1. Introduction

The level of ecological awareness and responsibility in the modern world increases every year. One of the ways to reduce the negative impact of humans on the natural environment is emission standards [

1,

2,

3].

Car manufacturers must adapt to the prevailing trends and increasingly restrictive legal regulations. Each car is designed to meet the environmental regulations of the country where it will be registered [

4,

5]. Older cars often meet outdated standards, which makes them less environmentally friendly than currently manufactured cars [

6,

7,

8].

At the beginning of 2021, the restrictive Euro 6d standards for exhaust emissions in passenger cars came into force in the European Union. According to the current standard, the CO

2 emission limit for passenger cars is only 95 g/km compared to the 130 g/km limit applicable in 2019. This translates into a fuel consumption of 4.1 litres of petrol per 100 km and 3.6 litres for diesel. Manufacturers account for the entire fleet of their cars sold. Their total emissions are divided by the number of units sold. Cars with only an internal combustion engine may not meet this emission standard, which forces the direction of automotive development towards hybrid and electric cars [

9,

10,

11,

12].

The spark plug is one of the key elements of the ignition system in petrol, CNG and LPG engines and affects how much fuel is burned in the combustion cycle. It is one of the smallest and cheapest operating elements of the internal combustion engine and performs one of the most important tasks, which is the initiation of fuel ignition in the cylinder. Using a worn or damaged spark plug, which operates at elevated temperatures in the combustion chamber, may cause uneven engine operation, a decrease in its power or increased fuel consumption [

13,

14]. The main tasks of the spark plug include the performance of a spark electric discharge of the required nature inside the combustion chamber while ensuring the repeatable operation of the engine in minimum isobaric and isothermal load conditions [

15,

16,

17]. The spark is triggered during the occurrence of the discharge between the central electrode, powered by high voltage and placed inside a ceramic insulator, and a side grounded electrode is inserted through the threaded plug body. The body is used to mount the spark plug in the socket of the engine head and to transfer heat from the electrode to it [

18,

19,

20].

In addition to meeting the durability and operational requirements of modern engine combustion systems, spark plug manufacturers must also meet the requirements arising from increasingly stringent regulations on exhaust emissions.

Most internal combustion engines currently use one spark plug per cylinder. However, some engines use two spark plugs per cylinder, such as Alfa Romeo cars equipped with the Twin Spark power system [

21,

22,

23].

Spark plugs must be properly selected for a specific engine. Its design, i.e., the shape of the combustion chamber; the location of the valves; the type of spark plug; and the operating parameters affect the temperatures reached in the cylinder. In practice, many types of spark plug designs are used and adapted to the operating conditions in the combustion chamber of a selected internal combustion engine: standard—with one side electrode; specialized—with several side electrodes; U-super—with a groove in the side electrode; and experimental designs with specially shaped insulators [

24,

25,

26,

27].

Spark plugs transfer the ignition energy to the combustion chamber and strike a spark between the grounded electrode and the central electrode, thus igniting the fuel–air mixture. They operate in difficult conditions, with large temperature fluctuations. The most important parameters that describe spark plugs are the self-cleaning temperature and the self-ignition temperature [

28,

29,

30].

There is no universal plug that would work well in every possible engine [

31,

32]. The temperatures reached in the combustion chamber vary; therefore, the plugs used for each type of engine should have a different thermal value, i.e., self-cleaning temperature and glow temperature. The self-cleaning temperature is the minimum temperature at which the spark plug is automatically cleaned of dirt generated during the combustion process in the combustion chamber (oil deposits, carbon deposits and soot particles). Any contamination that has built up on the surface of the spark plug must burn itself out. Each spark plug has its maximum operating temperature called the glow temperature. This temperature causes the spontaneous glowing of the central electrode, which results in the self-ignition of the combustible mixture at undefined points of rotation of the crankshaft during engine operation. This determines the uneven operation of the engine in an idle gear or under a heavy load. A correctly selected thermal value of the spark plug enables its electrodes to work at the optimal temperature, which can be defined at the level of 550 °C to 750 °C. This is when the self-cleaning of the electrodes occurs. When the plug is too cold, this phenomenon does not occur, and the electrodes are covered with carbon deposits, which may hinder or disable striking a spark. When the spark plug is too hot, the high temperature can lead to the knocking and melting of the electrodes. There are different temperatures inside the combustion chamber, depending on the engine construction type [

33,

34,

35].

The general parameter of the spark plug heat value has been introduced, which determines the ability of the plug to dissipate heat, while the plugs themselves fall into two categories. The first is the cold spark plug; the second is the hot spark plug. The cold plug has a low tendency to accumulate heat and dissipate it quickly thanks to the short insulator nose stuck inside a small-capacity heat chamber. The hot plug, on the other hand, has a long insulator nose and a larger heat chamber, which means it dissipates heat for a longer time. The heat factor of the spark plug is given in the form of a digital code. Unfortunately, manufacturers use different designations of their own. For example, according to the companies NGK and Iskra, the higher the value of the heat value coefficient, the colder the plug. However, Bosch inverted the numbering, in which a higher number means a hot plug, and a lower number means a cold one [

36,

37,

38].

The use of spark plugs with a higher thermal value than indicated by the manufacturer may cause them not to reach the required self-cleaning temperature (approx. 550–750 °C). Spark plugs with too low a thermal value are prone to overheating, which can cause the premature ignition of the mixture in the engine combustion chamber. On average, a spark plug must provide between 500 and 3500 ignitions per minute.

When analysing spark plugs, we must pay attention to the spark plug thread diameter, the spark plug thread length, the number of side electrodes, the main electrode material, the spacing between electrodes, and the tightening torque values. The most popular spark plug threads are those with diameters of 10, 12, 14 and 18 mm. Combustion engine designers aim to reduce the thread diameter in order to increase the free space in the engine head for a greater number of valves or a special positioning of the injector body, e.g., piezoelectric injectors. The standard length of the spark plug thread is 19 or 26.5 mm. Plugs with a longer thread are used in heads made of aluminium alloys or magnesium alloys as the heads made of these materials have a lower strength than the heads of older engines made of cast iron. The longer thread prevents the spark plug thread from breaking in the head socket. The number of side electrodes may be 1, 2, 3 or 4. It should be noted that a larger number of side electrodes is not always related to the effectiveness of the spark plug since a spark plug with a larger number of side electrodes may not be suitable for the engine, particularly with the electronic control of the ignition moment of the fuel–air mixture. The material used in the construction of the electrode must be a good conductor; e.g., iride, platinum, copper and nickel are used. An important parameter is the distance between the electrodes. Too large a gap between the electrodes may prevent the electrical charge from moving, while too small a gap may make it difficult to start a warm engine and limit the energy of the spark. The torque values depend on the thread diameter. For new candles, the tightening torque ranges from 10 to 30 Nm.

The operating temperature of an engine powered by LPG, CNG or LNG is much higher than that of a petrol engine (the mixture of gas and air burns at a higher temperature), which, combined with the increased electrical erosion caused by alternative fuels, translates into a different spark plug lifetime in this type of engine. The difference in comparison to a petrol-powered engine can be quite significant and depends on the specific case. The ignition voltage required for a mixture of LPG and air is also much higher than for that of petrol and air. This means that the spark plugs must be supplied from the ignition coil with the voltage approximately 50% higher. In petrol engines, the ignition voltage of 10–15 kV is usually sufficient, while LPG-powered engines require a higher voltage of approx. 25–30 kV [

39,

40,

41].

