Partial Photoluminescence Imaging for Inspection of Photovoltaic Cells: Artificial LED Excitation and Sunlight Excitation

Abstract

1. Introduction

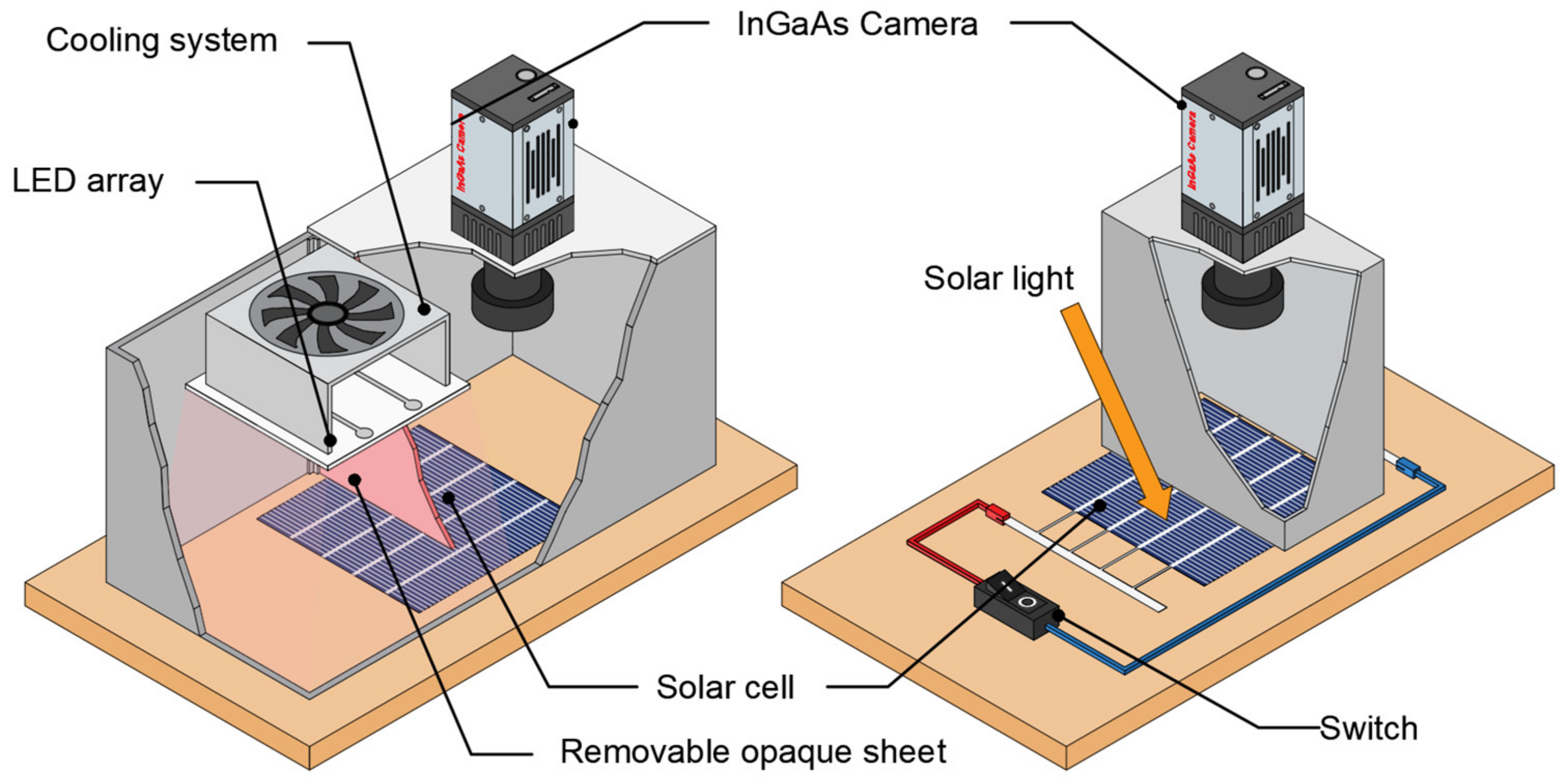

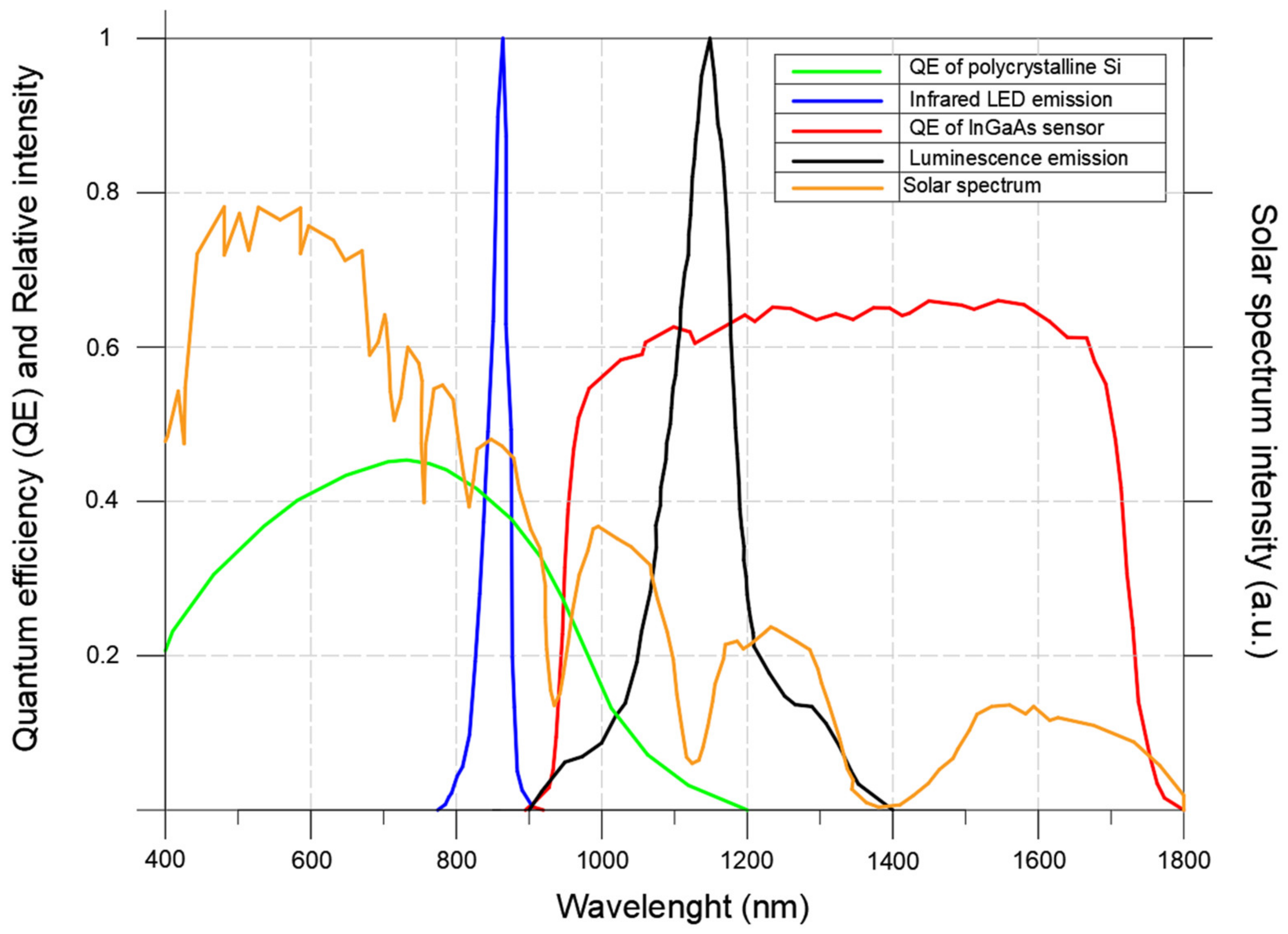

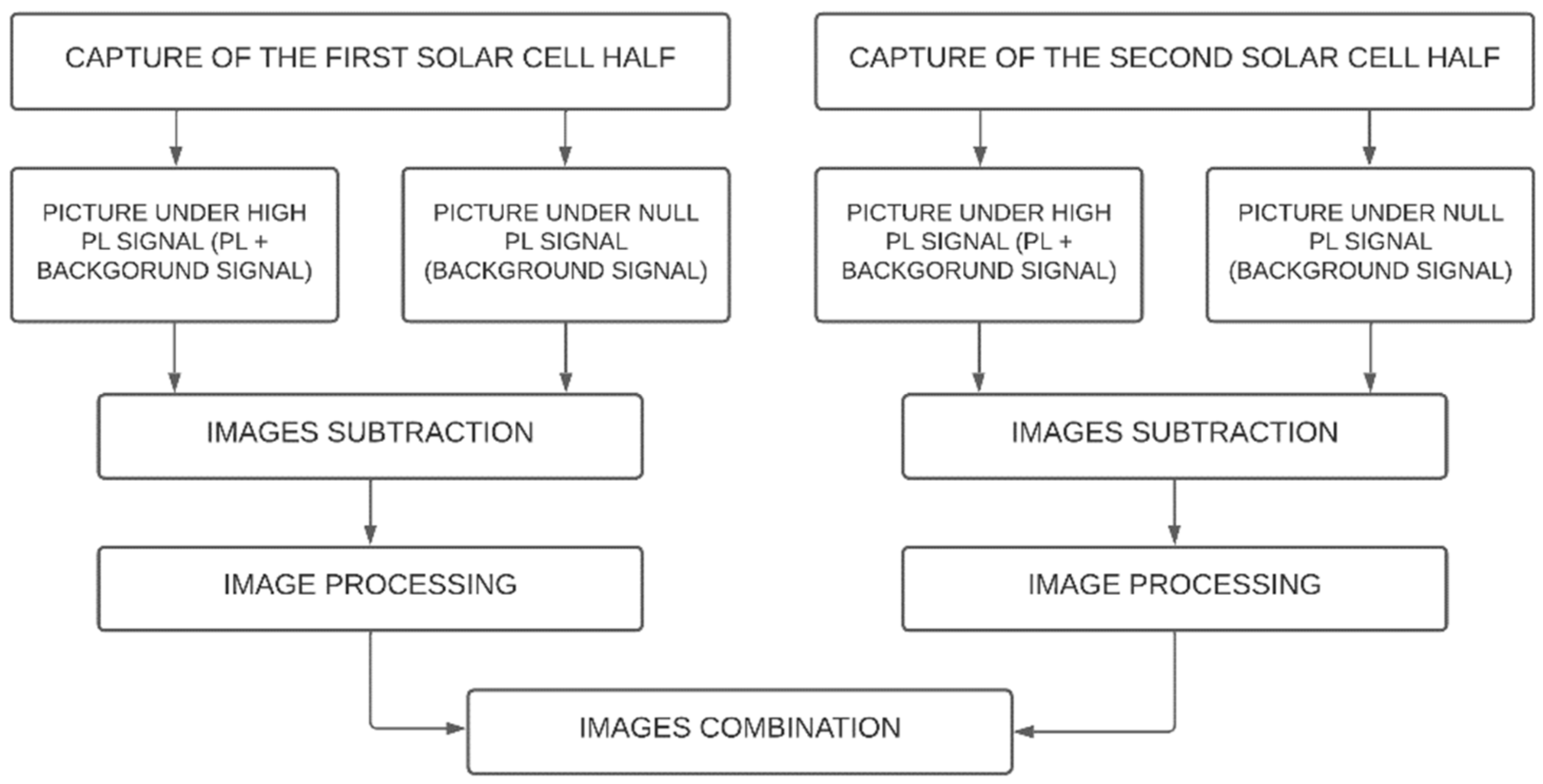

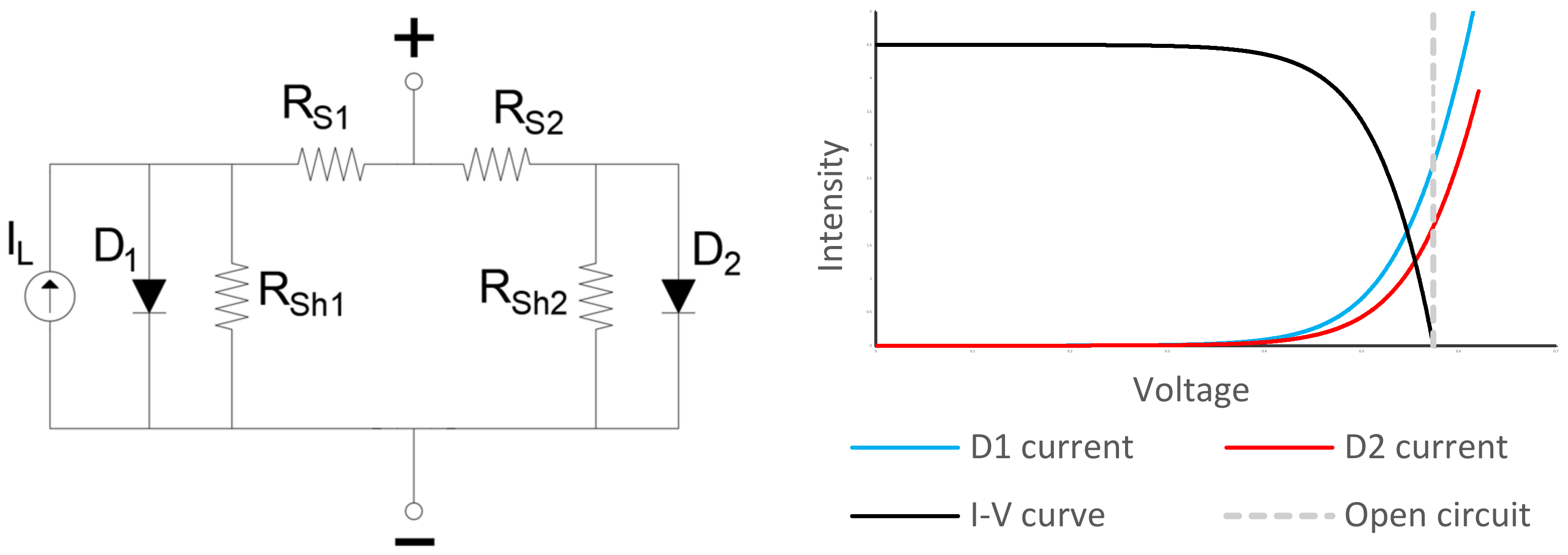

2. Materials and Methods

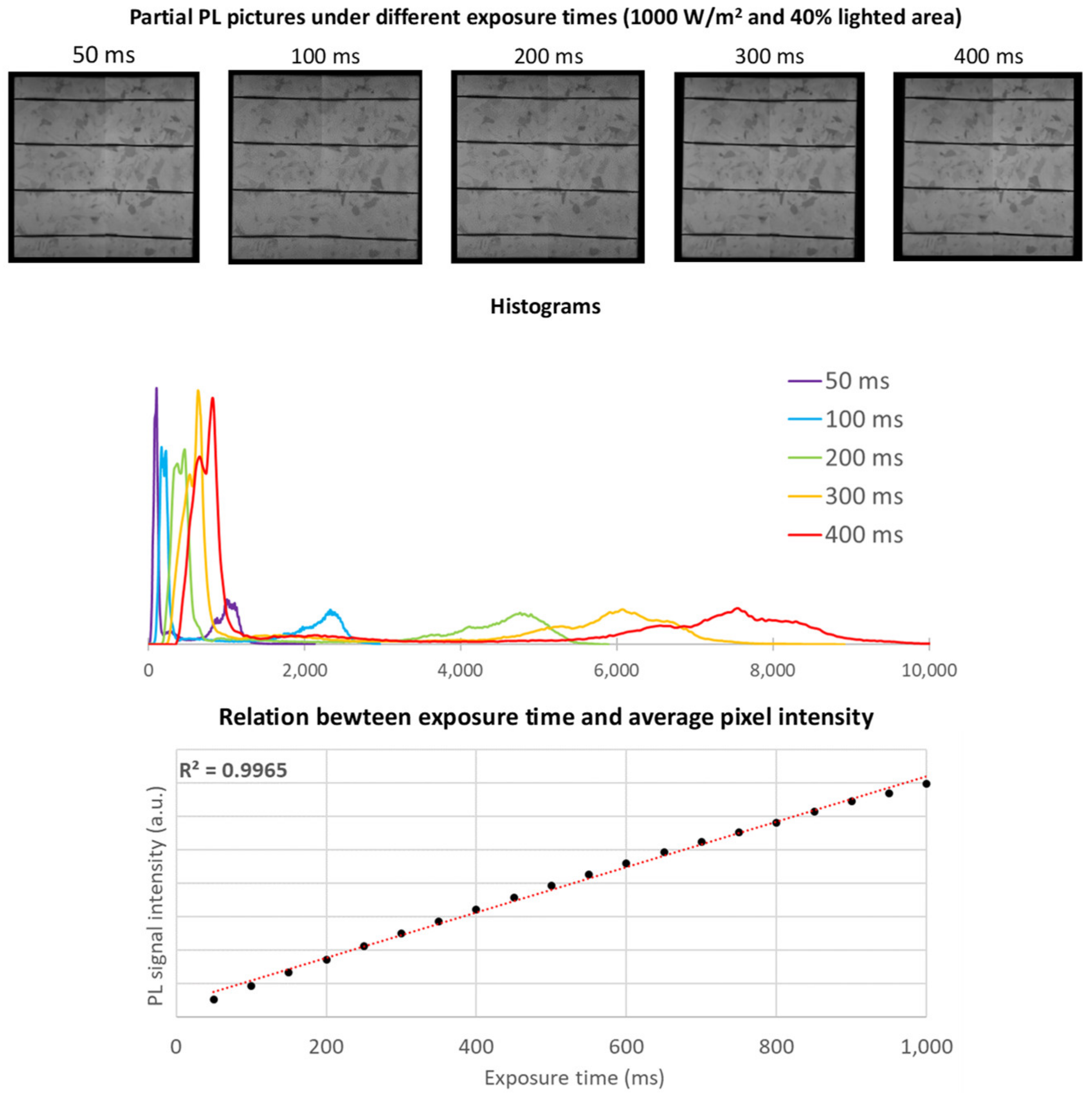

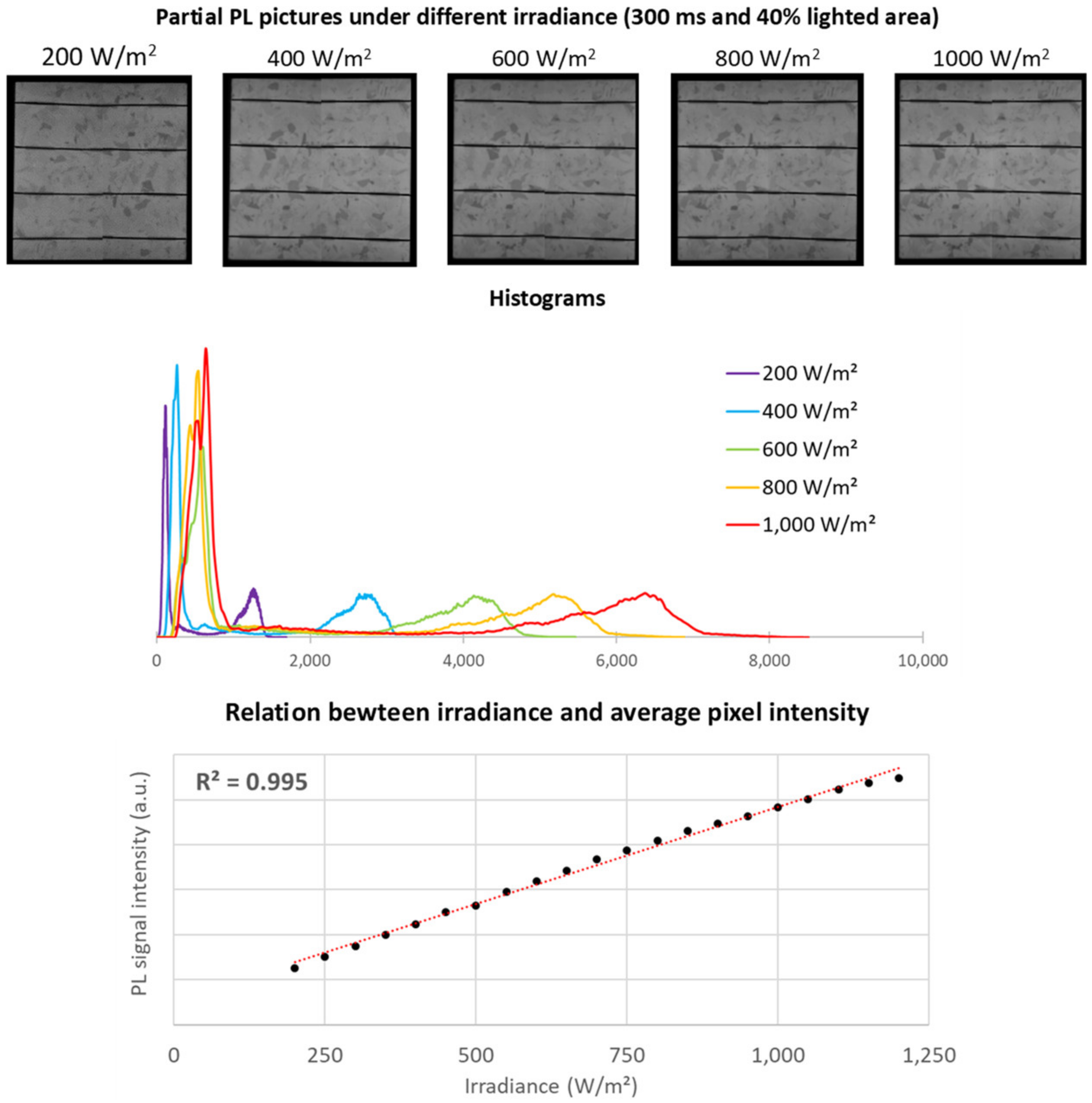

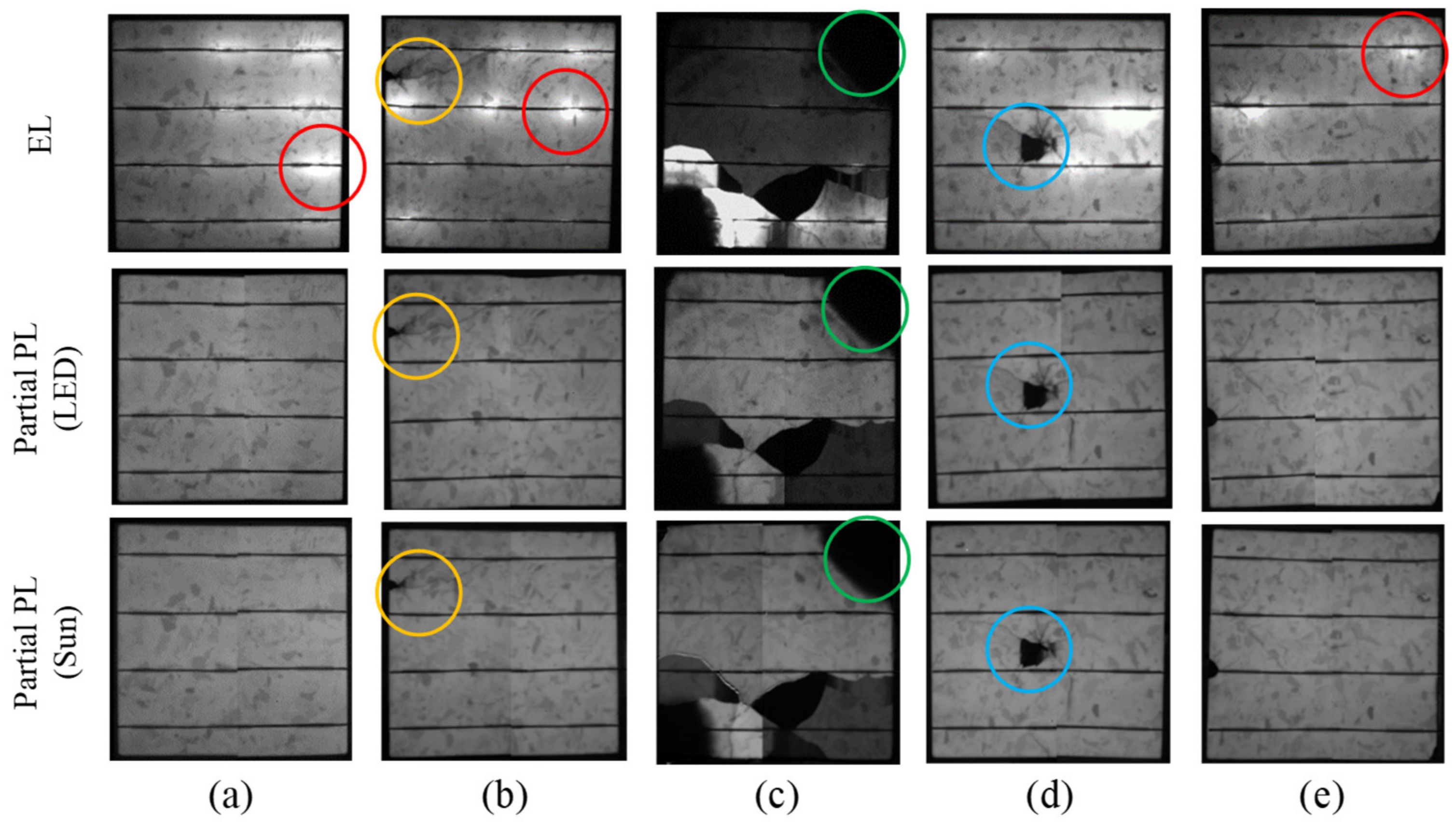

