Experiments on Water-Gas Flow Characteristics under Reservoir Condition in a Sandstone Gas Reservoir

Abstract

:1. Introduction

2. Experimental Samples and Fluid Properties

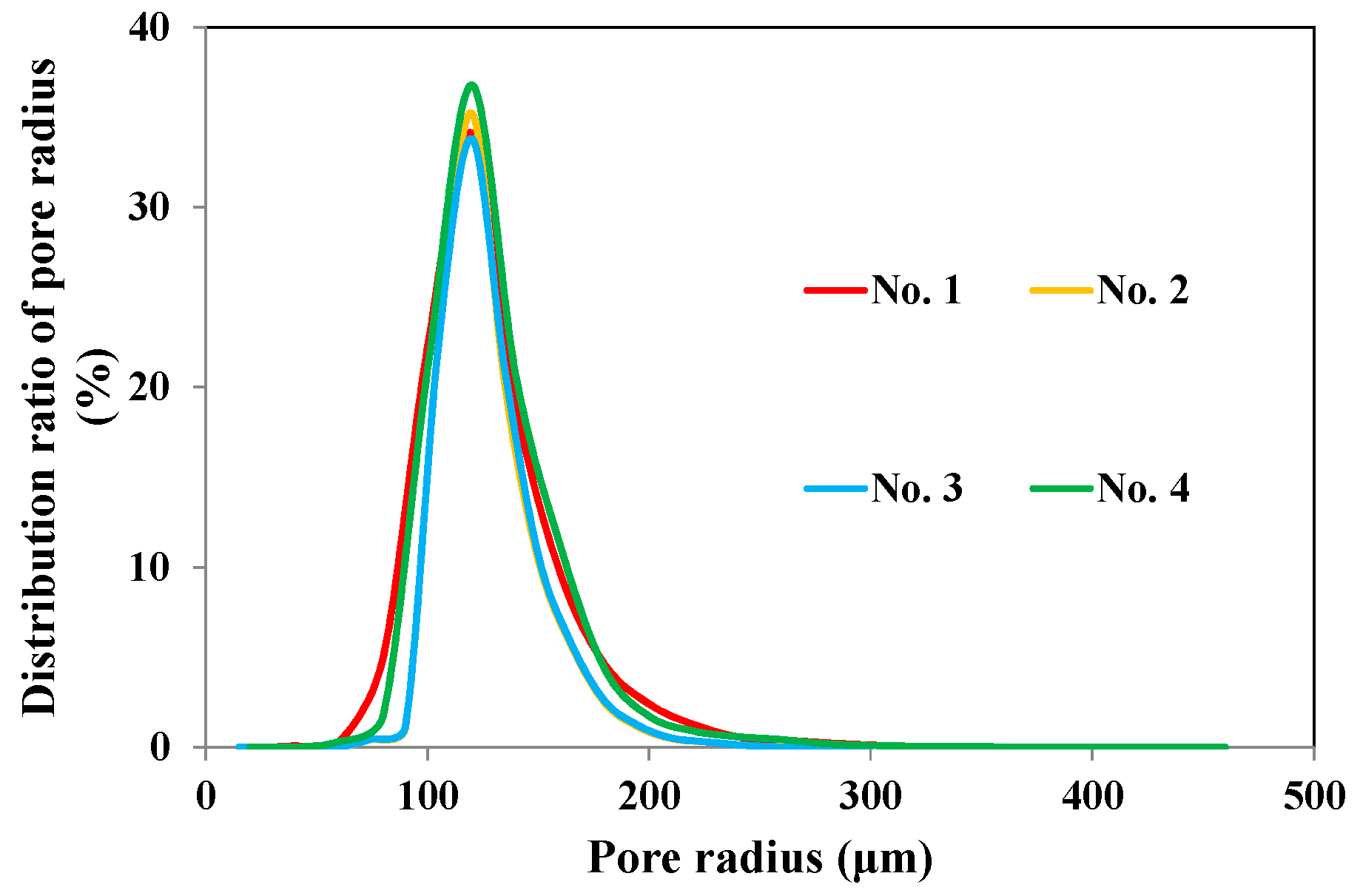

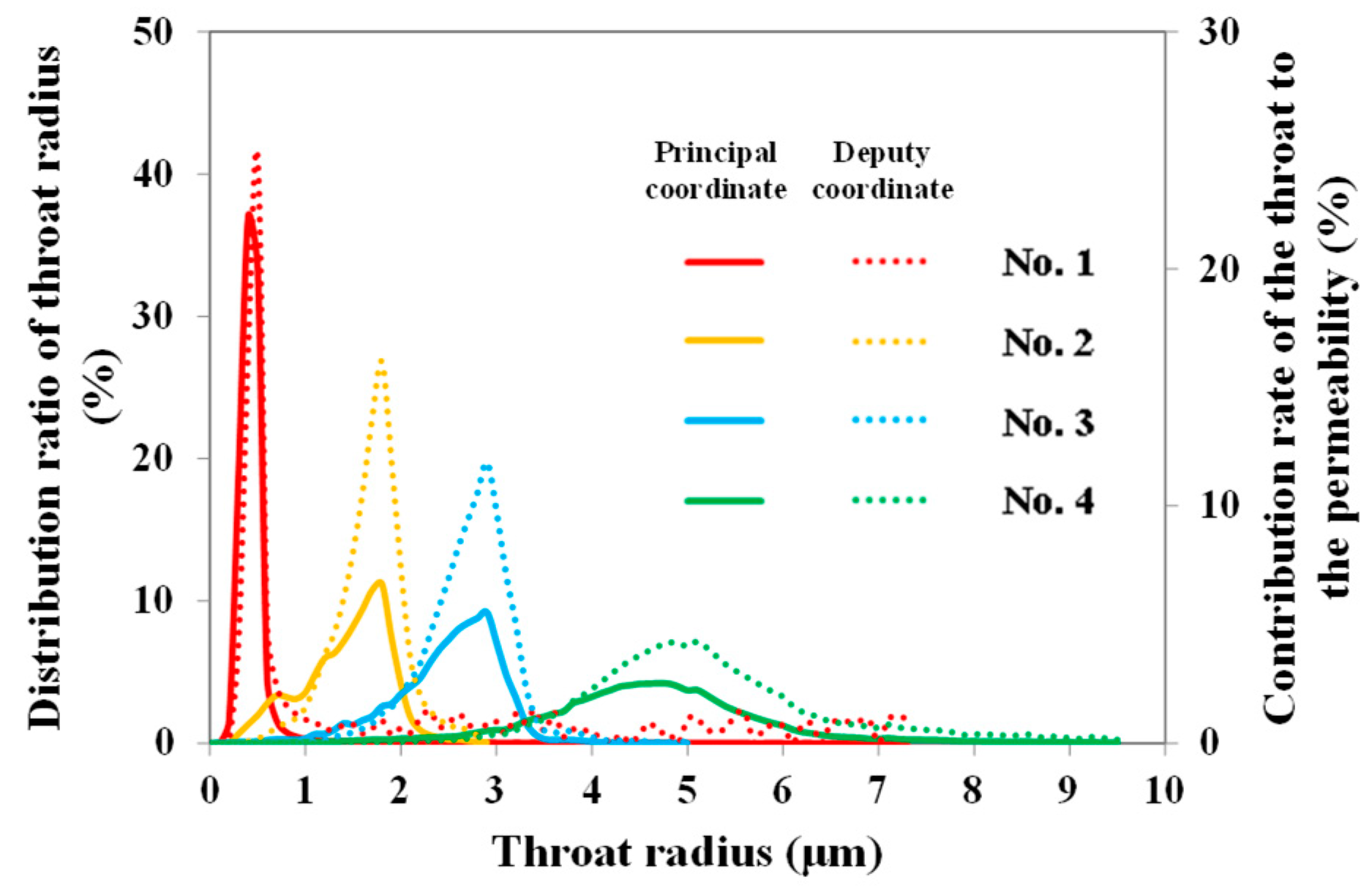

2.1. Properties of Experimental Samples

2.2. Properties of Experimental Fluid

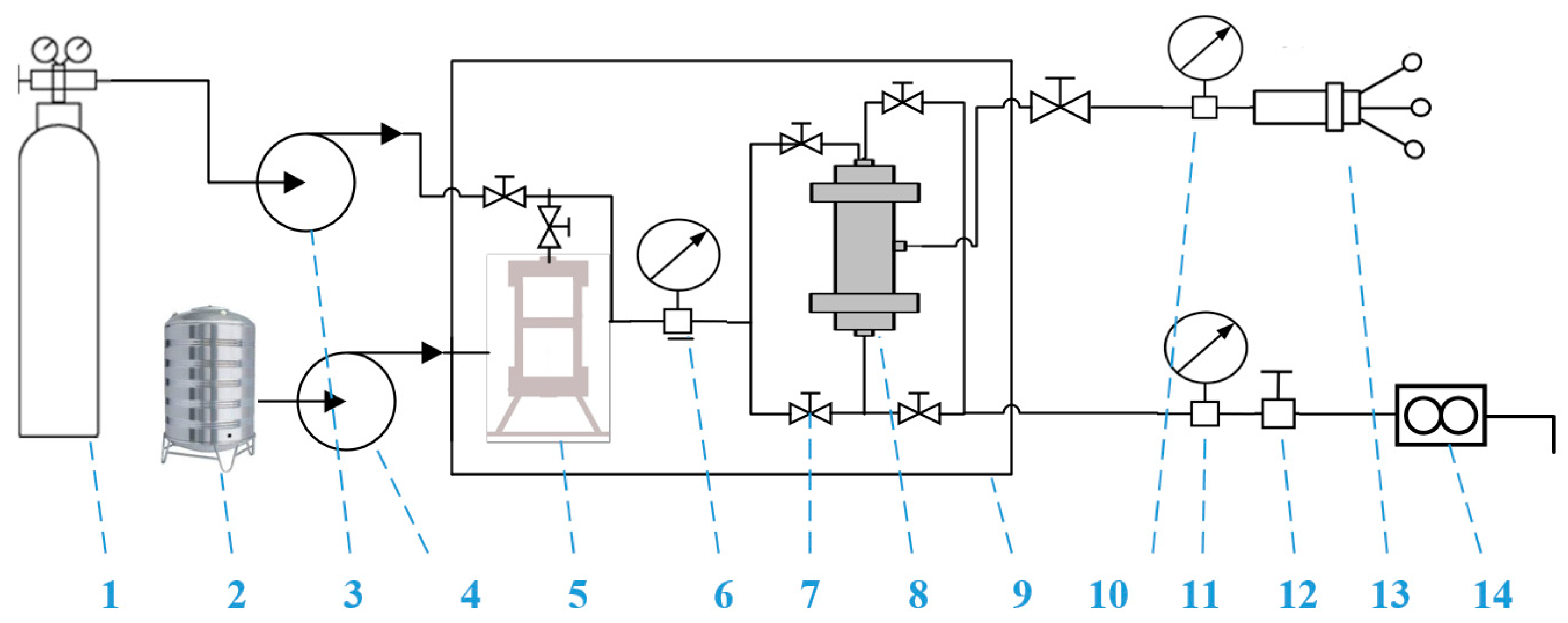

3. Experimental Conditions and Procedures

4. Experimental Results and Analysis

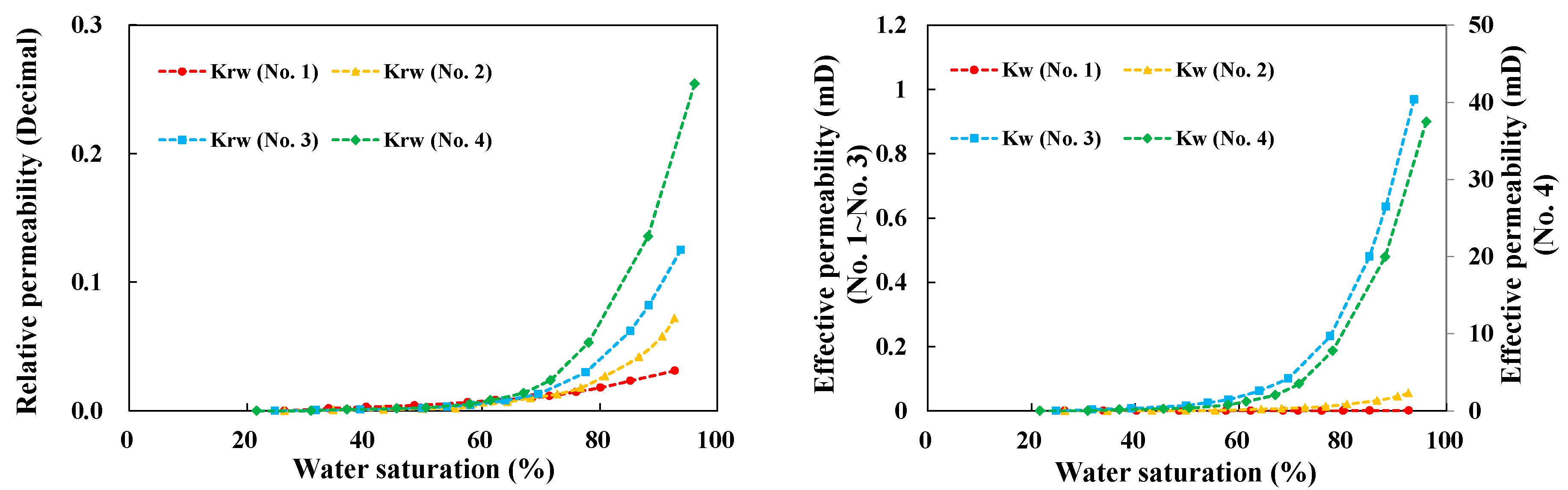

4.1. Water Phase Flow Capacity

4.1.1. Irreducible Water Saturation

4.1.2. Water Relative Permeability under Residual Gas Saturation

4.1.3. Water Effective Permeability under Residual Gas Saturation

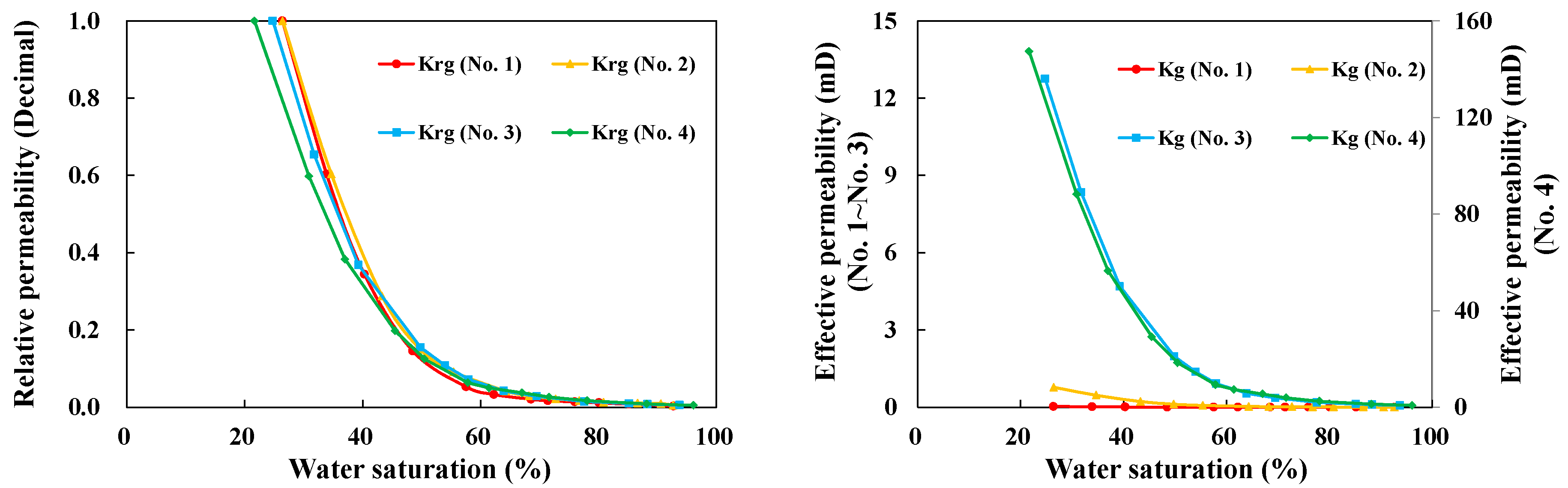

4.2. Gas Phase Flow Capacity

4.2.1. Residual Gas Saturation

4.2.2. Gas Effective Permeability under Irreducible Water Saturation

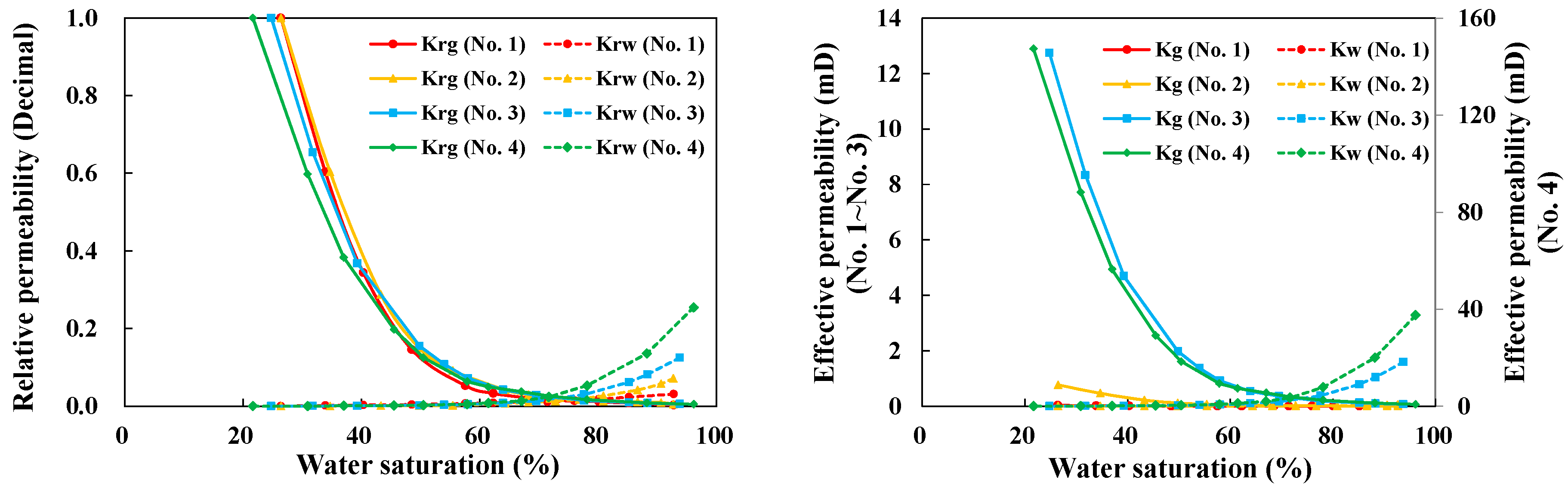

4.3. Integrated Flow Capacity

4.3.1. Two-Phase Co-Flow Area

4.3.2. Water Saturation at the Iso-Permeability Point

5. Conclusions

- (1)

- When sandstone samples have similar clay content, the average throat radius is four times larger, its irreducible water saturation decreased by 1.63%, and the larger the throat radius and the lower the clay content, the greater the relative permeability of the water phase under residual gas saturation.

