Abstract

The treatment and disposal of sewage sludge is one of the most important and critical problems of wastewater treatment plants. 8.7 million tonnes of dry matter of sewage sludge were produced annually in the European Union in the year 2020. Due to the fact that sewage sludge contains a large number of substances that are not beneficial for human health, the conditions for sludge management will be significantly tightened in the EU countries. One option for sludge liquidation is the production of biofuel in a form of granules or pellets from sewage sludge enriched by waste celluloses. The achieved results show that the resulting quality of such alternative biofuel is fully comparable to conventional fossil fuels. The economic analysis is based on the simulation of cash flows associated with the implementation of the project over the lifetime and the calculation of levelised cost (LCOE). Results shows (under the current economic situation) that solar dryer technology ensures the lowest LCOE at the level of 26 EUR/GJ in fuel. If the LCOE of the alternative biofuel includes the price of the saved emission allowance and the future costs of sewage sludge disposal, the resulting price is directly competitive with lignite. The results thus clearly show that there is an ecological and economically competitive substitute for solid fossil fuels, which may be an important step for the future use of local combustion sources such as district heating plants.

1. Introduction

The treatment and disposal of sewage sludge from wastewater treatment plants is one of the most important and critical problems of wastewater treatment and management. Sewage sludge is contaminated with a wide range of hazardous substances and organic pollutants that are harmful to human health, and therefore its proper treatment is essential [1]. The volume of wastewater and how it is managed depends on the level of economic development of a country. According to [2,3] 9.6 million tonnes of dry matter of sewage sludge were produced annually in the European Union in the years 2009–2011. Sludge production is declining only very slowly, according to the EurEau Association [4], the EU sludge production in 2020 was 8.7 million tonnes of dry matter. Historically, there are three basic methods of sludge recovery or disposal: direct application to agricultural land for fertilisation, off-farm application to produce industrial composts and reclamation substrates, and thermal treatment. Authors of [5] compared the existing strategies of the treatment of sewage sludge. They proposed the environmental, economic, and technical evaluation of different systems, and recognized sewage sludge as a valuable source of energy. Syed-Hassan et al. [6] and Tsybina and Wuensch [7] discuss possible options for converting sewage sludge to energy and fuel via three main thermochemical conversion processes, namely pyrolysis (discussed also by authors in [8]), gasification (investigated in detail by [9]), and combustion (incineration). They are stating the fundamental behaviour of sewage sludge and the challenges of each technology.

Incineration of sewage sludge has been, in recent years, an increasingly discussed and frequently tested alternative to proper and environmentally safe disposal of sewage sludge instead of its application to agricultural land [10]. This disposal method of thermal treatment of sewage sludge offers sufficient heating value for its possible usage as an alternative fuel for energy production, as indicated by [11]. A promising and frequently tested method of liquidation of sewage sludge is its combustion and co-combustion with other fuels. Raw sludge can be burned with other fuel, usually but not only with coal, as is proven by many authors, such as [12,13,14,15] or dried to improve its calorific value for mono-combustion [16,17].

The authors of [18] discussed the potential of energy utilization of sewage sludge. They focused on calorific values of various sewage sludge that ranges from approximately 6 GJ/tonne to 16 GJ/tonne depending on the water content and the level of fermentation performed. The calorific value of ordinary brown coal burned for energy purposes is generally lower than 15 GJ/tonne. The thermal treatment of sludge is also supported by the recent legislative tightening of the EU rules. This legislation regulates the required hygienic properties of sludge before its final use. In other words, this legislation prescribes the need to properly sanitize the sludge before its further use. In practice, this usually means that the dewatered sewage sludge is treated at a sufficiently high temperature for the necessary period of time to ensure its healthfulness. This additional energy must be spent only on sludge disposal. Therefore, if sanitation is followed by sludge disposal only, this would be contrary to the idea of a circular economy.

A circular economy is based on the elimination of waste and the deliberate recycling and reuse of materials. It thus departs from the ‘Take-Make-Dispose’ approach used so far in the linear economic model and tries to find workable solutions in which the waste from one process is the input to the downstream process [19]. The circular economy principles of sewage sludge management are also supported by increasing landfill charges and decreasing landfill capacity [20]. Tsybina and Wuensch [6] mentioned problems with the disposal of sewage sludge in agriculture and deposition in landfills associated with environmental pollution. They also concluded that in thermal treatment methods energy can be recovered and used, some hazardous materials can be destroyed, and valuable nutrients such as phosphorus can be recovered. They also analysed the three thermal treatment methods–incineration, gasification, and pyrolysis based on cost, energy efficiency, nutrient recovery, product market value, and flexibility. They found that the incineration of sewage sludge performs best in terms of treatment costs, energy efficiency, nutrient recovery, and flexibility concerning feedstock dry matter content. Pyrolysis performs best in terms of the market value of the generated products and flexibility regarding plant size.

