Dynamic Simulation of Partial Load Operation of an Organic Rankine Cycle with Two Parallel Expanders

Abstract

1. Introduction

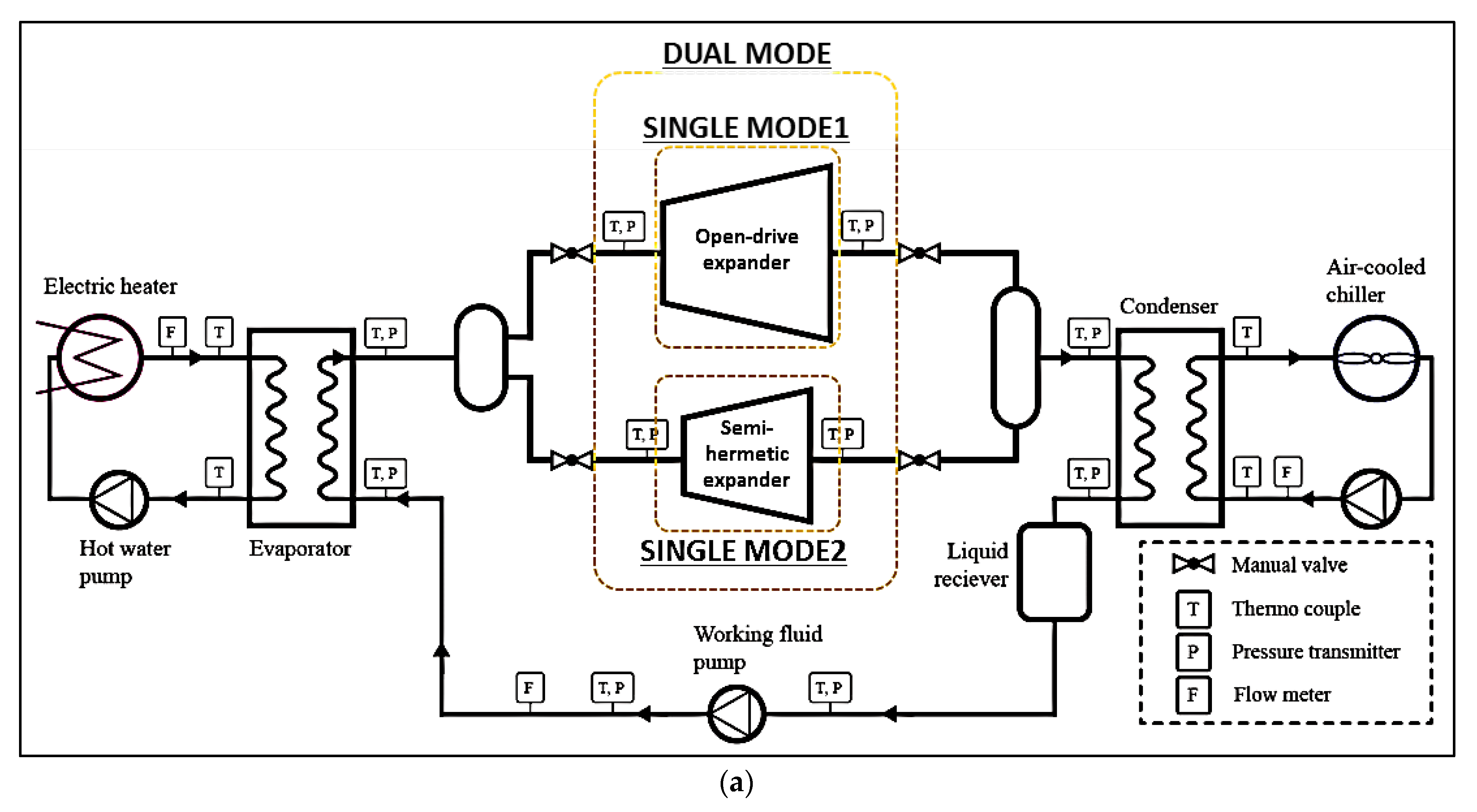

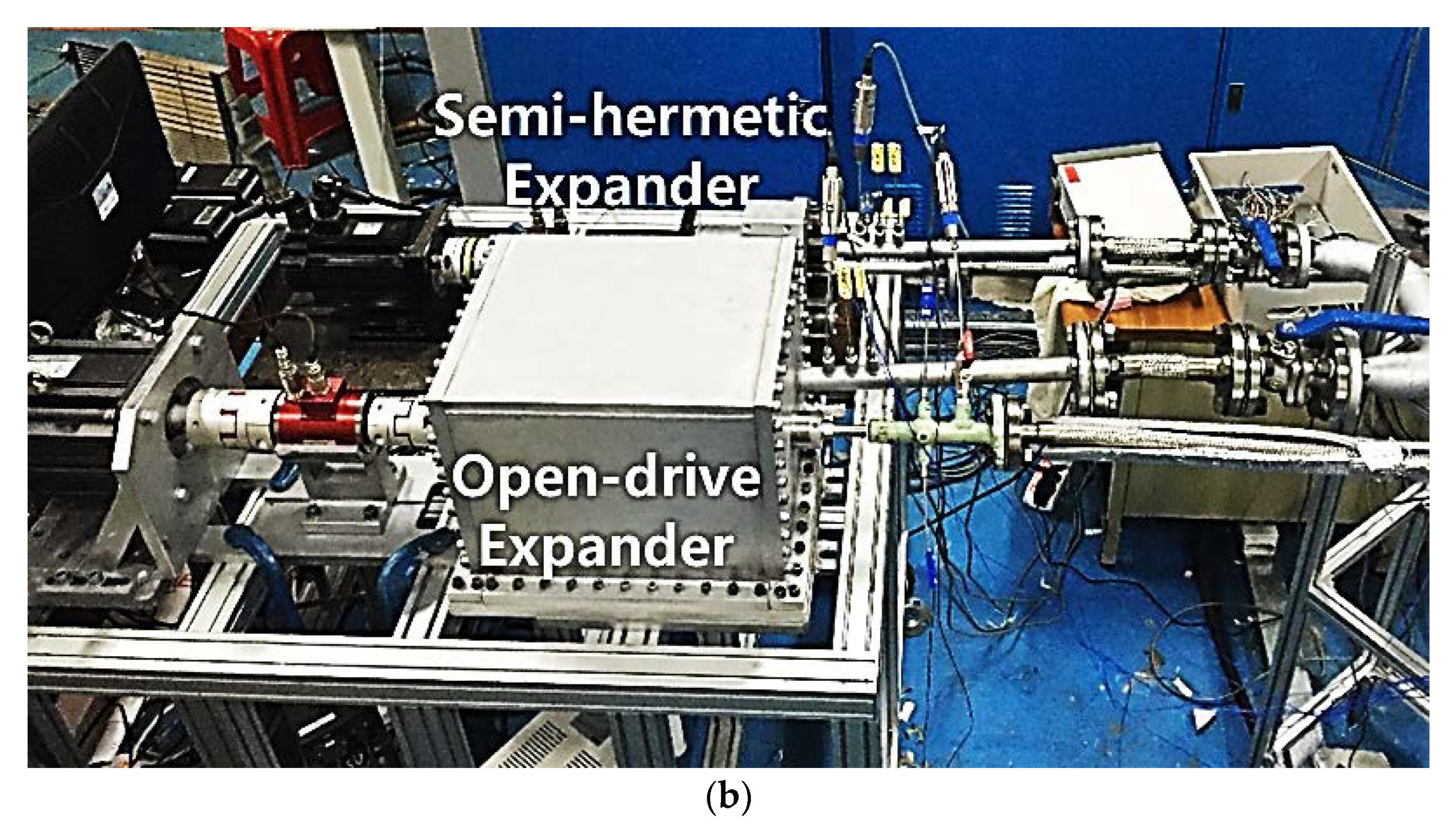

2. Overview of Experimental Setup and Data

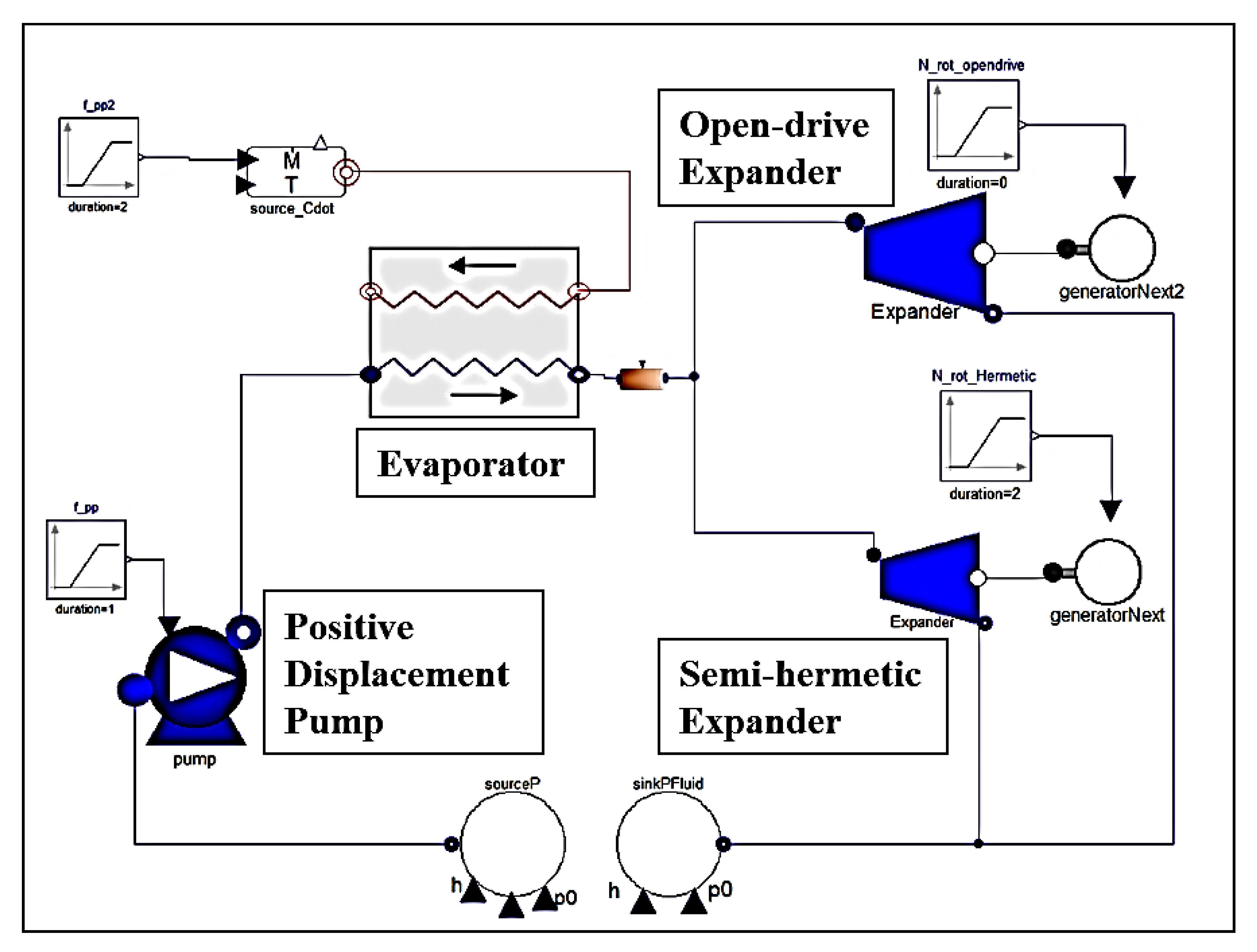

3. Mathematical Modelling

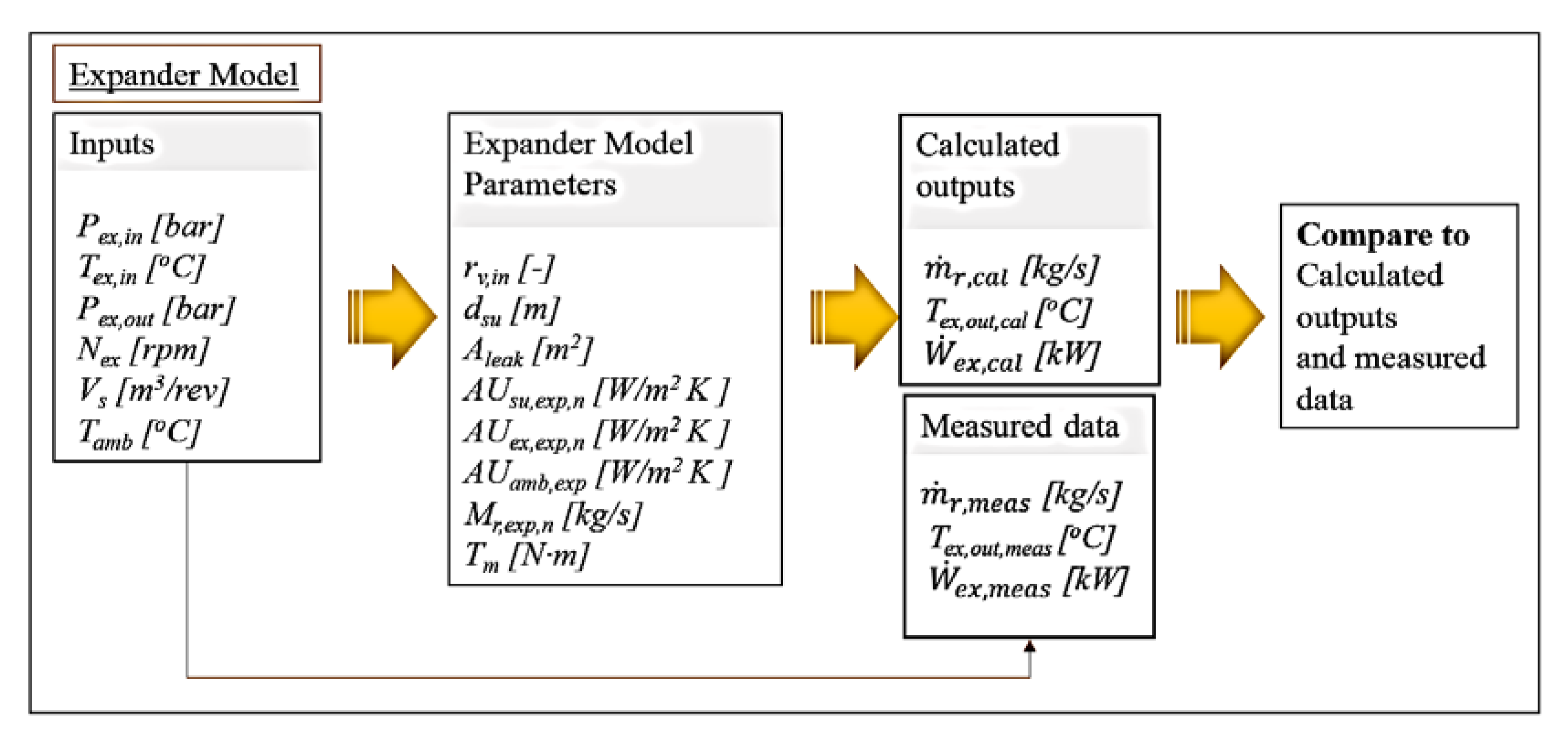

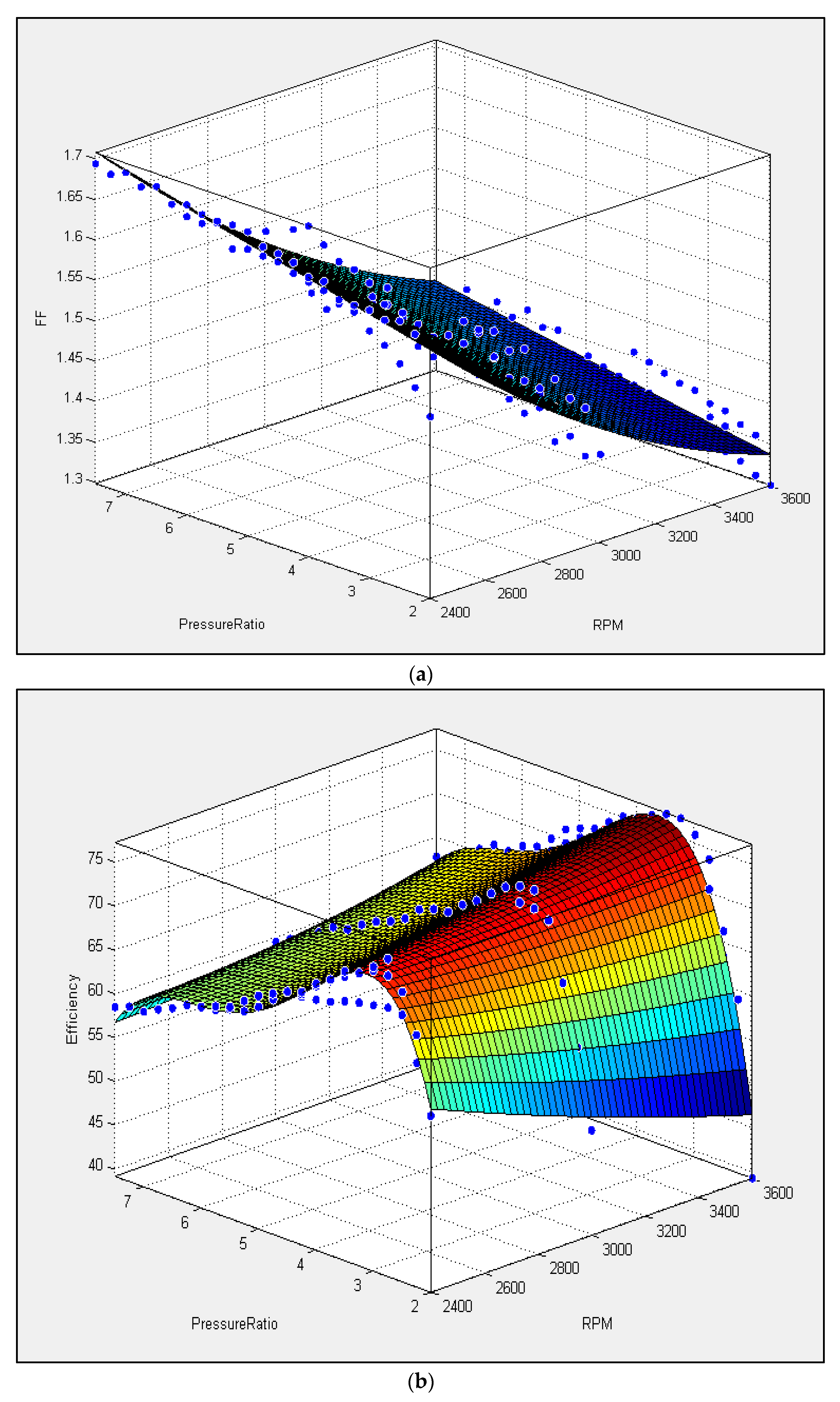