LPG (liquefied petroleum gas) is a mixture of propane and butane gases obtained either as a by-product of petroleum refining or directly from natural gas deposits. It differs significantly from petrol (PB95) primarily in its chemical composition. Conventional fuel consists of around 100 different hydrocarbons, while LPG consists only of propane and butane and various types of irrigation agents. The main difference in the combustion of a mixture of LPG and petrol is the combustion time and the energy value obtained. LPG has a higher octane number, which translates into a longer combustion period of the fuel–air mixture in the cylinder. The combustion process of both fuels, although it is actually different, is not very different. The fuel–air mixture burns longer, but this occurs during operation without loading the engine. When the engine is operating at an increased rpm under load, the differences in combustion speed are ignored. There is a much higher rate of combustion of gaseous fuel compared to gasoline; i.e., the mixture is characterized by a higher degree of burnout as a function of crankshaft rotations [

42,

43]. A higher octane number of LPG is very often used in cars supercharged with increased power, and gas fuel allows for the proper combustion of the mixture, despite higher cylinder pressures, which results in higher engine power than petrol. Lower engine power when running on LPG is observed in low-suction engines. This is not a big difference and is mainly due to the greater demand for air when burning 1 kg of LPG (15.5 kg compared to 14.7 kg for petrol). However, the drop in power is imperceptible; the difference is 2–3%. The differences between LPG and petrol are also due to the fact that LPG is a “dry” fuel. The jump of the spark in the combustion chamber is then difficult and requires more energy to be generated. It should also be borne in mind that LPG usually has a longer journey from the injector to the combustion chamber, moving slower due to a pressure that is several times lower than that of the base fuel. The calorific value of the combustion of LPG and gasoline actually differs. For LPG, it is approx. 46 MJ/kg; for Pb, it is ca. 42 MJ/kg. That is, the combustion temperature of LPG is higher by approx. 8–9%. It should be noted that petrol is fed into the chamber in a liquid state (fuel mist), while gas is in a volatile (gaseous) form, so the charge of the given fuel is different. In addition, the stoichiometric point for the LPG/air mixture in the combustion chamber is higher. All this affects the final combustion temperature. For the LPG combustion temperature, one assumption shall be that the quantity of gas in the fuel–air mixture must be correctly selected, resulting in a proper lambda during operation for the engine under test. While maintaining the same AFR (air-to-fuel ratio) for gas and petrol, we observe practically the same combustion temperatures of both fuels. The old I and II generation gas installations were unable to deliver the right amount of gas in every load and speed range. The engine often worked on a lean mixture, and this was associated with an increase in the combustion temperature. However, it should be borne in mind that the combustion of the fuel–air mixture in a spark-ignition engine always raises the combustion temperature for lean mixtures, regardless of the type of fuel. One of the reasons (and maybe even the main one) for a higher spark plug breakdown voltage in gas engines is the use of a lean mixture.

The increased voltage and increased combustion temperature of LPG mean that the spark plugs in these engines should be replaced much more frequently. Therefore, it is recommended to use iridium and platinum spark plugs for LPG-powered engines.

There is no specific spark plug replacement time for all spark ignition engines. Each car manufacturer includes this information in the owner’s manual or service book. In practice, the spark plug replacement mileages are every 30,000 km for nickel–lithium plugs; every 60,000 km for iridium plugs; every 100,000 km in the case of platinum plugs. These are the mileages for petrol-powered cars. For LPG or CNG, the plugs should be replaced after 15,000 (standard plugs) and 30,000 km (iridium or platinum plugs) [

44,

45].

The correct combustion of the fuel–air mixture in vehicle engines depends on many parameters provided by the sensors. The engine temperature sensor measures the temperature of the coolant in the engine cooling system. It is usually placed in the thermostat housing or in its mounting space. Based on the changes in the value of the output signal sent from the temperature sensor to the engine controller, the injected fuel dose, the injection time, the injection and ignition advance angles, and the adjustable engine idle operation are calculated. If the sensor detects too low a liquid temperature in the engine cooling system, the injection time is delayed. The output signal is also used to set the throttle opening angle and enrich the fuel–air mixture during engine warm-up, a sudden load increase or engine braking. In the absence of an output signal from the temperature sensor (indicating a power circuit break, a signal or ground break, or sensor failure), the engine controller shall determine a replacement characteristic. The diagnostics of coolant temperature sensors are carried out in several ways: a universal meter; an oscilloscope measurement; a diagnostic measurement; a sensor at the radiator outlet.

One example is an intake air temperature sensor, which measures the temperature in the air supply pipe to the engine and transmits this information to the engine controller (e.g., the VW Beetle).

The aim of the research presented in this paper was to assess the effect of the type of spark plug on the emission of hydrocarbons, carbon monoxide, carbon dioxide and oxygen for five vehicles: the Volkswagen Beetle 1300 (spark plugs: nickel NGK B5HS and iridium NGK BPR 6HIX), the Honda Nighthawk 650 motorcycle (spark plugs: nickel NGK DPR8EA-9 and iridium NGK DPR8EIX-9), the BMW e46 318i (spark plugs: Silver BRISK SILVER, platinum NGK BKR6EQUP, and iridium Bosch FR6KI332S), Hyundai i10 (spark plugs: nickel NGK BKR5ES 11 and iridium NGK 1496), and the Audi A4 B6 (spark plugs: nickel Bosch FR7DC and iridium Denso IK16TT).

2. Materials and Methods

Exhaust emission tests presented in the paper were performed at a local district vehicle inspection station. The following assumptions were made to achieve the results: all measurements were performed using the same DGA 1500 Sun measuring device (complying with the MID Directive ISO 3930) [

46]; all spark plugs used in the tests were brand new; each set of spark plugs was tested in five independent tests under identical operating conditions (ambient temperature, engine temperature, engine rotational speed, and type of fuel used); when alternative fuels could be used, all tests were carried out independently; each vehicle for each type of spark plug was heated to engine operating temperature prior to emission measurement.

In order to verify the manufacturers’ guarantees about the impact of the spark plugs on exhaust gas emissions, the vehicles used in the measurements had different engine designs, ignition systems and fuel and exhaust systems. Some vehicles do not have exhaust catalytic converters. It is advantageous to record changes in exhaust emissions after spark plugs have been changed since the catalyst can in many cases eliminate environmentally harmful HCs and CO at the exhaust. However, this does not mean that there is no actual emission of these compounds from the vehicle engine.

The vehicles subjected to the tests were divided into two categories. The first one involved fuel supplied by the carburettor, no lambda probes and a manually set ignition timing and included the Volkswagen Beetle 1300 and the Honda Nighthawk 650 motorcycle.

The second category of vehicles tested included computer-controlled ignition, direct injection fuel, emission testing sensors and factory-fitted catalytic converters that reduce exhaust emissions and included the BMW e46 318i, the Hyundai i10 and the Audi A4 B6.

One of the criteria for selecting the vehicles under analysis was their popularity among users. The year of manufacture of the vehicles and the fact that they were subject to different type-approval procedures were also taken into account.