There are already multiple approaches to processing and transforming sewage sludge to recover valuable resources and energy in the context of a circular economy. These procedures are discussed in detail by the authors of [21]. Sakiewicz et al. [22] demonstrated the high sorption ability of ashes with nanostructural additives (halloysite, kaolinite) from the combustion of sewage sludge after the anaerobic fermentation for nutrients important in agriculture (Na+, K+, NO3−, SO42−, PO43−, Cl−). For the purpose of this research, valorisation in the form of solid biofuel production without any additives was chosen. The non-use of additives was done especially for the initial verification of the chemical properties of the pure biofuel for subsequent combustion. The second reason was to try to quantify the lowest possible production costs to verify competitiveness. However, the idea of adding additives is very promising for the future, but the choice of a specific additive will depend on the specific situation (input parameters, specific parameters of the combustion source, other requirements for ash utilization, etc.). The reason for this specific valorisation is the urgent need to replace fossil lignite in existing combustion sources in the very near future.

The first and most energy intensive step in this process is the actual drying (and sanitisation) of the sludge. The sludge has to be dried in a solar, rotary drum, or low-temperature belt dryer to 15 to 20% moisture before processing as a fuel for combustion boilers. When drying the dewatered sludge at temperatures of 70–80 °C, the time required for full sanitation of the sludge is about 10–30 min [23]. The use of a rotary tumble dryer is highly efficient and time-saving, but energy and capital intensive, which leads to high operating costs and reduced economy of the entire process. Solar dryers use the heat of solar radiation, and achieving sanitation requires a more extended period. However, this type of drying is energy and cost inexpensive, and its use achieves a significantly better overall economy of the sludge fuel production process.

According to the findings in [24], sewage sludge is understood as a form of biomass. Co-incineration of sewage sludge with other suitable fuels in the form of pellets is more frequent than the combustion of sludge itself. Adding suitable additives, most often coal, or various forms of biomass improves both pelletizing (dewatering, pressure, and temperature as indicated in [18]) and combustion process [25], respectively.

The properties of pure paper sludge and the economics of its incineration are discussed in [26]. In this study, the waste cellulose mill sludge was used as fuel for a fluidized bed boiler with a nominal thermal output of 17.2 MW and a maximum combustion capacity of 140 tons of examined fuel per day. Electricity was produced by an electric generator with a nominal electrical output of 4.9 MW using the heat produced in a fluidized bed boiler. The results show better properties of paper sludge compared to sewage sludge. For this reason (to improve the properties of the resulting biofuel), the sewage sludge was enriched with paper sludge in a ratio of 2:1 within our experiments. This ratio is based on preliminary tests and takes into account the lower availability of paper sludge compared to sewage sludge. However, this ratio can be modified on the basis of available inputs, or the substitution of paper sludge with other suitable wastes can be considered.

In the current moment of extremely high energy prices, the issue of production costs of fossil fuel substitutes is coming to the front. However, there is currently a lack of relevant data and discussion in this area. Therefore, the main objective of our research is to verify the possibility of using an alternative biofuel (based on sewage and paper sludge) as a substitute for fossil fuels, including the detailed calculation of the production cost of this biofuel.

2. Materials and Methods

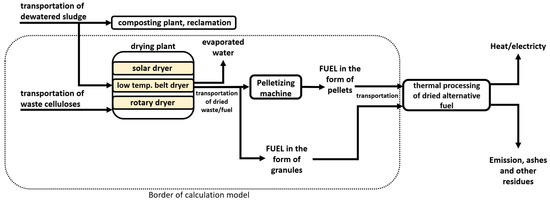

The proposed methodology of the technological process and its individual main steps for the production of alternative fuel from the investigated mixture of sewage sludge and waste celluloses is shown in Figure 1.

Figure 1.

Technology of production of fuel from a mixture of sewage sludge and waste celluloses.

Processing and utilization of sludges produced by municipal wastewater treatment or other biomass waste treatment comprises a series of processes and can be divided into the following basic stages in terms of economic assessment:

Wastewater treatment

- Sludge production and primary sludge dewatering (before transporting to the processing site or input into the next process) are logically implemented directly at the sludge production sites. Significant thickening of the sludge (dewatering) allows us to significantly reduce the requirements (and costs) for transportation of the sludge to the next processing site. From the point of view of optimising investment costs, it can be assumed that the sludge drying facilities will be supplied from several treatment plants. This may lead to regional centres promoting local energy independence.