3.1. Expander

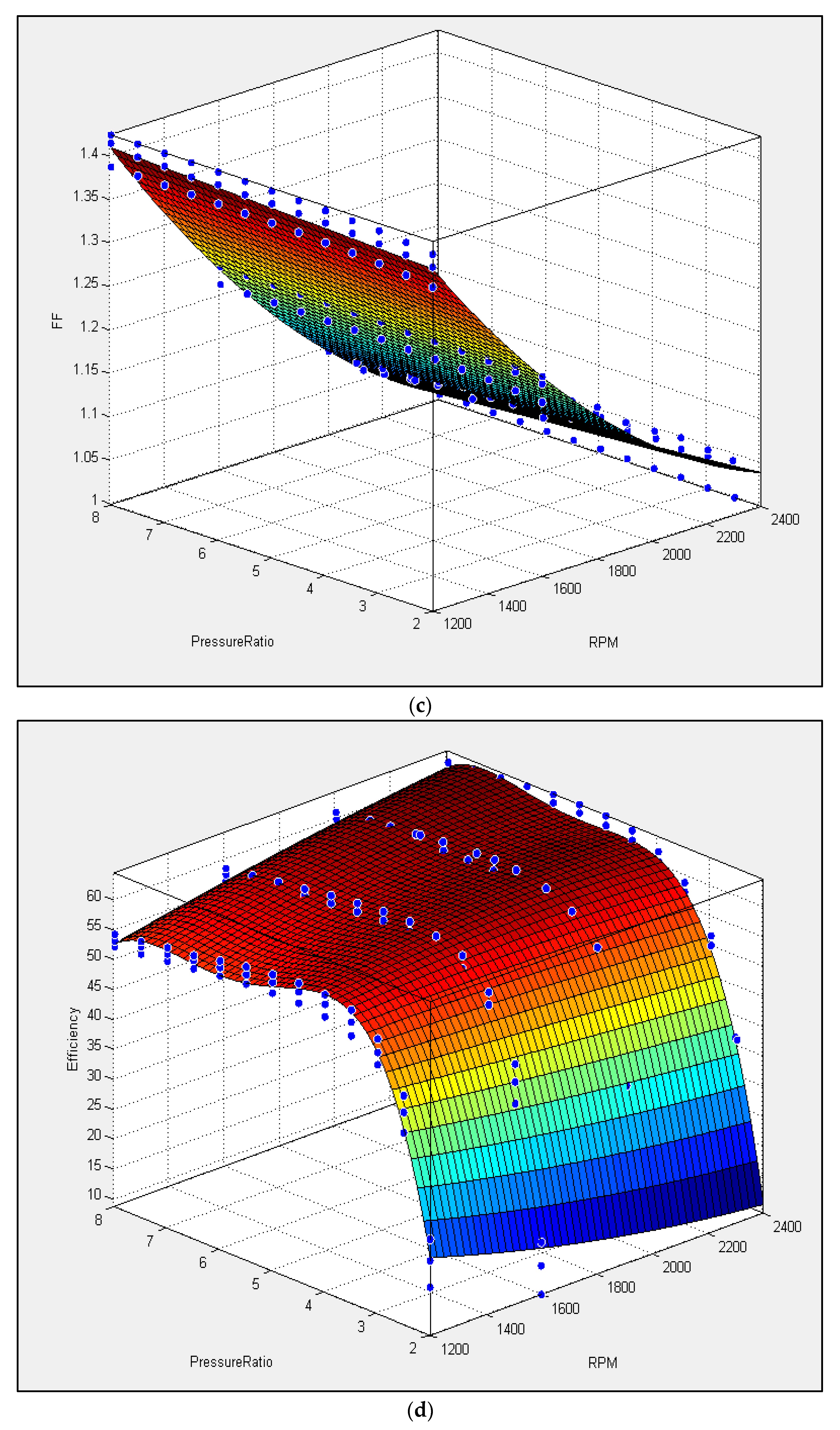

3.2. Evaporator

3.3. Pump

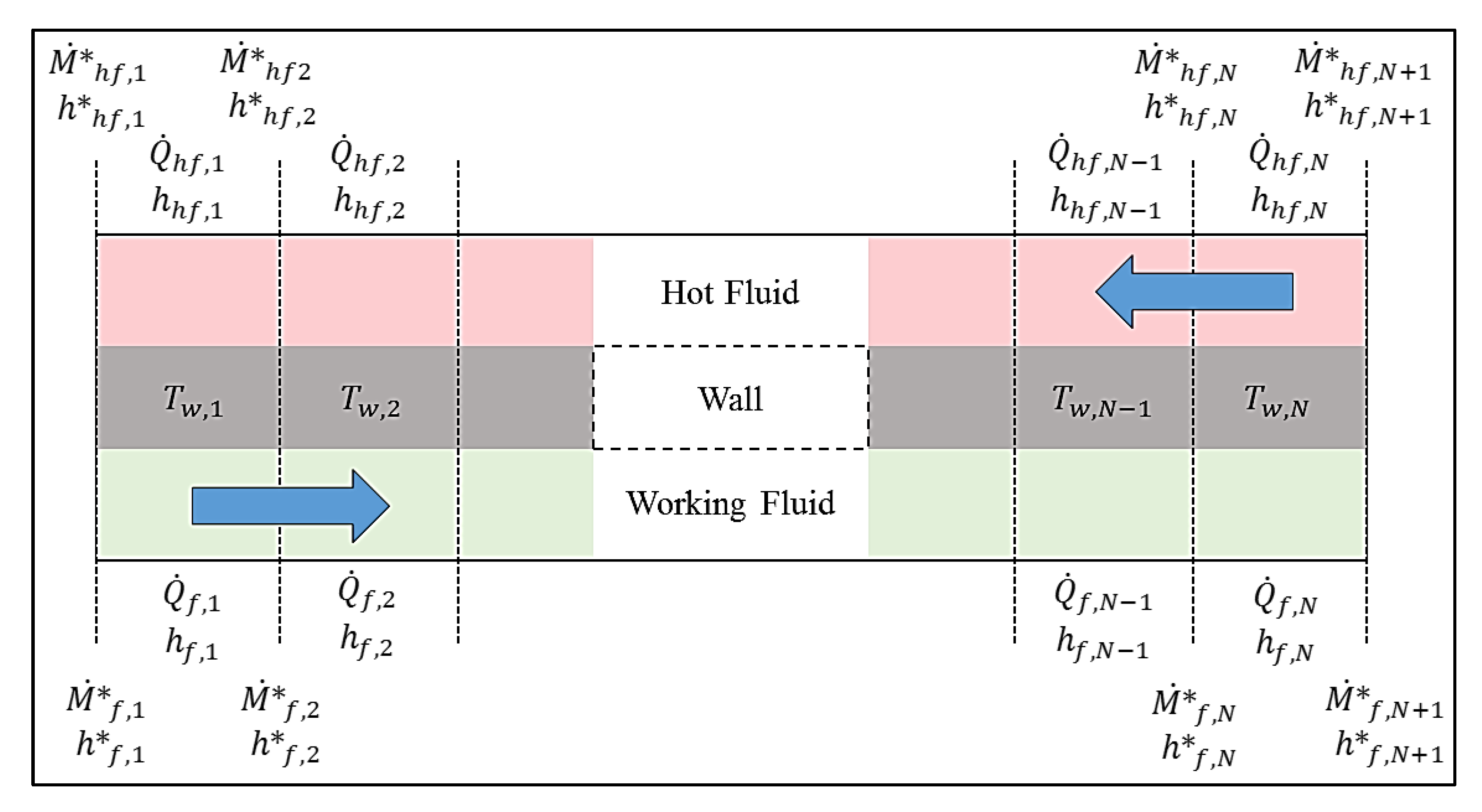

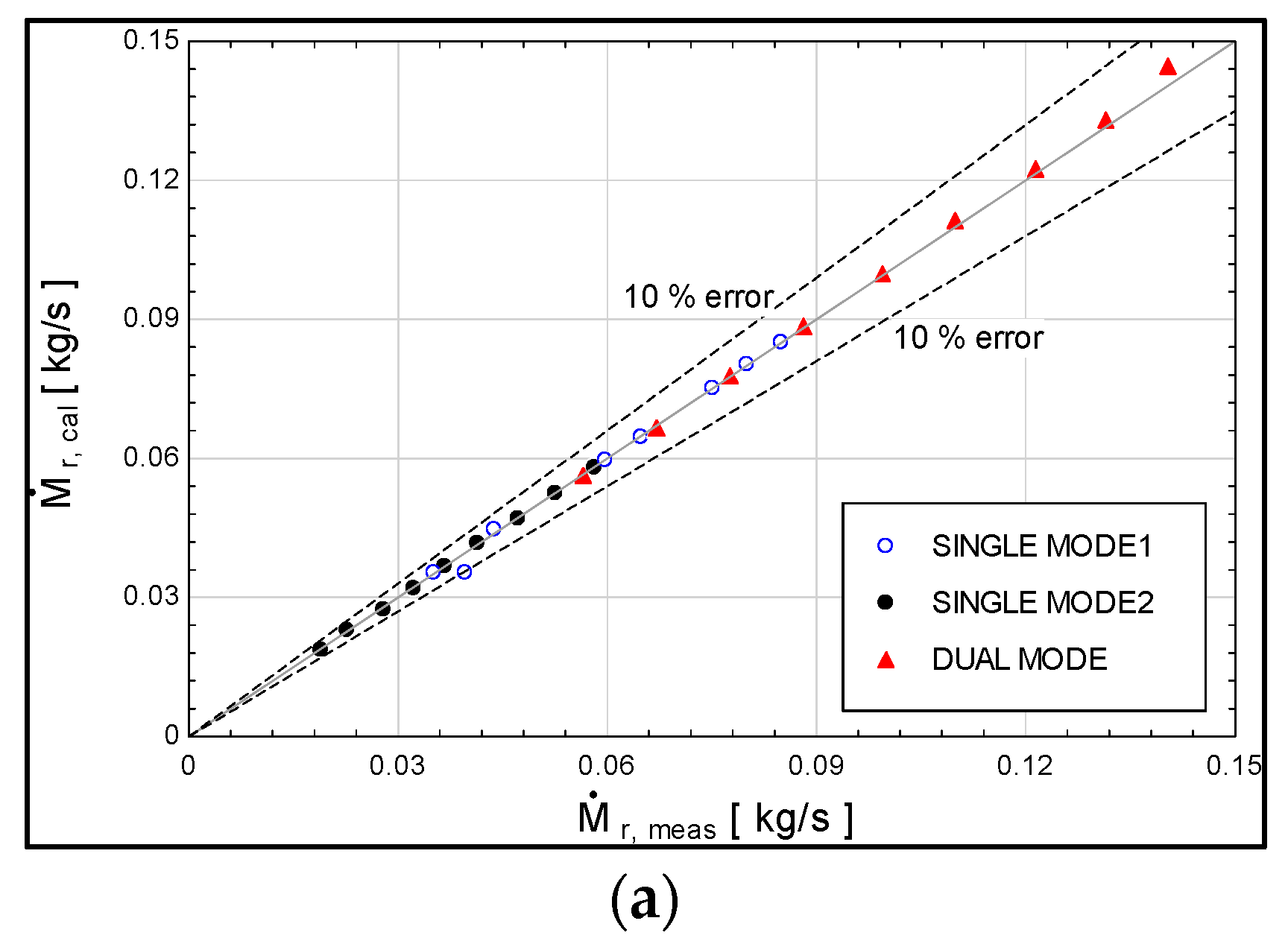

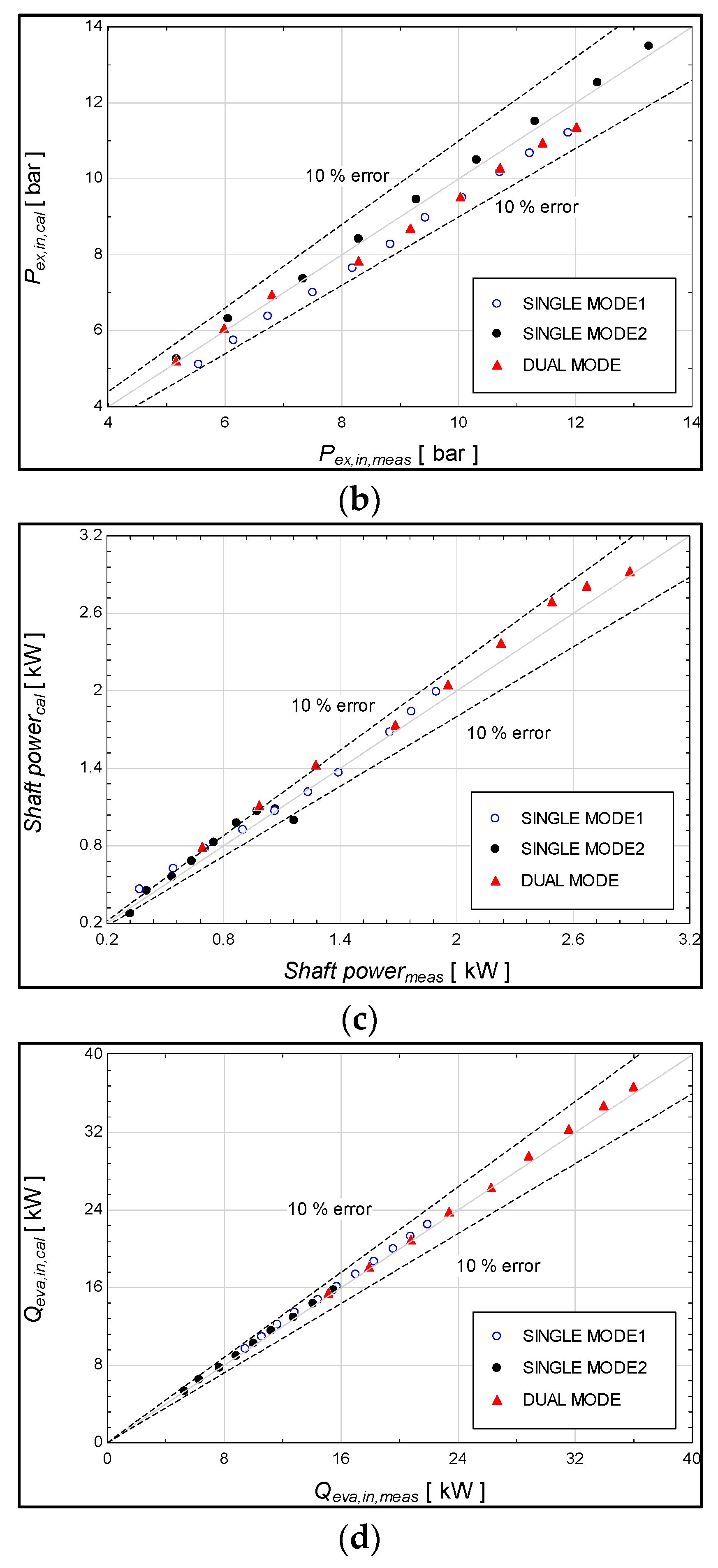

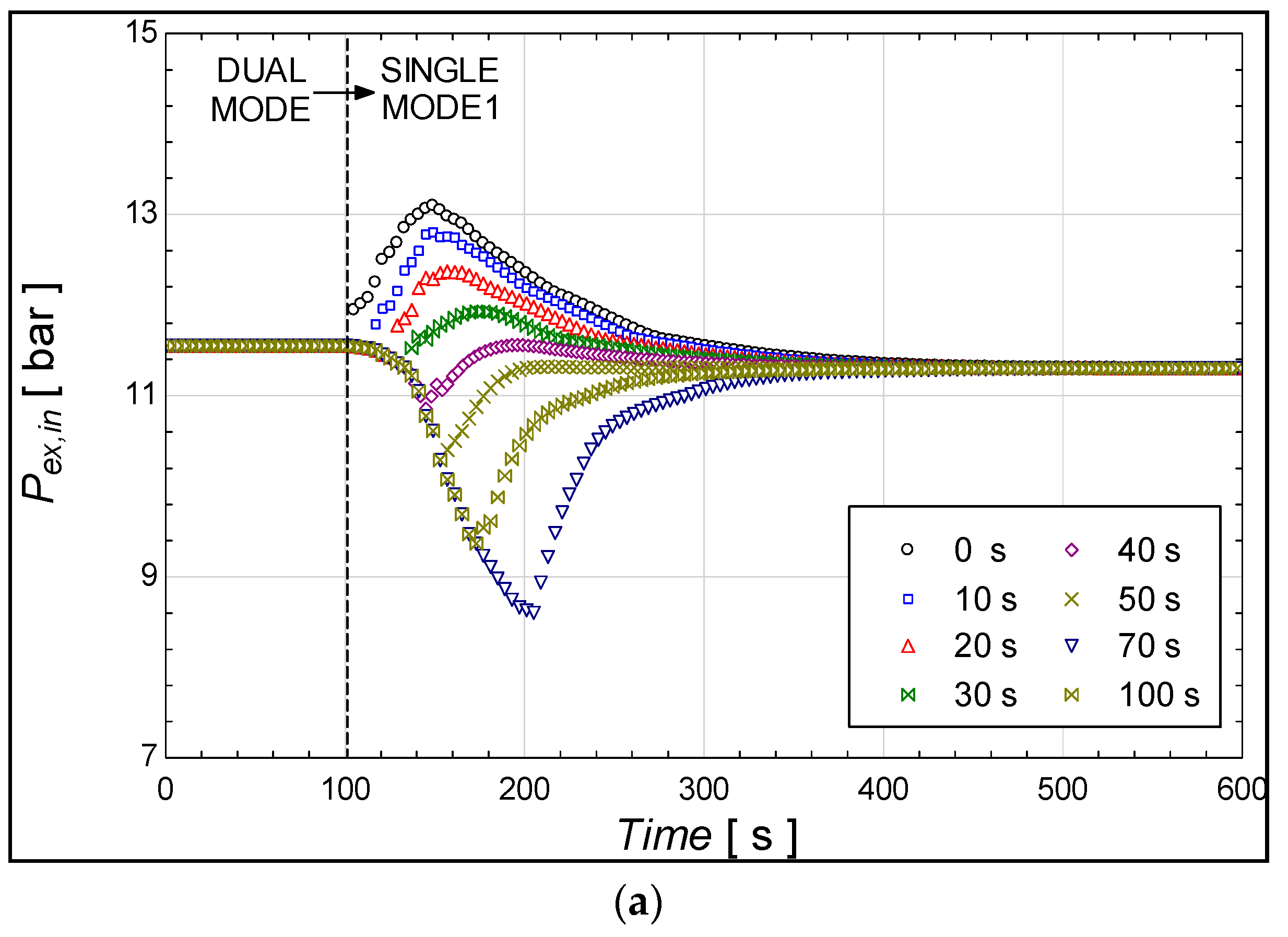

3.4. Model Validation

4. Results and Discussion

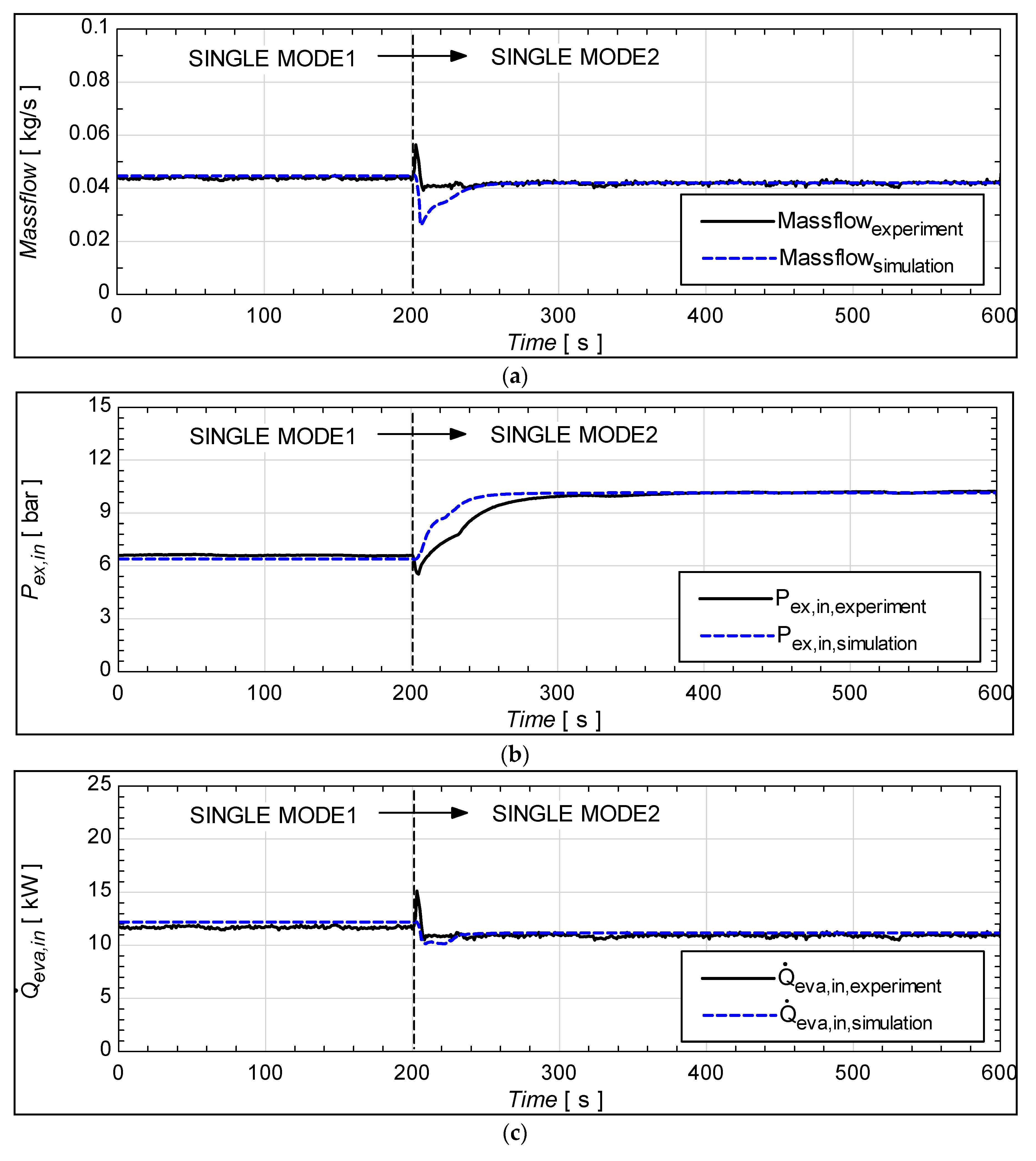

4.1. Mode Change Operation

