Single- and Double-Sided Coated Gas Diffusion Layers Used in Polymer Electrolyte Fuel Cells: A Numerical Study

Abstract

:1. Introduction

2. Model Description and Transport Equations

2.1. Model Assumptions

- The fuel cell operates in a steady state;

- The flow in the flow channels is laminar as the Reynolds numbers are low;

- The membrane is impermeable to gases;

- There is uniform compression on all components of the fuel cell;

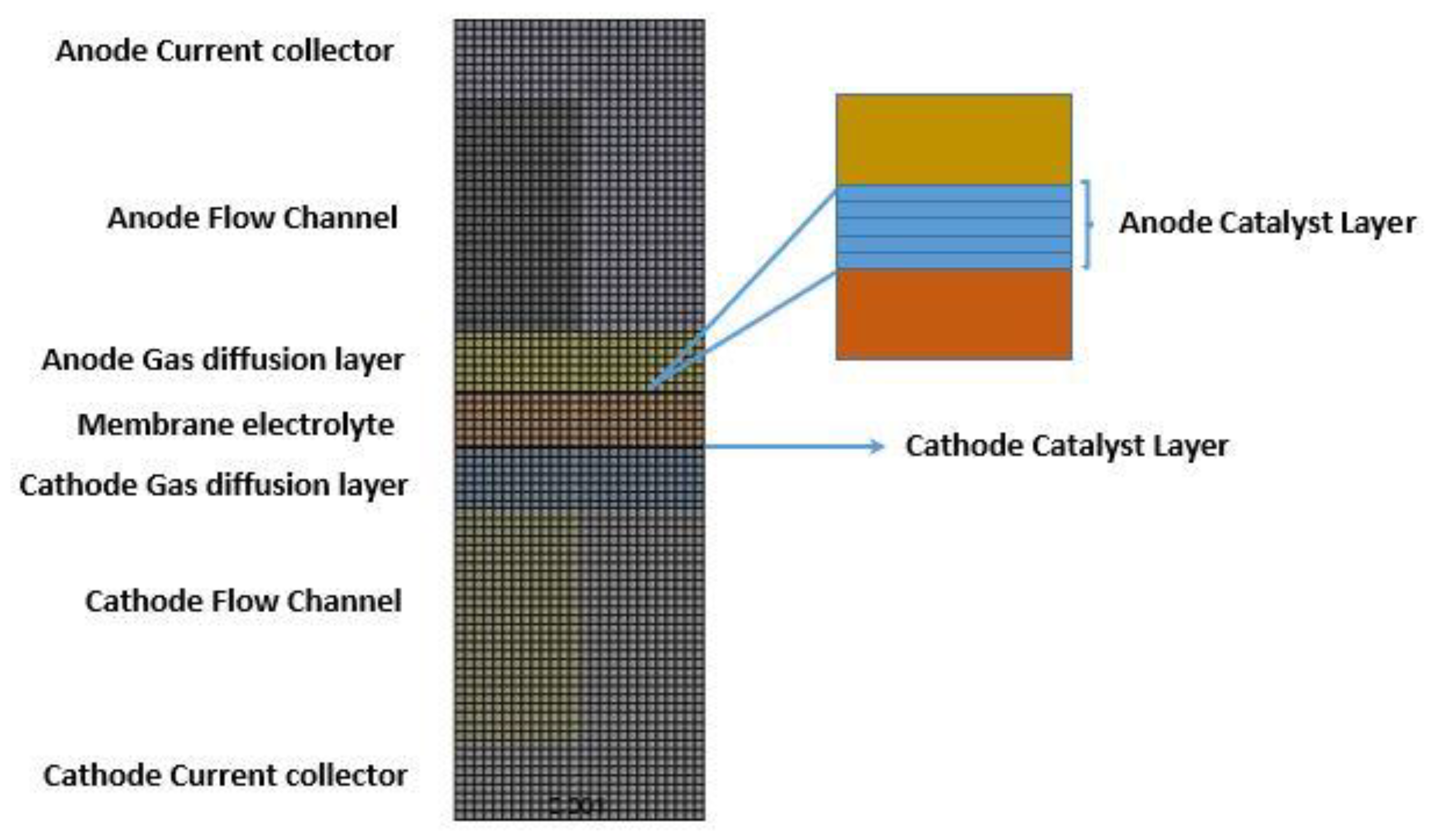

- The catalyst layer is coated on the gas diffusion media instead of the membrane.

