The Experimental Investigation of a Diesel Engine Using Ternary Blends of Algae Biodiesel, Ethanol and Diesel Fuels

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Blend Preparation

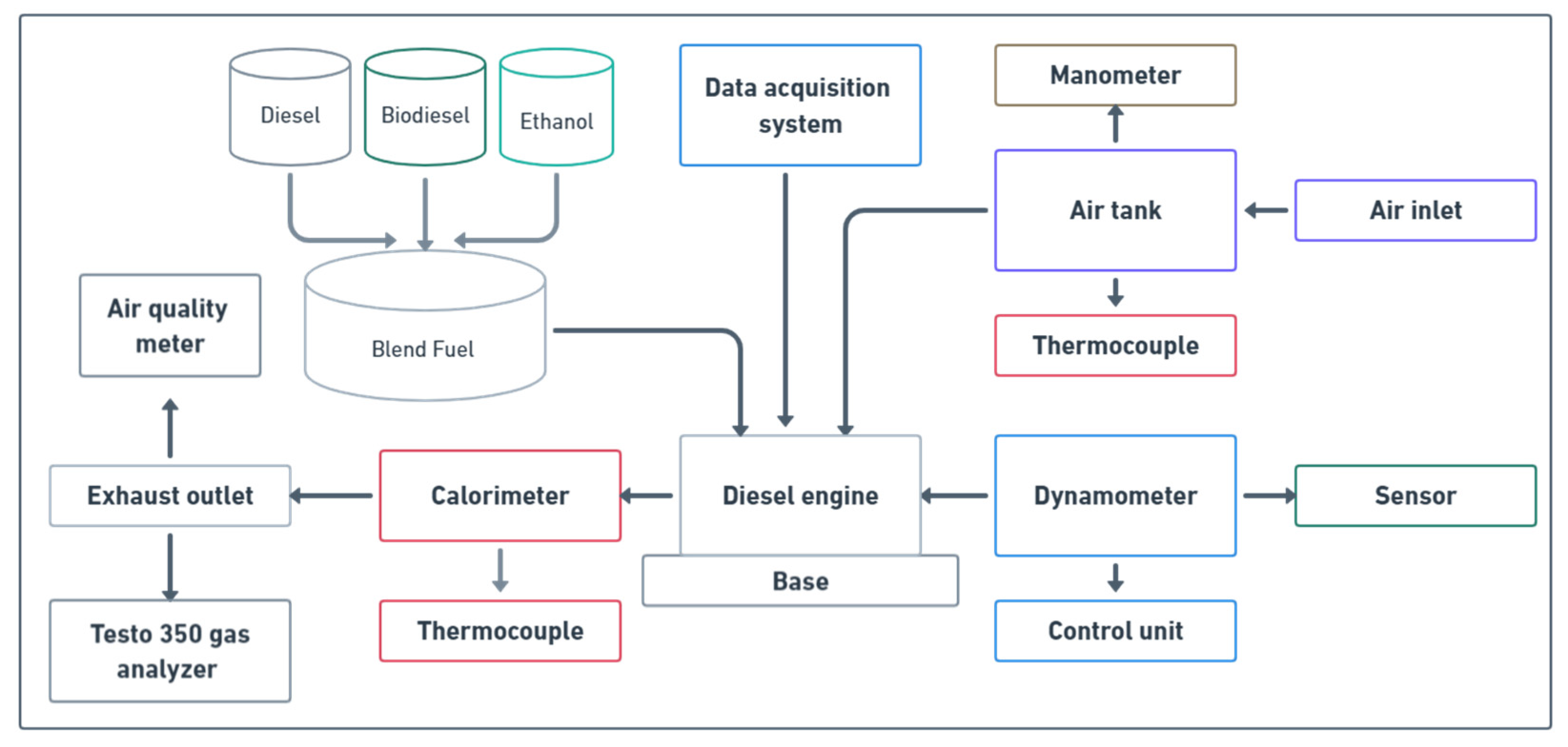

2.3. Test Engine

2.4. Test Procedure

2.5. Uncertainty Analysis

3. Results

3.1. Combustion Characteristics

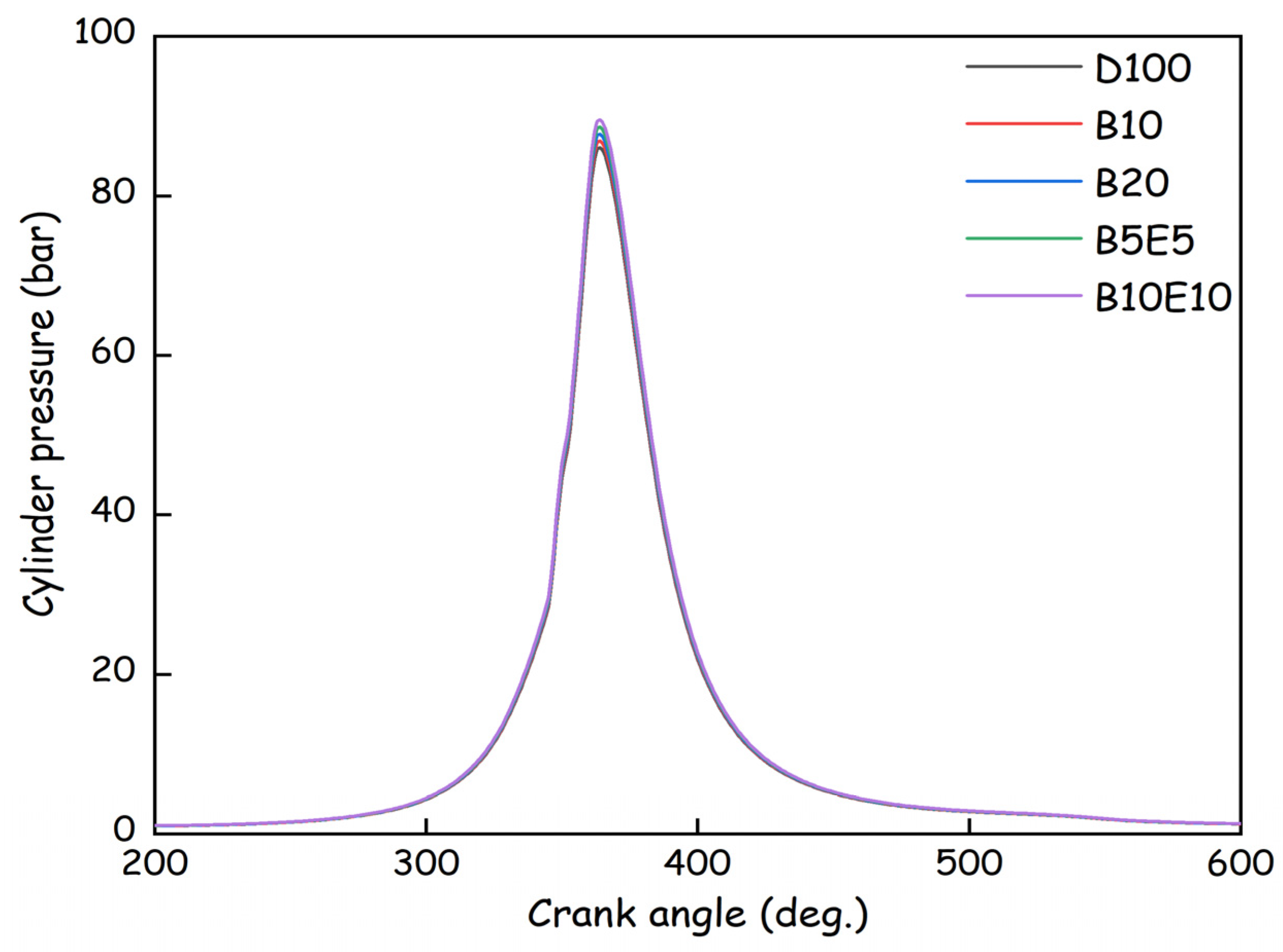

3.1.1. Cylinder Pressure

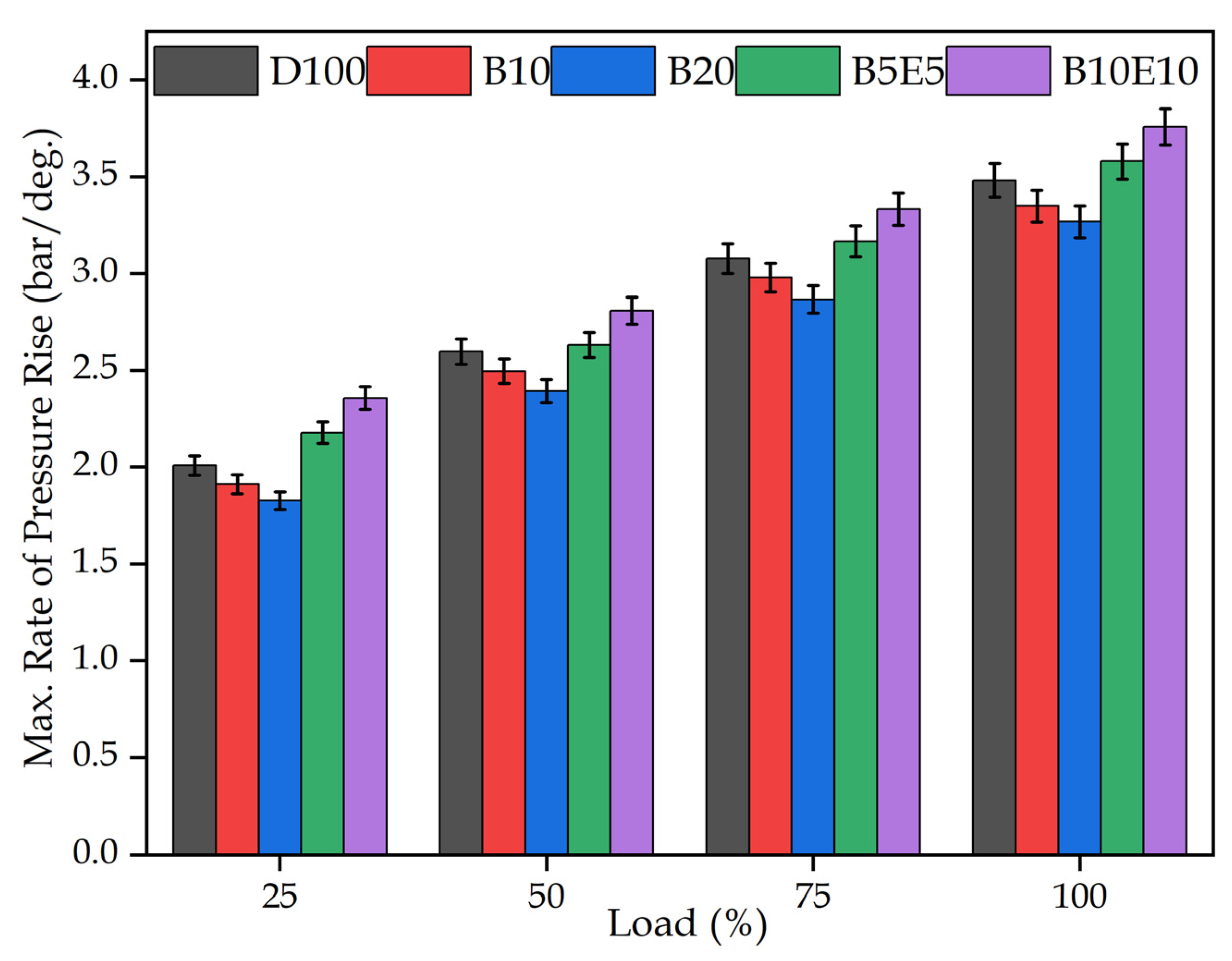

3.1.2. Maximum Pressure Rises Rate

3.1.3. Heat Release Rate

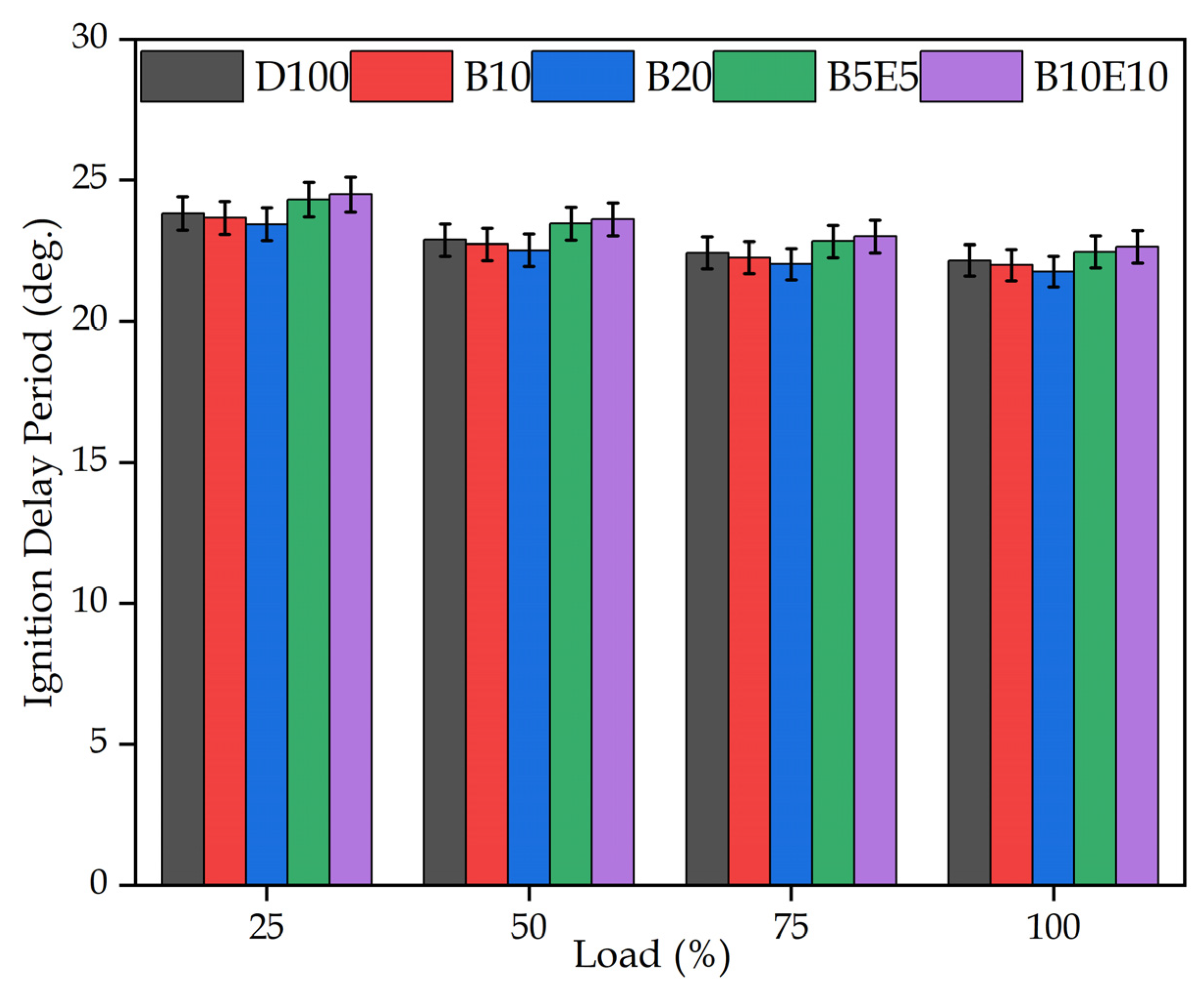

3.1.4. Ignition Delay Period (IDP)

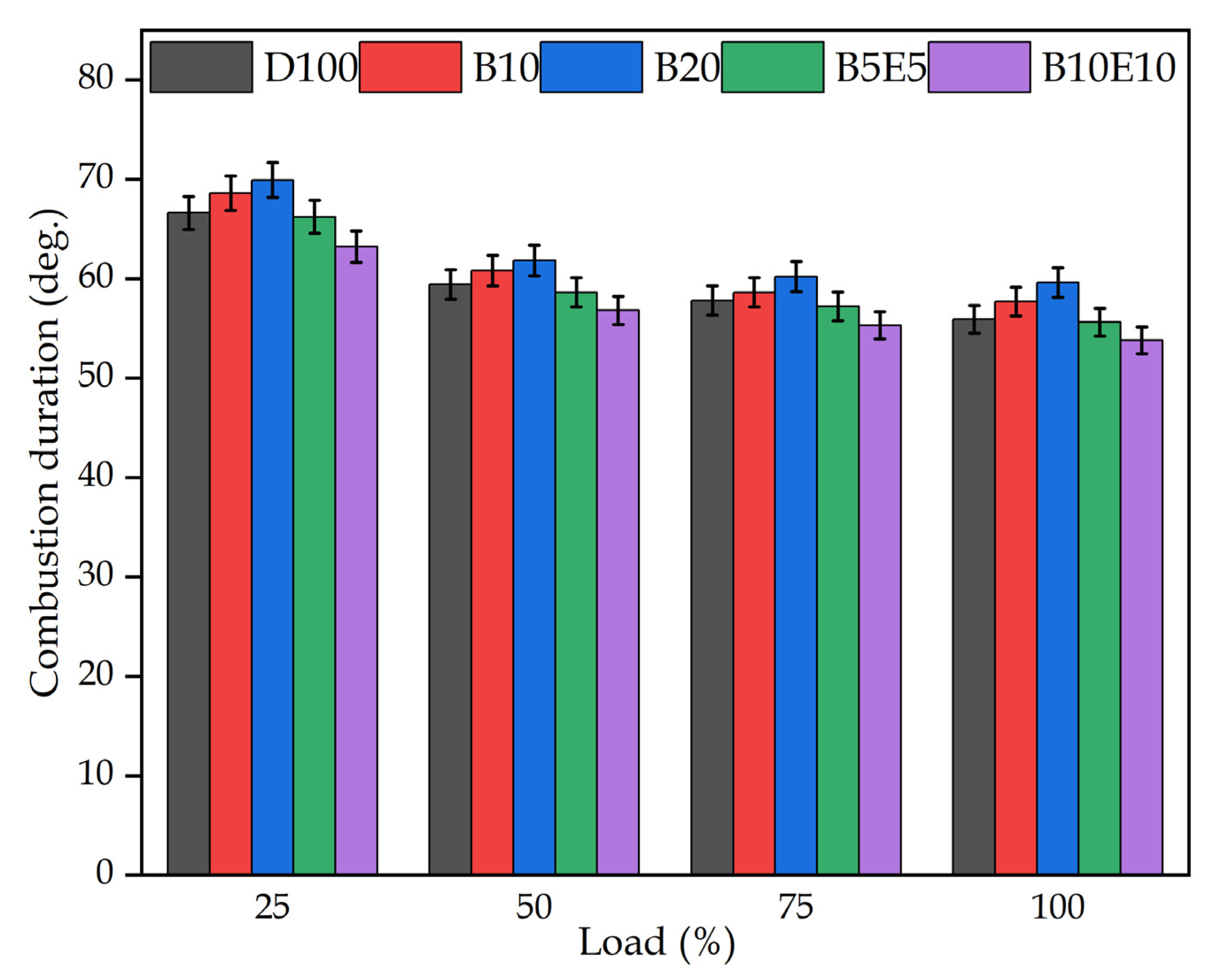

3.1.5. Combustion Duration

3.2. Performance Characteristics

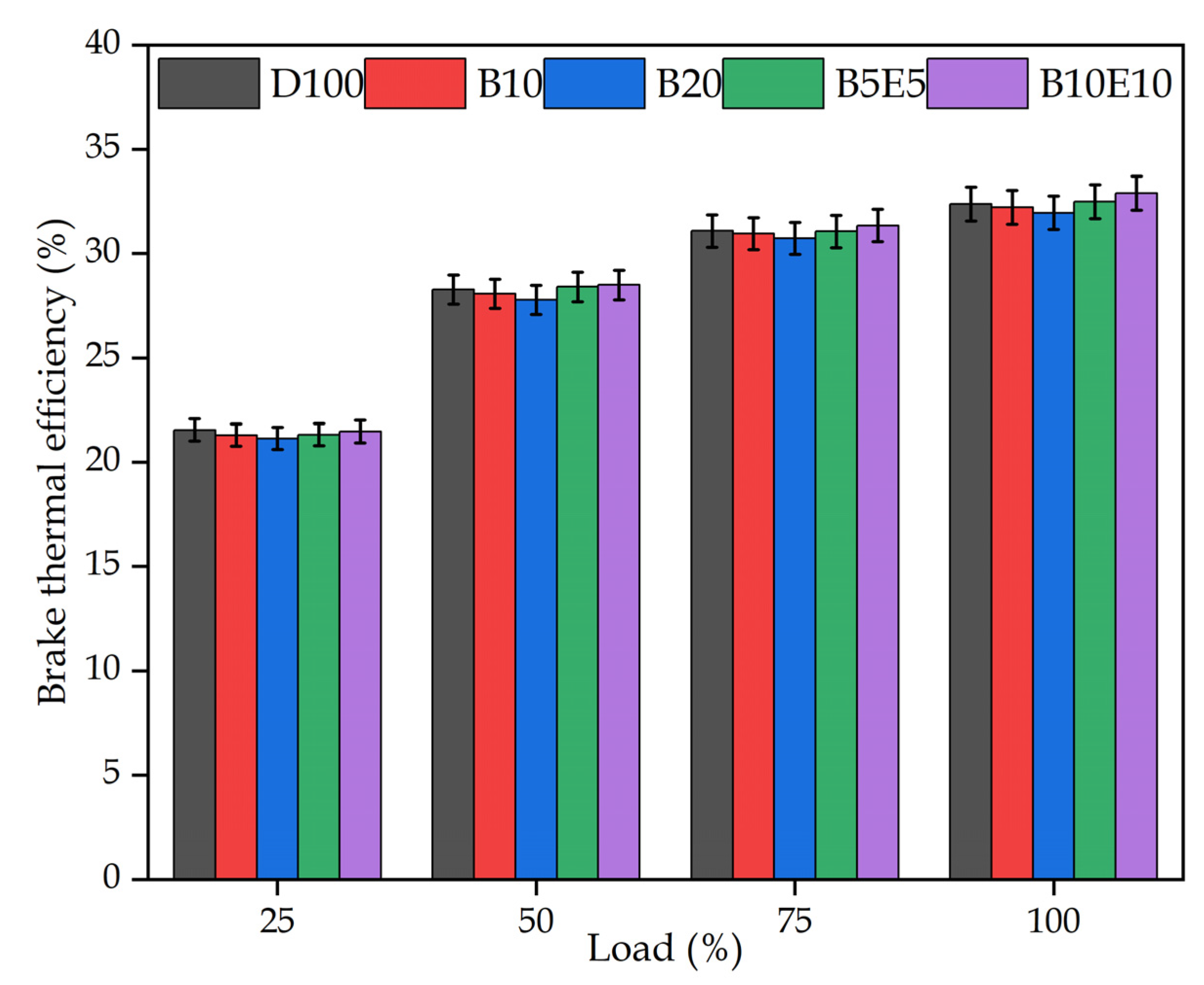

3.2.1. Brake Thermal Efficiency

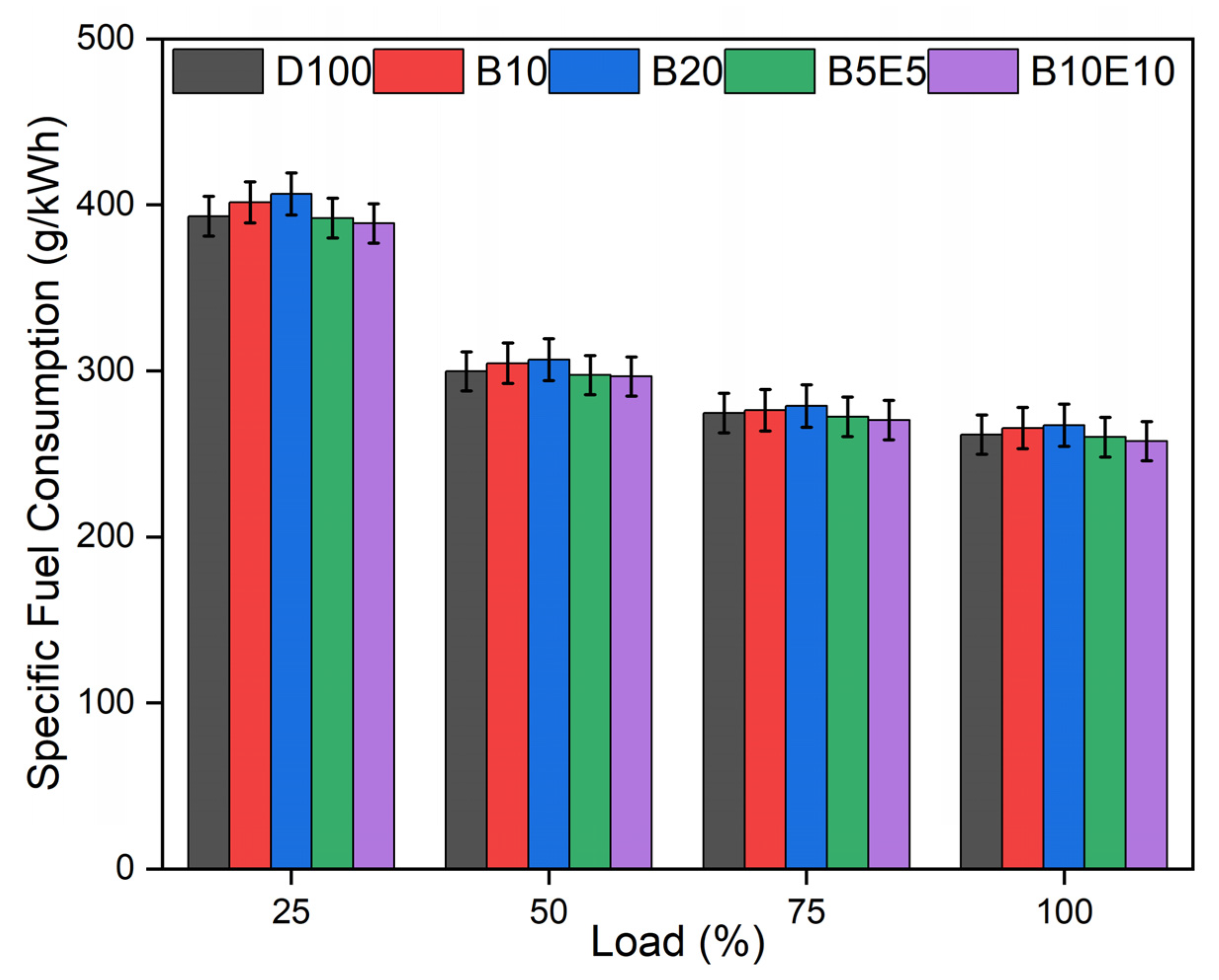

3.2.2. Specific Fuel Consumption

3.2.3. Exhaust Gas Temperature (EGT)

3.3. Emission Characteristics

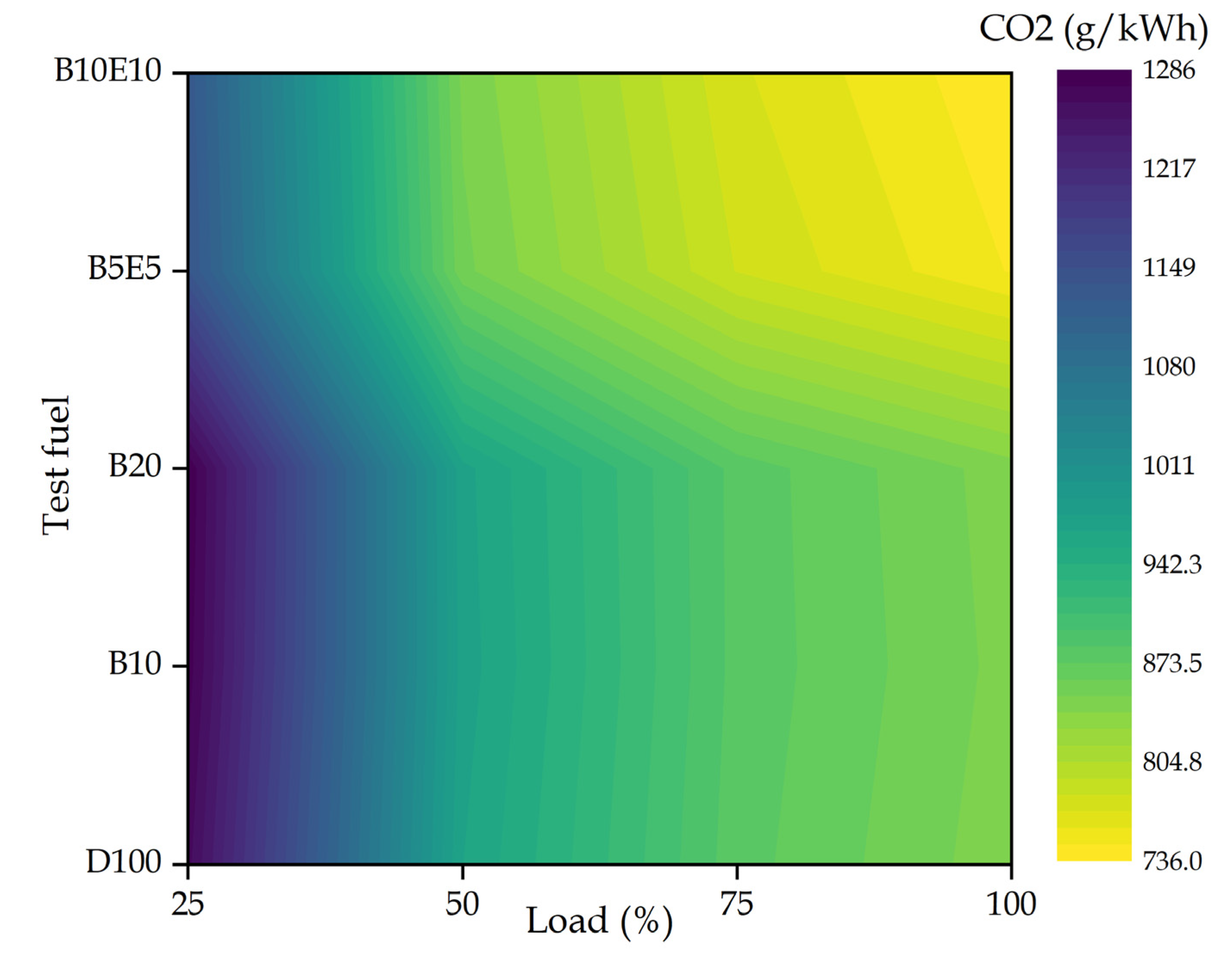

3.3.1. Carbon Dioxide

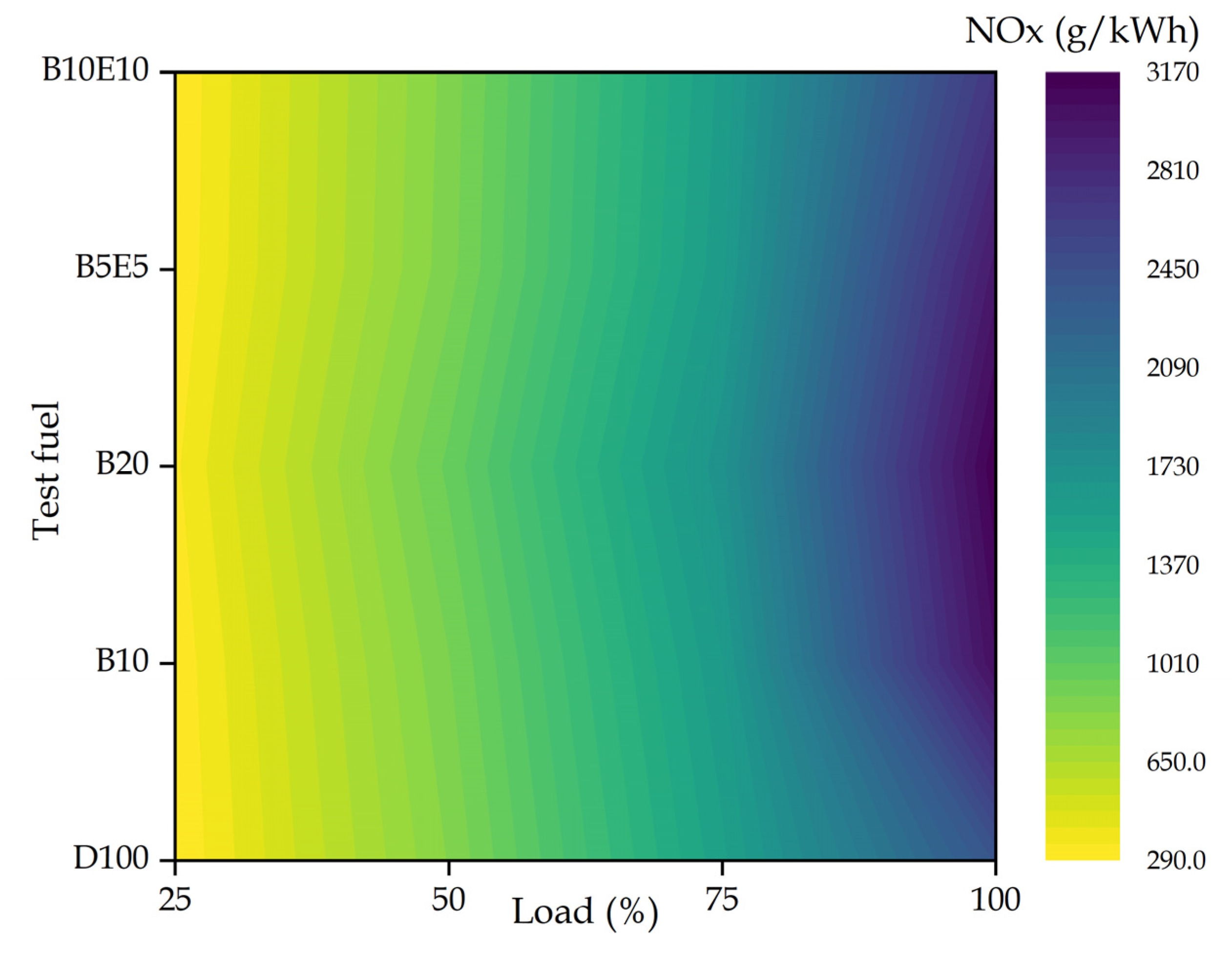

3.3.2. Oxides of Nitrogen

