Merging Climate Action with Energy Security through CCS—A Multi-Disciplinary Framework for Assessment

Abstract

1. Introduction

1.1. Literature Review

1.1.1. CDR Technologies

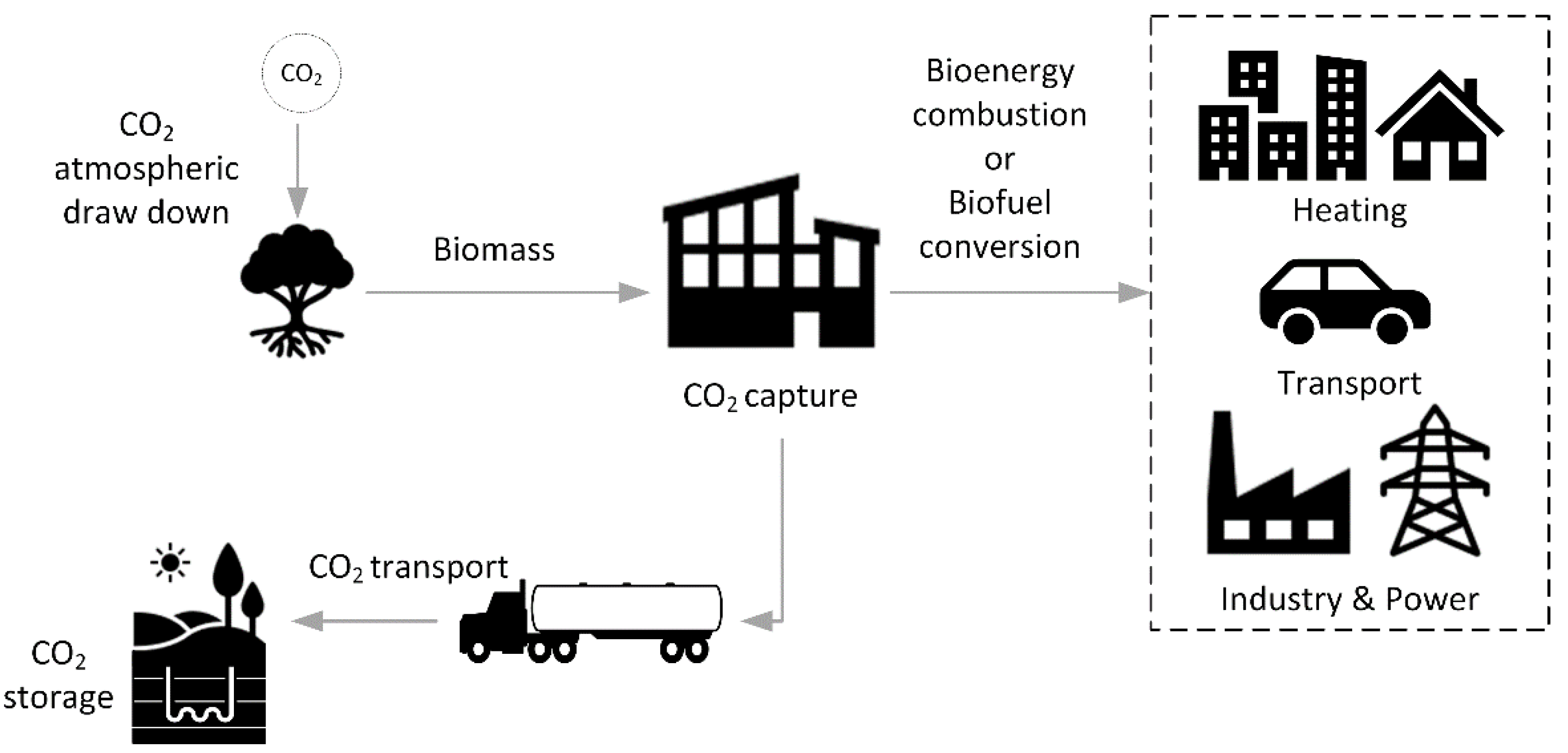

- bio-chemical biofuels production;

- thermo-chemical production of biofuels and biochemicals;

- biomass combustion for electricity generation and/or heat production [6].

- Pre-combustion—CO2 separation from the H2 with physical absorption methods. CO2 and H2 are main components of a shifted gas produced after gasification or steam methane reforming;

- Oxy-combustion—CO2 separation via a condensation process from flue gas after burning fuel with oxygen and recycled CO2;

- Post-combustion—CO2 separation from flue gas after fuel combustion, with chemical absorption processes applied [16].

1.1.2. CDR Assessment (Energy, Economic and Environmental)

1.1.3. Carbon Dioxide Removal Policies Review

European Union

United Kingdom

United States of America

Australia

Poland

2. Materials and Methods

2.1. Case Studies Selection

2.1.1. Power Plants in Poland

- Hard coal power plant—based on Łagisza 460 MW unit (HC_REF),

- Lignite power plant—based on Bełchatów 380 MW unit (L_REF),

- Biomass power plant—based on Połaniec 225 MW unit (BE_REF)

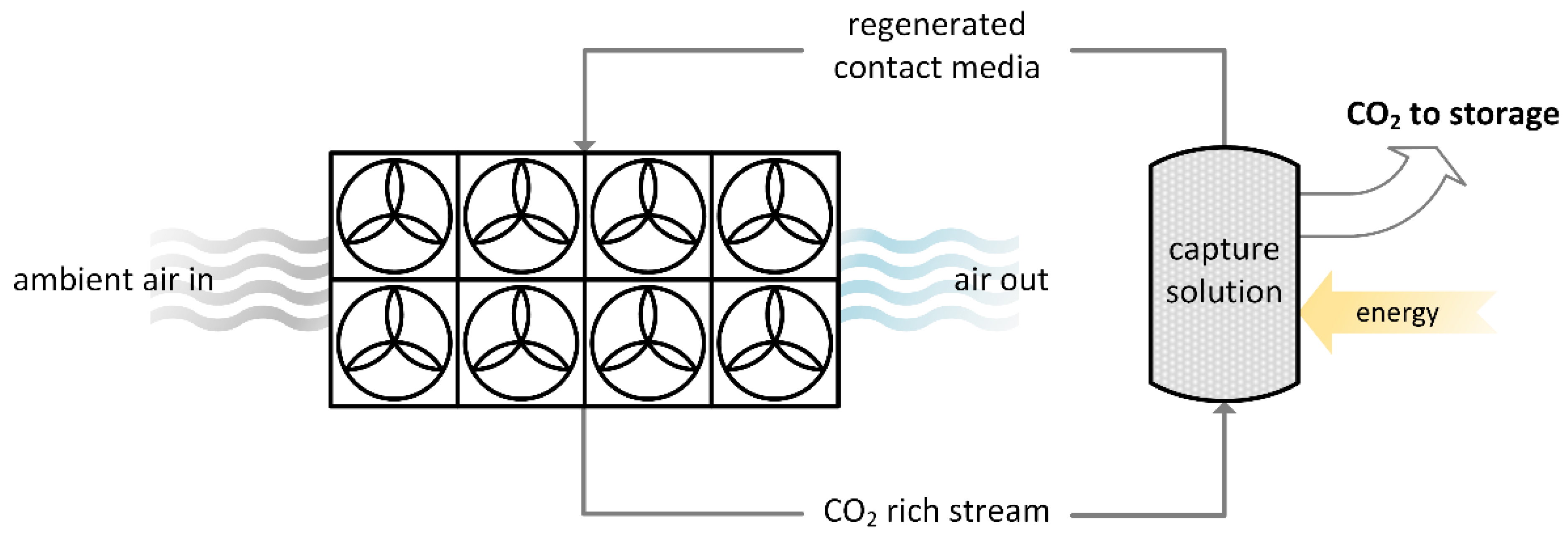

2.1.2. Direct Air Capture Installations

- High-temperature aqueous (DAC_HT),

- Low-temperature solid sorbent, with two options for heat supply:

- -

- waste heat from industrial processes (DAC_LTWH),

- -

- heat pump (DAC_LTHP).

