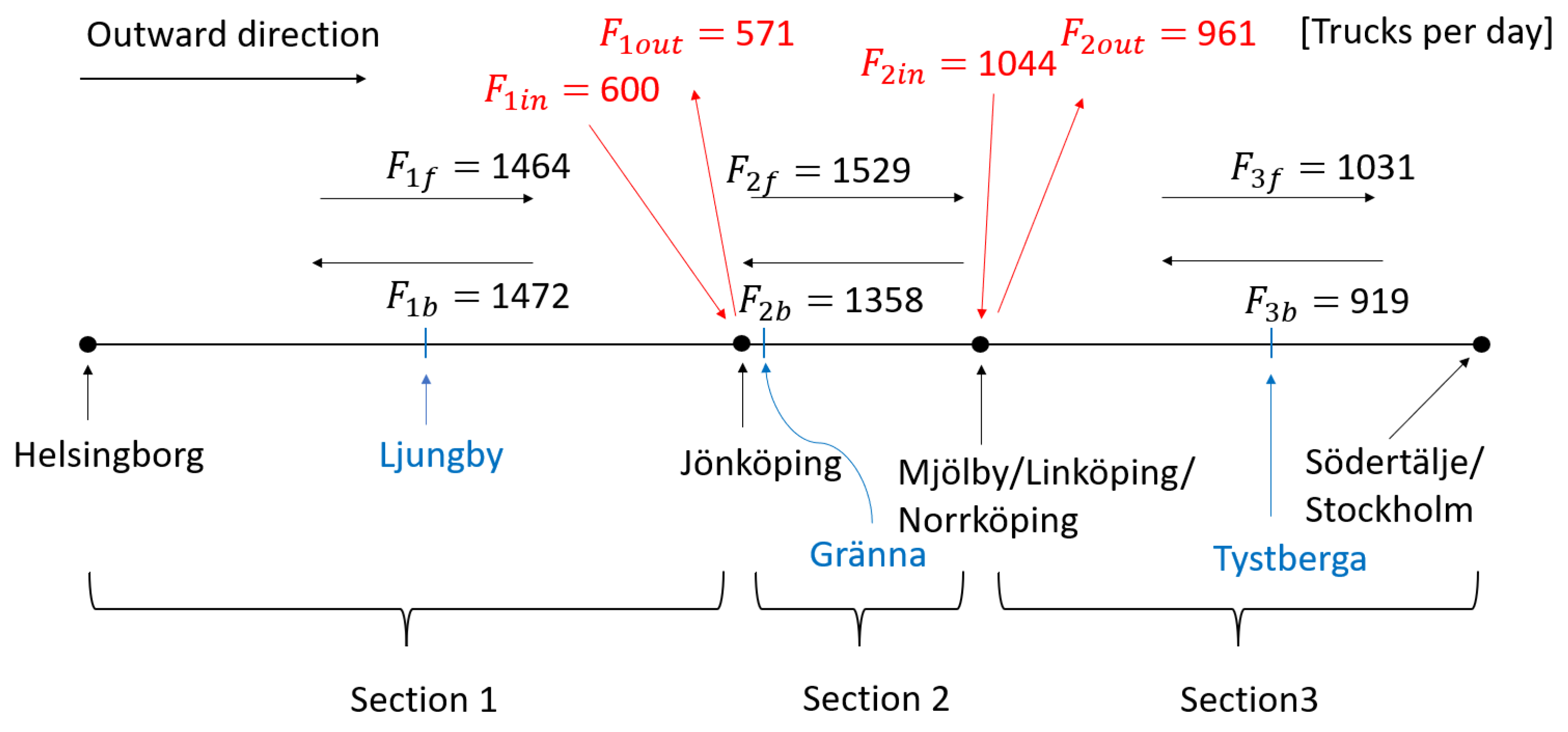

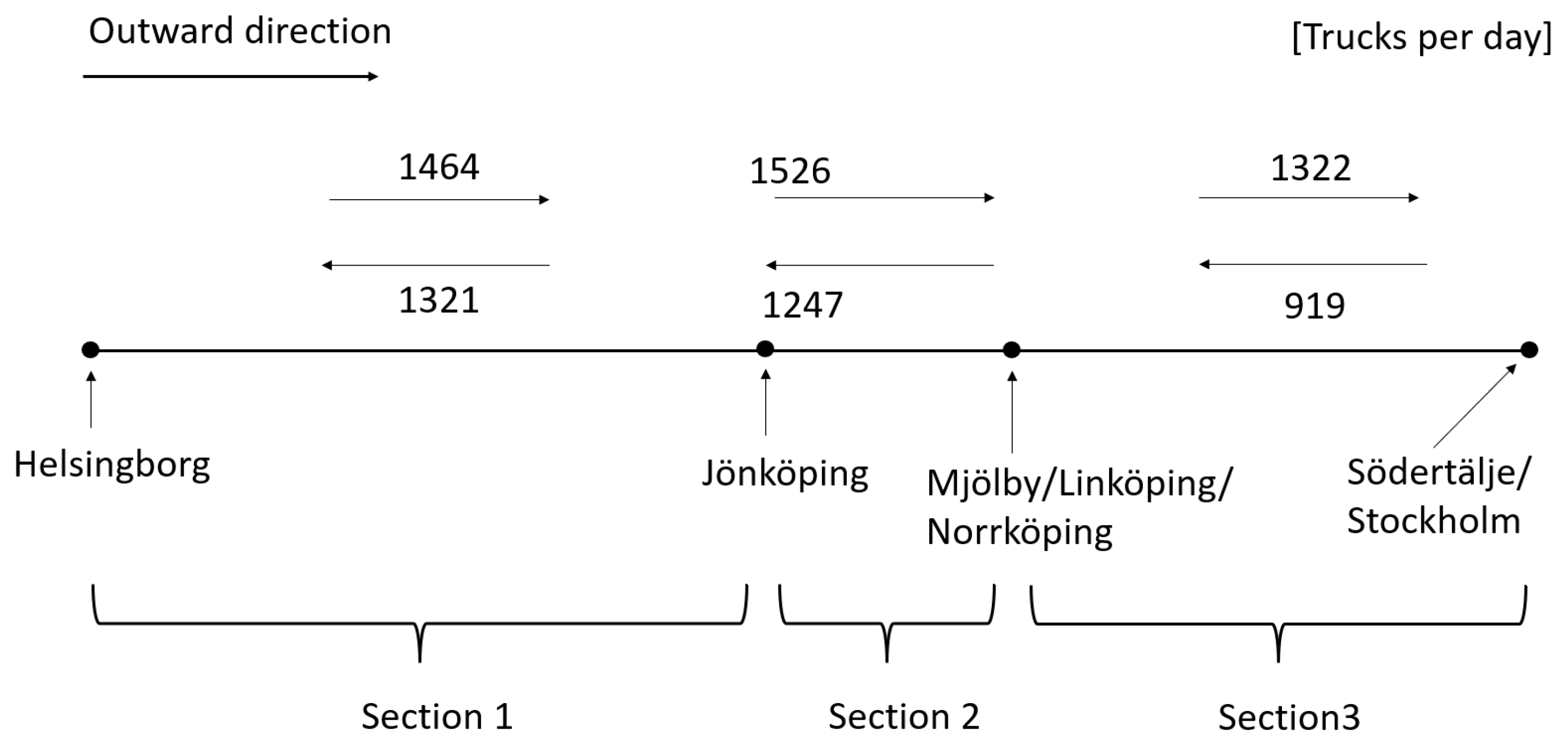

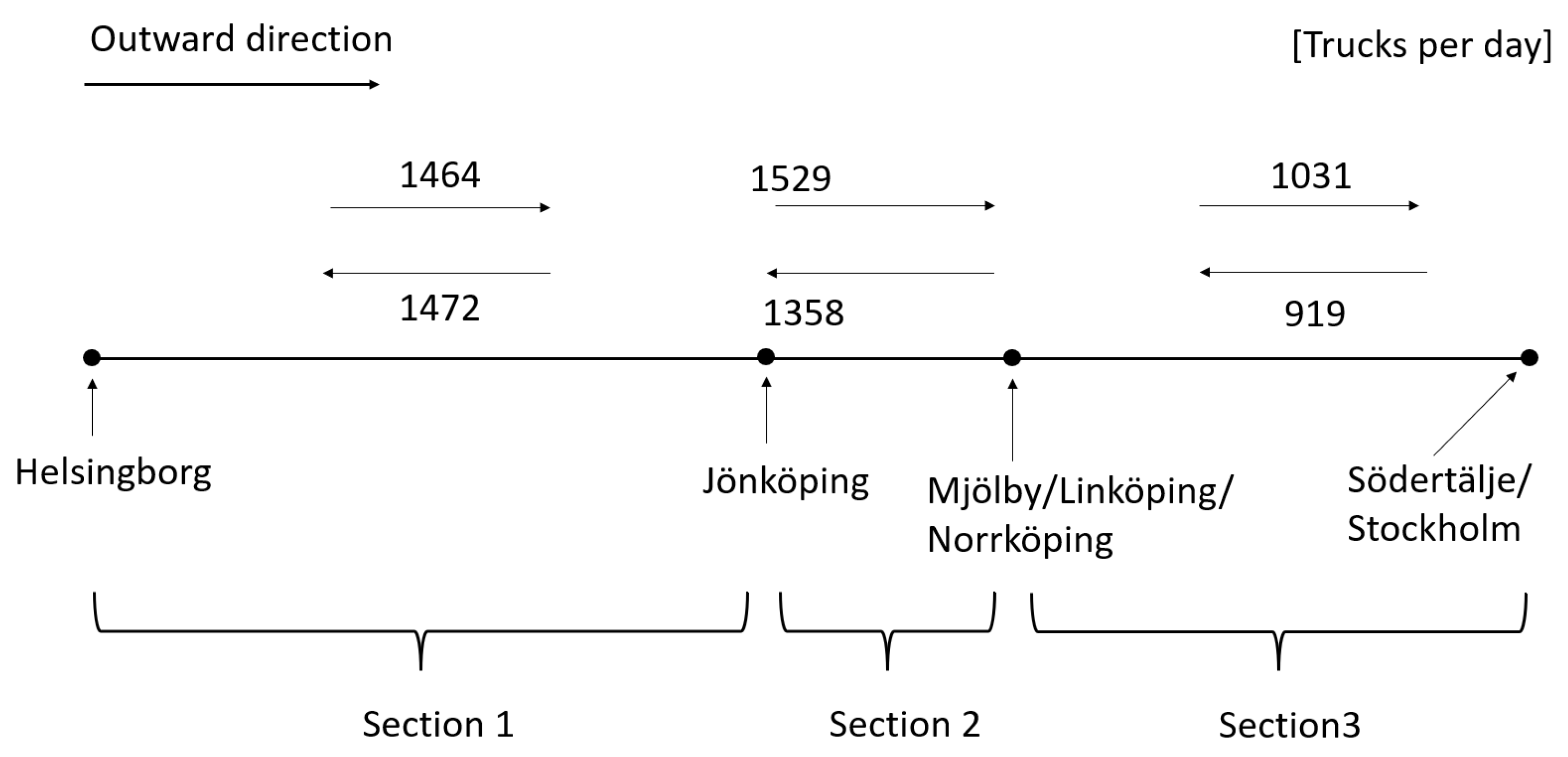

This paper aims to investigate the charging need, the utilisation of public fast chargers and the potential queuing problems at charging stations along the highway between the Swedish cities of Helsingborg and Stockholm, if all trucks currently driving on that road were battery electric. Helsingborg is located on Sweden’s west coast, while Stockholm (the capital) is located on the east coast. The two cities are connected by the E4 highway, and the distance between them is given as 553 km by Google Maps, with the E4 shown as a wavy blue line on the map in

Figure 1. The investigations were made using an agent-based model in which each truck counts as one agent. Each truck will have a starting location with a set departure time and state of charge (SoC), plus a set destination with a required SoC upon reaching it. However, the agents will choose where to charge according to a set of rules. This paper focuses on analysing long-haul trucks and we mean only them when referring to “traffic flow”. Where the trucks start and stop, when they start and how many there are have been derived from data from the Swedish Transport Administration [

20]. The aim is for this traffic flow to approximate the traffic flow for a typical weekday. The data, the traffic flow produced and the agent-based model will be presented in detail in subsequent sections. An agent-based model was used because it is hard to determine the outcome on a system level from a macroscopic model, but it is much easier to set up reasonable rules for each truck. The agent-based model provides an opportunity to obtain macroscopic results and to draw system conclusions just by designing rules on the microscopic level.

The main results of this paper are that the future system of electric trucks and charging stations along the studied road apparently has the potential to charge all the trucks with a high charger utilisation rate, few problems with queuing and robustness concerning increased traffic flow or unexpected peaks.