- (2)

- When sandstone samples have similar clay content, the average throat radius is four times larger, its residual gas saturation decreased by 1.00%, and the larger the throat radius and the lower the clay content, the higher the effective permeability of gas phases under irreducible water saturation.

- (3)

- When sandstone samples have similar clay content, the average throat radius is four times larger, and the two-phase co-seepage zone increased by 2.63%. When the sandstone sample’s clay content increased by 4.70%, the two-phase seepage zone decreased by 0.12%. This entails that the larger the throat radius of the sandstone sample and the lower the clay content, the wider the two-phase co-permeation zone, which is more conducive to gas-liquid flow.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Permeability under reservoir conditions, % | |

| Mean throat radius, μm | |

| Clay content, % | |

| Irreducible water saturation, % | |

| Water relative permeability at the residual gas saturation, dimensionless | |

| Water effective permeability at the residual gas saturation, mD | |

| Residual gas saturation, % | |

| Gas effective permeability at the irreducible water saturation, mD | |

| Water saturation at the iso-permeability point, % | |

| Two-phase co-flow area, % |

Abbreviations

| , | Cumulative water production, cumulative gas production, cm3 |

| , | Cumulative water production after correction and cumulative gas production after correction, cm3 |

| The compression factor of water, decimals | |

| The compression factor of gas, decimals | |

| Gas water ratio, decimals | |

| Water content, decimal | |

| Dimensionless cumulative water recovery, decimal | |

| Dimensionless cumulative total output, decimal | |

| Volume of pore, cm3 | |

| Water phase relative permeability | |

| Relative to injection capacity or flow capacity, dimensionless, decimal | |

| , | Water production flow of rock sample outlet face at initial time and time t, cm3/s |

| , | Displacement pressure difference at the initial time and at t, MPa |

| Gas phase relative permeability | |

| , | Gas and water viscosity, mPa.s |

| Gas saturation of rock sample outlet end face, decimal |

Appendix A

| No. | Cumulative Time (s) | Pressure Drop (MPa) | Cumulative Gas Production at Atmospheric Pressure (mL) | Cumulative Water Production at Atmospheric Pressure (mL) |

|---|---|---|---|---|

| 1 | 132 | 0.31 | 0.08 | 0.00 |

| 2 | 162 | 0.31 | 0.49 | 0.01 |

| 3 | 192 | 0.31 | 1.00 | 0.02 |

| 4 | 222 | 0.31 | 1.11 | 0.03 |

| 5 | 252 | 0.31 | 1.22 | 0.04 |