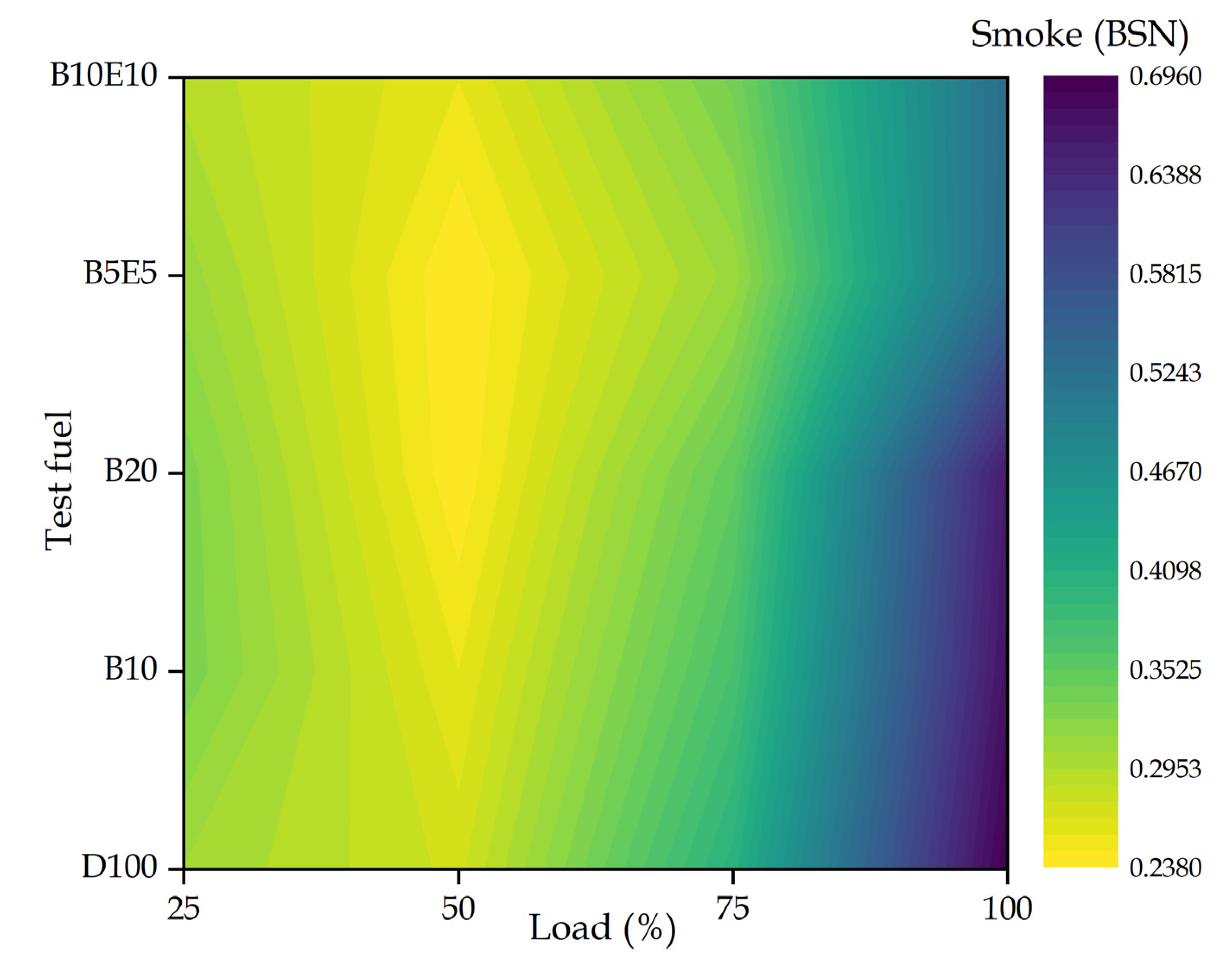

3.3.3. Smoke Emission

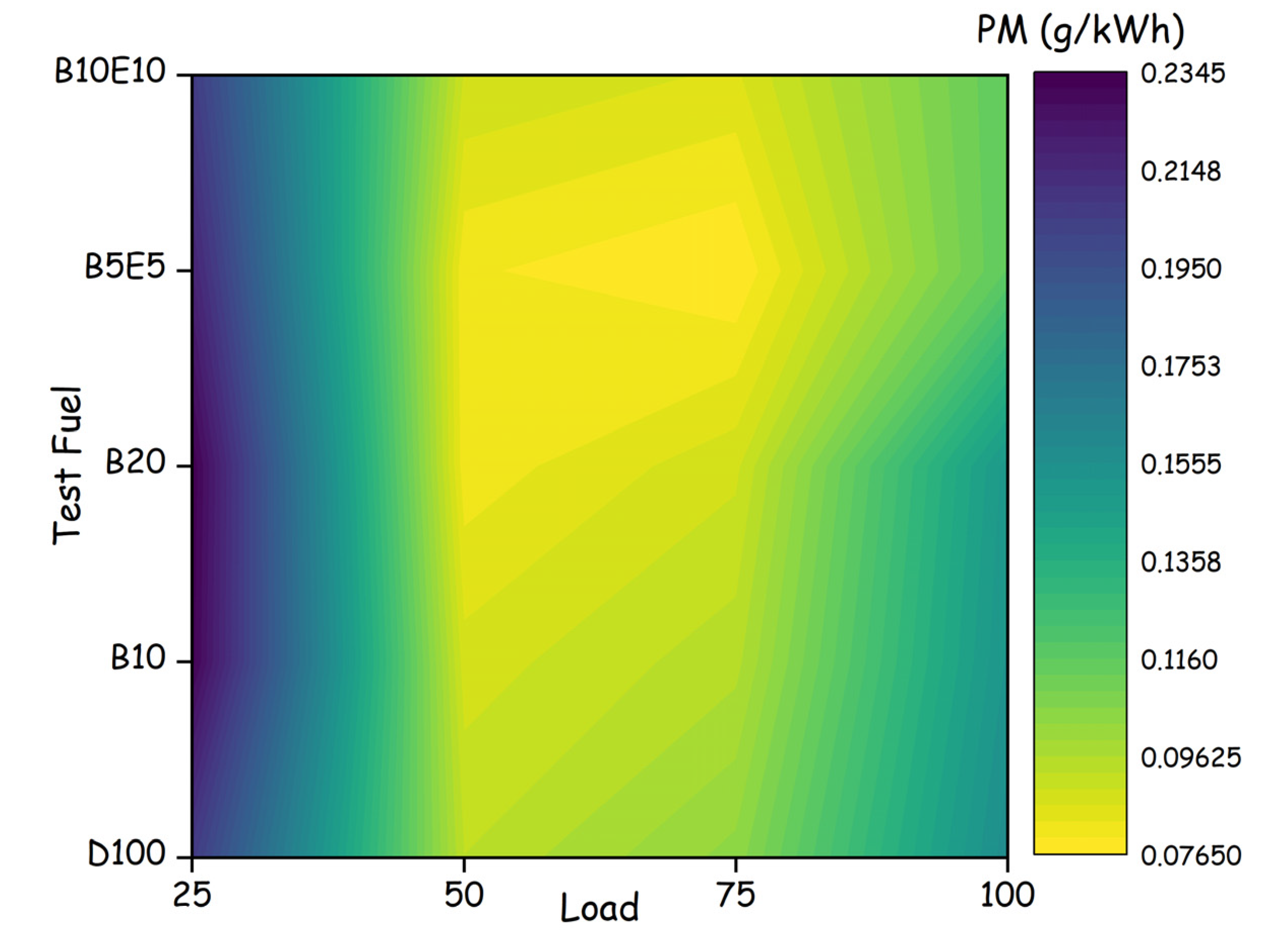

3.3.4. Particulate Matter

4. Conclusions

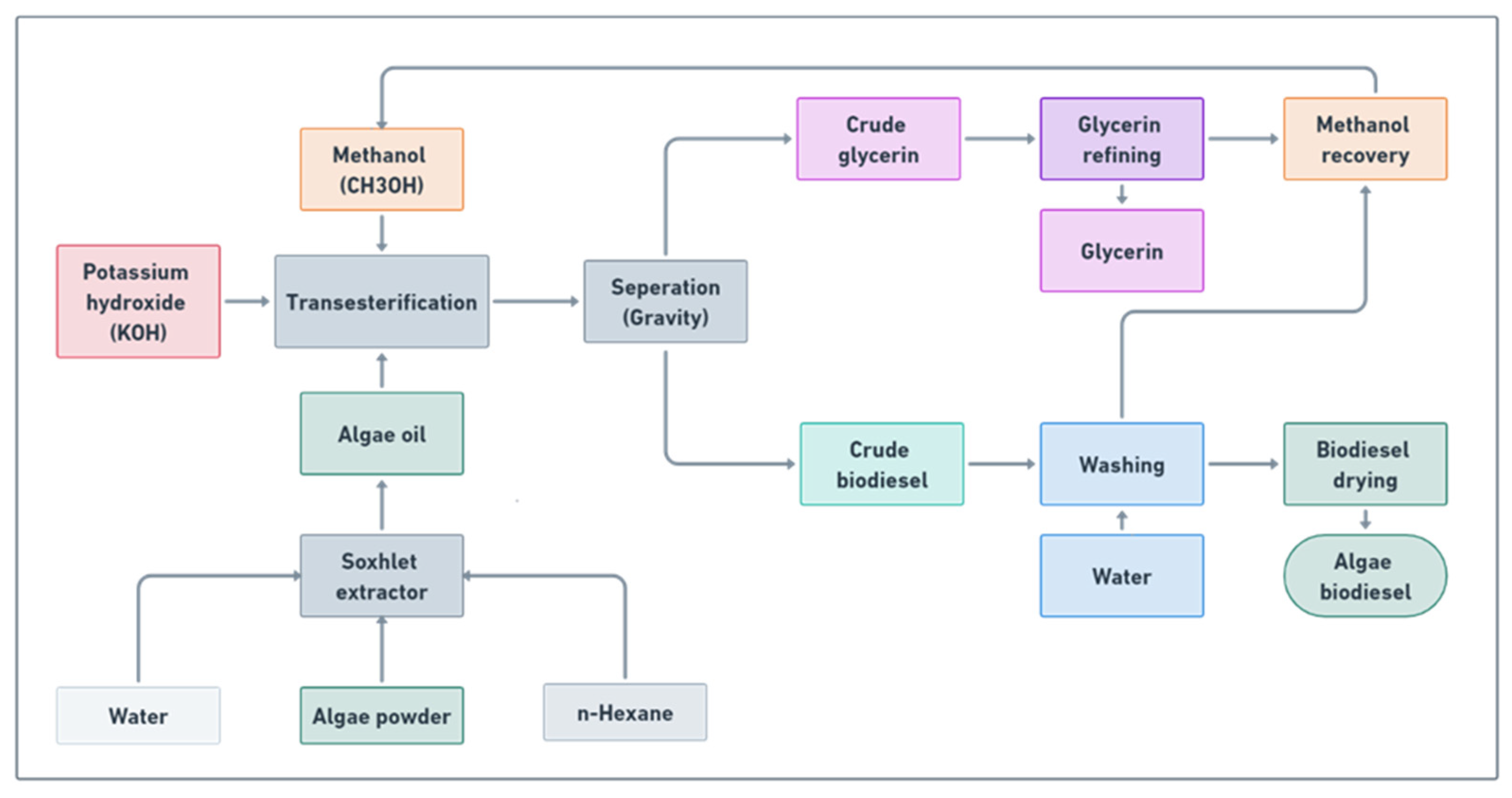

- Algae oil is extracted using n-Hexane solvent and biodiesel produced employing 6:1 methanol to oil ratio, and (0.9% wt.) KOH catalyst (0.9% wt.) at 65 °C for 80 min. The maximum 91% biodiesel yield was obtained employing the transesterification method.

- Binary (B10 and B20) and ternary (B5E5, B10E10) blends of test fuels were prepared using diesel, biodiesel, and ethanol and tested using a diesel engine.

- The diesel-biodiesel and ethanol blends had higher cylinder pressure and heat release rate as compared to diesel fuel. It was found that cylinder pressure increased by 1%, 2%, 3%, and 4% and peak heat release rate reduced by 3.41% and 4.04% and increased by 1.69%, and 2.23% for B10, B20, B5E5, and B10E10 respectively as compared to diesel fuel.