2.2. Process Synthesis and Design

- MEA post-combustion CO2 capture technology,

- CO2 capture efficiency of 90%,

- reboiler heat duty equal to 3 MJ/kg, with reboiler temperature of 130 °C,

- steam for reboiler is extracted on the crossover pipe and its pressure is adapted to fit with capture unit requirements by means of valve (retrofit cases) or dedicated turbine (new build),

- steam de-superheating options considered are associated with mixing with a fraction of the condensate (retrofit cases) or introduction of an additional heat exchanger (new build),

- in new-build cases, the heat integration is acknowledged by means of partial replacement of condensate and boiler feedwater preheaters,

- CO2 pressure for transport equal to 130 bar.

2.3. Assessment Methods

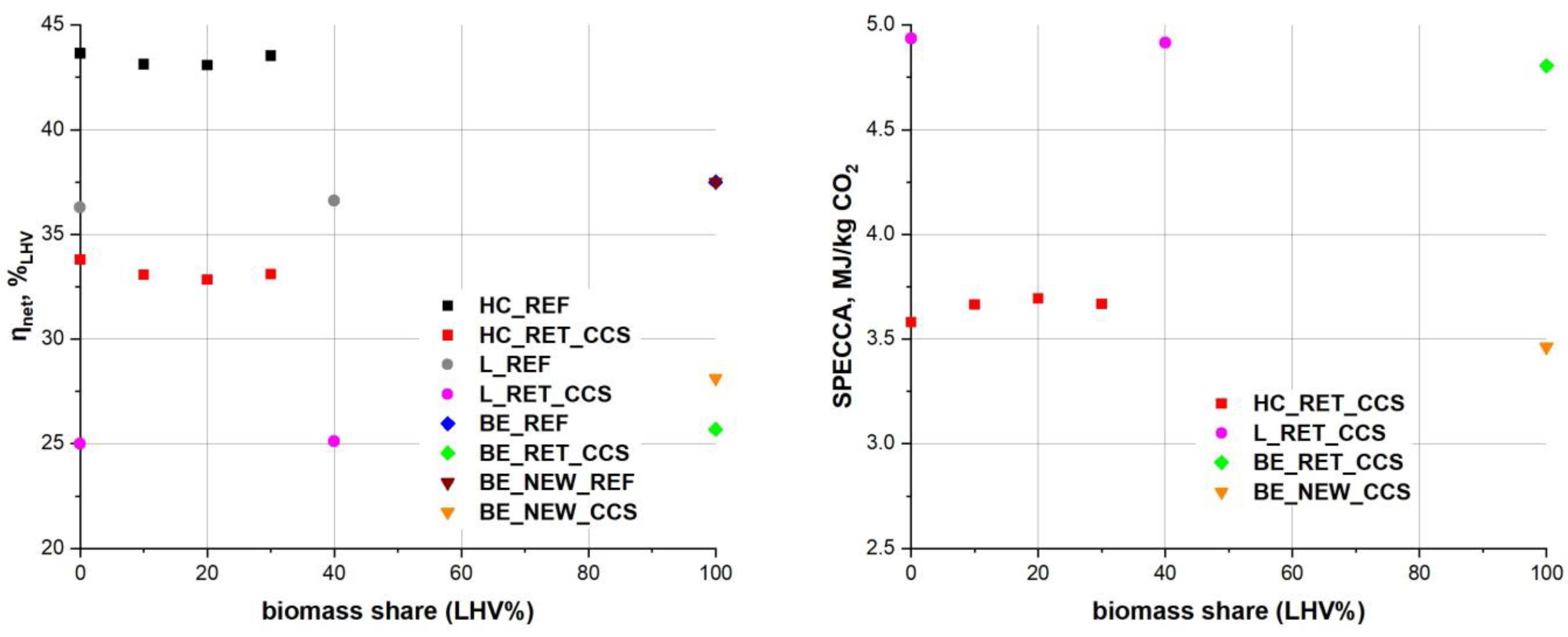

2.3.1. Performance Indexes

- net electrical efficiency (ηnet, %LHV):

- loss of net electrical efficiency (Δηnet, % pts.):

- specific primary energy consumption for CO2 avoided (SPECCA, MJLHV/kg CO2):where is annual net electricity production, MWhel, is annual consumption of i-th fuel, MWhLHV, is unit fuel consumption per net electricity production, MJLHV/MWhel and is specific direct CO2 emission, kg CO2/MWhel.

2.3.2. Negative Emissions Calculation Methods

- indicates the type of CO2 we intended to be capture (e.g., =1 if CO2 comes from geological sources or =0 if whole intended CO2 comes from atmosphere),

- indicates the amount of CO2 captured and which we intended to be re-emitted to atmosphere (e.g., =0 when whole CO2 is being permanently stored or =1 when CO2 will be re-emitted thru utilization process through means of synthetic fuels or other products),

- indicates the additional CO2 emissions in the CCUS technological chain that must be accounted for. Thus, it can be calculated as a sum of CO2 resulting from capture, conversion, use or storage, plus the re-emitted amount added.

2.3.3. Thermo-Ecological Cost Assessment

2.3.4. Negative Emissions Readiness Index

- direct policies that provide either encouraging or punishing incentives for deploying CDR;

- enabling policies, facilitating innovation and infrastructure;

- integrating policies that build connections with other policies.