3. Description of the Agent-Based Model

3.1. Assumptions

The model tries to predict how battery electric trucks will charge on the highway between Helsingborg on Sweden’s west coast and Stockholm on its east cost. However, the problem only considers one road and does not consider the full road network. This is necessary and reasonable in order to keep the scope of the problem reasonable and to expend a sensible amount of work investigating it. Limiting the problem also makes it easier to explore basic behaviour. The road has a length of km. All the trucks in the simulation have a useful battery capacity of kWh, a speed of km/h and an energy consumption of kWh/km. In reality, these three last mentioned parameters are not the same for all trucks. However, we think that these values are representative for the mean value of future heavy electric trucks. Since we analyse a big fleet of trucks, much of the random individual variations from the mean values will cancel on a system level. Still, there are systematic variations in energy consumption, such as during days when there is heavy rain. Such effects are not modelled, and the utilisation of chargers and batteries will be a little lower if such variations are included. To ensure good initial conditions, the model is run through a typical day twice, starting with empty charging stations. The results presented are from the second of the two days. The prices for charging are the same for the two days and for the day after the second day (some of the trucks will decide whether to charge at the end of the typical day or at the beginning of the next day). Each truck in the simulation has a starting location and a destination in Helsingborg, Jönköping, Linköping or Stockholm. Each truck enters the highway at a certain time with a certain SoC and has an individual SoC requirement at its destination. However, none of the trucks enter the highway with less than 50% SoC, and no truck has to have more than 40% remaining SoC when it exits the highway. The aim is to represent a typical weekday; the traffic flow used in the simulation was presented in the previous section.