The analysed spark plugs were selected according to the information provided on the manufacturer’s website (for which vehicle the spark plug can be a replacement). In addition, the coding of spark plug markings was analysed in detail taking into account the heat range, electrode position and electrode spacing (gap).

2.1. Volkswagen Beetle 1300

The vehicle was produced until 2003 with a boxer engine mounted in the rear of the car. The engine is air-cooled, and the cooling is effectively supported by an oil cooler. The ignition of the vehicle is set manually when adjusting the spark advance angle. Petrol is supplied to the cylinders by the carburettor.

Table 1 presents the basic parameters of the tested vehicle [

47], and

Table 2 presents the parameters of the spark plugs used in the Volkswagen Beetle 1300 exhaust emission test [

24,

47].

The information contained in [

48] was used to analyse NGK’s spark plug markings. Information on spark plug equivalents was obtained from car parts web portals [

49,

50] and from the manufacturer’s information [

51]. In the literature [

48,

49,

50,

51,

52], you can also find all the technical parameters of the spark plugs used. Both of the spark plugs used are considered hot spark plugs according to the manufacturer’s information.

Table 2.

Parameters of the spark plugs used in the Volkswagen Beetle 1300 exhaust emission test [

24,

52].

Table 2.

Parameters of the spark plugs used in the Volkswagen Beetle 1300 exhaust emission test [

24,

52].

| Parameter | Value |

|---|

| Manufacturer | NGK | NGK |

| Index | B5HS | BPR6HIX |

| Thread length (mm) | 12.7 | 12.7 |

| Thread diameter (mm) | 14 | 14 |

| Spanner size (mm) | 20.8 | 20.8 |

| Electrode position (mm) | 2 | 4 |

| Electrode gap (mm) | 0.6 | 0.9 |

| Number of poles | 1 | 1 |

| Central electrode (material) | Nickel | Iridium |

| Maximum lifetime (km) | 20,000 | 60,000 |

| Resistance (kOhm) | Uninterrupted | 5 |

2.2. Honda Nighthawk 650 Motorcycle

The Honda CB 650 SC Nighthawk (factory designation RC13; in some markets it is the CBX 650) is a representative of cruiser motorcycles offered for sale from 1983 to 1985. The motorcycle does not have a computer-controlled ignition map. The motorcycle is equipped with an oil cooler.

Table 3 presents the basic parameters of the tested vehicle [

53], and

Table 4 presents the parameters of the spark plugs used in the exhaust emission test of the Honda Nighthawk 650 motorcycle [

24,

48].

For the selection of spark plugs for the Honda Nighthawk 650 motorcycle, the manufacturer’s spark plug code was also analysed in the first phase [

48], followed by a catalogue of replacement spark plugs for motorcycles [

54].

Technical parameters of NGK spark plugs can be found in the literature [

48,

54].

Table 4.

Parameters of the spark plugs used in the Honda Nighthawk 650 motorcycle exhaust emission test [

24,

48,

54].

Table 4.

Parameters of the spark plugs used in the Honda Nighthawk 650 motorcycle exhaust emission test [

24,

48,

54].

| Parameter | Value |

|---|

| Manufacturer | NGK | NGK |

| Index | DPR8EA-9 | DPR8EIX-9 |

| Thread length (mm) | 19 | 19 |

| Thread diameter (mm) | 12 | 12 |

| Spanner size (mm) | 18 | 18 |

| Electrode position (mm) | 3 | 3 |

| Electrode gap (mm) | 0.9 | 0.9 |

| Number of poles | 1 | 1 |

| Central electrode (material) | Nickel | Iridium |

| Maximum lifetime (km) | 40,000 | 100,000 |

| Resistance (kOhm) | 5 | 5 |

2.3. BMW e46 318i

The BMW e46 318i is a mid-range passenger car. The vehicle was equipped with the N42B20 engine with the Valvetronic system controlling the suction valve stroke, which takes over the throttle function in this engine. The car did not have a catalytic converter. The car was additionally fitted with an LPG system.

Table 5 presents the basic parameters of the tested vehicle [

55,

56], and

Table 6 presents the parameters of the spark plugs used in the BMW e46 318i exhaust emission test [

57,

58,

59,

60].

In order to select spark plugs for the BMW e46 318i, the code of the spark plug manufacturers NGK, Brisk and Bosch [

48,

61,

62,

63] was analysed in the first phase, followed by the catalogue of spark plug replacements [

49,

51,

64,

65].

The literature [

48,

61,

62] contains the technical parameters of the analysed spark plugs of Brisk, NGK and Bosch. According to the manufacturer’s information, all three spark plugs used are considered hot spark plugs.

Table 6.

Parameters of the spark plugs used in the BMW e46 318i exhaust emission test [

48,

61,

62,

65].

Table 6.

Parameters of the spark plugs used in the BMW e46 318i exhaust emission test [

48,

61,

62,

65].

| Parameter | Value |

|---|

| Manufacturer | BRISK | NGK | BOSCH |

| Index | BR15YS | BRK6EQUP | FR6KI332S |

| Thread length (mm) | 19 | 19 | 19 |

| Thread diameter (mm) | 14 | 14 | 14 |

| Spanner size (mm) | 16 | 16 | 16 |

| Electrode position (mm) | 4 | 3,5 | 4 |

| Electrode gap (mm) | 0.7 | 0.7 | 0.7 |

| Number of poles | 1 | 4 | 1 |

| Central electrode (material) | Silver | Platinum | Iridium |

| Maximum lifetime (km) | 40,000 | 60,000 | 100,000 |

| Resistance (kOhm) | 5 | 5 | 6 |

2.4. Hyundai i10

The Hyundai i10 is a vehicle designed for city driving. A small four-cylinder engine with a capacity of 1086 cm3 provides 66 HP. The ignition of the vehicle is computer-controlled.

Table 7 presents the basic parameters of the tested vehicle [

66], and

Table 8 shows the parameters of the spark plugs used in the Hyundai i10 exhaust emission test [

24,

48].

The starting point was the analysis of the NGK spark plug markings [

48]. Subsequently, the available information on spark plug replacements [

49,

50], including the information from the manufacturer [

51], was analysed. In the literature [

48,

49,

50,

51,

52], you can also find all the technical parameters of the spark plugs used (heat range, electrode position, electrode spacing and construction). Both of the spark plugs used are considered hot spark plugs according to the manufacturer’s information.

2.5. Audi A4 B6

The Audi A4 B6 is a mid-range car. The engine in the car is mounted lengthwise, as in units with rear-wheel drive. This vehicle has an LPG installation and a new catalytic converter.

Table 9 presents the basic parameters of the tested vehicle [

67], and

Table 10 presents the parameters of the spark plugs used in the Audi A4 B6 exhaust emission test [

26,

45].

The starting point was the analysis of the Bosch and Denso spark plug markings [

26,

62,

63,

68]. The information provided on the replacement of spark plugs for the Audi A4 B6 [

38,

45,

60,

68] and the information provided by the manufacturer [

57,

65] were then analysed. Based on the literature [

26,

45,

60,

65], all technical parameters concerning spark plugs were analysed. In this study, the used spark plugs are considered to be hot spark plugs.