Transport of dewatered (condensed) sludge

- Transport of dewatered sludge is the first major cost item. The reference model assumes a situation where sludge processing is done in close vicinity of a wastewater treatment plant, and the average transport distance does not exceed 10 km.

Sludge drying

- Sludge drying can be implemented using different technologies. Three specific options are calculated in the economic evaluation, namely solar dryer, low-temperature belt dyer, and rotary dryer. These technologies differ mainly in the speed of drying and the energy input requirements. Their technical and economic parameters are compared in detail in the following text.

Sludge processing into final fuel

- The resulting fuel form is derived from the requirements of the combustion source. In the case of a solar dryer, the resulting product can be used as a fuel granulate that can be burned directly in larger (fluid bed) boilers. In the case of the low-temperature belt dryer and rotary dryer, the pelletization process provides the resulting fuel form. The aim is to obtain a resulting fuel that can be used as a direct substitute for lignite.

A summary and localisation of all the described processes are given in Table 1. The process flowrates are depending mainly on the capacity of the dryer and the availability of sludge. The capacity of the pelletizing line should be determined not only by the size of the equipment but also by the decision whether it will be used in one-shift, two-shift, or possibly a three-shift operation. In the current conditions, it seems economical to consider only single-shift operations because of the increased personnel costs in the other options. Therefore, the additional capacity of production for pelletization is usually available if needed.

Table 1.

Main steps in the technology of fuel production from sewage sludge and waste biomass.

As part of the research, the mechanical properties of the pellets were tested. The mechanical resistance of pellets is expressed as PDI (Pellet Durability Index) using a Holmen NHP 1000 apparatus. In the test, 100 g of pellets are pneumatically moving in a cell with perforated walls for 60 s. After the test, the value of PDI is calculated as a mass percentage of particles greater than 3.15 mm. The hardness of pellets is expressed as a weight load (in kg) that the pellet could withstand without destruction. Tester KAHL ak-1 was used for this purpose. The Wettability index (WI) is the last to be quantified. This index indicates the amount of distilled water absorbed by pellets after 30 s exposure.

Economic Assessment of Sludge Processing

Due to the significantly stricter requirements for sludge use, laid down by MoE Decree no. 437/2016 Coll. starting from 2023 (sludge sanitization, etc.), a considerable increase in the energy application of sludge can be expected. That is why the economy of the whole sludge energy use process needs to be considered in detail, and its economy ratio has to be assessed against other sludge disposal and reuse methods.

The assessment of economic effectiveness (competitiveness) of sludge energy use applies an economic model that involves the typical processes associated with the chosen sludge processing technique. Reference technical-economic parameters then have to be defined for these processes, including the quantity of sludge. It is important due to the relatively high share of investment costs (or constant costs arising from them) in the total costs of sludge processing. The reason is that the total investment costs of technology are not in direct proportion to the quantity of waste processed. The quantity of sludge produced in wastewater treatment is the function of the number of equivalent inhabitants connected. One equivalent inhabitant produces approx. 20 kg of sludge (measured as dry matter). That corresponds to a production of approx. 207 thousand tonnes of sludge dry matter for all of Czechia (see [3]). Thus, an area with 50 thousand equivalent inhabitants produces approx. 1000 tonnes of sludge dry matter a year.

The model for analysis of the economic effectiveness of sludge disposal is based on two basic principles: the relevant cost inclusion principle and the opportunity cost principle. The principle of including only relevant costs and revenues means counting only those costs of sludge processing and reuse for energy purposes that are directly induced by processes related to this method of sludge processing. In other words, it excludes costs that would have to be expended regardless of the sludge processing and reuse method, such as dewatering units at wastewater treatment facilities. Examples of such costs include costs of wastewater treatment plant operation and primary sludge condensation to enable sludge transport, regardless of the method of further processing and utilization.

The opportunity cost principle consists in including (as an economic benefit) costs saved by this sludge disposal and utilization method. On the benefit side, therefore, the economic model may include costs of acquisition of emission permits that are saved (if combustion of the sludge, or fuel made from it, displaces fossil fuels, e.g., coal combusted in fluid bed boilers). Another potential benefit is the saving of current costs of sludge treatment and disposal incurred by wastewater treatment plant operators. This may take the form of the sludge originator (i.e., wastewater treatment plant operator) paying for the sludge removal.

The economic model captures processes from the transport of condensed sludge from its place of origin to the processing site, its drying, and pelletizing if any. The costs of using pellets in the energy source (boiler) cause no significant additional costs in comparison with, e.g., coal, which is partially or entirely replaced with sludge. Continuous pellet production is assumed (in conjunction with continuous sludge production and processing), and costs of pellet storage and logistics at the point of consumption are neglected (consumption of original fuel decreases, and so do the costs of its logistics, which saving is offset against the costs of pellet logistics).

