Methods and Test Benches for Cutting Tools Testing—A Review

Abstract

:1. Introduction

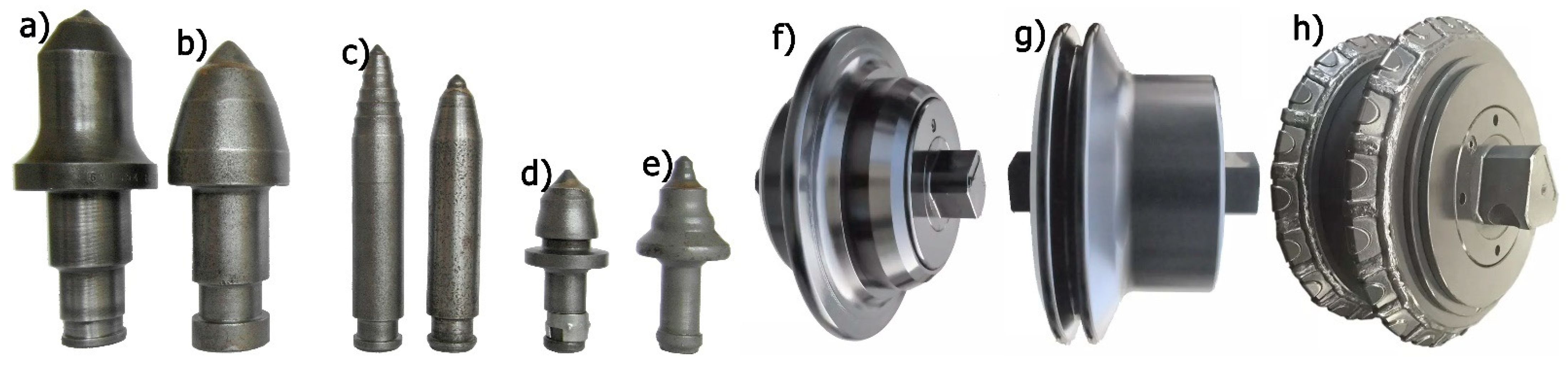

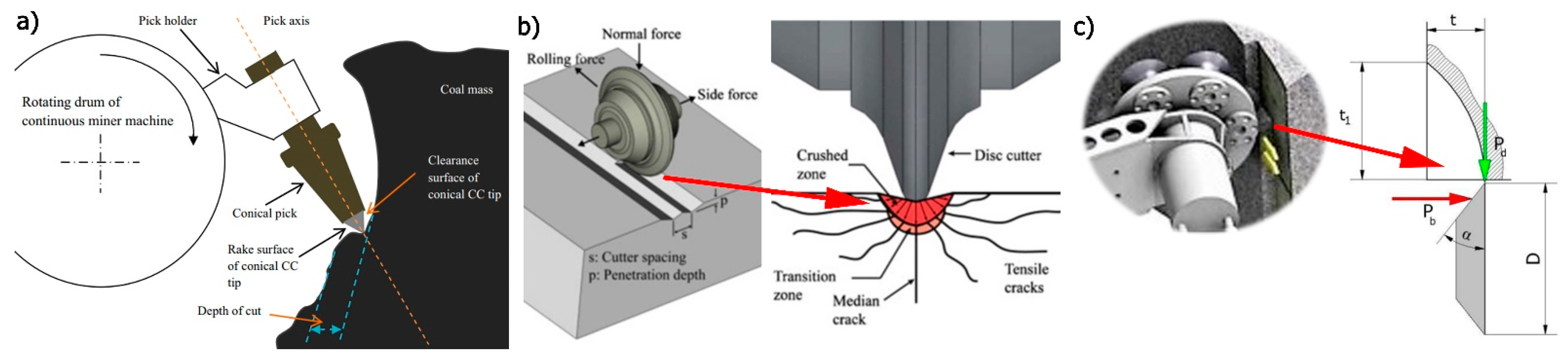

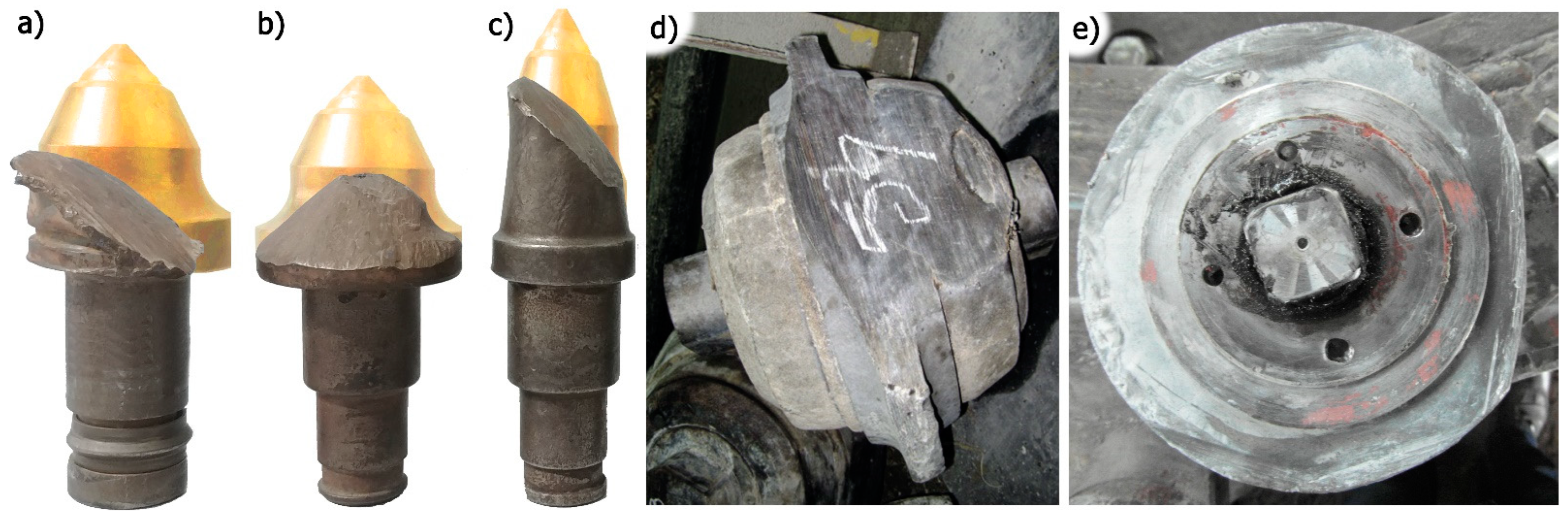

2. Mechanical Mining of Rocks

3. Methods and Test Benches

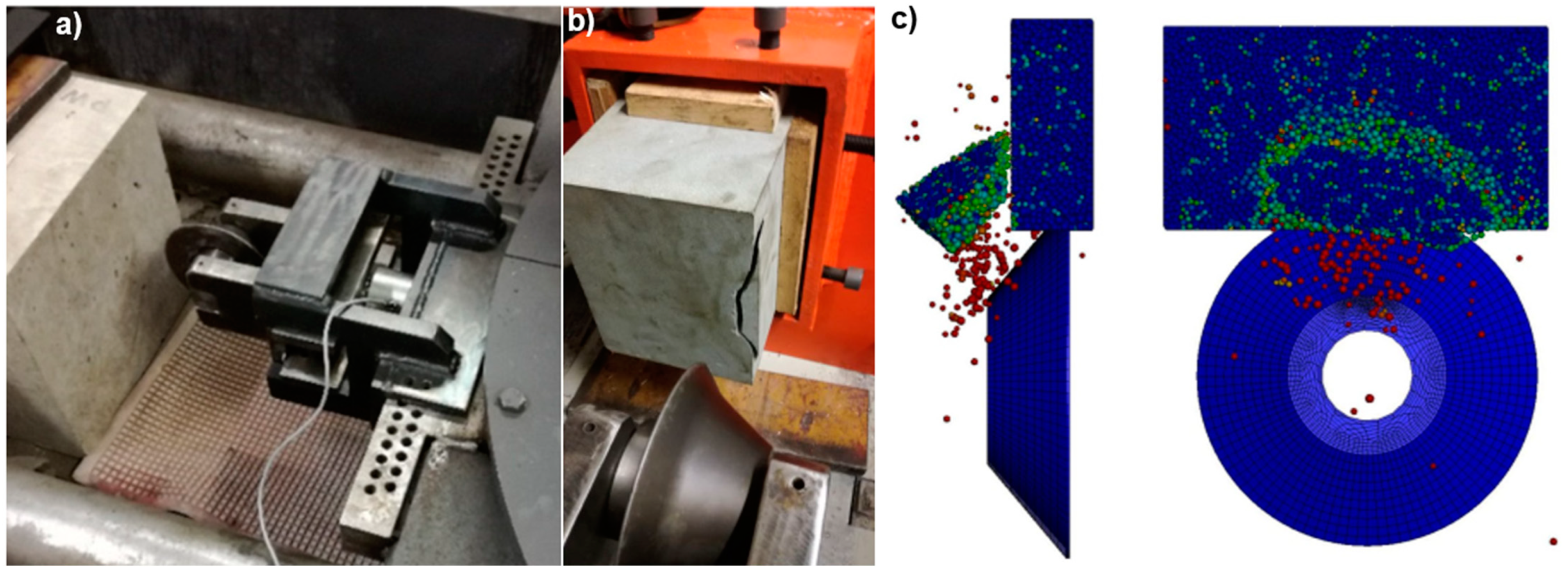

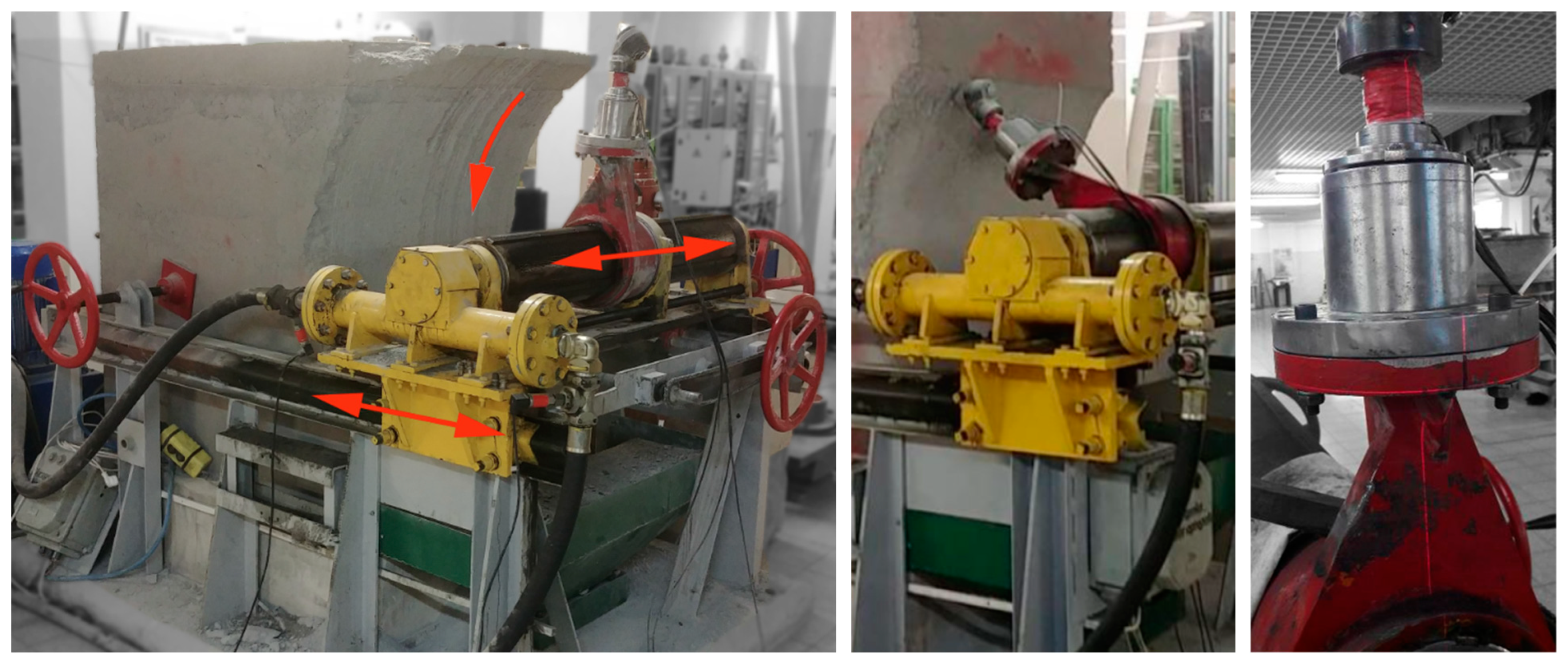

3.1. Benches for Testing the Process of Rock Destruction

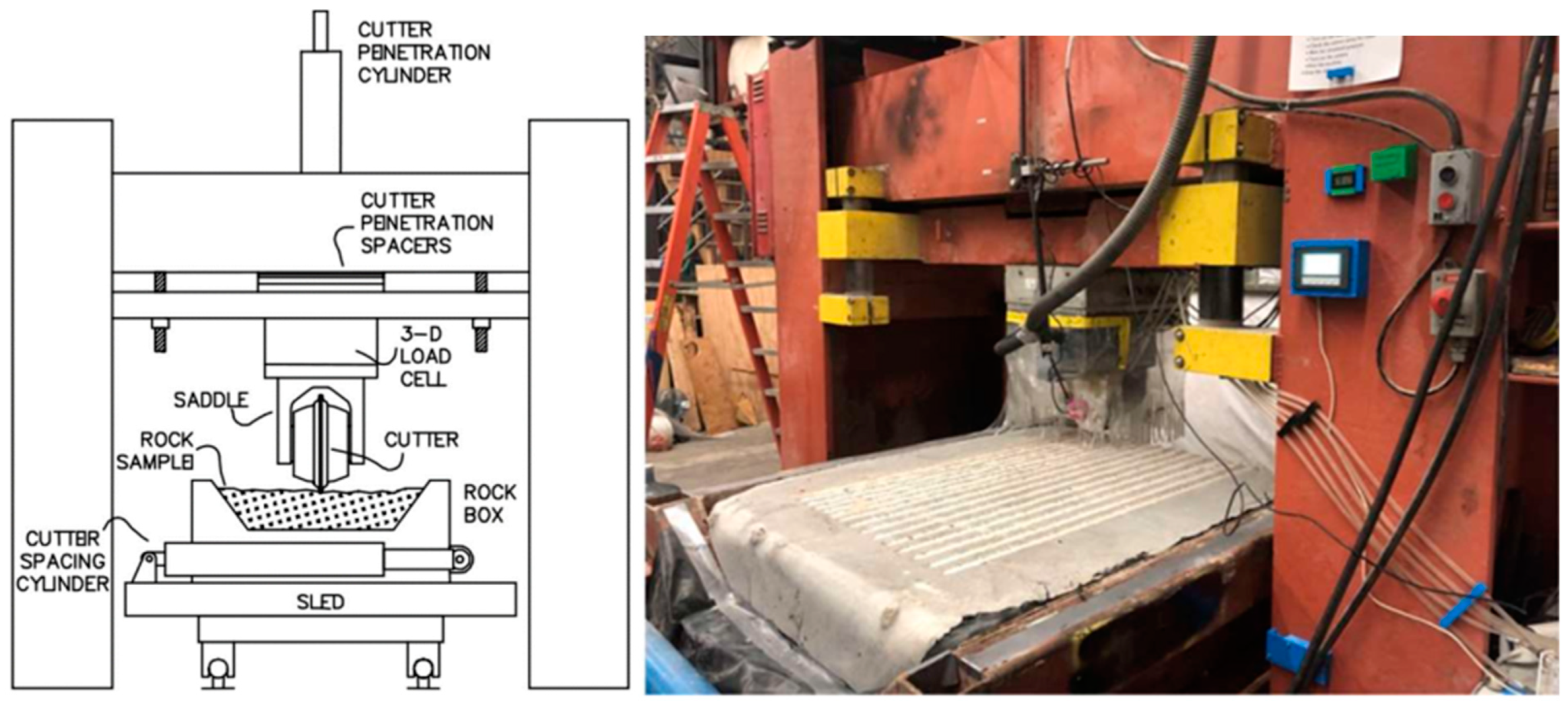

3.2. LCM (Linear-Cutting Machines) Test Benches

- Laboratory and numerical tests of the pick cutting process as a function of various process parameters [15],

- Laboratory and numerical tests of generated stresses and temperature during cutting [42],

- Investigations into the mining process in terms of the mining machine selection [43],

- Efficiency of granite mining with discs [44],

- Comparison of the efficiency of disc mining methods [45],

- Research on the impact of selected process parameters on the tangential force [46],

- Investigations into the impact of the mined rock’s strength on the cutting resistance [47],

- Investigations into the influence of the depth of cutting with discs on the normal force [48],

- Comparison of the results of laboratory tests and the theoretical model for calculating the cutting forces in terms of the stiffness of the LCM bench frame [49],

- Determination of the cutting process parameters with the greatest influence on the generated forces [50],

- Comparison of the theoretical model and the results of cutting resistance tests [51],

- Determination of the optimal cutting pitch when cutting with discs [52],

- Comparison of sandstone cutting resistance from laboratory tests and from the TBM machine [53],

- Testing of undercutting with discs for the needs of a narrow machine for vein deposits [54],

- Comparison of the results of investigations into pick cutting carried out on the LCM test bench with the results of tests conducted at a stand equipped with a rotary head (described in the next subsection) [55],

- Laboratory and numerical tests of the influence of selected parameters on the efficiency of the cutting process [56],

- Evaluation of the effectiveness of the use of picks coated in the SMART*CUT technology [57].