2.6. Measuring Station Specification

The DGA1500 exhaust gas analyser made by SUN was used to test the vehicles [

69]. The technical specification of the device is presented below (

Table 11).

The spark plugs tested were selected for specific vehicles in accordance with the manufacturers’ recommendations. All vehicles were refuelled at the same petrol station. The tests were carried out at an air temperature of above 5 °C.

The measurement of the content of hydrocarbons (HC) and carbon monoxide (CO) in the exhaust gases is made at an initially increased engine speed (2000 rpm) and then at idling speed, and then, the results are read after the indications on the DGA 1500 measuring device have stabilised. The idling speed was 900 rpm, and the readings were conducted only for the first category of vehicles: Honda Nighthawk 650 and Volkswagen Beetle 1300.

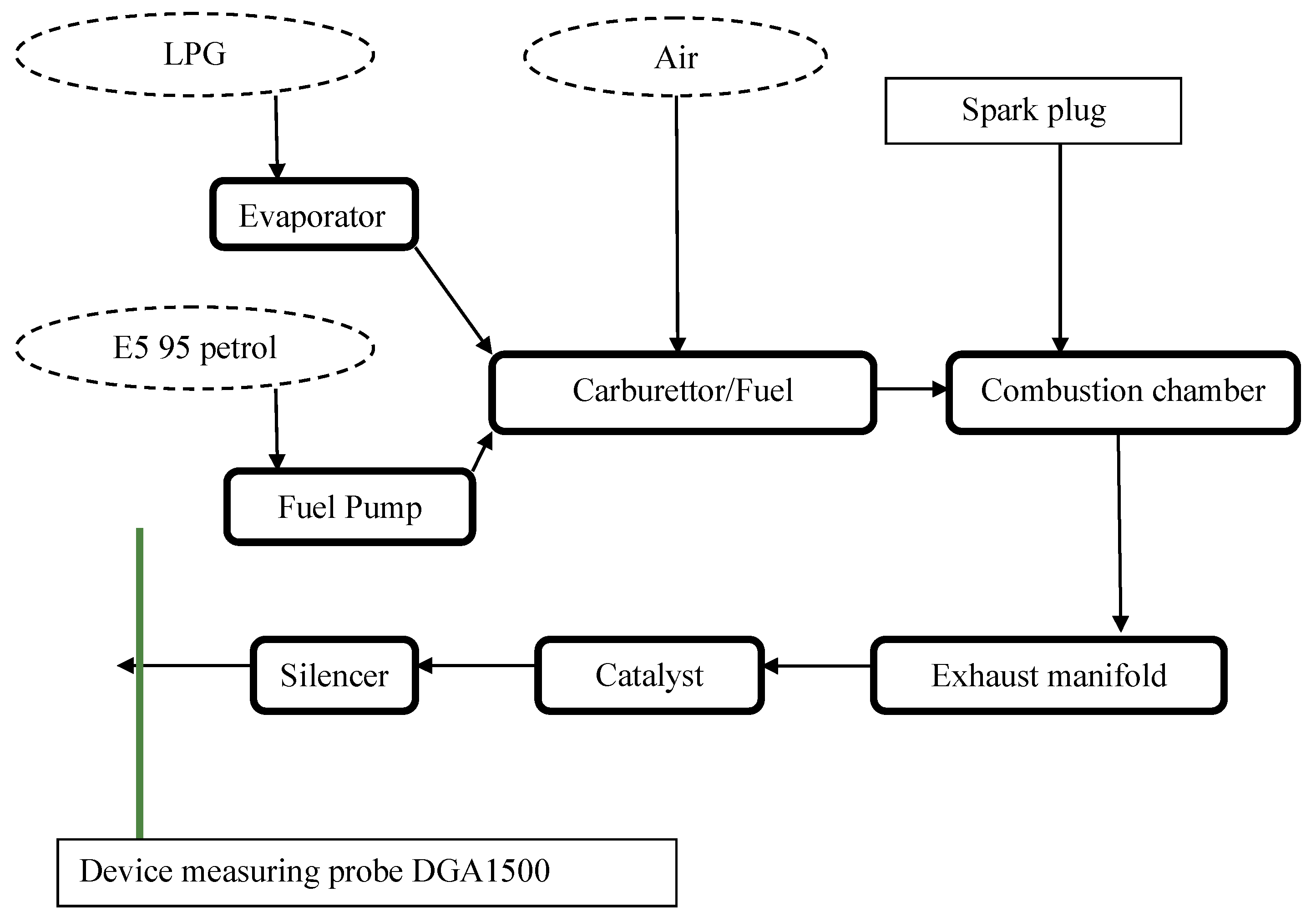

After installing a new set of spark plugs in the cylinder head, the vehicle was run for 10 min to bring the engine to operating temperature. Before starting the tests, the next step was to cover a distance of about 5 km in order to burn out the spark plugs under load conditions. The next step was to connect the measuring probe according to the diagram below (

Figure 1).

The probe of the DGA1500 device is equipped with a clamping bracket that prevents it from becoming unhooked during the examination (

Figure 2).

Between the first test and the next one, the probe was disassembled, and the vehicle was idling for about a minute and then worked at an increased speed for about 10 s. The test was repeated five times for each type of spark plug. The test procedure has been established in accordance with the relevant European Union legislation [

70].

In the case of cars with LPG, the engine fuel was changed to LPG after five tests on E5 95 petrol, and the car was subjected to the same procedures. LPG has a higher combustion temperature than E5 95 petrol, which should affect the differences in exhaust emissions in relation to E5 95 petrol.

After all measurements were taken, the engine was shut down to install the next set of spark plugs.

For the Honda Nighthawk 650, a complementary comparative test at 3000 rpm was added (this is due to the performance characteristics of the engine).

An important parameter that directly affects not only the composition of the exhaust gas but also the ignition conditions of the mixture, and the average combustion temperature is the excess air coefficient λ, which determines the ratio of the actual amount of air in which the fuel is burned in the engine compartment to the stoichiometric amount. This is the weight ratio of air to fuel in the fuel–air mixture.

The λ coefficient was deliberately omitted from the study. It determines the excess of air, which has a significant impact on the composition of exhaust gases. The purpose of the test, however, is not to search for the cause of possible irregularities for individual vehicles but only to assess the impact of changing spark plugs. If there is an abnormality for a particular vehicle, it is the same for all types of spark plugs used.

Research on the analysis of the influence of the λ coefficient on the combustion of fuels in internal combustion engines will be the subject of the next publication of the authors.

3. Results

Presented below are the results of the exhaust emission tests of the individual vehicles performed with the use of the spark plugs selected above. There are abbreviations in the tables that require explanation.

The standard deviation (S.D.) was calculated by Formula (1):

where:

xi—single measurement, while i = 1, 2,…, 5;

AAvg—arithmetic average of the results.