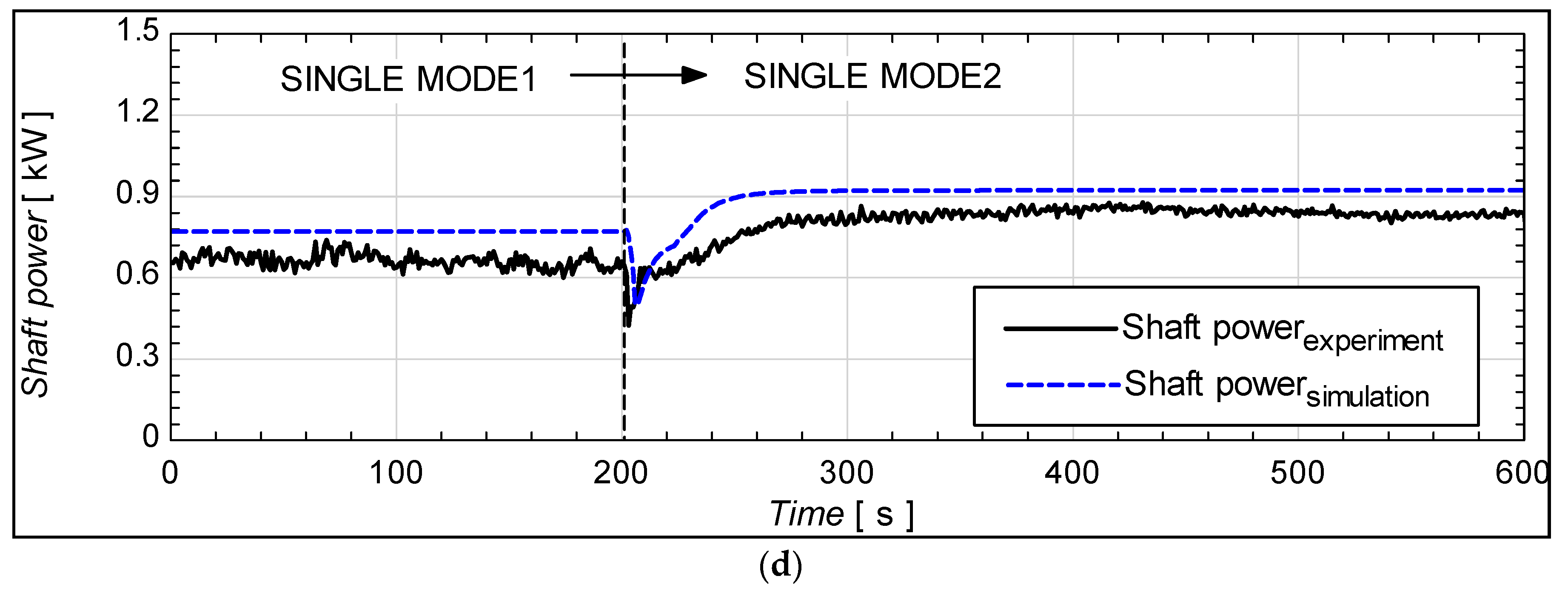

4.2. Pump Control Simulation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Specific heat, kJ/kg.K | |

| Mass flow rate, kg/s | |

| Rotational speed, Revolutions Per Minute (RPM) | |

| Pressure, kPa | |

| Heat capacity, kW | |

| Pressure ratio | |

| Temperature, °C | |

| Time, s | |

| Volumetric flow rate, m3 | |

| Shaft work, kJ | |