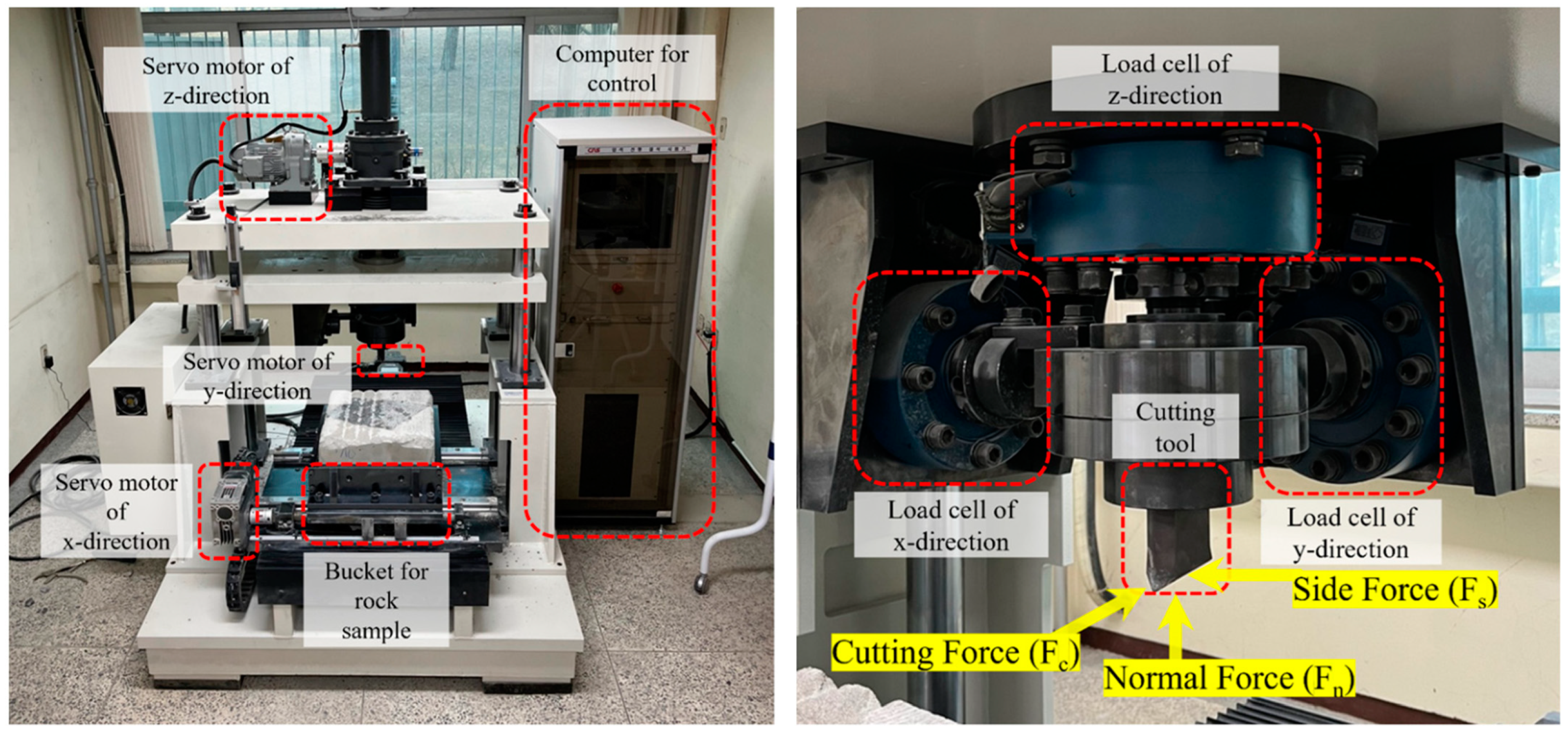

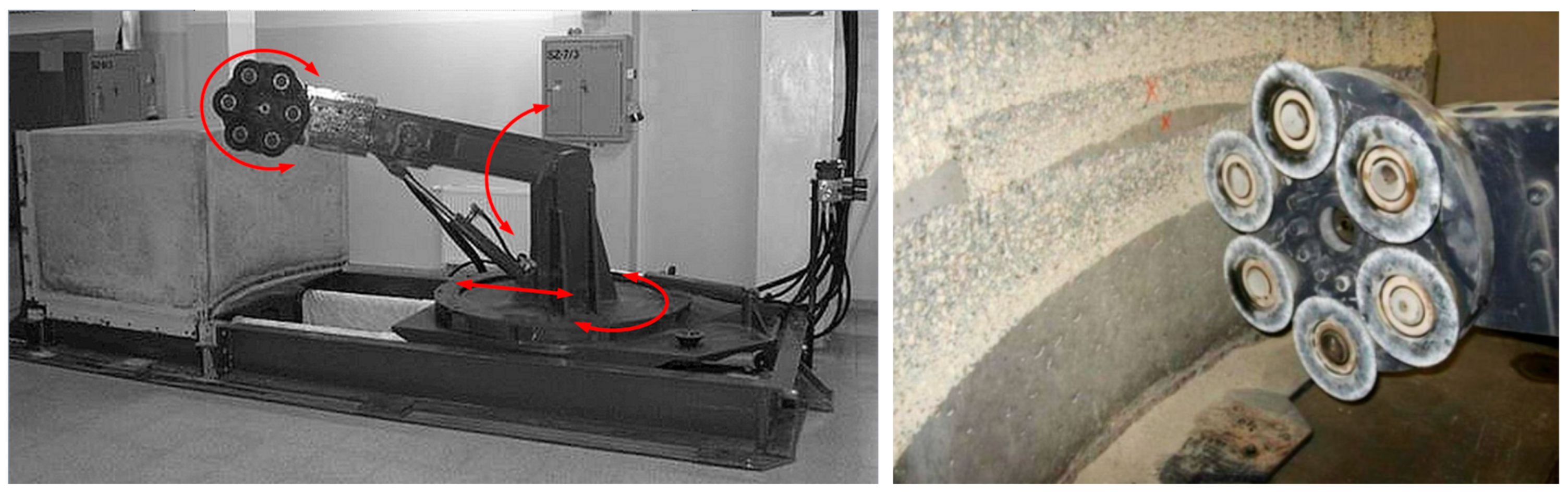

3.3. Revolving Cutting Test Benches

- Research on the impact of the strength of a sample subjected to cutting and of the cutting process parameters, such as the depth of the cut or the blade diameter, on the cutting forces [64],

- Investigations into the influence of the arrangement and pitch between the picks mounted on the head on the grain size of the output [65],

- Studies on the impact of the form and degree of wear of the conical pick on the cutting resistance [66],

- Research on the influence of the longitudinal geometry of the cutting head of a road header on the torque and normal force of the head [67].

- Testing of the quality of picks in order to select the optimal offer [70],

- Testing of new materials and coatings for conical picks [69],

- Research on grain size and dustiness,

- Investigations into the impact of process parameters on the cutting resistance,

- Research on the impact of the cutter head design on the cutting resistance and power demand.

