1. Introduction

New regulations concerning the introduction of new ecological energy sources to the market are in line with the European Union (EU) policy, the Green Deal, on combating climate change. Consequently, the automotive industry is also seeking and placing emphasis on the development of electromobility (e-mobility) and the associated charging infrastructure. The new regulations proposal, setting the target of at least 55% net emission reduction by 2030 [

1], forces European countries to reduce emissions in the transport sector, which is responsible for 21.76% of CO

2 pollution in relation to other economic sectors worldwide [

2]. This means that increased the production and development of electric vehicles (EVs) is inevitable, and European cities will enjoy less air pollution and improved living comfort.

The increase in the number of vehicles brings many benefits to society, as described in Noel et al. [

3,

4], most notably reducing CO

2 [

5] and particulate matter (PM10) emissions [

6] and lowering exploitation costs, but it will also create new challenges for the transmission and distribution system operator [

7,

8]. The increase in electricity demand is an integral part of the transformation of the transport sector. Furthermore, vehicles, whose charging process has been described by various authors [

9,

10,

11,

12], have a significant impact on momentary changes in the power distribution in the system. The issue is well-known and has been described quite extensively [

13,

14]. Simulation results were published by Chen et al. [

15] which indicate an increase in the energy demand by 3% in the local power grid after the installation of 60 charging stations for electric buses. Other articles indicate a projected increase in energy consumption within the distribution network [

16].

Accordingly, reasonable solutions are being considered to eliminate the messy side effects of vehicle charging [

17]. Mechanisms that are currently being developed in the energy market are system services, such as peak load shaving, load management and line loss reduction. These services and implementations have been the subject of research for many years, and a description and example application of a peak shaving service for system needs has been described previously [

15,

18,

19,

20]. An example of the application of this service in Shanghai—China being a rapidly developing e-mobility country—has been given by Li et. al. [

21]. Other articles [

22,

23] also describe the possibility of intelligent load management using the regulation capabilities of EVs. Chung et al. [

24] also applied modern methods of data analysis based on machine learning, allowing for optimal energy management based on algorithms that predict the behaviour of EV users. The occurrence of power losses, which are an undesirable phenomenon and one that could be eliminated by using the energy resources of EVs, has also been described [

25,

26]. Moreover, additional system functions for fleets of EVs are also indicated, and have been described in reference materials: spinning reserve [

27,

28], stabilizing grid voltage [

29,

30] and frequency control [

31,

32,

33,

34].

Rapid changes in EU legislation enforcing reductions of all kinds of emissions and increasing energy consumption in both the industrial and private sectors are driving the energy transition [

35,

36,

37]. A transformation has started with the development of renewable energy sources, the introduction of energy-efficient appliances [

38,

39,

40], and the storage of heat and electricity. In this context, we are increasingly talking about the coupling of energy sectors allowing for greater flexibility in energy supply, load and storage. The principle of this energy sector coupling has been described in detail [

41,

42] and critically [

43]. Development results in the implementation of new technologies, such as 5G-V2X [

44,

45,

46] and machine learning [

47] for e-mobility. In the case of the latter, this transformation is taking place at the fastest rate due, among other aspects, to the falling prices of batteries for EVs. Battery prices have fallen by 89%, from a global average of 1200

$ US per kWh in 2010 to 132

$ US per kWh in 2021 [

48]. This has started a trend toward EV fleets dedicated to public transport. Berlin, Germany, for example, ordered 122 e-buses in 2020. Hamburg ordered 583 e-buses, which will be delivered by 2025. Paris, France, has ordered 4500 new e-buses, which will also be delivered by 2025 [

48]. In addition, battery-as-a-service technology has been strongly developed in recent years [

49,

50,

51]. The leading manufacturer is NIO from China, which has set up 700 battery replacement facilities since 2000. A report [

48] states that this action reduces the price of a vehicle by 10,000

$ US.

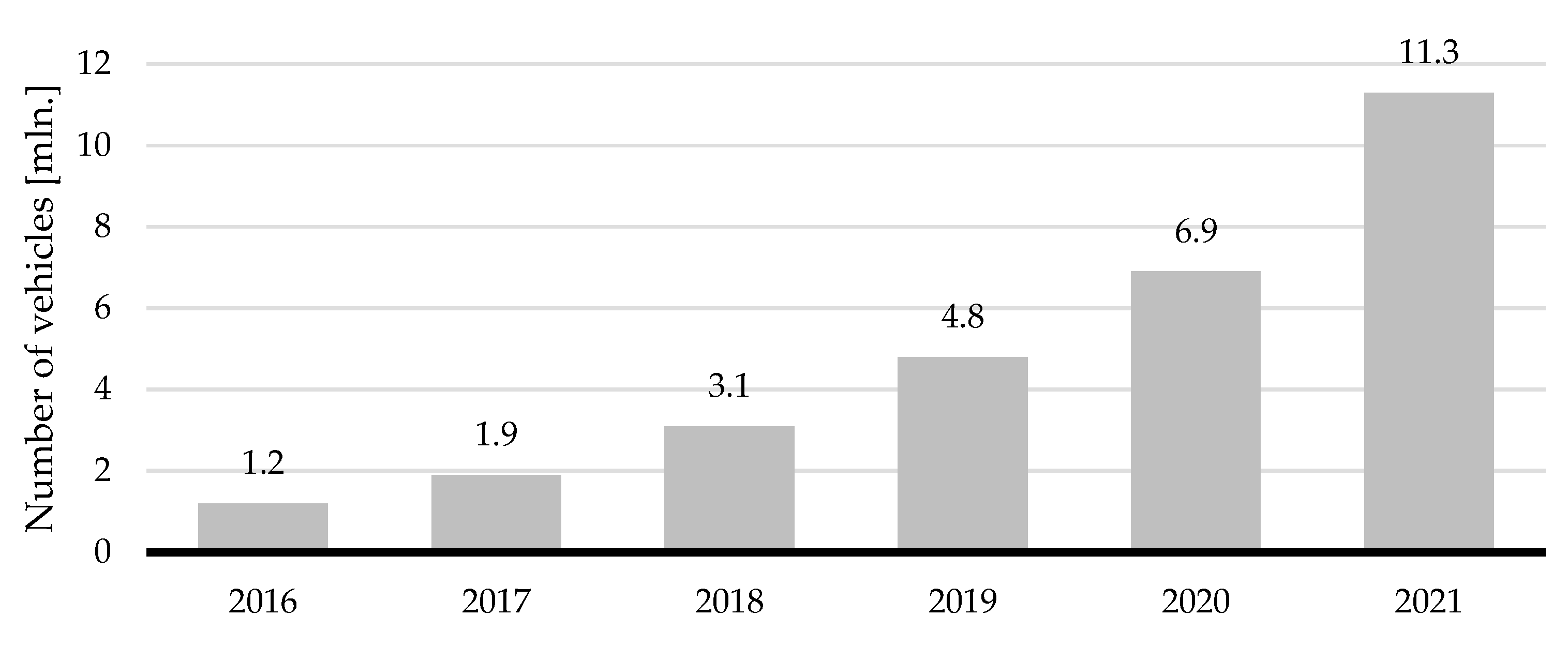

Transport and especially the developing infrastructure of EVs is gaining importance during the energy transition and the merging of energy sectors. Based on the 2021 IEA report [

52], it can be observed that there are already more than 10 million vehicles with electric propulsion systems in circulation worldwide, of which 1.5 million are in the EU.

