Modeling and Optimization of Natural Gas CCHP System in the Severe Cold Region

Abstract

1. Introduction

2. Model of Combined Cooling, Heating, and Power System

- (1)

- Optimization variables: Optimization variables refers to the relevant variables to be determined in the optimization problem to be studied, i.e., the optimization objects to be analyzed. Adjustments can be made later in the relevant commissioning to reduce the related operating costs for the design and construction of the combined cooling, heating, and power system;

- (2)

- Constraints: The functional equations and the corresponding constraints in the solution process, for example, the equation constraints of many energy balances listed in this paper and the inequality constraints established by the existence of upper and lower limits of the output force of different devices;

- (3)

- Objective function: The function to be sought, usually as the result of the entire optimization problem, to evaluate the criteria. Generally, there will be a single objective function of the economy: the evaluation index, economic indicators, environmental indicators, and other indicators of the composite multi−objective function. In this process, different indicators are given corresponding weights.

- (1)

- To avoid inefficiency caused by the power unit operating at a low load rate for an extended period, the prime mover must be set at a minimum load rate (0.25 in this paper). Otherwise, it may stall and not work. At the same time, other equipment can be operated at each operating point between the upper and lower limits of the operating capacity, ignoring the influence of environmental factors;

- (2)

- When making equipment capacity selections, the capacity values of the different equipment are effectively discrete, and this paper assumes that the entire distribution is continuous;

- (3)

- The corresponding power consumption processes and losses are neglected for equipment other than electric chillers;

- (4)

- The output values can be switched at any time for different devices in the system regardless of the response time;

- (5)

- Energy losses due to transmission during the process are ignored.