2.3.5. Economic Assessment

3. Results

3.1. Energy Assessment

3.2. Achieving Negative Emissions

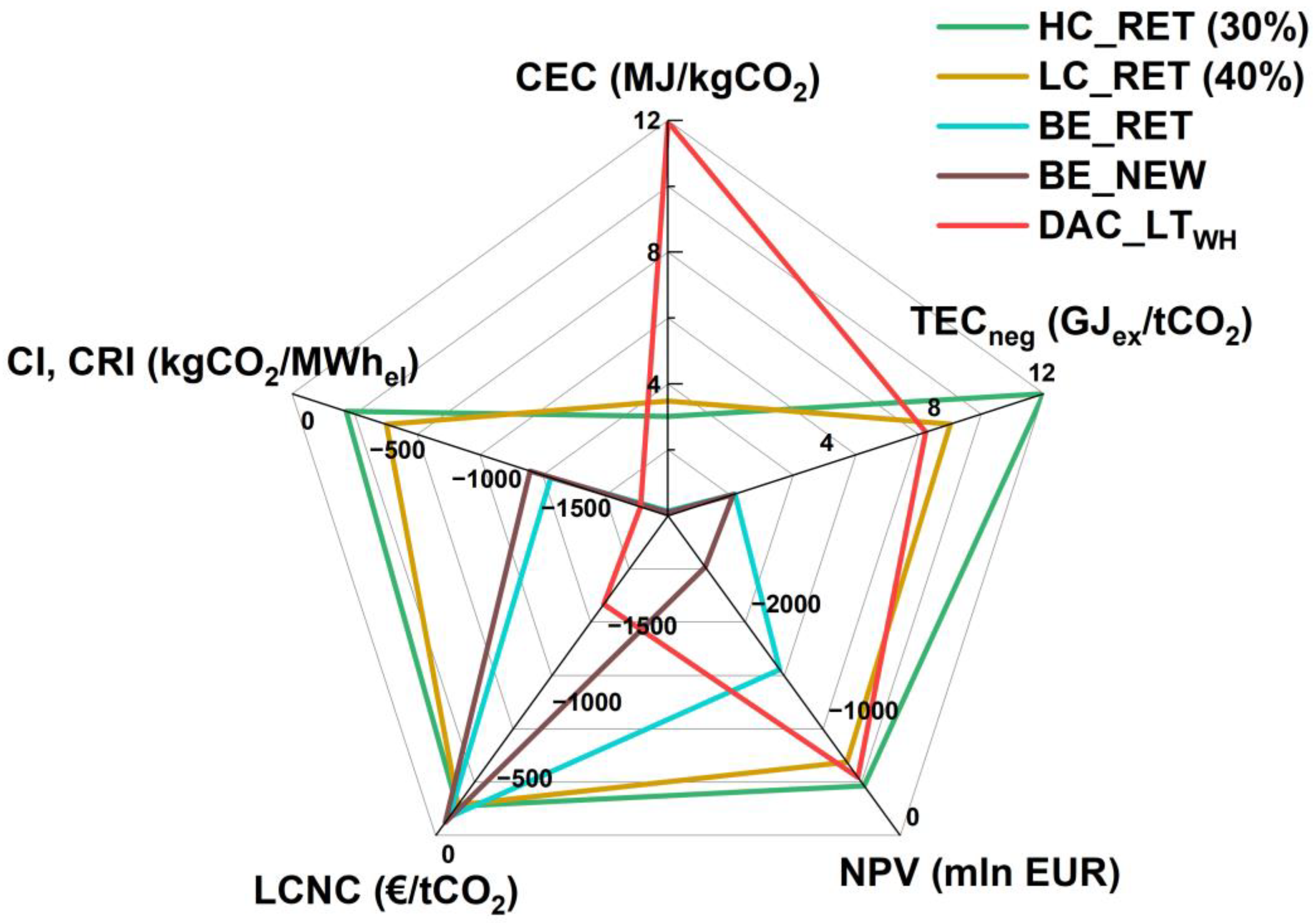

3.3. Thermo-Ecological Cost of Negative Emissions

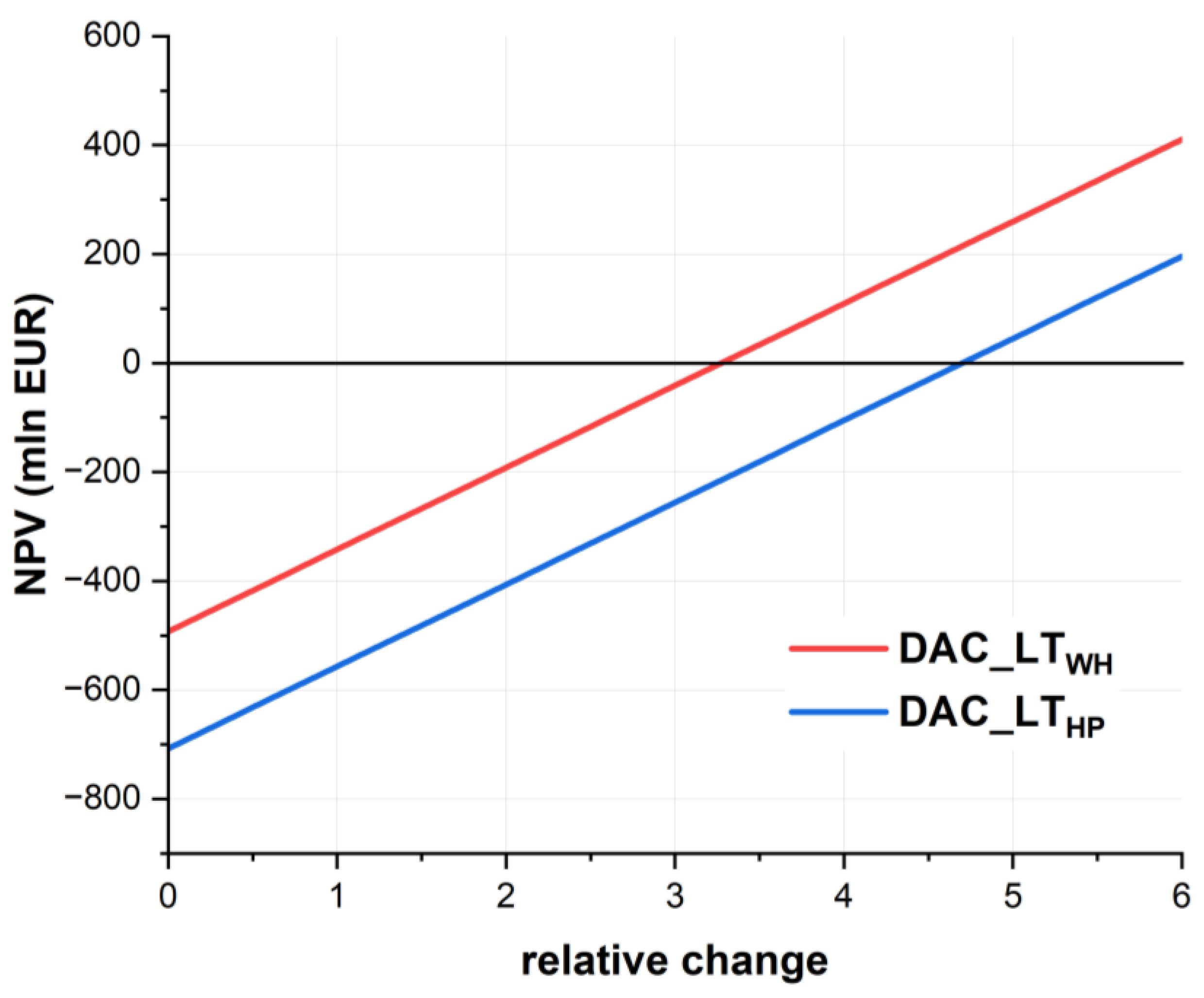

3.4. Economic Evaluation

4. Conclusions

- Thermo-ecological cost can be a suitable tool for the assessment of the burdens associated with obtaining negative CO2 emissions with different technologies and processes.