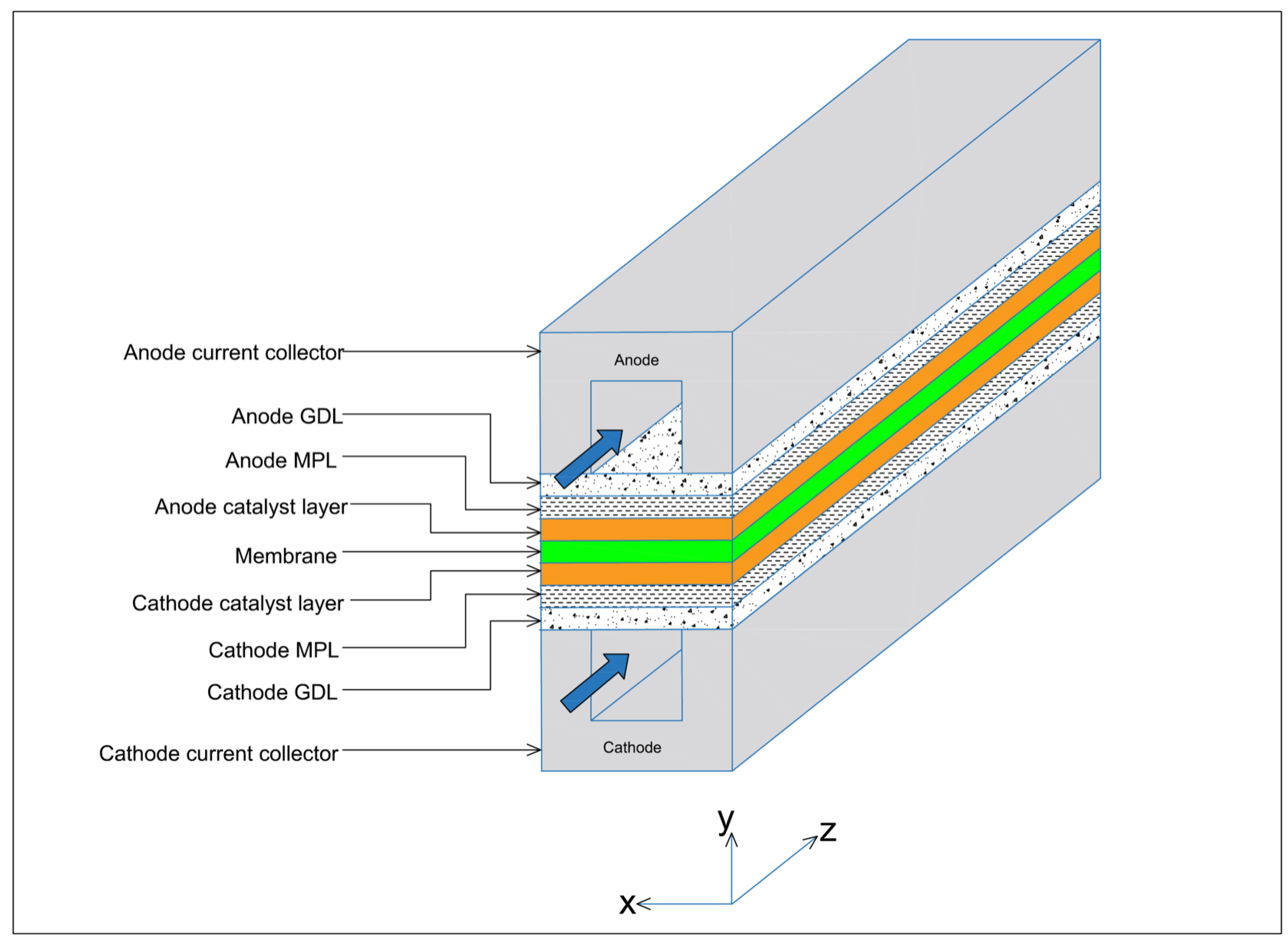

2.2. Model Geometry

2.3. Governing Equations

2.4. Boundary Conditions and Numerical Procedure

3. Results and Discussion

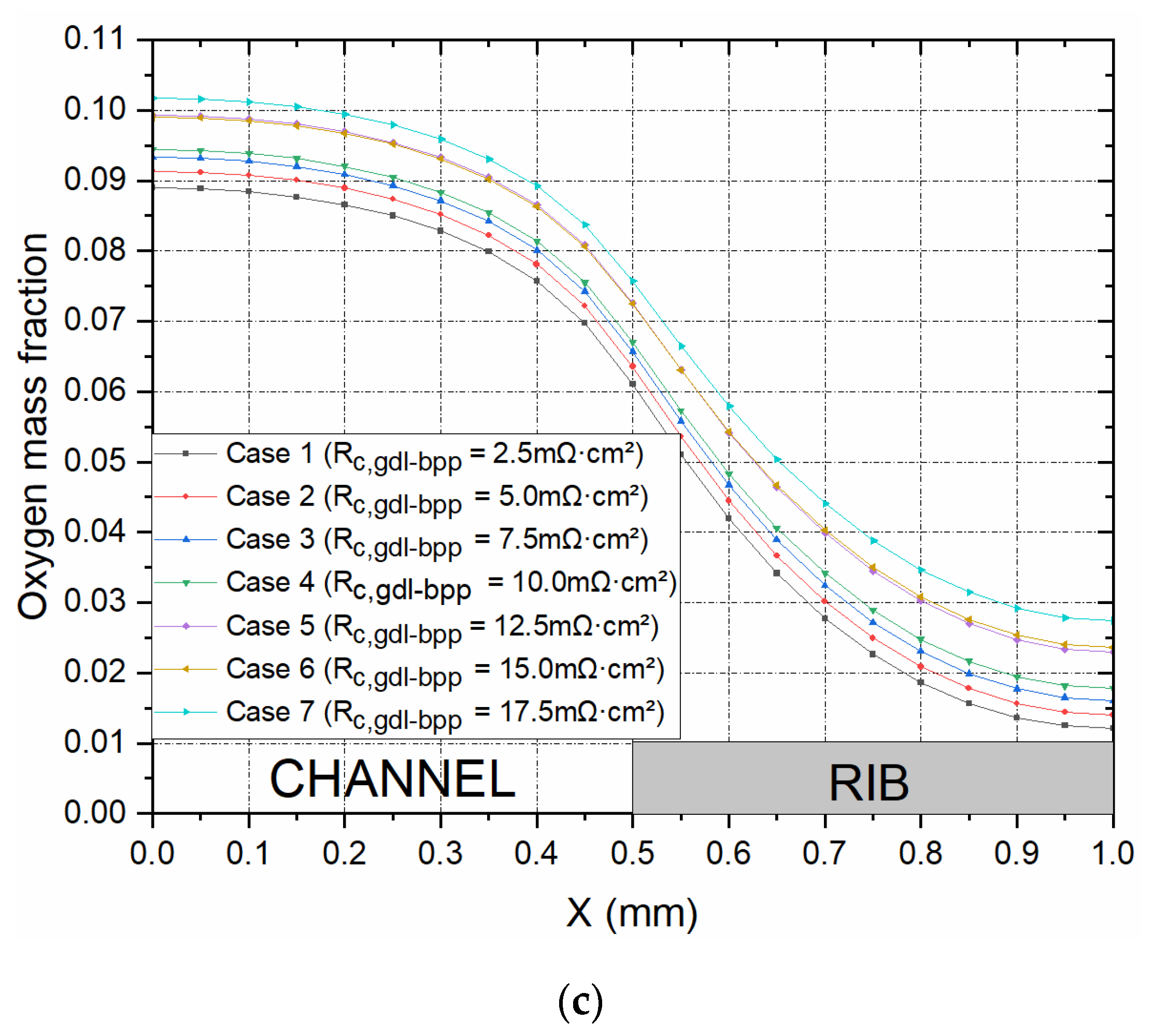

3.1. Contact Resistance between the GDL and the Bipolar Plate

3.2. Contact Resistance between the MPL and the Catalyst Layer

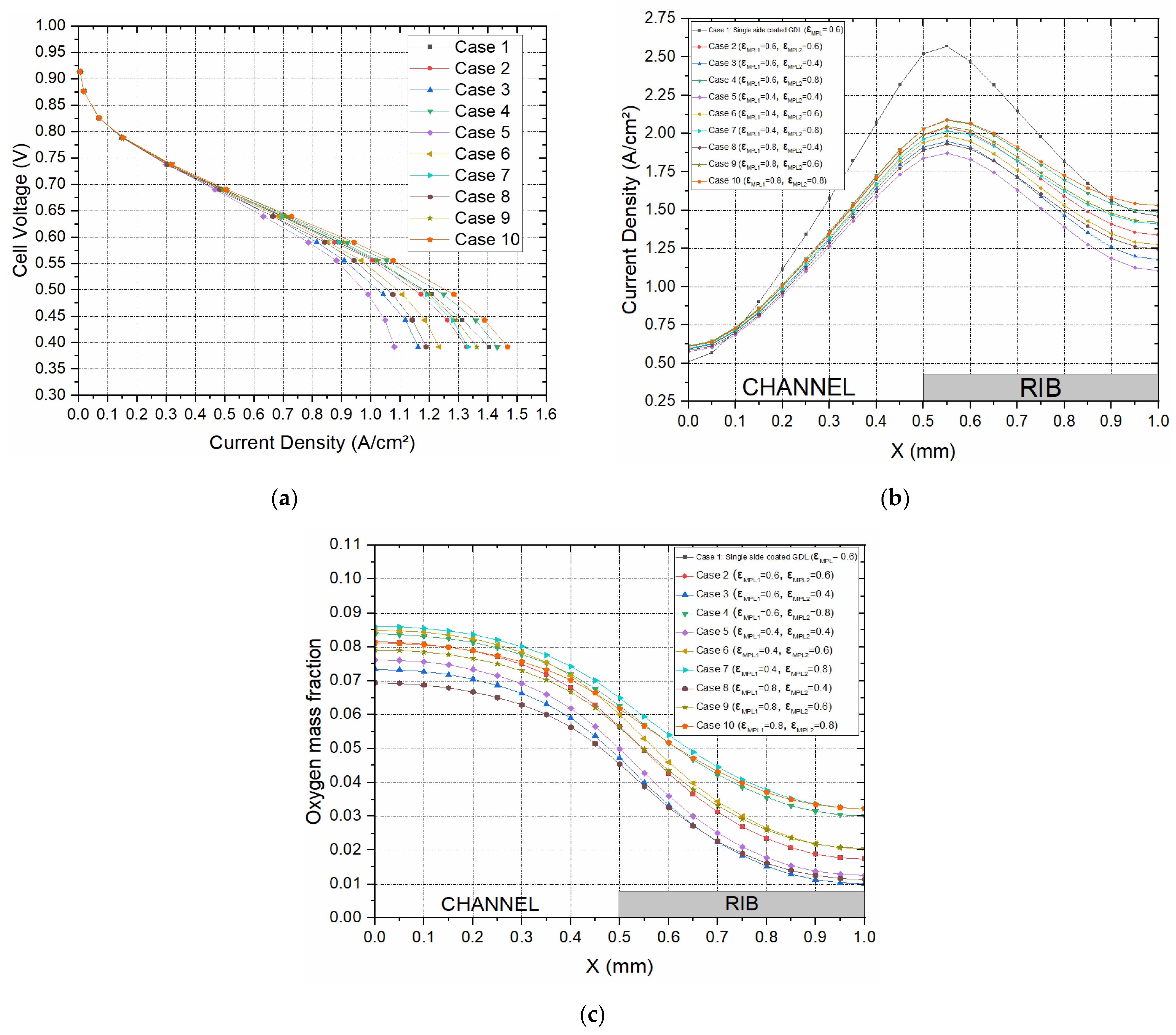

3.3. Impact of MPL Porosity

4. Conclusions

- The interfacial contact resistance between the MPL and the catalyst layer needs to be captured in the modelled PEFC. Otherwise, the fuel cell performance could be overestimated by up to 6%;

- Incorporating an extra MPL at the interface between the GDL and the bipolar plate could significantly improve the fuel cell performance by up to 30%, and this is due to the reduction in the contact resistance between the GDL and the bipolar plate;