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kammen, D.M.; Sunter, D.A. City-Integrated Renewable Energy for Urban Sustainability. Science 2016, 352, 922–928. [Google Scholar] [CrossRef] [PubMed]

- Goel, M.; Verma, V.S.; Tripathi, N.G. Solar Energy in Cities. In Solar Energy: Made Simple for a Sustainable Future; Springer Nature: Singapore, 2022; pp. 161–173. ISBN 978-9-81192-099-8. [Google Scholar]

- Hernández-Callejo, L.; Gallardo-Saavedra, S.; Alonso-Gómez, V. A Review of Photovoltaic Systems: Design, Operation and Maintenance. Sol. Energy 2019, 188, 426–440. [Google Scholar] [CrossRef]

- Köntges, M.; Kurtz, S.; Packard, C.; Jahn, U.; Berger, K.A.; Kato, K.; Friesen, T.; Liu, H.; Van Iseghem, M. Review of Failures of Photovoltaic Modules; IEA-PVPS: Paris, France, 2014. [Google Scholar]

- Niccolai, A.; Gandelli, A.; Grimaccia, F.; Zich, R.; Leva, S. Overview on Photovoltaic Inspections Procedure by Means of Unmanned Aerial Vehicles. In Proceedings of the 2019 IEEE Milan PowerTech, Milan, Italy, 23–27 June 2019; IEEE: New York, NY, USA, 2019; pp. 1–6. [Google Scholar]

- Høiaas, I.; Grujic, K.; Imenes, A.G.; Burud, I.; Olsen, E.; Belbachir, N. Inspection and Condition Monitoring of Large-Scale Photovoltaic Power Plants: A Review of Imaging Technologies. Renew. Sustain. Energy Rev. 2022, 161, 112353. [Google Scholar] [CrossRef]

- Potthoff, T.; Bothe, K.; Eitner, U.; Hinken, D.; Köntges, M. Detection of the Voltage Distribution in Photovoltaic Modules by Electroluminescence Imaging. Prog. Photovolt. Res. Appl. 2010, 18, 100–106. [Google Scholar] [CrossRef]

- Colvin, D.J.; Schneller, E.J.; Davis, K.O. Extracting Cell Level Characteristics from Photovoltaic Module Electroluminescence Images. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; IEEE: New York, NY, USA, 2019; pp. 2740–2742. [Google Scholar]

- Kropp, T.; Schubert, M.; Werner, J. Quantitative Prediction of Power Loss for Damaged Photovoltaic Modules Using Electroluminescence. Energies 2018, 11, 1172. [Google Scholar] [CrossRef]

- Ulrike, J.; Magnus, H.; Marc, K.; David, P.; Marco, P.; Ioannis, T.; Joshua, S.; Karl, B.; Samuli, R.; Roger, F.; et al. Review on Infrared and Electroluminescence Imaging for PV Field Applications; IEA-PVPS: Paris, France, 2018. [Google Scholar]