| Greek Letter | |

| Isentropic efficiency | |

| υ | Specific volume, m3/kg |

| Density, kg/m3 | |

| Difference | |

| Filling factor | |

| Subscript | |

| Expander | |

| hf | Hot fluid |

| in | Inlet |

| op | Open drive |

| p | Pressure ratio |

| Pump | |

| t | Rotational |

| Supply | |

| Semi hermetic | |

| wf | Working fluid |

References

- Fan, J.; Yeom, E. Numerical investigation on thermal hydraulic performance of supercritical LNG in PCHEs with straight, zigzag, and sinusoidal channels. J. Vis. 2022, 25, 247–261. [Google Scholar] [CrossRef]

- Papapetrou, M.; Kosmadakis, G.; Cipollina, A.; La Commare, U.; Micale, G. Industrial waste heat: Estimation of the technically available resource in the EU per industrial sector, temperature level and country. Appl. Therm. Eng. 2018, 138, 207–216. [Google Scholar] [CrossRef]

- Cimac Working Group Gas Engines. Transient Response Behaviour of Gas Engines; Position Paper; International Council on Combustion Engines: Frankfurt, Germany, 2011; pp. 1–7. [Google Scholar]

- Hoang, A.T. Waste heat recovery from diesel engines based on Organic Rankine Cycle. Appl. Energy 2018, 231, 138–166. [Google Scholar] [CrossRef]