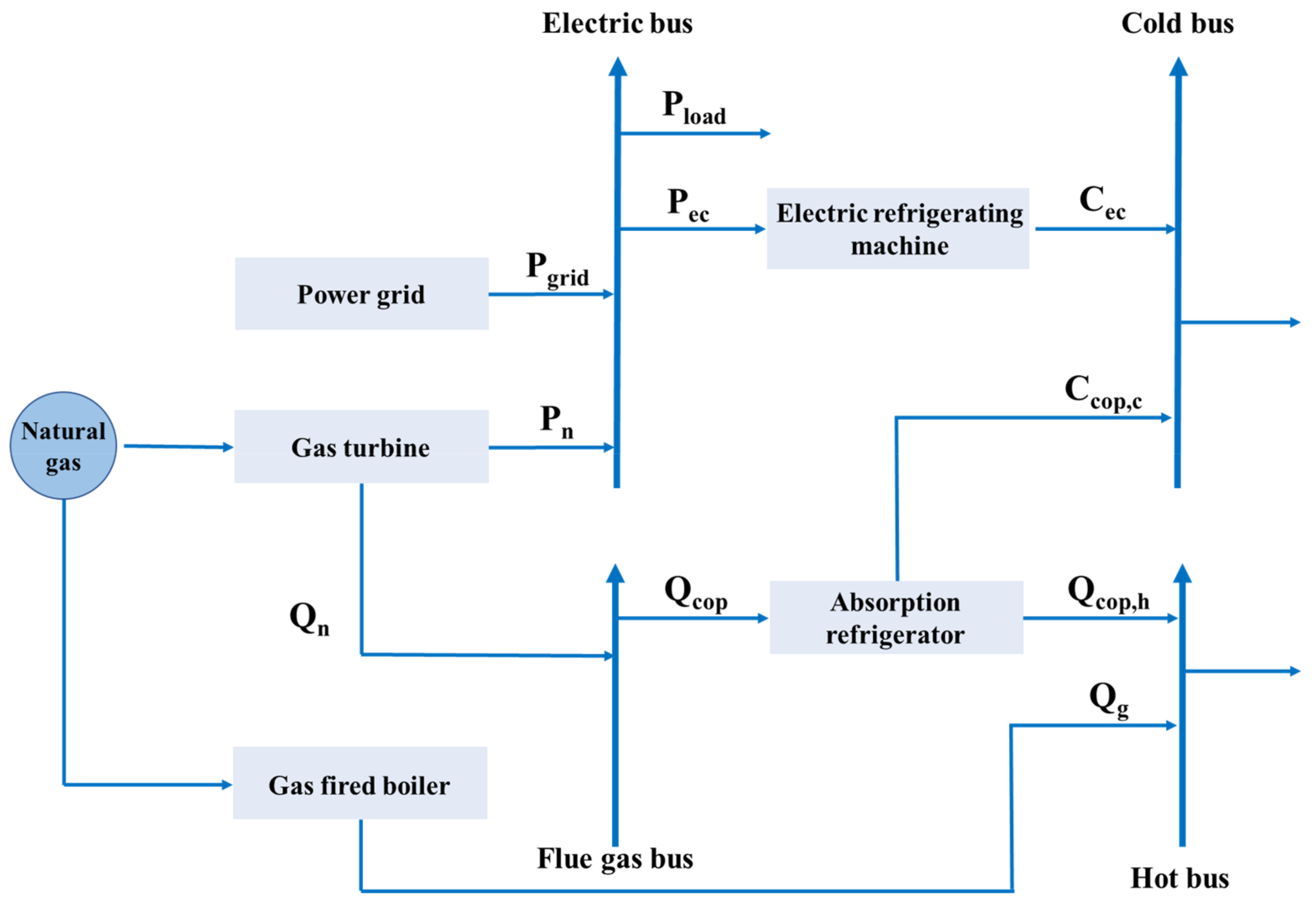

2.1. Power Unit for Combined Cooling, Heating, and Power System Model

2.1.1. Gas Turbine Model

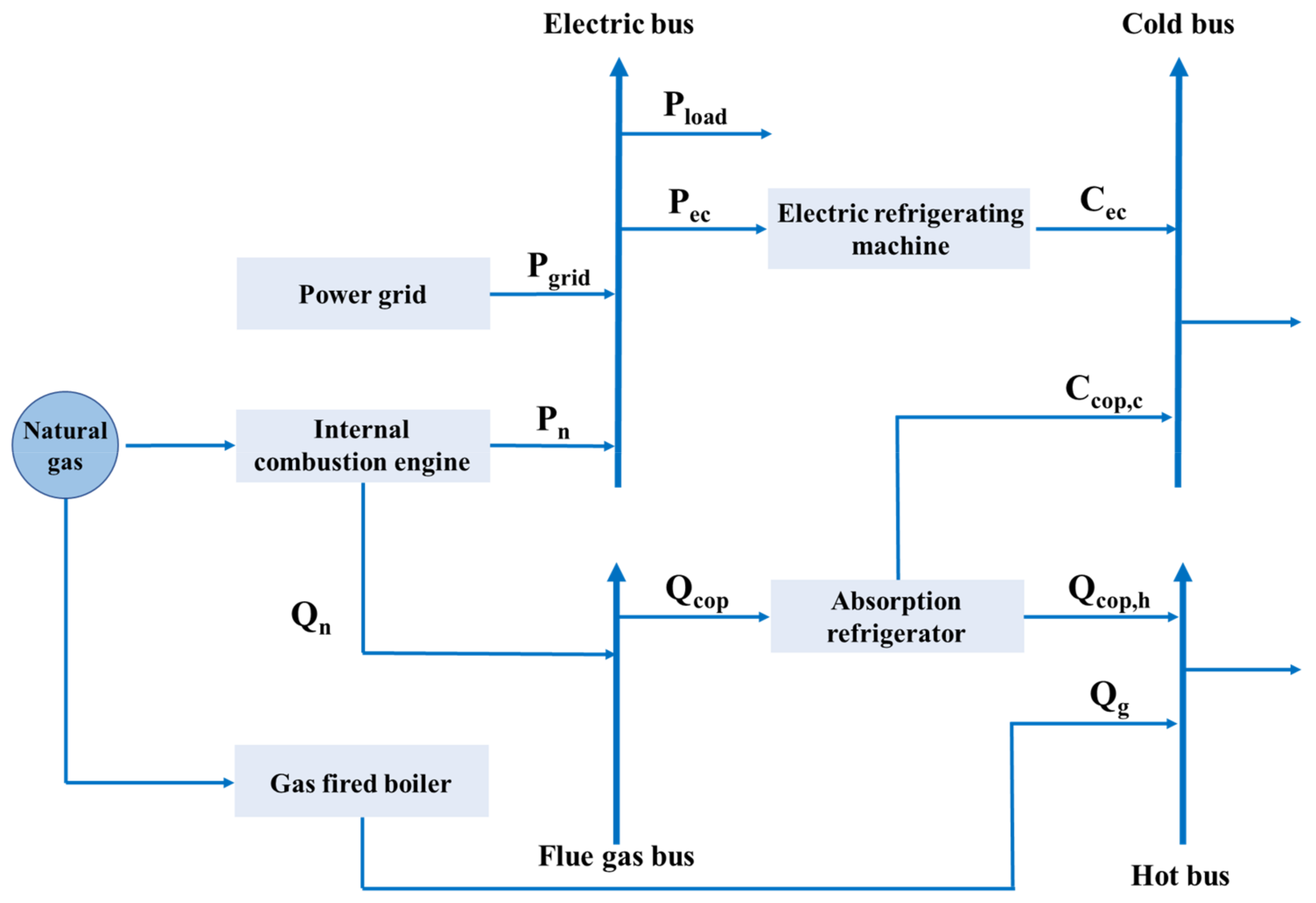

2.1.2. Gas Internal Combustion Engine Model

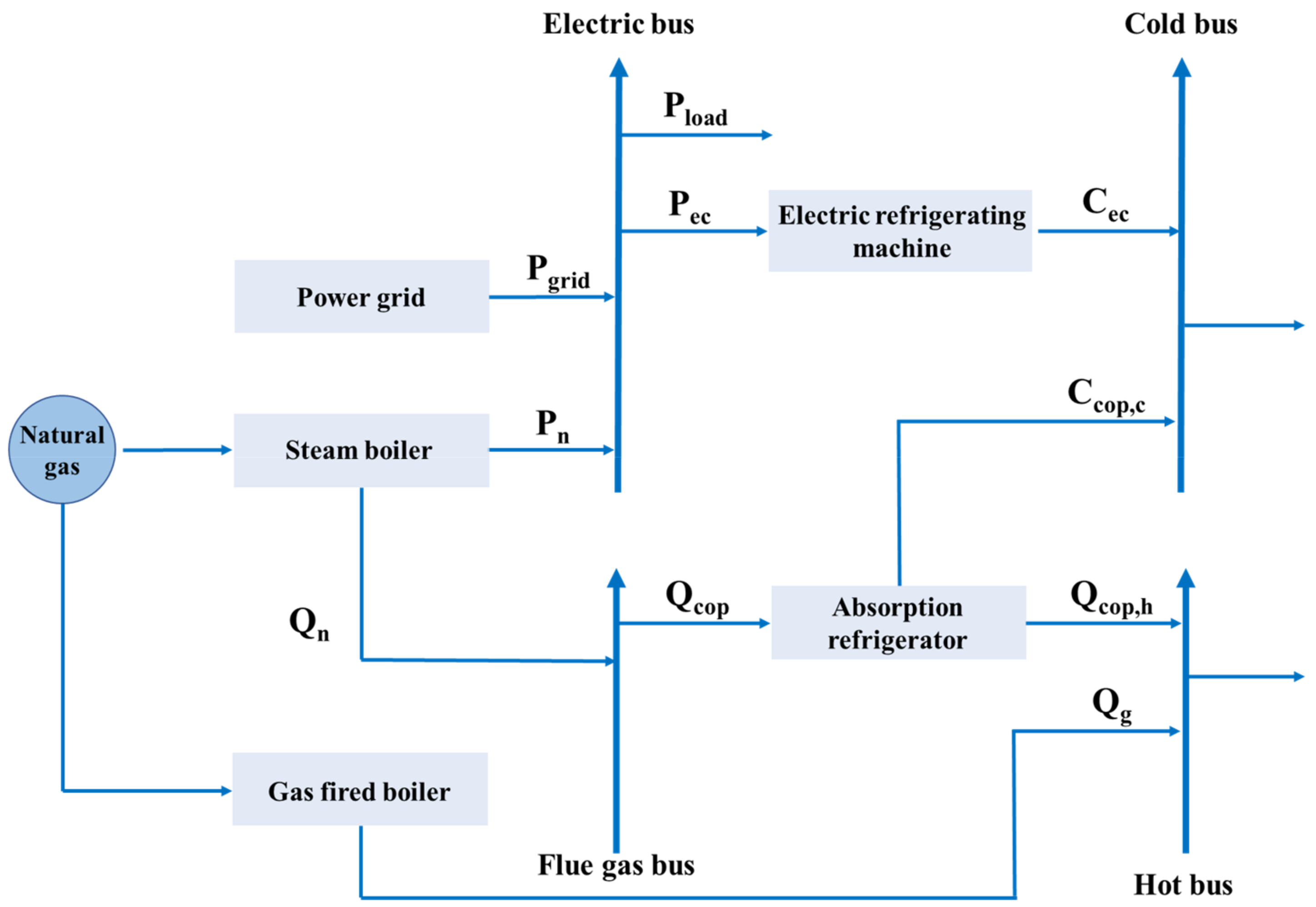

2.1.3. Gas Steam Boiler Model

2.2. Other Device Models for Combined Cooling, Heating, and Power Systems

2.2.1. Waste Heat Recovery Unit Model [44,45,46]

2.2.2. Combustion Supplement Device Model [47,48,49,50]

2.3. Constraints

3. System Operation Optimization Analysis

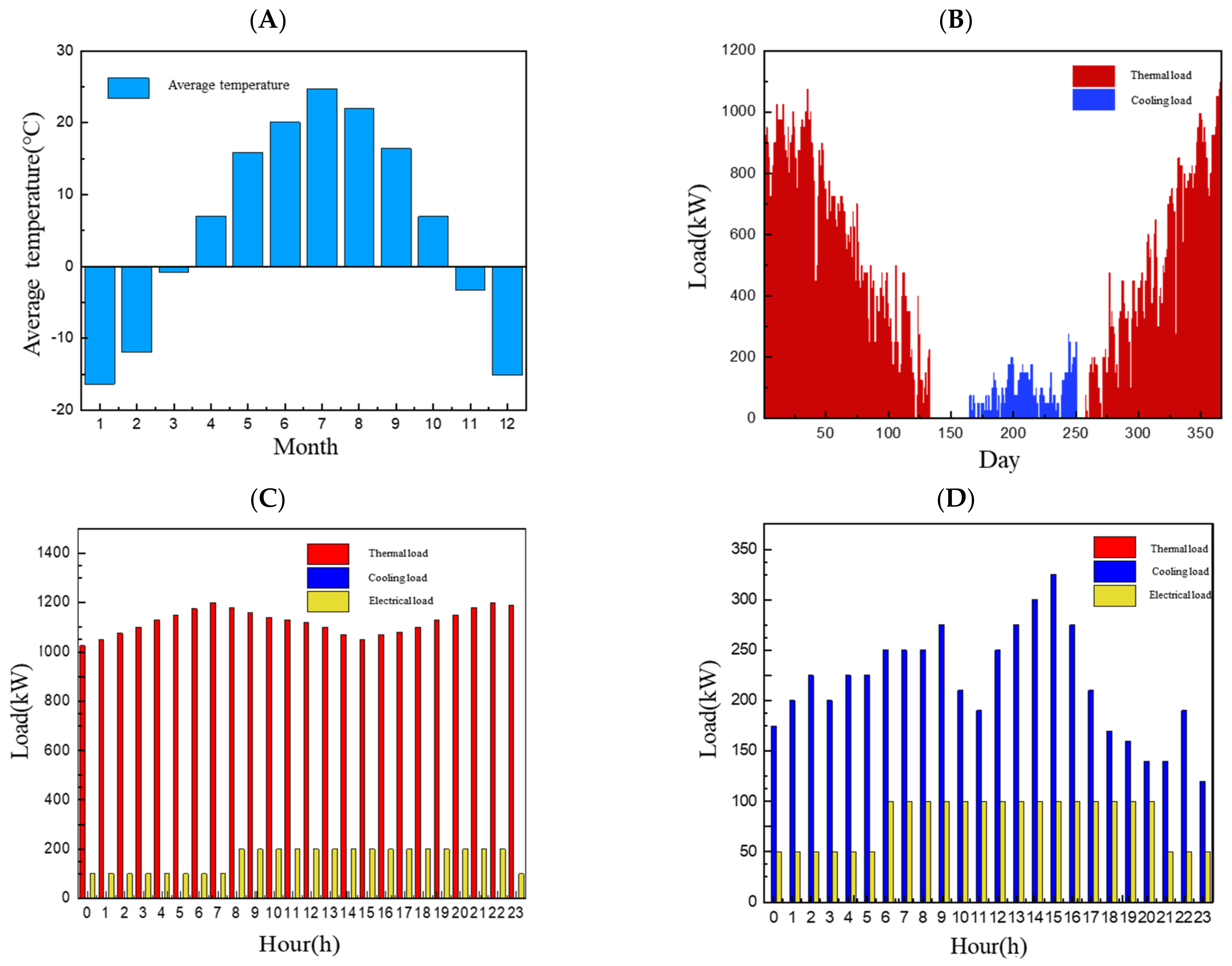

3.1. Load Analysis in the Harbin Area

- (1)

- The use characteristics of the electrical load are relatively similar from season to season. However, a comprehensive analysis of the corresponding load characteristics shows that the daily peak of electricity consumption is concentrated around two o’clock in the afternoon, mainly after the lunch break when the equipment starts, as well as in the summer when the work intensity of air conditioning and other equipment is higher, especially in the afternoon;

- (2)

- The value of the cooling load in the residential category is much smaller than the demand for heat load, with a greater demand for cooling during the daytime concentrated around two o’clock in the afternoon and a corresponding load at night. The demand for cold load is mainly concentrated in summer, especially in August, when the demand is significant;

- (3)

- Regarding the demand for heat load, it is mainly concentrated from October to mid–late April of the following year, which is about six months of heating time. The climatic conditions of Harbin and the geographical division of the cold region determine a more extended period for the heat load demand each year. The comparative analysis of Figure 5A shows that the value of the heat load and the time of supply–demand occupy a key and essential part of the year, indirectly reflecting the characteristics of the load demand in the cold region;

- (4)

- The average daily value of the thermal load is 1100 kW, and the average daily value of the cold load is 210 kW, with a peak thermal load of 1200 kW on a typical day in winter and a peak cold load of 330 kW on a typical day in summer. As the Harbin area is a severe cold region, the proportion of thermal load is significantly different, with the maximum ratio of thermal load to electrical load for customers in winter being 12, while the maximum ratio of cold load to the electrical load in summer is 4.5, which indicates that high thermal load is a representative feature of the load in the severe cold region.

