Cost Assessment of Centralizing Swine Manure and Corn Stover Co-Digestion Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Scenario Description

2.2. Digester Input

2.3. Biogas Production

2.4. Digestate Production

2.5. Capital Costs

2.6. Operating Costs

2.7. Renewable Fuel Identification Numbers and the Low-Carbon Fuel Standard

2.8. Final Cost Calculation

2.9. Natural Gas Comparison

3. Results and Discussion

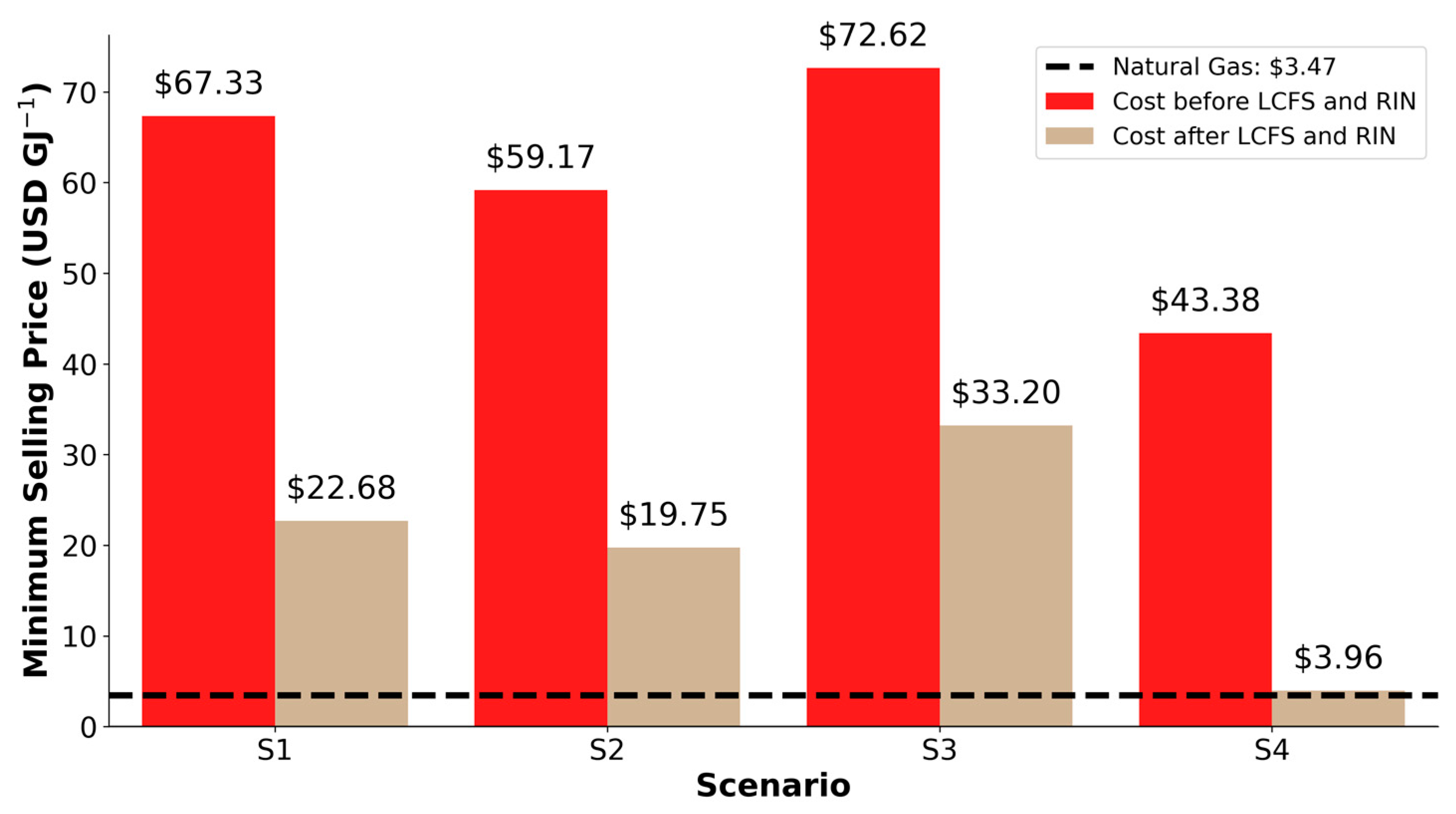

3.1. Annual Production and Costs

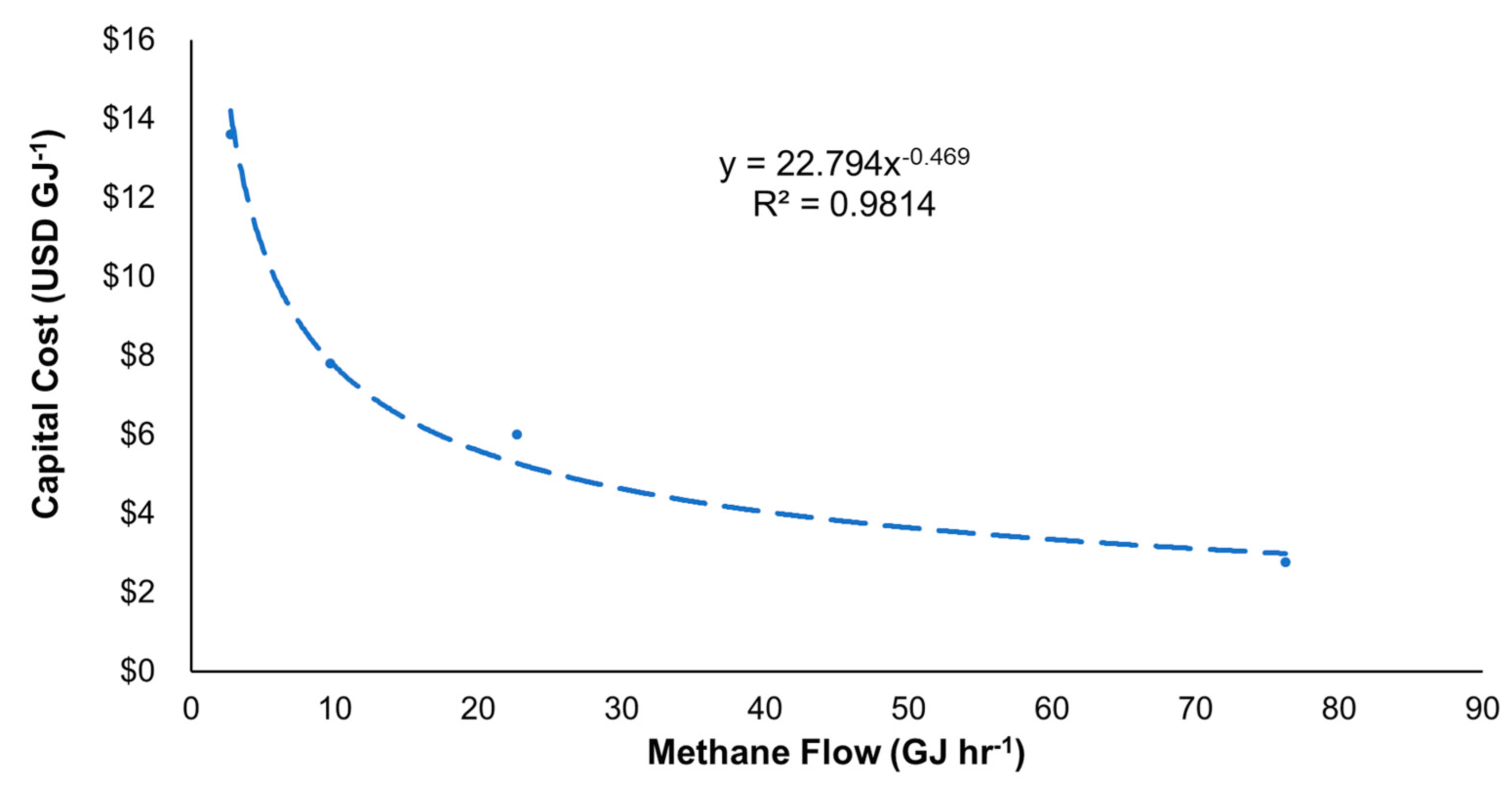

