Investigation of the Selectivity of the Water Shutoff Technology

Abstract

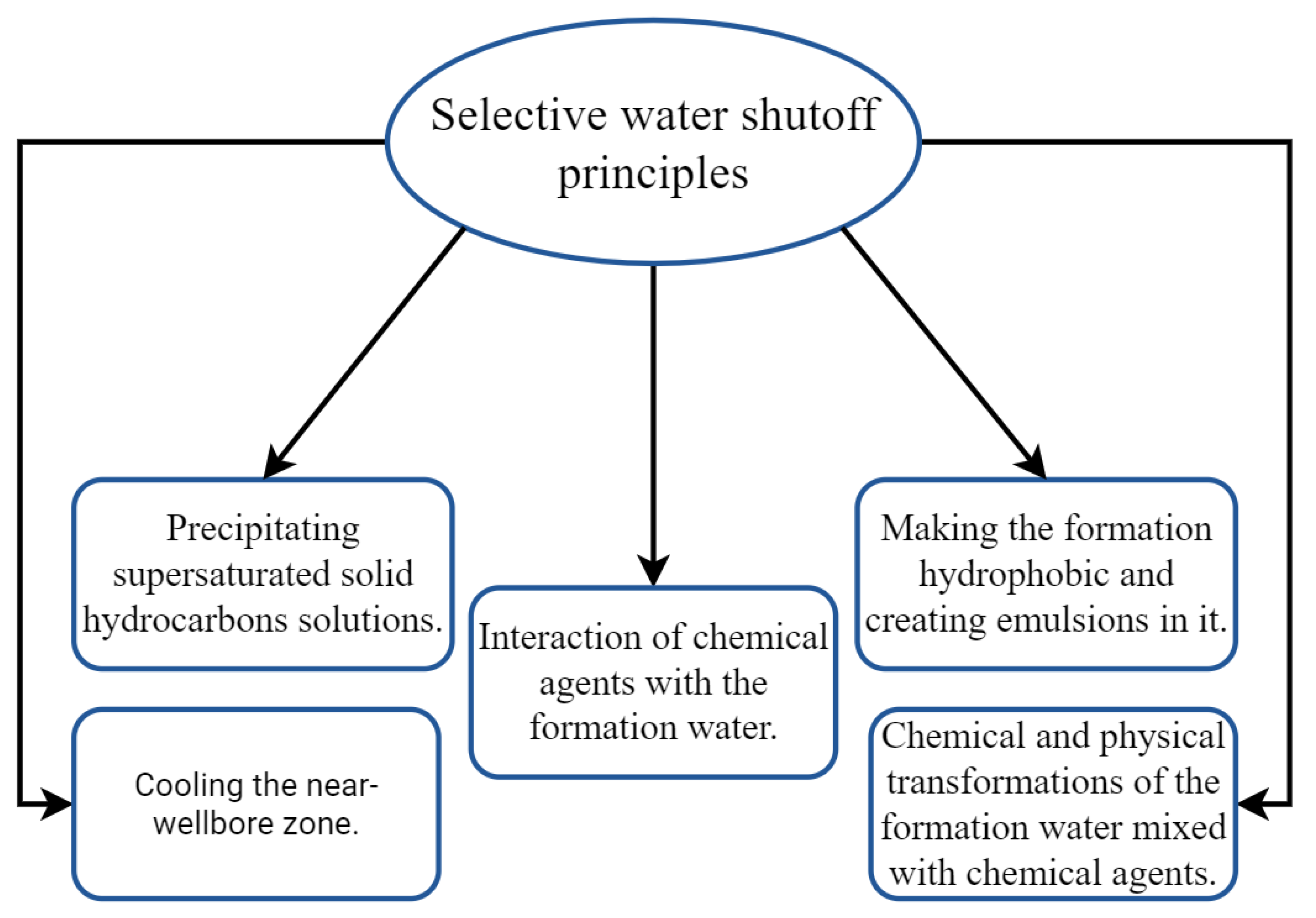

:1. Introduction

- adhesive capability,

- impact on the permeability of oil- and water-saturated samples,

- selectivity coefficient.