In reality, there are laws controlling how long drivers can drive. For example, drivers must take a break after no more than 4.5 h of driving. This constraint is not implemented in the model, but with the selected battery size, the truck cannot run for more than 4.5 h without charging.

There are charging stations along the road, and the number of charging stations, their location and the individual number of chargers at each station vary from simulation to simulation. The price for charging depends on the station and the time but has been set at the same value in almost all simulations. However, all simulations will have at least three charging stations along the way, and these will be uniformly distributed along the highway. In this paper, all the chargers have a power kW. It is assumed that this power can be used for all trucks regardless of SoC. This implies that a truck will charge its whole useful capacity in 43 min.

3.2. The Charging Behaviour of the Trucks

In the simulation, each truck (i.e., each agent) will act according to the following rules:

The trucks will only charge when they need to complete their mission and only what is necessary to have the required SoC at their destination.

The trucks will not charge more times than necessary. Taken with the assumptions presented earlier, this implies that none of the trucks will charge more than twice. The assumptions also prevent a truck from reaching zero SoC before it reaches a charging station.

If a truck needs to charge twice, it will take a full charge the first time.

A truck arriving to charge at a charging station will continue to the next charging station if there are too many queuing trucks and if it is able. A queue is deemed too long if the ratio of queuing trucks divided by the total number of chargers at the station is greater than the parameter .

Trucks that can choose between stations while following the above rules will choose to charge at the lowest cost. Trucks that charge twice minimise the cost of the first charge. If the price at the two stations is the same, the truck selects the nearest one.

3.3. Algorithm Description

Firstly, by studying the most extreme trip possible under the assumptions, it is established that no truck has to charge more than twice. The truck starts in Helsingborg with 50% SoC and should reach Stockholm with 40% SoC. According to the assumptions, there must be at least stations at the 138, 276 and 414 km locations. The truck starts at location 0 km and can drive the distance km. This means that it reaches the first station, where it charges to 100% SoC. The truck can now drive the distance km without charging, which means that it will reach the station at the 414 km location. At this station, it can, if necessary, charge to 100% SoC again. Thus, the truck needs kWh of energy to drive to Stockholm from the station. Arriving in Stockholm, it should then have kWh of energy stored in the battery; thus, it must leave the station with energy of kWh stored in its battery. Hence, no truck has to charge more the twice.

Before the simulations, it is determined whether each truck can avoid charging or whether it will have to charge once or twice. This is determined as follows. Firstly, the energy the truck is allowed to use without charging is determined as the difference between the starting SoC and the required destination SoC, multiplied by the useful battery capacity. If this energy is greater than needed for the truck to move from its starting location to its destination, then the truck will not need to charge and is removed from the simulation. If the stored energy is not enough, then the truck must charge at least once. A calculation then determines how long the truck could drive with the available energy in the battery. This is compared with the distance to the stations along the road but before the destination. The station nearest the destination that can be reached without charging is then determined. It is then calculated whether the destination can be reached with the prescribed arrival SoC if the truck leaves the station with 100% SoC. If so, then the truck must charge once; if not, it must charge twice.

The simulations are run using a time-iterating, agent-based model. At the start of the simulation, the time equals h, with a typical day simulated twice to obtain proper initial conditions for the second day. The time then increases in increments of until it reaches 24 h. In the simulations conducted in this paper, the time step is set at one minute. The fact that the time step is not extremely small can result in some small errors, meaning that, in some cases, the battery might be overcharged by up to 2%. However, this does not significantly affect the results, and thus, the time step is considered sufficiently small.

At the time h, the roads and charging stations are empty. Before each time iteration, new trucks enter the highway according to the traffic flow described in the previous section. Each truck that has the maximum distance to a charging station decides whether it should charge by following the charging rules for trucks presented earlier. The decision algorithm proceeds in the following way.

If the truck has one charging session left to use, an initial check is made to see that it can drive (starting with a full charge) from the current station to its destination and arrive with the prescribed SoC. If not, then no charging takes place at this station. If it is possible, then a check is made to see whether other stations can be reached before charging. If not, the truck must charge at the current station. If there are alternatives, then it becomes a matter of considering the queue. If there are more queuing trucks per charger than the parameter , then the truck does not charge at this station. If the queue is shorter, the truck calculates its destination time at the other stations and compares the prices. If none of the other possible stations has a lower price, it charges at the current station. If any of the other possible stations has a lower price, then the truck does not charge at the current station. If a truck decides to not charge, it simply continues driving and must go through the same decision algorithm again when passing the next station. If the truck decides to charge, it takes only the necessary charge in order to reach its destination with the prescribed destination SoC.

If the truck has two charging sessions left to use, the closest station is determined which must be reached for the second charge so that the truck can reach its destination with the required SoC. If this station cannot be reached by fully charging at the current station, then no charge is taken at the current station. If this station can be reached, it is then determined whether other stations can be reached before a charge is needed. If not, then charging must happen at the current station. If there are possibilities to charge at several stations, one considers the queue. If there are more queuing trucks per charger than , then the truck is not charged at the current station. If the queue is not too long, then prices are compared, as described earlier. Charging takes place at the current station if there are no other stations with cheaper fast charging. If there should be other stations, however, then charging does not take place at the current one. If the truck decides to charge, it charges fully.

The trucks that do not charge update their location and SoC according to:

where

is the location of truck

i and

where

is the SoC of truck

i. Then, there are queued trucks waiting for charging. These are neither moving nor charging, but the trucks’ total queuing time is updated by adding the queuing time

. Finally, there are trucks that are charging. These update their SoC according to:

For each charging station

j, the total energy delivered from the charging station,

, is updated according to:

where

is the number of charging trucks at station

j at the time

t. Before commencing a new time step, the trucks that have reached their target SoC leave the charging station. If a truck that has finished charging only needs to charge once, it is now removed from the simulation. If it must charge twice, it will continue on the highway until it stops for its second charge and then be removed after the second charge. At the end of each time step, the number of queuing trucks is registered at each station.

4. Simulated Cases and Results

The model is executed for different cases which are presented below in the results. In all the simulated cases, except for Case 9, the total number of chargers for the system is 105. In this section, the maximum queuing time, the average queuing time, the charger utilisation factor for an individual charging station and the system charger utilisation factor are presented as results from the simulations alongside the number of queuing trucks per charger, as a function of time for the different stations. The maximum queuing time and average queuing time refer to the queuing time per truck during a typical day and not per charge (some of the trucks charge twice). The maximum queuing time is the longest total time a truck has to wait for charging on a typical day. The average queuing time is the mean queuing time for the trucks that actually charge. The charger utilisation factor for an individual charging station is defined as the energy delivered by all the chargers at the station during the typical day, divided by the highest possible energy that can be delivered by the station during that day. The system charger utilisation factor is the total energy delivered by all the chargers in the system during a typical day divided by the maximum amount of energy that can be delivered by all the chargers in the system over one day.

Case 1 is a reference case which was defined by manually testing combinations of various different charging stations, their location and the number of chargers until it resulted in a high charger utilisation rate and lingering minor queuing problems. All nine presented cases are described below, but first, an overall description of how the different cases differ from Case 1 is presented in

Table 3.