3.2. Capital

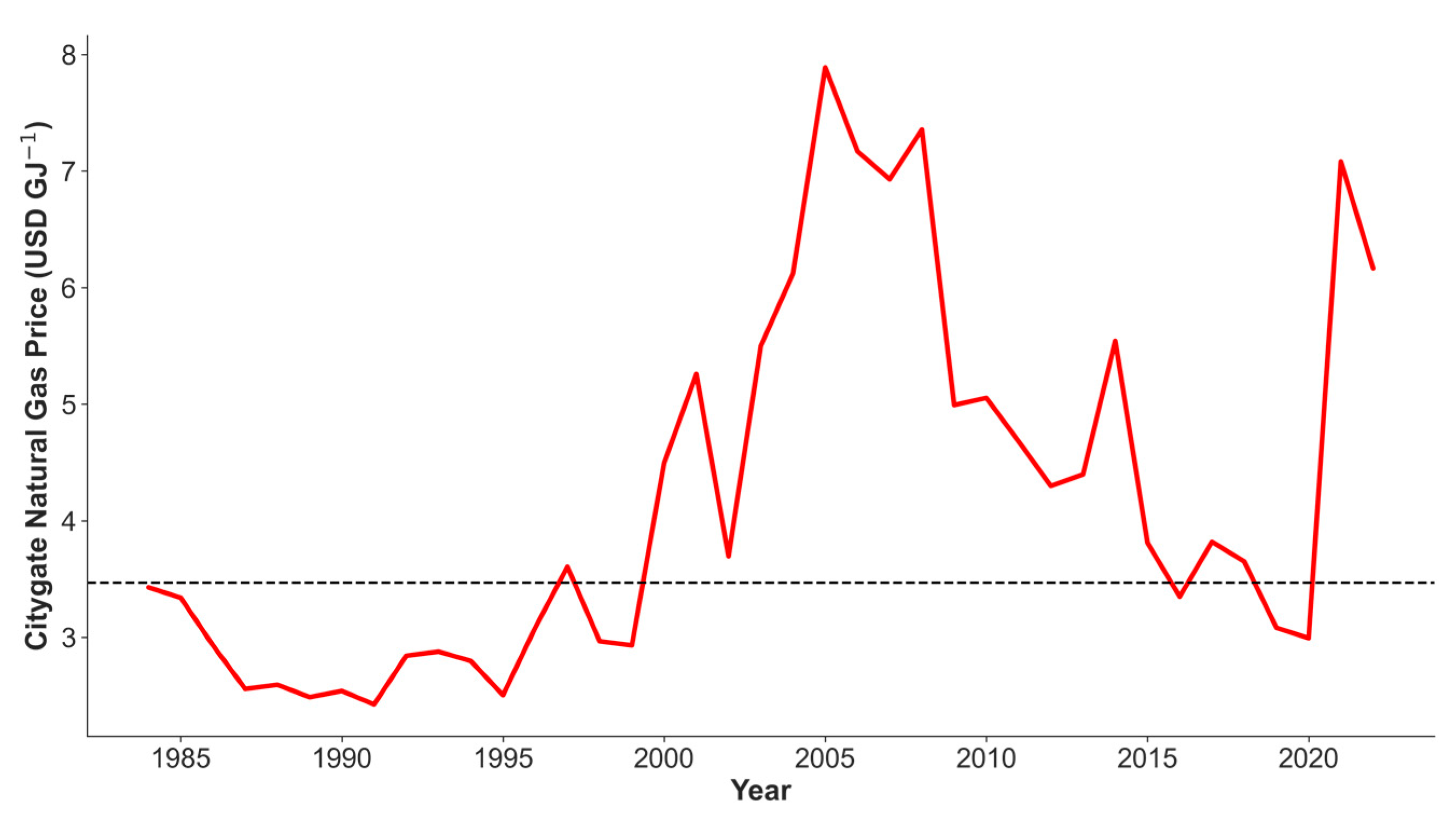

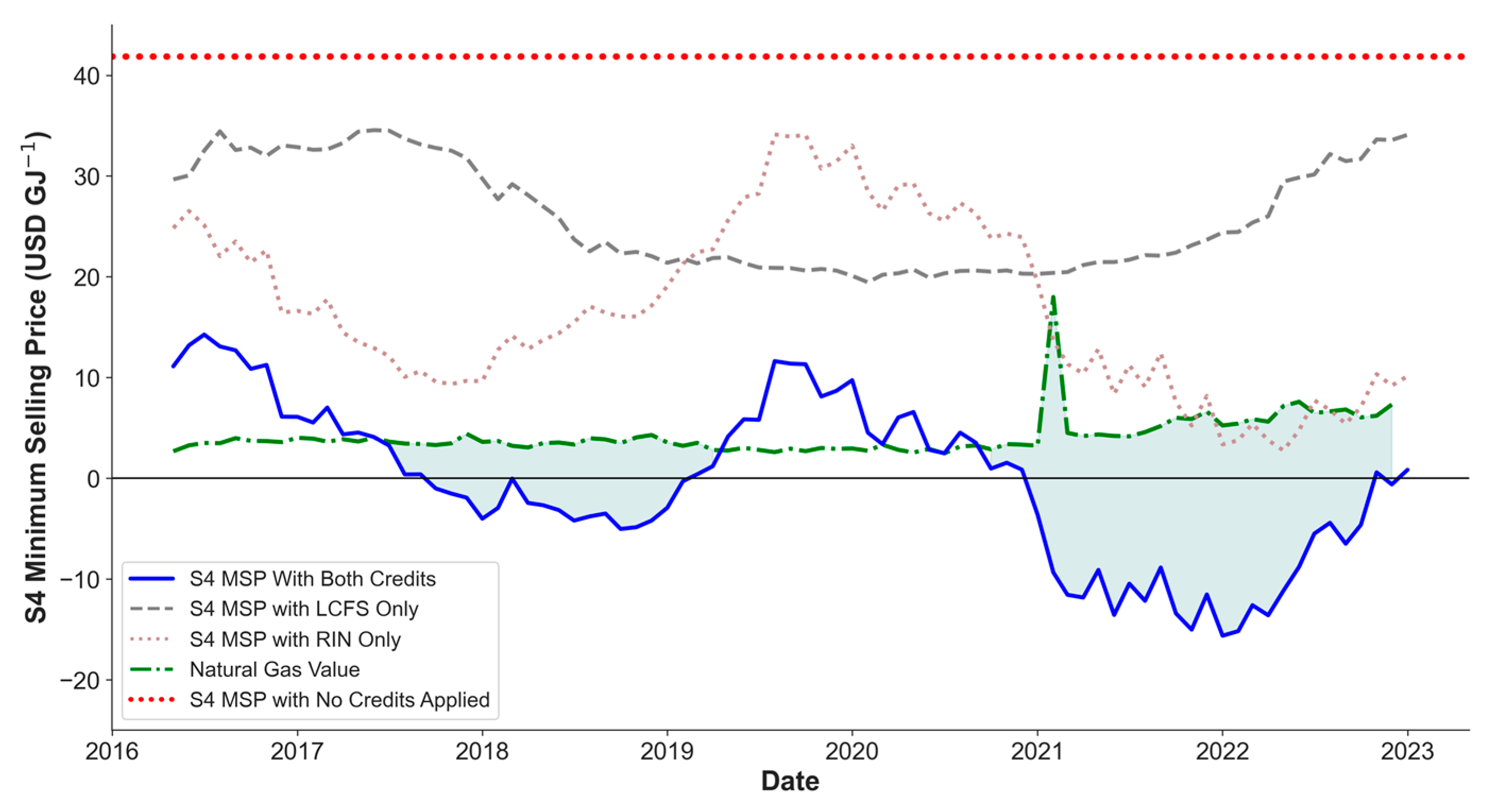

3.3. Natural Gas Comparison

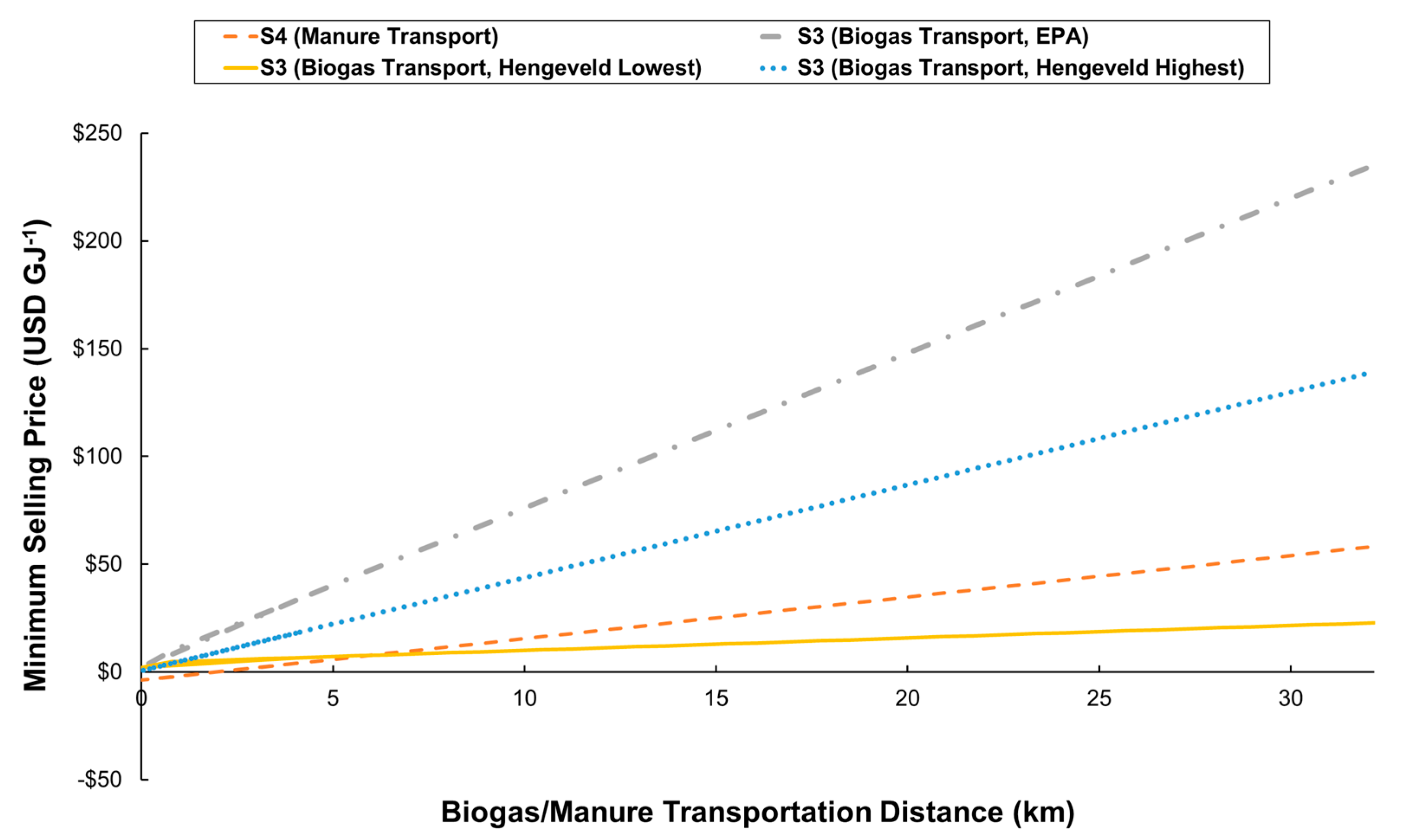

3.4. Effect of Transportation Distances

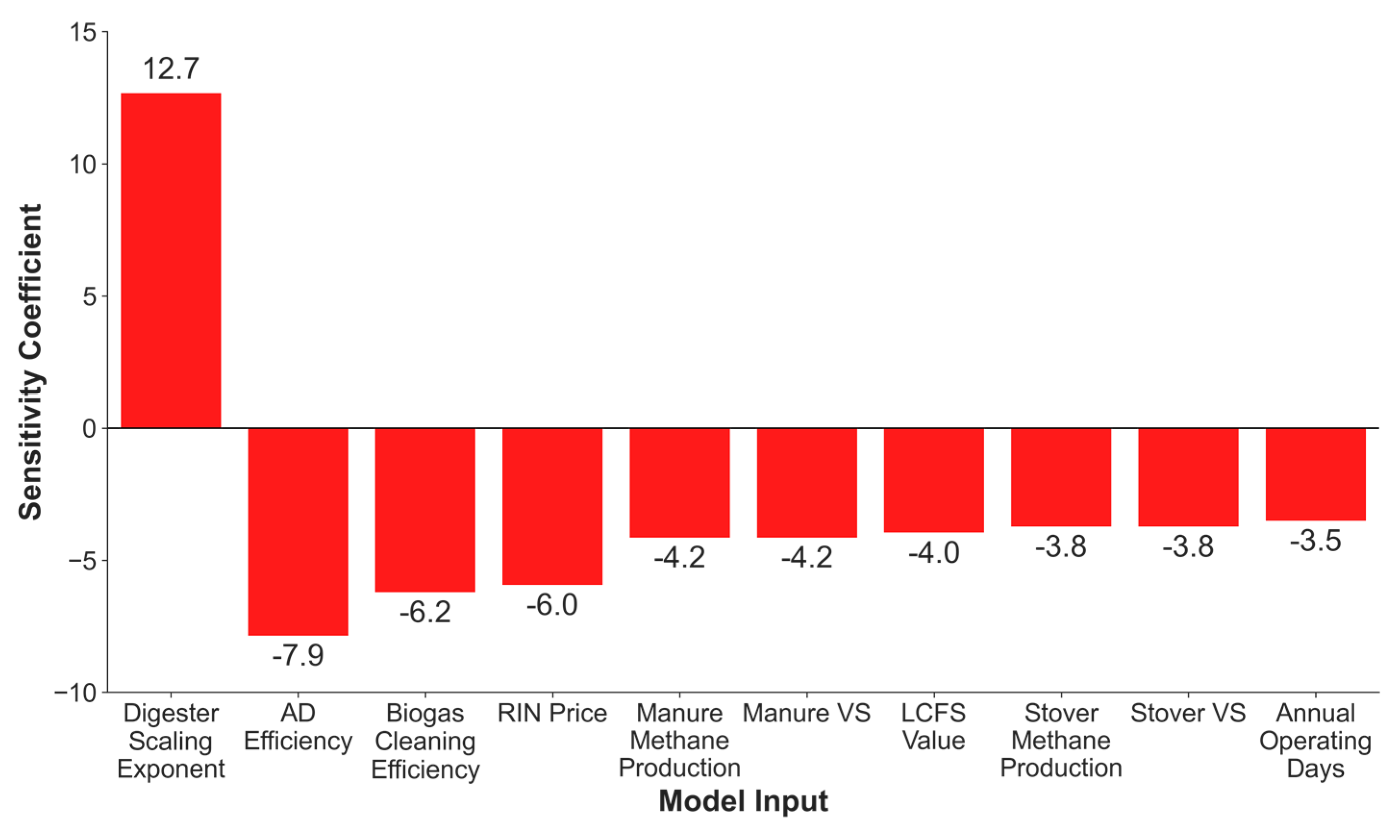

3.5. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| US | United States of America |

| AD | Anaerobic Digestion/Digester |

| RIN | Renewable Identification Number |

| RFS | Renewable Fuels Standard |

| LCFS | Low-Carbon Fuel Standard |

| USD | United States Dollar |

| RNG | Renewable Natural Gas |

| TS | Total Solids |

| VS | Volatile Solids |

| S1, S2, S3, S4 | Scenarios 1–4 |

| EPA | United States Environmental Protection Agency |

| CI | Carbon Intensity |

| CARB | California Air Resources Board |

| MSP | Minimum Selling Price |

References

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimisation of the Anaerobic Digestion of Agricultural Resources. Bioresour. Technol. 2008, 99, 7928–7940. [Google Scholar] [CrossRef] [PubMed]

- Chiumenti, R.; Chiumenti, A.; da Borso, F.; Limina, S.; Landa, A. Anaerobic Digestion of Swine Manure in Conventional and Hybrid Pilot Scale Plants: Performance and Gaseous Emissions Reduction. In Proceedings of the 2009 ASABE Annual International Meeting, Reno, NV, USA, 21–24 June 2009; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2009. [Google Scholar]

- EPA. Environmental Benefits of Anaerobic Digestion (AD). Available online: https://www.epa.gov/anaerobic-digestion/environmental-benefits-anaerobic-digestion-ad (accessed on 2 February 2023).