- Guada, M.; Moretón, Á.; Rodríguez-Conde, S.; Sánchez, L.A.; Martínez, M.; González, M.Á.; Jiménez, J.; Pérez, L.; Parra, V.; Martínez, O. Daylight Luminescence System for Silicon Solar Panels Based on a Bias Switching Method. Energy Sci. Eng. 2020, 8, 3839–3853. [Google Scholar] [CrossRef]

- Bhoopathy, R.; Kunz, O.; Juhl, M.; Trupke, T.; Hameiri, Z. Outdoor Photoluminescence Imaging of Photovoltaic Modules with Sunlight Excitation. Prog. Photovolt. Res. Appl. 2018, 26, 69–73. [Google Scholar] [CrossRef]

- Kunz, O.; Rey, G.; Juhl, M.K.; Trupke, T. High Throughput Outdoor Photoluminescence Imaging via PV String Modulation. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Fort Lauderdale, FL, USA, 20 June 2021; IEEE: New York, NY, USA, 2021; pp. 0346–0350. [Google Scholar]

- Bhoopathy, R.; Kunz, O.; Juhl, M.; Trupke, T.; Hameiri, Z. Outdoor Photoluminescence Imaging of Solar Panels by Contactless Switching: Technical Considerations and Applications. Prog. Photovolt. Res. Appl. 2020, 28, 217–228. [Google Scholar] [CrossRef]

- Koester, L.; Astigarraga, A.; Lindig, S.; Moser, D. Development of Daylight Photoluminescence Technique for Photovoltaic Modules and Investigation of Temperature Dependency. In Proceedings of the 37th European Photovoltaic Solar Energy Conference and Exhibition (EU PVSEC), Online. 7–11 September 2020; pp. 908–913. [Google Scholar]

- Vuković, M.; Høiaas, I.E.; Jakovljević, M.; Flø, A.S.; Olsen, E.; Burud, I. Outdoor Photoluminescence and Electroluminescence Imaging of Photovoltaic Silicon Modules in a String. In Proceedings of the 11th International Conference on Crystalline Silicon Photovoltaics (SILICONPV 2021), Hamelin, Germany, 19–23 April 2022; p. 030012. [Google Scholar]

- Kropp, T.; Berner, M.; Stoicescu, L.; Werner, J.H. Self-Sourced Daylight Electroluminescence from Photovoltaic Modules. IEEE J. Photovolt. 2017, 7, 1184–1189. [Google Scholar] [CrossRef]

- Coello, J.; Pérez, L.; Domínguez, F.; Navarrete, M. On-Site Quality Control of Photovoltaic Modules with the PV MOBILE LAB. In Proceedings of the Energy Procedia: 2013 ISES Solar World Congress; Elsevier: Amsterdam, The Netherlands, 2014; Volume 57, pp. 89–98. [Google Scholar]

- Navarrete, M.; Pérez, L.; Domínguez, F.; Castillo, G.; Gómez, R.; Martínez, M.; Coello, J.; Parra, V. On-Site Inspection of PV Modules Using an Internationally Accredited PV Mobile Lab: A Three-Years Experience Operating Worldwide. In Proceedings of the 31st European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 14–18 September 2015; pp. 1989–1991. [Google Scholar]

- Ballestín-Fuertes, J.; Muñoz-Cruzado-Alba, J.; Sanz-Osorio, J.F.; Hernández-Callejo, L.; Alonso-Gómez, V.; Morales-Aragones, J.I.; Gallardo-Saavedra, S.; Martínez-Sacristan, O.; Moretón-Fernández, Á. Novel Utility-Scale Photovoltaic Plant Electroluminescence Maintenance Technique by Means of Bidirectional Power Inverter Controller. Appl. Sci. 2020, 10, 3084. [Google Scholar] [CrossRef]

- Kunz, O.; Rey, G.; Bhoopathy, R.; Hameiri, Z.; Trupke, T. Outdoor PL Imaging of Crystalline Silicon Modules at Constant Operating Point. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 14 June 2020; IEEE: New York, NY, USA, 2020; pp. 2140–2143. [Google Scholar]

- Juhl, M.; Weber, J.W.; Zafirovska, I.; Juhl, M.K.; Weber, J.W.; Kunz, O.; Trupke, T. Module Inspection Using Line Scanning Photoluminescence Imaging. In Proceedings of the 32nd European Photovoltaic Solar Energy Conference and Exhibition, Munich, Germany, 20–24 June 2016. [Google Scholar] [CrossRef]

- Iskra, Z.; Juhl, M.K.; Weber, J.W.; Wong, J.; Trupke, T. Detection of Finger Interruptions in Silicon Solar Cells Using Line Scan Photoluminescence Imaging. IEEE J. Photovolt. 2017, 7, 1496–1502. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory; Johnston, S. Contactless Electroluminescence Imaging for Cell and Module Characterization. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC 2015), New Orleans, LA, USA, 14 December 2015; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2015. [Google Scholar]

- Sulas, D.B.; Johnston, S.; Jordan, D.C. Comparison of Photovoltaic Module Luminescence Imaging Techniques: Assessing the Influence of Lateral Currents in High-Efficiency Device Structures. Sol. Energy Mater. Sol. Cells 2019, 192, 81–87. [Google Scholar] [CrossRef]

- OpenCV: Camera Calibration. Available online: https://docs.opencv.org/4.x/dc/dbb/tutorial_py_calibration.html (accessed on 15 May 2023).