2. Materials and Methods

2.1. Materials

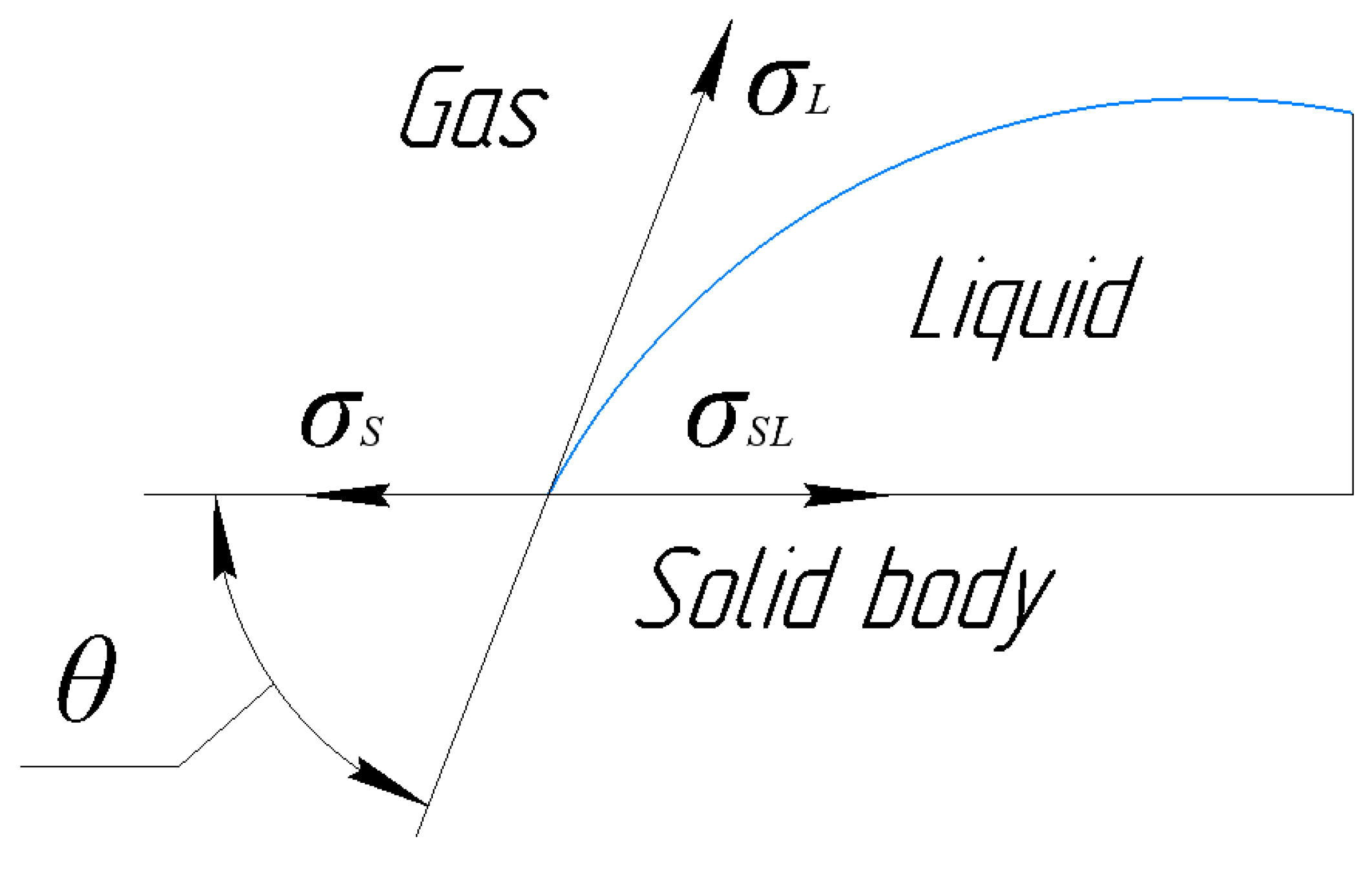

2.2. Evaluation of Adhesive Capability

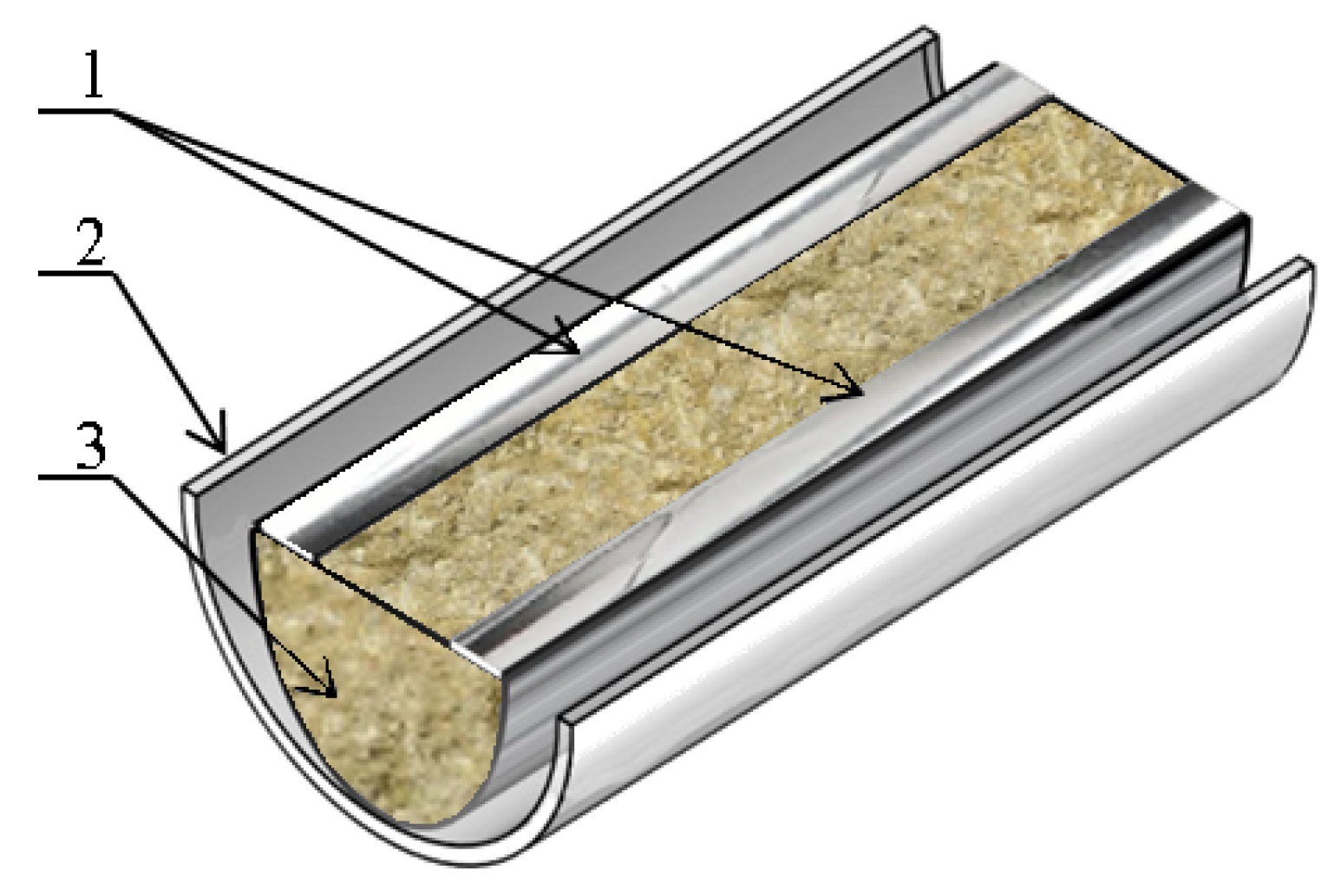

2.3. Preparation of Fractured Porous Core Samples

- the core is cut into equal halves;

- two strips of three-layer aluminum foil 5 mm in width are put on the cut surface;

- the core halves are connected, placed into a heat shrink sleeve and then tightened with a hot air gun.