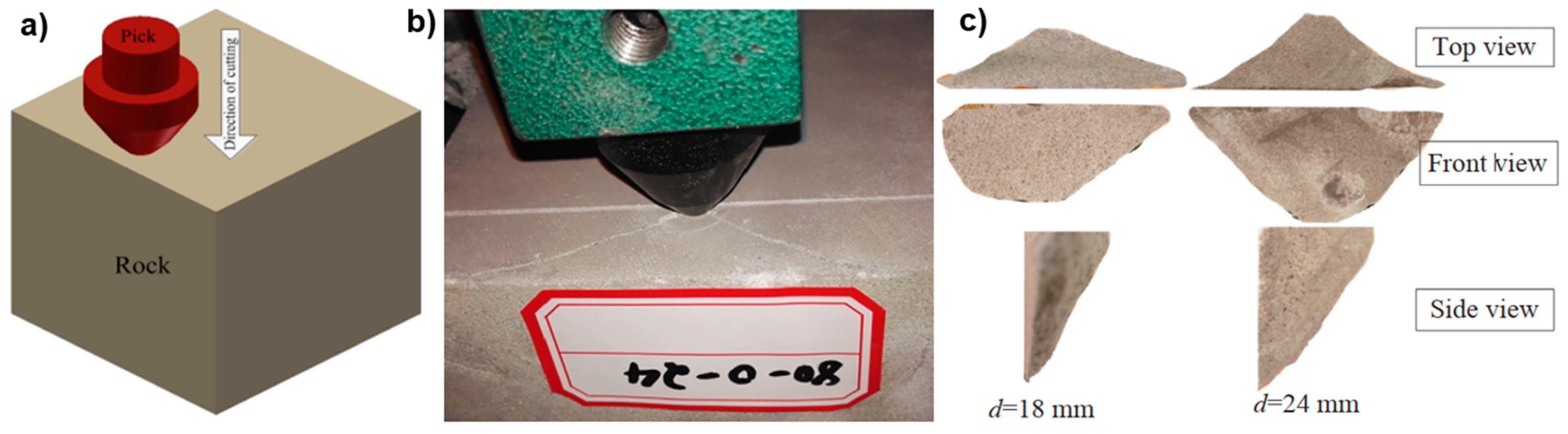

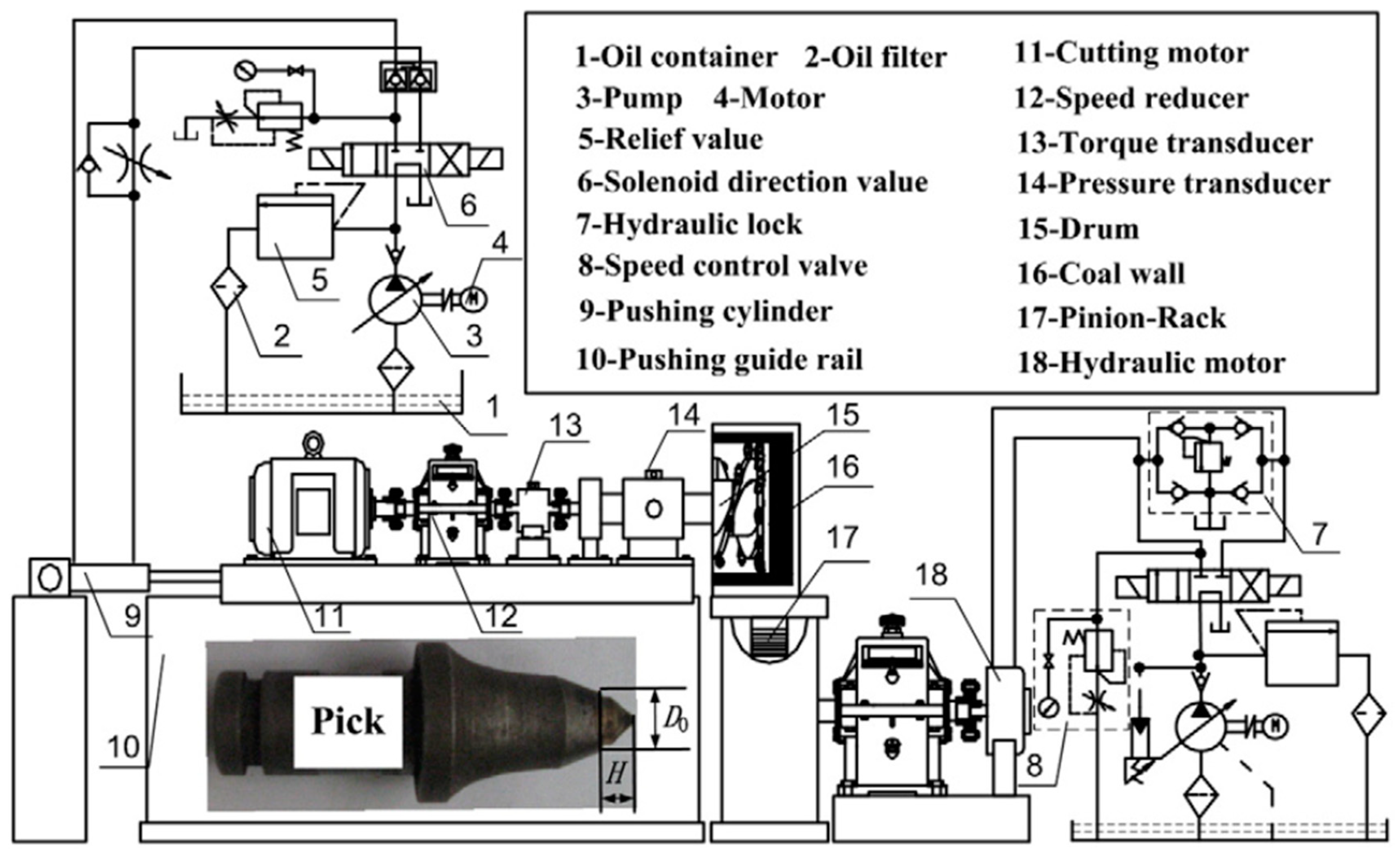

3.4. Other Test Stands

4. Conclusions

5. Future Directions

- Testing of finished tools in laboratory conditions,

- Testing of ready tools in real conditions,

- Testing of wear rate by mechanical engineering methods.

- Testing of many solutions, various samples on the proposed test bench, ended with the selection of the several best solutions that will be used to produce mining tools. During these tests, cutting resistance is irrelevant.

- Testing of ready-made tools on a laboratory stand ended with the selection of the best solution. During these tests, cutting resistance should be checked in addition to wear rate.