| 6 | 282 | 0.31 | 1.38 | 0.19 |

| 7 | 312 | 0.31 | 1.74 | 0.49 |

| 8 | 330 | 0.31 | 2.06 | 0.63 |

| 9 | 348 | 0.31 | 2.41 | 0.71 |

| 10 | 366 | 0.31 | 2.78 | 0.74 |

| 11 | 384 | 0.31 | 2.92 | 0.76 |

| 12 | 402 | 0.31 | 3.23 | 0.78 |

| 13 | 420 | 0.31 | 3.53 | 0.80 |

| 14 | 474 | 0.31 | 4.47 | 0.85 |

| 15 | 528 | 0.31 | 5.53 | 0.90 |

| 16 | 546 | 0.31 | 6.09 | 0.91 |

| 17 | 600 | 0.31 | 7.26 | 0.95 |

| 18 | 618 | 0.31 | 7.64 | 0.96 |

| 19 | 684 | 0.31 | 9.11 | 1.00 |

| 20 | 774 | 0.31 | 11.70 | 1.05 |

| 21 | 804 | 0.31 | 12.72 | 1.06 |

| 22 | 894 | 0.31 | 29.79 | 1.11 |

| 23 | 1014 | 0.31 | 33.78 | 1.15 |

| 24 | 1254 | 0.31 | 42.40 | 1.23 |

| 25 | 1494 | 0.31 | 51.74 | 1.28 |

| 26 | 1734 | 0.31 | 78.85 | 1.33 |

| 27 | 2034 | 0.31 | 92.10 | 1.38 |

| 28 | 2334 | 0.31 | 105.93 | 1.43 |

| 29 | 2934 | 0.31 | 135.74 | 1.48 |

| 30 | 3534 | 0.31 | 169.62 | 1.55 |

| 31 | 5334 | 0.31 | 268.92 | 1.64 |

| 32 | 7134 | 0.31 | 380.67 | 1.75 |

| 33 | 8934 | 0.31 | 496.52 | 1.80 |

| 34 | 10,734 | 0.31 | 650.42 | 1.86 |

| 35 | 11,934 | 0.31 | 799.90 | 1.90 |

| 36 | 15,534 | 0.31 | 1208.21 | 1.95 |

| 37 | 19,734 | 0.31 | 1690.86 | 2.00 |

| No. | Cumulative Time (s) | Pressure Drop (MPa) | Cumulative Gas Production at Atmospheric Pressure(mL) | Cumulative Water Production at Atmospheric Pressure (mL) |