- BTE was found lower while SFC was found higher for algae biodiesel and diesel blends due to their lower heating value and a higher percentage of oxygen as compared to diesel fuel. However, adding ethanol concentration increases the BTE and lowers the SFC of ethanol blended fuel as compared to diesel fuel.

- BTE was reduced by 0.49% and 1.29% for B10 and B20 blends while BTE was increased by 0.37% and 1.60% respectively. However, SFC increases by 1.45%, 2.14%, 3.18%, and 3.78% respectively for B10, B20, B5E5, and B10E10 with respect to diesel fuel.

- The emission characteristics, including NOx, CO2, PM, and smoke, have been studied at different load employing binary and ternary blended fuels. PM, smoke, and CO2 emission were decreased for all the biodiesel blends while NOx increased as compared to diesel fuel when the biodiesel blend was used as compared to diesel fuel.

- Ethanol is added in biodiesel blend fuel to reduce the greenhouse gas emission. The addition of ethanol further reduces the emission of PM, smoke, CO2, and NOx emission as compared to diesel fuel.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hoang, A.T.; Nižetić, S.; Ong, H.C.; Tarelko, W.; Pham, V.V.; Le, T.H.; Chau, M.Q.; Nguyen, X.P. A review on application of artificial neural network (ANN) for performance and emission characteristics of diesel engine fueled with biodiesel-based fuels. Sustain. Energy Technol. Assess. 2021, 47, 101416. [Google Scholar] [CrossRef]

- India Oil Reserves, Production and Consumption Statistics. Available online: https://www.worldometers.info/oil/india-oil/#oil-production (accessed on 3 May 2022).

- Oil Production by Country. Available online: https://www.worldometers.info/oil/oil-production-by-country/ (accessed on 3 May 2022).

- Mahesh, S.E.; Ramanathan, A.; Begum, K.M.S.; Narayanan, A. Biodiesel production from waste cooking oil using KBr impregnated CaO as catalyst. Energy Convers. Manag. 2015, 91, 442–450. [Google Scholar] [CrossRef]

- Çelik, M.; Bayındırlı, C.; Mehregan, M. Multi-objective optimization of a diesel engine fueled with different fuel types containing additives using grey-based Taguchi approach. Environ. Sci. Pollut. Res. 2022, 29, 30277–30284. [Google Scholar] [CrossRef] [PubMed]