There is also a sharp increase in the number of new EVs due to the tightening of climate policy.

Figure 1 shows the change in the number of vehicles worldwide over the past six years.

The development of e-mobility is strictly dependent on the level of CO

2 emissions into the atmosphere, and two possible development scenarios have been adopted by the EU: the Stated Policies Scenario and the Sustainable Development Scenario [

52]. Each of them defines the percentage growth of vehicles and charging points until 2030. This growth is related to the replacement of traditional vehicles used by individual users or vehicle fleets of companies and enterprises. There were 14,033 electric, light commercial vehicles in Germany in 2021, making it the second highest in Europe in terms of the use of EVs in the commercial sector [

48]. A higher exploitation of the vehicles’ potential occurs in the United Kingdom, Korea and China. This growth is associated with the need to expand the existing charging infrastructure, which is integral to the transformation of this sector. This entails a number of changes, including the need to upgrade supply lines, replace medium- and low-voltage transformers, and expand substations and distribution systems. These changes will be most visible in the networks of companies with significant vehicle fleets, which will be transformed into electric fleets in the near future. This process will mainly affect the load on the network and the costs associated with vehicle modernization. The changes on the part of the distribution network operator and the need to modernize its networks are not relevant for companies. However, the changes resulting from the need to convert the fleet into EVs involves certain investments that the company has to consider and budget for. This process is often time-consuming.

According to one source [

54], the number of light commercial vehicles registered in Germany is increasing steadily. Globally, 26.29 million light-duty vehicles (LDVs) and 56.4 million passenger vehicles were sold in 2021 [

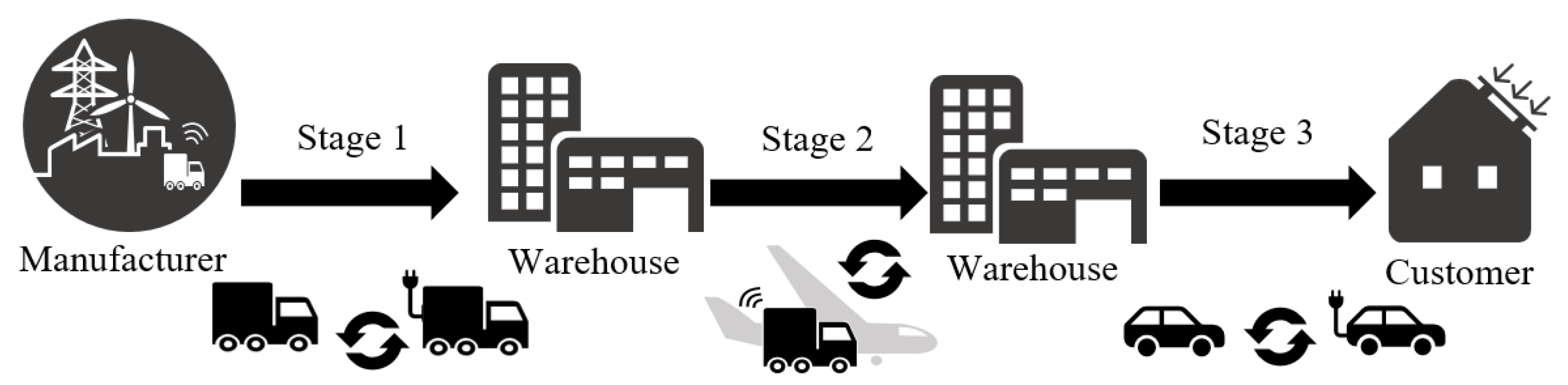

55]. Commercial vehicles account for about 30% of vehicles sold. The most common use of commercial vehicles is in the supply chain, as shown in

Figure 2. The product produced by the manufacturer is initially transported to the sorting facility/warehouse, where it is then transported to the warehouse covering the area for the distribution of goods to the customer. We can now see the electrification of vehicles at stage 3. Companies such as Amazon and DHL Post are already using EVs within cities to deliver ordered products. Stage 1 and 2 electrification is less common and poses a lot more challenges, but it is also feasible. The electrification of the transport sector is the subject of an analysis described previously [

56].

The multi-criteria evaluation indicates the benefits of the planned and undertaken measures. In this case, the assessment helps to confirm the benefits of the concurrent development of renewable energy sources as the primary power source for electric vehicles. While electric vehicles are currently popular in the private sector, their further development in other parts of the economy is also advisable. In most scientific works, a multi-criteria assessment is made in relation to the power grid [

58,

59,

60] and the impact of vehicles on the grid, its parameters and system operations. In this case, the work is focused on analyzing the benefits of operating two different types of vehicles for the company, rather than the power grid. The work is intended to encourage companies to change their company model to one that is more beneficial to the environment with minimal investment. The price ratio of raw materials and electricity plays a large role in the decision-making process and also forces not only electric vehicle manufacturers but also internal combustion vehicle manufacturers to take measures to improve efficiency and effectiveness and to reduce the harmful emissions of conventional vehicles, which improves the competitiveness of the automotive market.