For each of the process stages separately, the economic model follows the costs of investment in technology and related infrastructure (e.g., buildings), so-called CAPEX, and costs of assuring operation (OPEX). The baseline method used for the assessment is the levelized cost (LCOE) method. The LCOE criterion was chosen mainly for its comparability (calculation using the same methodological approach). Most economic comparisons are made on a cost of production basis. This approach is also used by recognised agencies such as International Energy Agency [27]. The advantage of this approach is the absence of the need to determine escalation factors for individual cost items, which again increases the comparability of the results obtained. The logic of the calculation for LCOE is provided in the following basic Equation (1):

where r = discount rate [%]; T = technology lifetime [years]; CRF = capital recovery factor [–]; CAPEX = technology acquisition expenditures [EUR]; OPEX = annual operating expenditures for the production size Q [EUR]; Q = annual production [t].

This LCOE methodology assesses the economic effectiveness of the process equipment itself without considering the effect of taxes and financing methods, but it includes the expected investment revenue (discount rate). CAPEX are converted to annual values using the capital recovery factor (CRF). The conversion respects the expected technical lifetime of the different primary investment components (typically process equipment and constructions separately).

Equation (1) assumes a constant quantity of waste processed throughout the equipment service life and also a constant value of OPEX during the whole lifetime. However, the LCOE criterion may be adjusted to reflect changes in cash flow and production volumes over the lifetime. The adjusted criterion is given in Equation (2):

where r = discount rate [%]; T = technology lifetime [years]; It = investment expenditures in the year t; FIXt = fixed cost in the year t [EUR]; VARt = variable cost in the year t [EUR]; Qt = annual production [t].

The levelized costs are expressed as EUR/GJ of energy content in output product for better comparability with other fuels such as lignite. The 2022 price level is applied in the calculations. The reference economic model is built for an area containing approx. 55 thousand equivalent inhabitants, which corresponds to an annual production of approx. 3600 tonnes of dewatered sewage sludge. All the process and logistics equipment and technologies are sized for this weight flow.

Drying is the key stage in terms of sludge processing costs. This is because of both the high investment costs (CAPEX) and high operating costs (OPEX) of drying technologies. Three possible drying techniques were analysed for the economic model: solar, low-temperature, and rotary dryers. The investment costs (CAPEX) for these technologies difference is below 15% with the same quantity of sludge processed. However, great differences occurred in the total quantified operating costs (OPEX). The detailed input information for the LCOE calculation are listed in the following Table 2, with the help of which the total LCOE of the blended biofuel is calculated. Information on individual drying technologies was obtained through discussions with individual construction companies. The assumed lifetime is set for 30 years respecting the need for reinvestments and repairs.

Table 2.

Calculation inputs.

The electricity and natural gas price was taken from long-term contracts and it does not reflect the current turbulent times in the electricity markets. Indeed, it can be assumed that the price will stabilise at this level within a few years (once the current panic and nervousness on the commodity markets will pass). The operating hours’ value indicates the operating time of the equipment, i.e., how long the equipment is in operation during the year. Specifically, for a solar dryer, this value indicates year-round operation without the need for downtime. Thus, this value does not have the meaning of the effective solar radiation time for a given location.

In order to be able to correctly compare the individual drying technologies, the LCOE calculation is first performed on the output of the drying technology. The subsequent pelletizing employs a standard pelletizing plant, which enables turning a wide range of raw materials (hay, wood waste, sludge, etc.) into pellets. According to [28] the pelletizing costs for a comparable volume and type of input material can be estimated at 5 EUR/GJ. Such pelleting costs are supported by findings in [29], where authors obtained a result of 6 EUR/GJ.

3. Results and Discussion

As mentioned, authors of [18] indicated that calorific values of various sewage sludge range from approximately 6 GJ/tonne to 16 GJ/tonne depending on the water content, the origin of sludge (the content of substances, carbon, and nutrients) and the level of fermentation performed before its final dewatering and drying process. This is also supported by our results, when our analysed biofuel fuel reaches the calorific value of 11.4 GJ/tonne in the form of pellets, respectively 10.8 GJ/tonne in the form of granulate as shown in Table 3. The resulting values in Table 3 were obtained by producing the fuel under laboratory conditions and then measuring the main characteristics. The calorific value of lignite used for energy purposes is generally lower than 15 GJ/tonne. With this comparison of calorific values, we can state that the incineration of sludge for energy purposes offers excellent potential, which can help reduce dependence on conventional fuels and at the same time bring ecological disposal of hazardous substances contained in the sludge, all this in support of the idea of a circular economy.

Table 3.

Fuel main characteristics.