- Global Transport CO2 Emissions Breakdown 2020. Available online: https://www.statista.com/statistics/1185535/transport-carbon-dioxide-emissions-breakdown/ (accessed on 19 August 2022).

- Sahoo, P.K.; Das, L.M. Process optimization for biodiesel production from Jatropha, Karanja and Polanga oils. Fuel 2009, 88, 1588–1594. [Google Scholar] [CrossRef]

- Ni, Z.-H.; Li, F.-S.; Wang, H.; Xiao, H. Prediction of physical parameters of Jatropha biodiesel-ethanol dual fuel based on topological indices. Appl. Energy 2022, 328, 120202. [Google Scholar] [CrossRef]

- Bin Mohiddin, M.N.; Tan, Y.H.; Seow, Y.X.; Kansedo, J.; Mubarak, N.; Abdullah, M.O.; Chan, Y.S.; Khalid, M. Evaluation on feedstock, technologies, catalyst and reactor for sustainable biodiesel production: A review. J. Ind. Eng. Chem. 2021, 98, 60–81. [Google Scholar] [CrossRef]

- Canabarro, N.I.; Silva-Ortiz, P.; Nogueira, L.A.H.; Cantarella, H.; Maciel-Filho, R.; Souza, G. Sustainability assessment of ethanol and biodiesel production in Argentina, Brazil, Colombia, and Guatemala. Renew. Sustain. Energy Rev. 2023, 171, 113019. [Google Scholar] [CrossRef]

- Madihi, R.; Pourfallah, M.; Gholinia, M.; Armin, M.; Ghadi, A. Thermofluids analysis of combustion, emissions, and energy in a biodiesel (C11H22O2) / natural gas heavy-duty engine with RCCI mode (Part II: Fuel injection time/Fuel injection rate). Int. J. Thermofluids 2022, 16, 100200. [Google Scholar] [CrossRef]

- Łagowski, P.; Wcisło, G.; Kurczyński, D. Comparison of the Combustion Process Parameters in a Diesel Engine Powered by Second-Generation Biodiesel Compared to the First-Generation Biodiesel. Energies 2022, 15, 6835. [Google Scholar] [CrossRef]

- Prabhu, A.; Venkata Ramanan, M.; Jayaprabakar, J. Effect of compression ratio on the performance of CI engine fuelled with freshwater algae biodiesel. Int. J. Ambient Energy 2018, 41, 80–83. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Periyasamy, M.; Prathima, A.; Sabariswaran, K. Performance analysis of diesel engine fueled with S. marginatum Macro algae biofuel-diesel blends. Mater. Today Proc. 2020, 33, 3464–3469. [Google Scholar] [CrossRef]