- AgSTAR. AgSTAR Data and Trends. Available online: https://www.epa.gov/agstar/agstar-data-and-trends (accessed on 2 February 2023).

- AgSTAR. Market Opportunities for Biogas Recovery Systems at U.S. Livestock Facilities; AgSTAR: Mankato, MN, USA, 2018. [Google Scholar]

- Decision Innovation Solutions. Iowa Pork Industry Contribution Study 2020; Decision Innovation Solutions: Urbandale, IA, USA, 2020. [Google Scholar]

- Bhatt, A.H.; Tao, L. Economic Perspectives of Biogas Production via Anaerobic Digestion. Bioengineering 2020, 7, 74. [Google Scholar] [CrossRef]

- EIA. Table A4. Approximate Heat Content of Natural Gas; U.S Energy Information Administration: Washington, DC, USA, 2021.

- EIA. Natural Gas Prices. Available online: https://www.eia.gov/dnav/ng/ng_pri_sum_dcu_SIA_a.htm (accessed on 2 February 2023).

- Beddoes, J.C.; Bracmort, K.S.; Burns, R.T.; Lazarus, W.F. An Analysis of Energy Production Costs from Anaerobic Digestion Systems on U.S. Livestock Production Facilities; Natural Resources Conservation Service United States Department of Agriculture: Washington, DC, USA, 2007. [Google Scholar]

- EIA. Levelized Costs of New Generation Resources in the Annual Energy Outlook; U.S Energy Information Administration: Washington, DC, USA, 2021.

- Faulhaber, C.R.; Raman, D.R.; Burns, R.T. An Engineering-Economic Model for Analyzing Dairy Plug-Flow Anaerobic Digesters: Cost Structures and Policy Implications. Trans. ASABE 2012, 55, 41247. [Google Scholar] [CrossRef]

- Lusk, P. Methane Recovery from Animal Manures the Current Opportunities Casebook; National Renewable Energy Laboratory: Golden, CO, USA, 1998.

- AgSTAR. Livestock Anaerobic Digester Database. Available online: https://www.epa.gov/agstar/livestock-anaerobic-digester-database (accessed on 20 December 2021).

- Aldrich, B.S.; Fiesinger, T. Centralized Anaerobic Digestion Options for Groups of Dairy Farms; Rural Business-Cooperative Service: Washington, DC, USA, 2005. [Google Scholar]

- Burmahl, B. Turning Waste to Energy: Tracking Renewable Natural Gas Transportation Projects. Available online: https://www.anl.gov/article/turning-waste-to-energy-tracking-renewable-natural-gas-transportation-projects (accessed on 2 February 2023).

- Homan, E. Biogas from Manure. Available online: https://extension.psu.edu/biogas-from-manure (accessed on 14 March 2023).

- Varol, A.; Ugurlu, A. Comparative Evaluation of Biogas Production from Dairy Manure and Co-Digestion with Maize Silage by CSTR and New Anaerobic Hybrid Reactor. Eng. Life Sci. 2017, 17, 402–412. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Xu, Z.; Li, X.; Yu, J.; Cai, M.; Jin, M. Integrated Bioethanol Production from Mixtures of Corn and Corn Stover. Bioresour. Technol. 2018, 258, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Fujita, M.; Scharer, J.M.; Moo-Young, M. Effect of Corn Stover Addition on the Anaerobic Digestion of Swine Manure. Agric. Wastes 1980, 2, 177–184. [Google Scholar] [CrossRef]

- González, R.; González, J.; Rosas, J.G.; Smith, R.; Gómez, X. Biochar and Energy Production: Valorizing Swine Manure through Coupling Co-Digestion and Pyrolysis. C-J. Carbon Res. 2020, 6, 43. [Google Scholar] [CrossRef]

- Kadam, K.L.; McMillan, J.D. Availability of Corn Stover as a Sustainable Feedstock for Bioethanol Production. Bioresour. Technol. 2003, 88, 17–25. [Google Scholar] [CrossRef]

- Miller, D. Designing ‘Greener’ Pig Barns. Available online: https://www.nationalhogfarmer.com/facilities-equipment/designing-greener-pig-barns-0919 (accessed on 22 February 2023).

- Vansickle, J. Double-Wide Wean-to-Finish Facilities. Available online: https://www.nationalhogfarmer.com/mag/farming_doublewide_weantofinish_facilities (accessed on 22 February 2023).

- Baldwin, S.; Anthony, L.; Wang, M. Development of a Calculator for the Techno-Economic Assessment of Anaerobic Digestion Systems; Final report submitted to BC Ministry of Agriculture and Land and BC Life Sciences; Chemical and Biological Engineering, University of British Columbia: Vancouver, BC, Canada, 2009. [Google Scholar]

- Hengeveld, E.J.; van Gemert, W.J.T.; Bekkering, J.; Broekhuis, A.A. When Does Decentralized Production of Biogas and Centralized Upgrading and Injection into the Natural Gas Grid Make Sense? Biomass Bioenergy 2014, 67, 363–371. [Google Scholar] [CrossRef]

- Iowa DNR. AFO Siting. Available online: https://programs.iowadnr.gov/maps/afo/ (accessed on 14 March 2023).

- Konopacky, J.; Rundquist, S. EWG Study and Mapping Show Large CAFOs in Iowa Up Fivefold Since 1990. Available online: https://www.ewg.org/interactive-maps/2020-iowa-cafos/ (accessed on 14 March 2023).