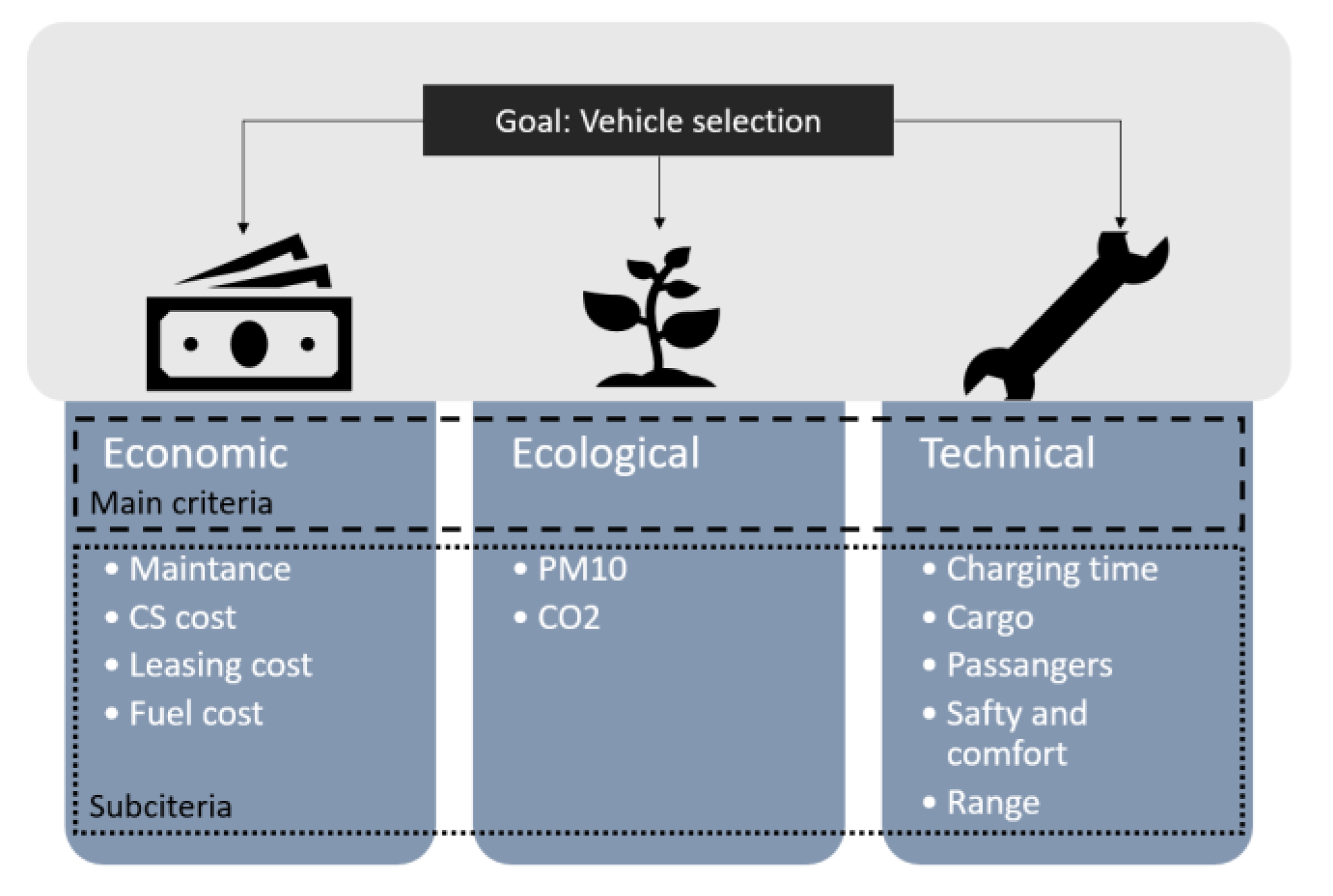

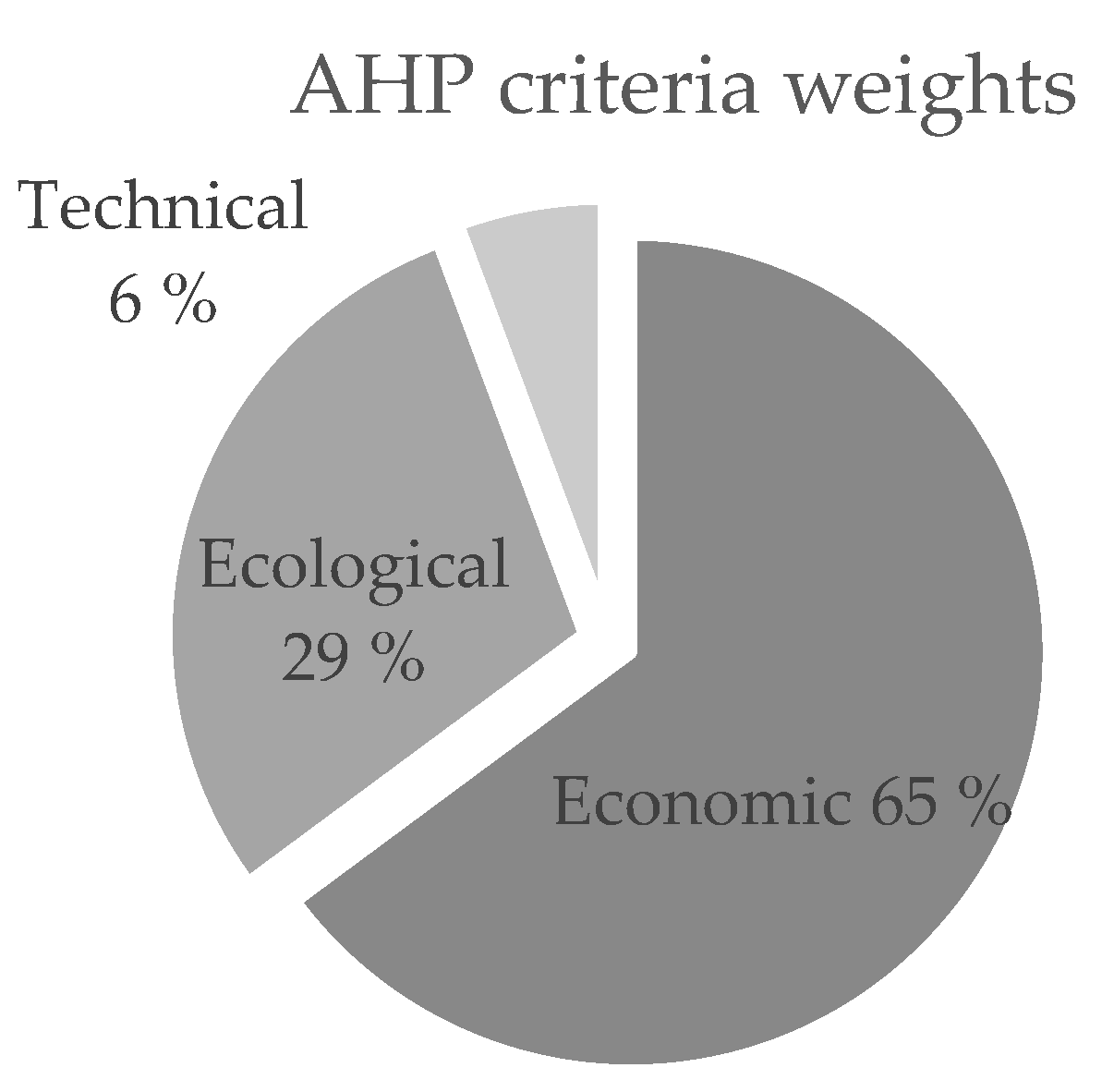

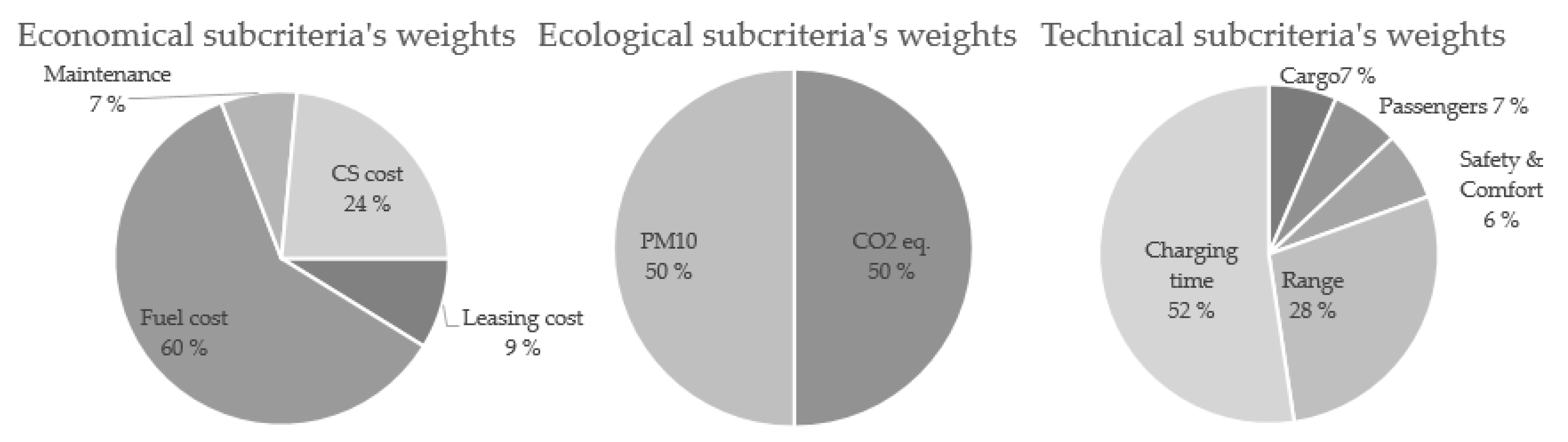

Therefore, this paper presents a model to compare the costs associated with the use of a fleet of combustion vehicles and a corresponding fleet of EVs. The cost associated with the use of vehicles of both types was determined. Based on the analytic hierarchy process (AHP) algorithm, the potential best solution for the company was determined based on three categories (economic, technical and ecological). The AHP method has been used, among other methods, for the dimensioning of microgrid components and has been described previously [

61,

62]. This description includes analyses based on real statistical and measurement data obtained as part of a realized research project. The economic situation influences the choice of the optimal vehicle significantly. The objective of this study is to examine the impact of changes in electricity and fuel prices on the purchase of a vehicle. In addition, a minimization analysis of the vehicle fleet and the number of charging stations for EVs was carried out based on global positioning system (GPS) measurement data. The aim is to present an algorithm to support the decision-making process that will accompany all enterprises during the transformation of the energy sector.

Section 2 describes the methods used including a description of the AHP algorithm employed, the GPS measurement data used and background information on the vehicle fleet adopted. The limitations and assumptions for the simulation carried out are also listed.

Section 3 presents the results of the analyses and simulations carried out. A comparison of the costs associated with the use of two types of vehicles is presented in

Section 4, and the costs that companies have to incur when replacing their vehicle fleet are determined. Conclusions are presented in

Section 5 based on the analyses carried out and the cost-effectiveness limit is indicated.

4. A Case Study

An exemplary techno-economic analysis was carried out using data provided by a commercial transport company. Measurement data, including real fuel consumption, operating costs and GPS data, were recorded for a fleet of 60 internal combustion LDVs. This data was used, in part, to develop the TCO analyses presented earlier and create profiles, i.e., the routes that the vehicle had to travel per day. An example route is shown in

Figure 13.

