An Algorithm for Managerial Actions on the Rational Use of Renewable Sources of Energy: Determination of the Energy Potential of Biomass in Lithuania

Abstract

1. Introduction

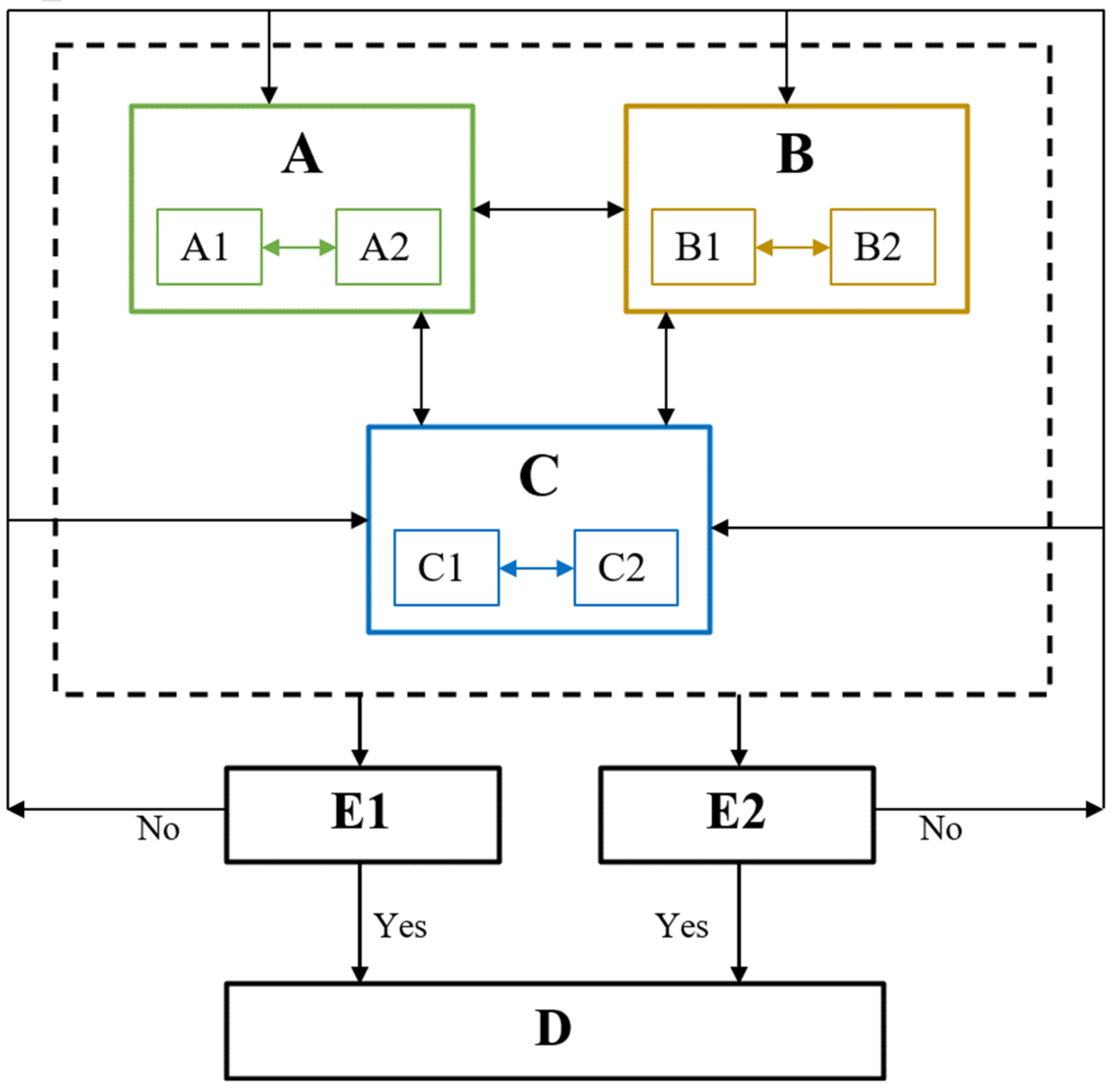

2. Materials and Methods

- Decision formation for choosing the most rational source of renewable energy;

- Formation of managerial decisions on the potential of the types of renewable energy (the amount of raw material needed to obtain renewable types of energy);

- Formation of managerial decisions on ways of obtaining and consuming renewable types of energy (ways of conversion).

- P1—the biomass potential (by-products), t;

- ai—the area allocated for growing i-crop, ha;

- ui—the yield capacity of i-crop, t/ha;

- k1—the coefficient of the biomass output of i-crop;

- k2—the coefficient of the biomass loss in the process of biomass collecting;

- k3—the coefficient that takes into account the biomass input in the support of humus balance;

- k4—the coefficient that takes into account some additional needs of the branches of the agricultural production for biomass.

- P2—the potential of diesel biofuel, t;

- aj—the area allocated for growing j-crop, ha;

- uj—the yield capacity of j-crop, t/ha;

- k5—the coefficient of waste (bran output);

- k6—the coefficient of oil production;

- k7—the coefficient of the production of diesel biofuel.

- P2—the potential of biomass for the production of biogas (biomethane, biohydrogen) m3;

- k8—the coefficient of using biomass for supporting humus level;

- k9—the coefficient of using biomass in biogas plants;

- nj—the number of j- species of animals or birds, items (heads);

- τj—the period of animal housing, days;

- mj—the weight of the waste of j-species of animals or birds, t/item (head) per day.