- Smith, B.C.; Andersen, D.S.; Harmon, J.D.; Stinn, J.P. Case Study of Swine Finishing Manure Nutrient Characteristics for Land Application. In Proceedings of the 2017 ASABE Annual International Meeting, Spokane, WA, USA, 16–19 July 2017; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2017. [Google Scholar]

- Andersen, D.S.; Van Weelden, M.B.; Trabue, S.L.; Pepple, L.M. Lab-Assay for Estimating Methane Emissions from Deep-Pit Swine Manure Storages. J. Environ. Manag. 2015, 159, 18–26. [Google Scholar] [CrossRef]

- California Air Resources Board. Compliance Offset Protocol Livestock Projects; California Air Resources Board: Sacramento, CA, USA, 2014. [Google Scholar]

- ASABE. ASAE D384.2 Manure Production and Characteristics; ASABE: St. Joseph, MI, USA, 2005. [Google Scholar]

- Sawyer, J.E.; Mallarino, A.P. Using Manure Nutrients for Crop Production; Iowa State University Extension and Outreach: Ames, IA, USA, 2016. [Google Scholar]

- Schnitkey, G.; Paulson, N.; Zulauf, C.; Swanson, K.; Baltz, J. Fertilizer Prices, Rates, and Costs for 2023; Department of Agricultural and Consumer Economics: Chicago, Il, USA, 2022. [Google Scholar]

- Ghafoori, E.; Flynn, P.; Feddes, J. Pipeline vs. Truck Transport of Beef Cattle Manure. Biomass Bioenergy 2007, 31, 168–175. [Google Scholar] [CrossRef]

- Moody, L.B.; Burns, R.T.; Bishop, G.; Sell, S.T.; Spajic, R. Using Biochemical Methane Potential Assays to Aid in Co-Substrate Selection for Co-Digestion. Appl. Eng. Agric. 2011, 27, 433–439. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; Liu, X.; Chen, C.; Xiao, X.; Feng, L.; He, Y.; Liu, G. Evaluating Methane Production from Anaerobic Mono- and Co-Digestion of Kitchen Waste, Corn Stover, and Chicken Manure. Energy Fuels 2013, 27, 2085–2091. [Google Scholar] [CrossRef]

- Liu, C.M.; Wachemo, A.C.; Yuan, H.R.; Zou, D.X.; Liu, Y.P.; Zhang, L.; Pang, Y.Z.; Li, X.J. Evaluation of Methane Yield Using Acidogenic Effluent of NaOH Pretreated Corn Stover in Anaerobic Digestion. Renew. Energy 2018, 116, 224–233. [Google Scholar] [CrossRef]

- Aui, A.; Wright, M. Life Cycle Cost Analysis of the Operations of Anaerobic Digesters in Iowa; Iowa State University: Ames, IA, USA, 2014. [Google Scholar]

- Aui, A.; Wang, Y.; Mba-Wright, M. Evaluating the Economic Feasibility of Cellulosic Ethanol: A Meta-Analysis of Techno-Economic Analysis Studies. Renew. Sustain. Energy Rev. 2021, 145, 111098. [Google Scholar] [CrossRef]

- Thompson, J.L.; Tyner, W.E. Corn Stover for Bioenergy Production: Cost Estimates and Farmer Supply Response. Biomass Bioenergy 2014, 62, 166–173. [Google Scholar] [CrossRef]

- Kazi, F.K.; Fortman, J.; Anex, R.; Kothandaraman, G.; Hsu, D.; Aden, A.; Dutta, A. Techno-Economic Analysis of Biochemical Scenarios for Production of Cellulosic Ethanol; National Renewable Energy Laboratory: Golden, CO, USA, 2010.

- Davis, R.E.; Grundl, N.J.; Tao, L.; Biddy, M.J.; Tan, E.C.; Beckham, G.T.; Humbird, D.; Thompson, D.N.; Roni, M.S. Process Design and Economics for the Conversion of Lignocellulosic Biomass to Hydrocarbon Fuels and Coproducts: 2018 Biochemical Design Case Update; Biochemical Deconstruction and Conversion of Biomass to Fuels and Products via Integrated Biorefinery Pathways; National Renewable Energy Laboratory: Golden, CO, USA, 2018. [Google Scholar]

- Ertl, D. 2013 Sustainable Corn Stover Harvest; Iowa Corn Promotion Board: Johnston, IA, USA, 2013. [Google Scholar]

- Edwards, W. Estimating a Value for Corn Stover; Iowa State University: Ames, IA, USA, 2020. [Google Scholar]

- Arora, K.; Licht, M.; Leibold, K. Industrial Corn Stover Harvest; Iowa State University: Ames, IA, USA, 2014. [Google Scholar]

- Khanna, M.; Paulson, N. To Harvest Stover or Not: Is It Worth It? Department of Agricultural and Consumer Economics: Chicago, Il, USA, 2016. [Google Scholar]

- Sawyer, J.E.; Mallarino, A.P. Nutrient Considerations with Corn Stover Harvest; Iowa State University: Ames, IA, USA, 2014. [Google Scholar]

- Comino, E.; Rosso, M.; Riggio, V. Investigation of Increasing Organic Loading Rate in the Co-Digestion of Energy Crops and Cow Manure Mix. Bioresour. Technol. 2010, 101, 3013–3019. [Google Scholar] [CrossRef]

- Lehtomäki, A.; Huttunen, S.; Rintala, J.A. Laboratory Investigations on Co-Digestion of Energy Crops and Crop Residues with Cow Manure for Methane Production: Effect of Crop to Manure Ratio. Resour. Conserv. Recycl. 2007, 51, 591–609. [Google Scholar] [CrossRef]

- Jie, L.; Liu, S.; Zhang, S.; Peng, L.; Wang, J.; Pan, Y. Biogas Yields during Anaerobic Co-Digestion of Corn Stover and Cattle Manure with Different Proportions. IOP Conf. Ser. Earth Environ. Sci. 2020, 546, 42045. [Google Scholar] [CrossRef]