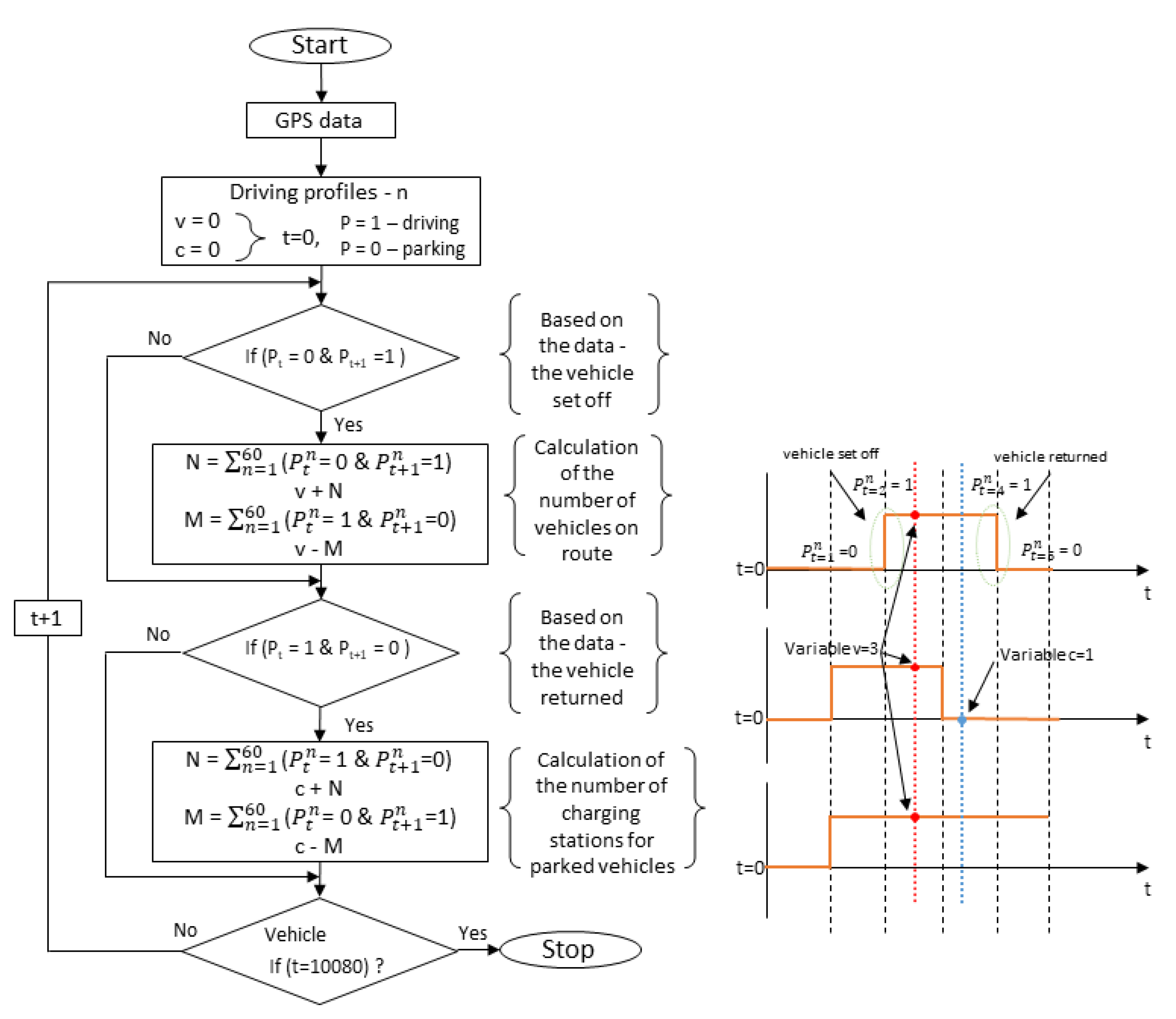

By having routes for 60 vehicles, it is possible to check whether the routes carried out by the fleet can be carried out by a smaller number of vehicles. Accordingly, a concept has been implemented to optimize the required minimum number of vehicles and charging stations that are able to fulfil the requirements defined by the daily profiles of the vehicles. The principle of the algorithm is shown in

Figure 14. The results of the algorithm are two values representing the number of vehicles that are on the road at the same time and the number of charging stations that would be sufficient to charge vehicles between routes. The algorithm checks whether the vehicle is on route or parked on company premises for each measurement point. The criterion that must be met is that all routes are completed within the designated intervals according to the profiles recorded.

Based on the analysis of 60 profiles, the algorithm reduced the original number of vehicles to 38. In a lot of cases, companies may have a certain number of replacement vehicles, which is not taken into account in this case. The result of 38 also corresponds to the installation of 38 charging stations, assuming that each vehicle is connected to the grid at night. Taking into account the technical and economic analysis carried out, the cost of using both the traditional fleet of ICEVs and EVs was determined. The results are shown in

Table 23.