- For the DAC units powered by renewable energy sources or dedicated BECCS power plants, the values of the TEC of negative CO2 emissions are significantly lower for the removal than the abatement of carbon dioxide.

- The sources of energy supply (biomass/coal and electricity) significantly impact the obtained results, and in less favorable cases the CDR technologies can actually add CO2 emissions to the atmosphere instead of removing it.

- The costs of CO2 capture varies due to capture technology, power system, plant design, fuel properties or economic factors.

- High capital expenditures for both retrofitted power plants and DAC installations indicate that there is a need to introduce a financial support system in Poland and economic incentives to make their use more economically feasible.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Level | Indicator | Measurement | Explanation/Comment | Poland’s Score | |

|---|---|---|---|---|---|

| Geo- political | 1. | Gas connections | Gas interconnectors capacity/CO2 emissions | Higher connectivity leads to more incentives to cooperate on carbon removal. Poland emitted 227 bln cubic meters of CO2 (source: Such, Piotr. “Sekwestracja CO2 w Polsce nie ma sensu?!.“ Nafta-Gaz 76 (2020).) Gas interconnectors export capacity is 0.5 bln cubic meters in 2021 but is projected to reach 10.1 bln in early 2020s. | 0.002 |

| 2. | Lock-in into climate policies | Number of climate policies implemented/number of climate treaties implemented by the top performer | Data acquired from the climate change mitigation policies and measures (PaM) database provided by the European Environment Agency. At the beginning of 2022, Poland has implemented 43 policies while leader—France—has affected155. | 0.27 | |

| 3. | Lock-in into international treaties | Number of climate treaties ratified/number of climate treaties ratified by the top performer | - | n.d. | |

| 4. | Level of ambition of climate agreements | Number of years to net zero/Number of years to net zero declared by the top performer | The top performer here is defined as the developed country with the nearest date of achieving net zero pledged internally (in law) or internationally (submitted to international body) | 0 | |

| 5. | International posture regarding climate change | Net-zero year declared? y/n | For net zero year declared country is given 1, with no such declaration being given 0. | 0 | |

| 6. | Domestic availability of hydrocarbon resources | Hydrocarbons imports | Higher dependency on imported hydrocarbons (oil & gas) leads to more incentives for carbon removal. Import dependency for crude oil it was 98.3%, and 77.6% for natural gas in 2018 (source: Energy statistics in 2018 and 2019 https://stat.gov.pl/files/gfx/portalinformacyjny/pl/defaultaktualnosci/5485/4/15/1/gospodarka_paliwowo-energetyczna_2018_i_2019.pdf, accessed on 4 January 2022) | 0.88 | |

| Domestic/ National | 7. | Location of and access to renewable energy resources (on-/offshore wind, solar potential, hydro potential) | 1-RES potential of electricity generation | Higher RES potential leads to less incentives for carbon removal. Data for Poland, 2050 from: Polish energy sector 2050 | 4 scenarios; https://forum-energii.eu/en/analizy/polska-energetyka-2050-4-scenariusze; renewable scenario (accessed on 4 January 2022) | 0.27 |

| 8. | A predictable and enduring policy environment | World Bank’s GCI 4.0: Government ensuring policy stability indicator | World Bank’s policy stability indicator is applied and scaled to fit 0–1 scale ((GCI/10) × 1.43). Data for Poland from 2019. | 0.42 | |

| 9. | Effective and comprehensive CCS law and regulation | Number of CCS policies in force/Number of CCS policies in force of the top performer | These numbers are taken from the IEA policy database. The top performer at the end of 2021 is the UK with 19 policies in force. | 0 | |

| 10. | Early storage site identification and site characterization | CCS Storage indicator | CCS Storage indicator, divided by 10. Alternatively, the indicator might be expressed as “Identified storage capacity/CO2 emissions”. However, it has been suggested that Poland’s storage capacity is relatively low and could potentially cover only 3.5 year of Polish emissions (source: Such, Piotr. “Sekwestracja CO2 w Polsce nie ma sensu?!.” Nafta-Gaz 76 (2020).) | 0.63 | |

| 11. | Research and development into cost reduction in CCS technologies | Spending on CCS R&D projects in millions of euros/spending climate change mitigation | The cost of Poland’s CCS program was assessed at the level of 624 million euro, without operating costs (from https://docplayer.pl/9230785-Budowa-instalacji-demonstracyjnej-ccs-zintegrowana-z-nowym-blokiem-858-mw-w-elektrowni-belchatow-warszawa-czerwiec-2011r.html, accessed on 4 January 2022). 100 mln euro should be added to adjust this number to current conditions—but the project was not finally funded. Rough estimation of climate protection is made by combining pollution abatement and R&D on environmental protection for Poland in 2019 (source: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Main_Page, accessed on 4 January 2022) | 0 | |

| 12. | Establishing a supporting scheme for CDR technologies | 1—(CCS costs/EU ETS allowance cost) | CCS costs assessed for unfinished CCS Bełchatów installation from 2011 (65 euro/t from https://docplayer.pl/9230785-Budowa-instalacji-demonstracyjnej-ccs-zintegrowana-z-nowym-blokiem-858-mw-w-elektrowni-belchatow-warszawa-czerwiec-2011r.html, accessed on 4 January 2022; would probably be lower today), EU ETS average median price in 2021 (ca. 52 eur/t) from https://afsgroup.nl/news/eu-ets-market-outlook-13-12-2021/, accessed on 4 January 2022 | −0.25 | |

| 13. | Legacy networks— electric grid | 1—Projected share of electricity in final energy consumption in 2050 | The legacy networks direct path dependencies. If a country is widely electrified (e.g., France), the switch to low levels of carbon is easier, hence less incentives for carbon removal. Lack of data. | ||

| 14. | Legacy networks— gas pipelines | Projected share of gas in final energy consumption in 2050 | The legacy networks direct path dependencies. If there is a large domestic/consumer gas distribution network, decision makers will be hesitant to change, hence carbon removal more likely. | 0 | |

| 15. | Dependency on industries difficult to decarbonize | Share of industry in a country’s GDP | dependency on industries that are difficult to decarbonize, e.g., aluminum, steelmaking, higher dependency on those leads to more incentives for carbon removal source: https://databank.worldbank.org/views/reports/reportwidget.aspx?Report_Name=CountryProfile&Id=b450fd57&tbar=y&dd=y&inf=n&zm=n&country=POL, accessed on 22 December 2021 | 0.28 | |