The total measurement uncertainty (TMU) was determined according to Formula (2):

where:

3.1. Volkswagen Beetle 1300 Test Results

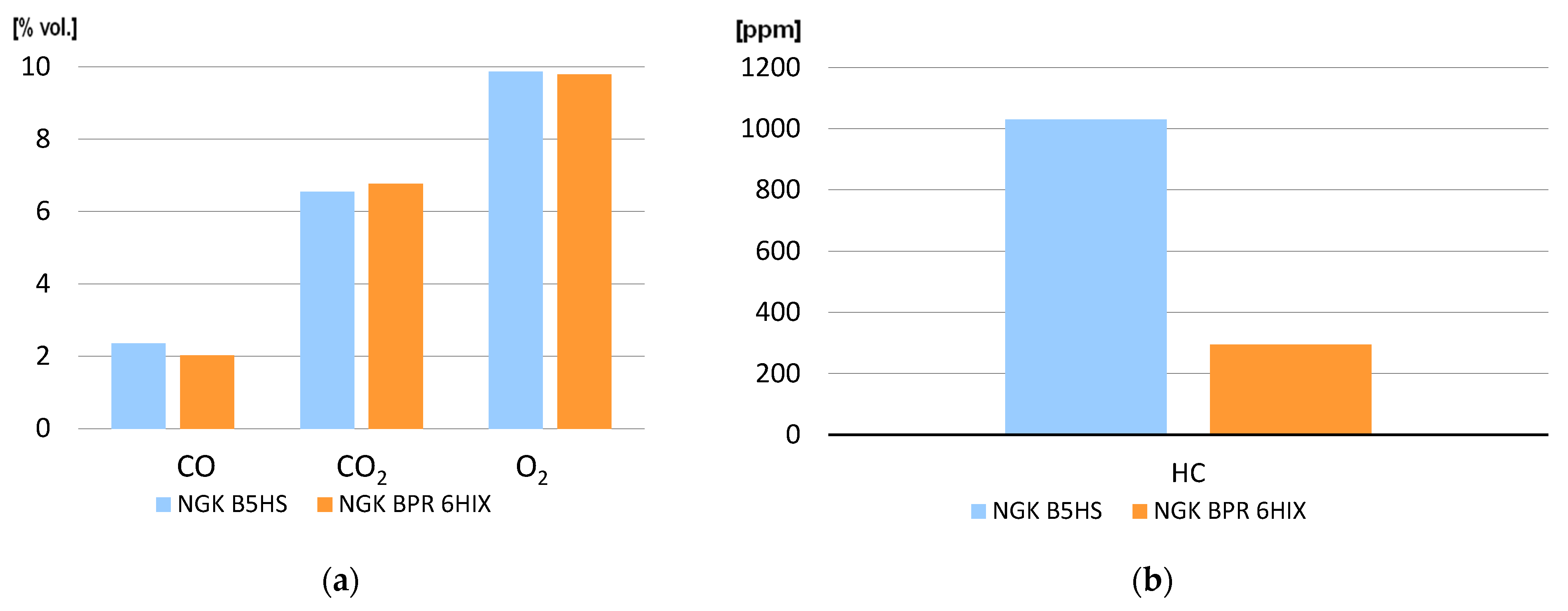

The third tested vehicle was the Volkswagen Beetle 1300. NGK B5HS spark plugs and NGK BPR 6HIX iridium spark plugs were used (

Table 12).

The measured emissions of CO, CO

2, O

2 and HCs for the Volkswagen Beetle 1300i when fuelled with E5 95 petrol are shown in

Figure 3.

Comparing the results of the exhaust emissions of environmentally harmful HCs, a large difference can be seen in the content of these gases in the exhaust. The NGK B5HS spark plugs designed for this type of car achieve a staggering emission level of 1029 ppm (considering the total measurement uncertainty, the results oscillate at the level of 992–1066 ppm) (

Table 12). This car is not subject to the emission standard for harmful HCs; however, in order to visualize the emission scale, the results were compared with the maximum emission standard, e.g., for a 2003 BMW e46 318i, which is 100 ppm. The results exceeded emission levels over 10 times. With the installation of the NGK BPR6HIX iridium spark plugs, the situation improves significantly. The exhaust emission result was 295 ppm, and, considering the total measurement uncertainty, it oscillated between 266–324 ppm. The emissions for the NGK BPR6HIX iridium spark plugs was almost three times the aforementioned standard, and, in an even better result, its emissions were more than three times that of the NGK B5HS spark plugs. Such a difference seems to be very significant for the environment.

The beneficial effect of the NGK BPR6IX iridium spark plugs can also be seen at the level of CO emissions, which was measured at 2.03% vol. (the total measurement uncertainty oscillates at the level of 2.24–2.45% vol.) for the NGK B5HS spark plugs. For this car, the maximum permissible emission standard is 4.5% vol. and is not exceeded. However, the difference of 0.32% vol. seems significant [

71]. An example maximum permissible limit for the BMW e46 318i at an increased engine speed is 0.3% vol.

3.2. Honda Nighthawk 650 Motorcycle Test Results

The last vehicle subjected to emission control was the Honda Nighthawk 650 motorcycle [

72]. Tests for this type of vehicle were carried out in an idle gear. Two sets of spark plugs, NGK DPR8EA-9 nickel and NGK DPR8EIX-9 iridium, were used for the research.

Table 13 presents the results of tests and calculations for the Honda Nighthawk 650 fuelled with E5 95 petrol in an idle gear, and

Table 14 presents the results of tests and calculations for the Honda Nighthawk 650 fuelled with E5 95 petrol at 3000 rpm.

The proper selection of a spark plug for a motorcycle is of great importance in terms of exhaust emissions. When compared, spark plugs from the same manufacturer, which differ in the material used in the main electrode, can achieve noticeably different emission results. The greatest advantage of the NGK DPR8EIX-9 iridium spark plug was noticed during idling (

Table 13). The HC emissions are at the level of 120 ppm, and the total measurement uncertainty results oscillate in the range of 97–143 ppm. The NGK DPR8EA-9 spark plugs with the main nickel electrode achieve an emission level of 359 ppm, and the total measurement uncertainty oscillates between 324–393 ppm. This motorcycle is not subject to the emission standards for HCs, but, compared with the maximum emission standard, e.g., for a 2003 BMW e46 318i, which is 100 ppm, the achieved difference of 253 ppm seems considerable.

The situation somewhat evens out at increased engine speeds. At 3000 rpm, the NGK DPR8EIX-9 iridium spark plugs emit 184 ppm (

Table 14), and considering the total measurement uncertainty, the result oscillates in the range of 163–205 ppm. The difference to the NGK DPR8EA-9 spark plugs is reduced to 37 ppm.

When it comes to CO emissions, the situation is similar. The NGK DPR8EA-9 spark plugs achieve an emission level of 0.49% vol. (total measurement uncertainty oscillates between 0.32–0.46% vol.), which is higher by 0.19% compared to the NGK DPR8EIX-9 iridium spark plugs vol., for which total measurement uncertainty oscillates between 0.24–0.36% vol. (result = 0.30% vol.)

When testing the same spark plugs at 3000 rpm, a difference of 0.77% vol. was obtained. For the NGK DPR8EA-9 spark plugs, the result oscillates between 3.60–3.91% vol. (result = 3.75% vol.) considering the total measurement uncertainty, and for the NGK DPR8EIX-9 iridium spark plugs, it is in the range of 2.80–3.16% vol. (result = 2.98% vol.). However, when quoting the maximum permissible emission standard, e.g., for the 2003 BMW e46 318i, which is 0.3% vol., the difference of 0.76% vol. seems to be significant.