Case 1 is designed to represent a good system solution. Case two shows an attempt to improve the system solution by pricing. Cases 3 and 8 investigate whether the unwillingness to queue is an important system-level attribute. Case 4 examines whether it is more beneficial to have a few stations with many chargers or many stations with few chargers. Cases 5 and 6 evaluate the system’s resistance to an overall increase in traffic flow. Case 7 explores whether an unexpected peak in the traffic flow can cause severe queues. Case 9 is designed to show a reasonable safety margin in selecting the number of chargers for the system.

Case 1: In this case,

queuing trucks per charger meaning that the trucks avoid large queues if possible. The price for charging is the same for all stations, regardless of time.

Table 4 shows how the chargers are distributed in this case.

Results for Case 1: The maximum queuing time was nine minutes and average queuing time 0.22 min. The system charger utilisation factor was 59%, and the individual charger utilisation factor for the stations was 60%, 59% and 58% for Stations 1, 2 and 3, respectively.

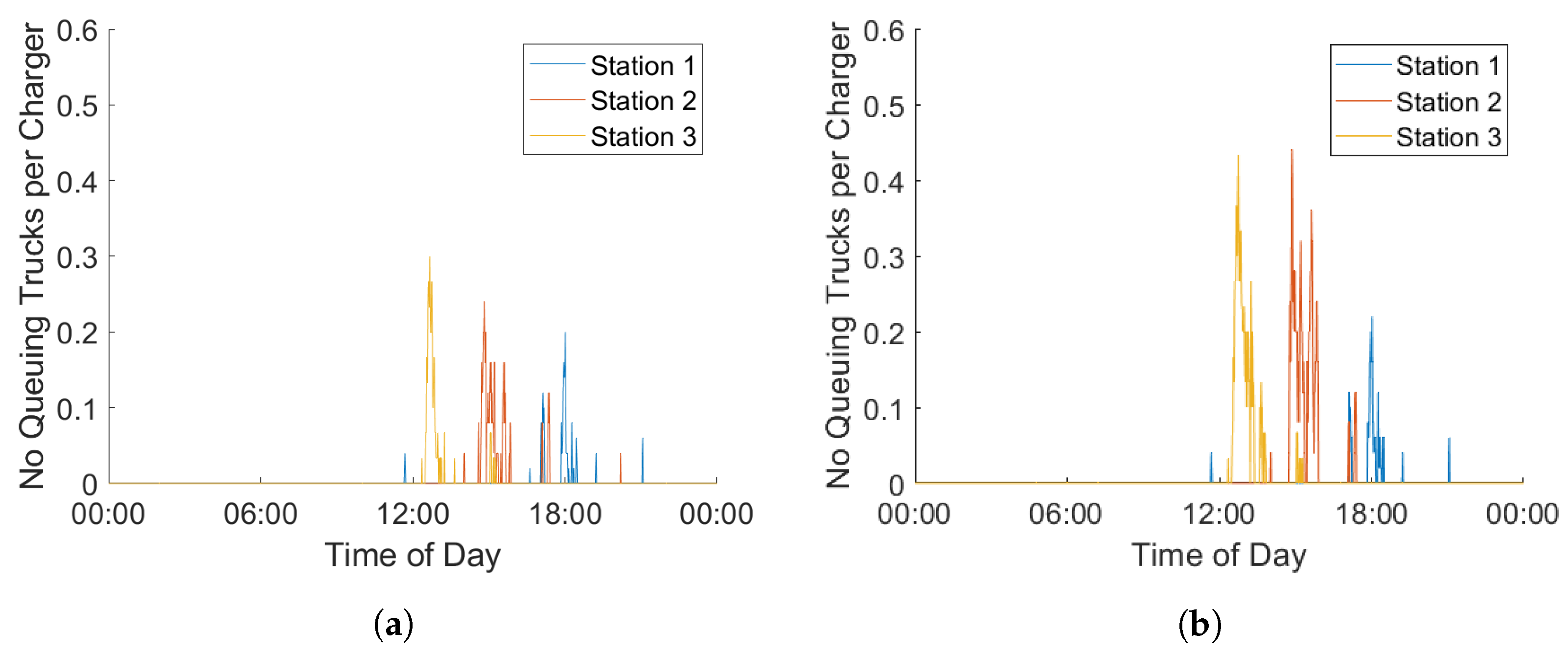

Figure 4a shows the number of queuing trucks per charger at the different stations as a function of time for Case 1. The results indicate that a high charger utilisation will be possible without having major problems with queuing at the charging stations.

Case 2: This case is identical to Case 1, with the exception that the price for charging is higher at Station 3 between 12:00 and 14:00, which is when there are many trucks queuing at Station 3 in Case 1; see the yellow spike in

Figure 4a.

Results for Case 2: The maximum queuing time was 12 min and average queuing time 0.22 min. The system charger utilisation factor was 59%, and the individual charger utilisation factor for the stations was 60%, 60% and 58% for Stations 1, 2 and 3, respectively.

Figure 4b shows the number of queuing trucks per charger at the different stations as a function of time for Case 2. The results seem to show that the queue moved from Station 3 to Station 2 but that the overall level of queuing did not improve. The maximum queuing time actually increased.

Case 3: This case is identical to Case 1, except that queuing trucks per charger. In this context, the implication is that the charging trucks do not take queuing time into account when selecting their charging stations.

Results for Case 3: The maximum queuing time was 15 min and average queuing time 0.36 min. The system charger utilisation factor was 59%, and the individual charger utilisation factors for the stations were 60% for Station 1, 59% for Station 2 and 58% for Station 3.