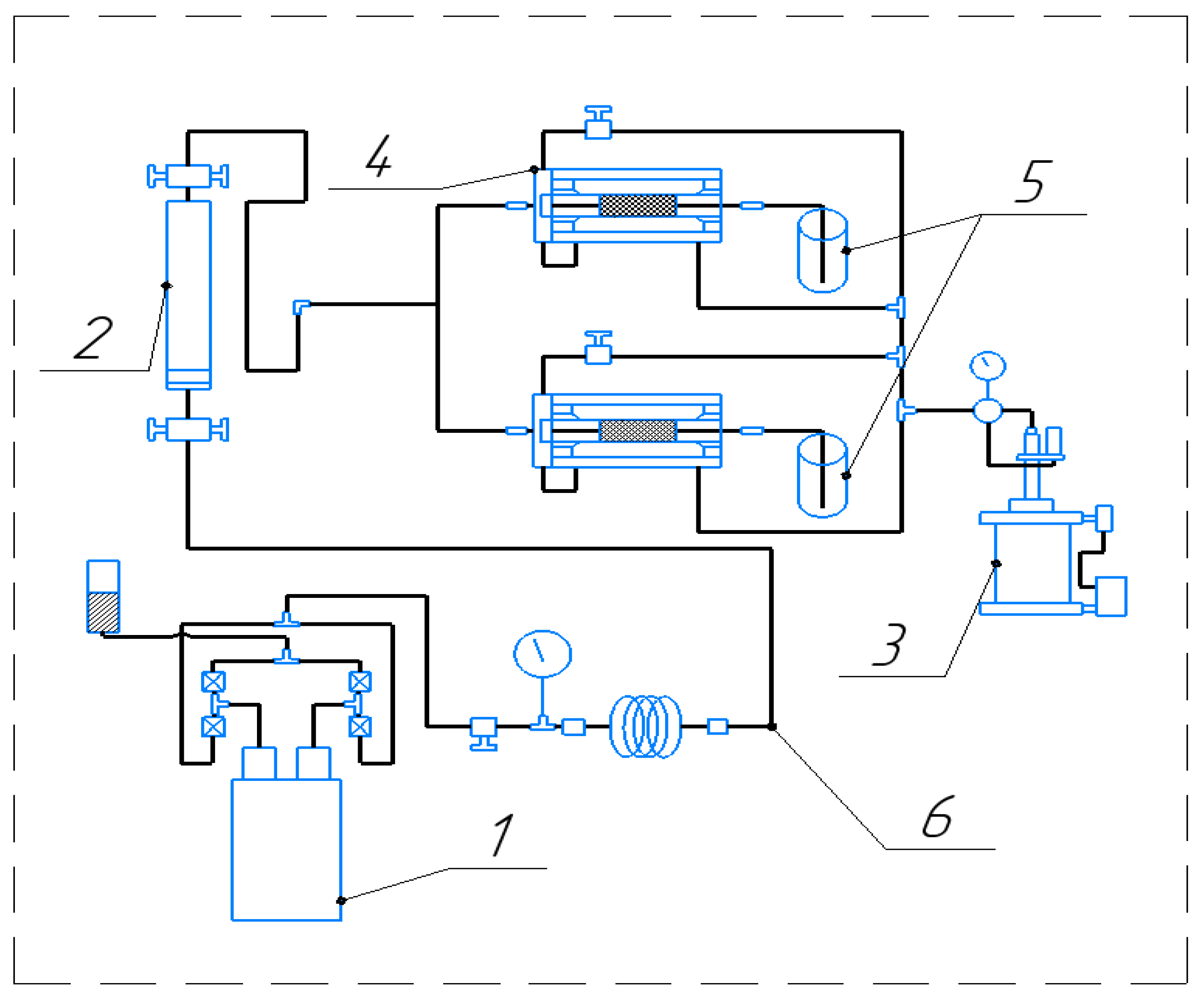

2.4. Shutoff Efficiency Evaluation in Single Core Sample Experiment

- The prepared core sample was vacuumed and saturated with preset brine water acting as reservoir water. After the sample was fully saturated, the pore volume was calculated by weighing the sample and measuring its mass change.

- The saturated core sample was placed into the sample holder of the FDES-645 unit, which later created pressure close to the reservoir one.

- The preset water (or oil, in the case of oil-saturated formation modeling) was injected into the core sample. Simultaneously, its relative permeability to brine water at a constant flow rate was measured until the differential pressure stabilization. The applied pressure was the same as the reservoir pressure, the temperature was normal, and the flow direction was considered “forward”.

- After switching the flow direction to “reverse”, 5 pore volumes (or the maximum volume possible at high pressure) of the shutoff composition were injected into the core sample. The volume of injected fluid was measured by scales at the rear side of the core.

- When the injection of the gel was finished, the core sample was heated up to the average reservoir temperature (37 °C), and the system was left quiescent for 24 h (on average) in constant PT conditions.

- Next, the brine water was injected in the “forward” direction, and the relative permeability of the core sample to water was gauged again at a constant flow rate until the differential pressure stabilization.

- After that, the flow direction was changed to “reverse” and 5 pore volumes of the breaker fluid (20% sodium hydroxide solution) were injected.

- At the end, the flow direction was switched back to “forward”, and the final relative permeability to water was measured at a constant flow rate until the differential pressure stabilization.

- Differential pressure values and mobility of brine water (or oil) were evaluated before and after the injection of the shutoff composition, and they were used to calculate the relative permeability to brine water (or oil) before and after the injection;

- The differential pressure values during the first and the last (5th) pore volume injections of the shutoff composition were recorded;

- The initial differential pressure of gel displacement was recorded at the final stage of the flooding experiment;

- The differential pressure values after the first and the last (5th) pore volume injections of the breaker fluid were recorded;

- The differential pressure of the water (or oil) injection was recorded at the final stage of the flooding experiment;

- The residual resistance factor of the core sample was calculated by the following equation:

- The maximum resistance factor of the core sample after the injection of the designed composition was evaluated by the following equation:

- The residual resistance factor of the core after the breaker fluid injection was calculated by the following equation:

2.5. Selectivity Evaluation in Dual Core Sample Experiment

- 5 pore volumes of the shutoff composition were simultaneously injected into both core samples at a constant flow rate, and the volume of fluids displaced from oil- and water-saturated cores was measured.

- After that, the flow direction was changed to “reverse”, and 5 pore volumes of the breaker fluid (20% sodium hydroxide solution) were simultaneously injected into both core samples.