- The fuel cell performance is more sensitive to the porosity of the MPL facing the bipolar plate than the MPL facing the catalyst layer. This is attributable to the fact that the MPL facing the bipolar plate is in direct contact with the flow channel, and hence the GDL is supplied with a larger amount of reactant gases as the porosity of this MPL increases;

- Likewise, the porosity of the MPL facing the bipolar plate is predominantly the limiting factor for the distribution of oxygen concentration within the cathode GDL.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, P.; Wu, C.W.; Ma, G.J. Contact resistance prediction and structure optimization of bipolar plates. J. Power Sources 2006, 159, 1115–1122. [Google Scholar] [CrossRef]

- Zhou, Y.; Lin, G.; Shih, A.J.; Hu, S.J. A micro-scale model for predicting contact resistance between bipolar plate and gas diffusion layer in PEM fuel cells. J. Power Sources 2007, 163, 777–783. [Google Scholar] [CrossRef]

- Qiu, D.; Janßen, H.; Peng, L.; Irmscher, P.; Lai, X.; Lehnert, W. Electrical resistance and microstructure of typical gas diffusion layers for proton exchange membrane fuel cell under compression. Appl. Energy 2018, 231, 127–137. [Google Scholar] [CrossRef]

- Lai, X.; Liu, D.; Peng, L.; Ni, J. A mechanical–electrical finite element method model for predicting contact resistance between bipolar plate and gas diffusion layer in PEM fuel cell. J. Power Sources 2008, 182, 153–159. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Song, H.; Wang, S.; Zhou, Y.; Hu, S.J. Estimation of contact resistance in proton exchange membrane fuel cells. J. Power Sources 2006, 162, 1165–1171. [Google Scholar] [CrossRef]

- Vikram, A.; Chowdhury, P.R.; Phillips, R.K.; Hoorfar, M. Measurement of effective bulk and contact resistance of gas diffusion layer under inhomogeneous compression—Part I: Electrical conductivity. J. Power Sources 2016, 320, 274–285. [Google Scholar] [CrossRef]

- Sow, P.K.; Prass, S.; Kalisvaart, P.; Merida, W. Deconvolution of electrical contact and bulk resistance of gas diffusion layers for fuel cell applications. Int. J. Hydrogen Energy 2015, 40, 2850–2861. [Google Scholar] [CrossRef]

- Ismail, M.S.; Ingham, D.B.; Ma, L.; Pourkashanian, M. The contact resistance between gas diffusion layers and bipolar plates as they are assembled in proton exchange membrane fuel cells. Renew. Energy 2013, 52, 40–45. [Google Scholar] [CrossRef]

- Ye, D.; Gauthier, E.; Benziger, J.B.; Pan, M. Bulk and contact resistances of gas diffusion layers in proton exchange membrane fuel cells. J. Power Sources 2014, 256, 449–456. [Google Scholar] [CrossRef]

- Atyabi, S.A.; Afshari, E.; Wongwises, S.; Yan, W.-M.; Hadjadj, A.; Shadloo, M.S. Effects of assembly pressure on PEM fuel cell performance by taking into accounts electrical and thermal contact resistances. Energy 2019, 179, 490–501. [Google Scholar] [CrossRef]