| 16. | Economic dependency on hydrocarbon industry | Mining contribution/Country GDP | Coal industry’s contribution to real GDP growth in Poland in 2013. (source: Whither are you headed, Polish coal? Development prospects of the Polish hard coal mining sector https://wise-europa.eu/wp-content/uploads/2016/03/Whither-are-you-headed-Polish-coal.pdf, accessed on 4 January 2022 | −0.15 | |

| 17. | Availability of biomass | (PJ of biomass potentially produced/year)/(PJ tons of produced/year) | Data for biomass potentially produced (900 PJ) from Gładysz P.: Analiza techniczna możliwości redukcji emisji dwutlenku węgla z elektrowni Bełchatów. 2018, data for production of primary energy in 2019 (2528. PJ) from Energy statistics in 2018 and 2019 (https://stat.gov.pl/download/gfx/portalinformacyjny/pl/defaultaktualnosci/5485/4/15/1/gospodarka_paliwowo-energetyczna_2018_i_2019.pdf, accessed on 4 January 2022) | 0.35 | |

| Average Score | 0.159 |

References

- Pires, J.C.M. Negative Emissions Technologies: A Complementary Solution for Climate Change Mitigation. Sci. Total Environ. 2019, 672, 502–514. [Google Scholar] [CrossRef] [PubMed]

- Schumer, C.; Lebling, K.; World Resources Institute. How are Countries Counting on Carbon Removal to Meet Climate Goals? Available online: https://www.wri.org/insights/carbon-removal-countries-climate-goals (accessed on 29 May 2022).

- Grant, N.; Hawkes, A.; Mittal, S.; Gambhir, A. The Policy Implications of an Uncertain Carbon Dioxide Removal Potential. Joule 2021, 5, 2593–2605. [Google Scholar] [CrossRef]

- IEAGHG. Potential for Biomass and Carbon Dioxide Capture and Storage. July 2011. Available online: https://legacy-assets.eenews.net/open_files/assets/2011/08/04/document_cw_01.pdf (accessed on 30 May 2022).

- Gładysz, P.; Ziebik, A. Environmental Analysis of Bio-CCS in an Integrated Oxy-Fuel Combustion Power Plant with CO2 Transport and Storage. Biomass Bioenergy 2016, 85, 109–118. [Google Scholar] [CrossRef]

- EuropeanTechnology Platform for Zero Emission Fossil Fuel Power Plants. Biomass with CO2 Capture and Storage (Bio-CCS). 2012. Available online: https://www.etipbioenergy.eu/images/EBTP-ZEP-Report-Bio-CCS-The-Way-Forward.pdf (accessed on 30 May 2022).

- Fasihi, M.; Efimova, O.; Breyer, C. Techno-Economic Assessment of CO2 Direct Air Capture Plants. J. Clean. Prod. 2019, 224, 957–980. [Google Scholar] [CrossRef]

- Szargut, J.; Zibik, A.; Stanek, W. Depletion of the Non-Renewable Natural Exergy Resources as a Measure of the Ecological Cost. Energy Convers. Manag. 2002, 43, 1149–1163. [Google Scholar] [CrossRef]

- Szargut, J. Exergy Method: Technical and Ecological Applications; WIT-Press: Southampton, UK, 2005; ISBN 978-1-85312-753-3. [Google Scholar]

- Stanek, W. Examples of Application of Exergy Analysis for the Evaluation of Ecological Effects in Thermal Processes; Silesian University of Technology Press: Gliwice, Poland, 2009. [Google Scholar]

- Czarnowska, L. Thermo-Ecological Cost of Products with Emphasis on External Environmental Costs. Ph.D. Thesis, Silesian University of Technology & National Technical University of Athens, Gliwice, Poland, 2014. [Google Scholar]

- International Energy Agency. Technology Perspectives Energy Special Report on Carbon Capture Utilisation and Storage CCUS in Clean Energy Transitions; International Energy Agency: Bengaluru, India, 2020. [Google Scholar]

- Economics, V. Greenhouse Gas Removal (GGR) Policy Options-Final Report; Vivid Economics: London, UK, 2019. [Google Scholar]

- Chen, C.; Tavoni, M. Direct Air Capture of CO2 and Climate Stabilization: A Model Based Assessment. Clim. Chang. 2013, 118, 59–72. [Google Scholar] [CrossRef]

- Global CCS Institute. Bioenergy and Carbon Capture and Storage, 2019 Perspective; Global CCS Institute: Melbourne, Australia, 2019. [Google Scholar]

- García-Freites, S.; Gough, C.; Röder, M. The Greenhouse Gas Removal Potential of Bioenergy with Carbon Capture and Storage (BECCS) to Support the UK’s Net-Zero Emission Target. Biomass Bioenergy 2021, 151, 106164. [Google Scholar] [CrossRef]

- Tamme, E. Brief Carbon Removal with CCS Technologies; Global CCS Institute: Melbourne, Australia, 2021. [Google Scholar]

- European Academies Science Advisory Council: What Role in Meeting Paris Agreement Targets? 2018. Available online: https://easac.eu/fileadmin/PDF_s/reports_statements/Negative_Carbon/EASAC_Report_on_Negative_Emission_Technologies.pdf (accessed on 31 May 2022).

- Fuss, S.; Lamb, W.F.; Callaghan, M.W.; Hilaire, J.; Creutzig, F.; Amann, T.; Beringer, T.; de Oliveira Garcia, W.; Hartmann, J.; Khanna, T.; et al. Negative Emissions—Part 2: Costs, Potentials and Side Effects. Environ. Res. Lett. 2018, 13, 063002. [Google Scholar] [CrossRef]

- Special Report on Climate Change and Land—IPCC Site. Available online: https://www.ipcc.ch/srccl/ (accessed on 29 May 2022).

- Marcucci, A.; Kypreos, S.; Panos, E. The Road to Achieving the Long-Term Paris Targets: Energy Transition and the Role of Direct Air Capture. Clim. Chang. 2017, 144, 181–193. [Google Scholar] [CrossRef]

- Bui, M.; Fajardy, M.; Mac Dowell, N. Bio-Energy with CCS (BECCS) Performance Evaluation: Efficiency Enhancement and Emissions Reduction. Appl. Energy 2017, 195, 289–302. [Google Scholar] [CrossRef]

- Fajardy, M.; Mac Dowell, N. Can BECCS Deliver Sustainable and Resource Efficient Negative Emissions? Energy Environ. Sci. 2017, 10, 1389–1426. [Google Scholar] [CrossRef]

- Deutz, S.; Bardow, A. Life-Cycle Assessment of an Industrial Direct Air Capture Process Based on Temperature–Vacuum Swing Adsorption. Nat. Energy 2021, 6, 203–213. [Google Scholar] [CrossRef]

- Slesinski, D.; Litzelman, S. How Low-Carbon Heat Requirements for Direct Air Capture of CO2 Can Enable the Expansion of Firm Low-Carbon Electricity Generation Resources. Front. Clim. 2021, 3, 101. [Google Scholar] [CrossRef]

- The Intergovernmental Panel on Climate Change. Global Warming of 1.5 °C—An IPCC Special Report. Summary for Policymakers. Switzerland, 2018. Available online: https://www.ipcc.ch/sr15/ (accessed on 4 January 2022).