The results of testing the mechanical properties of the pellets are summarized in the following Table 4.

Table 4.

Mechanical properties of pellets.

Mechanical resistance of pellets expressed as PDI (Pellet Durability Index) provided values marginally smaller than 97.5%, a value generally recommended. However, values of PDI between 89.1 to 97.8% for various biomass pellets are common. The hardness parameter of all samples is in the range of 22–27 kg. From our experience, the value of 25 kg ensures sufficient material hardness for material processing, while border values are 22–25 kg. In the range of 19–22 kg, problems with the formation of fines may be expected, which are even more serious at the parameter value below 19 kg. However, the mechanical properties of fuel pellets used in this process do not indicate any problems with their storage, transport, and processing.

All samples had a good hygroscopic resistance expressed by a low value of index WI compared to biomass values of WI generally exceeding 30%. On the scale, materials with WI 0–5% were fully hydrophobic, 5–10% mildly hydrophobic, 10–15% slightly moisture absorbing, 15–25% highly moisture absorbing, and 25% and over materials highly moisture absorbing and swelling. Low hygroscopicity is an important property of fuels.

The verification of mechanical properties confirmed the applicability of this alternative biofuel in conventional combustion sources without the need for major additional technology modifications. The addition of paper sludge improved the mechanical and chemical properties of the final biofuel. This results in a greater similarity to the key parameters of lignite as a direct substitute. From a technical point of view, a significant competitive advantage of the solar dryer was confirmed. The output fuel of this technology is already granulated and suitable for direct use in combustion processes in fluidized bed boilers, thus eliminating the need for additional fuel treatment (pelletization) and the associated additional costs. This type of fuel has not been mechanically tested. This was due to the absence of input granulation from the actual operation of a solar dryer processing a mixture of paper mill waste and sewage sludge.

An additional advantage of sewage waste incineration is that valuable substances and nutrients can be regenerated from the ash. Tsybina and Wuensch [7] state the ash content of phosphorus is up to 8.6% by mass compared to 3.83% by mass in our experimental measurement. During the mono-incineration process, the phosphorus remains chemically unchanged and thus passes fully into the ash. They also conclude that the phosphorus content in ash (after incineration of sewage sludge) is significantly lower compared to crude phosphate fertilizer (app. 50–70% lower). However, this value is still high enough to justify the back isolation of phosphorus for further recovery (according to the authors, up to 90% can be recovered). On the other hand, it must be said that if phosphorus recovery is required, it is necessary to use fuels without additional additives and also to keep to mono-combustion. For these reasons, the incineration of sewage sludge may be an important source of phosphorus, especially in the event of future mining declines or other shortages of this mineral.

The LCOE quantification for each drying technology is shown in Table 5.

Table 5.

Final LCOE.

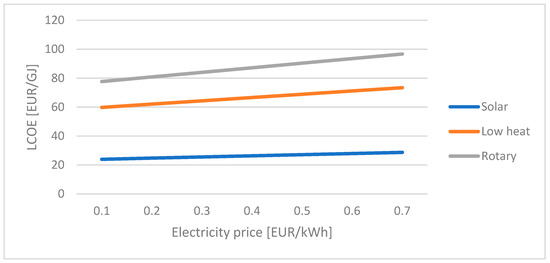

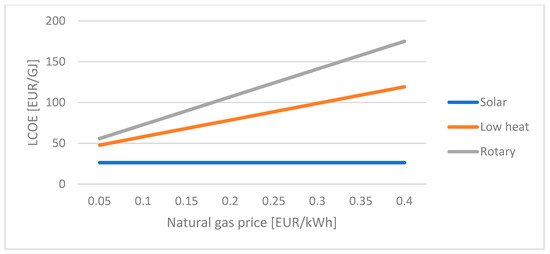

These results indicate the cost per GJ in fuel at the dryer output. The difference in prices is mainly due to different operating cost requirements, in particular the cost of natural gas, which is used as a heat source for the low-temperature belt dryer and the rotary dryer. The dependence of the resulting LCOE on the price of gas and electricity is shown in the form of a sensitivity analysis in the following Figure 2 and Figure 3.

Figure 2.

Sensitivity analysis on electricity price.

Figure 3.

Sensitivity analysis on natural gas price.

It can be seen that the solar dryer is completely independent of the price of natural gas (it does not use it for its operation) and only slightly dependent on the price of electricity. Thus, it can be concluded that for solar technology, most of the LCOE is fixed in the form of an investment at the beginning of the project and the price is relatively stable over the lifetime. In contrast, energy-intensive technologies (low heat and rotary) can be seen to be very sensitive to changes in the input price, particularly of natural gas. This means, however, that in the current situation these technologies become significantly more expensive to operate, and consequently, the resulting biofuel loses its economic competitiveness against its substitutes. We must also not forget that both of these technologies require subsequent processing of the dried sludge in a pelletizing line, which increases the LCOE by another 5–6 EUR/GJ.