- Lecompte, S.; Oyewunmi, O.A.; Markides, C.N.; Lazova, M.; Kaya, A.; Van Den Broek, M.; De Paepe, M. Case study of an organic Rankine cycle (ORC) for waste heat recovery from an electric arc furnace (EAF). Energies 2017, 10, 649. [Google Scholar] [CrossRef]

- Tauseef Nasir, M.; Chukwuemeka Ekwonu, M.; Esfahani, J.A.; Kim, K.C. Integrated vapor compression chiller with bottoming organic rankine cycle and onsite low-grade renewable energy. Energies 2021, 14, 6401. [Google Scholar] [CrossRef]

- Bao, J.; Zhao, L. A review of working fluid and expander selections for organic Rankine cycle. Renew. Sustain. Energy Rev. 2013, 24, 325–342. [Google Scholar] [CrossRef]

- Qyyum, M.A.; Khan, A.; Ali, S.; Khurram, M.S.; Mao, N.; Naquash, A.; Noon, A.A.; He, T.; Lee, M. Assessment of working fluids, thermal resources and cooling utilities for Organic Rankine Cycles: State-of-the-art comparison, challenges, commercial status, and future prospects. Energy Convers. Manag. 2022, 252, 115055. [Google Scholar] [CrossRef]

- Lecompte, S.; Huisseune, H.; Van Den Broek, M.; Vanslambrouck, B.; De Paepe, M. Review of organic Rankine cycle (ORC) architectures for waste heat recovery. Renew. Sustain. Energy Rev. 2015, 47, 448–461. [Google Scholar] [CrossRef]

- Song, P.; Wei, M.; Shi, L.; Danish, S.N.; Ma, C. A review of scroll expanders for organic rankine cycle systems. Appl. Therm. Eng. 2015, 75, 54–64. [Google Scholar] [CrossRef]

- Imran, M.; Usman, M.; Park, B.S.; Lee, D.H. Volumetric expanders for low grade heat and waste heat recovery applications. Renew. Sustain. Energy Rev. 2016, 57, 1090–1109. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, G.; Li, L.; Yang, Q.; Tang, B.; Liu, Y. Expansion devices for organic Rankine cycle (ORC) using in low temperature heat recovery: A review. Energy Convers. Manag. 2019, 199, 111944. [Google Scholar] [CrossRef]

- Pethurajan, V.; Sivan, S.; Joy, G.C. Issues, comparisons, turbine selections and applications—An overview in organic Rankine cycle. Energy Convers. Manag. 2018, 166, 474–488. [Google Scholar] [CrossRef]

- Schuster, S.; Markides, C.N.; White, A.J. Design and off-design optimisation of an organic Rankine cycle (ORC) system with an integrated radial turbine model. Appl. Therm. Eng. 2020, 174, 115192. [Google Scholar] [CrossRef]

- Imran, M.; Park, B.S.; Kim, H.J.; Lee, D.H.; Usman, M. Economic assessment of greenhouse gas reduction through low-grade waste heat recovery using organic Rankine cycle (ORC). J. Mech. Sci. Technol. 2015, 29, 835–843. [Google Scholar] [CrossRef]

- Imran, M.; Pili, R.; Usman, M.; Haglind, F. Dynamic modeling and control strategies of organic Rankine cycle systems: Methods and challenges. Appl. Energy 2020, 276, 115537. [Google Scholar] [CrossRef]

- Wei, D.; Lu, X.; Lu, Z.; Gu, J. Dynamic modeling and simulation of an Organic Rankine Cycle (ORC) system for waste heat recovery. Appl. Therm. Eng. 2008, 28, 1216–1224. [Google Scholar] [CrossRef]

- Quoilin, S.; Aumann, R.; Grill, A.; Schuster, A.; Lemort, V.; Spliethoff, H. Dynamic modeling and optimal control strategy of waste heat recovery Organic Rankine Cycles. Appl. Energy 2011, 88, 2183–2190. [Google Scholar] [CrossRef]

- Casella, F.; Mathijssen, T.; Colonna, P.; van Buijtenen, J. Dynamic Modeling of Organic Rankine Cycle Power Systems. J. Eng. Gas Turbines Power 2013, 135, 042310. [Google Scholar] [CrossRef]

- Quoilin, S.; Desideri, A.; Wronski, J.; Bell, I.; Lemort, V. ThermoCycle: A Modelica library for the simulation of thermodynamic systems. In Proceedings of the 10th International Modelica Conference, Lund, Sweden, 10–12 March 2014; Volume 96, pp. 683–692. [Google Scholar] [CrossRef]

- Pierobon, L.; Casati, E.; Casella, F.; Haglind, F.; Colonna, P. Design methodology for flexible energy conversion systems accounting for dynamic performance. Energy 2014, 68, 667–679. [Google Scholar] [CrossRef]

- Lakhani, S.; Raul, A.; Saha, S.K. Dynamic modelling of ORC-based solar thermal power plant integrated with multitube shell and tube latent heat thermal storage system. Appl. Therm. Eng. 2017, 123, 458–470. [Google Scholar] [CrossRef]

- Huster, W.R.; Vaupel, Y.; Mhamdi, A.; Mitsos, A. Validated dynamic model of an organic Rankine cycle (ORC) for waste heat recovery in a diesel truck. Energy 2018, 151, 647–661. [Google Scholar] [CrossRef]

- Shu, G.; Wang, X.; Tian, H.; Liu, P.; Jing, D.; Li, X. Scan of working fluids based on dynamic response characters for Organic Rankine Cycle using for engine waste heat recovery. Energy 2017, 133, 609–620. [Google Scholar] [CrossRef]

- Palagi, L.; Pesyridis, A.; Sciubba, E.; Tocci, L. Machine Learning for the prediction of the dynamic behavior of a small scale ORC system. Energy 2019, 166, 72–82. [Google Scholar] [CrossRef]

- Peralez, J.; Nadri, M.; Dufour, P.; Tona, P.; Sciarretta, A. Organic Rankine Cycle for Vehicles: Control Design and Experimental Results. IEEE Trans. Control Syst. Technol. 2017, 25, 952–965. [Google Scholar] [CrossRef]

- Bamgbopa, M.O.; Uzgoren, E. Numerical analysis of an organic Rankine cycle under steady and variable heat input. Appl. Energy 2013, 107, 219–228. [Google Scholar] [CrossRef]

- Yousefzadeh, M.; Uzgoren, E. Mass-conserving dynamic organic Rankine cycle model to investigate the link between mass distribution and system state. Energy 2015, 93, 1128–1139. [Google Scholar] [CrossRef]

- Zhou, Y.; Ruan, J.; Hong, G.; Miao, Z. Dynamic Modeling and Comparison Study of Control Strategies of a Small-Scale Organic Rankine Cycle. Energies 2022, 15, 5505. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, Z.; Huang, H.; Yan, Y. Effect of resistive load on the performance of an organic Rankine cycle with a scroll expander. Energy 2016, 95, 21–28. [Google Scholar] [CrossRef]

- Kaczmarczyk, T.Z. Experimental research of a small biomass organic Rankine cycle plant with multiple scroll expanders intended for domestic use. Energy Convers. Manag. 2021, 244, 114437. [Google Scholar] [CrossRef]

- Witanowski, Ł.; Klonowicz, P.; Lampart, P.; Klimaszewski, P.; Suchocki, T.; Jędrzejewski, Ł.; Zaniewski, D.; Ziółkowski, P. Impact of Rotor Geometry Optimization on the Off-Design ORC Turbine Performance. SSRN Electron. J. 2022, 265. [Google Scholar] [CrossRef]

- Kaczmarczyk, T.Z.; Żywica, G. Experimental research of a micropower volumetric expander for domestic applications at constant electrical load. Sustain. Energy Technol. Assess. 2022, 49, 101755. [Google Scholar] [CrossRef]