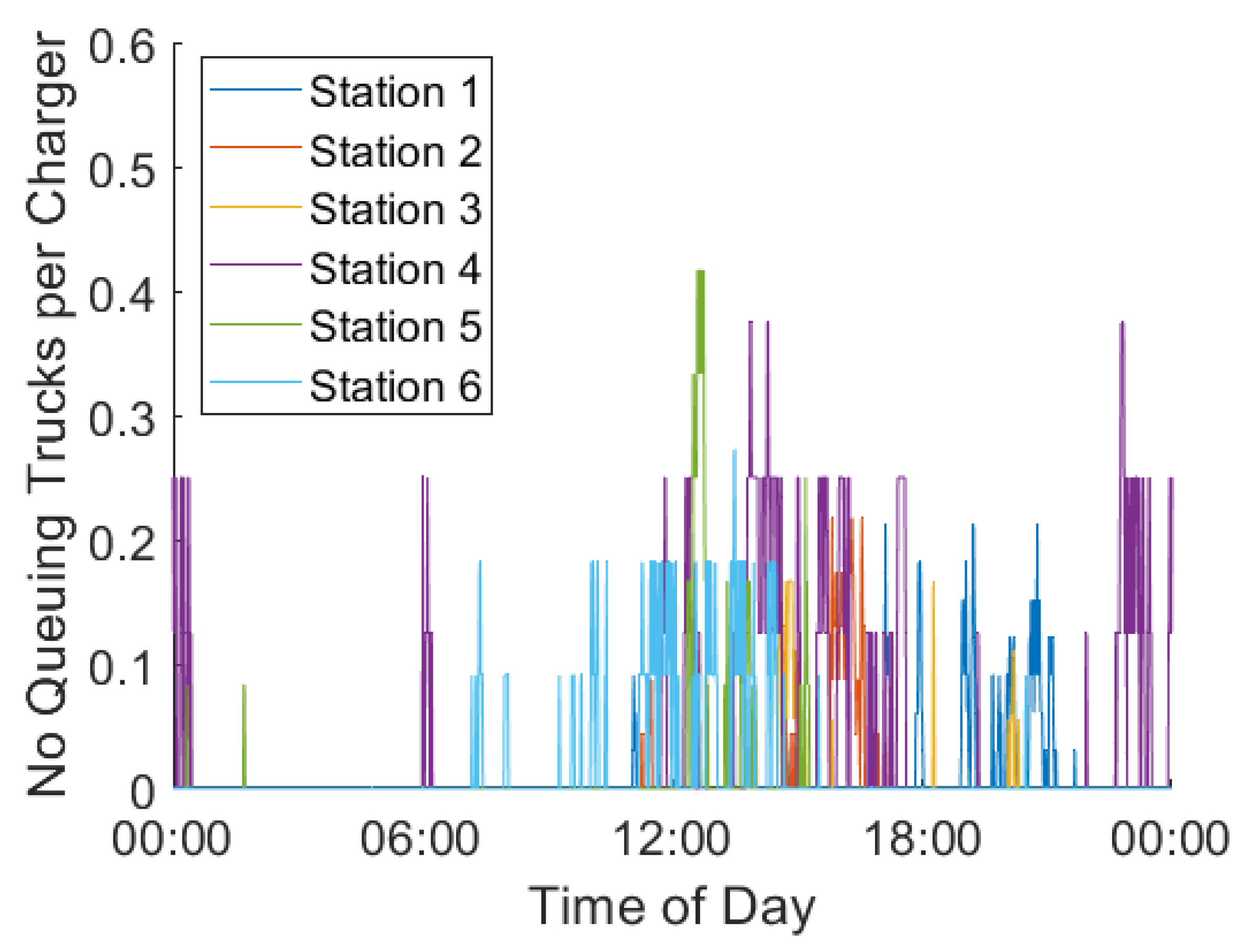

Figure 5 shows the number of queuing trucks per charger at the different stations as a function of time,

Figure 5a shows the results from Case 1 and

Figure 5b the results from Case 3. These results show that the station queuing conditions clearly worsened when the agents did not avoid queues.

Case 4: This case is designed to test whether it is better to distribute the same number of chargers across more stations or fewer. The system now has six stations distributed according to

Table 5, and the number of chargers at each station was manually selected to minimise queuing problems. For this case

queuing trucks per charger and the price of charging is the same for all stations, regardless of time. The placement of the additional charging stations and the number of chargers at each station has not been fully optimised, but many combinations have been tried, and Case 4 has been chosen because it resulted in good system performance. However, it is likely that there can be even better ways to add three more charging stations.

Results for Case 4: The maximum queuing time was 17 min and average queuing time 0.55 min. The system charger utilisation factor was 59%, and the individual charger utilisation factor was 57% for Station 1, 62% for Station 2, 61% for Station 3, 64% for Station 4, 54% for Station 5 and 60% for Station 6.

Figure 6 shows the number of queuing trucks per charger at the different stations as a function of time for Case 4. The results indicate that it is beneficial to have fewer stations with many chargers rather than many stations with few chargers.

Case 5: This case is the same as Case 1, but 480 departing trucks have been added compared to the typical day. These extra trucks have been distributed so that 120 of them start from each city. The extra trucks in each city have three possible destinations, with 40 of them going to each alternative destination. The departure times for the extra trucks have been drawn from a uniform random distribution with minute precision. The extra 480 trucks correspond to an 11% increase in the number of daily trucks.

Results for Case 5: The maximum queuing time was 16 min and average queuing time 0.62 min. The system charger utilisation factor was 65%, and the individual charger utilisation factor was 65% for Station 1, 65% for Station 2 and 66% for Station 3.

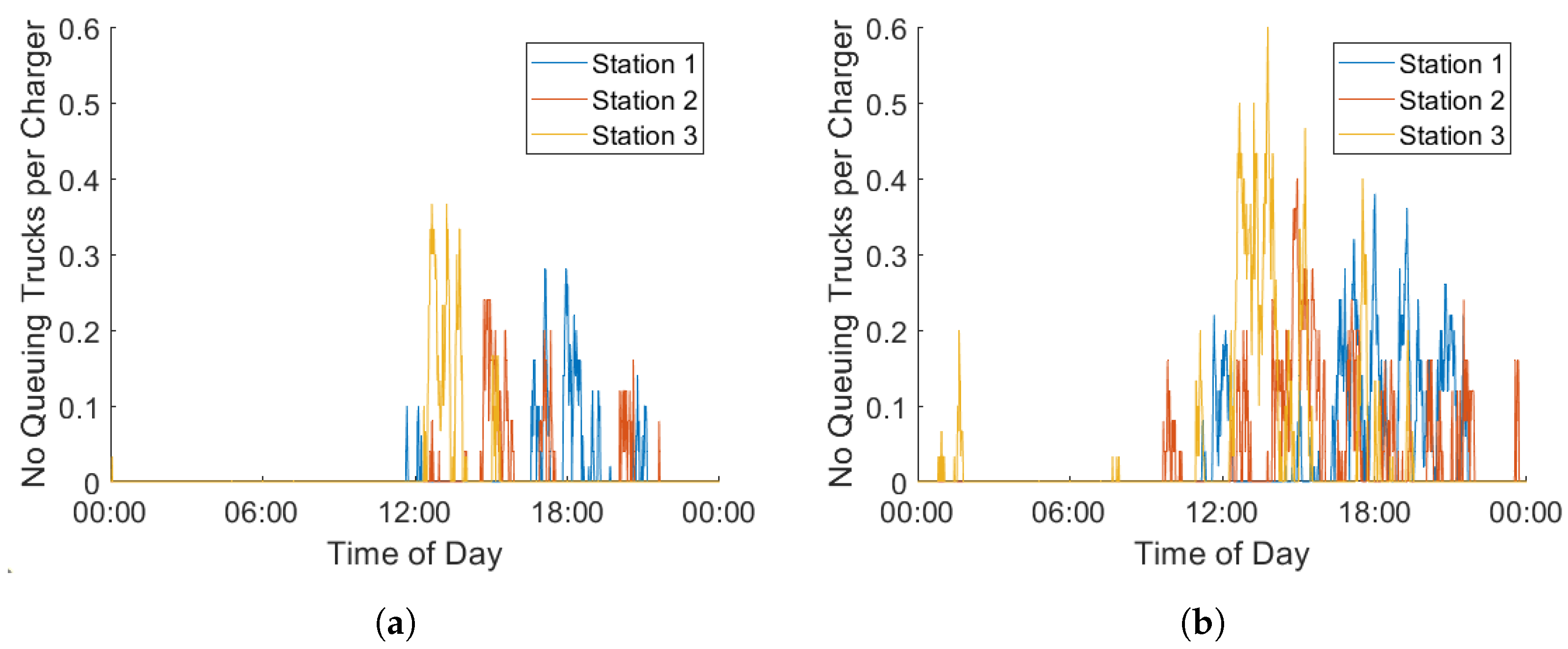

Figure 7a shows the number of queuing trucks per charger at the different stations as a function of time for Case 5. The results show that this increase in the traffic flow is handled quite well by the charging stations.