- Wang, H.; Lim, T.T.; Duong, C.; Zhang, W.; Xu, C.; Yan, L.; Mei, Z.; Wang, W. Long-Term Mesophilic Anaerobic Co-Digestion of Swine Manure with Corn Stover and Microbial Community Analysis. Microorganisms 2020, 8, 188. [Google Scholar] [CrossRef]

- Gontupil, J.; Darwin, M.; Liu, Z.; Cheng, J.J.; Chen, H.C. Anaerobic Co-Digestion of Swine Manure and Corn Stover for Biogas Production. In Proceedings of the 2012 ASABE Annual International Meeting, Dallas, TX, USA, 29 July–1 August 2012; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2012. [Google Scholar]

- Angel, S.; Sanchez, B.; Marcy, C. EIA Uses the Heat Content of Fossil Fuels to Compare and Aggregate Energy Sources. Available online: https://www.eia.gov/todayinenergy/detail.php?id=40833# (accessed on 2 February 2023).

- Bekkering, J.; Broekhuis, T.A.; van Gemert, W.J.T. Operational Modeling of a Sustainable Gas Supply Chain. Eng. Life Sci. 2010, 10, 585–594. [Google Scholar] [CrossRef]

- Estevez, M.M.; Sapci, Z.; Linjordet, R.; Schnürer, A.; Morken, J. Semi-Continuous Anaerobic Co-Digestion of Cow Manure and Steam-Exploded Salix with Recirculation of Liquid Digestate. J. Environ. Manag. 2014, 136, 9–15. [Google Scholar] [CrossRef] [PubMed]

- Zeb, I.; Ma, J.; Frear, C.; Zhao, Q.; Ndegwa, P.; Yao, Y.; Kafle, G.K. Recycling Separated Liquid-Effluent to Dilute Feedstock in Anaerobic Digestion of Dairy Manure. Energy 2017, 119, 1144–1151. [Google Scholar] [CrossRef]

- Williams, R.; Ely, C.; Martynowicz, T.; Kosusko, M. Evaluating the Air Quality, Climate, and Economic Impacts of Biogas Management Technologies; United States Environmental Protection Agency: Washington, DC, USA, 2016. [Google Scholar]

- EPA. Landfill Gas Energy Cost Model User’s Manual Version 3.5; U.S Energy Information Administration: Washington, DC, USA, 2021.

- Møller, H.; Lund, I.; Sommer, S.G. Solid–Liquid Separation of Livestock Slurry: Efficiency and Cost. Bioresour. Technol. 2000, 74, 223–229. [Google Scholar] [CrossRef]

- NRCS. Costs Associated with Development and Implementation of Comprehensive Nutrient Management Plans; U.S. Department of Agriculture: Washington, DC, USA, 2003.

- Chastain, J.P. Covers: A Method to Reduce Odor from Manure Storages; Clemson University: Clemson, SC, USA, 2008. [Google Scholar]

- EIA. Electric Power Monthly. Available online: https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=epmt_5_6_a (accessed on 1 March 2021).

- EPA. Renewable Identification Numbers (RINs) under the Renewable Fuel Standard Program. Available online: https://www.epa.gov/renewable-fuel-standard-program/renewable-identification-numbers-rins-under-renewable-fuel-standard (accessed on 2 February 2023).

- EPA. RIN Trades and Price Information. Available online: https://www.epa.gov/fuels-registration-reporting-and-compliance-help/rin-trades-and-price-information#:~:text=Price%3A%240.05%26Max.Price%3A%243.50 (accessed on 2 February 2023).

- California Air Resources Board. Low Carbon Fuel Standard. Available online: https://ww2.arb.ca.gov/our-work/programs/low-carbon-fuel-standard (accessed on 2 February 2023).

- California Air Resources Board. Weekly LCFS Credit Transfer Activity Reports. Available online: https://ww2.arb.ca.gov/resources/documents/weekly-lcfs-credit-transfer-activity-reports (accessed on 2 February 2023).

- Hamby, D.M. A Review of Techniques for Parameter Sensitivity Analysis of Environmental Models. Environ. Monit. Assess. 1994, 32, 135–154. [Google Scholar] [CrossRef]

- EIA. Heat Content of Natural Gas Consumed. Available online: https://www.eia.gov/dnav/ng/ng_cons_heat_a_EPG0_VGTH_btucf_a.htm (accessed on 1 March 2021).

- World Bank Group. Commodity Markets Outlook: Causes and Consequences of Metal Price Shocks, April 2021; World Bank: Washington, DC, USA, 2021. [Google Scholar]

- Seaman, J.S.; Fangman, T.J. Biosecurity for Today’s Swine Operation. Available online: https://extension.missouri.edu/publications/g2340 (accessed on 11 April 2023).

| Parameter | S1 | S2 | S3 | S4 |

|---|---|---|---|---|

| Farm size | 4800 pigs | 4800 pigs | 4800 pigs | 5 farms of 4800 pigs |

| Location of digester | On-farm | On-farm | On-farm | Centralized location: 2.5 miles from 5 farms |

| Water addition | None | Equivalent to manure volume | Equivalent to manure volume | Equivalent to manure volume |

| Corn stover | Added to 12% AD TS | Added to 12% AD TS | Added to 12% AD TS | Added to 12% AD TS |

| Biogas upgrading | On-farm | On-farm | Centralized location: 2.5 miles from 5 farms | At centralized AD site |

| Unit | S1 | S2 | S3 | S4 | |

|---|---|---|---|---|---|

| Corn stover demand | Mg yr−1 | 375 | 1500 | 1500 | 7500 |

| Corn stover harvest rate | Mg ha−1 | 6.7 | 6.7 | 6.7 | 6.7 |

| Corn stover harvest land requirement | ha yr−1 | 56 | 223 | 223 | 1116 |

| Digestate nitrogen content | Mg yr−1 | 46.3 | 53 | 53 | 265 |

| Land application requirement | ha yr−1 | 275 | 315 | 315 | 1576 |

| Portion of land application area needed for stover harvest | 20% | 71% | 71% | 71% |