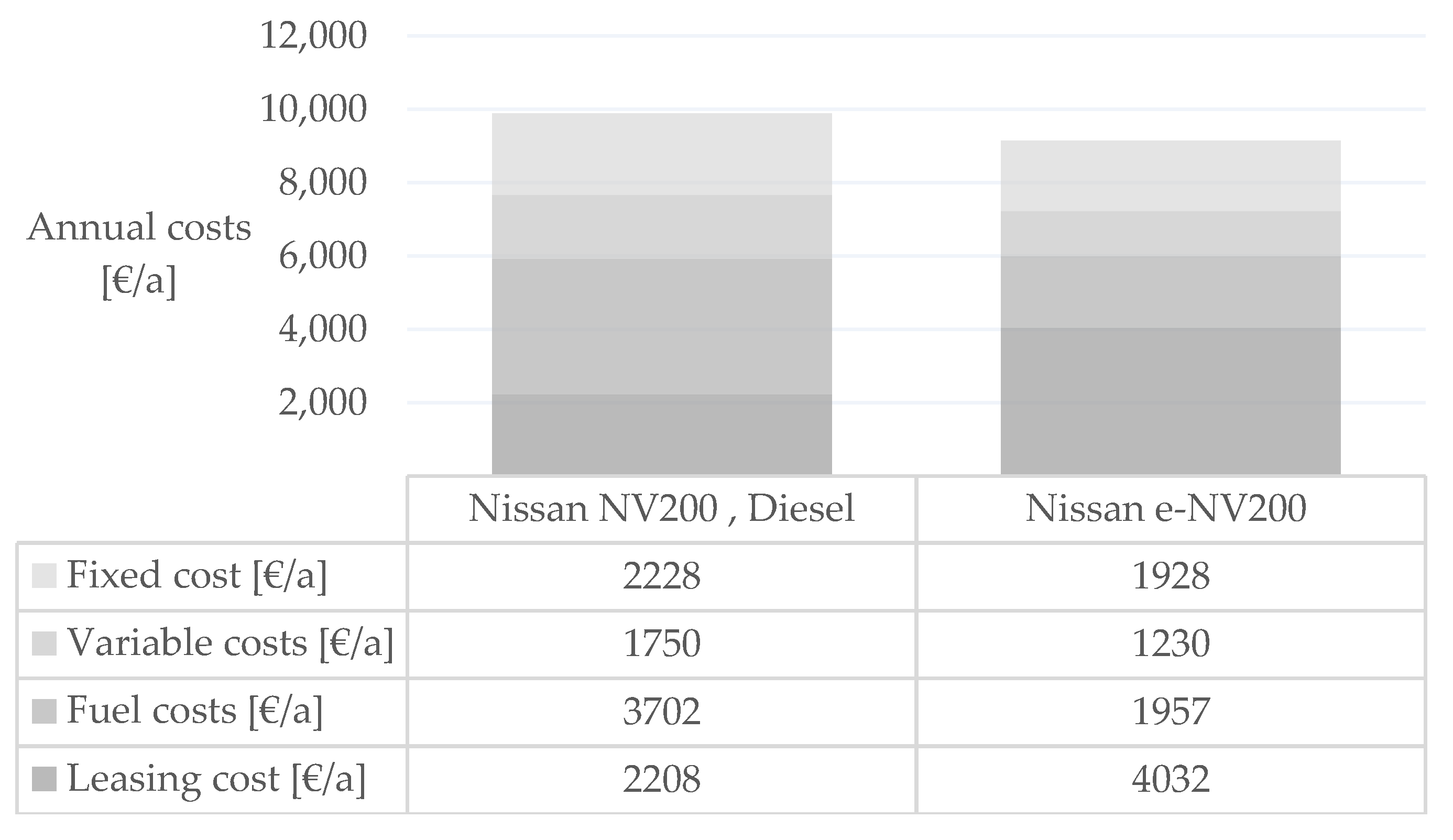

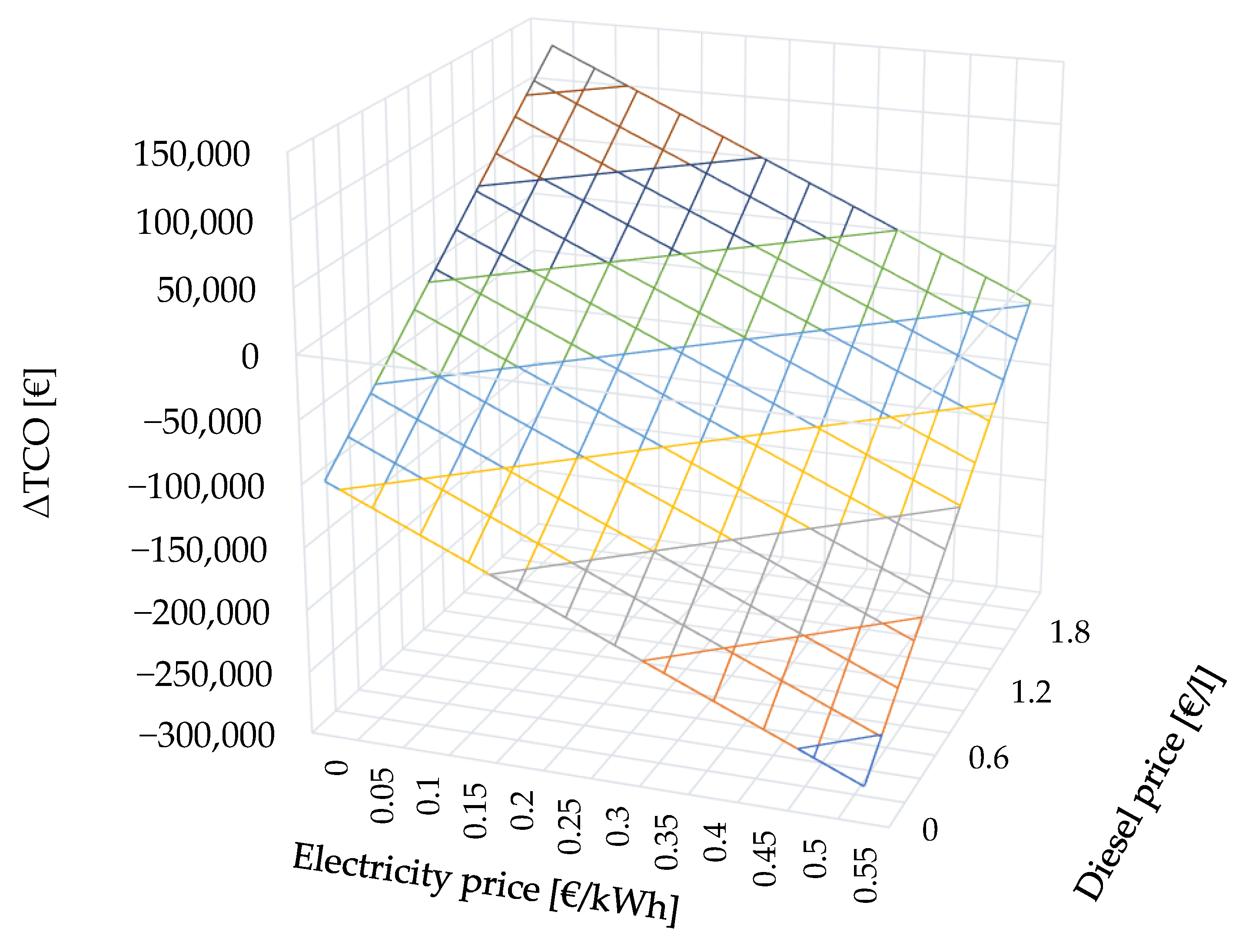

It can be seen that the fleet cost is higher for a fleet of EVs. The biggest impact here is the installation of the charging infrastructure, which is necessary for the proper operation of the BEV fleet. This is, nevertheless, a one-off cost, occurring at the beginning of the investment. As shown in the earlier analysis, costs for the electric fleet decrease over time within a few years of the investment. In addition, a fuel price can be determined for the fleet at which an EV becomes economically preferable. The objective function in this case will take the form ∆TCO ≥ 0.

Based on the economic analysis carried out, values were determined for the price of diesel and electricity at which the so-called breakpoint occurs and the use of an EV fleet is profitable. The price of electricity for commercial companies was 21.38 ct/kWh on 1 April 2021 [

92]. The price of 1.6 €/L for diesel makes it more cost-effective to use a fleet of EVs. The average diesel price from 1 January to 19 July 2022 was 200.52 ct/L. However, the price of electricity has not remained the same and is now 26.64 ct/kWh for commercial companies [

92]. Regarding this price distribution, it is clearly more advantageous to use a fleet of electric vehicles. In this case, the purchase of energy in its entirety from the distributor was considered without taking into account the possibility of reducing energy prices through additional energy storage or renewable sources. The distribution of cost-effectiveness relationships is shown in

Figure 15.