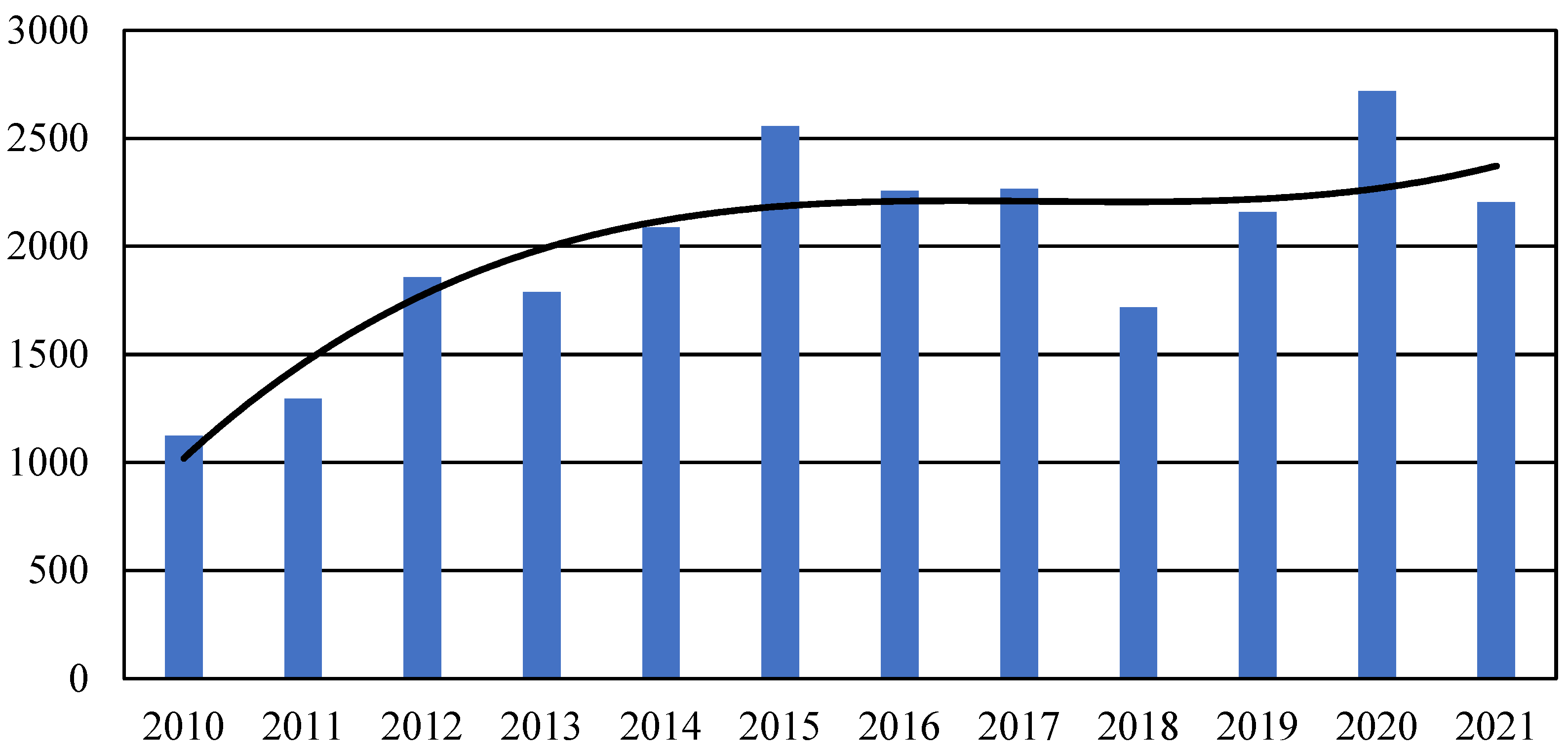

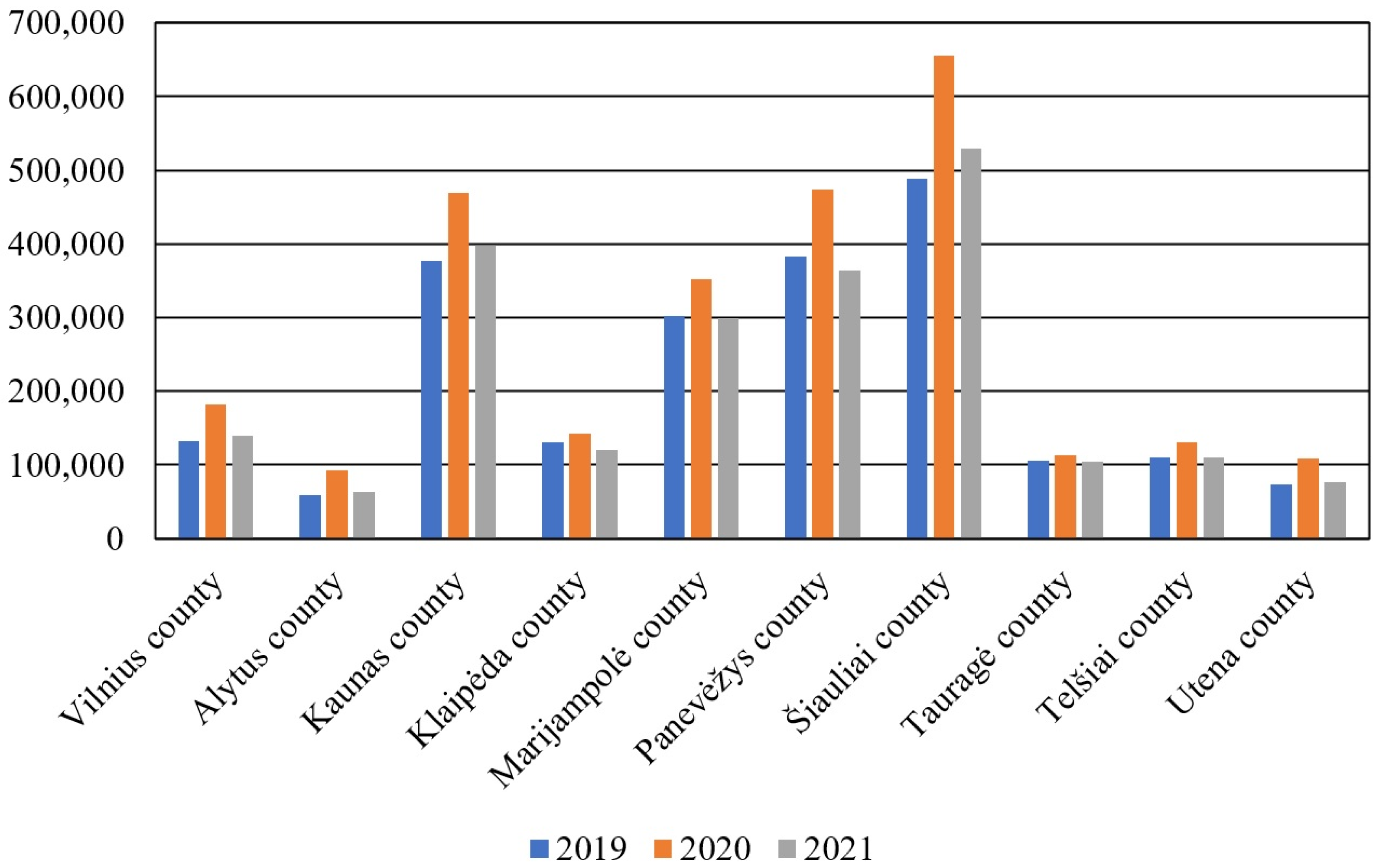

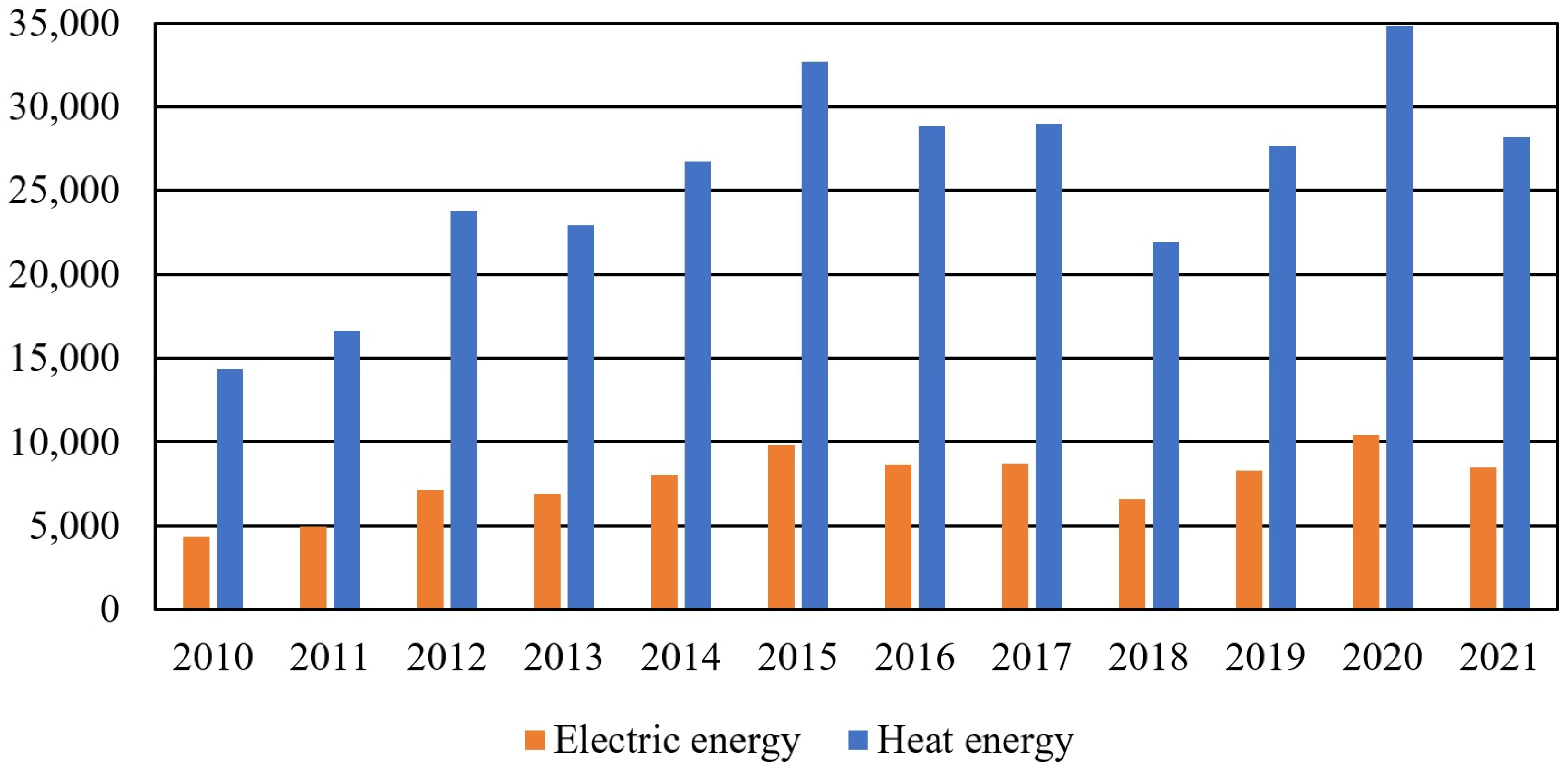

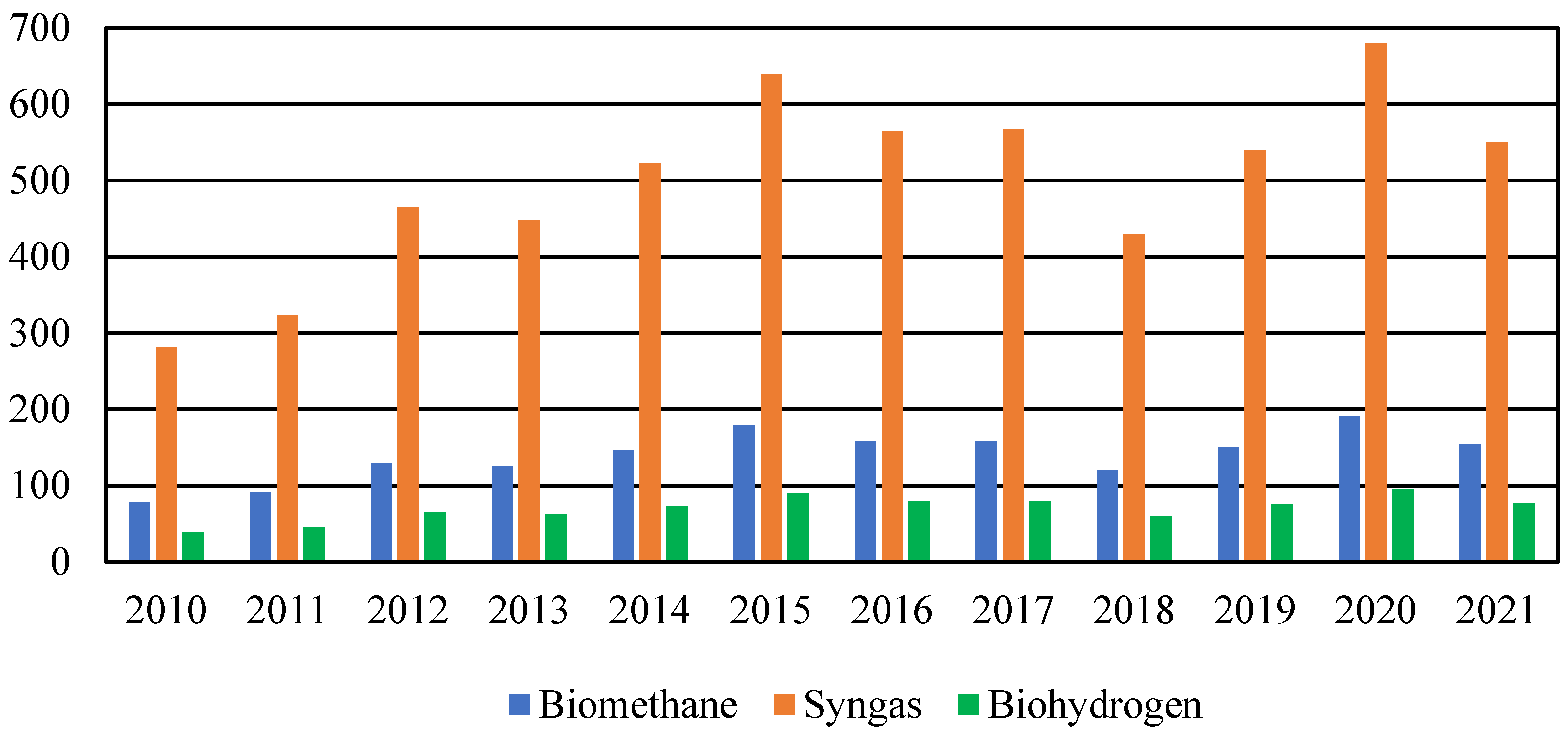

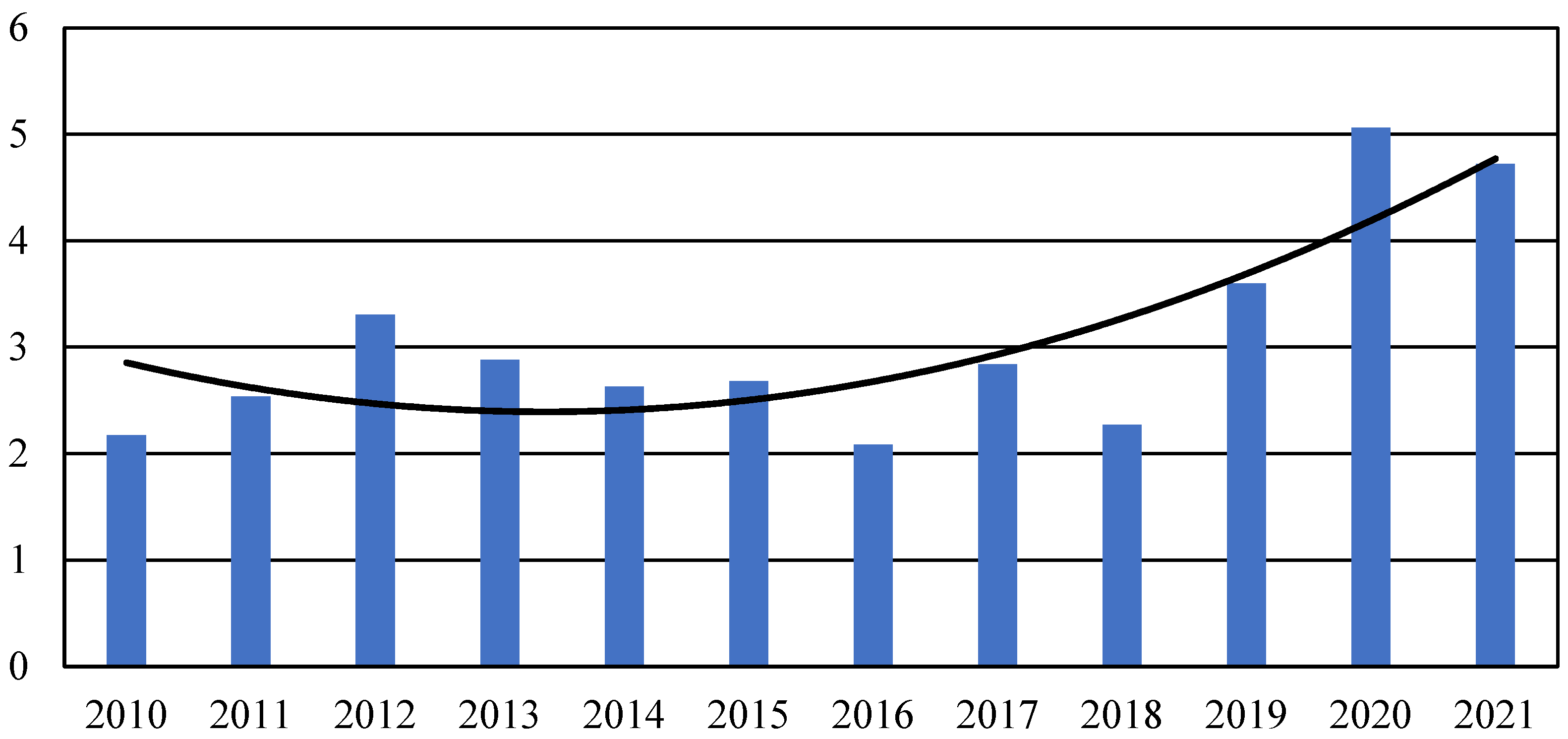

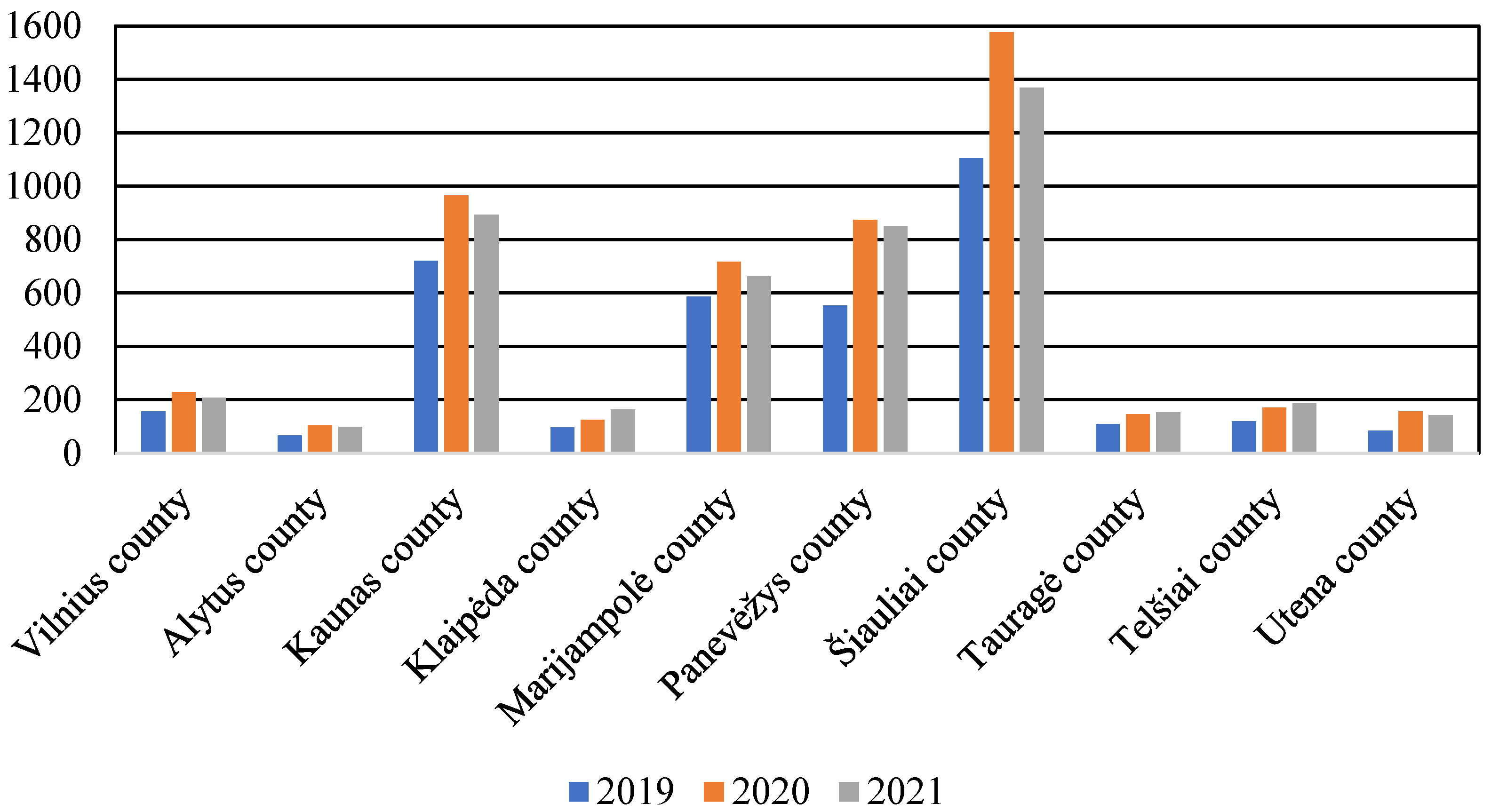

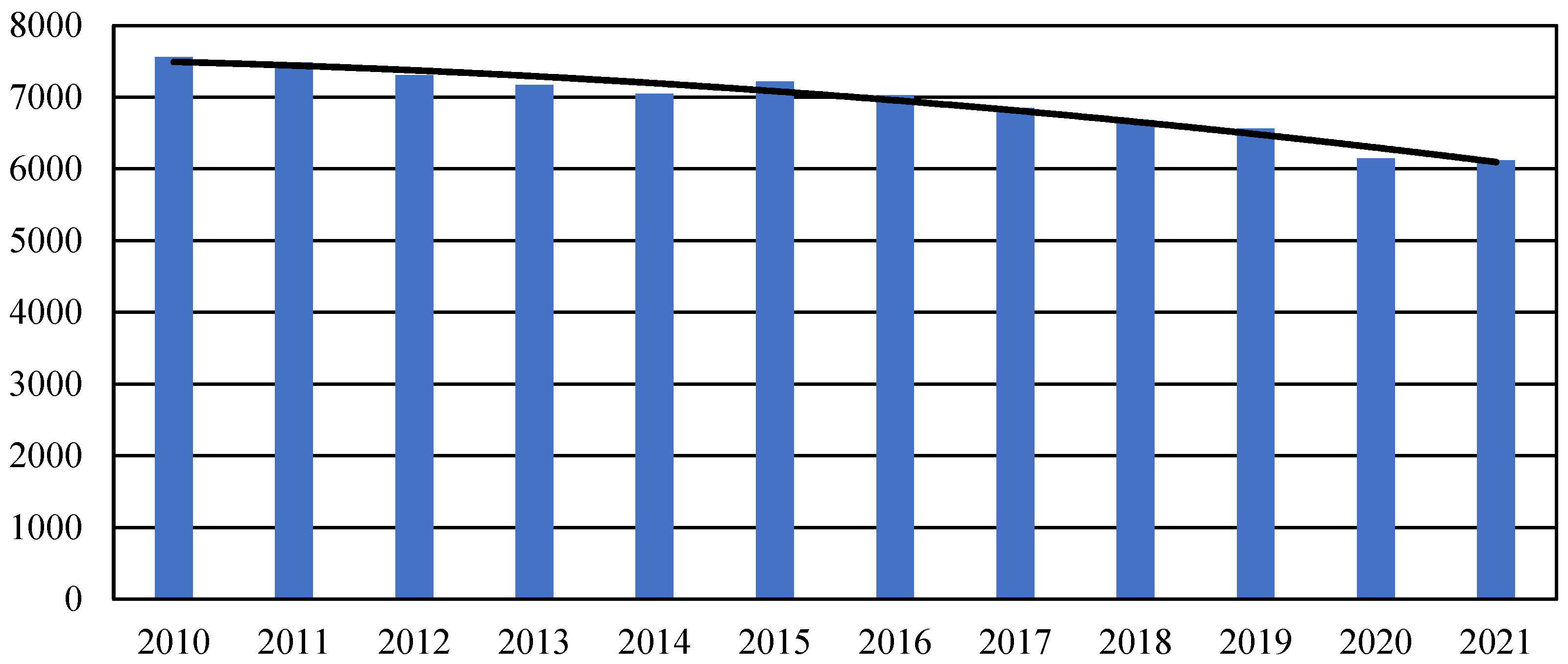

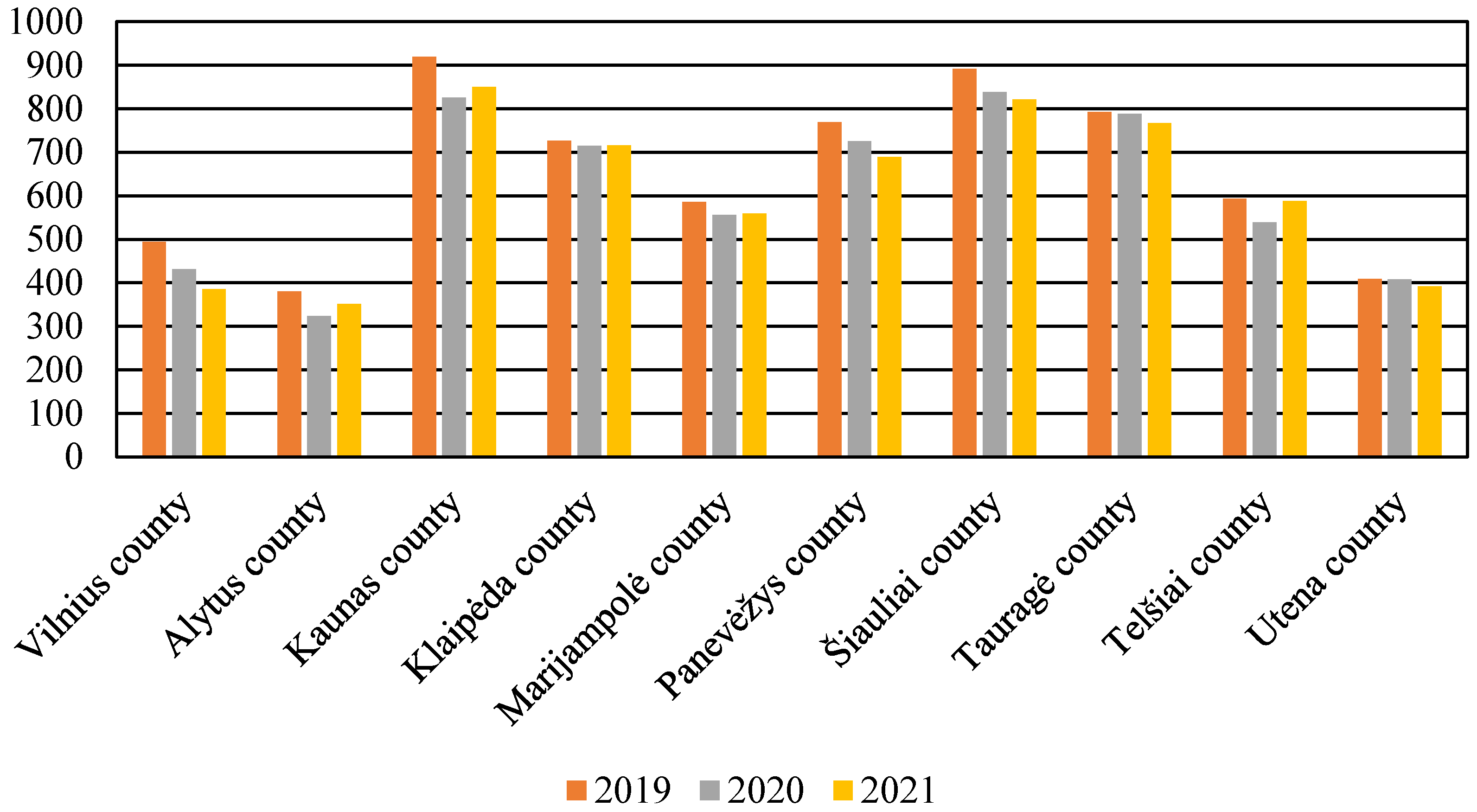

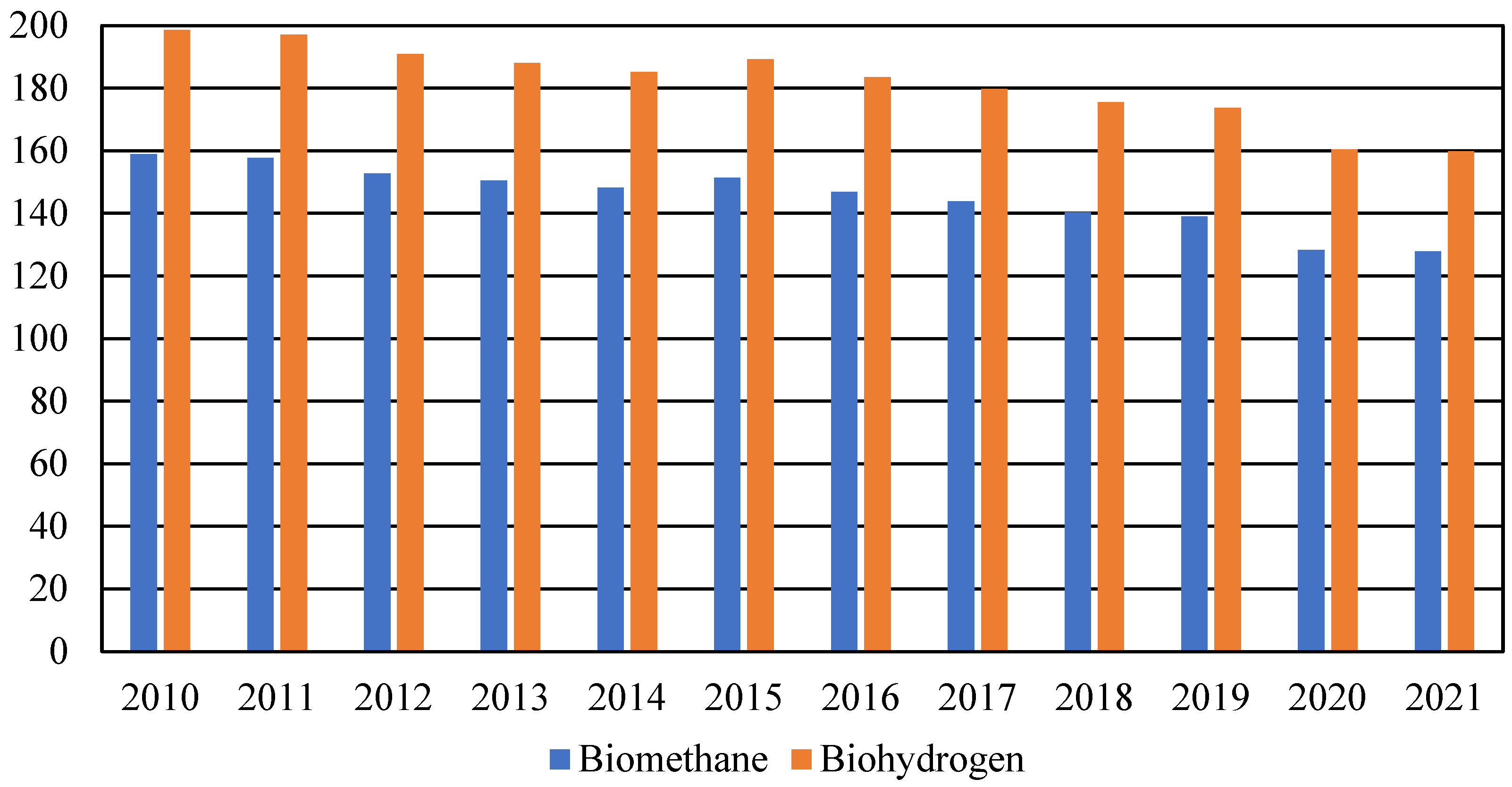

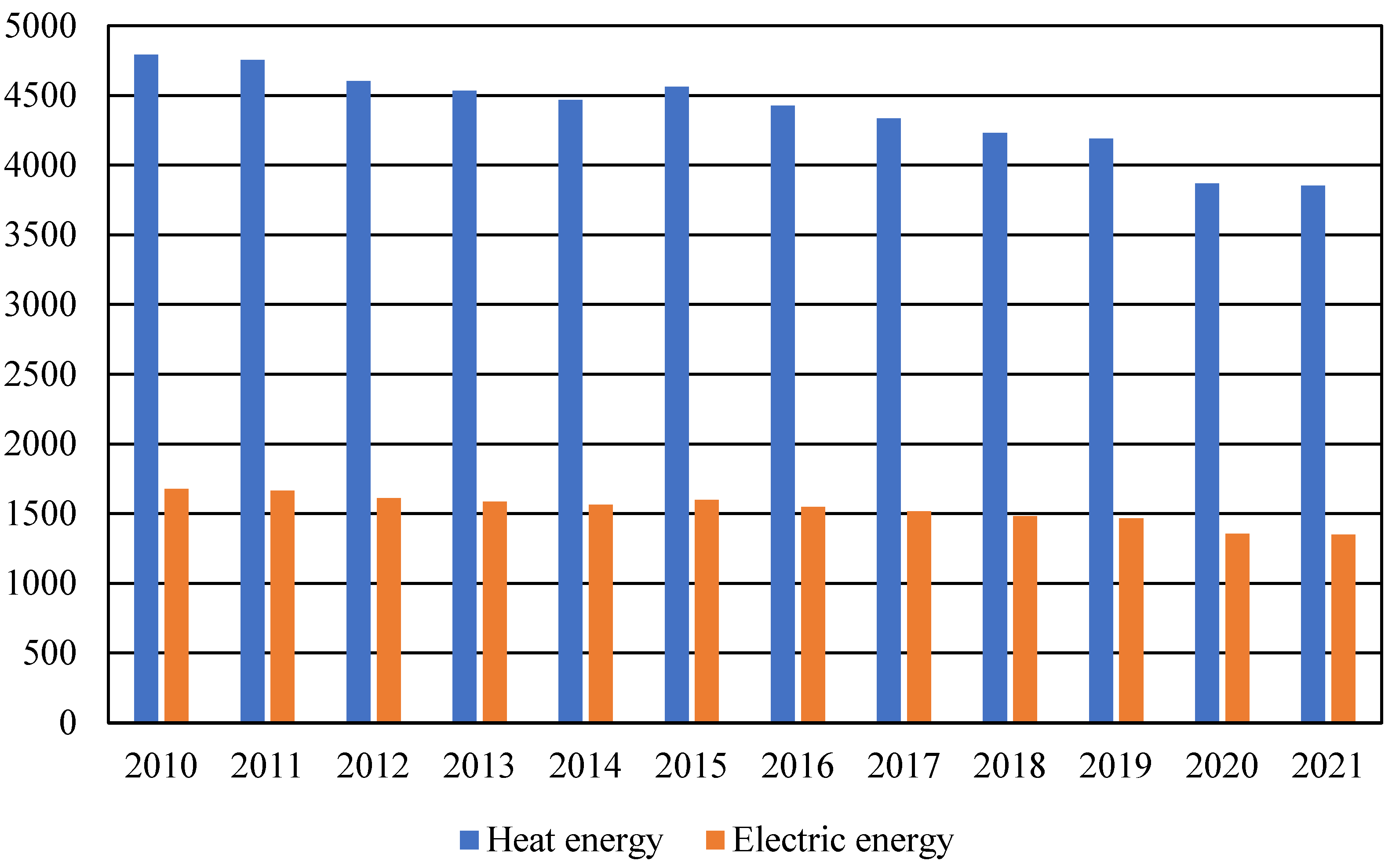

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tvaronavičienė, M.; Nesterova, K.; Kováčik, V. Energy security and long-term energy efficiency: Case of selected counties. J. Secur. Sustain. Issues 2017, 7, 349–357. [Google Scholar] [PubMed]

- Tryhuba, A.; Hutsol, T.; Kuboń, M.; Tryhuba, I.; Komarnitskyi, S.; Tabor, S.; Kwaśniewski, D.; Mudryk, K.; Faichuk, O.; Hohol, T. Taxonomy and Stakeholder Risk Management in Integrated Projects of the European Green Deal. Energies 2022, 15, 2015. [Google Scholar] [CrossRef]