- Kaczmarczyk, T.Z.; Żywica, G.; Ihnatowicz, E. Experimental research on scroll expanders operating in parallel in an organic Rankine cycle system with a biomass boiler. Energy Convers. Manag. 2020, 224, 113390. [Google Scholar] [CrossRef]

- Yun, E.; Kim, D.; Lee, M.; Baek, S.; Yoon, S.Y.; Kim, K.C. Parallel-expander Organic Rankine cycle using dual expanders with different capacities. Energy 2016, 113, 204–214. [Google Scholar] [CrossRef]

- Guangbin, L.; Yuanyang, Z.; Yunxia, L.; Liansheng, L. Simulation of the dynamic processes in a scroll expander-generator used for small-scale organic Rankine cycle system. Proc. Inst. Mech. Eng. Part A J. Power Energy 2011, 225, 141–149. [Google Scholar] [CrossRef]

- Lemort, V.; Quoilin, S.; Cuevas, C.; Lebrun, J. Testing and modeling a scroll expander integrated into an Organic Rankine Cycle. Appl. Therm. Eng. 2009, 29, 3094–3102. [Google Scholar] [CrossRef]

- Desideri, A.; Dechesne, B.; Wronski, J.; Van Den Broek, M.; Gusev, S.; Lemort, V.; Quoilin, S. Comparison of moving boundary and finite-volume heat exchanger models in the Modelica language. Energies 2016, 9, 339. [Google Scholar] [CrossRef]

- Farraj, A.R.; Farraj, A.; Hrnjak, P. Local Heat Transfer Coefficient of R245fa Flow Boiling in Plate Heat Exchanger with Simultaneous Flow Visualization. In Proceedings of the 19th International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 10–14 July 2022. [Google Scholar]

| Operating Mode | Open-Drive Scroll Expander (Rotating Speed: 2000 rpm) | Hermetic Scroll Expander (Rotating Speed: 2200 rpm) |

|---|---|---|

| SINGLE MODE 1 | ON | OFF |

| SINGLE MODE 2 | OFF | ON |

| DUAL MODE | ON | ON |

| Operating Mode | Thf,in [°C] | Pump [Hz] | Pexp, in [bar] | Texp,in [°C] | Pexp, out [bar] | Texp, out [°C] | Qin [kW] | Wshaft [kW] | ||

|---|---|---|---|---|---|---|---|---|---|---|

| SINGLE | 1.66 | 110 | 8 | 0.0352 | 5.548 | 88.5 | 1.454 | 70.45 | 9.448 | 0.368 |

| MODE 1 | 9 | 0.0396 | 6.146 | 92.75 | 1.507 | 70.79 | 10.59 | 0.5428 | ||

| 10 | 0.0438 | 6.735 | 95.42 | 1.574 | 70.35 | 11.63 | 0.705 | |||

| 11 | 0.0485 | 7.503 | 97.36 | 1.759 | 68.90 | 12.82 | 0.9007 | |||

| 12 | 0.0547 | 8.184 | 98.71 | 1.671 | 68.00 | 14.42 | 1.065 | |||

| 13 | 0.0598 | 8.832 | 99.94 | 1.687 | 66.93 | 15.7 | 1.236 | |||

| 14 | 0.0648 | 9.431 | 101.2 | 1.665 | 66.29 | 17 | 1.393 | |||

| 15 | 0.0699 | 10.06 | 102.2 | 1.662 | 66.10 | 18.26 | 1.507 | |||

| 16 | 0.0751 | 10.71 | 103.3 | 1.666 | 65.53 | 19.57 | 1.657 | |||

| 17 | 0.08 | 11.22 | 104 | 1.569 | 65.03 | 20.76 | 1.767 | |||

| 18 | 0.0849 | 11.88 | 104.9 | 1.621 | 64.53 | 21.92 | 1.895 | |||

| SINGLE | 1.65 | 120 | 5 | 0.0189 | 5.169 | 100.8 | 1.233 | 77.72 | 5.274 | 0.3198 |

| MODE 2 | 6 | 0.0228 | 6.053 | 101.9 | 1.305 | 76.69 | 6.292 | 0.4049 | ||

| 7 | 0.0279 | 7.337 | 103.5 | 1.526 | 75.18 | 7.681 | 0.5354 | |||

| 8 | 0.0322 | 8.29 | 104.7 | 1.583 | 74.33 | 8.825 | 0.6366 | |||

| 9 | 0.0367 | 9.279 | 105.9 | 1.634 | 73.28 | 10.01 | 0.7502 | |||

| 10 | 0.0414 | 10.31 | 107.4 | 1.685 | 72.64 | 11.23 | 0.8676 | |||

| 11 | 0.0472 | 11.31 | 108.4 | 1.477 | 71.73 | 12.74 | 0.9736 | |||

| 12 | 0.0526 | 12.38 | 109.7 | 1.421 | 71.31 | 14.09 | 1.067 | |||

| 13 | 0.0581 | 13.26 | 110.7 | 1.155 | 70.35 | 15.48 | 1.163 | |||

| DUAL | 1.65 | 120 | 12 | 0.0566 | 5.158 | 89.51 | 1.526 | 70.70 | 15.13 | 0.6906 |

| MODE | 14 | 0.0671 | 5.983 | 93.6 | 1.492 | 71.05 | 17.91 | 0.9839 | ||

| 16 | 0.0777 | 6.799 | 98.84 | 1.443 | 73.52 | 20.76 | 1.275 | |||

| 18 | 0.0881 | 8.287 | 100.34 | 2.077 | 70.91 | 23.38 | 1.685 | |||

| 20 | 0.0994 | 9.175 | 101.35 | 2.040 | 69.69 | 26.23 | 1.955 | |||

| 22 | 0.1099 | 10.03 | 102.4 | 2.041 | 68.55 | 28.81 | 2.228 | |||

| 24 | 0.1214 | 10.71 | 103.4 | 1.782 | 67.50 | 31.56 | 2.49 | |||

| 26 | 0.1315 | 11.44 | 104.1 | 1.688 | 66.75 | 33.95 | 2.669 | |||

| 28 | 0.1404 | 12.02 | 104.7 | 1.541 | 65.54 | 35.99 | 2.89 |

| Parameter | Value | Unit |

|---|---|---|

| A | 8.06 | m2 |

| Mw | 30 | kg |

| N | 50 | - |

| Uhotfluid | 1000 | W/m2 K |

| Ufluid,liquid | 260 | W/m2 K |

| Ufluid,twophase [39] | 900 | W/m2 K |

| Ufluid,gas | 360 | W/m2 K |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ekwonu, M.C.; Kim, M.; Chen, B.; Tauseef Nasir, M.; Kim, K.C. Dynamic Simulation of Partial Load Operation of an Organic Rankine Cycle with Two Parallel Expanders. Energies 2023, 16, 519. https://doi.org/10.3390/en16010519

Ekwonu MC, Kim M, Chen B, Tauseef Nasir M, Kim KC. Dynamic Simulation of Partial Load Operation of an Organic Rankine Cycle with Two Parallel Expanders. Energies. 2023; 16(1):519. https://doi.org/10.3390/en16010519

Chicago/Turabian StyleEkwonu, Michael Chukwuemeka, Mirae Kim, Binqi Chen, Muhammad Tauseef Nasir, and Kyung Chun Kim. 2023. "Dynamic Simulation of Partial Load Operation of an Organic Rankine Cycle with Two Parallel Expanders" Energies 16, no. 1: 519. https://doi.org/10.3390/en16010519

APA StyleEkwonu, M. C., Kim, M., Chen, B., Tauseef Nasir, M., & Kim, K. C. (2023). Dynamic Simulation of Partial Load Operation of an Organic Rankine Cycle with Two Parallel Expanders. Energies, 16(1), 519. https://doi.org/10.3390/en16010519