|---|---|---|---|---|

| 1 | 36 | 0.20 | 0.70 | 0.05 |

| 2 | 48 | 0.20 | 1.77 | 0.11 |

| 3 | 60 | 0.20 | 3.53 | 0.55 |

| 4 | 72 | 0.20 | 5.59 | 0.66 |

| 5 | 96 | 0.20 | 11.54 | 0.78 |

| 6 | 192 | 0.20 | 51.69 | 0.95 |

| 7 | 402 | 0.20 | 188.76 | 1.40 |

| 8 | 672 | 0.20 | 417.55 | 1.50 |

| 9 | 702 | 0.20 | 446.57 | 1.55 |

| 10 | 2082 | 0.20 | 1991.08 | 2.00 |

| 11 | 2142 | 0.20 | 2051.61 | 2.05 |

| 12 | 2442 | 0.20 | 2443.42 | 2.08 |

| 13 | 2742 | 0.20 | 2827.21 | 2.15 |

| 14 | 3042 | 0.20 | 3214.24 | 2.20 |

| 15 | 3342 | 0.20 | 3602.74 | 2.25 |

| 16 | 3582 | 0.20 | 3918.17 | 2.33 |

| 17 | 3642 | 0.20 | 4098.94 | 2.35 |

| 18 | 4242 | 0.20 | 4920.09 | 2.45 |

| 19 | 4842 | 0.20 | 5713.16 | 2.55 |

| 20 | 5022 | 0.20 | 5950.61 | 2.60 |

| 21 | 5082 | 0.20 | 6028.61 | 2.63 |

| No. | Cumulative Time (s) | Pressure Drop (MPa) | Cumulative Gas Production at Atmospheric Pressure (mL) | Cumulative Water Production at Atmospheric Pressure (mL) |

|---|---|---|---|---|

| 1 | 12 | 2.10 | 0.17 | 0.00 |

| 2 | 72 | 2.10 | 0.60 | 0.00 |

| 3 | 132 | 2.10 | 0.90 | 0.15 |

| 4 | 192 | 2.10 | 1.82 | 0.33 |

| 5 | 252 | 2.10 | 2.88 | 0.35 |

| 6 | 312 | 2.10 | 4.16 | 0.37 |

| 7 | 372 | 2.10 | 5.08 | 0.39 |

| 8 | 792 | 2.10 | 10.13 | 0.44 |

| 9 | 972 | 2.10 | 16.41 | 0.46 |

| 10 | 1152 | 2.10 | 24.18 | 0.47 |

| 11 | 1332 | 2.10 | 33.46 | 0.49 |

| 12 | 1512 | 2.10 | 44.08 | 0.50 |

| 13 | 2412 | 2.10 | 114.45 | 0.52 |

| 14 | 4032 | 2.10 | 303.79 | 0.54 |

| 15 | 4752 | 2.10 | 407.97 | 0.57 |

| 16 | 6492 | 2.10 | 697.73 | 0.60 |

| 17 | 7692 | 2.10 | 922.59 | 0.63 |

| 18 | 9695 | 2.10 | 1162.22 | 0.67 |

| 19 | 10,895 | 2.10 | 1415.75 | 0.70 |

| 20 | 13,295 | 2.10 | 1905.12 | 0.72 |

| 21 | 18,000 | 2.10 | 2481.82 | 0.74 |

| No. | Cumulative Time (s) | Pressure Drop (MPa) | Cumulative Gas Production at Atmospheric Pressure (mL) | Cumulative Water Production at Atmospheric Pressure (mL) |