- Parisi, C.; Ronzon, T. A global view of bio-based industries: Benchmarking and monitoring their economic importance and future developments. In Proceedings of the EU-Brazil Sector Dialogues Workshop, Seville, Spain, 18–19 February 2016. [Google Scholar] [CrossRef]

- Aszódi, A.; Biró, B.; Adorján, L.; Dobos, Á.C.; Illés, G.; Tóth, N.K.; Zagyi, D.; Zsiborás, Z.T. Comparative analysis of national energy strategies of 19 European countries in light of the green deal’s objectives. Energy Convers. Manag. X 2021, 12, 100136. [Google Scholar] [CrossRef]

- Gaigalis, V.; Katinas, V. Analysis of the renewable energy implementation and prediction prospects in compliance with the EU policy: A case of Lithuania. Renew. Energym 2020, 151, 1016–1027. [Google Scholar] [CrossRef]

- Bórawski, P.; Bełdycka-Bórawska, A.; Szymańska, E.J.; Jankowski, K.J.; Dubis, B.; Dunn, J.W. Development of renewable energy sources market and biofuels in The European Union. J. Clean. Prod. 2019, 28, 467–484. [Google Scholar] [CrossRef]

- Huterski, R.; Huterska, A.; Zdunek-Rosa, E.; Voss, G. Evaluation of the Level of Electricity Generation from Renewable Energy Sources in European Union Countries. Energies 2021, 14, 8150. [Google Scholar] [CrossRef]

- Babaremu, K.; Olumba, N.; Chris-Okoro, I.; Chuckwuma, K.; Jen, T.-C.; Oladijo, O.; Akinlabi, E. Overview of Solar–Wind Hybrid Products: Prominent Challenges and Possible Solutions. Energies 2022, 15, 6014. [Google Scholar] [CrossRef]

- Das, S.S.; Das, A.; Dawn, S.; Gope, S.; Ustun, T.S. A Joint Scheduling Strategy for Wind and Solar Photovoltaic Systems to Grasp Imbalance Cost in Competitive Market. Sustainability 2022, 14, 5005. [Google Scholar] [CrossRef]