- Bouziane, K.; Khetabi, E.; Lachat, R.; Zamel, N.; Meyer, Y.; Candusso, N. Impact of cyclic mechanical compression on the electrical contact resistance between the gas diffusion layer and the bipolar plate of a polymer electrolyte membrane fuel cell. Renew. Energy 2020, 153, 349–361. [Google Scholar] [CrossRef]

- Chen, S.; Feng, S.; Lu, W.; Chen, Q. Numerical study on the impact of interface contact resistance on the performance of a PEMFC with serpentine flow field. IOP Conf. Ser. Earth Environ. Sci. 2021, 675, 012200. [Google Scholar] [CrossRef]

- Lee, F.C.; Ismail, M.S.; Ingham, D.B.; Hughes, K.J.; Ma, L.; Lyth, S.M.; Pourkashanian, M. Alternative architectures and materials for PEMFC gas diffusion layers: A review and outlook. Renew. Sustain. Energy Rev. 2022, 166, 112640. [Google Scholar] [CrossRef]

- Zamel, N.; Xianguo, L. Effective transport properties for polymer electrolyte membrane fuel cell-With focus on the gas diffusion layer. Prog. Energy Combust. Sci. 2013, 39, 111–146. [Google Scholar] [CrossRef]

- El-Kharouf, A.; Pollet, B.G. Gas Diffusion Media and Their Degradation. In Polymer Electrolyte Fuel Cell Degradation; Academic Press: Boston, MA, USA, 2012; Chapter 4; pp. 215–247. [Google Scholar]

- Ozden, A.; Shahgaldi, S.; Li, X.; Hamdullahpur, F. A review of gas diffusion layers for proton exchange membrane fuel cells—With a focus on characteristics, characterization techniques, materials and designs. Prog. Energy Combust. Sci. 2019, 74, 50–102. [Google Scholar] [CrossRef]

- Kitahara, T.; Konomi, T.; Nakajima, H. Microporous layer coated gas diffusion layers for enhanced performance of polymer electrolyte fuel cells. J. Power Sources 2010, 195, 2202–2211. [Google Scholar] [CrossRef]

- Kitaharaa, T.; Nakajimaa, H.; Moria, K.; Inamoto, M. Influence of Hydrophilic and Hydrophobic Double MPL Coated GDL on PEFC Performance. ECS Trans. 2012, 50, 437–444. [Google Scholar] [CrossRef]

- Chun, J.H.; Park, K.T.; Jo, D.H.; Lee, J.Y.; Kim, S.G.; Park, S.H.; Lee, E.S.; Jyoung, J.-Y.; Kim, S.H. Development of a novel hydrophobic/hydrophilic double micro porous layer for use in a cathode gas diffusion layer in PEMFC. Int. J. Hydrogen Energy 2011, 36, 8422–8428. [Google Scholar] [CrossRef]

- Park, S.; Popov, B.N. Effect of cathode GDL characteristics on mass transport in PEM fuel cells. Fuel 2009, 88, 2068–2073. [Google Scholar] [CrossRef]

- Qi, Z.; Kaufman, A. Improvement of water management by a microporous sublayer for PEM fuel cells. J. Power Sources 2002, 109, 38–46. [Google Scholar] [CrossRef]

- Nam, J.H.; Lee, K.-J.; Hwang, G.-S.; Kim, C.-J.; Kaviany, M. Microporous layer for water morphology control in PEMFC. Int. J. Heat Mass Transf. 2009, 52, 2779–2791. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Zhang, J.; Xu, H.; Zhu, X.; Chen, J.; Yi, B. A bi-functional micro-porous layer with composite carbon black for PEM fuel cells. J. Power Sources 2006, 162, 474–479. [Google Scholar] [CrossRef]

- Wang, X.L.; Zhang, H.M.; Zhang, J.L.; Xu, H.F.; Tian, Z.Q.; Chen, J.; Zhong, H.X.; Liang, Y.M.; Yi, B.L. Micro-porous layer with composite carbon black for PEM fuel cells. Electrochim. Acta 2006, 51, 4909–4915. [Google Scholar] [CrossRef]