The key input, which is significantly influencing the final economy of sewage and waste cellulose industry sludges, is the potential fees for acceptance and subsequent disposal of wastewater treatment plant sludge. The presented economic model adopts rather conservative assumptions: it does consider zero payments by the waste producers (in the current situation, the waste celluloses are taken by a third party for free and sewage sludge disposal costs are very low). In the case of an obligation to sanitize all wastewater treatment plant sludge, which is to come into force in Czechia in 2023 (there is also an ongoing discussion about the revision of the EU directive governing the management of sewage sludge, however currently, each member state is responsible for its own regulation), we can expect the possibility of business dealings about sludge acceptance for a fee paid by the wastewater treatment plant operator. The fee would reflect the saved costs of construction and operation of a sanitization unit within wastewater treatment plant premises. Sludge sanitization occurs during the drying process, and the subsequent destruction of all pharmaceutical substances completes the sludge disposal during the combustion process. Current discussions at the level of wastewater treatment plant operators indicate possible payments of 40 to 50 EUR per tonne of thickened sludge, depending on individual parameters. This money can thus be seen as income. If we apply this to our case, we get a reduction in LCOE of 6 to 8 EUR/GJ at the dryer output.

In order to draw relevant conclusions about the LCOE of the biofuel we have examined, it is necessary to compare this price against the price of the main substitute, namely lignite. Here, however, we encounter the problem that the price of lignite is subject to bilateral contracts and thus there is no commodity exchange market in which data could be used for comparison. However, this problem has been addressed by the authors of [30]. As one of the methods, they propose a procedure for determining the price of lignite based on the price of exchange-traded hard coal. The main idea behind this approach is to establish a price coefficient between lignite and hard coal based on their chemical parameters. This approach leads to a resulting coefficient of 0,8 for the price of hard coal on the Rotterdam exchange (ARA). The current futures price, depending on the time specification, is around 240 EUR/t [31]. When converted into the energy contained in the fuel, we get 10 EUR/GJ.

In the current European market, the use of lignite in larger combustion sources is linked to the obligation to pay for emission allowances. If we accept the assumption that sludge-based biofuels will remain outside the emission allowance system, the switch away from lignite is associated with emission allowance savings. Thus, if we convert the price of an emission allowance into energy in lignite (assuming 85 EUR/tCO2 as the value around which the current price oscillates [32]), we get an additional saving of 6 EUR/GJ.

4. Conclusions

The results clearly demonstrate that it is technically feasible to process a mixed alternative biofuel based on sewage and paper sludge. This fuel achieves comparable energy values to lignite. This was also confirmed in preliminary combustion tests in a fluidised bed boiler. The fluidized bed boiler in which the investigated fuel mixture combustion process had been examined has a nominal thermal output of 17.2 MW. Combustion tests confirmed the suitability of the investigated fuel as a possible alternative fuel for boilers of this type.

The promotion of the use of waste sludge will be also supported in the future by stricter legislation on waste sludge management. The dewatered sludge will have to undergo ‘hygienisation’, which corresponds to the requirement that it be heated so that it is not in any way harmful to health. From the point of view of health safety, the drying and subsequent thermal treatment of sludge guarantees absolute health safety.

The final price of this biofuel is strongly dependent on the drying method. The only competitive technology is solar drying. This is due to comparable investment costs and significantly lower operating costs compared with the other two evaluated technical variants. It uses the heat obtained from solar radiation and uses the greenhouse effect to enhance the drying effect. The airflow, which removes the released moisture from the top layer of dried sludge, is ensured by air conditioning. In case of insufficient input solar energy, the air flowing inside the solar dryer can be additively heated to ensure the drying process’s optimal course. An additional advantage of solar technology is that it is also capable of producing fuel in the form of granulates, where additional pelletization is no longer needed. This again reduces the overall production costs.

In a direct price comparison, the LCOE of the solar variant is 26 EUR/GJ in fuel. Both other options considered show significantly higher LCOE values in the current conditions (67–87 EUR/GJ). These values may appear significantly higher in direct comparison with the lignite price of 10 €/GJ. However, if the price of the saved emission allowance (6 EUR/GJ) and the future price for sludge disposal (6–8 EUR/GJ) are included in the comparison, the price differences even out. It can thus be concluded that if the right technology is chosen to produce the sludge-based alternative biofuel, and all relevant costs and revenues are included, the resulting cost price is comparable to that of lignite.