5. Conclusions

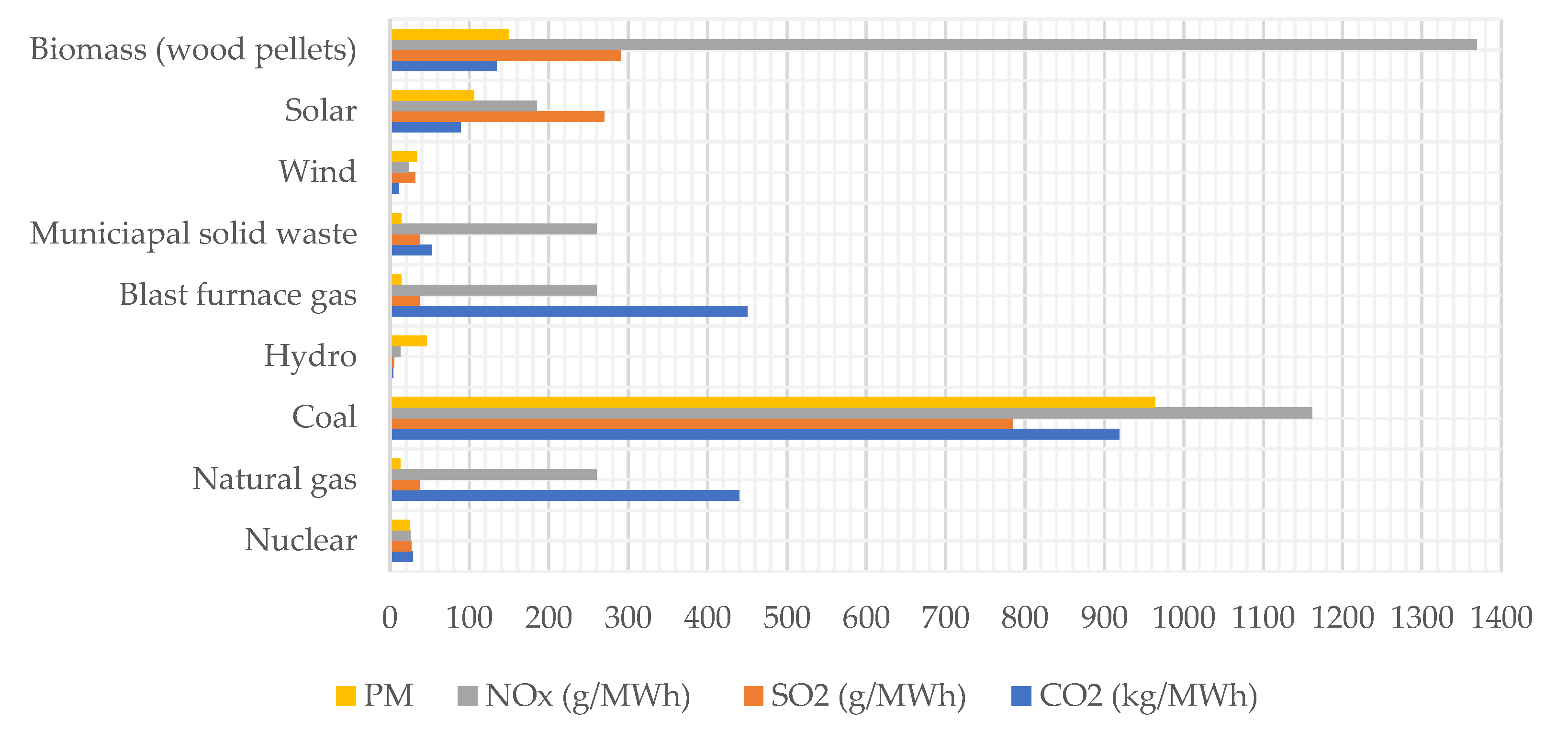

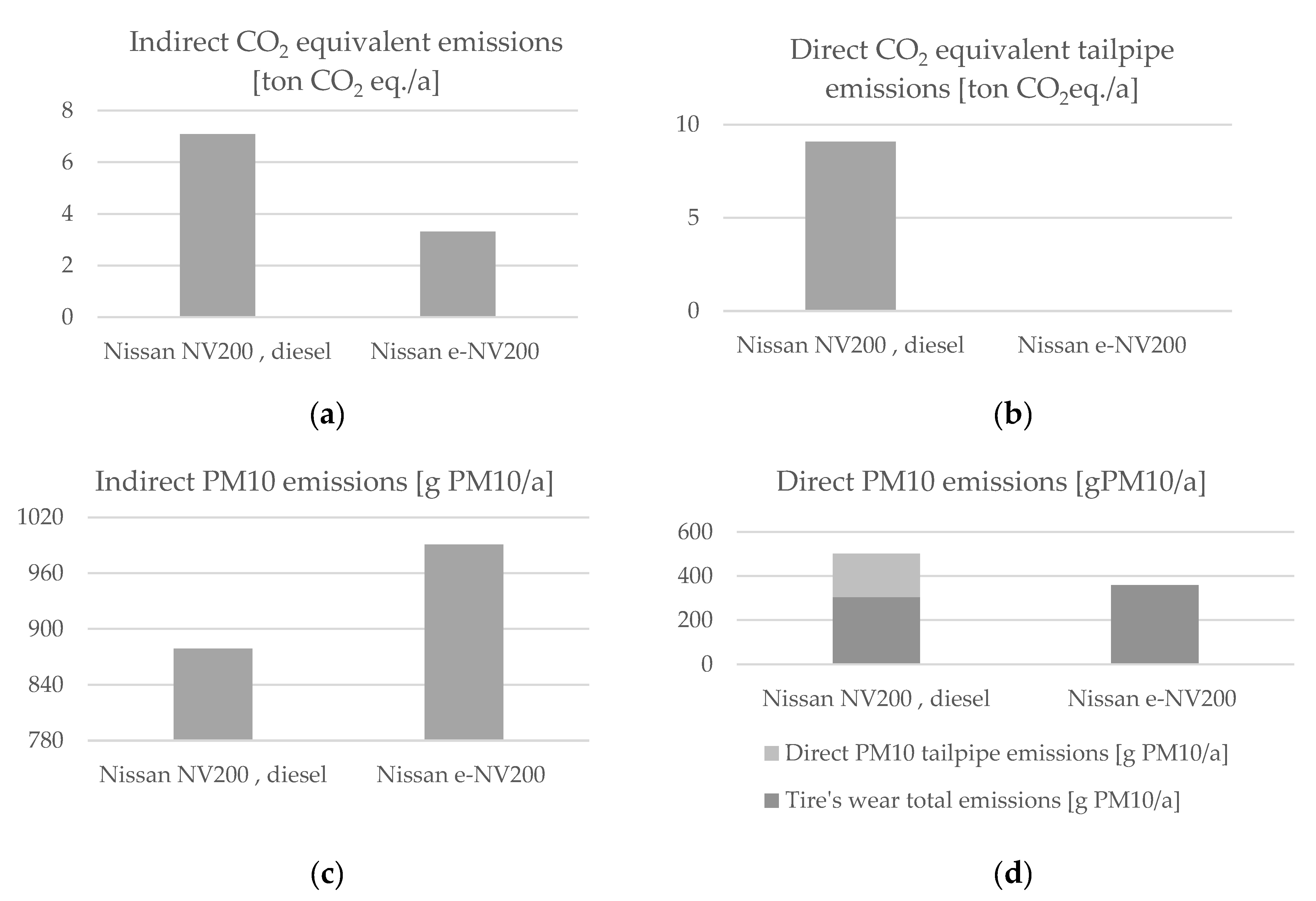

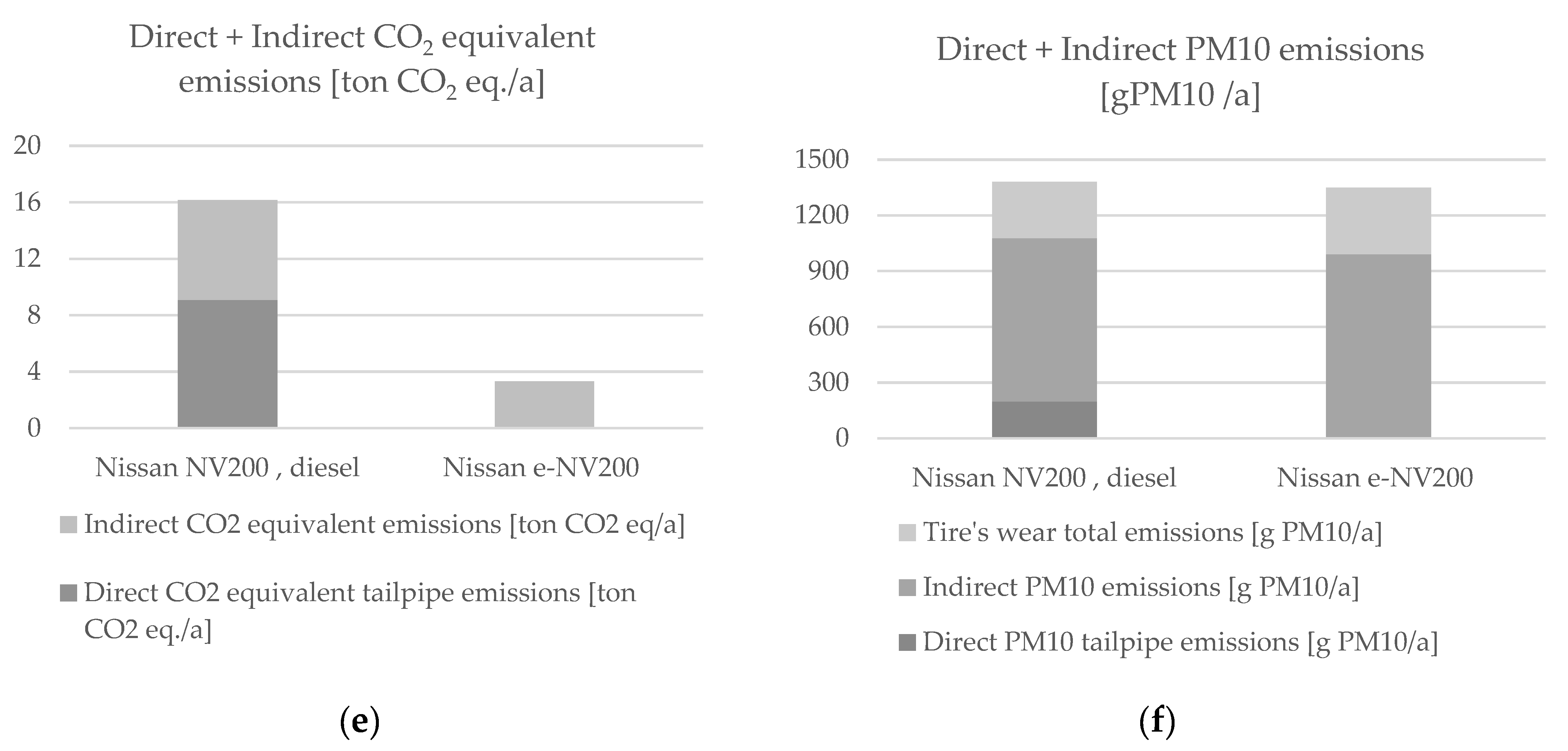

This paper analyses the technical, environmental and economic transformation of a vehicle fleet to reduce atmospheric emissions. Following on from the considerations, assumptions and assessments already discussed, an electric powertrain is suitable for a commercial LDV fleet. However, the EV fleet is a more expensive option and also includes the design and construction of the charging infrastructure; this can be assessed as a disadvantage of the BEV fleet. Moreover, environmentally, the electric LDV fleet results in a considerable reduction (up to 80%) in GHG emissions and a small reduction in PM10 emissions. The PM10 emissions are strongly linked to the national energy mix. CO2 equivalent emissions are reduced by almost 80%, with major environmental benefits. These values are closely linked to the mix of electricity sources, meaning that if the company were to build its power plant using renewable energy, the emissions associated with its energy production would be zero.

The work presents the conclusions of the analysis on the basis of data, available and reliable from studies, reports and own recorded values. The work is aimed at businesses as an argument for the use of electric vehicles to carry out logistics tasks. For policymakers, it is an argument that the introduced restrictions make sense and the emissions of harmful substances into the atmosphere are gradually reduced. The introduction of other methods that use measurement data can contribute to more precise results that would describe the process more accurately. Nevertheless, the methods presented in this work can be easily implemented in any company and indicate theoretical and practical savings for the company.

Following the results of the analysis, a hierarchy was proposed between the three criteria analyzed. This hierarchy helps to determine, depending on the needs of the company, which technology reflects their needs. The development of an AHP calculated a score for each alternative, resulting in a higher score for the EV fleet. Considering the increasing importance of the environmental factor, the EV fleet achieves a higher final score. The hypothesis made earlier regarding the hierarchy of the criteria justifies this result: the economic criterion has a higher weighting than the other criteria and, consequently, the sub-criteria.