- KC, R.; Föhr, J.; Gyawali, A.; Ranta, T. Investment and Profitability of Community Heating Systems Using Bioenergy in Finland: Opportunities and Challenges. Sustainability 2021, 13, 11757. [Google Scholar] [CrossRef]

- Song, C.; He, J.; Zhang, H. Comprehensive zoning of biomass energy heating in EU countries reference for China from European experience. Chin. J. Popul. Resour. Environ. 2020, 19, 321–329. [Google Scholar] [CrossRef]

- Jonynas, R.; Puida, E.; Poškas, R.; Paukštaitis, L.; Jouhara, H.; Gudzinskas, J.; Miliauskas, G.; Lukoševičius, V. Renewables for district heating: The case of Lithuania. Energy 2020, 211, 119064. [Google Scholar] [CrossRef]

- Lu, J.; Wang, C.; Zhang, C.; Guan, H.; Skare, M.; Streimikisv, J. Avoided external energy costs due to penetration of renewables: Evidence form Baltic States. J. Environ. Manag. 2021, 296, 113247. [Google Scholar] [CrossRef] [PubMed]

- Latõšov, E.; Umbleja, S.; Volkova, A. Promoting efficient district heating in Estonia. Util. Policy 2022, 75, 101332. [Google Scholar] [CrossRef]

- Ryabchenko, O.; Golub, G.; Turčeková, N.; Adamičková, I.; Zapototskyi, S. Sustainable business modeling of circular agriculture production: Case study of circular bioeconomy. J. Secur. Sustain. Issues 2017, 7, 301–309. [Google Scholar] [CrossRef] [PubMed]

- Rzeznik, W.; Mielcarek, P. Agricultural biogas plants in Poland. Eng. Rural Dev. Proc. 2018, 17, 1760–1765. [Google Scholar] [CrossRef]

- Melece, L.; Krieviņa, A. Bioenergy in Latvia: Sector value and impacts. Eng. Rural Dev. Proc. 2016, 15, 1170–1176. [Google Scholar]

- Kukharets, S.; Hutsol, T.; Glowacki, S.; Sukmaniuk, O.; Rozkosz, A.; Tkach, O. Concept of biohydrogen production by agricultural enterprises. Agric. Eng. 2021, 25, 63–72. [Google Scholar] [CrossRef]