|---|---|---|---|---|

| 1 | 12 | 0.02 | 0.10 | 0.00 |

| 2 | 24 | 0.02 | 0.50 | 0.05 |

| 3 | 36 | 0.02 | 1.50 | 0.37 |

| 4 | 48 | 0.02 | 3.00 | 0.75 |

| 5 | 132 | 0.02 | 5.47 | 1.14 |

| 6 | 252 | 0.02 | 50.00 | 1.31 |

| 7 | 400 | 0.02 | 100.00 | 1.50 |

| 8 | 700 | 0.02 | 200.00 | 1.75 |

| 9 | 1000 | 0.02 | 300.00 | 1.90 |

| 10 | 1500 | 0.02 | 500.00 | 2.05 |

| 11 | 2100 | 0.02 | 700.00 | 2.20 |

| 12 | 2600 | 0.02 | 900.00 | 2.33 |

| 13 | 3162 | 0.02 | 1400.00 | 2.41 |

| 14 | 3462 | 0.02 | 1600.00 | 2.49 |

| 15 | 3762 | 0.02 | 1900.00 | 2.58 |

| 16 | 4062 | 0.02 | 2200.00 | 2.66 |

| 17 | 4362 | 0.02 | 2600.00 | 2.75 |

| 18 | 4962 | 0.02 | 3500.00 | 2.84 |

| 19 | 5262 | 0.02 | 5000.00 | 2.98 |

Appendix B

Appendix C

| No. | Saturation of Water (%) | Krg | Krw |

|---|---|---|---|

| 1 | 92.76 | 0.0032 | 0.0313 |

| 2 | 85.20 | 0.0080 | 0.0233 |

| 3 | 80.12 | 0.0117 | 0.0181 |

| 4 | 75.98 | 0.0139 | 0.0148 |

| 5 | 71.43 | 0.0168 | 0.0116 |

| 6 | 68.54 | 0.0206 | 0.0104 |

| 7 | 62.26 | 0.0329 | 0.0085 |

| 8 | 57.74 | 0.0530 | 0.0067 |

| 9 | 48.51 | 0.1455 | 0.0043 |

| 10 | 40.30 | 0.3440 | 0.0031 |

| 11 | 33.89 | 0.6032 | 0.0019 |

| 12 | 26.39 | 1.0000 | 0.0000 |

| No. | Saturation of Water (%) | Krg | Krw |

|---|---|---|---|

| 1 | 92.68 | 0.0053 | 0.0720 |

| 2 | 90.60 | 0.0094 | 0.0580 |

| 3 | 86.65 | 0.0108 | 0.0420 |

| 4 | 80.86 | 0.0128 | 0.0270 |

| 5 | 76.78 | 0.0170 | 0.0180 |

| 6 | 72.78 | 0.0214 | 0.0130 |

| 7 | 68.23 | 0.0294 | 0.0100 |

| 8 | 64.31 | 0.0420 | 0.0070 |

| 9 | 55.43 | 0.0920 | 0.0020 |

| 10 | 49.78 | 0.1500 | 0.0016 |

| 11 | 43.29 | 0.2876 | 0.0011 |

| 12 | 34.69 | 0.6033 | 0.0005 |

| 13 | 26.43 | 1.0000 | 0.0000 |

| No. | Saturation of Water (%) | Krg | Krw |

|---|---|---|---|

| 1 | 93.76 | 0.0055 | 0.1250 |

| 2 | 88.33 | 0.0078 | 0.0820 |

| 3 | 85.19 | 0.0098 | 0.0620 |

| 4 | 77.61 | 0.0148 | 0.0300 |

| 5 | 69.54 | 0.0284 | 0.0130 |

| 6 | 63.92 | 0.0422 | 0.0080 |

| 7 | 58.00 | 0.0720 | 0.0045 |

| 8 | 54.00 | 0.1080 | 0.0033 |

| 9 | 49.83 | 0.1550 | 0.0021 |

| 10 | 39.28 | 0.3680 | 0.0010 |

| 11 | 31.8 | 0.6540 | 0.0006 |

| 12 | 24.76 | 1.0000 | 0.0000 |

| No. | Saturation of Water (%) | Krg | Krw |

|---|---|---|---|

| 1 | 96.12 | 0.0051 | 0.2543 |

| 2 | 88.20 | 0.0087 | 0.1356 |

| 3 | 78.10 | 0.0170 | 0.0530 |

| 4 | 71.64 | 0.0266 | 0.0237 |

| 5 | 67.03 | 0.0375 | 0.0137 |

| 6 | 61.44 | 0.0497 | 0.0082 |

| 7 | 57.88 | 0.0634 | 0.0052 |

| 8 | 50.47 | 0.1250 | 0.0025 |

| 9 | 45.48 | 0.1980 | 0.0018 |

| 10 | 37.00 | 0.3830 | 0.0011 |

| 11 | 30.89 | 0.5980 | 0.0000 |

| 12 | 21.65 | 1.0000 | 0.0000 |

References

- Wang, F.; Li, X.; Couples, G.; Shi, J.; Zhang, J.; Tepinhi, Y.; Wu, L. Stress arching effect on stress sensitivity of permeability and gas well production in Sulige gas field. J. Pet. Sci. Eng. 2015, 125, 234–246. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, F.; Xu, W.; Wang, J. Performance evaluation on water-producing gas wells based on gas & water relative permeability curves: A case study of tight sandstone gas reservoirs in the Sulige gas field, Ordos Basin. Nat. Gas Ind. B 2016, 3, 52–58. [Google Scholar]

- Zhao, K.; Du, P. Performance of horizontal wells in composite tight gas reservoirs considering stress sensitivity. Adv. Geo-Energy Res. 2019, 3, 287–303. [Google Scholar] [CrossRef]

- Johnson, E.F.; Bossler, D.P.; Naumann, V.O. Calculation of relative permeability from displacement experiments. Trans. AIME 1959, 216, 370–372. [Google Scholar] [CrossRef]

- Brace, W.F.; Walsh, J.B.; Frangos, W.T. Permeability of granite under high pressure. J. Geophys. Res. 1968, 73, 2225–2236. [Google Scholar] [CrossRef]

- Hsieh, P.A.; Tracy, J.V.; Neuzit, C.E.; Bredehoeft, J.D.; Silliman, S.E. A transient laboratory method for determining the hydraulic properties of ‘tight’ rocks- I. Theory. Int. J. Rock Mech. Min. Sci. 1981, 18, 245–252. [Google Scholar] [CrossRef]

- Yang, Z.; Bryant, S.; Dong, M. A method to measure ultralow permeabilities of shale core in multiple directions using pressure-pulse decay technique. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24 September 2018. SPE191511-MS. [Google Scholar]

- Toth, J.; Bodi, T.; Szucs, P.; Civan, F. Convenient formulae for determination of relative permeability from unsteady-state fluid displacements in core plugs. J. Pet. Sci. Eng. 2002, 36, 33–44. [Google Scholar] [CrossRef]

- Fu, X.; Agostini, F.; Skoczylas, F.; Jeannin, L. Experimental study of the stress dependence of the absolute and relative permeabilities of some tight gas sandstones. Int. J. Rock Mech. Min. Sci. 2015, 77, 36–43. [Google Scholar] [CrossRef]

- Mamudu, A.; Taiwo, S.; Olafuyi, O. Comparative Approach to Relative Permeability Predictions. In Proceedings of the Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 31 July 2017. SPE189174-MS. [Google Scholar]

- Fatemi, S.M.; Sohrabi, M. Relative permeabilities hysteresis for oil/water, gas/water and gas/oil systems in mixed-wet rocks. J. Pet. Sci. Eng. 2018, 161, 559–591. [Google Scholar] [CrossRef]

- Babadagli, T.; Raza, S.; Ren, X.; Develi, K. Effect of surface roughness and lithology on the water-gas and water-oil relative permeability ratios of oil-wet single fractures. Int. J. Multiph. Flow 2015, 75, 68–81. [Google Scholar] [CrossRef]

- Guo, X.; Zou, G.; Wang, Y.; Wang, Y.; Cao, T. Investigation of the temperature effect on rock permeability sensitivity. J. Pet. Sci. Eng. 2017, 156, 616–622. [Google Scholar] [CrossRef]

- Yacoub, A.; Djerbi, A.; Fen-Chong, T. The effect of the drying temperature on water porosity and gas permeability of recycled sand mortar. Constr. Build. Mater. 2019, 214, 677–684. [Google Scholar] [CrossRef]

- Guo, P.; Zhang, H.; Du, J.; Wang, Z.; Zhang, W.; Ren, H. Study on gas-liquid relative permeability experiments of fractured-porous reservoirs. Petroleum 2017, 3, 348–354. [Google Scholar] [CrossRef]