- Cotfas, D.T.; Cotfas, P.A.; Kaplanis, S. Methods to Determine the Dc Parameters of Solar Cells: A Critical Review. Renew. Sustain. Energy Rev. 2013, 28, 588–596. [Google Scholar] [CrossRef]

| Method | EL/PL | Day/Night | Discussion |

|---|---|---|---|

| Mobile laboratory [18,19] | EL | Day/Night | A truck equipped with several measuring devices allows for the full characterization of PV modules, including EL images, infrared thermography images, current–voltage measurements, and insulation testing. However, this method requires the disassembly of the PV modules. |

| Bidirectional inverter [20] | EL | Night | A bidirectional inverter is capable of functioning as a conventional solar inverter as well as a power supply, enabling current injection in the PV array and inducing the EL effect. |

| Bias switching method [11] | EL/PL | Day/Night | For daylight EL and PL imaging using lock-in technique, an electronic device is connected between the PV array and a power supply. This device allows for the injection of current for EL imaging or to shift the operating point between the open circuit (OC) and short circuit (SC) for PL imaging. |

| Control cell method [12,13,14] | PL | Day | Daylight PL method that uses a lock-in technique to achieve a shift between two operating points: OC and Maximum Power Point (MPP), which is conducted through a control cell. If the control cell is shaded, all cells that make up the same substring will operate in OC. Conversely, if the control cell is not shaded, all cells will operate in MPP. |

| Inverter control method [15,16] | PL | Day | Daylight PL method that uses a lock-in technique to achieve a shift between two operating points: OC and MPP, which is achieved by the solar inverter. Unlike other methods, the shift between OC and MPP is not instantaneous, taking approximately 6 s due to the Maximum Power Point Tracking (MPTT) algorithm. Therefore, a batch method is used. First, all the MPP images are captured and then the OC images are taken. This approach reduces the time required for image acquisition and also avoids the noise generated by changing irradiance conditions. |

| Self-sourced EL [17] | EL | Day | Daylight EL method that uses a lock-in technique to image solar cells. An electronic device is used to store the energy generated by the PV modules in capacitors. After that, it boosts the voltage and injects current into the module, which leads to the EL effect. |

| Constant operational point PL [21] | PL | Day | Daylight PL method at a constant operational point. In this approach, several images are captured using different optical filters. A main filter is used to allow the PL transmission, resulting in pictures with a high PL signal. A secondary filter is used to block the PL transmission, resulting in pictures with a low PL signal. By properly subtracting these images, the background noise can be eliminated, allowing for accurate measurements of the PL signal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Redondo Plaza, A.; Ngungu, V.N.; Gallardo Saavedra, S.; Morales Aragonés, J.I.; Alonso Gómez, V.; Obregón, L.J.; Hernández Callejo, L. Partial Photoluminescence Imaging for Inspection of Photovoltaic Cells: Artificial LED Excitation and Sunlight Excitation. Energies 2023, 16, 4531. https://doi.org/10.3390/en16114531

Redondo Plaza A, Ngungu VN, Gallardo Saavedra S, Morales Aragonés JI, Alonso Gómez V, Obregón LJ, Hernández Callejo L. Partial Photoluminescence Imaging for Inspection of Photovoltaic Cells: Artificial LED Excitation and Sunlight Excitation. Energies. 2023; 16(11):4531. https://doi.org/10.3390/en16114531

Chicago/Turabian StyleRedondo Plaza, Alberto, Victor Ndeti Ngungu, Sara Gallardo Saavedra, José Ignacio Morales Aragonés, Víctor Alonso Gómez, Lilian Johanna Obregón, and Luis Hernández Callejo. 2023. "Partial Photoluminescence Imaging for Inspection of Photovoltaic Cells: Artificial LED Excitation and Sunlight Excitation" Energies 16, no. 11: 4531. https://doi.org/10.3390/en16114531

APA StyleRedondo Plaza, A., Ngungu, V. N., Gallardo Saavedra, S., Morales Aragonés, J. I., Alonso Gómez, V., Obregón, L. J., & Hernández Callejo, L. (2023). Partial Photoluminescence Imaging for Inspection of Photovoltaic Cells: Artificial LED Excitation and Sunlight Excitation. Energies, 16(11), 4531. https://doi.org/10.3390/en16114531