- Subramaniam, M.; Solomon, J.M.; Nadanakumar, V.; Anaimuthu, S.; Sathyamurthy, R. Experimental investigation on performance, combustion and emission characteristics of DI diesel engine using algae as a biodiesel. Energy Rep. 2020, 6, 1382–1392. [Google Scholar] [CrossRef]

- Kurczyński, D.; Wcisło, G.; Łagowski, P. Experimental Study of Fuel Consumption and Exhaust Gas Composition of a Diesel Engine Powered by Biodiesel from Waste of Animal Origin. Energies 2021, 14, 3472. [Google Scholar] [CrossRef]

- Rajak, U.; Singh, T.S.; Verma, T.N.; Chaurasiya, P.K.; Shaik, S.; Afzal, A.; Cuce, E.; Rajhi, A.A.; Saleel, C.A. Experimental and parametric studies on the effect of waste cooking oil methyl ester with diesel fuel in compression ignition engine. Sustain. Energy Technol. Assess. 2022, 53, 102705. [Google Scholar] [CrossRef]

- Singh, T.S.; Rajak, U.; Verma, T.N.; Nashine, P.; Mehboob, H.; Manokar, A.M.; Afzal, A. Exhaust emission characteristics study of light and heavy-duty diesel vehicles in India. Case Stud. Therm. Eng. 2021, 29, 101709. [Google Scholar] [CrossRef]

- Lee, C.C.; Tran, M.-V.; Tan, B.T.; Scribano, G.; Chong, C.T. A comprehensive review on the effects of additives on fundamental combustion characteristics and pollutant formation of biodiesel and ethanol. Fuel 2020, 288, 119749. [Google Scholar] [CrossRef]

- Karin, P.; Tripatara, A.; Wai, P.; Oh, B.-S.; Charoenphonphanich, C.; Chollacoop, N.; Kosaka, H. Influence of ethanol-biodiesel blends on diesel engines combustion behavior and particulate matter physicochemical characteristics. Case Stud. Chem. Environ. Eng. 2022, 6, 100249. [Google Scholar] [CrossRef]

- Sathish, T.; Mohanavel, V.; Arunkumar, M.; Rajan, K.; Soudagar, M.E.M.; Mujtaba, M.; Salmen, S.H.; Al Obaid, S.; Fayaz, H.; Sivakumar, S. Utilization of Azadirachta indica biodiesel, ethanol and diesel blends for diesel engine applications with engine emission profile. Fuel 2022, 319, 123798. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Sarıdemir, S.; Albayrak, S. Experimental investigation of combustion, performance and emission characteristics of a diesel engine fuelled with diesel–biodiesel–alcohol blends. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 389. [Google Scholar] [CrossRef]

- Gangolu, N.R.; Chunchu, B.R.K.; Yallamati, A.; Gopidesi, R.K. Assessment of diesel engine characteristics by using soybean oil as a biofuel. Environ. Dev. Sustain. 2021, 24, 7579–7592. [Google Scholar] [CrossRef]

- Ashfaque Ahmed, S.; Soudagar, M.E.M.; Rahamathullah, I.; Basha, J.S.; Khan, T.Y.; Javed, S.; Elfasakhany, A.; Kalam, M. Investigation of ternary blends of animal fat biodiesel-diethyl ether-diesel fuel on CMFIS-CI engine characteristics. Fuel 2023, 332, 126200. [Google Scholar] [CrossRef]

- Sachuthananthan, B.; Krupakaran, R.L.; Balaji, G. Exploration on the behaviour pattern of a DI diesel engine using magnesium oxide nano additive with plastic pyrolysis oil as alternate fuel. Int. J. Ambient. Energy 2019, 42, 701–712. [Google Scholar] [CrossRef]

- Nayak, S.K.; Hoang, A.T.; Nižetić, S.; Nguyen, X.P.; Le, T.H. Effects of advanced injection timing and inducted gaseous fuel on performance, combustion and emission characteristics of a diesel engine operated in dual-fuel mode. Fuel 2021, 310, 122232. [Google Scholar] [CrossRef]

- Balasubramanian, D.; Hoang, A.T.; Venugopal, I.P.; Shanmugam, A.; Gao, J.; Wongwuttanasatian, T. Numerical and experimental evaluation on the pooled effect of waste cooking oil biodiesel/diesel blends and exhaust gas recirculation in a twin-cylinder diesel engine. Fuel 2020, 287, 119815. [Google Scholar] [CrossRef]

- Kavitha, K.R.; Jayaprabakar, J.; Prabhu, A. Exergy and energy analyses on biodiesel–diesel-ethanol blends in a diesel engine. Int. J. Ambient. Energy 2022, 43, 778–782. [Google Scholar] [CrossRef]

- Wai, P.; Kanokkhanarat, P.; Oh, B.-S.; Wongpattharaworakul, V.; Depaiwa, N.; Po-Ngaen, W.; Chollacoop, N.; Srisurangkul, C.; Kosaka, H.; Yamakita, M.; et al. Experimental investigation of the influence of ethanol and biodiesel on common rail direct injection diesel Engine’s combustion and emission characteristics. Case Stud. Therm. Eng. 2022, 39, 102430. [Google Scholar] [CrossRef]

- Mukhtar, M.N.A.; Hagos, F.Y.; Aziz, A.R.A.; Abdulah, A.A.; Karim, Z.A.A. Combustion characteristics of tri-fuel (diesel-ethanol-biodiesel) emulsion fuels in CI engine with micro-explosion phenomenon attributes. Fuel 2022, 312, 122933. [Google Scholar] [CrossRef]

- Emma, A.F.; Alangar, S.; Yadav, A.K. Extraction and characterization of coffee husk biodiesel and investigation of its effect on performance, combustion, and emission characteristics in a diesel engine. Energy Convers. Manag. X 2022, 14, 100214. [Google Scholar] [CrossRef]

- Rajendran, S.; Govindasamy, M. Effect of isopropyl alcohol on the performance, combustion and emission Characteristics variable compression ratio engine using rubber seed oil blends. Energy Sources Part A Recover. Util. Environ. Eff. 2021, 1–16. [Google Scholar] [CrossRef]

- Nautiyal, P.; Subramanian, K.; Dastidar, M.; Kumar, A. Experimental assessment of performance, combustion and emissions of a compression ignition engine fuelled with Spirulina platensis biodiesel. Energy 2020, 193, 116861. [Google Scholar] [CrossRef]

- Rajendra Prasad Reddy, B.; Rana Prathap Reddy, N.; Manne, B.; Srikanth, H.V. Performance, combustion and emission characteristics of a diesel engine fuelled with Schizochytrium micro-algae biodiesel and its blends. Int. J. Ambient Energy 2020, 43, 2090–2096. [Google Scholar] [CrossRef]

- Kuszewski, H. Experimental investigation of the autoignition properties of ethanol–biodiesel fuel blends. Fuel 2019, 235, 1301–1308. [Google Scholar] [CrossRef]

- Geng, L.; Bi, L.; Li, Q.; Chen, H.; Xie, Y. Experimental study on spray characteristics, combustion stability, and emission performance of a CRDI diesel engine operated with biodiesel–ethanol blends. Energy Rep. 2021, 7, 904–915. [Google Scholar] [CrossRef]

- Ooi, J.B.; Chow, M.R.; Chee, K.M.; Pun, C.H.; Tran, M.-V.; Leong, J.C.K.; Lim, S. Effects of ethanol on the evaporation and burning characteristics of palm-oil based biodiesel droplet. J. Energy Inst. 2021, 98, 35–43. [Google Scholar] [CrossRef]

- Choudhary, K.D.; Nayyar, A.; Dasgupta, M. Effect of compression ratio on combustion and emission characteristics of C.I. Engine operated with acetylene in conjunction with diesel fuel. Fuel 2018, 214, 489–496. [Google Scholar] [CrossRef]

- AVSL, S.B.; Subramaniapillai, N.; Mohamed, M.S.B.K.; Narayanan, A. Effect of rubber seed oil biodiesel on engine performance and emission analysis. Fuel 2021, 296, 120708. [Google Scholar] [CrossRef]

- Kulanthaivel, V.; Jayaraman, A.; Rajamanickam, T.; Selvam, S. Impact of diesel–Algae biodiesel-Anhydrous Ethanol blends on the performance of CI engines. J. Clean. Prod. 2021, 295, 126422. [Google Scholar] [CrossRef]

- Ye, X.; An, X.; Zhang, H.; Wang, S.; Guo, B.; Yu, A. Process simulation on atomization and evaporation of desulfurization wastewater and its application. Powder Technol. 2021, 389, 178–188. [Google Scholar] [CrossRef]