Case 6: This scenario is the same as in Case 1, but 1440 departing trucks have been added to the typical day. These extra trucks have been distributed so that 360 of them start from each city. The extra trucks in each city have three possible destinations, with 120 of them going to each alternative destination. The departure times for the extra trucks have been drawn from a uniform random distribution with minute precision. The extra 1440 trucks correspond to a 32% increase in the number of daily trucks.

Results for Case 6: The maximum queuing time was 21 min and average queuing time 1.56 min. The system charger utilisation factor was 77%, and the individual charger utilisation factor was 74% for Station 1, 77% for Station 2 and 81% for Station 3.

Figure 7b shows the number of queuing trucks per charger at the different stations as a function of time for Case 6. The results show that this increase in the traffic flow causes some queuing problems at the charging stations.

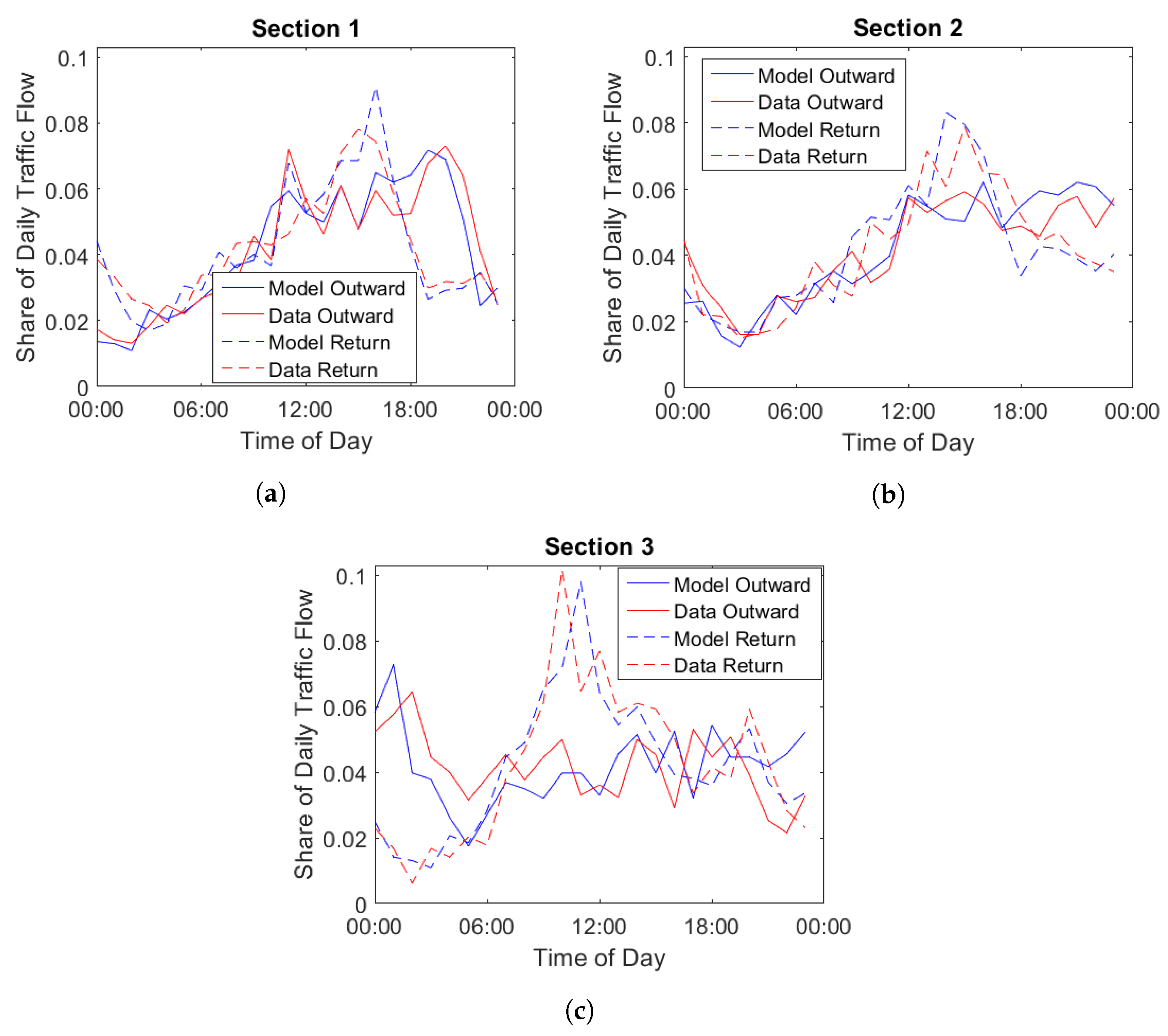

Case 7: This case is the same as in Case 1, but there are 90 extra departing trucks compared to the typical day. All the extra trucks start from Stockholm, with 30 of them driving to Linköping, 30 to Jönköping and 30 all the way to Helsingborg. The departure times for the extra trucks have been drawn from a uniform random distribution in the interval [9.4, 10.4] hours, with minute precision where zero corresponds to midnight. This added truck flow is designed to roughly double the peak of Section 3’s return flow; see the blue dashed line in the lower part of

Figure 3.