- Li, S.; Yuan, J.; Andersson, M.; Xie, G.; Sunden, B. Influence of anisotropic gas diffusion layers on transport phenomena in a proton exchange membrane fuel cell. Int. J. Energy Res 2017, 41, 2034–2050. [Google Scholar] [CrossRef]

- Okereke, I.C.; Ismail, M.S.; Ingham, D.; Hughes, K.J.; Ma, L.; Pourkashanian, M. The effects of GDL anisotropic transport properties on the PEFC performance. Int. J. Numer. Methods Heat Fluid Flow 2023, 33, 648–672. [Google Scholar] [CrossRef]

- Bruggeman, D.A.G. Calculation of various physics constants in heterogeneous substances I dielectricity constants and conductivity of mixed bodies from isotropic substances. Ann. Phys. 1935, 24, 636–664. [Google Scholar] [CrossRef]

- Ismail, M.S.; Hughes, K.J.; Ingham, D.B.; Ma, L.; Pourkashanian, M. Effects of anisotropic permeability and electrical conductivity of gas diffusion layers on the performance of proton exchange membrane fuel cells. Appl. Energy 2012, 95, 50–63. [Google Scholar] [CrossRef]

- Wang, L.; Husar, A.; Zhou, T.; Liu, H. A parametric study of PEM fuel cell performances. Int. J. Hydrogen Energy 2003, 28, 1263–1272. [Google Scholar] [CrossRef]

- Ismail, M.S.; Ingham, D.B.; Hughes, K.J.; Ma, L.; Pourkashanian, M. Effective diffusivity of polymer electrolyte fuel cell gas diffusion layers: An overview and numerical study. Int. J. Hydrogen Energy 2015, 40, 10994–11010. [Google Scholar] [CrossRef]

- Alhazmi, N.; Ismail, M.S.; Ingham, D.B.; Hughes, K.J.; Ma, L.; Pourkashanian, M. The in-plane thermal conductivity and the contact resistance of the components of the membrane electrode assembly in proton exchange membrane fuel cells. J. Power Sources 2013, 241, 136–145. [Google Scholar] [CrossRef]

- Zawodzinski, T.A.; Springer, T.E.; Uribe, F.; Gottesfeld, S. Characterisation of polymer electrolytes for fuel cell applications. Solid State Ionics 1993, 60, 199–211. [Google Scholar] [CrossRef]

- Gostick, J.T.; Fowler, M.W.; Pritzker, M.D.; Ioannidis, M.A.; Behra, L.M. In-plane and through-plane gas permeability of carbon fibre electrode backing layers. J. Power Sources 2006, 162, 228–238. [Google Scholar] [CrossRef]

- Pharaoh, J.G.; Karan, K.; Sun, W. On effective transport coefficients in PEM fuel cell electrodes: Anisotropy of the porous transport layers. J. Power Sources 2006, 161, 214–224. [Google Scholar] [CrossRef]

- Springer, T.E.; Zawodzinski, T.A.; Gottesfeld, S. Polymer electrolyte fuel-cell model. J. Electrochem. Soc. 1991, 138, 2334–2342. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Channel length | 5 × 10−2 m |