- Alberto, B.; Dante, H.D.; Oscar, C.; Armando, G.; Baltasar, M.; Roberto, M. Experimental study of the effect of wettability on the relative permeability for air-water flow through porous media. Int. J. Multiph. Flow 2019, 120, 103091. [Google Scholar]

- Fan, J.; Zhou, H.; Liu, S.; Liu, K. Gas-water Two phases Flow Characterization and its Influencing Factors in Low Permeability Tight Sandstone. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 12–14 August 2013. SPE URTEC2013-278. [Google Scholar]

- Yin, X.; Shu, J.; Li, Y.; Wei, G.; Lu, J.; Wu, P.; Ma, L. Impact of pore structure and clay content on the water-gas relative permeability curve within tight sandstones: A case study from the LS block, eastern Ordos Basin, China. J. Nat. Gas. Sci. Eng. 2020, 81, 103418. [Google Scholar]

- Agostinil, F.; Egermann, P.; Jeannin, L.; Portier, E.; Skoczylas, F.; Wang, Y. Loading Effects on Gas Relative Permeability of a Low-Permeability Sandstone. Petrophysics 2019, 60, 326–334. [Google Scholar]

- Mo, S.Y.; He, S.L.; Lei, G.; Gai, S.H.; Liu, Z.K. Effect of the drawdown pressure on the relative permeability in tight gas: A theoretical and experimental study. J. Nat. Gas. Sc.i Eng. 2015, 24, 264–271. [Google Scholar] [CrossRef]

- Farahani, M.; Aghaei, H.; Asadolahpour, S.R. Sensitivity of unsteady-state gas-water relative permeability to experimental artefacts and interpretation techniques; case study from a gas reservoir in south Iran. J. Nat. Gas. Sci. Eng. 2019, 71, 102998. [Google Scholar] [CrossRef]

- Adenutsi, C.D.; Li, Z.; Xu, Z.; Sun, L. Influence of net confining stress on NMR T2 distribution and two-phase relative permeability. J. Pet. Sci. Eng. 2019, 178, 766–777. [Google Scholar] [CrossRef]

- Moghadasi, L.; Guadagnini, A.; Inzoli, F.; Bartosek, M.; Renna, D. Characterization of two- and three-phase relative permeability of water-wet porous media through X-Ray saturation measurements. J. Pet. Sci. Eng. 2016, 145, 453–463. [Google Scholar] [CrossRef]

- Zhang, G.; Yao, G.; Li, J.; Wu, H.; Liu, Z.; Li, D. A new experimental method for measuring the three-phase relative permeability of oil, gas, and water. J. Pet. Sci. Eng. 2018, 170, 611–619. [Google Scholar] [CrossRef]

- Andersen, P.Ø. Analytical modeling and correction of steady state relative permeability experiments with capillary end effects–An improved intercept method, scaling and general capillary numbers. Oil Gas Sci. Technol. Rev. D’ifp Energ. Nouv. 2021, 76, 61. [Google Scholar] [CrossRef]

- Andersen, P.Ø.; Salomonsen, L.; Sleveland, D.S. Characteristic forced and spontaneous imbibition behavior in strongly water-wet sandstones based on experiments and simulation. Energies 2022, 15, 3531. [Google Scholar] [CrossRef]

- Andersen, P.Ø.; Nesvik, E.K.; Standnes, D.C. Analytical solutions for forced and spontaneous imbibition accounting for viscous coupling. J. Pet. Sci. Eng. 2020, 186, 106717. [Google Scholar] [CrossRef]

- Zhang, T.; Li, X.; Sun, Z.; Feng, D.; Miao, Y.; Li, P.; Zhang, Z. An analytical model for relative permeability in water-wet nanoporous media. Chem. Eng. Sci. 2017, 174, 1–12. [Google Scholar] [CrossRef]

- Zhu, H.; Tang, X.; Liu, Q.; Liu, S.; Zhang, B.; Jiang, S.; McLennan, J.D. Permeability stress-sensitivity in 4D flow-geomechanical coupling of Shouyang CBM reservoir, Qinshui Basin, China. Fuel 2018, 232, 817–832. [Google Scholar] [CrossRef]

- Salimi, H.; Bruining, J.; Joekar-Niasar, V. Comparison of modified effective-medium approximation to pore-network theory for relative permeabilities. J. Pet. Sci. Eng. 2019, 184, 106594. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Teng, S.; Xu, D. Improved models to predict gas-water relative permeability in fractures and porous media. J. Nat. Gas. Sci. Eng. 2014, 19, 190–201. [Google Scholar] [CrossRef]

- Lai, B.; Miskimins, J.L. A new technique for accurately measuring two-phase relative permeability under non-Darcy flow conditions. J. Pet. Sci. Eng. 2015, 127, 398–408. [Google Scholar] [CrossRef]

- Zhou, C. Predicting water permeability and relative gas permeability of unsaturated cement-based material from hydraulic diffusivity. Cem. Concr. Res. 2014, 58, 143–151. [Google Scholar] [CrossRef]

- Daigle, H. Relative permeability to water or gas in the presence of hydrates in porous media from critical path analysis. J. Pet. Sci. Eng. 2016, 146, 526–535. [Google Scholar] [CrossRef]

- Wu, F.; Fan, Q.; Huang, D.; Ma, L.; Liang, X.; Sima, L. Predicting gas-water relative permeability using Nuclear Magnetic Resonance and Mercury Injection Capillary Pressure measurements. J. Nat. Gas. Sci. Eng. 2016, 32, 35–47. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, N.; Alyafei, N.; Wang, Y.H.; Fadlelmula, M. Numerical Relative Permeability Upscaling Based on Digital Rock Analysis. In Proceedings of the Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, UAE, 17 September 2019. SPE196687-MS. [Google Scholar]

- Mo, F.; Peng, X.; Devegowda, D.; Tang, Y.; Sun, H.S. Permeability jail for two-phase flow in tight sandstones: Formulation, application and sensitivity studies. J. Pet. Sci. Eng. 2020, 184, 106583. [Google Scholar] [CrossRef]