3.2. Operation of a Gas Turbine Core Combined Cooling, Heating, and Power System Analysis

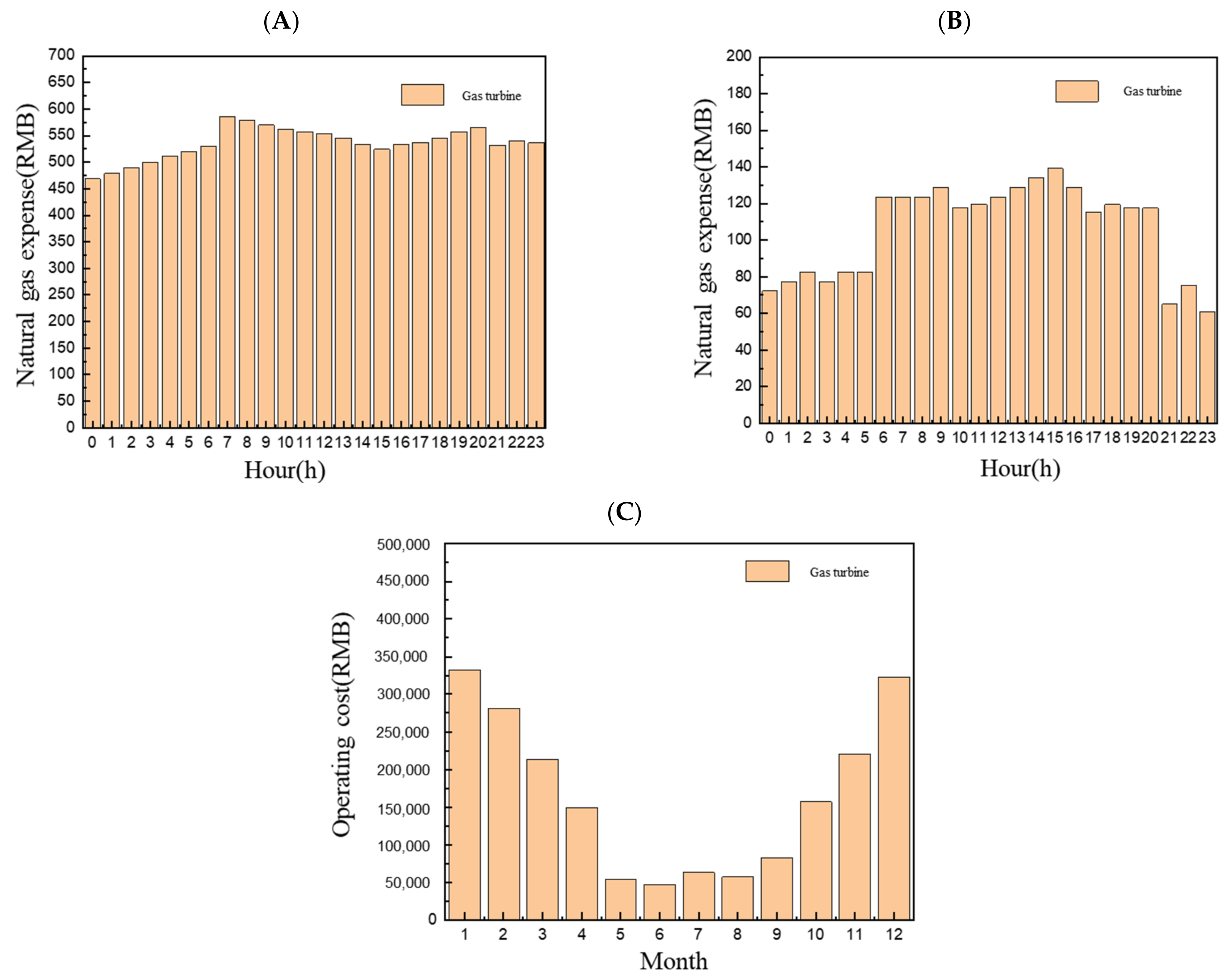

3.2.1. Analysis of Typical Winter Day Systems

3.2.2. Summer Typical Day System Analysis

3.2.3. Month−by−Month Cost Analysis Based on a Full Year

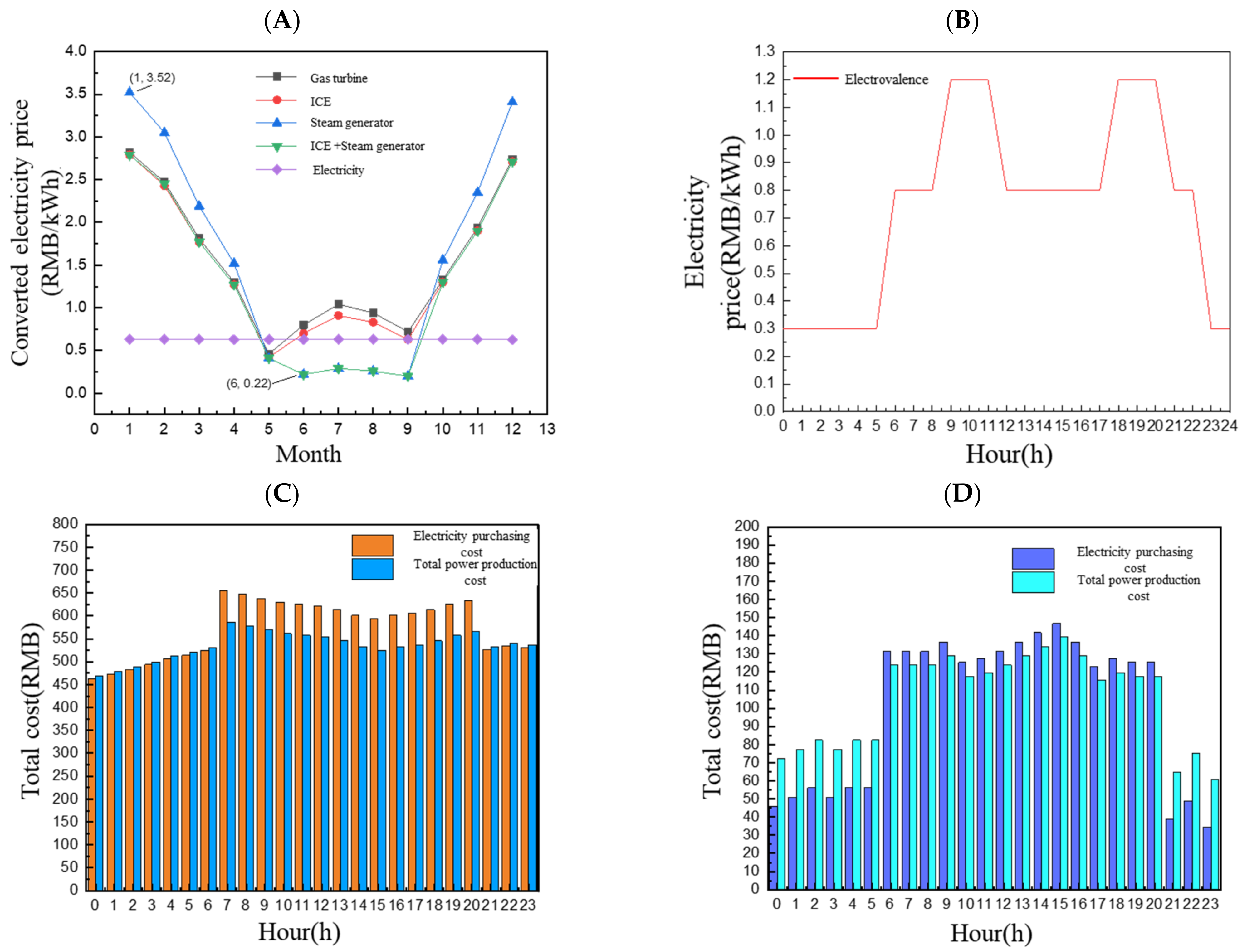

3.3. Typical Daily Cost Analysis Considering Power Purchase Scenario

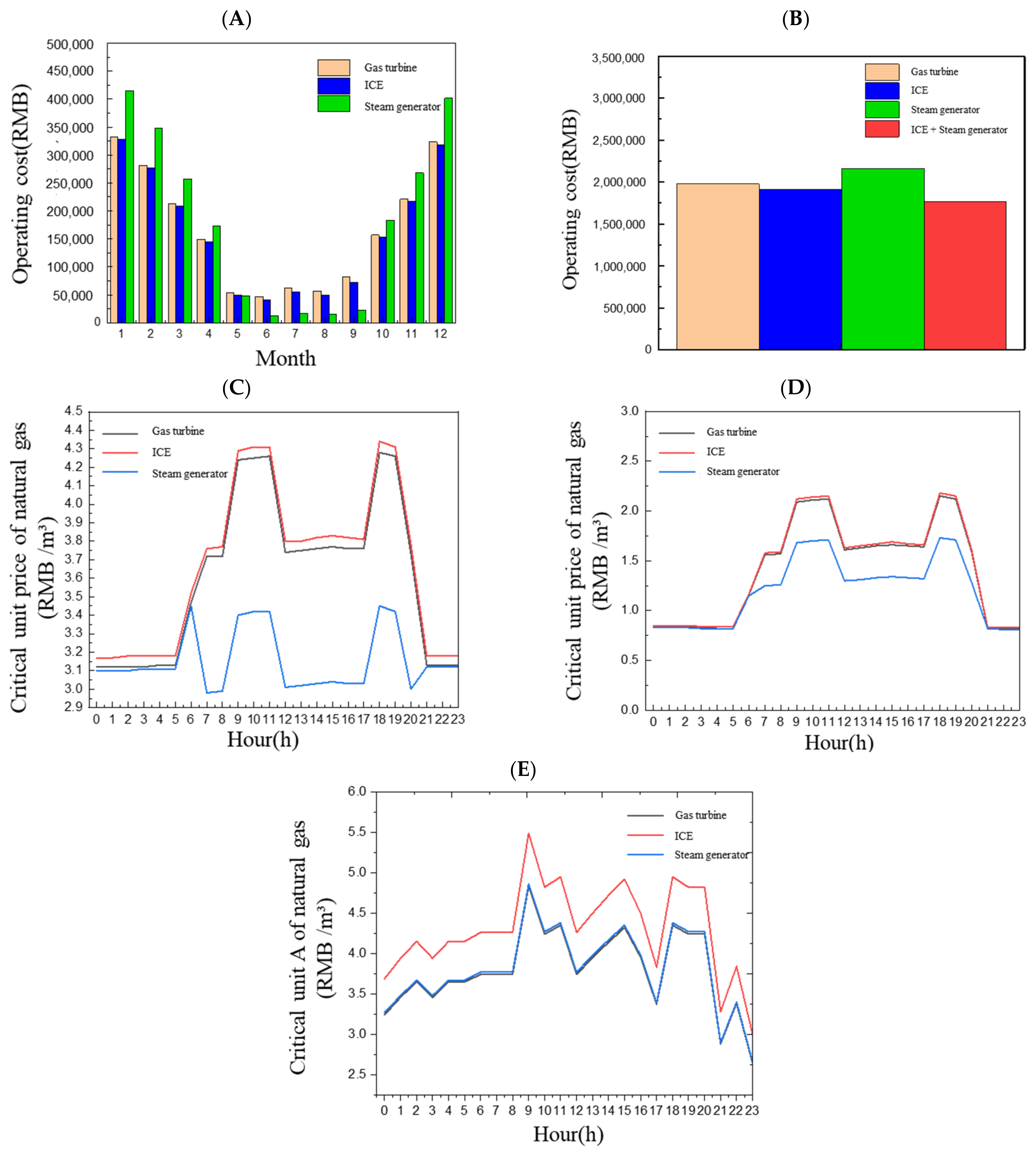

3.4. Comparative Analysis of the Annual Operating Costs of the Three Systems

- (1)

- Load estimation using 2020 climate data shows that the CCHP subsystem with an internal combustion engine as the power unit has the lowest operating cost of RMB 1915.306 million (USD 276.882 million) from January to April; the gas turbine system is the second lowest at RMB 1978.663 million (USD 286.042 million); and the steam boiler CCHP system has the highest operating cost of RMB 2162.728 million (USD 312.650 million). The difference in operating costs between the internal combustion engine and gas−turbine−driven combined cooling, heating, and power subsystems is slight;

- (2)

- Customers only need to meet the electrical and cooling loads from June to September. The results show that during these four months, the system used as the power unit of the combined cooling, heating, and power system has the lowest operating cost, followed by the gas turbine system, while the combined cooling, heating, and power system with an internal combustion engine has the highest operating cost;

- (3)

- From October to December, Harbin enters the heating season. The results show that the system using an internal combustion engine as the power unit has the lowest total operating costs during these months, followed by a gas turbine, while the steam boiler system has the highest operating costs. The difference in operating costs between the combined cooling, heating, and power subsystems driven by internal combustion engines and gas turbines was minor.