- El-Sheekh, M.M.; Bedaiwy, M.Y.; El-Nagar, A.A.; ElKelawy, M.; Bastawissi, H.A.-E. Ethanol biofuel production and characteristics optimization from wheat straw hydrolysate: Performance and emission study of DI-diesel engine fueled with diesel/biodiesel/ethanol blends. Renew. Energy 2022, 191, 591–607. [Google Scholar] [CrossRef]

- Teoh, Y.H.; Yu, K.H.; How, H.G.; Nguyen, H.-T. Experimental Investigation of Performance, Emission and Combustion Characteristics of a Common-Rail Diesel Engine Fuelled with Bioethanol as a Fuel Additive in Coconut Oil Biodiesel Blends. Energies 2019, 12, 1954. [Google Scholar] [CrossRef]

- Dabi, M.; Saha, U.K. Performance, combustion and emissions analyses of a single-cylinder stationary compression ignition engine powered by Mesua Ferrea Linn oil-ethanol-diesel blend. Clean. Eng. Technol. 2022, 8, 100458. [Google Scholar] [CrossRef]

- Thiyagarajan, S.; Sonthalia, A.; Geo, V.E.; Prakash, T.; Karthickeyan, V.; Ashok, B.; Nanthagopal, K.; Dhinesh, B. Effect of manifold injection of methanol/n-pentanol in safflower biodiesel fuelled CI engine. Fuel 2019, 261, 116378. [Google Scholar] [CrossRef]

- Al-Lwayzy, S.H.; Yusaf, T. Diesel engine performance and exhaust gas emissions using Microalgae Chlorella protothecoides biodiesel. Renew. Energy 2017, 101, 690–701. [Google Scholar] [CrossRef]

- Sathiyamoorthi, R.; Sankaranarayanan, G.; Kumaar, S.A.; Chiranjeevi, T.; Kumar, D.D. Experimental investigation on performance, combustion and emission characteristics of a single cylinder diesel engine fuelled by biodiesel derived from Cymbopogon Martinii. Renew. Energy 2018, 132, 394–415. [Google Scholar] [CrossRef]

- Wai, P.; Karin, P.; Phairote, W.; Chollacoop, N.; Kosaka, H.; Po-Ngen, W. Experimental investigation of the impact ethanol-biodiesel-diesel blended fuels on combustion, emission, and performance of compression ignition diesel engine. Mater. Today Proc. 2022, 66, 2830–2835. [Google Scholar] [CrossRef]

- Sakthivadivel, D.; Kumar, P.G.; Prabakaran, R.; Vigneswaran, V.; Nithyanandhan, K.; Kim, S.C. A neem oil-based biodiesel with DEE enriched ethanol and Al2O3 nano additive: An experimental investigation on the diesel engine performance. Case Stud. Therm. Eng. 2022, 34, 102021. [Google Scholar] [CrossRef]

- Vergel-Ortega, M.; Valencia-Ochoa, G.; Duarte-Forero, J. Experimental study of emissions in single-cylinder diesel engine operating with diesel-biodiesel blends of palm oil-sunflower oil and ethanol. Case Stud. Therm. Eng. 2021, 26, 101190. [Google Scholar] [CrossRef]

- Wojs, M.K.; Orliński, P.; Horaczyński, D. Influence of the use of bioethanol additive on waste cooking oil methyl ester on the parameters of the CI engine and emissions of toxic exhaust components. In Proceedings of the 23rd International Scientific Conference Transport Means 2019, Palanga, Lithunia, 2–4 October 2019; pp. 330–337. [Google Scholar]

- Emiroğlu, A.O.; Şen, M. Combustion, performance and emission characteristics of various alcohol blends in a single cylinder diesel engine. Fuel 2018, 212, 34–40. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jaworski, A.; Ustrzycki, A.; Lejda, K.; Balawender, K.; Woś, P. Use of the constant volume combustion chamber to examine the properties of autoignition and derived cetane number of mixtures of diesel fuel and ethanol. Fuel 2017, 200, 564–575. [Google Scholar] [CrossRef]

- Kalil Rahiman, M.; Santhoshkumar, S.; Subramaniam, D.; Avinash, A.; Pugazhendhi, A. Effects of oxygenated fuel pertaining to fuel analysis on diesel engine combustion and emission characteristics. Energy 2021, 239, 122373. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Dong, R.; Zou, Z.; Gao, S.; Tan, D. Performance, combustion and emission characteristics investigations on a diesel engine fueled with diesel/ ethanol /n-butanol blends. Energy 2022, 249, 123733. [Google Scholar] [CrossRef]

- Mofijur, M.; Rasul, M.; Hassan, N.M.S.; Uddin, M.N. Investigation of exhaust emissions from a stationary diesel engine fuelled with biodiesel. Energy Procedia 2019, 160, 791–797. [Google Scholar] [CrossRef]

| Fuel Properties | Test Method | Ethanol | Diesel | Algae Biodiesel |

|---|---|---|---|---|

| Carbon (mass%) | ASTM D 5291 | 52.2 | 87 | 78 |

| Hydrogen (mass%) | 13.0 | 12.6 | 12 | |

| Oxygen (mass%) | 34.8 | 0.4 | 10 | |

| Density at 25 °C (kg/m3) | ASTM D 1298 | 789 | 830 | 871 |

| Viscosity @ 40 °C (mm2/s) | ASTM D 445 | 1.2 | 2.6 | 5.2 |

| Calorific value (MJ/kg) | ASTM D 240 | 28.32 | 42.5 | 40 |

| Cetane number | - | 8 | 48 | 52 |

| Auto ignition temperature (°C) | - | 365 | 210 | - |

| Fuel Blend | Carbon (mass%) | Hydrogen (mass%) | Oxygen (mass%) | Density (kg/m3) | Viscosity (mm2/s) | C. Value (MJ/kg) | Cetane Number |

|---|---|---|---|---|---|---|---|

| D100 | 87.0 | 12.6 | 0.4 | 830 | 2.6 | 42.5 | 48 |

| B10 | 86.1 | 12.5 | 1.4 | 834 | 3.1 | 42.1 | 48.4 |

| B20 | 85.3 | 12.4 | 2.3 | 838 | 3.5 | 41.9 | 48.9 |

| B5E5 | 75.5 | 12.6 | 11.9 | 829 | 2.8 | 41.5 | 47.8 |

| B10E10 | 73.9 | 12.7 | 13.4 | 826 | 2.6 | 41.1 | 47.6 |

| Measure Parameters | Range | Accuracy | Uncertainties |

|---|---|---|---|

| Brake power | - | 0.03 kW | ±1.0% |

| SFC | - | ±5 g/kW h | ±0.8% |

| Cylinder pressure | 1–25 MPa | ±10 kPa | ±0.5% |

| EGT | 0–1000 °C | ±1 °C | ±0.25 |

| Smoke | 0–100 | ±1% | ±1.0% |

| NOx | 2000–4800 ppm | ±20 ppm | ±1.0% |

| CO2 | 0–50 vol. % | ±0.3 vol.% + 1% of mv (0 to 25 Vol.%) | ±1.25% |

| ±0.5 Vol.% + 1.5% of mv (>25 to 50 Vol.%) | |||

| PM | 0–300 mg/m3 | 0.1 mg/m3 | ±0.2% |

| Smoke | 0–4800 ppm | ±10 ppm | ±0.2% |

| Crank angle encoder | 0–720 °CA | ± 0.2 °CA b TDC | ±0.3% |

| Time | - | ±0.6 s | ±0.2% |

| Engine speed | 0–10,000 rpm | ±10 rpm | ±0.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kesharvani, S.; Dwivedi, G.; Verma, T.N.; Verma, P. The Experimental Investigation of a Diesel Engine Using Ternary Blends of Algae Biodiesel, Ethanol and Diesel Fuels. Energies 2023, 16, 229. https://doi.org/10.3390/en16010229

Kesharvani S, Dwivedi G, Verma TN, Verma P. The Experimental Investigation of a Diesel Engine Using Ternary Blends of Algae Biodiesel, Ethanol and Diesel Fuels. Energies. 2023; 16(1):229. https://doi.org/10.3390/en16010229

Chicago/Turabian StyleKesharvani, Sujeet, Gaurav Dwivedi, Tikendra Nath Verma, and Puneet Verma. 2023. "The Experimental Investigation of a Diesel Engine Using Ternary Blends of Algae Biodiesel, Ethanol and Diesel Fuels" Energies 16, no. 1: 229. https://doi.org/10.3390/en16010229

APA StyleKesharvani, S., Dwivedi, G., Verma, T. N., & Verma, P. (2023). The Experimental Investigation of a Diesel Engine Using Ternary Blends of Algae Biodiesel, Ethanol and Diesel Fuels. Energies, 16(1), 229. https://doi.org/10.3390/en16010229