- Testing of a selected solution of a mining tool in real conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Krauze, K.; Bołoz, Ł.; Wydro, T. Mechanized Shaft Sinking System. Arch. Min. Sci. 2018, 63, 891–902. [Google Scholar] [CrossRef]

- Bołoz, Ł. Interpretation of the Results of Mechanical Rock Properties Testing with Respect to Mining Methods. AMS 2020, 25, 81–93. [Google Scholar] [CrossRef]

- Kotwica, K. Asymmetrical Mini Disk Tools—Possibilities of Use and Directions for Further Development. New Trends Prod. Eng. 2019, 2, 223–232. [Google Scholar] [CrossRef] [Green Version]

- Krzysztof, K.; Piotr, M. Methods of Mechanical Mining of Compact-Rock—A Comparison of Efficiency and Energy Consumption. Energies 2019, 12, 3562. [Google Scholar] [CrossRef] [Green Version]

- Biały, W.; Fries, J.; Galecki, G. Determination of Coal Cutting Forces Using the Cutting Head of POU-BW/01-WAP Device. Multidiscip. Asp. Prod. Eng. 2021, 4, 281–289. [Google Scholar] [CrossRef]

- Biały, W. Determination of Workloads in Cutting Head of Longwall Tumble Heading Machine. Manag. Syst. Prod. Eng. 2016, 21, 45–54. [Google Scholar] [CrossRef]

- Bołoz, Ł.; Krauze, K. Ability to Mill Rocks in Open-Pit Mining. In Proceedings of the 18th International Multidisciplinary Scientific GeoConference SGEM 2018, Albena, Bulgaria, 20 June 2018. [Google Scholar]

- Bołoz, Ł.; Krauze, K.; Kubín, T. Mechanisation of Longwall Extraction of Hard and Abrasive Rocks. Multidiscip. Asp. Prod. Eng. 2018, 1, 331–337. [Google Scholar] [CrossRef] [Green Version]

- Krauze, K.; Bołoz, Ł.; Wydro, T. Parametric Factors for the Tangential-Rotary Picks Quality Assessment. Arch. Min. Sci. 2015, 60, 265–281. [Google Scholar] [CrossRef]

- Dehkhoda, S.; Detournay, E. Rock Cutting Experiments with an Actuated Disc. Rock Mech. Rock Eng. 2019, 52, 3443–3458. [Google Scholar] [CrossRef]

- Gajewski, J.; Podgórski, J.; Jonak, J.; Szkudlarek, Z. Numerical Simulation of Brittle Rock Loosening during Mining Process. Comput. Mater. Sci. 2008, 43, 115–118. [Google Scholar] [CrossRef]

- Krauze, K.; Mucha, K.; Wydro, T.; Pieczora, E. Functional and Operational Requirements to Be Fulfilled by Conical Picks Regarding Their Wear Rate and Investment Costs. Energies 2021, 14, 3696. [Google Scholar] [CrossRef]

- Krauze, K.; Bołoz, Ł.; Wydro, T.; Mucha, K. Durability Testing of Tangential-Rotary Picks Made of Different Materials. Min. Inform. Autom. Electr. Eng. 2017, 1, 68. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, K.; Dong, W.; Zhang, B. Study of Rock-Cutting Process by Disc Cutters in Mixed Ground Based on Three-Dimensional Particle Flow Model. Rock Mech. Rock Eng. 2020, 53, 3485–3506. [Google Scholar] [CrossRef]

- Li, H.S.; Liu, S.Y.; Xu, P.P. Numerical Simulation on Interaction Stress Analysis of Rock with Conical Picks. Tunn. Undergr. Space Technol. 2019, 85, 231–242. [Google Scholar] [CrossRef]

- Slouka, S.; Brune, J.; Rostami, J.; Tsai, C.; Sidrow, E. Characterization of Respirable Dust Generated from Full Scale Cutting Tests in Limestone with Conical Picks at Three Stages of Wear. Minerals 2022, 12, 930. [Google Scholar] [CrossRef]

- Bołoz, Ł.; Kalukiewicz, A. Machines for Mechanical Mining of Hardly Workable and Abrasive Rocks. Multidiscip. Asp. Prod. Eng. 2020, 3, 150–160. [Google Scholar] [CrossRef]

- Vogt, D. A Review of Rock Cutting for Underground Mining: Past, Present, and Future. J. South. Afr. Inst. Min. Metall. 2016, 116, 1011–1026. [Google Scholar] [CrossRef] [Green Version]

- Stoxreiter, T.; Martin, A.; Teza, D.; Galler, R. Hard Rock Cutting with High Pressure Jets in Various Ambient Pressure Regimes. Int. J. Rock Mech. Min. Sci. 2018, 108, 179–188. [Google Scholar] [CrossRef]

- Kotwica, K. Hard Rock Mining Using Disk Tools Supported by High-Pressure Water Jets in the Aspect of Reducing Energy Consumption. Energies 2021, 14, 2595. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Zhang, Y.; Yang, F.; Liang, C.; Tan, S. Using a High-Pressure Water Jet-Assisted Tunnel Boring Machine to Break Rock. Adv. Mech. Eng. 2020, 12, 168781402096229. [Google Scholar] [CrossRef]

- Ramezanzadeh, A.; Hood, M. A State-of-the-Art Review of Mechanical Rock Excavation Technologies. J. Min. Environ. 2010, 1, 29–39. [Google Scholar] [CrossRef]

- Sifferlinger, N.A.; Hartlieb, P.; Moser, P. The Importance of Research on Alternative and Hybrid Rock Extraction Methods. Berg Huettenmaenn Mon. 2017, 162, 58–66. [Google Scholar] [CrossRef] [Green Version]

- Bołoz, Ł. Directions for Increasing Conical Picks’ Durability. New Trends Prod. Eng. 2019, 2, 277–286. [Google Scholar] [CrossRef] [Green Version]

- Shandong Techgong Geotechnical Engineering Equipment Co., Ltd. Available online: https://www.techgong.com (accessed on 19 November 2022).

- Bołoz, Ł. Conical Picks for Undeground Mining. New Trends Prod. Eng. 2020, 3, 221–230. [Google Scholar] [CrossRef]

- Bołoz, Ł.; Kalukiewicz, A.; Galecki, G.; Romanyshyn, L.; Romanyshyn, T.; Giménez, R.B. Conical Pick Production Process. New Trends Prod. Eng. 2020, 3, 231–240. [Google Scholar] [CrossRef]

- Gospodarczyk, P.; Kotwica, K.; Stopka, G. A New Generation Mining Head with Disc Tool of Complex Trajectory. Arch. Min. Sci. 2013, 58, 985–1006. [Google Scholar] [CrossRef] [Green Version]

- Dewangan, S.; Chattopadhyaya, S. Characterization of Wear Mechanisms in Distorted Conical Picks After Coal Cutting. Rock Mech. Rock Eng. 2016, 49, 225–242. [Google Scholar] [CrossRef]

- Bołoz, Ł. Results of a Study on the Quality of Conical Picks for Public Procurement Purposes. New Trends Prod. Eng. 2018, 1, 687–693. [Google Scholar] [CrossRef] [Green Version]

- Bołoz, Ł.; Krauze, K. Disc Unit Dedicated to Mine Abrasive Rocks and in Particular Copper Ores. In Proceedings of the 18th International Multidisciplinary Scientific GeoConference SGEM 2018, Albena, Bulgaria, 20 June 2018. [Google Scholar]

- The Next Revolution in EPB Cutters—New Cutter Designs Make an Impression in Mixed Ground. Available online: https://www.tunnel-online.info/en/artikel/tunnel_the_next_revolution_in_epb_cutters_new_cutter_designs_make_an_impression_1734178.html (accessed on 19 November 2022).