- The Intergovernmental Panel on Climate Change. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Switzerland, 2014. Available online: https://www.ipcc.ch/report/ar5/syr/ (accessed on 4 January 2022).

- Möller, I. Political Perspectives on Geoengineering: Navigating Problem Definition and Institutional Fit. Glob. Environ. Politics 2020, 20, 57–82. [Google Scholar] [CrossRef]

- Armeni, C.; Redgwell, C. International Legal and Regulatory Issues of Climate Geoengineering Governance: Rethinking the Approach. Clim. Geoengin. Gov. Work. Pap. Ser. 2015, 21, 6–8. [Google Scholar]

- Consoli, C.; Havercroft, I.; Irlam, L. Carbon Capture and Storage Readiness Index; Global CCS Institute: Melbourne, Australia, 2016. [Google Scholar]

- Committee on Climate Change. UK Climate Action Following the Paris Agreement. 2016. Available online: https://www.theccc.org.uk/publication/uk-action-following-paris/ (accessed on 4 January 2022).

- Geden, O.; Schenuit, F. Carbon Dioxide Removal as a New Approach in EU Climate Policy; Stiftung Wissenschaft und Politik: Berlin, Germany, 2020. [Google Scholar] [CrossRef]

- European Comission. A Clean Planet for All. A European Long-Term Strategic Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy. Communication 2018, 773, 188–190. [Google Scholar]

- EURACTIV. Official: EU Taking First Steps to Bring Forestry into Carbon Market. Available online: https://www.euractiv.com/section/energy-environment/interview/official-eu-taking-first-steps-to-bring-forestry-into-carbon-market (accessed on 29 May 2022).

- European Commission: Direct Air Capture (DAC) (N.d.). Retrieved November 5, 2020. Available online: https://ec.europa.eu/jrc/sites/jrcsh/files/factsheet_direct_air_capture_04.pdf (accessed on 4 January 2022).

- Daggash, H.A.; Mac Dowell, N. Structural Evolution of the UK Electricity System in a below 2 °C World. Joule 2019, 3, 1239–1251. [Google Scholar] [CrossRef]

- Jeffery, L.; Höhne, N.; Moisio, M.; Day, T.; Lawless, B. Options for Supporting Carbon Dioxide Removal. Discussion Paper. NewClimate Institute. 2020. Available online: https://newclimate.org/sites/default/files/2020/07/Options-for-supporting-Carbon-Dioxide-Removal_July_2020.pdf (accessed on 5 October 2022).

- Friedmann, S.J. Engineered CO2 Removal, Climate Restoration, and Humility. Front. Clim. 2019, 1, 3. [Google Scholar] [CrossRef]

- Larsen, J.; Herndon, W.; Grant, M.; Marsters, P. Capturing Leadership: Policies for the US to Advance Direct Air Capture Technology. 2019. Available online: https://rhg.com/wp-content/uploads/2019/05/Rhodium_CapturingLeadership_May2019-1.pdf (accessed on 2 April 2021).

- House Select Committee on the Climate Crisis. Solving the Climate Crisis: The Congressional Action Plan for a Clean Energy Economy and a Healthy and Just America; Majority Staff Report 2020. Available online: https://climatecrisis.house.gov/sites/climatecrisis.house.gov/files/Climate%20Crisis%20Action%20Plan.pdf (accessed on 4 January 2022).

- Wolske, K.S.; Raimi, K.T.; Campbell-Arvai, V.; Hart, P.S. Public Support for Carbon Dioxide Removal Strategies: The Role of Tampering with Nature Perceptions. Clim. Chang. 2019, 152, 345–361. [Google Scholar] [CrossRef]

- Pour, N.; Webley, P.A.; Cook, P.J. Opportunities for Application of BECCS in the Australian Power Sector. Appl. Energy 2018, 224, 615–635. [Google Scholar] [CrossRef]

- Ministry of Economy. Polityka energetyczna Polski do 2030 roku. 2009, pp. 23–25. Available online: https://www.pigeor.pl/media/js/kcfinder/upload/files/Polityka-energetyczna-Polski-do-2030r.pdf (accessed on 4 January 2022).

- Ministry of Economy. Ocena realizacji Polityki energetycznej Polski do 2030 roku—Wersja 0.5. Available online: https://www.toe.pl/pl/wybrane-dokumenty/rok-2014?download=1303:ocena-realizacji-pep-2030&start=20 (accessed on 4 January 2022).

- Ministry of Economy. Projekt Polityki Energetycznej Polski do 2050 r.—Wersja.0.6. p. 37. Available online: https://www.gov.pl/documents/33372/436746/DE_projekt_PEP2050_2015-08-03.doc/57c5150f-f50e-e8a7-6b27-49c330ab9d4d (accessed on 4 January 2022).

- Ministry of Economy. Wnioski z Analiz Prognostycznych na Potrzeby Polityki Energetycznej Polski do 2050 roku, Załącznik 2. do Polityki Energetycznej Polski do 2050 Roku, Wer. 0.2. Available online: https://www.cire.pl/pliki/2/2wnioskizanalizprognostycznych_20150803.pdf (accessed on 4 January 2022).

- Ministry of Climate and Environment. Krajowy Plan na Rzecz Energii i Klimatu na Lata 2021–2030. Available online: https://www.gov.pl/web/klimat/krajowy-plan-na-rzecz-energii-i-klimatu (accessed on 4 January 2022).

- Ministry of Climate and Environment. Polityka Energetyczna Polski Do 2040 r. Załącznik Do Uchwały Nr 22/2021 Rady Mini-Strów z Dnia 2 Lutego 2021. Available online: https://www.gov.pl/web/klimat/polityka-energetyczna-polski (accessed on 4 January 2022).

- Bukowski, M.; Błocka, M.; Śniegocki, A.; Porębna, K.; Wetmańska, Z. A New Chapter—WiseEuropa Report on Shifting Poland to Net-Zero Economy. 2019. Available online: https://wise-europa.eu/wp-content/uploads/2019/03/New_chapter_Poland_net-zero.pdf (accessed on 4 January 2022).

- Engel, H.; van der Pluijm, P.; Purta, M.; Speelman, E.; Szarek, G. Carbon-Neutral Poland 2050: Turning a Challenge into an Opportunity, McKinsey & Company Report. 2020. Available online: https://www.mckinsey.com/pl/~/media/mckinsey/locations/europe%20and%20middle%20east/polska/raporty/carbon%20neutral%20poland%202050/carbon%20neutral%20poland_mckinsey%20report.pdf (accessed on 4 January 2022).