3. Results

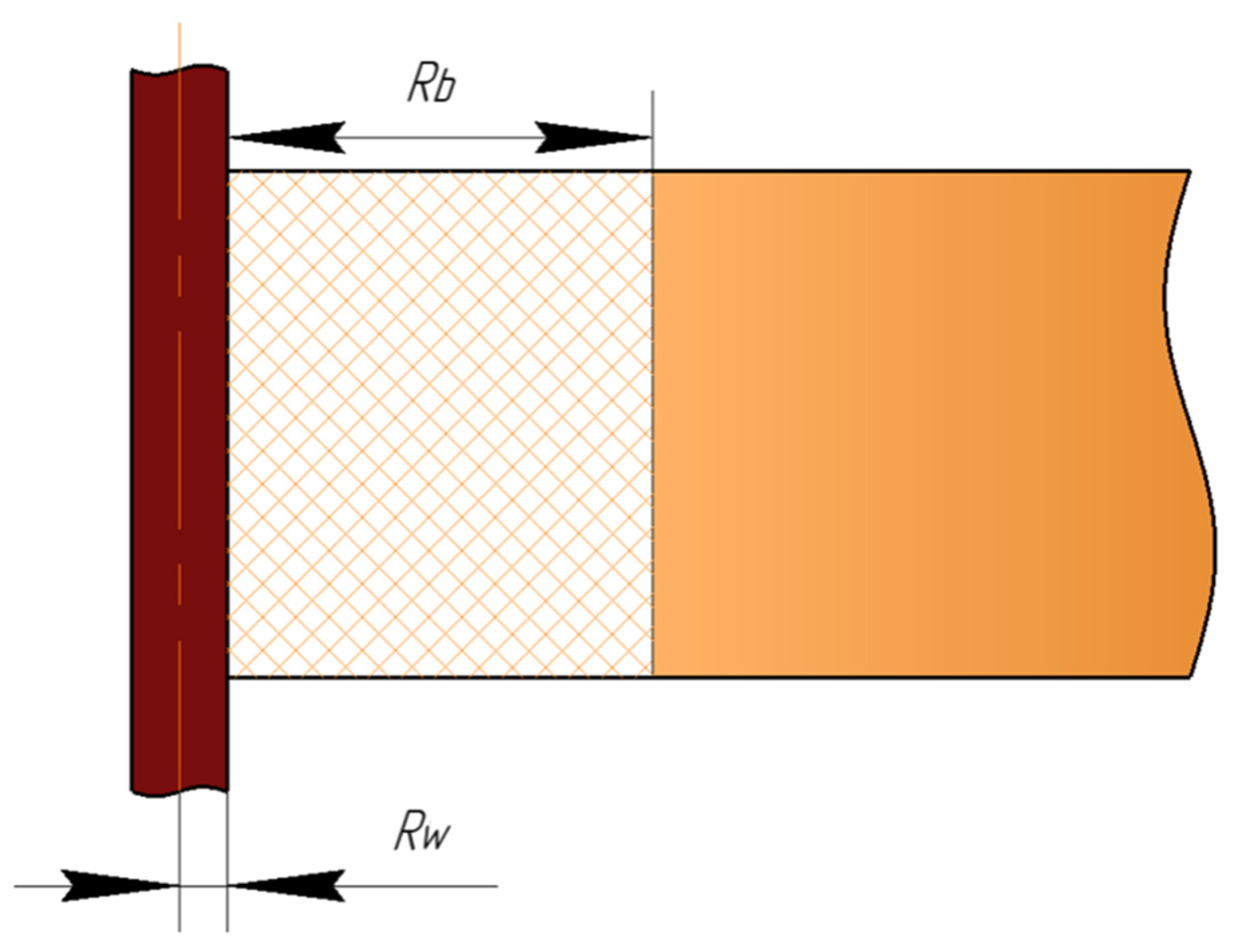

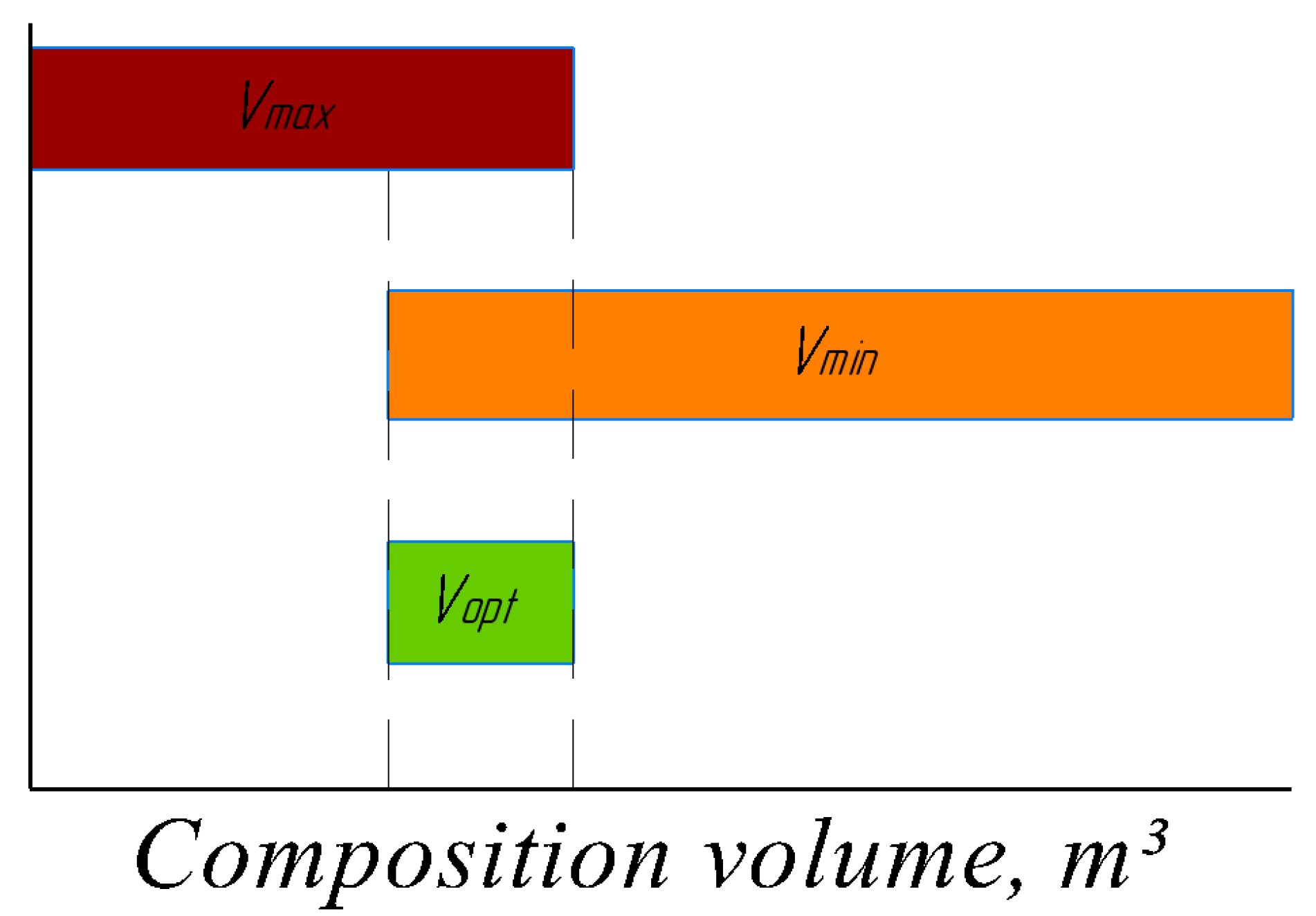

- wellbore radius—0.2 m;

- pressure drawdown during the well operation—10 MPa;

- differential pressure of gel displacement—5 MPa/m;

- length of the water zone that is required to be blocked—15 m;

- average fracture intensity in the shutting zone—37 m−1;

- average fracture aperture in the shutting zone изoляции—179 μm.

4. Conclusions

- In this study, the new gel-forming composition based on sodium silicate was developed to limit the water inflow in fractured porous reservoirs. Inorganic chromium (III) salt was used as a crosslinking agent due to its ability to initiate gelation throughout the volume of the composition.