- Bołoz, Ł.; Midor, K. Process Innovations in the Mining Industry and the Effects of Their Implementation Presented on the Example of Longwall Milling Heads. AMS 2018, 23, 81–93. [Google Scholar]

- Biały, W. Innovative Solutions Applied in Tools for Determining Coal Mechanical Proprerties. Manag. Syst. Prod. Eng. 2015, 4, 202–209. [Google Scholar] [CrossRef]

- Wang, X.; Su, O. Specific Energy Analysis of Rock Cutting Based on Fracture Mechanics: A Case Study Using a Conical Pick on Sandstone. Eng. Fract. Mech. 2019, 213, 197–205. [Google Scholar] [CrossRef]

- Lin, Q.; Cao, P.; Cao, R. Experimental Investigation of Jointed Rock Breaking under a Disc Cutter with Different Confining Stresses. Comptes Rendus Mécanique 2018, 346, 833–843. [Google Scholar] [CrossRef]

- Jaime, M.C.; Zhou, Y.; Lin, J.-S.; Gamwo, I.K. Finite Element Modeling of Rock Cutting and Its Fragmentation Process. Int. J. Rock Mech. Min. Sci. 2015, 80, 137–146. [Google Scholar] [CrossRef] [Green Version]

- Stopka, G. Laboratory Research on the Influence of Selected Technological Parameters on Cutting Forces during Hard Rock Mining with Asymmetric Disc Tools. AMS 2020, 25, 94–104. [Google Scholar] [CrossRef]

- Kotwica, K.; Stopka, G.; Prostański, D. Study and Application of Asymmetrical Disk Tools for Hard Rock Mining. Energies 2021, 14, 1826. [Google Scholar] [CrossRef]

- Stopka, G. Modelling of Rock Cutting with Asymmetrical Disc Tool Using Discrete-Element Method (DEM). Rock Mech. Rock Eng. 2021, 54, 6265–6279. [Google Scholar] [CrossRef]

- Kang, H.; Cho, J.-W.; Park, J.-Y.; Jang, J.-S.; Kim, J.-H.; Kim, K.-W.; Rostami, J.; Lee, J.-W. A New Linear Cutting Machine for Assessing the Rock-Cutting Performance of a Pick Cutter. Int. J. Rock Mech. Min. Sci. 2016, 88, 129–136. [Google Scholar] [CrossRef]

- Dewangan, S.; Ponsingh Jomy, A.; Ashwin Nethran, G. Modelling and Simulation of Stress Generation and Temperature Distribution in Conical Picks during Linear Coal-Cutting Process. Mater. Today Proc. 2022, 62, 1458–1464. [Google Scholar] [CrossRef]

- Balci, C.; Bilgin, N. Correlative Study of Linear Small and Full-Scale Rock Cutting Tests to Select Mechanized Excavation Machines. Int. J. Rock Mech. Min. Sci. 2007, 44, 468–476. [Google Scholar] [CrossRef]

- Cho, J.-W.; Jeon, S.; Jeong, H.-Y.; Chang, S.-H. Evaluation of Cutting Efficiency during TBM Disc Cutter Excavation within a Korean Granitic Rock Using Linear-Cutting-Machine Testing and Photogrammetric Measurement. Tunn. Undergr. Space Technol. 2013, 35, 37–54. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, Y.; Tan, Q.; Wu, D. Comparison Study on the Rock Cutting Characteristics of Disc Cutter under Free-Face-Assisted and Conventional Cutting Methods. KSCE J. Civ. Eng. 2018, 22, 4155–4162. [Google Scholar] [CrossRef]

- Copur, H.; Bilgin, N.; Balci, C.; Tumac, D.; Avunduk, E. Effects of Different Cutting Patterns and Experimental Conditions on the Performance of a Conical Drag Tool. Rock Mech. Rock Eng. 2017, 50, 1585–1609. [Google Scholar] [CrossRef]

- Wang, S.; Sun, L.; Li, X.; Zhou, J.; Du, K.; Wang, S.; Khandelwal, M. Experimental Investigation and Theoretical Analysis of Indentations on Cuboid Hard Rock Using a Conical Pick under Uniaxial Lateral Stress. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 34. [Google Scholar] [CrossRef]

- Liu, Q.; Pan, Y.; Liu, J.; Kong, X.; Shi, K. Comparison and Discussion on Fragmentation Behavior of Soft Rock in Multi-Indentation Tests by a Single TBM Disc Cutter. Tunn. Undergr. Space Technol. 2016, 57, 151–161. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, Q.; Liu, J.; Huang, X.; Liu, Q.; Peng, X. Comparison between Experimental and Semi-Theoretical Disc Cutter Cutting Forces: Implications for Frame Stiffness of the Linear Cutting Machine. Arab. J. Geosci. 2018, 11, 266. [Google Scholar] [CrossRef]

- Bilgin, N.; Demircin, M.A.; Copur, H.; Balci, C.; Tuncdemir, H.; Akcin, N. Dominant Rock Properties Affecting the Performance of Conical Picks and the Comparison of Some Experimental and Theoretical Results. Int. J. Rock Mech. Min. Sci. 2006, 43, 139–156. [Google Scholar] [CrossRef]

- Yasar, S.; Yilmaz, A.O. Drag Pick Cutting Tests: A Comparison between Experimental and Theoretical Results. J. Rock Mech. Geotech. Eng. 2018, 10, 893–906. [Google Scholar] [CrossRef]

- Xia, Y.; Shi, Y.; Lin, L.; Zhang, Y.; Tan, Q.; Yang, Y. Experimental Evaluation of Fragments from TBM Disc Cutting under Different Load Cases. Period. Polytech. Civ. Eng. 2018, 62, 746–756. [Google Scholar] [CrossRef] [Green Version]