The measured emissions of CO, CO

2, O

2 and HCs for the Honda Nighthawk 650 when fuelled with E5 95 petrol are shown in

Figure 4.

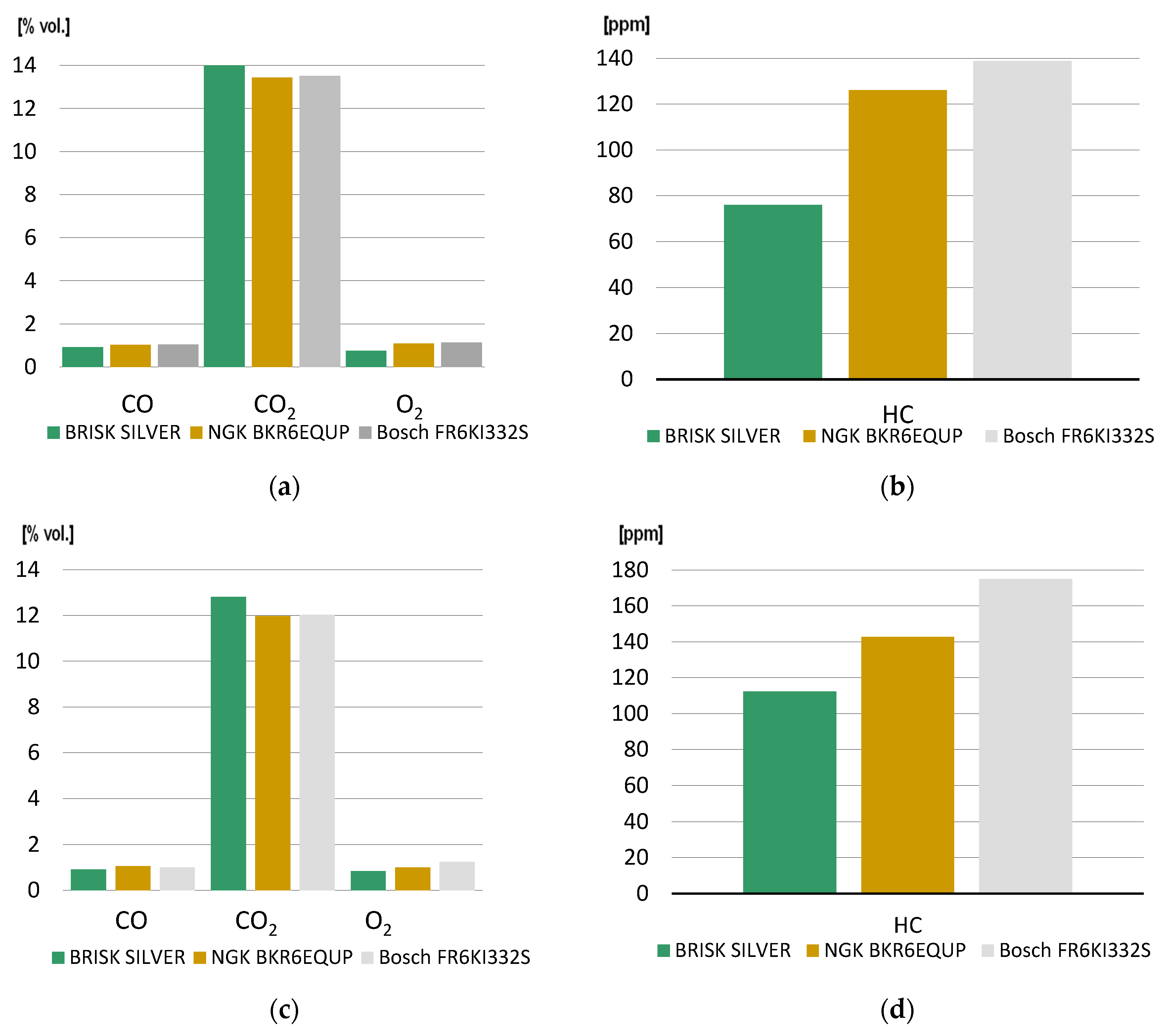

3.3. BMW e46 318i Test Results

The tests were carried out for three sets of spark plugs—silver BRISK SILVER, platinum NGK BKR6EQUP and iridium Bosch FR6KI332S. The emissions were measured with E5 95 petrol (

Table 15) and LPG (

Table 16).

The measured emissions of CO, CO

2, O

2 and HCs for the BMW e46 318i when fuelled with E5 95 petrol and LPG are shown in

Figure 5.

In the case of the BMW e46 318i, three types of spark plugs were used. It is the only vehicle for which none of the spark plugs has a nickel main electrode.

When burning environmentally harmful HCs, Brisk Silver spark plugs with a silver main electrode gain a decisive advantage when working on both E5 95 petrol and LPG. In the case of E5 95 petrol, the emissions of harmful HCs were 76 ppm (considering the total measurement uncertainty, the results oscillate between 61–91 ppm), which is the only result in the full range that does not exceed the maximum permissible emission standard of 100 ppm for this type of vehicle. This is also 50 ppm better than NGK BKR6EQUP platinum spark plugs and 63 ppm better than Bosch FR6KI332S iridium spark plugs [

72]. In the case of LPG, the emission result for Brisk Silver spark plugs is 112 ppm (total measurement uncertainty oscillates between 96–128 ppm), which is 31 ppm better than the result obtained by NGK BKR6EQUP platinum spark plugs and 63 ppm better than the measured result for Bosch FR6KI332S iridium spark plugs. The lower threshold of the total measurement uncertainty is below the maximum permissible emission standard of 100 ppm.

The carbon monoxide emissions of Brisk Silver spark plugs are the lowest. The test result of 0.92% vol. (total measurement uncertainty oscillates between 0.86–0.97% vol.) for E5 95 petrol is 0.11% vol. better than the result obtained by NGK BRK6EQUP platinum spark plugs and 0.12% vol. smaller than that of Bosch FR6KI332S iridium spark plugs. The difference between the NGK BRK6EQUP spark plugs and the Bosch FR6KI332S spark plugs is only 0.01% vol. in favour of the former, and the total measurement uncertainty oscillates in the range of 0.96–1.09% vol. and 0.96–1.12% vol., respectively. It follows that these two types of spark plugs are almost identical in this category.

In the case of LPG fuelling, the lowest CO emissions were achieved with the use of Brisk Silver spark plugs, obtaining the emission level of 0.90% vol. (total measurement uncertainty at the level of 0.78–1.02% vol.). The second rank was taken by Bosch FR6KI332S iridium spark plugs with the result of 0.99% vol. (total measurement uncertainty oscillates in the range of 0.94–1.04% vol.), which is 0.09% vol. more carbon monoxide emissions compared to Brisk Silver spark plugs. The highest CO emissions of 1.05% vol. (total measurement uncertainty 0.98–1.12% vol.) were recorded by the NGK BRK6EQUP platinum plugs.

3.4. Hyundai i10 Test Results

Two sets of NGK BKR5ES 11 spark plugs with a nickel electrode and NGK 1496 iridium spark plugs were used to perform the tests. The emissions were measured on E5 95 petrol (

Table 17).

From the results of the tests carried out on the Hyundai i10 (

Table 17), it is not possible to determine the actual difference of the effect of the spark plugs used in the comparison.