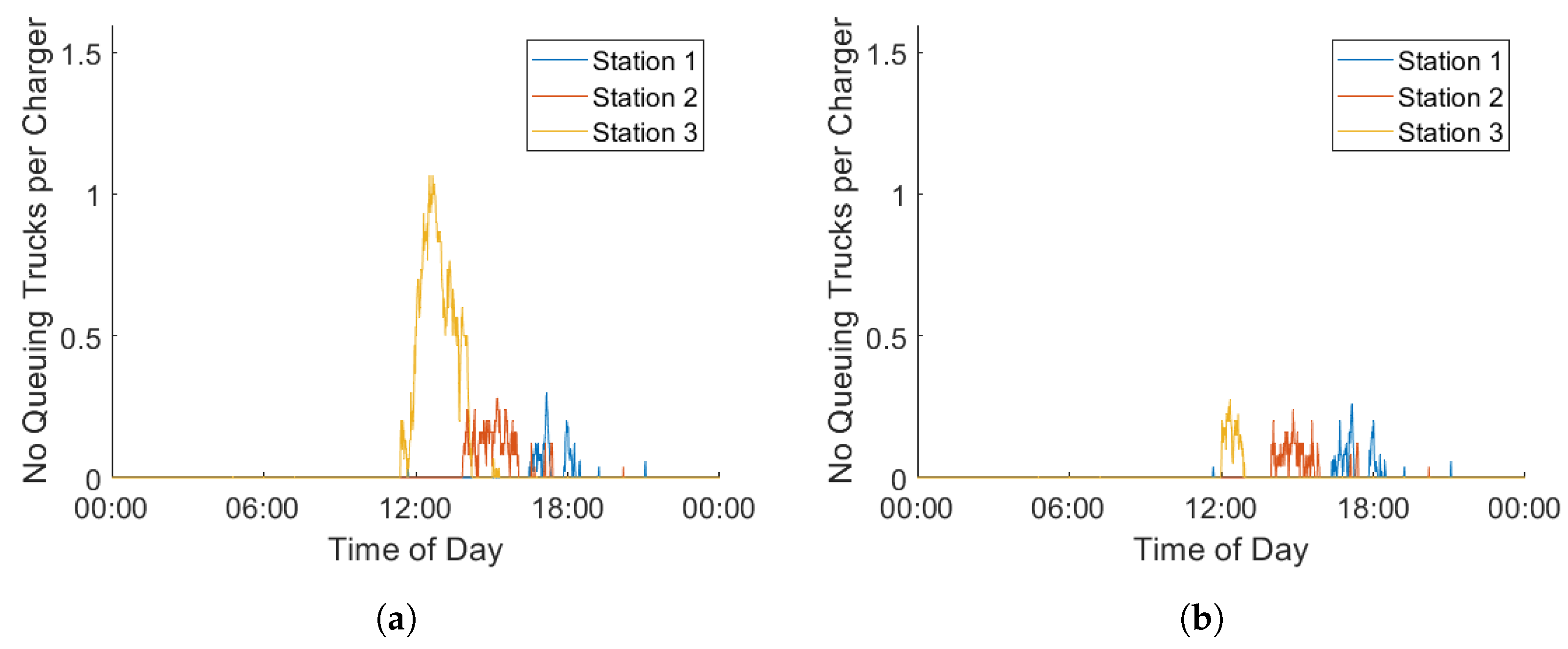

Results for Case 7: The maximum queuing time was 39 min and average queuing time 1.21 min. The system charger utilisation factor was 61%, and the individual charger utilisation factor was 60% for Station 1, 61% for Station 2 and 62% for Station 3.

Figure 8a shows the number of queuing trucks per charger at the different stations as a function of time for Case 7. The results show that this system is not resistant to strong, unexpected peaks in the traffic flow. This will be further discussed in the next section.

Case 8: This case is the same as in Case 7 with the exception that queuing trucks per charger. In this context, that implies that the charging trucks are not taking the queuing time into account when selecting charging stations.

Results for Case 8: The maximum queuing time was 68 min and average queuing time 2.26 min. The system charger utilisation factor was 61%, and the individual charger utilisation factor for the stations was 60% for Station 1, 60% for Station 2 and 62% for Station 3.

Figure 7b shows the number of queuing trucks per charger at different stations as a function of time for Case 8. Again, the results show that the trucks’ unwillingness to queue is an important attribute of the overall system.

Case 9: This scenario is the same as in Case 7 with the exception that 10 extra chargers have been added to Station 3, bringing the total number of chargers for the system to 115. This is the only case in which the total number of chargers is not 105.

Results for Case 9: The maximum queuing time was 10 min and average queuing time 0.40 min. The system charger utilisation factor was 55%, and the individual charger utilisation factor for the stations was 60% for Station 1, 60% for Station 2 and 46% for Station 3.

Figure 9b shows the number of queuing trucks per charger at the different stations as a function of time for Case 9, while

Figure 9a shows the results from Case 7. These results show that it is possible to achieve a system strongly resistant towards unexpected peaks in the traffic flow by increasing the number of chargers. This is trivial, but the results will support the discussion of a realistic system of charger utilisation in the next section. The main results from all cases are summarised in

Table 6.

5. Discussion and Conclusions

5.1. Promising Results

The results from Case 1 indicate a promising future for the system of chargers and battery electric trucks along the highway between Helsingborg and Stockholm. Having a well-functioning system with low queuing times and system charger utilisation as high as 59% gives great opportunities for cheap public fast charging and profitable charging stations [

5]. The reason for this high system charger utilisation factor is that the variation in traffic flow over the day is not that great. The trucks operate throughout the day, and there is even a significant flow of trucks through the night. This makes it possible to select the number of chargers to almost meet the rush hour demand without having too much overcapacity in the calmer hours.

Moreover, according to the results of Cases 5 and 6, the system seems fairly robust in coping with increased traffic if it is uniformly distributed across the day. The simulation in Case 6 resulted in a maximum queuing time of 21 min. This is not so much given that the simulation involved almost 5800 trucks and especially not if this extra-high level of traffic is rare. Still, this case had some problems with queues at the stations. The system charger utilisation for the case was 77%, which constitutes a very high value. However, although this seems promising, believing in a well-functioning system with low queuing times and a system charger utilisation factor as high as 59% is perhaps overly optimistic. This is discussed in the next subsection, which presents a more realistic system utilisation factor.

5.2. A More Realistic System Charger Utilisation Factor

The results of Case 1 indicate that the system charger utilisation factor could be as high as 59%. However, when considering the results of Case 7, with its strong increase in one of the traffic flow peaks, it becomes apparent that Station 3 does not have the capacity to provide charging for trucks during rush hour; see

Figure 6a. For Case 7, the maximum queuing time was 39 min, which is too long. There were also queues during several hours at Station 3. By adding 10 more chargers at Station 3 (as in Case 9), the system works well again; see

Figure 6b. For Case 9, the maximum queuing time is down to 10 min which should be acceptable. However, this comes at the cost of a reduction in charger utilisation. One might wonder whether it is necessary to scale the number of chargers for such extreme events as a doubling in traffic peak. However, this only represents a 2% increase in the total daily traffic flow. The system may not be deemed sufficiently robust if such long lines can be created at a single charging station even if the extra trucks start during rush hour. Thus, there is a need for 10 extra chargers at Station 3, corresponding to an increase of 33%. Since it is not just Station 3 that can be affected by extra peak demand for charging, the 33% increase should be made for all charging stations, resulting in 140 chargers overall (1.33 × 105 chargers). By assuming that the average demand is represented by the demand for a typical day used in the simulations, we obtain a new system charger utilisation factor of

, where 105 is the old number of chargers, 140 is the new number of chargers, and 0.59 is the old system charger utilisation factor. Taking a restrictive point of view, one might ask whether the same number of trucks is on the roads at weekends as on weekdays. The answer is probably not. If we assume that each truck is on the road only once per weekend, then the new system charger utilisation factor is

. Another factor which will lower the utilisation is if the charging power varies during a charging session. Typically, batteries accept high power during the initial charging phase and then less and less power as the battery’s state of charge is increased. In other words, having an average power of 700 kW will typically require a 900 kW charger. That lowers the charger utilisation by a factor of 700/900. This effect need not be reflected by an equally low grid utilisation. Ultimately, it results in a new, more realistic utilisation factor of

; not as high as 59% but clearly still high and promising.

What does a system charger utilisation factor of 30% mean for the price of public fast charging? Previous studies [

5] presented a difference per kWh between the price of public fast charging and the price of electricity paid by the charge point operator.

has to follow the following inequality in order to to achieve profitable charging stations:

where

is a combined price for the cost of the chargers and grid connection per unit of time with a typical value of 117 EUR/kW/year = 0.0134 EUR/kWh and

is the charger utilisation factor. Given a charger utilisation factor of 30%, we obtain:

This allows for both cheap public fast charging and profitable charging stations. In addition, the system should have few problems with queuing and should be robust in that it can handle increased traffic flow or an unusually high peak in it.

This paper has assumed that there is one charger per charging truck. Furthermore, it has been assumed that this charger has access to its own grid capacity corresponding to its maximum power and that this power is constant during the charging session. This made it easy to define a charger utilisation factor and is a reasonable simplification which still allows analysis of one of the main system trade-offs. However, it also hides some interesting ways to allow for the high availability of chargers while still making effective use of the charger power electronics and grid capacity. Future studies should therefore also consider the possibility of offering charger power that can be distributed to different trucks depending on which truck needs the power, as well as perhaps offering more charging outlets for trucks than the total available charger power and grid capacity. This will avoid drivers having to queue for a charger before they can park their trucks and take their mandatory breaks.