Author Contributions

Conceptualization: K.V., T.K. and O.Š.; Methodology: K.V., T.K., L.J. and M.Č.; Software, O.Š.; Validation, K.V., T.K., L.J., O.Š., K.S. and M.V.; Formal analysis, K.V., T.K., L.J. and O.Š.; Investigation, K.V., T.K., L.J., O.Š. and K.S.; Resources, K.V., O.Š., M.Č. and K.S.; Data curation, T.K., L.J., O.Š., M.Č. and M.V.; Writing–original draft, K.V., T.K., L.J., O.Š. and M.Č.; Writing–review & editing, K.V., T.K., L.J., O.Š. and K.S.; Visualization, T.K.; Supervision, K.V. and O.Š. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Czech Technology Agency, grant number TN01000048 (Biorefining as circulation technology).

Data Availability Statement

Not applicable.

Acknowledgments

The ash analysis, done by the Technical University of Ostrava, is highly appreciated.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Moško, J.; Pohořelý, M.; Cajthaml, T.; Jeremiáš, M.; Robles-Aguilar, A.A.; Skoblia, S.; Beňo, Z.; Innemanová, P.; Linhartová, L.; Michalíková, K.; et al. Effect of pyrolysis temperature on removal of organic pollutants present in anaerobically stabilized sewage sludge. Chemosphere 2021, 265, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Eurostat. Sewage Sludge Production and Disposal from Urban Wastewater (In Dry Substance (d.s)). Products Datasets. Available online: https://ec.europa.eu/eurostat/web/products-datasets/-/ten00030 (accessed on 5 December 2021).

- Pellegrini, M.; Saccani, C.; Bianchini, A.; Bonfiglioli, L. Sewage sludge management in Europe: A critical analysis of data quality. Int. J. Environ. Waste Manag. 2016, 18, 226. [Google Scholar] [CrossRef]

- EurEau. Waste Water Treatment-Sludge Management. May 2021. Available online: https://www.eureau.org/resources/briefing-notes/5629-briefing-note-on-sludge-management/file (accessed on 15 December 2022).

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Syed-Hassan, S.S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical processing of sewage sludge to energy and fuel: Fundamentals, challenges and considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- Tsybina, A.; Wuensch, C. Analysis of sewage sludge thermal treatment methods in the context of circular economy. Detritus 2018, 2, 3–15. [Google Scholar] [CrossRef]

- Kim, Y.; Parker, W. A technical and economic evaluation of the pyrolysis of sewage sludge for the production of bio-oil. Bioresour. Technol. 2008, 99, 1409–1416. [Google Scholar] [CrossRef] [PubMed]

- García, G.; Arauzo, J.; Gonzalo, A.; Sánchez, J.L.; Ábrego, J. Influence of feedstock composition in fluidised bed co-gasification of mixtures of lignite, bituminous coal and sewage sludge. Chem. Eng. J. 2013, 222, 345–352. [Google Scholar] [CrossRef]

- Jang, H.N.; Kim, J.H.; Back, S.K.; Sung, J.H.; Yoo, H.M.; Choi, H.S.; Seo, Y.C. Combustion characteristics of waste sludge at air and oxy-fuel combustion conditions in a circulating fluidized bed reactor. Fuel 2016, 170, 92–99. [Google Scholar] [CrossRef]

- Werle, S.; Wilk, R.K. A review of methods for the thermal utilization of sewage sludge: The Polish perspective. Renew. Energy 2010, 35, 1914–1919. [Google Scholar] [CrossRef]

- Otero, M.; Díez, C.; Calvo, L.F.; García, A.I.; Morán, A. Analysis of the co-combustion of sewage sludge and coal by TG-MS. Biomass Bioenergy 2002, 22, 319–329. [Google Scholar] [CrossRef]

- Botha, M.F.; Biyela, S.L.; Fry, M.R.; Paladh, R. Sewage-sludge incineration in South Africa using a fluidized-bed reactor. In Proceedings of the 4th Conference on Industrial Fluidisation, Johannesburg, South Africa, 16–17 November 2011; Volume 315, pp. 315–323. [Google Scholar]

- Naidoo, K. The performance of KwaMashu waste water sludge incineration and dryer plant. In Proceedings of the Water Institute of Southern Africa (WISA) Biennial Conference, Cape Town, South Africa, 2–6 May 2004; pp. 1316–1326. Available online: https://wisa.org.za/wp-content/uploads/2018/12/WISA2004-P112.pdf (accessed on 6 December 2021).