Analysis of the Impact of Natural Gas Prices

4. Conclusions

- (1)

- Using the climatic conditions of the Harbin area as a background, the load index method was used to analyze the cooling, heating, and electricity demand of a residential house with a usable area of 10,000 square meters in different seasons, on typical days, and for typical users throughout the year, and it was concluded that the peak of heat load was 1200 kW on a typical day in winter. The peak of the cooling load was 300 kW on a typical day in summer, with significant differences in heat, cooling, and electricity demand;

- (2)

- According to the load demand of different energy, the operating economy of independent gas turbine system, internal combustion engine system, and steam boiler system was studied, and the optimized selection scheme of host equipment was given when the proportion of cold and hot load was different. In the steam boiler, at this time, the electric chiller and absorption refrigeration capacity accounted for 30% and 70%, respectively, only when there was a heat load using an internal combustion engine. The cost of this combination is RMB 1.766 million (USD 0.255 million), which is 10.7%, 7.8%, and 18.3% less than the cost of three single−equipment subsystems, respectively, and achieves the decoupling of cold, heat, and electrical loads. In summary, the “internal combustion engine + steam boiler” model achieves efficient energy use and energy conversion diversity at a lower cost, improves energy reliability and safety, and reduces energy consumption and environmental pollution. Therefore, the “internal combustion engine + steam boiler” model is essential in constructing multi−energy heterogeneous integrated energy systems;

- (3)

- The simulation and optimal operation method of the cooling, heating, and power system under multiple energy input conditions were studied. The critical curves of typical daily costs and gas price effects in winter and summer were obtained. At the same rate of gas price reduction, the internal combustion engine system can achieve the economic optimum of system power generation faster throughout the year. If the gas price is lower than the corresponding predicted value, purchasing natural gas for power generation is considered. It is vice versa for grid power, and the optimal deployment scheme is given.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wei, G.; Zhi, W.; Rui, B.; Wei, L.; Gan, Z.; Wu, C.; Wu, Z. Modeling, planning and optimal energy management of combined cooling, heating and power microgrid: A review. Int. J. Electr. Power Energy Syst. 2014, 54, 26–37. [Google Scholar]

- Wang, C.; Hong, B.; Guo, L.; Zhang, D.; Liu, W. A General Modeling Method for Optimal Dispatch of Combined Cooling, Heating and Power Microgrid. Proc. Csee 2013, 33, 26–33. [Google Scholar]

- Gu, W.; Wang, Z.; Wu, Z.; Luo, Z.; Tang, Y.; Wang, J. An Online Optimal Dispatch Schedule for CCHP Microgrids Based on Model Predictive Control. IEEE Trans. Smart Grid 2017, 8, 2332–2342. [Google Scholar] [CrossRef]

- Wang, R.; Wei, G.U.; Zhi, W.U. Economic and Optimal Operation of a Combined Heat and Power Microgrid with Renewable Energy Resources. Autom. Electr. Power Syst. 2011, 35, 22–27. [Google Scholar]

- Matthias, M.; Daniel, S.; Georg, L.; Christoph, L.; Carlo, C.; Hans, A. Beyond Traditional Energy Sector Coupling: Conserving and Efficient Use of Local Resources. Sustainability 2022, 14, 7445. [Google Scholar]

- Liu, Y.; Yang, X.; Wang, M. Global Transmission of Returns among Financial, Traditional Energy, Renewable Energy and Carbon Markets: New Evidence. Energies 2021, 14, 7286. [Google Scholar] [CrossRef]

- Feng, D.; Shang, Q.; Dong, H.; Zhang, Y.; Wang, Z.; Li, D.; Xie, M.; Wei, Q.; Zhao, Y.; Sun, S. Catalytic mechanism of Na on coal pyrolysis-derived carbon black formation: Experiment and DFT simulation. Fuel Process. Technol. 2021, 224, 107011. [Google Scholar] [CrossRef]

- Zhang, Y.; Shang, Q.; Feng, D.; Sun, H.; Wang, F.; Hu, Z.; Cheng, Z.; Zhou, Z.; Zhao, Y.; Sun, S. Interaction mechanism of in-situ catalytic coal H2O-gasification over biochar catalysts for H2O-H-2-tar reforming and active sites conversion. Fuel Process. Technol. 2022, 233, 107307. [Google Scholar] [CrossRef]

- Feng, D.; Guo, D.; Shang, Q.; Zhao, Y.; Zhang, L.; Guo, X.; Cheng, J.; Chang, G.; Guo, Q.; Sun, S. Mechanism of biochar-gas-tar-soot formation during pyrolysis of different biomass feedstocks: Effect of inherent metal species. Fuel 2021, 293, 120409. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Feng, D.; Gao, J.; Dong, L.; Zhao, Y.; Sun, S.; Huang, Y.; Qin, Y. Functional Biochar Synergistic Solid/Liquid-Phase CO2 Capture: A Review. Energy Fuels 2022, 36, 2945–2970. [Google Scholar] [CrossRef]

- Feng, D.; Guo, D.; Zhang, Y.; Sun, S.; Zhao, Y.; Chang, G.; Guo, Q.; Qin, Y. Adsorption-enrichment characterization of CO2 and dynamic retention of free NH3 in functionalized biochar with H2O/NH3·H2O activation for promotion of new ammonia-based carbon capture. Chem. Eng. J. 2021, 409, 128193. [Google Scholar] [CrossRef]

- Alireza, D.; Alireza, Z.; Sajjad, M.S. Conceptual design and technical analysis of a hybrid natural gas/molten carbonate fuel cell system for combined cooling, heating, and power applications. Energy Build. 2022, 273, 112402. [Google Scholar]

- He, X.; Li, C.; Wang, H. Thermodynamics analysis of a combined cooling, heating and power system integrating compressed air energy storage and gas-steam combined cycle. Energy 2022, 260, 125105. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, W.; Tao, H.; Wu, D.; Meng, J. Research on capacity and strategy optimization of combined cooling, heating and power systems with solar photovoltaic and multiple energy storage. Energy Convers. Manag. 2022, 268, 115965. [Google Scholar] [CrossRef]

- Guo, L.; Liu, W.; Cai, J.; Hong, B.; Wang, C. A two-stage optimal planning and design method for combined cooling, heat and power microgrid system. Energy Convers. Manag. 2013, 74, 433–445. [Google Scholar] [CrossRef]

- Rezvan, A.T.; Gharneh, N.S.; Gharehpetian, G.B. Optimization of distributed generation capacities in buildings under uncertainty in load demand. Energy Build. 2013, 57, 58–64. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, Y.; Zhao, Y.; Sun, S.; Wu, J.; Tan, H. Mechanism of in-situ dynamic catalysis and selective deactivation of H 2 O-activated biochar for biomass tar reforming. Fuel 2020, 279, 118450. [Google Scholar] [CrossRef]