| Parameter | Calculation | Comment |

|---|---|---|

| AD cost | capital cost of digester = volume of digester, m3 Adapted from Faulhaber et al. [12] | |

| S1 and S2 pipeline cost | USD 600,000 | Pipeline for RNG to injection point: EPA [59] suggestion for pipelines shorter than 1.6 km |

| S3 pipeline cost | USD 620,000 km−1 | Pipeline for raw biogas to centralized upgrading and injection point: EPA [59] suggestion for pipelines longer than 1.6 km |

| Lagoon | USD 7.34 m−3 (lagoon) USD 11 m−2 (cover) | Storage calculated for one year of manure volume |

| Upgrading and injection | x = Unit capital cost of the upgrading and injection equipment, USD GJ−1 Adapted from Williams et al. [58] | |

| S3 biogas compressor | Investment cost of biogas compressor, USD 1000 s = hourly biogas flow, m3 hr−1 Adapted from Hengeveld et al. [26] | |

| S3 biogas dewatering and H2S removal | USD 7800 | Adapted from Hengeveld et al. [26] |

| Screw press cost | USD 18,890 | Adapted from Møller et al. [60]: assumed one needed in S1–S3, five needed in S4 |

| Interest rate | 7% | Assumption |

| Project lifetime | 15 years | Assumption |

| Parameter | Value | Note |

|---|---|---|

| Manure cost | USD 86.40 m−3 | Based on the plant-available nitrogen content of the manure, discussed in Section 2.2 |

| Corn stover cost | USD 51 Mg−1 | From Edwards [45]; range discussed in Section 2.2 and explored in Section 3.5 |

| S4 manure transportation | d = two-way transportation distance, km Adapted from Ghafoori et al. [35] | |

| Labor | USD 0.08 m−3 biogas production | Adapted from Aui and Wright [39] |

| Upgrading and injection, O and M | USD 42,400 m−3 min−1 | Annual cost based on capacity; adapted from EPA [59] |

| Solid digestate handling | USD 5 Mg−1 | Aui and Wright [39] |

| Digester energy demand | 1.234 Mg m−3 biogas | Hengeveld et al. [26] |

| Screw press energy demand | 0.53 kWh Mg−1 digestate | Møller et al. [60] |

| Energy cost | USD 0.0689 kWh−1 | Iowa industrial energy cost [63] |

| Other maintenance | 10% of capital | Applied to all capital costs, except upgrading and injection |

| Parameter | S1 | S2 | S3 | S4 |

|---|---|---|---|---|

| Digester size (m3) | 1.22 × 103 | 3.68 × 103 | 3.68 × 103 | 18.4 × 103 |

| Manure processed (m3 yr−1) | 7340 | 7340 | 7340 | 36,700 |

| Corn stover processed (Mg yr−1) | 375 | 1500 | 1500 | 7500 |

| Solid digestate produced (Mg yr−1) | 6.46 × 105 | 1.45 × 106 | 1.45 × 106 | 7.17 × 106 |

| Biogas (m3 yr−1) | 2.64 × 105 | 4.77 × 105 | 4.77 × 105 | 2.39 × 106 |

| Methane (m3 yr−1) | 1.53 × 105 | 2.78 × 105 | 2.78 × 105 | 1.39 × 106 |

| Energy (GJ yr−1) | 5780 | 10,500 | 10,500 | 52,300 |

| Costs (USD GJ−1) | S1 | S2 | S3 | S4 |

|---|---|---|---|---|

| Manure | USD 7.66 | USD 4.24 | USD 4.24 | USD 4.24 |

| Corn stover | USD 3.31 | USD 7.32 | USD 7.32 | USD 7.32 |

| Manure transport | USD 0.00 | USD 0.00 | USD 0.00 | USD 9.78 |

| Capital | USD 53.91 | USD 42.38 | USD 53.63 | USD 18.15 |

| Operating costs | USD 10.33 | USD 9.93 | USD 12.13 | USD 8.58 |

| MSP (pre-credit) | USD 75.20 | USD 63.87 | USD 77.32 | USD 48.08 |

| Digestate credit | USD −7.87 | USD −4.69 | USD −4.69 | USD −4.69 |

| RIN | USD −23.63 | USD −23.63 | USD −23.63 | USD −23.63 |

| LCFS | USD −21.02 | USD −15.79 | USD −15.79 | USD −15.79 |

| MSP (including credits) | USD 22.68 | USD 19.75 | USD 33.20 | USD 3.96 |

| Component | S1 | S2 | S3 | S4 |

|---|---|---|---|---|

| Digester | USD 14.00 | USD 14.83 | USD 14.83 | USD 7.67 |

| Upgrading and injection | USD 38.19 | USD 26.60 | USD 9.54 | USD 9.54 |

| Biogas transport | USD 0.00 | USD 0.00 | USD 28.31 | USD 0.00 |

| Storage and separation | USD 1.71 | USD 0.95 | USD 0.95 | USD 0.95 |

| Total | USD 53.91 | USD 42.38 | USD 53.63 | USD 18.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Myers, G.M.; Andersen, D.S.; Martens, B.J.; Raman, D.R. Cost Assessment of Centralizing Swine Manure and Corn Stover Co-Digestion Systems. Energies 2023, 16, 4315. https://doi.org/10.3390/en16114315

Myers GM, Andersen DS, Martens BJ, Raman DR. Cost Assessment of Centralizing Swine Manure and Corn Stover Co-Digestion Systems. Energies. 2023; 16(11):4315. https://doi.org/10.3390/en16114315

Chicago/Turabian StyleMyers, Gabrielle M., Daniel S. Andersen, Bobby J. Martens, and D. Raj Raman. 2023. "Cost Assessment of Centralizing Swine Manure and Corn Stover Co-Digestion Systems" Energies 16, no. 11: 4315. https://doi.org/10.3390/en16114315

APA StyleMyers, G. M., Andersen, D. S., Martens, B. J., & Raman, D. R. (2023). Cost Assessment of Centralizing Swine Manure and Corn Stover Co-Digestion Systems. Energies, 16(11), 4315. https://doi.org/10.3390/en16114315