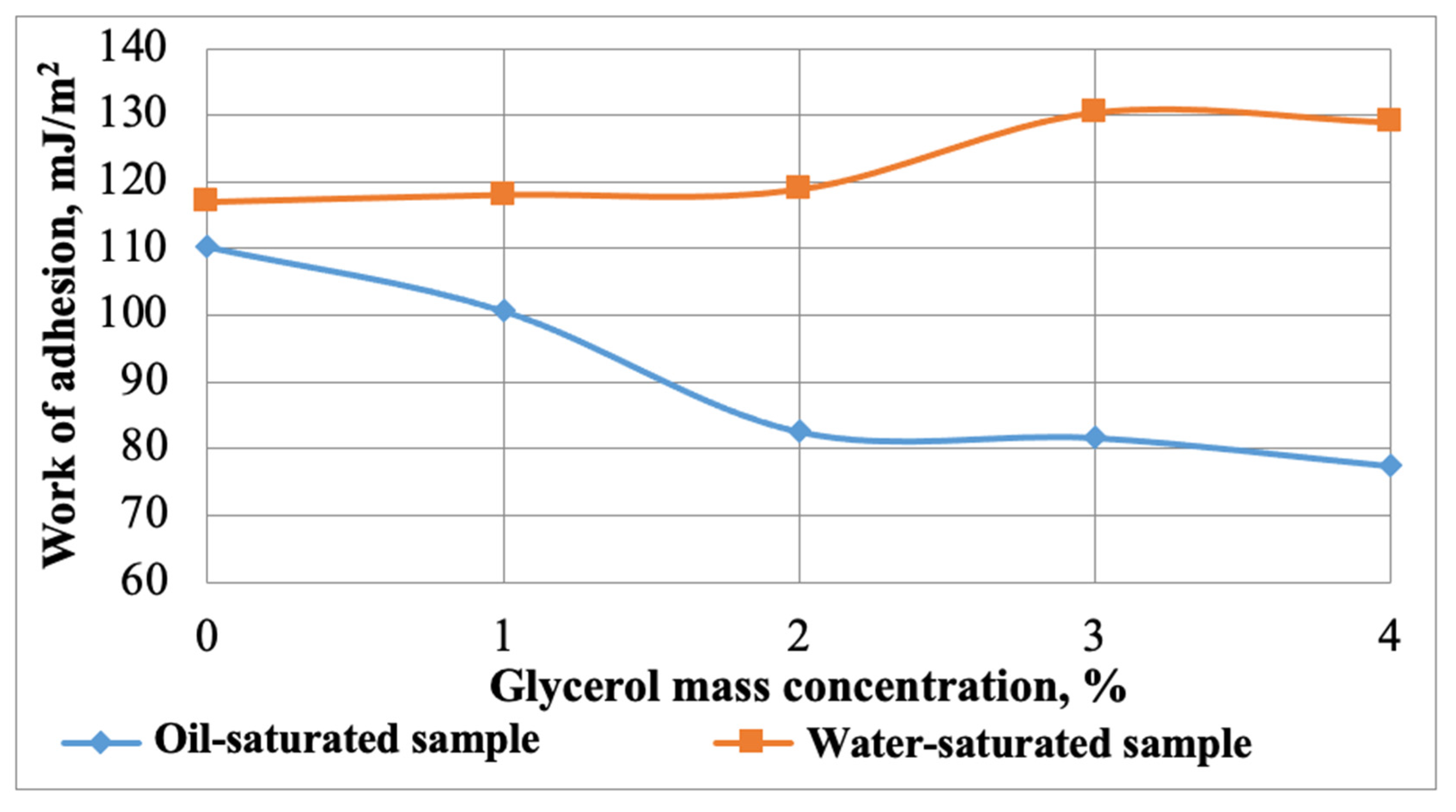

- It was revealed that polyatomic alcohol can influence the selectivity of the designed composition by enhancing its hydrophilic behavior in water-saturated rocks (work of adhesion increases from 117 to 129 mJ/m2) and reducing the hydrophobic behavior in oil-saturated rocks (work of adhesion drops from 110.3 to 77.4 mJ/m2).

- Moreover, the selectivity of the composition’s performance was experimentally validated by the fact that the permeability of the water-saturated fractured porous core samples decreased to a greater extent than the permeability of the oil-saturated ones. The experimental value of the selectivity coefficient is 152.14.

- The calculation methodology for evaluating the injection volume of the developed gel-forming composition was suggested. It was based on the necessity of creating the shutoff barrier that not only would tolerate pressure fluctuations occurring during well operation processes, but also would consider limitations for the injection time.

- Furthermore, it was confirmed that the injection of sodium hydroxide water solution may effectively dissolve the shutoff barrier in situ. The filtration properties of oil-saturated zones were almost completely restored after being exposed to the breaker fluid (the residual resistance factor is 1.19), and water-saturated zones had a higher residual resistance factor due to the composition’s better wettability of water-saturated rocks (the residual resistance factor is 180.14), which is several times higher than similar indicators in studies carried out on related specifics [23,38,41,42,43]. This indicates the higher efficiency of the considered technology.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raupov, I.; Burkhanov, R.; Lutfullin, A.; Maksyutin, A.; Lebedev, A.; Safiullina, E. Experience in the Application of Hydrocarbon Optical Studies in Oil Field Development. Energies 2022, 15, 3626. [Google Scholar] [CrossRef]

- Mardashov, D.V.; Bondarenko, А.V.; Raupov, I.R. Technique for calculating technological parameters of non-Newtonian liquids injection into oil well during workover. J. Min. Inst. Volume 000. 2022, 1–14. [Google Scholar] [CrossRef]

- Tananykhin, D.; Grigorev, M.; Korolev, M.; Solovyev, T.; Mikhailov, N.; Nesterov, M. Experimental Evaluation of the Multiphase Flow Effect on Sand Production Process: Prepack Sand Retention Testing Results. Energies 2022, 15, 4657. [Google Scholar] [CrossRef]

- Raupov, I.R.; Milic, J. Improvement of operational efficiency of high water-cut oil wells. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; Volume 1021, p. 012077. [Google Scholar]

- Deng, B.; Wei, L. Water Control of Horizontal Wells Using Foam-Gel: Lessons Learnt in a Heavy Oil Reservoir with Strong Waterdrive. In Proceedings of the Paper presented at the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Jakarta, Indonesia, 17–19 October 2017. [Google Scholar]

- Wiggett, A.J. Water—Chemical Treatment and Management. In Proceedings of the Paper Presented at the SPE Oilfield Water Management Conference and Exhibition, Kuwait City, Kuwait, 21–22 April 2014. [Google Scholar]

- Rebecca, F.; Morgan, J.C.; Stevens, D.G.; Thrasher, D.R. Water Shut-Off in Oil Production Wells—Lessons from 12 Treatments. In Proceedings of the Paper presented at the 7th Abu Dhabi international Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 13–16 October 1996. [Google Scholar]

- Zhang, G.; Liu, Z.; Li, Y.; Jia, X.; Sun, Z.; Lv, Z. Pilot Test and Effect Evaluation for the Water Shutoff Technology with Concentric Tube in Horizontal Well of Bohai Oilfield. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019. [Google Scholar]

- Burdin, K.; Kichigin, A.; Mazitov, R.; Lobov, M.; Bravkov, P.; Stepanov, V.; Eliseev, D.; Zemchihin, A.; Byakov, A. Gas shutoff treatment in mega rich horizontal well with coiled tubing inflatable packer for North Caspian. In Proceedings of the Society of Petroleum Engineers—SPE Russian Petroleum Technology Conference, Moscow, Russia, 26–28 October 2015; SPE: Moscow, Russia, 2015. [Google Scholar]

- Prischepa Oleg, M.; Nefedov, Y.V.; Kochneva, O.Y. Raw material base of hard-to-extract oil reserves of Russia. Period. Tche Quim. 2020, 17, 915–924. [Google Scholar] [CrossRef]

- Cherepovitsyn, A.; Metkin, D.; Gladilin, A. An Algorithm of Management Decision-Making Regarding the Feasibility of Investing in Geological Studies of Forecasted Hydrocarbon Resources. Resources 2018, 7, 47. [Google Scholar] [CrossRef] [Green Version]

- Mavliev, A.R.; Rogachev, M.K.; Mardashov, D.V. Substantiation of pumped volumes of flow angularity compositions in injection wells. J. Min. Inst. 2011, 189, 182. [Google Scholar]