- Barbieri, E.S.; Spina, P.R.; Venturini, M. Analysis of innovative micro-CHP systems to meet household energy demands. Appl. Energy 2012, 97, 723–733. [Google Scholar] [CrossRef]

- Dincer, I. On thermal energy storage systems and applications in buildings. Energy Build. 2002, 34, 377–388. [Google Scholar] [CrossRef]

- Pagliarini, G.; Rainieri, S. Modeling of a thermal energy storage system coupled with combined heat and power generation for the heating requirements of a University Campus. Appl. Therm. Eng. 2010, 30, 1255–1261. [Google Scholar] [CrossRef]

- Huicochea, A.; Rivera, W.; Gutiérrez-Urueta, G.; Bruno, J.C.; Coronas, A. Thermodynamic analysis of a trigeneration system consisting of a micro gas turbine and a double effect absorption chiller. Appl. Therm. Eng. 2011, 31, 3347–3353. [Google Scholar] [CrossRef]

- Feng, D.; Zhao, Y.; Zhang, Y.; Xu, H.; Zhang, L.; Sun, S. Catalytic mechanism of ion-exchanging alkali and alkaline earth metallic species on biochar reactivity during CO2/H2O gasification. Fuel 2018, 212, 523–532. [Google Scholar] [CrossRef]

- Bassols, J.; Kuckelkorn, B.; Langreck, J.; Schneider, R.; Veelken, H. Trigeneration in the food industry. Appl. Therm. Eng. 2002, 22, 595–602. [Google Scholar] [CrossRef]

- Khatri, K.K.; Sharma, D.; Soni, S.; Tanwar, D. Experimental investigation of CI engine operated Micro-Trigeneration system. Appl. Therm. Eng. 2010, 30, 1505–1509. [Google Scholar] [CrossRef]

- Kong, X.Q.; Wang, R.Z.; Huang, X.H. Energy optimization model for a CCHP system with available gas turbines. Appl. Therm. Eng. 2004, 25, 377–391. [Google Scholar] [CrossRef]

- Feng, D.; Guo, D.; Zhang, Y.; Sun, S.; Zhao, Y.; Shang, Q.; Sun, H.; Wu, J.; Tan, H. Functionalized construction of biochar with hierarchical pore structures and surface O-/N-containing groups for phenol adsorption. Chem. Eng. J. 2020, 410, 127707. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, B.; Zheng, Y.; Zhang, R.; Liu, P.; An, Z. Economic assessment and regional adaptability analysis of CCHP system coupled with biomass-gas based on year-round performance—ScienceDirect. Sustain. Energy Technol. Assess. 2021, 45, 101141. [Google Scholar]

- Mago, P.J.; Chamra, L.M. Analysis and optimization of CCHP systems based on energy, economical, and environmental considerations. Energy Build. 2009, 41, 1099–1106. [Google Scholar] [CrossRef]

- Chicco, G.; Mancarella, P. Matrix modelling of small-scale trigeneration systems and application to operational optimization. Energy 2009, 34, 261–273. [Google Scholar] [CrossRef]

- Yosten, A.J.; Henze, G.P. Modeling and Optimal Control of Distributed Generation Systems for Demand and Energy Management. In Proceedings of the ASME 2009 3rd International Conference on Energy Sustainability collocated with the Heat Transfer and InterPACK09 Conferences, San Francisco, CA, USA, 19–23 July 2009; pp. 109–119. [Google Scholar]

- Murai, M.; Sakamoto, Y.; Shinozaki, T. An optimizing control for district heating and cooling plant. In Proceedings of IEEE International Conference on Control Applications, Kohala Coast, HI, USA, 22–27 August 1999; pp. 600–604. [Google Scholar]

- Liu, X.; Wu, J.; Jenkins, N.; Bagdanavicius, A. Combined analysis of electricity and heat networks. Appl. Energy 2016, 162, 1238–1250. [Google Scholar] [CrossRef]

- Ruotong, W. Optimal Operation Strategies for Multi-Energy Systems in Industrial Parks. Bachelor’s Thesis, North China University of Electric Power, Beijing, China, 2021. [Google Scholar]

- Li, N.; Gu, J.; Liu, B.; Lu, H. Optimal configuration and operation strategy of multi-energy complementary microgrid system based on improved particle swarm algorithm. Electr. Energy Effic. Manag. Technol. 2017, 19, 53–64. [Google Scholar]

- Cao, C.; Liu, L.; Quan, C.; Zhang, R. Study on the application of multi-energy complementary heating system for civil buildings in severe cold regions. Qinghai Technol. 2022, 29, 111–119. [Google Scholar]

- Xu, L. Multi-Energy Complementary Distributed Energy Systems for Renewable Energy in Harsh Cold Regions. Master’s Thesis, North China Electric Power University, Beijing, China, 2022. [Google Scholar]

- Wang, X.; Xu, Y.; Fu, Z.; Guo, J.; Bao, Z.; Li, W.; Zhu, Y. A dynamic interactive optimization model of CCHP system involving demand-side and supply-side impacts of climate change. Part II: Application to a hospital in Shanghai, China. Energy Convers. Manag. 2022, 252, 115112. [Google Scholar] [CrossRef]

- Tan, Q.; Chen, L.; Wu, P.; Xu, H.; Tang, W.; Yin, J. Robust Scheduling Optimization Model for Combined Cooling, Heating and Power System in Industrial Parks. J. Phys. Conf. Ser. 2022, 2160, 012048. [Google Scholar] [CrossRef]

- Liu, Y. Research on Optimization of Building Type Natural Gas Cooling, Heating and Power Trigeneration System in Severe Cold Areas. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2019. [Google Scholar]

- Wang, C.; Hong, B.; Guo, L.; Zhang, D.; Liu, W. General modeling method for optimal scheduling of microgrid with combined power supply. Proc. CSEE 2013, 33, 26–33+23. [Google Scholar] [CrossRef]

- Gao, L.; Hwang, Y.; Cao, T. An overview of optimization technologies applied in combined cooling, heating and power systems. Renew. Sustain. Energy Rev. 2019, 114, 109344. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, J.; Sun, Y.; Wei, C.; Wang, J.; Liao, S.; Ke, D.; Li, X.; Yang, J.; Peng, X. Coordinated operation of gas-electricity integrated distribution system with multi-CCHP and distributed renewable energy sources. Appl. Energy 2018, 211, 237–248. [Google Scholar] [CrossRef]

- Wang, J.; Xie, X.; Lu, Y.; Liu, B.; Li, X. Thermodynamic performance analysis and comparison of a combined cooling heating and power system integrated with two types of thermal energy storage. Appl. Energy 2018, 219, 114–122. [Google Scholar] [CrossRef]