Both the NGK BKR5ES11 spark plugs and the NGK 1496 iridium spark plugs had zero harmful HC emissions.

The NGK BKR5ES11 spark plugs generated CO emissions of 0.02% vol. and the NGK 1496 spark plugs showed no carbon monoxide emissions. The total measurement uncertainty for NGK BKR5ES11 spark plugs is 0.05–0.69% vol., and for NGK 1496 iridium spark plugs, it is 0.03–0.63% vol.

The measured emissions of CO, CO

2 and O

2 for the Hyundai i10 when fuelled with E5 95 petrol are shown in

Figure 6.

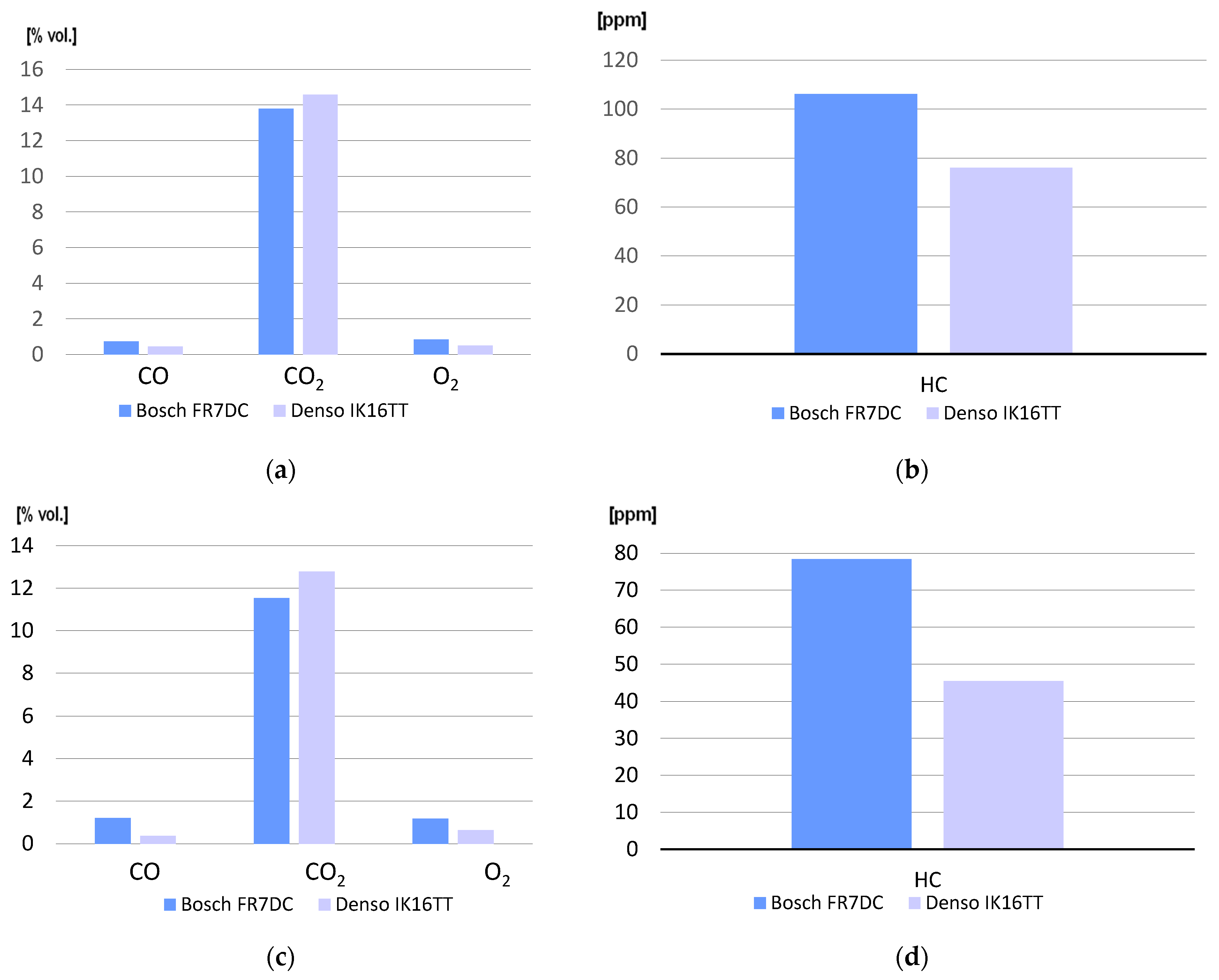

3.5. Audi A4 B6 Test Results

The fourth vehicle to be tested for exhaust emissions was the Audi A4 B6. In the case of this car, the tests were carried out separately on E5 95 petrol (

Table 18) and then on LPG (

Table 19). Two types of spark plugs were used: Bosch FR7DC and Denso IK16TT iridium.

From the point of view of the emission standards for the Audi A4 B6, the design of the spark plug turns out to be important. The standard nickel main electrode spark plug used in this car model and tested during this experiment performs noticeably worse than the alternative iridium spark plug also used in the study.

When running on E5 95 petrol (

Table 18), the car meets the HC emission standards thanks to the Denso IK16TT iridium spark plugs. For the Bosch FR7DC spark plugs with nickel electrodes, the maximum permissible HC content of 100 ppm is exceeded.

Considering the total measurement uncertainty, the HC emission results for the Bosch FR7DC spark plugs fit in the range of 89–123 ppm (the average result being 106 ppm), and for the Denso IK16TT iridium spark plugs, they are in the range of 59–93 ppm (the average result is 76 ppm). It follows that when checking the total measurement uncertainty for the Denso IK16TT iridium spark plugs, the maximum amount of HCs is not exceeded.

The difference in the emissions of HCs when fuelling with LPG (

Table 19) is almost twice as environmentally friendly when the Denso IK16TT iridium spark plugs are used, which is confirmed by the result of 45 ppm against 78 ppm achieved by the Bosch FR7DC spark plugs. The permissible limit of this gas was not exceeded.

The CO emission standard is below 0.3% vol. Thanks to the operation of the Denso IK16TT iridium spark plugs, almost half as much CO is emitted on E5 95 petrol and more than three times less CO is emitted on LPG compared to the Bosch FR7DC spark plugs.

Considering the total measurement uncertainty, the CO emission results for the Bosch FR7DC spark plugs range from 0.64 to 0.84% vol. (0.74% vol. result) for E5 95 petrol and from 1.10 to 1.30% vol. (1.2% vol. result) in the case of LPG.

In comparison, the Denso IK16TT iridium spark plugs produce emissions in the range of 0.32–0.58% vol. (0.45% vol. result) for E5 95 petrol and 0.29–0.45% vol. (0.37% vol. result) for LPG.

The lower emissions of HCs and CO into the environment with the use of the Denso IK16TT iridium spark plugs is confirmed by the increase in CO2 emissions by over 1% vol., which implies better combustion of the fuel–air mixture, both in the case of E5 95 and LPG.

The measured emissions of CO, CO

2, O

2 and HCs for the Audi A4 B6 when fuelled with E5 95 petrol and LPG are shown in

Figure 7.

4. Discussion

The acquisition of new solutions in the construction of spark plugs results from many factors. The market offers single-pole, two-pole, three-pole and four-pole spark plugs, with the main electrode made of nickel, platinum, iridium or silver. The material with a better conductivity coefficient used for the production of the main electrode affects the quality of the combustion of the fuel–air mixture and, thus, the results of exhaust emissions.