- Shagiakhmetov, A.; Yushchenko, S. Substantiation of In Situ Water Shut-Off Technology in Carbonate Oil Reservoirs. Energies 2022, 15, 5059. [Google Scholar] [CrossRef]

- Rogachev, M.K.; Mukhametshin, V.V.; Kuleshova, L. Improving the efficiency of using resource base of liquid hydrocarbons in Jurassic deposits of Western Siberia. J. Min. Inst. 2019, 240, 711. [Google Scholar] [CrossRef] [Green Version]

- Prischepa, O.M.; Nefedov, Y.V.; Ibatullin, A.H. Assessment of the hydrocarbon potential of the domanik deposits of the tpp on the basis of quantitative models of generation and assessment of the saturation of the pore space. In EAGE/SPE Workshop on Shale Science 2021: New Challenges; European Association of Geoscientists and Engineers; EAGE: Moscow, Russia, 2021; Volume 2021, pp. 1–5. [Google Scholar]

- Galkin, V.I.; Ponomareva, I.N.; Martyushev, D.A. Prediction of reservoir pressure and study of its behavior in the development of oil fields based on the construction of multilevel multidimensional probabilistic-statistical models. Georesursy 2021, 23, 73–82. [Google Scholar] [CrossRef]

- Lekomtsev, A.V.; Iliushin, P.Y.; Korobov, G.Y. Modeling and proving of design solutions for the reconstruction of treatment facility of oil and water. Tche Quim. Group 2020, 17, 269–281. [Google Scholar] [CrossRef]

- Ketova, Y.A.; Bai, B.; Khizhnyak, G.P.; Gladkikh, Y.A.; Galkin, S.V. Testing of preformed particles polymer gel technology on core filtration models to limit water inflows. J. Min. Inst. 2020, 241, 91. [Google Scholar] [CrossRef]

- Liu, T.; Leusheva, E.; Morenov, V.; Li, L.; Jiang, G.; Fang, C.; Zhang, L.; Zheng, S.; Yu, Y. Influence of Polymer Reagents in the Drilling Fluids on the Efficiency of Deviated and Horizontal Wells Drilling. Energies 2020, 13, 4704. [Google Scholar] [CrossRef]

- Matthews, M.D. Treatise of Petroleum Geology. In Handbook of Petroleum Geology: Exploring for Oil and Gas Traps; Chapter 7: Migration of Petroleum; American Association Of Petroleum Geologists: Tulsa, OK, USA, 1999. [Google Scholar]

- Burkhanov, R.N.; Lutfullin, A.A.; Maksyutin, A.V.; Raupov, I.R.; Valiullin, I.V.; Farrakhov, I.M.; Shvydenko, M.V. Retrospective analysis algorithm for identifying and localizing residual reserves of the developed multilayer oil field. Georesursy 2022, 24, 125–138. [Google Scholar] [CrossRef]

- Buckley, S.; Leverett, M. Mechanism of Fluid Displacement in Sands. Trans. AIME 1942, 146, 107–116. [Google Scholar] [CrossRef]

- Demir, M.; Topguder NN, S.; Yilmaz, M.; Ince, Y.; Karabakal, U.; Gould, J.H. Water Shutoff Gels Improved Oil Recovery in Naturally Fractured Raman Heavy Oilfield. In SPE Russian Oil and Gas Technical Conference and Exhibition, Moscow, Russia, 20–22 October 2008; OnePetro: Moscow, Russia, 2008; Volume 2, pp. 912–922. [Google Scholar]

- Shagiakhmetov, A.M.; Tananykhin, D.S. The development of a water proofing polymeric composition based on carboxymethylcellulose for carbonate reservoirs. Int. J. Appl. Eng. Res. 2017, 12, 273–276. [Google Scholar]

- Shagiakhmetov, A.M.; Petrakov, D.G. Investigation of Selective Properties of the Gel-Forming Composition in the Limitation of Water Inflow in Carbonate Reservoirs Conditions. Int. Res. J. 2016, 5, 47. [Google Scholar]

- Fan, G.; Li, M.; Chen, X.; Palyanitsina, A.; Timoshin, A. Polymer-Nanosilica-assisted to evaluate oil recovery performances in sandstone reservoirs. Energy Rep. 2021, 7, 2588–2593. [Google Scholar] [CrossRef]

- Wei, Z.; Zhu, S.; Dai, X.; Wang, X.; Yapanto, L.M.; Raupov, I.R. Multi-criteria decision making approaches to select appropriate enhanced oil recovery techniques in petroleum industries. Energy Rep. 2021, 7, 2751–2758. [Google Scholar] [CrossRef]

- Mardashov, D.V. Development of blocking compositions with a bridging agent for oil well killing in conditions of abnormally low formation pressure and carbonate reservoir rocks. J. Min. Inst. 2021, 251, 617–626. [Google Scholar] [CrossRef]

- Rybakov, A.A.; Guskova, I.A.; Gabdrakhmanov, A.T. Monitoring EOR and Well Stimulation Techniques by Oil Optical Properties Measurement. In Society of Petroleum Engineers—SPE Russian Oil and Gas Exploration and Production Technical Conference and Exhibition 2014, RO and G 2014—Sustaining and Optimising Production: Challenging the Limits with Technology; OnePetro: Moscow, Russia, 2014; Volume 2, pp. 984–991. [Google Scholar]

- Islamov, S.R.; Bondarenko, A.V.; Gabibov, A.F.; Mardashov, D.V. Polymer compositions for well killing operation in fractured reservoirs. In Advances in Raw Material Industries for Sustainable Development Goals; CRC Press/Balkema: Boca Raton, FL, USA, 2021; pp. 343–351. [Google Scholar]

- Kume, N. An Engineering Approach To Predicting Post-Treatment Well Performance Using Selective Chemical Water Shut-Off Techniques: An RPM Example. In Society of Petroleum Engineers (SPE); OnePetro: Moscow, Russia, 2003; pp. 4071–4081. [Google Scholar]

- Mullins, O.C.; Joshi, N.B.; Groenzin, H.; Daigle, T.; Crowell, C.; Joseph, M.T.; Jamaluddin, A. Linearity of Near-Infrared Spectra of Alkanes; SAGE PublicationsSage UK: London, UK, 2016; Volume 54, pp. 624–629. [Google Scholar] [CrossRef]

- Beloglazov, I.I.; Morenov, V.A.; Leusheva, E.L.; Gudmestad, O.T. Modeling of Heavy-Oil Flow with Regard to Their Rheological Properties. Energies 2021, 14, 359. [Google Scholar] [CrossRef]

- Islamov, S.R.; Bondarenko, A.V.; Mardashov, D.V. Substantiation of a well killing technology for fractured carbonate reservoirs. In Proceedings of the Youth Technical Sessions Proceedings—Proceedings of the 6th Youth Forum of the World Petroleum Council-Future Leaders Forum, Saint Petersburg, Russia, 23–28 June 2019; pp. 256–264. [Google Scholar]