The BEV fleet fully meets the characteristics required by the vehicle usage profile. The TCO of the electric fleet is higher than that of the conventional fleet due to the infrastructure costs of the charging stations. These costs are spread over a period of five years, after which only the maintenance of the charging stations is taken into account. Once the investment in charging stations has been recouped, the TCO of the electric fleet is lower than that of the conventional fleet.

The company obtains advantages both in terms of economic benefits, special permits for circulation and for the image of company. Employing a fleet of electric LDVs for a logistics company operating in the publishing industry to make and receive deliveries that cover 30,000 km per year has been shown to be an environmentally, economically and technologically beneficial option.

The proposed solution can provide a basis for practical analysis on the basis of real data for other car models and their assessment of compliance with the requirements of new regulations and directives on environmental protection and reduction of harmful emissions. In addition, it can give a basis for preparing a product in the form of an application for commercial use and offering services to enterprises. Eventually, it can also form part of an audit for some specialized companies.

The model is based on values that are included in the lease contract for which prices remain unchanged for the length of the lease. In contrast, the analysis carried out depends heavily on prices, such as fuel and electricity prices, which cannot be considered relatively stable in 2022. It is difficult to predict the behavior of resources prices in the energy market. A possible solution to this problem is to dynamically integrate price volatility into the model. In addition, the model will work more correctly and provide more accurate results if the human factor, i.e., the driver’s driving style and weather conditions, are taken into account. It is advisable to use instantaneous values in the model and to take into account the unit prices of the equipment for the time period considered. The inclusion of random factors, e.g., the failure of a particular vehicle and therefore the inability of the vehicle to meet its targets, is an appropriate implementation to improve the performance of the algorithm. Increasing the frequency of measurement samples recorded during vehicle operation is also a beneficial factor in the results obtained. The model is valid when the input data are updated for a given time period. Further work will focus on increasing the number of parameters affecting vehicle costs and performance.