Table 20 presents a summary of the results of the conducted tests.

In the case of older vehicles not equipped with an ignition control computer, fuel injection, a lambda probe or sensors measuring vehicle engine parameters, the quality of the spark from the plugs is very important for the operation of the engine and the mixture of exhaust gases. Two research objects can be included in this category: the 1970 Volkswagen Beetle 1300 car (

Table 5) and the 1985 Honda Nighthawk 650 motorcycle (

Table 9).

The use of iridium spark plugs significantly reduced hydrocarbon emissions. In the case of the Volkswagen Beetle 1300 and the Honda Nighthawk 650, there is a threefold reduction in hydrocarbon emissions in an idle gear (

Table 20). After increasing the speed, the difference in the results for the spark plugs used decreases, which can be explained by the increased temperature in the combustion chamber and, thus, the better combustion of harmful hydrocarbons, which also occur in the case of spark plugs with a nickel electrode.

For these vehicles, the use of iridium spark plugs also significantly reduced carbon monoxide emissions. In the case of the Volkswagen Beetle 1300, the spark plugs with a nickel electrode obtained a result of 2.35% vol. (

Table 15), and the iridium plugs obtained a result of 2.03% vol. The difference of 0.32% vol. is higher than the maximum permissible emission standard for this gas for the BMW e46 318i.

The next three test objects are an ignition control computer, a lambda probe, and sensors monitoring the condition of the engine. The BMW e46 318i is the only one in the group without a catalytic converter.

The Hyundai i10 did not show any hydrocarbon or carbon oxide emissions (

Table 14). It is difficult to assess how much of this result is affected by the relatively new catalytic converter. It is highly unlikely, however, that there is a total lack of emission of these poisonous chemicals by the engine. These compounds are neutralized in the catalytic converter located in front of the measuring probe.

The next object of research was the 2002 Audi A4 B6. It is also one of the two vehicles additionally fuelled with LPG (

Table 17). In the case of this car, the use of iridium spark plugs brought the car significantly closer to meeting the maximum emission standards or to actually meet them. The emission of hydrocarbons in the case of E5 95 petrol was 106 ppm and 76 ppm for the nickel electrode spark plugs and the iridium spark plugs, respectively (

Table 16). The maximum permissible emission standard for these compounds for this type of car cannot exceed 100 ppm (in the case of LPG, 78 ppm and 45 ppm was emitted, respectively).

The situation is similar in the case of the carbon monoxide analysis. On E5 95 petrol, the emissions were at the level of 0.74% vol. for classic spark plugs and 0.45% vol. for iridium spark plugs (

Table 16). For LPG, the emissions were at a level of 1.20% vol. and 0.37% vol., respectively (

Table 17). The limit specified in the standard, which the car cannot exceed, is 0.3% vol. Looking at this list, it can be seen that the use of the iridium spark plugs significantly improves the results of the exhaust emissions, both from the point of view of the environment and possible exhaust quality control.

The last object of research presented in the paper is the BMW e46 318i car with an LPG installation. Without a catalytic converter, this car will have increased emissions of hydrocarbons and carbon monoxide. As the only one, it was not tested on nickel spark plugs. In this case, sets of plugs with electrodes made of silver, platinum and iridium were used.

Spark plugs with a silver electrode obtained the best result of exhaust gas emissions, both when using E5 95 petrol and LPG (

Table 20). This is best seen in the amount of hydrocarbons emitted, which was measured at 76 ppm for E5 95 petrol and 112 ppm for LPG (it should be noted that the result obtained by these plugs on petrol is the only one that meets the exhaust emission standard of max. 100 ppm). The results obtained by the platinum spark plugs were 126 ppm on E5 95 petrol and 143 ppm on LPG. The iridium spark plugs achieved the results of 139 ppm when using E5 95 petrol and 175 ppm when using LPG. It can be seen from this summary that the last presented results significantly deviate from the imposed maximum standard of 100 ppm.

When analysing the emission of carbon monoxide, the silver spark plugs had emissions of 0.92% vol. for E5 95 petrol (

Table 12) and 0.90% vol. for LPG (

Table 13). The platinum and iridium spark plugs cope with carbon monoxide emissions very similarly in this case. The platinum ones achieved the results of 1.03% vol. on E5 95 petrol and 1.05% vol. on LPG, while the iridium ones recorded 1.04% vol. and 0.99% vol. on E5 95 and LPG, respectively.

The limit set by the emission standard, which a given car should not exceed, is 0.3% vol. [

71]. The results obtained are high due to the lack of a catalytic converter; however, it can be seen that by selecting proper spark plugs it is possible to support the work of this converter in obtaining a better exhaust emission result.

The studies carried out are important from the point of view of both the development of research on alternative fuels and issues of electromobility [

73,

74].

The correct temperature for plugs is selected at the engine design and testing stage and is determined by combustion temperatures.

Spark plugs must be suitably matched to the particular engine. Its design, e.g., the shape of the combustion chamber, the location of the valves and the candle itself, as well as the operating parameters, affect the temperatures reached in the cylinder. The temperatures achieved in the combustion chamber differ from each other, and therefore, plugs with a different thermal value should be used for each type of engine.

The heat range of the spark plug is the speed at which the spark plug can transfer heat from the ignition tip to the water jacket of the cylinder head and to the cooling system. The heat ranges of spark plugs can vary greatly depending on the candle and can be recorded in many different ways, which makes comparison between brands rather difficult. In particular, if the spark plug is too hot, the engine may experience detonation, pre-ignition or power loss. If the spark plug is too cold, it will not be able to clean itself properly by burning carbon sludge. Therefore, choosing the right heat range is crucial for high-performance engines. The operating temperature of the spark plug is the actual physical temperature at the tip of the spark plug inside the working engine, which is usually 500–800 °C. This is important because it determines the effectiveness of self-cleaning. If a spark plug is “hot”, it means it is a good thermal insulator, retaining more heat at the tip of the spark plug. A spark plug is called “cold” if it can dissipate more heat from the tip of the spark plug and lower the temperature of the tip. This parameter is called the thermal characteristic. The range of heat of a spark plug is usually given numerically, with some manufacturers using ascending numbers for hotter candles and others doing the opposite—assigning ascending numbers for progressively colder candles.

The choice of a spark plug should always be dictated by the vehicle manufacturer’s recommendations. In addition to the geometric dimensions that directly indicate whether the candle can be mounted, the heat of the candle or its resistance should be taken into account. The safest solution is to verify whether the vehicle manufacturer allows the use of other spark plugs (replacement).

The temperature range of NGK spark plugs ranges from 2 to 12, Denso from 9 to 37, Bosch from 9 to 2 and Brisk from 19 to 8 (

Table 21). Some manufacturers’ numbering systems are opposite to each other. For NGK and Denso, the higher the number, the colder the plug.

Table 21 shows that all spark plugs used in the test are hot but not the hottest, according to the heat range scales. Data on the subject are included in the spark plug index. This is shown by the first digit in the indexes, already mentioned in the tables with spark characteristics (

Table 2,

Table 4,

Table 6,

Table 8 and

Table 10).