5.3. Reducing Queues with Pricing

This study has attempted to reduce the amount of queuing at the stations through pricing. For example, consider the results of Case 1, in the left-hand part of

Figure 4. There is a clear spike at noon for Station 3. Although this spike is slender, it raises the question of whether better results might be obtained by temporarily increasing the price of charging during it. This would make some trucks select another station, even if some chargers were vacant when they arrived. The right-hand part of the figure illustrates this. The queuing peak is a little lower for Case 2, but a couple of hours later, the peak at Station 2 has increased. The maximum queuing time for the system is now 12 min instead of 9 min, and the average queuing time has not improved. Thus, pricing has slightly improved the local queuing conditions but worsened them a little at system level. There will likely be a situation in which pricing can improve the overall solution, but this example illustrates that there is no guarantee that it can be improved by pricing, even if there is local improvement. In the simulations, the trucks that did not charge at one station had to go and charge elsewhere. Thus, if a lot of trucks reject a station during rush hour, they must charge at a subsequent station and will once again arrive simultaneously. It might seem that expensive charging during rush hour and lower pricing when demand falls would cause some haulage companies to reschedule their departure times, thus improving the queuing conditions on a system level. However, this has not been investigated.

5.4. Queuing Reluctance Improves the System Solution

Case 3 is identical to Case 1 with the only exception that in Case 3, the trucks do not take the queuing conditions into account when selecting a charging station. The same goes for Case 8, which is identical to Case 7 but without queuing resistance. When comparing the results from the system in which trucks avoid charging at stations with long queues, with the results from the system in which long queues are not a concern, it is clear that the better solution is for the trucks to take some steps to avoid long queues. This is consistent with what was anticipated. In the simulated cases, both the maximum and average queuing times are increased by roughly 70% when the trucks’ queuing avoidance is removed. A clear queuing difference is shown in

Figure 5 and

Figure 8. The behaviour of avoiding long queues is undoubtedly realistic, and the simulations show that this property is important in achieving good system solutions more easily. The system has some ability to regulate itself; this may make charger booking systems less important or even redundant.

5.5. Benefits of Gathering Chargers at Fewer Stations

To gain more choice as to where to charge along the road, simulations with more than three charging stations were run. Since the results were to be compared with Case 1, the number of chargers was kept the same. However, it was not possible to improve upon or even equal the results of Case 1 by using more charging stations. The simulation in Case 4 used six charging stations and resulted in the maximum queuing time and average queuing time being approximately doubled. To some extent, this might be explained by the fact that it is harder to find well-distributed chargers across six stations than across three, as there has been no “proper” optimisation. However, this cannot explain everything, as many different combinations of charger distributions were tested. Even the location and number of new stations was changed.

Thus, the simulations indicate that it is better to have fewer stations with many chargers than many stations with fewer chargers. This can be explained by the following two arguments. Firstly, consider a station with fewer chargers and another one with many. Both stations have the same number of queuing trucks per charger. If the trucks at the smaller station are unlucky, all of the (fewer) trucks charging at this station will have just started charging, leading to long queuing times. The probability of this scenario should be significantly less for the larger station with many chargers. This explains the longer maximum queuing time for the case with many stations and fewer chargers. Secondly, if we compare a situation in which all the chargers at one station are occupied, there will be no queue. Now imagine another case in which these chargers are distributed across several stations. Since the trucks are unlikely to always distribute in the exact same way, there will often be unused chargers at some stations and queues at others, despite the number of charging trucks being the same as the number of chargers. This is one reason why the average queuing time increases when there are many stations with few chargers.

5.6. Limitations of the Study

This paper has studied a complex system using a fairly simple model. As with any model, this one has weaknesses, and the results and conclusions should be regarded as estimates and not absolute truth. For example, the method for finding the origins and destinations involves some assumptions which are not based on data. The data are a few years old and may not be representative of the traffic flow in the future. The data for the time variations of the flow are especially important to the results. The time variations are taken from just a few days, and no long-term data were available at the measurement sites to allow for a study of how representative these days were.

Although the rules for the agents sound reasonable, real drivers might not behave in this way. The simulations assumed that a truck moves on immediately when it has completed its charging, making the charger available again. However, is it probable that a driver taking a break might move their truck just because the truck has finished charging? This behaviour influences the result. One way to address this problem is to have the drivers pay for the time spent at the charger and not just the energy. Then, staying longer than necessary might not be so attractive (and if the truck lingers, the charge point operator will be paid for the extra time). However, this behaviour still leads to a blocked charger that might have been used by another truck. Another way to reduce this problem is to have more charger outlets than chargers at the station and to design things so that the available chargers can be directed to the charger outlets which need them at that moment. In other words, a truck that lingers at a charger will not prevent that charger from being used, as it occupies just one outlet.

The results of this system seem very promising, with the number of chargers selected to meet demand by a necessary margin. The goal was to satisfy users, but having fewer chargers results in high utilisation and necessitates accepting some minor queues. However, is this the case in the free market? If the system has all the chargers it needs, works well and is profitable, what is there to stop a new charge point operator from entering the market if there is money to be made? All the charge point operators might still profit, but the system has too many chargers. Thus, if utilisation becomes high enough, a free, competitive market may result in no queues, even during rush hour.

This subsection began with the fact that a complex system has been simulated by a fairly simple model. Naturally, it is possible to make the model more complicated, but there is absolutely no guarantee that a more complicated model would yield more accurate results or a better understanding of the simulated system.

5.7. Conclusions

Despite having to rely on some assumptions (including ones about charging behaviour) to model how long-haul trucks drive, this investigation has produced some interesting conclusions on how well a system of public chargers for long-haul trucks might perform and on some factors influencing its effectiveness.

This type of agent-based model seems a good way of investigating a suitable design for a charging system and how to make it cost-effective while providing high availability of chargers with a low risk of queuing. The study also shows that many more things need to be included in the model and that better data are needed before the results can be used in a real system design.

Hourly data on the flow of heavy trucks with trailers on the E4 between Helsingborg and Stockholm suggest that long-haul trucks flow quite evenly throughout the day and with significant numbers at night. Combining the truck flow data with some assumptions about battery sizes and charging behaviour suggests that charging demand may also be quite even.

A future system of battery electric trucks and public fast chargers along the highway between Helsingborg and Stockholm seems likely to work well. The relatively uniform traffic flow of trucks results in high charger utilisation, which may lead to a system with low prices for public fast charging and profitable charging stations. Moreover, there seemed to be few queuing problems at the charging stations. The system will also be robust in the face of increased traffic flow or unusual peaks in traffic flow, as queuing times are not especially high even when the number of trucks increases.

It has been estimated that full electrification of the long-haul truck fleet would require 140 chargers along the highway between Helsingborg and Stockholm, each with the power of 900 kW.

The system charger utilisation factor has been estimated at 30%, which is very high, especially considering that it is achievable with such minor queuing problems.

The study indicates that a system with a constant number of chargers will better resist queues if there are few charging stations with many chargers rather than many charging stations with few chargers.

One simulation shows that varying the charging price may lead to more queuing across the whole system, even if it improves the local queuing at one particular station.

The truck drivers’ unwillingness to queue is important and leads to less queuing on the system level.