| Channel height | 1.0 × 10−3 m |

| Channel width | 1.0 × 10−3 m |

| Current collector rib width | 1.0 × 10−3 m |

| Current collector height | 1.5 × 10−3 m |

| GDL thickness | 2.0 × 10−4 m |

| MPL thickness | 5.0 × 10−5 m |

| Catalyst layer thickness | 1.0 × 10−5 m |

| Membrane thickness | 5.0 × 10−5 m |

| Operating temperature | 353 K |

| Gauge pressure at anode | 1 atm |

| Gauge pressure at cathode | 1 atm |

| Relative humidity of inlet gases | 100% |

| Stoichiometric ratio, anode | 1.5 |

| Stoichiometric ratio, cathode | 2 |

| Oxygen/nitrogen molar ratio in air | 0.21/0.79 |

| Catalyst layer porosity | 0.2 |

| GDL porosity | 0.7 |

| MPL porosity | 0.6 |

| Reference hydrogen concentration, | 56.4 mol/m3 |

| Reference oxygen concentration, | 3.39 mol/m3 |

| Electrical conductivity of current collector | 20,000 S/m |

| Electrical conductivity of GDL | 5000 S/m |

| Electrical conductivity of catalyst layer | 2000 S/m |

| Electrical conductivity of MPL | 5000 S/m |

| GDL permeability | 3.0 × 10−12 m2 |

| MPL permeability | 1.0 × 10−1 m2 |

| Catalyst layer permeability | 2 × 10−13 m2 |

| Membrane permeability | 1.8 × 10−18 m2 |

| Thermal conductivity of GDLs | |

| Thermal conductivity of MPL | |

| Thermal conductivity of catalyst layers | |

| Thermal conductivity of current collector | |

| Thermal conductivity of the membrane | |

| GDL/MPL/CL contact angle | 110/130/95 |

| Faraday’s constant | 96,485 C/mol |

| Universal gas constant | 8.314 J/ |

| Anode inlet mass fraction of hydrogen | 0.1105 |

| Anode inlet mass fraction of water | 0.8895 |

| Cathode inlet mass fraction of oxygen | 0.1503 |

| Cathode inlet mass fraction of water | 0.3541 |

| Anode flow rate | 1.3518 × 10−7 kg/s |

| Cathode flow rate | 1.10331 × 10−6 kg/s |

| Anode concentration exponents | 0.5 |

| Cathode concentration exponents | 1 |

| 100 A/m² | |

| Cathode reference exchange current density, | 0.0001760881 A/m² |

| Transfer coefficients for anode reaction | 0.5 |

| Transfer coefficients for cathode reaction | 1 |

| Anode specific surface area, | 1.0 × 107 m−1 |

| Cathode specific surface area, | 1.0 × 107 m−1 |

| Case No. | ||

|---|---|---|

| 1 (Single MPL) | 0.6 | NA |

| 2 | 0.6 | 0.6 |

| 3 | 0.6 | 0.4 |

| 4 | 0.6 | 0.8 |

| 5 | 0.4 | 0.4 |

| 6 | 0.4 | 0.6 |

| 7 | 0.4 | 0.8 |

| 8 | 0.8 | 0.4 |

| 9 | 0.8 | 0.6 |

| 10 | 0.8 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okereke, I.C.; Ismail, M.S.; Ingham, D.B.; Hughes, K.; Ma, L.; Pourkashanian, M. Single- and Double-Sided Coated Gas Diffusion Layers Used in Polymer Electrolyte Fuel Cells: A Numerical Study. Energies 2023, 16, 4363. https://doi.org/10.3390/en16114363

Okereke IC, Ismail MS, Ingham DB, Hughes K, Ma L, Pourkashanian M. Single- and Double-Sided Coated Gas Diffusion Layers Used in Polymer Electrolyte Fuel Cells: A Numerical Study. Energies. 2023; 16(11):4363. https://doi.org/10.3390/en16114363

Chicago/Turabian StyleOkereke, Isaac C., Mohammed S. Ismail, Derek B. Ingham, Kevin Hughes, Lin Ma, and Mohamed Pourkashanian. 2023. "Single- and Double-Sided Coated Gas Diffusion Layers Used in Polymer Electrolyte Fuel Cells: A Numerical Study" Energies 16, no. 11: 4363. https://doi.org/10.3390/en16114363

APA StyleOkereke, I. C., Ismail, M. S., Ingham, D. B., Hughes, K., Ma, L., & Pourkashanian, M. (2023). Single- and Double-Sided Coated Gas Diffusion Layers Used in Polymer Electrolyte Fuel Cells: A Numerical Study. Energies, 16(11), 4363. https://doi.org/10.3390/en16114363