- Calvo, A.I.; Tarelho, L.A.C.; Teixeira, E.R.; Alves, C.; Nunes, T.; Duarte, M.; Coz, E.; Custodio, D.; Castro, A.; Artiñano, B.; et al. Particulate emissions from the co-combustion of forest biomass and sewage sludge in a bubbling fluidised bed reactor. Fuel Process. Technol. 2013, 114, 58–68. [Google Scholar] [CrossRef]

- Fleischman, N.D.; Botha, M.; Germanis, J. Sewage sludge and biomass incineration in South Africa using a fluidized-bed reactor. South African J. Chem. Eng. 2014, 19, 91–103. [Google Scholar]

- Prasad, L.S.V.; Sheshubabu, D. Design Aspects of Bubbling Fluidised Bed Boiler for Municipal Solid Waste. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 5, 1–14. [Google Scholar] [CrossRef]

- Yilmaz, E.; Wzorek, M.; Akçay, S. Co-pelletization of sewage sludge and agricultural wastes. J. Environ. Manag. 2018, 216, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Smol, M.; Kulczycka, J.; Henclik, A.; Gorazda, K.; Wzorek, Z. The possible use of sewage sludge ash (SSA) in the construction industry as a way towards a circular economy. J. Clean. Prod. 2015, 95, 45–54. [Google Scholar] [CrossRef]

- Nguyen, M.D.; Thomas, M.; Surapaneni, A.; Moon, E.M.; Milne, N.A. Beneficial reuse of water treatment sludge in the context of circular economy. Environ. Technol. Innov. 2022, 28, 102651. [Google Scholar] [CrossRef]

- Gherghel, A.; Teodosiu, C.; De Gisi, S. A review on wastewater sludge valorisation and its challenges in the context of circular economy. J. Clean. Prod. 2019, 228, 244–263. [Google Scholar] [CrossRef]

- Sakiewicz, P.; Piotrowski, K.; Rajca, M.; Maj, I.; Kalisz, S.; Ober, J.; Karwot, J.; Pagilla, K.R. Innovative Technological Approach for the Cyclic Nutrients Adsorption by Post-Digestion Sewage Sludge-Based Ash Co-Formed with Some Nanostructural Additives under a Circular Economy Framework. Int. J. Environ. Res. Public Health 2022, 19, 11119. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Environmental Regulations and Technology: Control of Pathogens and Vector Attraction in Sewage Sludge. 2003. Available online: https://www.epa.gov/sites/default/files/2015-04/documents/control_of_pathogens_and_vector_attraction_in_sewage_sludge_july_2003.pdf (accessed on 5 December 2021).

- Kijo-Kleczkowska, A.; Środa, K.; Kosowska-Golachowska, M.; Musiał, T.; Wolski, K. Experimental research of sewage sludge with coal and biomass co-combustion, in pellet form. Waste Manag. 2016, 53, 165–181. [Google Scholar] [CrossRef]

- Parshetti, G.K.; Liu, Z.; Jain, A.; Srinivasan, M.P.; Balasubramanian, R. Hydrothermal carbonization of sewage sludge for energy production with. Fuel 2013, 111, 201–210. [Google Scholar] [CrossRef]

- Caputo, A.C.; Pelagagge, P.M. Waste-to-energy plant for paper industry sludges disposal: Technical-economic study. J. Hazard. Mater. 2001, 81, 265–283. [Google Scholar] [CrossRef] [PubMed]

- Levelised Cost of Electricity Calculator—Data Tools—IEA. Available online: https://www.iea.org/data-and-statistics/data-tools/levelised-cost-of-electricity-calculator (accessed on 25 November 2022).

- Králík, T.; Knápek, J.; Dvořáček, L.; Vávrová, K. Impact of pelleting cost on competitiveness of intentionally grown biomass for local space heating: Case example of the Czech Republic. Energy Rep. 2020, 6, 732–737. [Google Scholar] [CrossRef]

- Nolan, A.; Mc Donnell, K.; Devlin, G.J.; Carroll, J.P.; Finnan, J. Economic Analysis of Manufacturing Costs of Pellet Production in the Republic of Ireland Using Non-Woody Biomass. Open Renew. Energy J. 2010, 3, 1–11. [Google Scholar] [CrossRef]

- Bejbl, J.; Bemš, J.; Králík, T.; Starý, O.; Vastl, J. New approach to brown coal pricing using internal rate of return methodology. Appl. Energy 2014, 133, 289–297. [Google Scholar] [CrossRef]

- ICE Europe—Rotterdam Coal Futures—ARA—baha.com. Available online: https://www.baha.com/quickbar/ice-europe-futures/rotterdam-ara?ts=1669450652887 (accessed on 26 November 2022).

- EU-ETS Carbon Pricing 2022|Statista. Available online: https://www.statista.com/statistics/1322214/carbon-prices-european-union-emission-trading-scheme/ (accessed on 26 November 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).