- Golub, G.; Chuba, V.; Lutak, V.; Yarosh, Y.; Kukharets, S. Researching of indicators of agroecosystem without external energy supply. J. Cent. Eur. Agric. (JCEA) 2021, 22, 397–407. [Google Scholar] [CrossRef]

- Umakanth, A.V.; Datta, A.; Reddy, B.S.; Bardhan, S. Chapter 3—Biomass feedstocks for advanced biofuels: Sustainability and supply chain management. In Advanced Biofuel Technologies; Elsevier: Amsterdam, The Netherlands, 2022; pp. 39–72. [Google Scholar] [CrossRef]

- Douvartzides, S.; Charisiou, N.D.; Wang, W.; Papadakis, V.G.; Polychronopoulou, K.; Goula, M.A. Catalytic fast pyrolysis of agricultural residues and dedicated energy crops for the production of high energy density transportation biofuels. Part I: Chemical pathways and bio-oil upgrading. Renew. Energy 2022, 185, 483–505. [Google Scholar] [CrossRef]

- Pehlken, A.; Wulf, K.; Grecksch, K.; Klenke, T.; Tsydenova, N. More Sustainable Bioenergy by Making Use of Regional Alternative Biomass? Sustainability 2020, 12, 7849. [Google Scholar] [CrossRef]

- Vaish, S.; Kaur, G.; Sharma, N.K.; Gakkhar, N. Estimation for Potential of Agricultural Biomass Sources as Projections of Bio-Briquettes in Indian Context. Sustainability 2022, 14, 5077. [Google Scholar] [CrossRef]

- Cavalaglio, G.; Cotana, F.; Nicolini, A.; Coccia, V.; Petrozzi, A.; Formica, A.; Bertini, A. Characterization of Various Biomass Feedstock Suitable for Small-Scale Energy Plants as Preliminary Activity of Biocheaper Project. Sustainability 2020, 12, 6678. [Google Scholar] [CrossRef]

- Verdade, L.M.; Piña, C.I.; Rosalino, L.M. Biofuels and biodiversity: Challenges and opportunities. Environ. Dev. 2015, 15, 64–78. [Google Scholar] [CrossRef]

- Gomiero, T. Large-scale biofuels production: A possible threat to soil conservation and environmental services. Appl. Soil Ecol. 2018, 123, 729–736. [Google Scholar] [CrossRef]

- Hunt, N.D.; Gower, S.T.; Nadelhoffer, K.; Lajtha, K.; Townsend, K.; Brye, K.R. Validation of an agroecosystem process model (AGRO-BGC) on annual and perennial bioenergy feedstocks. Ecol. Model. 2016, 321, 23–34. [Google Scholar] [CrossRef]

- Saleem, M. Possibility of utilizing agriculture biomass as a renewable and sustainable future energy source. Heliyon 2022, 8, e08905. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, N.; Sukichandran, P.; Chaudhari, P.; Thakur, A.K.; Kumar, R. Energy analysis and feasibility studies for algal biomass and biofuels. Mater. Today: Proc. 2022, 57, 1448–1454. [Google Scholar] [CrossRef]

- Golub, G.A.; Kukharets, S.M.; Yarosh, Y.D.; Kukharets, V.V. Integrated use of bioenergy conversion technologies in agroecosystems. INMATEH Agric. Eng. 2017, 51, 93–100. [Google Scholar]

- Mockshell, J.; Villarino, M.E. Agroecological intensification: Potential and limitations to achieving food security and sustainability. Encycl. Food Secur. Sustain. 2019, 3, 64–70. [Google Scholar] [CrossRef]

- Kazemi, H.; Klug, H.; Kamkar, B. New services and roles of biodiversity in modern agroecosystems: A review. Ecol. Indic. 2018, 93, 1126–1135. [Google Scholar] [CrossRef]

- Peterson, C.A.; Eviner, V.T.; Gaudin, A.C. Ways forward for resilience research in agroecosystems. Agric. Syst. 2018, 162, 19–27. [Google Scholar] [CrossRef]

- Popp, J.; Kot, S.; Lakner, Z.; Oláh, J. Biofuel use: Peculiarities and implications. J. Secur. Sustain. Issues 2018, 7, 477–493. [Google Scholar] [CrossRef] [PubMed]

- Boro, M.; Verma, A.K.; Chettri, D.; Yata, V.K.; Verma, A.K. Strategies involved in biofuel production from agro-based lignocellulose biomass. Environ. Technol. Innov. 2022, 28, 102679. [Google Scholar] [CrossRef]

- Wang, G.; Sadiq, M.; Bashir, T.; Jain, V.; Ali, S.A.; Shabbir, M.S. The dynamic association between different strategies of renewable energy sources and sustainable economic growth under SDGs. Energy Strategy Rev. 2022, 42, 100886. [Google Scholar] [CrossRef]

- Žičkienė, A.; Morkunas, M.; Volkov, A.; Balezentis, T.; Streimikiene, D.; Siksnelyte-Butkiene, I. Sustainable Energy Development and Climate Change Mitigation at the Local Level through the Lens of Renewable Energy: Evidence from Lithuanian Case Study. Energies 2022, 15, 980. [Google Scholar] [CrossRef]

- Kochanek, E. The Energy Transition in the Visegrad Group Countries. Energies 2021, 14, 2212. [Google Scholar] [CrossRef]

- Barry, F.; Sawadogo, M.; Bologo, M.; Ouédraogo, I.W.K.; Dogot, T. Key Barriers to the Adoption of Biomass Gasification in Burkina Faso. Sustainability 2021, 13, 7324. [Google Scholar] [CrossRef]

- Ochieng, R.; Gebremedhin, A.; Sarker, S. Integration of Waste to Bioenergy Conversion Systems: A Critical Review. Energies 2022, 15, 2697. [Google Scholar] [CrossRef]

- Tropea, A. Biofuels Production and Processing Technology. Fermentation 2022, 8, 319. [Google Scholar] [CrossRef]

- Baba, T.; Nomura, H.; Srean, P.; Than, T.; Ito, K. Effects of Mechanization and Investments on the Technical Efficiency of Cassava Farms in Cambodia. Agriculture 2022, 12, 441. [Google Scholar] [CrossRef]

- Golub, G.; Skydan, O.; Kukharets, V.; Yarosh, Y.; Kukharets, S. The estimation of energetically self-sufficient agroecosystem’s model. J. Cent. Eur. Agric. 2020, 21, 168–175. [Google Scholar] [CrossRef]

- Kucher, O.; Hutsol, T.; Glowacki, S.; Andreitseva, I.; Dibrova, A.; Muzychenko, A.; Szeląg-Sikora, A.; Szparaga, A.; Kocira, S. Energy Potential of Biogas Production in Ukraine. Energies 2022, 15, 1710. [Google Scholar] [CrossRef]

- Lian, H.; Wang, Z.; Li, Y.; Xu, H.; Zhang, H.; Gong, X.; Qi, H.; Jiang, Y. Straw Strip Return Increases Soil Organic Carbon Sequestration by Optimizing Organic and Humus Carbon in Aggregates of Mollisols in Northeast China. Agronomy 2022, 12, 784. [Google Scholar] [CrossRef]

- Fan, W.; Wu, J.; Ahmed, S.; Hu, J.; Chen, X.; Li, X.; Zhu, W.; Opoku-Kwanowaa, Y. Short-Term Effects of Different Straw Returning Methods on the Soil Physicochemical Properties and Quality Index in Dryland Farming in NE China. Sustainability 2020, 12, 2631. [Google Scholar] [CrossRef]

- Tsoutsos, T.; Tournaki, S.; Gkouskos, Z.; Paraíba, O.; Giglio, F.; García, P.Q.; Braga, J.; Adrianos, H.; Filice, M. Quality Characteristics of Biodiesel Produced from Used Cooking Oil in Southern Europe. ChemEngineering 2019, 3, 19. [Google Scholar] [CrossRef]

- National Energy and Climate Action Plan of the Republic of Lithuania for 2021–2030. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/lt_final_necp_main_en.pdf (accessed on 4 November 2022).