- Podoprigora, D.; Raupov, I. Research of the influence of polymeric drilling mud on the filtration-capacitive properties of polymictic sandstones. Acta Tech. CSAV Ceskoslovensk Akad. Ved 2018, 63, 537–546. [Google Scholar]

- Rogachev, M.K.; Kondrashev, A.O. Substantiation of intrastratal water shutoff technology in low permeability reservoirs. J. Min. Inst. 2016, 217, 55. [Google Scholar]

- Lakatos, I.; Szentes, G.; Toro, M.; Karaffa, Z.; Vago, A. Mitigation of Formation Damage Caused by Chemical Overdosing in Water Shut-Off Treatments. In Proceedings of the SPE International Symposium on Formation Damage Control, Lafayette, OR, USA, 19–22 February 2020; OnePetro: Moscow, Russia, 2020. [Google Scholar]

- Dupuis, G.; Bouillot, J.; Zaitoun, A.; Caremi, G.; Burrafato, G. Combined Water/Sand Control Polymer Treatments in Offshore Gas Wells. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 21–23 March 2016. [Google Scholar]

- Parton, C.; Singh, D.; Khamatnurova, T.; Lewis, C.; Vo, L.K. Long Interval Foamed Diversion Treatment: A Mid-Scale Multizone Diversion Treatment Study. In SPE European Formation Damage Conference and Exhibition, Budapest, Hungary, 3–5 June 2015; OnePetro: Moscow, Russia, 2015; pp. 718–731. [Google Scholar]

- El-Karsani, K.S.; Al-Muntasheri, G.A.; Sultan, A.S.; Hussein, I.A. Gelation of a Water-Shutoff Gel at High Pressure and High Temperature: Rheological Investigation. Soc. Pet. Eng. 2015, 20, 1103–1112. [Google Scholar] [CrossRef]

- Dai, L.C.; You, Q.; Yuhong, X.; Long, H.; Ya, C.; Fulin, Z. Case Study on Polymer Gel to Control Water Coning for Horizontal Well in Offshore Oilfield. In Proceedings of the Paper Presented at the Offshore Technology Conference, Houston, TX, USA, 1–3 May 2011. [Google Scholar]

- Jain, P.; Sharma, V.; Raju, A.V.; Patra, S.K. Polymer Gel Squeeze for Gas Shutoff, Water Shutoff and Injection Profile Improvement in Bombay High Pilot Wells. In Proceedings of the Paper presented at the SPE Asia Pacific Oil and Gas Conference and Exhibition, Brisbane, Australia, 17–19 October 2000. [Google Scholar]

- Caili, D.; Qing, Y.; Yefei, W.; Fulin, Z.; Shuler, P. Research on Reutilization Technology of Residual Polymer in Formation After Polymer Flooding. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010. [Google Scholar]

| Glycerol Mass Concentration, % | Surface Tension, mN/m | Contact Angle, Deg | |

|---|---|---|---|

| Oil-Saturated Sample | Water-Saturated Sample | ||

| 0 | 73.4 | 59.9 | 53.5 |

| 1 | 72.4 | 67.0 | 50.8 |

| 2 | 71.7 | 81.3 | 48.9 |

| 3 | 71.3 | 81.7 | 33.9 |

| 4 | 70.1 | 84.0 | 32.8 |

| Glycerol Mass Concentration, % | Surface Tension, mN/m | Work of Adhesion, mJ/m2 | |

|---|---|---|---|

| Oil-Saturated Sample | Water-Saturated Sample | ||

| 0 | 73.4 | 110.3 | 117.1 |

| 1 | 72.4 | 100.7 | 118.1 |

| 2 | 71.7 | 82.6 | 118.9 |

| 3 | 71.3 | 81.7 | 130.5 |

| 4 | 70.1 | 77.4 | 129.0 |

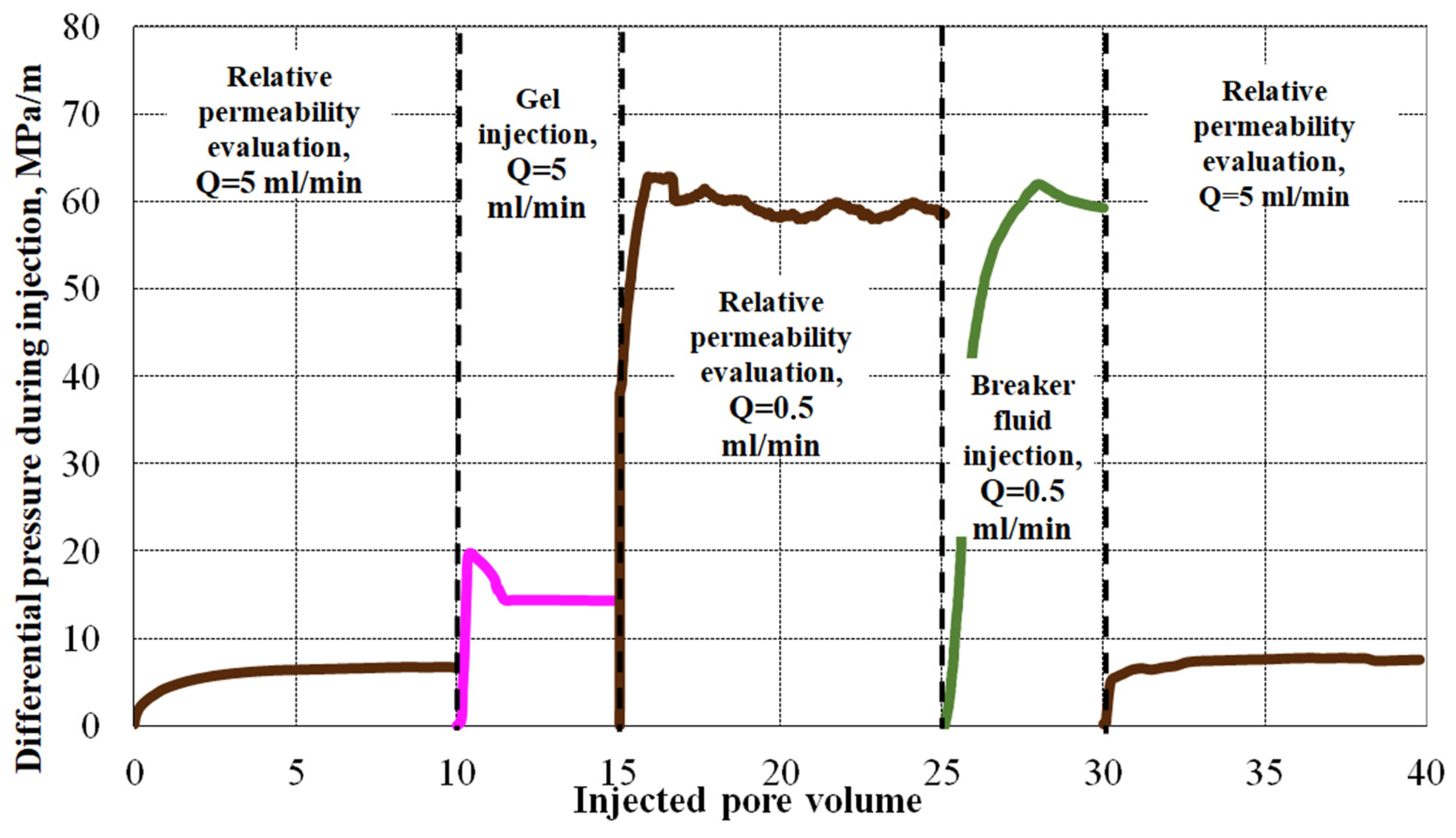

| Characteristic | Unit | Before the Gel Injection | After the Gel Injection | After the Breaker Fluid Injection |