- Pan, Y.; Liu, Q.; Kong, X.; Liu, J.; Peng, X.; Liu, Q. Full-Scale Linear Cutting Test in Chongqing Sandstone and the Comparison with Field TBM Excavation Performance. Acta Geotech. 2019, 14, 1249–1268. [Google Scholar] [CrossRef]

- Jackson, E.; Clarke, D. Minimole: Development and Field Testing of a Narrow—Vein Hard Rock Mechanical Mining Machine; SME: Chandler, AZ, USA, 2007. [Google Scholar]

- Xiaohui, L.; Songyong, L.; Xinxia, C.; Ping, T. Interference Model of Conical Pick in Cutting Process. J. Vibroengineering 2014, 16, 103–115. [Google Scholar]

- Wang, Z.; Zeng, Q.; Wan, L.; Lu, Z.; Wang, H. Investigation of the Influence of Cutting Parameters on Conical Pick Cutting Performance and Rock Damage. Machines 2022, 10, 1034. [Google Scholar] [CrossRef]

- Shao, W.; Li, X.; Sun, Y.; Huang, H. Parametric Study of Rock Cutting with SMART∗CUT Picks. Tunn. Undergr. Space Technol. 2017, 61, 134–144. [Google Scholar] [CrossRef]

- Li, B.; Zhang, B.; Hu, M.; Liu, B.; Cao, W.; Xu, B. Full-Scale Linear Cutting Tests to Study the Influence of Pre-Groove Depth on Rock-Cutting Performance by TBM Disc Cutter. Tunn. Undergr. Space Technol. 2022, 122, 104366. [Google Scholar] [CrossRef]

- Liu, X.; Liu, S.; Li, L.; Cui, X. Experiment on Conical Pick Cutting Rock Material Assisted with Front and Rear Water Jet. Adv. Mater. Sci. Eng. 2015, 2015, 506579. [Google Scholar] [CrossRef] [Green Version]

- Lu, G.; Zhou, J.; Zhang, L.; Gao, W. Experimental Investigation on the Influence of Microwave Exposure on the Cutting Performance of TBM Disc Cutter Cutting of Hard Rocks. Results Eng. 2021, 12, 100285. [Google Scholar] [CrossRef]

- Ghamgosar, M.; Erarslan, N. A Numerical Study on Oscillating Disc Cutting (ODC) Technology for Hard Rock Cutting. In Proceedings of the 13th ISRM International Congress of Rock Mechanics, Montreal, QC, Canada, 10–13 May 2015. [Google Scholar] [CrossRef]

- Rock Cutting Equipment Actuated Undercutting Disc Test-Unit Dubbed as Wobble. Available online: https://research.csiro.au/hardrockcutting/facilities/actuated-undercutting-disc-test-unit-wobble (accessed on 21 November 2022).

- Kim, H.; Nam, K.; Kyeon, T.; Rehman, H.; Yoo, H. Analysis of the Effect of the Tool Shape on the Performance of Pre-Cutting Machines during Tunneling Using Linear Cutting Tests. Appl. Sci. 2022, 12, 4489. [Google Scholar] [CrossRef]

- Liu, S.; Du, C.; Cui, X. Research on the Cutting Force of a Pick. Min. Sci. Technol. 2009, 19, 514–517. [Google Scholar] [CrossRef]

- Liu, X.; Liu, S.; Tang, P. Coal Fragment Size Model in Cutting Process. Powder Technol. 2015, 272, 282–289. [Google Scholar] [CrossRef]

- Liu, S.; Ji, H.; Liu, X.; Jiang, H. Experimental Research on Wear of Conical Pick Interacting with Coal-Rock. Eng. Fail. Anal. 2017, 74, 172–187. [Google Scholar] [CrossRef]

- Fu, L.; Du, C.; Li, J.; Zheng, K. Influence of Pick Working Angle on Cutting Performance of Auger Miner’s Aiguille. Adv. Mech. Eng. 2015, 7, 168781401558542. [Google Scholar] [CrossRef] [Green Version]

- Gajewski, J.; Jedliński, Ł.; Jonak, J. Classification of Wear Level of Mining Tools with the Use of Fuzzy Neural Network. Tunn. Undergr. Space Technol. 2013, 35, 30–36. [Google Scholar] [CrossRef]

- Krauze, K.; Bołoz, Ł.; Wydro, T.; Mucha, K. Investigations into the Wear Rate of Conical Picks with Abrasion-Resistant Coatings in Laboratory Conditions. IOP Conf. Ser. Mater. Sci. Eng. 2019, 679, 012012. [Google Scholar] [CrossRef]

- Bołoz, Ł.; Midor, K. The Procedure of Choosing an Optimal Offer for a Conical Pick as an Element of Realizing the Sustainable Development Concept in Mining Enterprises. AMS 2019, 24, 140–150. [Google Scholar]

- Cheluszka, P. Optimization of the Cutting Process Parameters to Ensure High Efficiency of Drilling Tunnels and Use the Technical Potential of the Boom-Type Roadheader. Energies 2020, 13, 6597. [Google Scholar] [CrossRef]

- Krauze, K.; Bołoz, Ł.; Mucha, K.; Rożenek, Z. Badania Laboratoryjne Określające Wpływ Zużycia Ściernego Noży Styczno-Obrotowych Na Opory Urabiania. In Mechanizacja, Automatyzacja i Robotyzacja w Górnictwie; Centrum Badań i Dozoru Górnictwa Podziemnego Sp. z o.o.: Lędziny, Poland, 2017; Volume 2. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bołoz, Ł.; Biały, W. Methods and Test Benches for Cutting Tools Testing—A Review. Energies 2023, 16, 445. https://doi.org/10.3390/en16010445

Bołoz Ł, Biały W. Methods and Test Benches for Cutting Tools Testing—A Review. Energies. 2023; 16(1):445. https://doi.org/10.3390/en16010445

Chicago/Turabian StyleBołoz, Łukasz, and Witold Biały. 2023. "Methods and Test Benches for Cutting Tools Testing—A Review" Energies 16, no. 1: 445. https://doi.org/10.3390/en16010445

APA StyleBołoz, Ł., & Biały, W. (2023). Methods and Test Benches for Cutting Tools Testing—A Review. Energies, 16(1), 445. https://doi.org/10.3390/en16010445