- Vert: Rugpjūčio Mėnesio Šilumos Kainų Statistika Lietuvoje. Available online: https://www.vert.lt/Puslapiai/naujienos/2022-metai/2022-08-16/vert-rugpjucio-menesio-silumos-kainu-statistika-lietuvoje.aspx (accessed on 4 November 2022).

- Official Statistic Portal: Agriculture. Available online: https://osp.stat.gov.lt/zemes-ukis1 (accessed on 4 November 2022).

- Di Vito Nolfi, G.; Gallucci, K.; Rossi, L. Green Diesel Production by Catalytic Hydrodeoxygenation of Vegetables Oils. Int. J. Environ. Res. Public Health 2021, 18, 13041. [Google Scholar] [CrossRef]

- 2022 m. Rugpjūčio Mėn. Didmeninių Elektros Energijos Kainų Palyginimas. Available online: https://www.jonavoszinios.lt/naujiena/2022-m-rugpjucio-men-didmeniniu-elektros-energijos-kainu-palyginimas (accessed on 4 November 2022).

- De Jong, S.; Hoefnagels, R.; Wetterlund, E.; Pettersson, K.; Faaij, A.; Junginger, M. Cost optimization of biofuel production—The impact of scale, integration, transport and supply chain configurations. Appl. Energy 2017, 195, 1055–1070. [Google Scholar] [CrossRef]

- Awais, F.; Flodén, J.; Svanberg, M. Logistic characteristics and requirements of Swedish wood biofuel heating plants. Renew. Sustain. Energy Rev. 2021, 138, 110650. [Google Scholar] [CrossRef]

- Bala-Litwiniak, A.; Musiał, D. Computational and Experimental Studies of Selected Types of Biomass Combustion in a Domestic Boiler. Materials 2022, 15, 4826. [Google Scholar] [CrossRef]

- Głowacki, S.; Salamon, A.; Sojak, M.; Tulej, W.; Bryś, A.; Hutsol, T.; Salamon, M.; Kukharets, S.; Janaszek-Mańkowska, M. The Use of Brewer’s Spent Grain after Beer Production for Energy Purposes. Materials 2022, 15, 3703. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, C.; Zhu, J.; Sang, Y.; Wang, J.; Zhao, W.; Zhuang, M. Carbon Footprint Analysis for Biomass-Fueled Combined Heat and Power Station: A Case Study. Agriculture 2022, 12, 1146. [Google Scholar] [CrossRef]

- Kheybari, S.; Rezaie, F.; Naji, S.; Najafi, F. Evaluation of energy production technologies from biomass using analytical hierarchy process: The case of Iran. J. Clean. Prod. 2019, 232, 257–265. [Google Scholar] [CrossRef]

- Kukharets, V.; Cingiene, R.; Savchenko, N.; Savchenko, R. Substantiation of economically expedient location of technological straw processing line. Eng. Rural Dev. Proc. 2021, 20, 366–372. [Google Scholar] [CrossRef]

- Svazas, M.; Navickas, V.; Bilan, Y.; Nakonieczny, J.; Spankova, J. Biomass Clusterization from a Regional Perspective: The Case of Lithuania. Energies 2021, 14, 6993. [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Junga, R.; Błaszczuk, A.; Modlinski, N.; Marczak-Grzesik, M.; Sobek, S.; Adrian, Ł.; Dzikuc, M. Numerical modeling of the co-firing process of an in situ steam-torrefied biomass with coal in a 230 MW industrial-scale boiler. Energy 2022, 263, 125918. [Google Scholar] [CrossRef]

- Piersa, P.; Unyay, H.; Szufa, S.; Lewandowska, W.; Modrzewski, R.; Ślężak, R.; Ledakowicz, S. An Extensive Review and Comparison of Modern Biomass Torrefaction Reactors vs. Biomass Pyrolysis—Part 1. Energies 2022, 15, 2227. [Google Scholar] [CrossRef]

- Yermakov, S.; Hutsol, T.; Glowacki, S.; Hulevskyi, V.; Pylypenko, V. Primary Assessment of the Degree of Torrefaction of Biomass Agricultural Crops. In Environment. Technology. Resources. In Proceedings of the International Scientific and Practical Conference, Rezekne, Latvia, 17–18 June 2021; Rezekne Academy of Technologies: Rezekne, Latvia, 2021; Volume 1, pp. 264–267. Available online: http://elar.tsatu.edu.ua/handle/123456789/14974 (accessed on 15 November 2022).

- Marczak-Grzesik, M.; Piersa, P.; Karczewski, M.; Szufa, S.; Ünyay, H.; Kędzierska-Sar, A.; Bochenek, P. Modified Fly Ash-Based Adsorbents (MFA) for Mercury and Carbon Dioxide Removal from Coal-Fired Flue Gases. Energies 2021, 14, 7101. [Google Scholar] [CrossRef]

- Evans, D.; Gruba, P.; Zobel, J. How to Write a Better Thesis; Springer International Publishing: Cham, Switzerland, 2014. [Google Scholar] [CrossRef]

- Senge, P. The Fifth Discipline: The Art and Practice of the Learning Organization; Doubleday/Currency: New York, NY, USA, 1990. [Google Scholar]

| Industry | Thermal Energy | Electric Energy | Biomethane | Biohydrogen | ||||

|---|---|---|---|---|---|---|---|---|

| Energy Equivalent, ×106 GJ | Cost Equivalent, Billion EUR | Energy Equivalent, ×106 GJ | Cost Equivalent, Billion EUR | Energy Equivalent, ×106 GJ | Cost Equivalent, Billion EUR | Energy Equivalent, ×106 GJ | * Cost Equivalent, Billion EUR | |

| Crop production | 25.632 | 7.613 | 7.689 | 13.298 | 4.696 | 1.610 | 9.111 | 3.936 |

| Animal husbandry | 4.385 | 1.302 | 1.535 | 2.654 | 4.872 | 1.670 | 23.634 | 10.210 |

| Total | 30.017 | 8.915 | 9.224 | 15.953 | 9.568 | 3.279 | 32.745 | 14.146 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kukharets, V.; Juočiūnienė, D.; Hutsol, T.; Sukmaniuk, O.; Čėsna, J.; Kukharets, S.; Piersa, P.; Szufa, S.; Horetska, I.; Shevtsova, A. An Algorithm for Managerial Actions on the Rational Use of Renewable Sources of Energy: Determination of the Energy Potential of Biomass in Lithuania. Energies 2023, 16, 548. https://doi.org/10.3390/en16010548

Kukharets V, Juočiūnienė D, Hutsol T, Sukmaniuk O, Čėsna J, Kukharets S, Piersa P, Szufa S, Horetska I, Shevtsova A. An Algorithm for Managerial Actions on the Rational Use of Renewable Sources of Energy: Determination of the Energy Potential of Biomass in Lithuania. Energies. 2023; 16(1):548. https://doi.org/10.3390/en16010548

Chicago/Turabian StyleKukharets, Valentyna, Dalia Juočiūnienė, Taras Hutsol, Olena Sukmaniuk, Jonas Čėsna, Savelii Kukharets, Piotr Piersa, Szymon Szufa, Iryna Horetska, and Alona Shevtsova. 2023. "An Algorithm for Managerial Actions on the Rational Use of Renewable Sources of Energy: Determination of the Energy Potential of Biomass in Lithuania" Energies 16, no. 1: 548. https://doi.org/10.3390/en16010548

APA StyleKukharets, V., Juočiūnienė, D., Hutsol, T., Sukmaniuk, O., Čėsna, J., Kukharets, S., Piersa, P., Szufa, S., Horetska, I., & Shevtsova, A. (2023). An Algorithm for Managerial Actions on the Rational Use of Renewable Sources of Energy: Determination of the Energy Potential of Biomass in Lithuania. Energies, 16(1), 548. https://doi.org/10.3390/en16010548