- Ahn, H.; Freihaut, J.D.; Rim, D. Economic feasibility of combined cooling, heating, and power (CCHP) systems considering electricity standby tariffs. Energy 2019, 169, 420–432. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, S.; Yu, L.; Zhou, Y. Comparison of combined cooling, heating and power (CCHP) systems with different cooling modes based on energetic, environmental and economic criteria. Energy Convers. Manag. 2018, 160, 60–73. [Google Scholar] [CrossRef]

- Fan, J.; Hong, H.; Zhu, L.; Jiang, Q.; Jin, H. Thermodynamic and environmental evaluation of biomass and coal co-fuelled gasification chemical looping combustion with CO2 capture for combined cooling, heating and power production. Appl. Energy 2017, 195, 861–876. [Google Scholar] [CrossRef]

- Gao, Y.; Deng, Y.; Yao, W.; Hang, Y. Optimization of combined cooling, heating, and power systems for rural scenario based on a two-layer optimization model. J. Build. Eng. 2022, 60, 105217. [Google Scholar] [CrossRef]

- Kuang, J.; Zhang, C.; Sun, B.; Hang, Y. Stochastic Dynamic Solution for Off-design Operation Optimization of Combined Cooling, Heating, and Power Systems With Energy Storage. Appl. Therm. Eng. 2019, 163, 114356. Available online: https://www.sciencedirect.com/science/article/abs/pii/S1359431119336294?via%3Dihub (accessed on 15 April 2023).

- Rajabi, M.; Mehrpooya, M.; Haibo, Z.; Huang, Z. Chemical looping technology in CHP (combined heat and power) and CCHP (combined cooling heating and power) systems: A critical review. Energy Ecol. 2019, 253, 113544. [Google Scholar] [CrossRef]

- Wu, H.; Liu, Q.; Xie, G.; Guo, S.; Zheng, J.; Su, B. Performance investigation of a novel hybrid combined cooling, heating and power system with solar thermochemistry in different climate zones. Energy 2020, 190, 116281. [Google Scholar] [CrossRef]

- Cui, Y.; Ao, X.; Cao, J.; Zhou, X.; Li, M.; Zhao, C.; Liu, M.; Lin, R. Effects of climate change on energy consumption of office buildings in typical cities of Northeast China. J. Meteorol. Environ. 2021, 37, 91–99. [Google Scholar]

- Pan, T.; Du, G.; Zhang, C.; Dong, J.; Li, Q.; Shi, F. Landsat TM analysis of surface temperature variation characteristics in Harbin City from 2001 to 2015. Geogr. Sci. 2016, 36, 1759–1766. [Google Scholar] [CrossRef]

- Song, L.; Han, J.; Liu, Y.; Zhou, C. Variation characteristics and forecast model of winter surface temperature in Harbin City. Meteorol. Heilongjiang 2014, 31, 28–30+38. [Google Scholar] [CrossRef]

| Symbols | Meaning | Symbols | Meaning |

|---|---|---|---|

| Gas turbine power generation efficiency, kW | Heat recovery coefficient | ||

| Rated power generation of gas turbine, kW | Low−level calorific constant, usually taken as 9.7 | ||

| Minimum power generated by gas turbine, kW | Heat generation, kW | ||

| Rated power generation of the gas turbine under design conditions, kW | Cooling factor of the unit | ||

| Temperature correction | Status parameters of the unit | ||

| Fuel calorific value, kW | Heat generation, kW | ||

| Exhaust smoke recoverable heat value, kW | Operating efficiency vs. rated efficiency | ||

| Design temperature, ℃ | Load factor | ||

| Actual working temperature of equipment, ℃ | Status parameters of the boiler | ||

| Coefficient, related to equipment capacity | Refrigeration capacity of the chiller, kW | ||

| Rated capacity of the gas−fired internal combustion engine, kW | Refrigeration coefficient of the refrigeration machine refrigeration unit | ||

| Rated thermal efficiency of internal combustion engines | Status parameters of the unit | ||

| Electrical efficiency of internal combustion engines at partial load rates | The minimum and maximum cooling capacity of the refrigerator, kW | ||

| Thermal efficiency of internal combustion engines at partial load rates | Heat supplied by boiler, kW | ||

| Load factor of internal combustion engine | Operating efficiency vs. rated efficiency | ||

| Power plant power generation, kW | Load factor | ||

| Power unit recovery waste heat, kW | Status parameters of the boiler | ||

| Amount of natural gas consumed, m³ |

| Gas Turbine Subsystem | Internal Combustion Engine Subsystem | Steam Boiler Subsystem | |

|---|---|---|---|

| Purchase of gas + purchase of electricity (RMB) | 6791.26 | 5778.45 | 4970.76 |

| Low−cost natural gas (RMB) | 5016.14 | 13,056.15 | 1837.73 |

| Cost savings rate | 26.1% | 63.0% |

| Gas Turbine Subsystem | Internal Combustion Engine Subsystem | Steam Boiler Subsystem | |

|---|---|---|---|

| Purchase of gas + purchase of electricity (RMB) | 15,023.71 | 14,156.85 | 14,352.15 |

| Low−cost natural gas (RMB) | 22,252.74 | 5746.39 | 6405.22 |

| Cost savings rate | 59.4% | 55.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Sun, Q.; Zhang, Y.; Da, Y.; Dong, H.; Zhang, H.; Du, Q.; Gao, J. Modeling and Optimization of Natural Gas CCHP System in the Severe Cold Region. Energies 2023, 16, 4582. https://doi.org/10.3390/en16124582

Song Y, Sun Q, Zhang Y, Da Y, Dong H, Zhang H, Du Q, Gao J. Modeling and Optimization of Natural Gas CCHP System in the Severe Cold Region. Energies. 2023; 16(12):4582. https://doi.org/10.3390/en16124582

Chicago/Turabian StyleSong, Yidan, Qiaoqun Sun, Yu Zhang, Yaodong Da, Heming Dong, Hebo Zhang, Qian Du, and Jianmin Gao. 2023. "Modeling and Optimization of Natural Gas CCHP System in the Severe Cold Region" Energies 16, no. 12: 4582. https://doi.org/10.3390/en16124582

APA StyleSong, Y., Sun, Q., Zhang, Y., Da, Y., Dong, H., Zhang, H., Du, Q., & Gao, J. (2023). Modeling and Optimization of Natural Gas CCHP System in the Severe Cold Region. Energies, 16(12), 4582. https://doi.org/10.3390/en16124582