- Tarkowski, R. CO2 storage capacity of geological structures located within Polish Lowlands’ Mesozoic formations. Gospod. Surowcami Miner. 2008, 24, 101–111. [Google Scholar]

- Hagi, H.; Neveux, T.; le Moullec, Y. Efficiency Evaluation Procedure of Coal-Fired Power Plants with CO2 Capture, Cogeneration and Hybridization. Energy 2015, 91, 306–323. [Google Scholar] [CrossRef]

- Cabral, R.P.; Bui, M.; Mac Dowell, N. A Synergistic Approach for the Simultaneous Decarbonisation of Power and Industry via Bioenergy with Carbon Capture and Storage (BECCS). Int. J. Greenh. Gas Control. 2019, 87, 221–237. [Google Scholar] [CrossRef]

- van der Meer, R.; De Coninck, E.; Helseth, J.; Whiriskey, K.; Perimenis, A.; Heberle, A. A Method to Calculate the Positive Effects of CCS and CCU on Climate Change; Zero Emission Platform 2020. Available online: https://zeroemissionsplatform.eu/wp-content/uploads/A-method-to-calculate-the-positive-effects-of-CCS-and-CCU-on-climate-change-July-2020.pdf (accessed on 10 December 2021).

- Gładysz, P.; Saari, J.; Czarnowska, L. Thermo-Ecological Cost Analysis of Cogeneration and Polygeneration Energy Systems—Case Study for Thermal Conversion of Biomass. Renew. Energy 2020, 145, 1748–1760. [Google Scholar] [CrossRef]

- Zuwała, J. Evaluation of Energy and Ecological Effects of Co-Combustion of Fossil Fuels and Biomass in Cogeneration Technologies; Prace Naukowe Głównego Instytutu: Katowice, Poland, 2013. [Google Scholar]

- Stanek, W.; Czarnowska, L.; Kalina, J. ECOS 2012 The 25th International Conference on Efficiency, Cost, Optimization and Simulation of Energy Conversion Systems and Processes (Perugia, 26–29 June 2012); Firenze University Press: Florence, Italy.

- SimaPro 8.0.1; PRé Consultants: Amersfoort, The Netherlands, 2014.

- Gładysz, P.; Ziebik, A. Life Cycle Assessment of an Integrated Oxy-Fuel Combustion Power Plant with CO2 Capture, Transport and Storage—Poland Case Study. Energy 2015, 92, 328–340. [Google Scholar] [CrossRef]

- Stanek, W.; Gładysz, P.; Czarnowska, L.; Simla, T. Thermo-Ecology: Exergy as a Measure of Sustainability; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780128131435. [Google Scholar]

- Parasuraman, A. Technology Readiness Index (Tri): A Multiple-Item Scale to Measure Readiness to Embrace New Technologies. J. Serv. Res. 2000, 2, 307–320. [Google Scholar] [CrossRef]

- Roussanaly, S. Calculating CO2 Avoidance Costs of Carbon Capture and Storage from Industry. Carbon Manag. 2019, 10, 105–112. [Google Scholar] [CrossRef]

- Morris, J.; Farrell, J.; Kheshgi, H.; Thomann, H.; Chen, H.; Paltsev, S.; Herzog, H. Representing the Costs of Low-Carbon Power Generation in Multi-Region Multi-Sector Energy-Economic Models. Int. J. Greenh. Gas Control. 2019, 87, 170–187. [Google Scholar] [CrossRef]

- Emenike, O.; Michailos, S.; Finney, K.N.; Hughes, K.J.; Ingham, D.; Pourkashanian, M. Initial Techno-Economic Screening of BECCS Technologies in Power Generation for a Range of Biomass Feedstock. Sustain. Energy Technol. Assess. 2020, 40, 100743. [Google Scholar] [CrossRef]

- Yang, B.; Wei, Y.M.; Liu, L.C.; Hou, Y.B.; Zhang, K.; Yang, L.; Feng, Y. Life Cycle Cost Assessment of Biomass Co-Firing Power Plants with CO2 Capture and Storage Considering Multiple Incentives. Energy Econ. 2021, 96, 105173. [Google Scholar] [CrossRef]

| Parameter | Łagisza Power Plant | Bełchatów Power Plant | Połaniec Power Plant |

|---|---|---|---|

| Gross electrical power | 459.80 MWel | 380.01 MWel | 225 MWel |

| Net electrical power | 444.50 MWel | 355.58 MWel | 208 MWel |

| Gross energy efficiency | 45.16%LHV | 38.78%LHV | 40.61%LHV |

| Net energy efficiency | 43.66%LHV | 36.28%LHV | 37.50%LHV |

| Chemical energy of fuel | 1018.2 MWch | 980.0 MWch | 554.05 MWch |

| Specific CO2 emission | 770.7 kg CO2/MWh | 1062.9 kg CO2/MWh | 1075.20 CO2/MWh |

| Parameter | High-Temperature Aqueous | Low-Temperature Solid Sorbent | |

|---|---|---|---|

| Waste Heat | Heat Pump | ||

| Capacity | 1,000,000 tpa | 360,000 tpa | |

| Direct electricity demand | 1535 kWhel/t CO2 | 250 kWhel/t CO2 | |

| Heat demand | 0 kWhth/t CO2 | 1750 kWhth/t CO2 | |

| COP of heat pump | - | 36.28%LHV | 3.0 |

| Indirect electricity demand | - | 980.0 MWch | 583.3 kWhel/t CO2 |

| CO2 outlet pressure | 1 bar | 1 bar | |

| C2A Indicator | CI, CRI, Indicators | Outcome |

|---|---|---|

| C2A ≥ 1 | CI, CRI, > 0 | No mitigation or even increase in emission (when compared with reference plants). |

| 0 < C2A < 1 | Potential for emissions reduction (when compared with reference plants). | |

| C2A = 0 | CI, CRI, = 0 | Potential to be carbon neutral. |

| −1 ≤ C2A < 0 | CI, CRI, < 0 | Potential for carbon dioxide removal. Processes with positive climate mitigation effects, also referred as carbon negative emission technologies. |

| Energy Carrier | Specific Thermo-Ecological Cost | Specific Cumulative CO2 Emission |

|---|---|---|

| Electricity—national energy system | 3.9 MJex/MJel | 931.2 kg CO2/MWhel |

| Electricity—wind turbines | 0.081 MJex/MJel | 10 kg CO2/MWhel |

| Biomass | 0.1 MJex/MJch | 12.24 kg CO2/MWhch |

| Hard coal | 1.202 MJex/MJch | 15.12 kg CO2/MWhch |

| Lignite | 1.364 MJex/MJch | 8.82 kg CO2/MWhch |

| Harmful emissions: | ||

| - SO2 | 136.24 MJex/kg | - |

| - NOx | 112.97 MJex/kg | |

| - PM | 72.89 MJex/kg |

| Parameter | Value |

|---|---|

| Cost base year | 2021 |

| Base currency | EUR |

| Project lifetime (power plant with CCS, DAC—HT aqueous solution, DAC—LT solid sorbent) | 30, 25, 20 |