|---|---|---|---|---|

| Differential pressure during the injection | MPa/m | 6.61 | 59.06 | 7.43 |

| Relative permeability to oil | 10−3 μm2 | 303.29 | 3.50 | 267.59 |

| Coefficient of permeability reduction | % | - | −8550 | −13 |

| Residual resistance factor | - | 86.53 | 1.13 | |

| Maximum differential pressure during the injection | MPa/m | 19.57 | ||

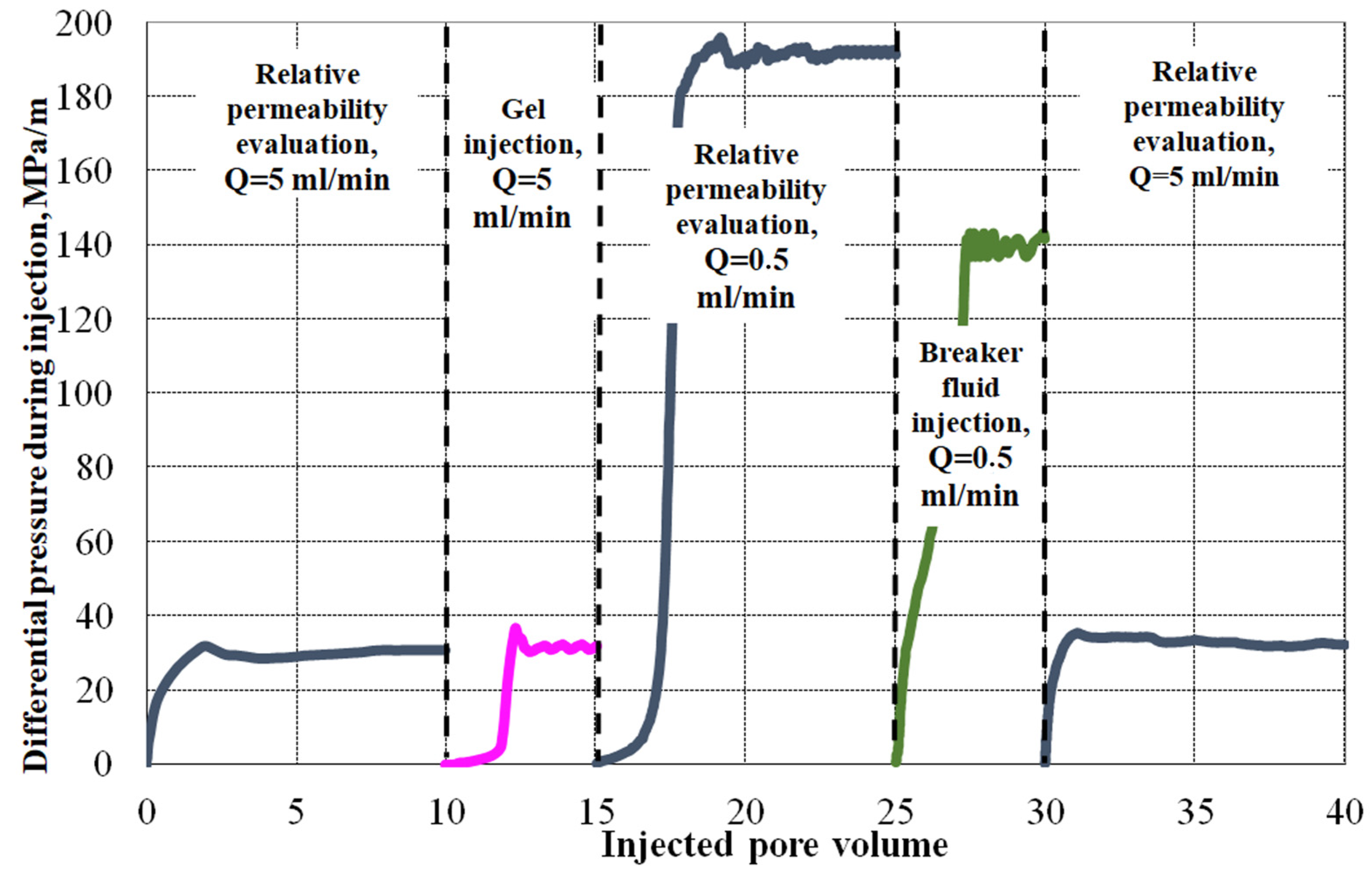

| Characteristic | Unit | Before the Gel Injection | After the Gel Injection | After the Breaker Fluid Injection |

|---|---|---|---|---|

| Differential pressure during the injection | MPa/m | 30.10 | 192.31 | 32.59 |

| Relative permeability to water | 10−3 μm2 | 80.07 | 1.19 | 7.40 |

| Coefficient of permeability reduction | % | - | −6600 | −980 |

| Residual resistance factor | - | 67.04 | 10.82 | |

| Maximum differential pressure during the injection | MPa/m | 36.84 | ||

| Characteristic | Unit | Before the Gel Injection | After the Gel Injection | After the Breaker Fluid Injection |

|---|---|---|---|---|

| Differential pressure of oil injection | MPa/m | 51.37 | 19.66 | 29.89 |

| Differential pressure of water injection | 3.87 | 164.82 | 101.60 | |

| Residual resistance factor of oil-saturated sample | – | 5.26 | 1.19 | |

| Residual resistance factor of water-saturated sample | – | 293.75 | 180.77 | |

| Selectivity coefficient | 55.55 | 152.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duryagin, V.; Nguyen Van, T.; Onegov, N.; Shamsutdinova, G. Investigation of the Selectivity of the Water Shutoff Technology. Energies 2023, 16, 366. https://doi.org/10.3390/en16010366

Duryagin V, Nguyen Van T, Onegov N, Shamsutdinova G. Investigation of the Selectivity of the Water Shutoff Technology. Energies. 2023; 16(1):366. https://doi.org/10.3390/en16010366

Chicago/Turabian StyleDuryagin, Victor, Thang Nguyen Van, Nikita Onegov, and Galiya Shamsutdinova. 2023. "Investigation of the Selectivity of the Water Shutoff Technology" Energies 16, no. 1: 366. https://doi.org/10.3390/en16010366

APA StyleDuryagin, V., Nguyen Van, T., Onegov, N., & Shamsutdinova, G. (2023). Investigation of the Selectivity of the Water Shutoff Technology. Energies, 16(1), 366. https://doi.org/10.3390/en16010366