- Tan, X.H.; Li, J.; Li, X.P.; Zhang, B.J.; Li, X.C. Flow model of a multi-stage hydraulic fractured horizontal well based on tree-shaped fractal fracture networks. J. Pet. Sci. Eng. 2018, 169, 494–503. [Google Scholar] [CrossRef]

- Tan, X.H.; Li, X.P.; Liu, J.Y.; Zhang, G.D.; Zhang, L.H. Analysis of permeability for transient two-phase flow in fractal porous media. J. Appl. Phys. 2014, 115, 113502. [Google Scholar] [CrossRef]

- Tan, X.H.; Liu, C.Y.; Li, X.P.; Wang, H.Q.; Deng, H. A stress sensitivity model for the permeability of porous media based on bi-dispersed fractal theory. Int. J. Mod. Phys. C 2018, 29, 1850019. [Google Scholar] [CrossRef]

- Han, X.B.; Tan, X.H.; Li, X.P. A water invasion unit numerical simulation model for the distribution of water and water invasion channel in complex edge water reservoir. J. Pet. Sci. Eng. 2022, 215, 2–20. [Google Scholar] [CrossRef]

- Liu, L.; Dai, S.; Ning, F.; Cai, J.C.; Liu, C.L.; Wu, N.Y. Fractal characteristics of unsaturated sands−implications to relative permeability in hydrate-bearing sediments. J. Nat. Gas. Sci. Eng. 2019, 66, 11–17. [Google Scholar] [CrossRef]

- Yang, J.P.; Chen, W.Z.; Tian, H.M.; Yu, H.D. Study of permeability evolutions in low permeability medium under different stresses and temperatures. Rock. Soil. Mech. 2009, 30, 3587–3595. [Google Scholar]

- Fang, J.; Guo, P.; Xiao, X.; Du, J.; Dong, C.; Xiong, Y.; Long, F. Gas-water relative permeability measurement of high temperature and high pressure tight gas reservoirs. Pet. Explor. Dev. 2015, 42, 92–96. [Google Scholar] [CrossRef]

- Li, Y.L.; Li, X.P.; Wu, F.; Lu, H.L.; Lei, X.; Wang, W.J.; Lu, R.B.; Tan, X.H. Experimental study on stress sensitivity of high-temperature and high-pressure sandstone gas reservoirs in Yingqiong Basin. Energy Sci. Eng. 2020, 8, 1–10. [Google Scholar] [CrossRef]

- GB/T 28912–2012; Test Method For Two Phase Relative Permeability In Rock. Standardization Administration of China: Beijing, China, 2012.

| No. | Diameter, cm | Length, cm | Porosity, % | Permeability, mD | ||

|---|---|---|---|---|---|---|

| Conventional Conditions | Reservoir Conditions | Conventional Conditions | Reservoir Conditions | |||

| 1 | 2.46 | 4.70 | 8.33 | 8.08 | 0.112 | 0.062 |

| 2 | 2.49 | 4.91 | 18.55 | 16.87 | 4.590 | 2.688 |

| 3 | 2.50 | 4.64 | 19.27 | 18.65 | 20.380 | 17.524 |

| 4 | 2.50 | 4.92 | 20.60 | 19.89 | 192.251 | 176.652 |

| No. | Non-Clay Minerals Composition, % | Clay Content, % | ||||

|---|---|---|---|---|---|---|

| Quartz | Feldspar | Calcite | Dolomite | Siderite | ||

| 1 | 70.7 | 16.2 | 6.6 | 1.2 | 0.2 | 5.1 |

| 2 | 65.2 | 13.9 | 5.2 | 4.6 | 1.3 | 9.8 |

| 3 | 71.1 | 15.5 | 4.9 | 3.0 | 0.0 | 5.5 |

| 4 | 70.3 | 14.7 | 4.7 | 3.9 | 0.2 | 6.2 |

| No. | ||||||

|---|---|---|---|---|---|---|

| 1 | 0.062 | 0.522 | 5.1 | 26.39 | 0.031 | 0.001 |

| 2 | 2.688 | 1.460 | 9.8 | 26.43 | 0.072 | 0.056 |

| 3 | 17.524 | 2.509 | 5.5 | 24.76 | 0.125 | 0.969 |

| 4 | 176.652 | 4.715 | 5.3 | 21.65 | 0.254 | 37.487 |

| No. | |||||

|---|---|---|---|---|---|

| 1 | 0.062 | 0.522 | 5.1 | 7.24 | 0.031 |

| 2 | 2.688 | 1.460 | 9.8 | 7.32 | 0.772 |

| 3 | 17.524 | 2.509 | 5.5 | 6.24 | 12.750 |

| 4 | 176.652 | 4.715 | 5.3 | 3.88 | 147.403 |

| No. | |||||

|---|---|---|---|---|---|

| 1 | 0.062 | 0.522 | 5.1 | 66.37 | 76.81 |

| 2 | 2.688 | 1.460 | 9.8 | 66.25 | 76.11 |

| 3 | 17.524 | 2.509 | 5.5 | 69.00 | 73.71 |

| 4 | 176.652 | 4.715 | 5.3 | 74.47 | 71.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Yang, H.; Li, X.; Kui, M.; Zhang, J. Experiments on Water-Gas Flow Characteristics under Reservoir Condition in a Sandstone Gas Reservoir. Energies 2023, 16, 36. https://doi.org/10.3390/en16010036

Li Y, Yang H, Li X, Kui M, Zhang J. Experiments on Water-Gas Flow Characteristics under Reservoir Condition in a Sandstone Gas Reservoir. Energies. 2023; 16(1):36. https://doi.org/10.3390/en16010036

Chicago/Turabian StyleLi, Yilong, Hao Yang, Xiaoping Li, Mingqing Kui, and Jiqiang Zhang. 2023. "Experiments on Water-Gas Flow Characteristics under Reservoir Condition in a Sandstone Gas Reservoir" Energies 16, no. 1: 36. https://doi.org/10.3390/en16010036

APA StyleLi, Y., Yang, H., Li, X., Kui, M., & Zhang, J. (2023). Experiments on Water-Gas Flow Characteristics under Reservoir Condition in a Sandstone Gas Reservoir. Energies, 16(1), 36. https://doi.org/10.3390/en16010036