| Capacity factor for power plants | 80% (7008 h) |

| Full load hours per year for DAC | 8000 |

| Discount rate | 6% |

| Electricity price | 110 EUR/MWh |

| Biomass price | 8 EUR/GJ |

| Coal price | 70 EUR/t (3.3 EUR/GJ) |

| Lignite price | 24 EUR/t (2.7 EUR/GJ) |

| EU-ETS emission allowance price | 45 EUR/tCO2 |

| Case | CI, kg CO2/MWhel | |||||

|---|---|---|---|---|---|---|

| Biomass Share, %LHV | ||||||

| 0 | 10 | 20 | 30 | 40 | 100 | |

| Łagisza power plant: | ||||||

| - without CCS (HC_REF) | 805.3 | 736.5 | 658.4 | 573.7 | - | |

| - with CCS (HC_RET_CCS) | 156.0 | 38.9 | −82.2 | −202.0 | - | |

| Bełchatów power plant | ||||||

| - without CCS (L_REF) | 1087.2 | - | - | - | 659.9 | - |

| - with CCS (L_RET_CCS) | 207.8 | - | - | - | −427.5 | - |

| Połaniec power plant: | ||||||

| - without CCS (BE_REF) | - | - | - | - | - | 32.6 |

| - with CCS (BE_RET_CCS) | - | - | - | - | - | −1346.3 |

| New build bioenergy power plant: | ||||||

| - without CCS (BE_NEW_REF)) | - | - | - | - | - | 32.6 |

| - with CCS (BE_NEW_CCS) | - | - | - | - | - | −1229.9 |

| Case | CRI, kg CO2/MWhel | |||||

| High-temperature aqueous | Low-temperature Solid sorbent | |||||

| waste heat | heat pump | |||||

| Electricity sources: | ||||||

| - PL national energy system | 323.73 | −1846.94 | −128.29 | |||

| - wind farms | −597.44 | −2768.12 | −1049.46 | |||

| Case | ||||||

|---|---|---|---|---|---|---|

| Biomass Share, %LHV | ||||||

| 0 | 10 | 20 | 30 | 40 | 100 | |

| Łagisza power plant: | ||||||

| - without CCS | 2.777 | 2.555 | 2.301 | 2.025 | - | |

| - with CCS | 3.617 | 3.364 | 3.053 | 2.698 | - | |

| Bełchatów power plant | ||||||

| - without CCS | 3.346 | - | - | - | 2.112 | - |

| - with CCS | 4.901 | - | - | - | 3.123 | - |

| Połaniec power plant: | ||||||

| - without CCS | - | - | - | - | - | 0.290 |

| - with CCS | - | - | - | - | - | 0.477 |

| New build bioenergy power plant: | ||||||

| - without CCS | - | - | - | - | - | 0.289 |

| - with CCS | - | - | - | - | - | 0.437 |

| Case | ||||

|---|---|---|---|---|

| Biomass Share, %LHV | ||||

| 20 | 30 | 40 | 100 | |

| Łagisza power plant: | 32.92 | 11.99 | n/a | |

| Bełchatów power plant | n/a | n/a | 8.52 | n/a |

| Połaniec power plant: | n/a | n/a | n/a | 0.50 |

| New build bioenergy power plant: | n/a | n/a | n/a | 0.43 |

| Case | , GJex/t CO2 | |||

| High-temperature aqueous | Low-temperature solid sorbent | |||

| waste heat | heat pump | |||

| Electricity sources: | ||||

| - PL national energy system | not CDR | 7.60 | 109.46 | |

| - wind farms | 0.49 | 0.11 | 0.28 | |

| Case | Biomass Share | CAPEX, MEUR | Fixed O&M, MEUR/y | Variable O&M, MEUR /y | Fuel Cost MEUR/y |

|---|---|---|---|---|---|

| Łagisza power plant: | 0% | 1260.1 | 20.6 | 13.3 | 84.0 |

| 10% | 1333.7 | 25.4 | 13.0 | 96.1 | |

| 20% | 1324.2 | 25.2 | 12.9 | 108.3 | |

| 30% | 1334.5 | 25.4 | 13.0 | 120.4 | |

| Bełchatów power plant: | 0% | 896.7 | 14.6 | 9.4 | 66.0 |

| 40% | 974.5 | 18.5 | 9.5 | 118.7 | |

| Połaniec power plant: | 100% | 1244.2 | 23.2 | 8.4 | 112.0 |

| New build bioenergy power plant: | 100% | 2275.1 | 25.4 | 9.2 | 112.0 |

| Case | CAPEX, MEUR | OPEX, MEUR/y | Electricity cost, MEUR/y | ||

| DAC High-temperature aqueous | 815 | 30.2 | 164.5 | ||

| DAC Low-temperature solid sorbent | Waste heat | 262.8 | 10.5 | 14.2 | |

| Heat pump | 262.8 | 10.5 | 37.3 |

| Case | BIOMASS SHARE | CO2 Captured tpa | LCOE EUR /MWh | LCNC EUR /tCO2 | LCAC EUR /tCO2 |

|---|---|---|---|---|---|

| Łagisza power plant: | 0% | 2,160,717 | 86.8 | n/a | −51.1 |

| 10% | 2,203,580 | 98.0 | n/a | −65.5 | |

| 20% | 2,246,443 | 103.5 | −261.3 | −78.3 | |

| 30% | 2,289,306 | 108.3 | −187.8 | −96.4 | |

| Bełchatów power plant: | 0% | 2,383,847 | 90.5 | n/a | −28.8 |

| 40% | 2,427,193 | 126.1 | −185.2 | −139.9 | |

| Połaniec power plant: | 100% | 1,410,552 | 234.3 | −103.4 | n/a |

| New build bioenergy power plant: | 100% | 1,410,552 | 273.2 | −74.5 | n/a |

| Case | CO2 captured tpa | LCOD EUR /tCO2 | LCNC EUR /tCO2 | ||

| DAC High-temperature aqueous | 1,000,000 | 274.8 | −3513.1 | ||

| DAC Low-temperature solid sorbent | Waste heat | 360,000 | 132.4 | −1518.6 | |

| Heat pump | 360,000 | 196.6 | −2254.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gładysz, P.; Strojny, M.; Bartela, Ł.; Hacaga, M.; Froehlich, T. Merging Climate Action with Energy Security through CCS—A Multi-Disciplinary Framework for Assessment. Energies 2023, 16, 35. https://doi.org/10.3390/en16010035

Gładysz P, Strojny M, Bartela Ł, Hacaga M, Froehlich T. Merging Climate Action with Energy Security through CCS—A Multi-Disciplinary Framework for Assessment. Energies. 2023; 16(1):35. https://doi.org/10.3390/en16010035

Chicago/Turabian StyleGładysz, Paweł, Magdalena Strojny, Łukasz Bartela, Maciej Hacaga, and Thomas Froehlich. 2023. "Merging Climate Action with Energy Security through CCS—A Multi-Disciplinary Framework for Assessment" Energies 16, no. 1: 35. https://doi.org/10.3390/en16010035

APA StyleGładysz, P., Strojny, M., Bartela, Ł., Hacaga, M., & Froehlich, T. (2023). Merging Climate Action with Energy Security through CCS—A Multi-Disciplinary Framework for Assessment. Energies, 16(1), 35. https://doi.org/10.3390/en16010035